Patents

Literature

677 results about "Bus network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bus network is a network topology in which nodes are directly connected to a common half-duplex link called a bus.

Wireless communication system

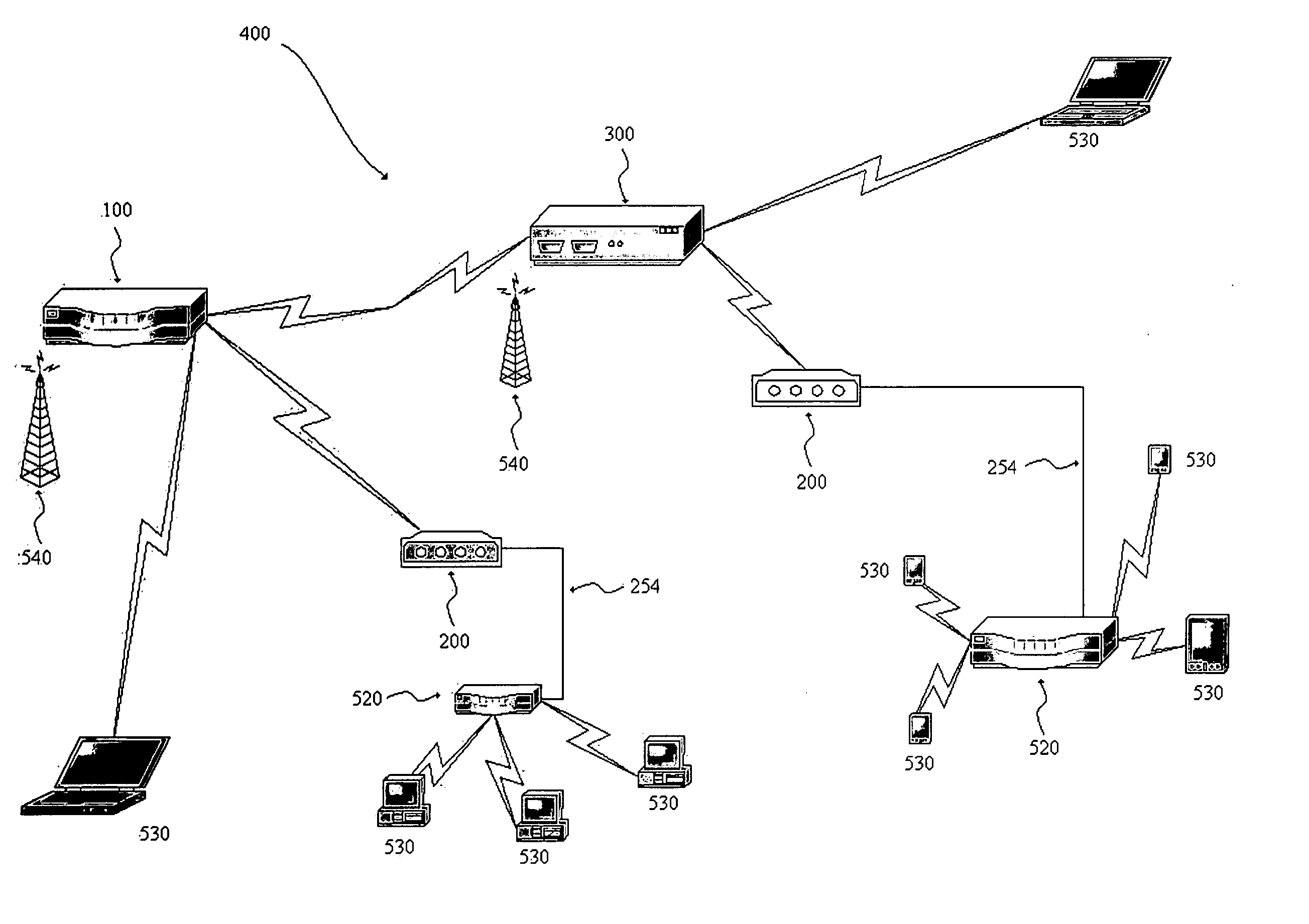

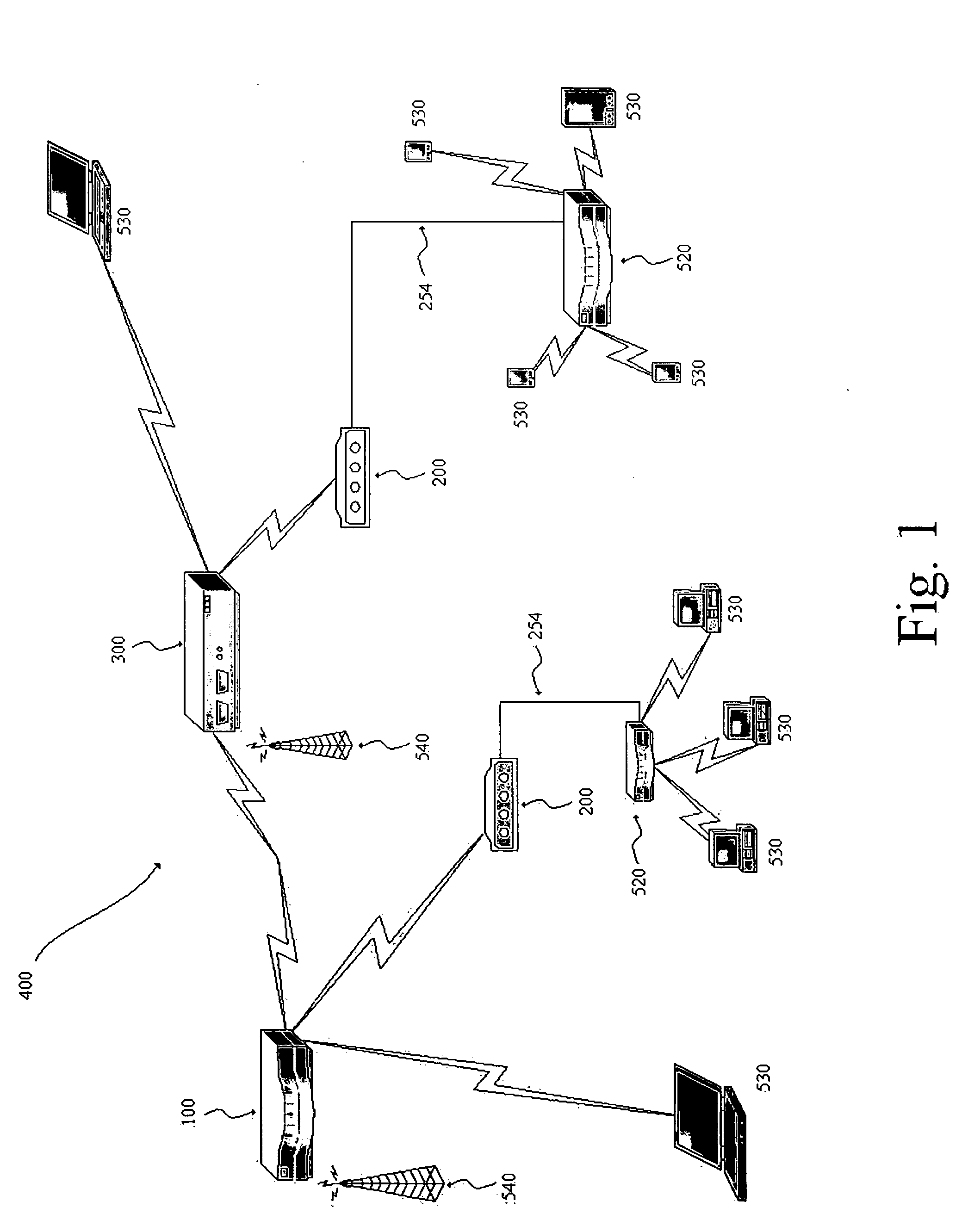

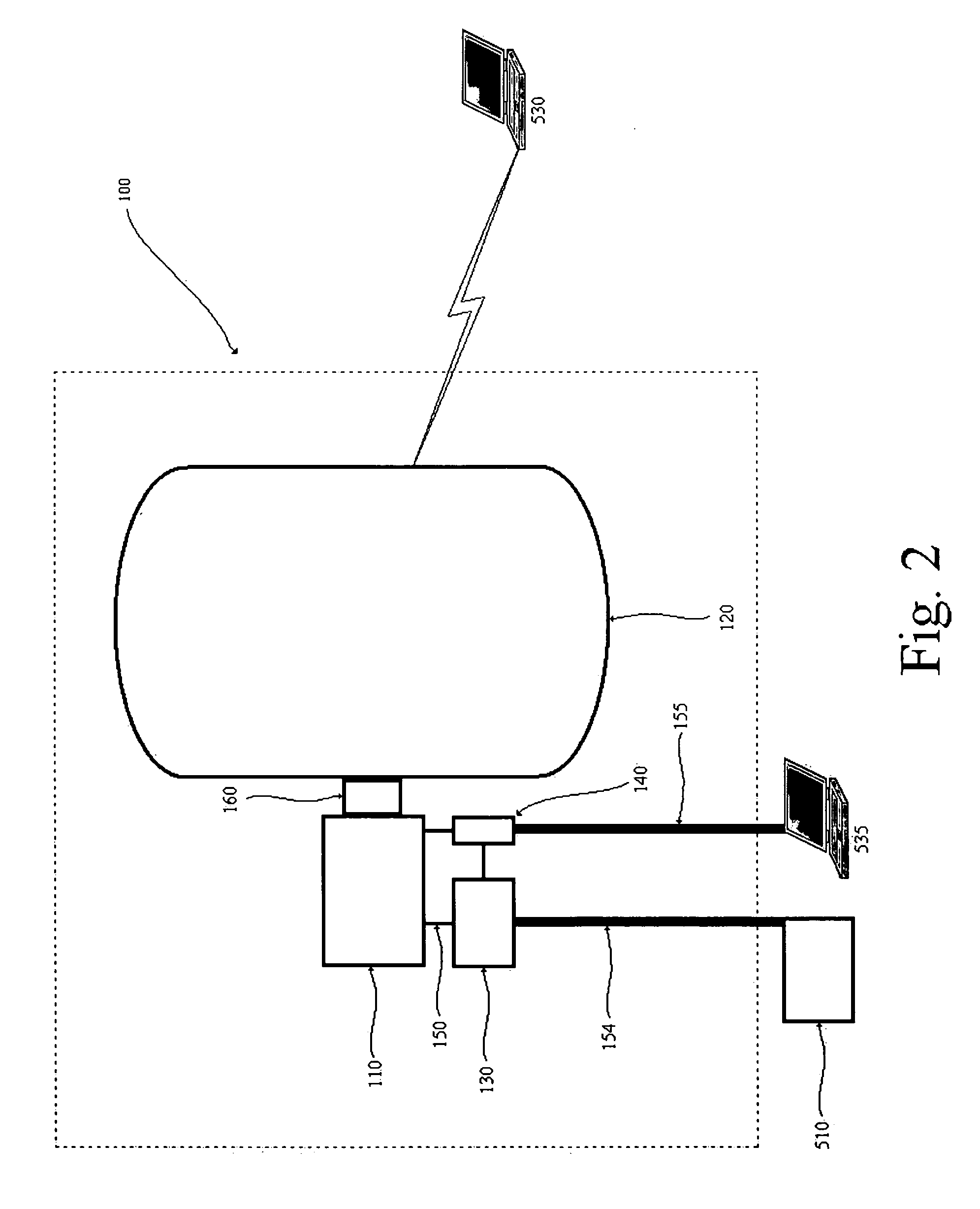

InactiveUS20070121648A1Increase distanceExpand the effective rangeData switching by path configurationNetwork connectionsWireless internet accessModularity

A modular wireless Internet access communications system designed to extend broadband 802.3 linear-bus topology up to fifteen miles beyond the physical limits of DSL or cable technologies through the integration of specialized wireless hardware devices, firmware, and protocols.

