Bauxite sintering furnace dust-removing purification device

A purification device and sintering kiln technology, applied in chemical instruments and methods, waste heat treatment, use of liquid separation agents, etc., can solve the problems of insignificant dust removal effect, no solution to the treatment and discharge of harmful substances in smoke and dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

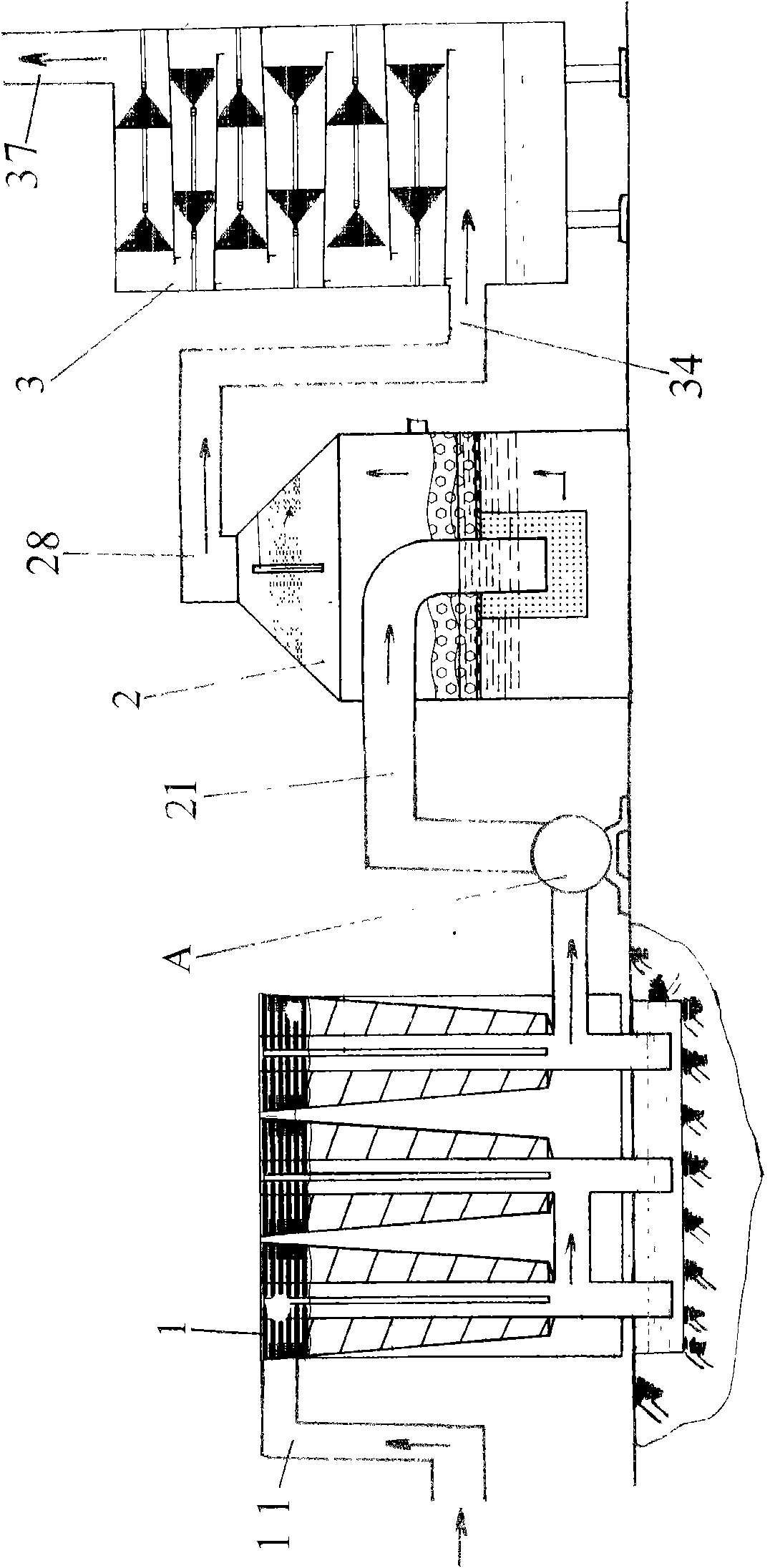

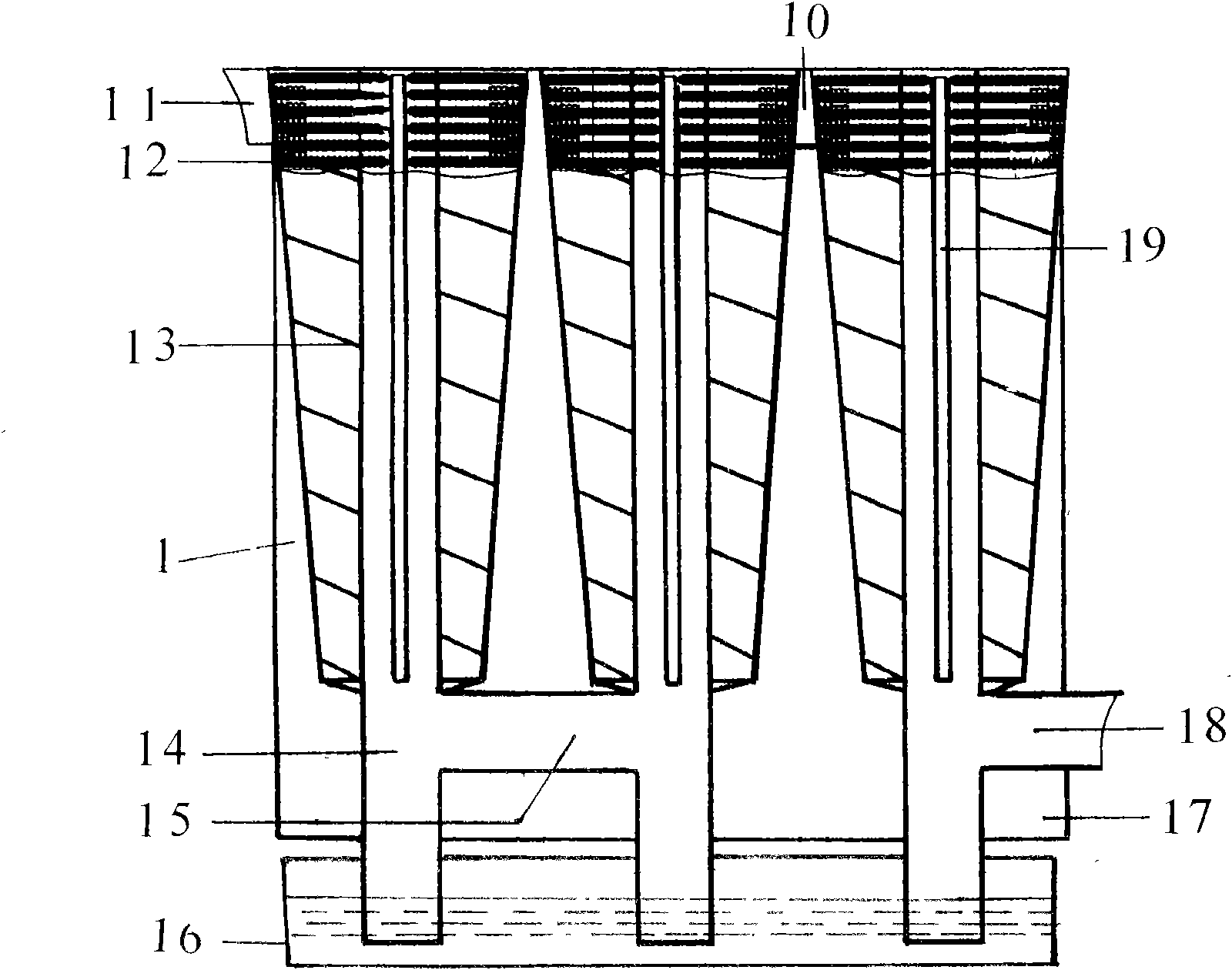

[0012] As shown in the figure, the bauxite sintering kiln dust removal and purification device of the present invention is mainly composed of a spray cooling dust collector 1, a smoke filter tank 2, an atomization purification neutralization reaction tank 3, and a high-pressure fan A; the bauxite sintering kiln The smoke and dust discharged from the inside are conveyed to the spray cooling dust collector by the air induction pipe 11, and after being treated by water mist spray cooling and dust removal, they are transported from the smoke and dust outlet pipe 18 through the high-pressure fan A, and then introduced into the smoke and dust filter tank 2 through the smoke and dust high-pressure pipe 21 , so far the primary cooling and dust removal treatment is completed.

