Emulsion waste oil sludge and coking system dust-removal ash briquette coal production process

A technology for emulsified waste oil sludge and production process, which is applied in the petroleum industry, coke oven and other directions, can solve the problems of increasing the burden on enterprises and polluting the environment, and achieves the effect of saving treatment costs and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

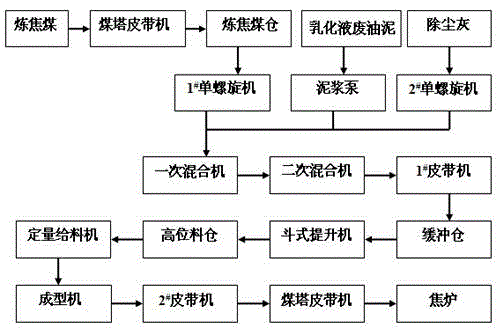

[0010] refer to figure 1 , the production process of emulsified liquid waste oil sludge and coking system dedusting ash to make briquettes. The process is as follows: the coking coal is intercepted from the coal tower belt conveyor sent to the coke oven and enters the coking coal bunker, and the coking coal bunker is discharged through the 1# single screw machine. into the primary mixer, the emulsion waste oil sludge is sent into the primary mixer through the mud pump, and the dedusting ash of the coking system is sent into the primary mixer through the 2# single screw machine, and the three materials entering the primary mixer are 15% by weight Emulsion waste oil sludge, 18% coking system dust, 67% coking coal are mixed and stirred, the addition ratio of coking coal is controlled by adjusting the rotation speed of 1# single screw machine, and the addition ratio of emulsion waste oil sludge is through the mud pump outlet pipe There is a regulating valve on the top to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com