Owner:HAHN PHILIP

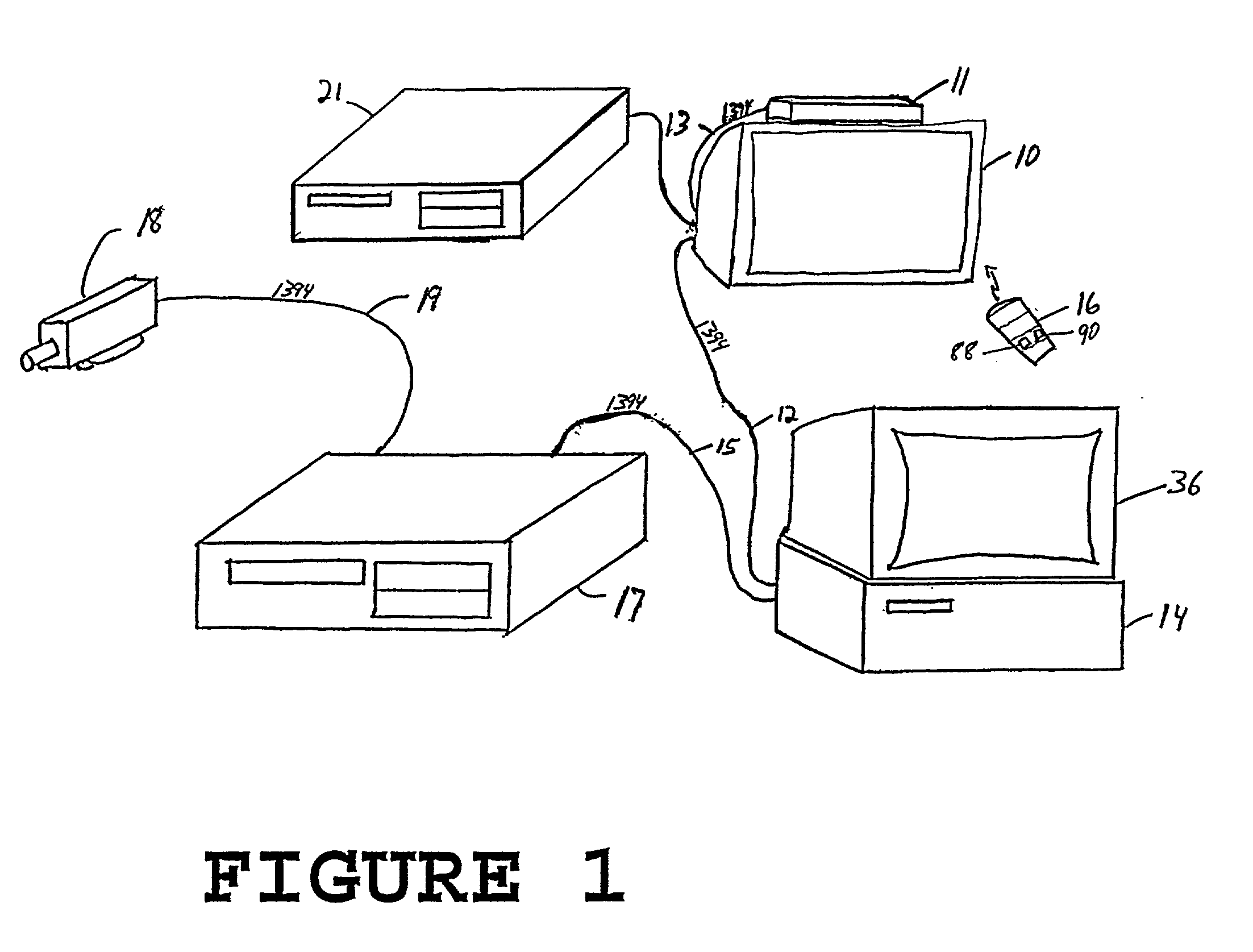

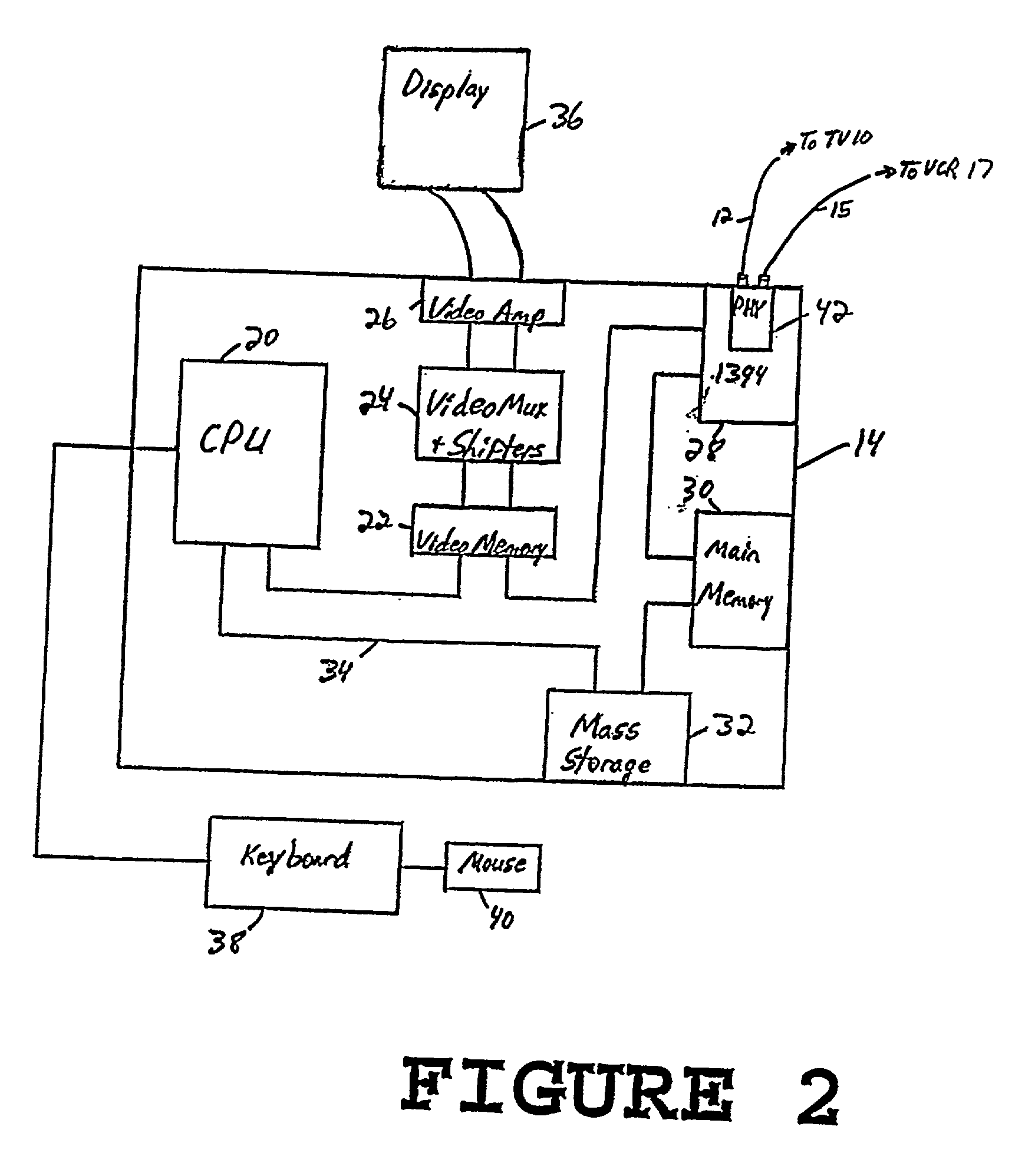

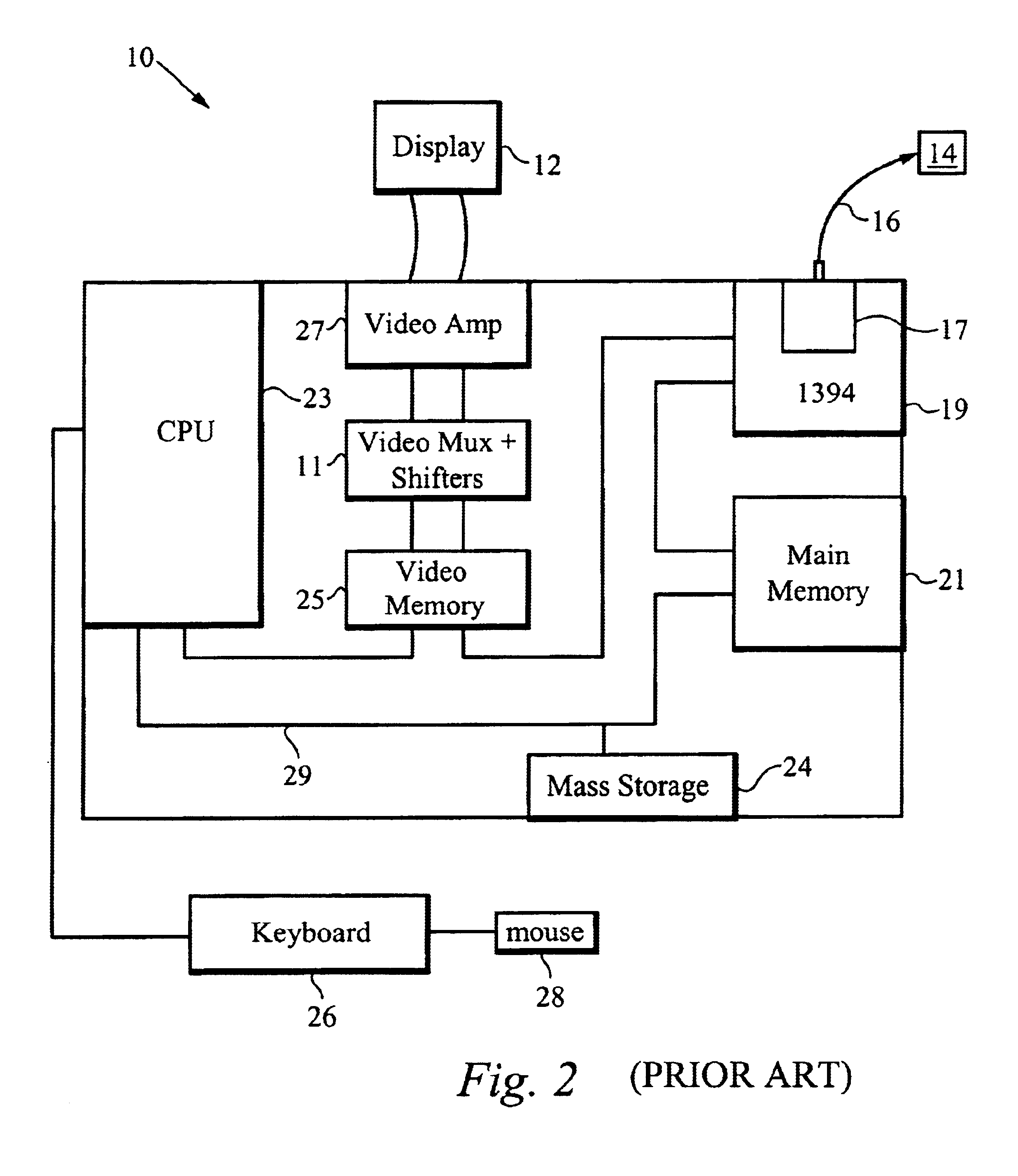

Video recording device including the ability to concurrently record and playback

InactiveUS20020057892A1Television system detailsElectronic editing analogue information signalsMass storageHard disc drive

