Friction driving conveying system conducting sorting in first-in first-out mode

A conveying system, first-in-first-out technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of disorderly sorting in the PBS area, restricting the conveying efficiency of the conveying system, etc., and achieve high degree of automation and high reliability , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

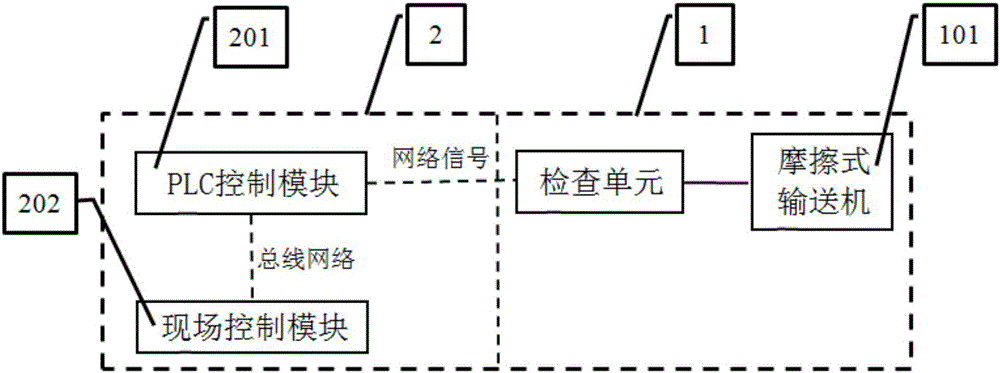

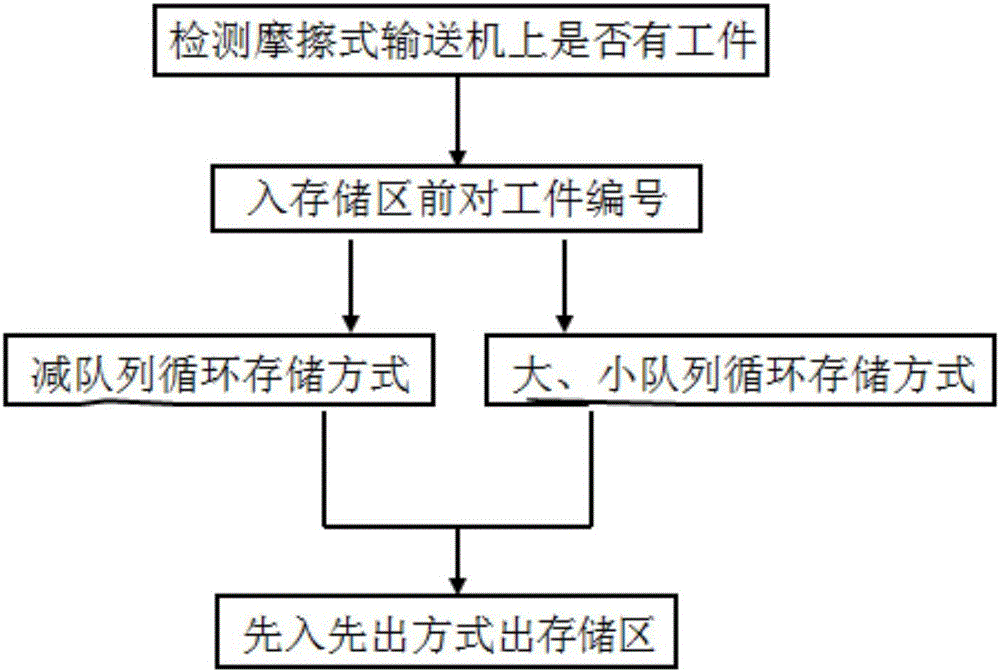

[0021] A friction-driven conveying system sorted in a first-in-first-out manner, including a conveying system 1 and a control system 2, the conveying system 1 and the control system 2 are connected through a bus network, and the control system 2 controls the transmission of the conveying system 1 through the bus network, It is characterized in that: the control system 2 controls the conveying system 1 to transmit workpieces according to the first-in-first-out storage method;

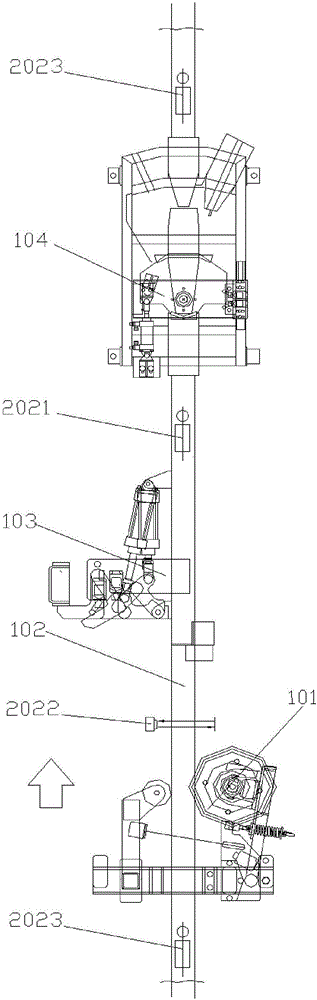

[0022] According to attached figure 1 and figure 2 As shown, the conveying system 1 includes a friction conveyor 101 for conveying workpieces, a track 102, a stopper 103 for blocking workpieces, a switch 104 for adjusting the order of workpieces or pulling out workpieces for maintenance, and a detection unit. The friction conveyor 101, the stopper 103 and the switch 104 are all arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com