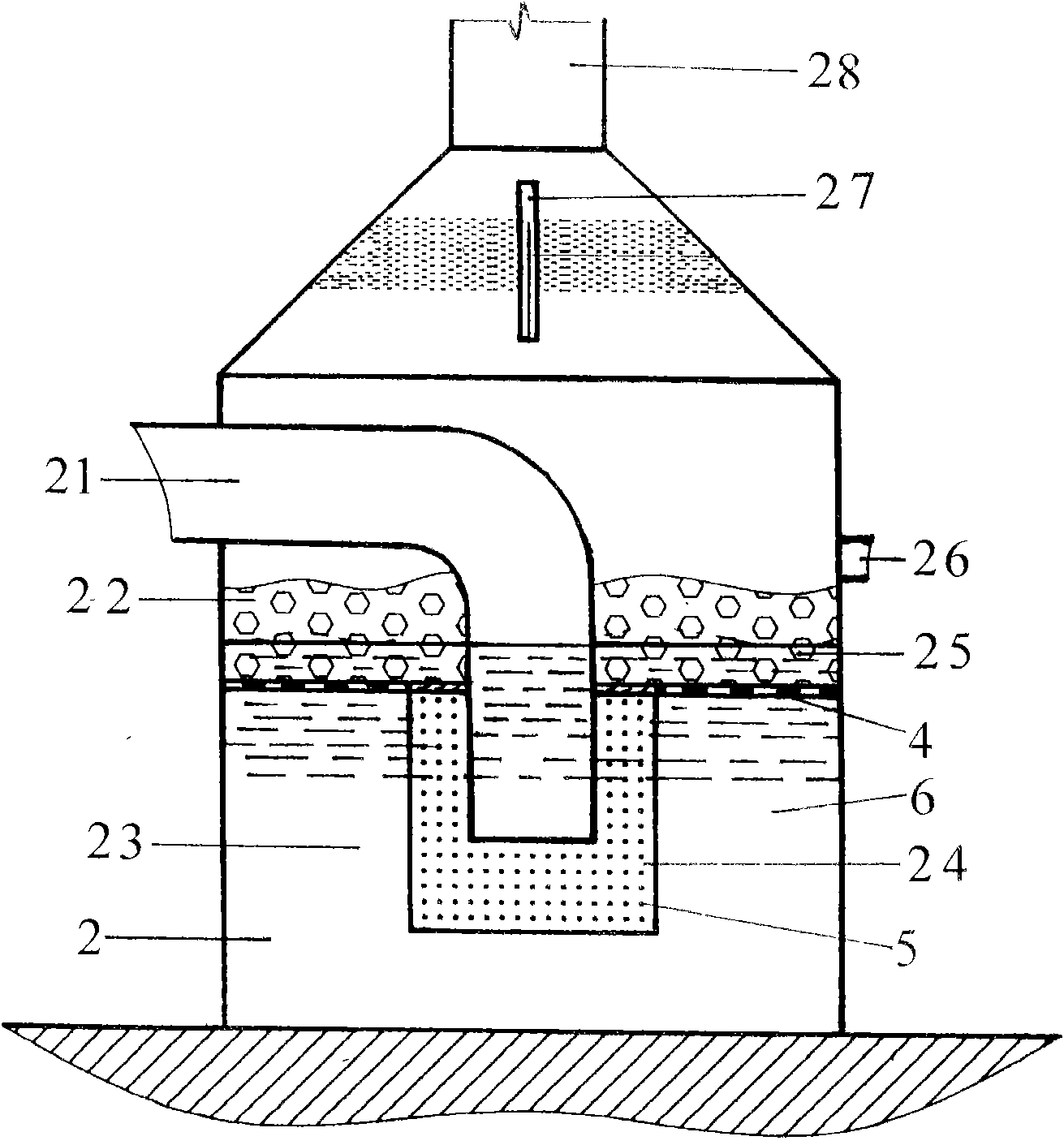

[0013] The soot filter tank 2 is a lime water spray filter reaction device, so that the CO contained in the soot 2 Combination reaction with lime water 25 reduces CO 2 content. After the treatment, the flue du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com