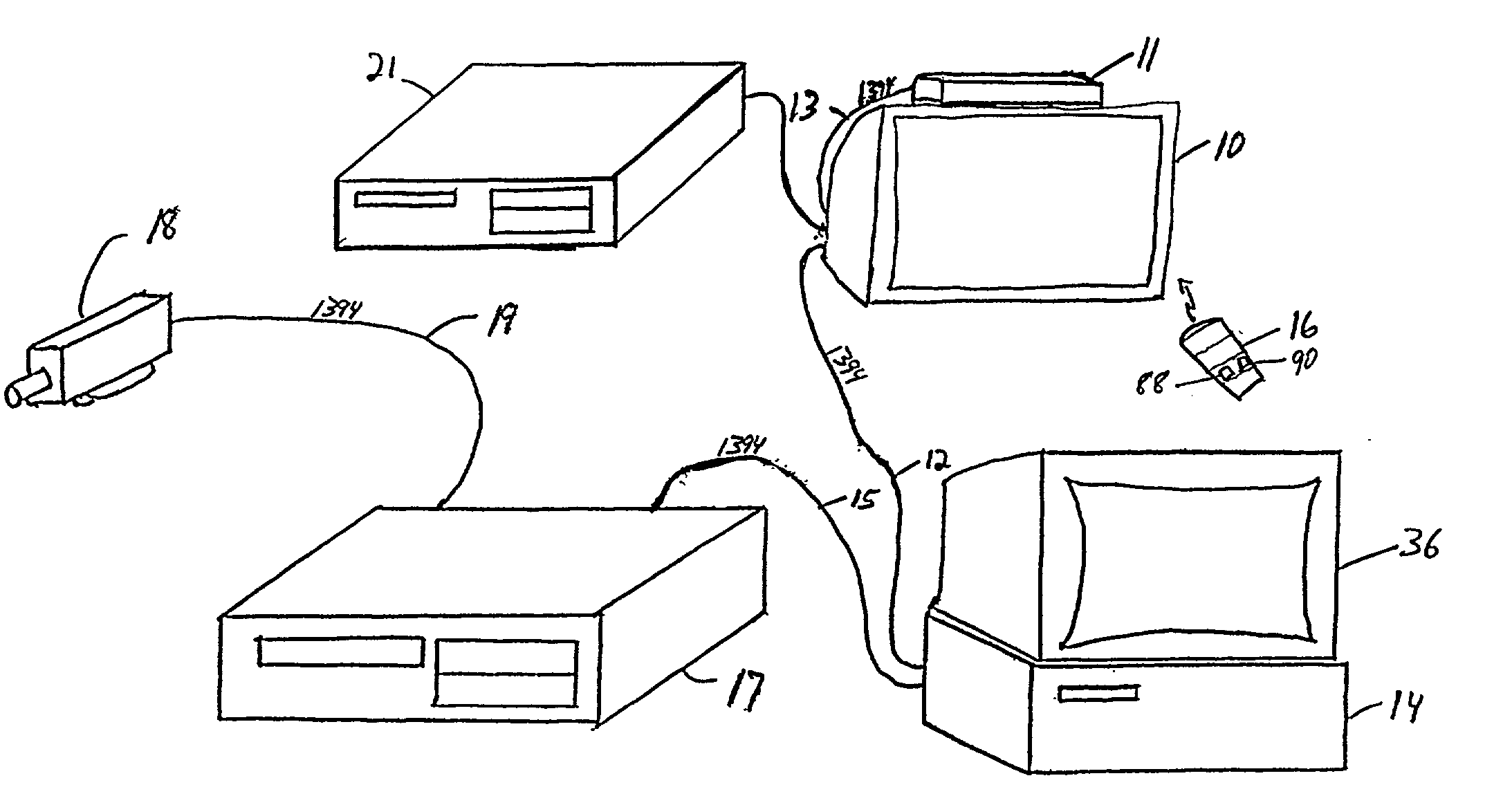

A video recording device includes the ability to record a video broadcast or video program while concurrently replaying a previously recorded video broadcast. This previously recorded video broadcast can be the same video broadcast that is recording or a different video broadcast. The record and playback operations are preferably triggered and controlled through a television on which the user can watch the playback of the recorded program. The viewer enters the data and commands for recording and playback preferably using a remote control device. Video programs are preferably recorded on a mass storage device. Preferably, the mass storage device is a hard disk drive coupled to the television through an IEEE 1394 serial bus network. Alternatively, any other appropriately configured memory device can be used to store the video programs. The television uses write commands to transmit to and record the program onto the mass storage device and read commands to retrieve previously recorded portions of a program to be replayed from the mass storage device. When playing back a previously recorded program or the recorded portions of a program which is still being recorded, the television will retrieve the packets of data from the mass storage device in sequence, using read commands to read from the appropriate locations where the appropriate packets have been stored. Each packet is then retrieved in sequence from the beginning of the program, even if the end portion of the program is still being recorded.

Owner:SONY CORP +1

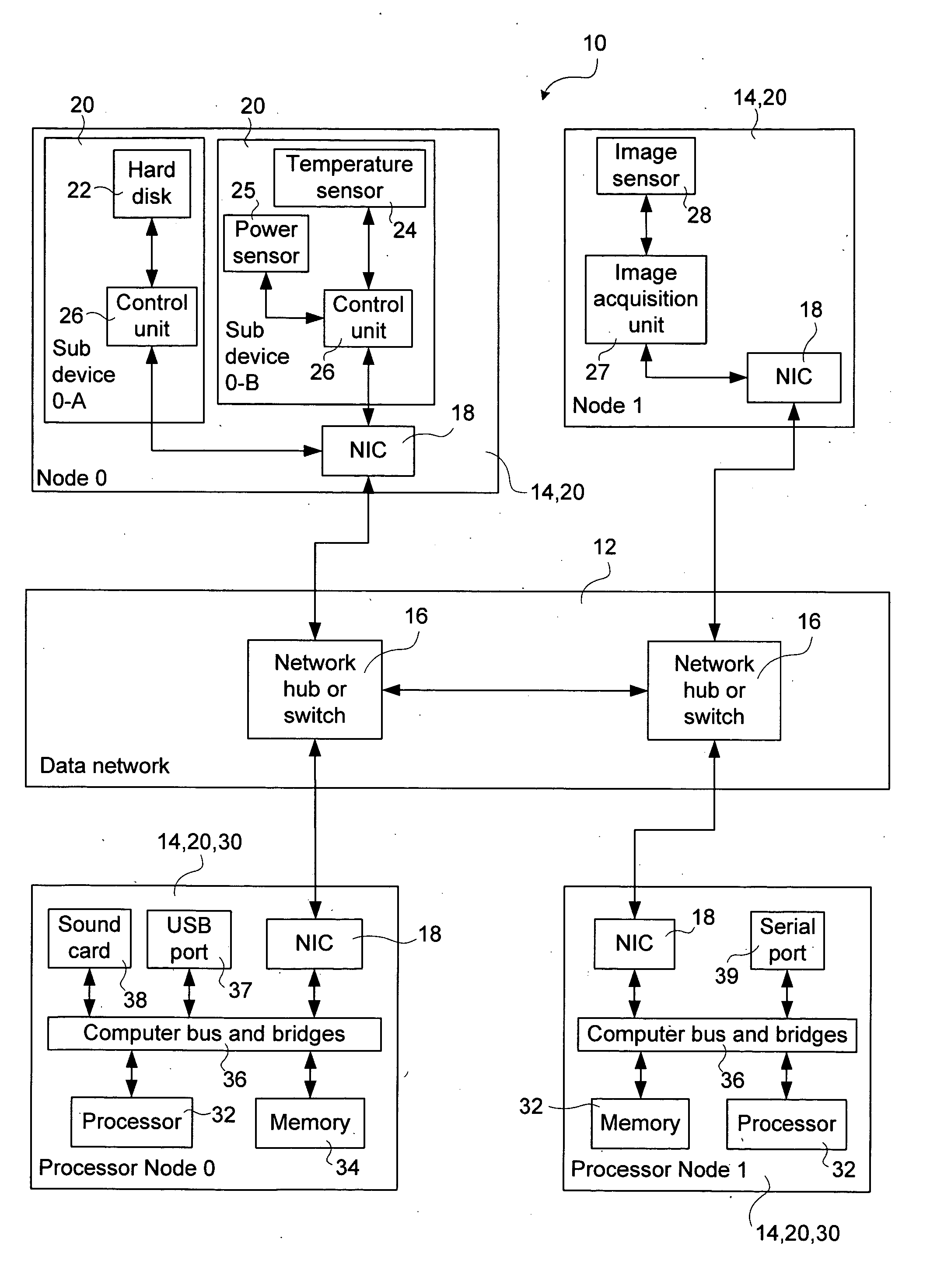

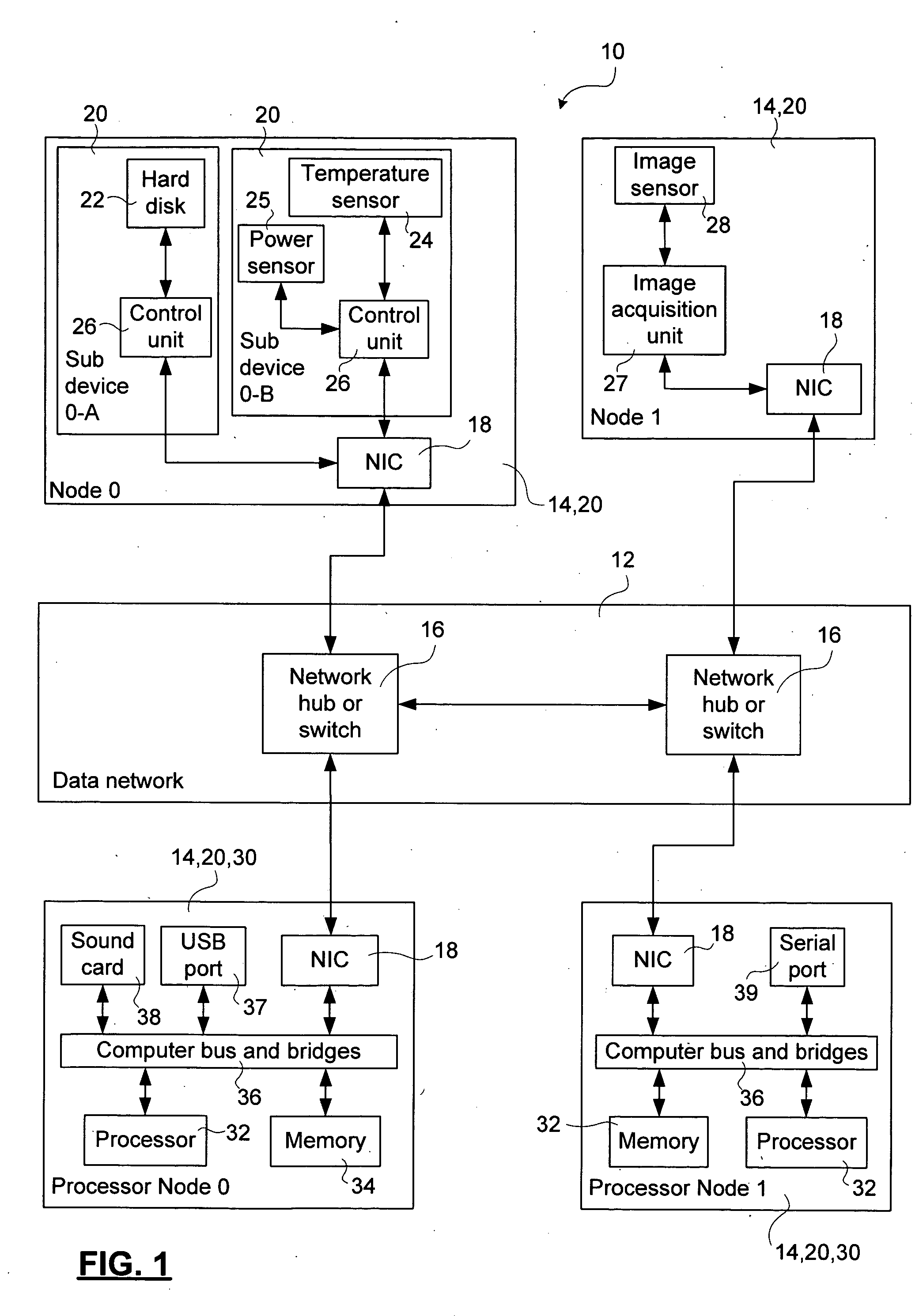

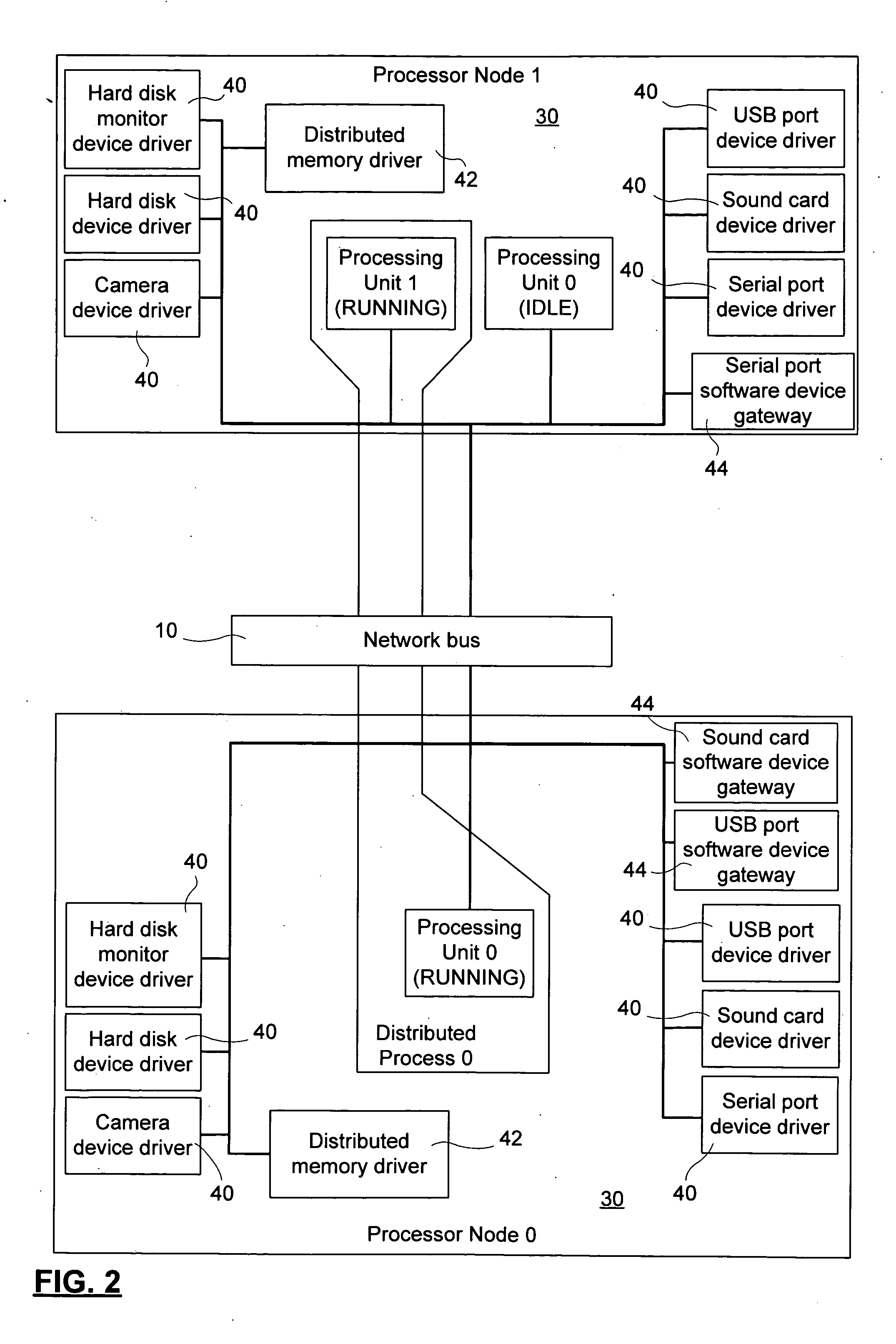

Methods and apparatus for enabling bus connectivity over a data network

ActiveUS20060059287A1Facilitate communicationSelectively leverage operating system capabilitiesProgram synchronisationMemory addressAbstraction layer

A method and system for interconnecting peripherals, processor nodes, and hardware devices to a data network to produce a network bus providing OS functionality for managing hardware devices connected to the network bus involves defining a network bus driver at each of the processor nodes that couples hardware device drivers to a network hardware abstraction layer of the processor node. The network bus can be constructed to account for the hot-swappable nature of the hardware devices using a device monitoring function, and plug and play functionality for adding and, removing device driver instances. The network bus can be used to provide a distributed processing system by defining a shared memory space at each processor node. Distributed memory pages are provided with bus-network-wide unique memory addresses, and a distributed memory manager is added to ensure consistency of the distributed memory pages, and to provide a library of functions for user mode applications.

Owner:PLEORA TECH

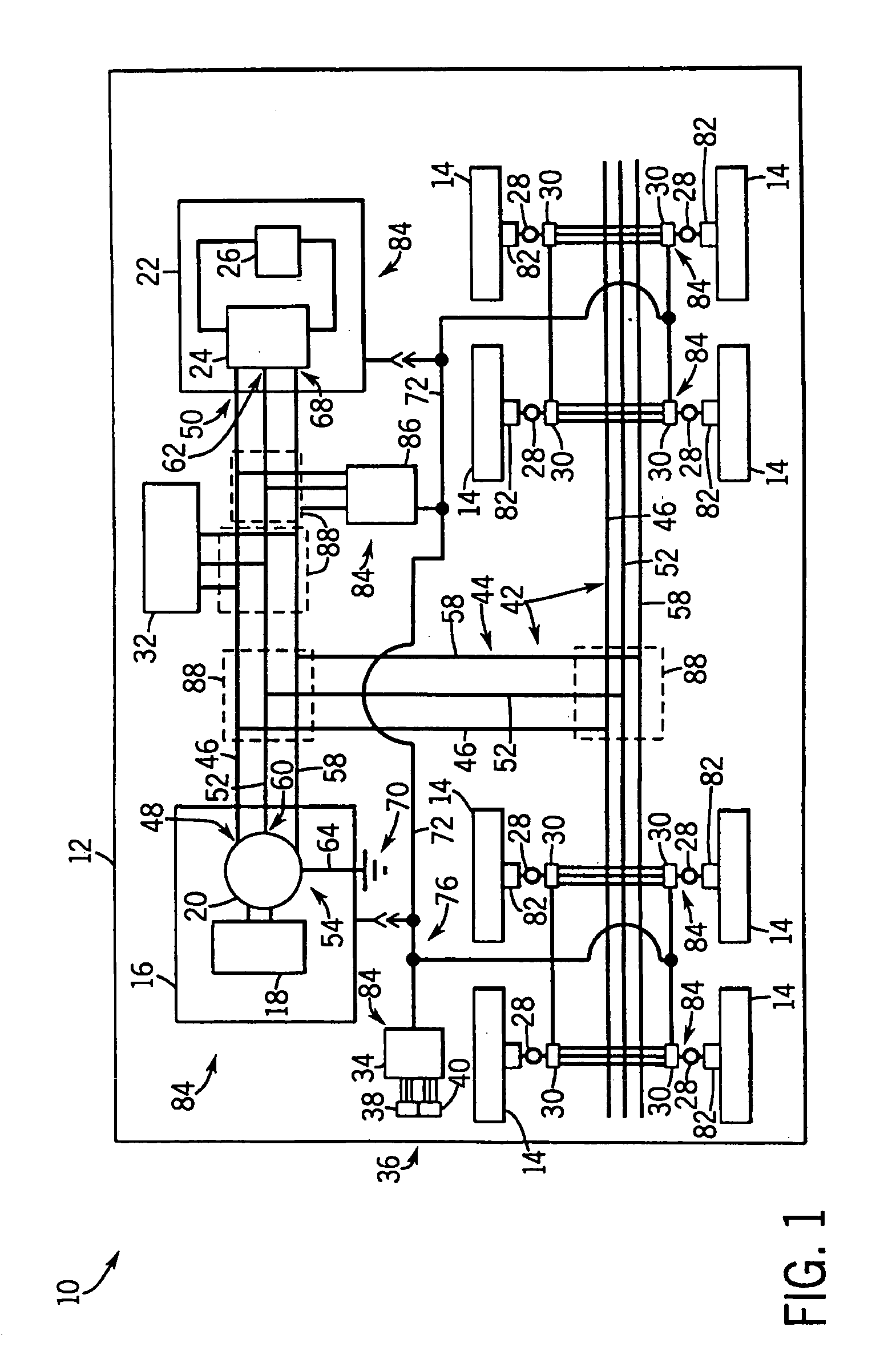

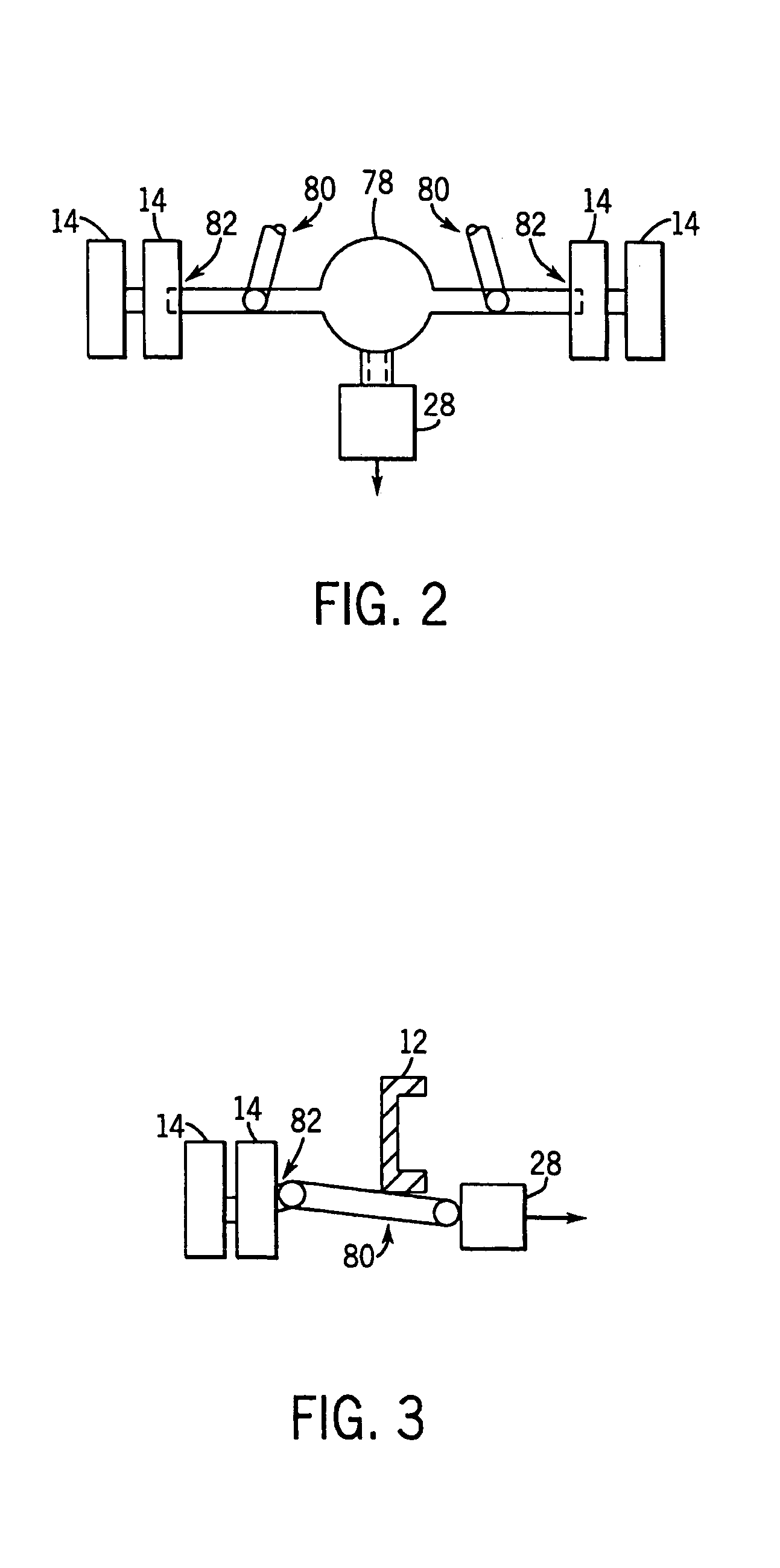

A/C bus assembly for electronic traction vehicle

An electronic traction vehicle comprising a principal power unit, a power storage unit mounted on a vehicle platform. A plurality of wheels are rotably mounted on the vehicle platform with an electric motor coupled to at least one wheel. A drive controller is coupled to the electric motor and a vehicle controller having an input and output terminal is coupled to the drive controller. A data bus network is coupled to the drive controller and the vehicle controller. An A / C bus assembly is coupled to the principal power unit, the power storage unit and the electric motor through the drive controller. Another embodiment of the electronic traction vehicle provides at least four electric motors and four drive controllers coupled to four wheels and the data bus network and A / C power bus assembly. Another embodiment of the electronic traction vehicle provides the components of the vehicle as moduled including an auxiliary module removably connected to the data bus network and the A / C bus assembly.

Owner:OSHKOSH CORPORATION

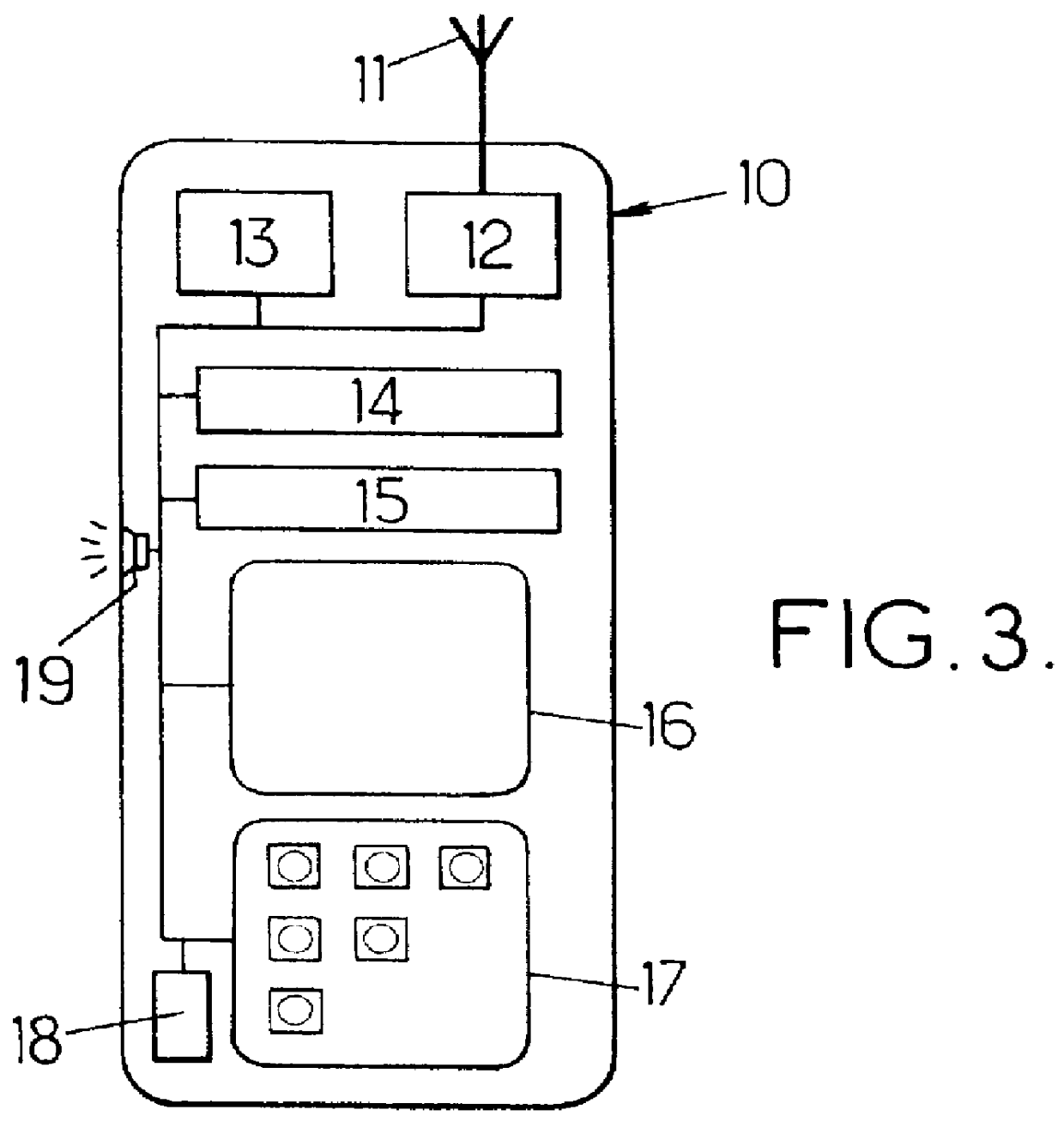

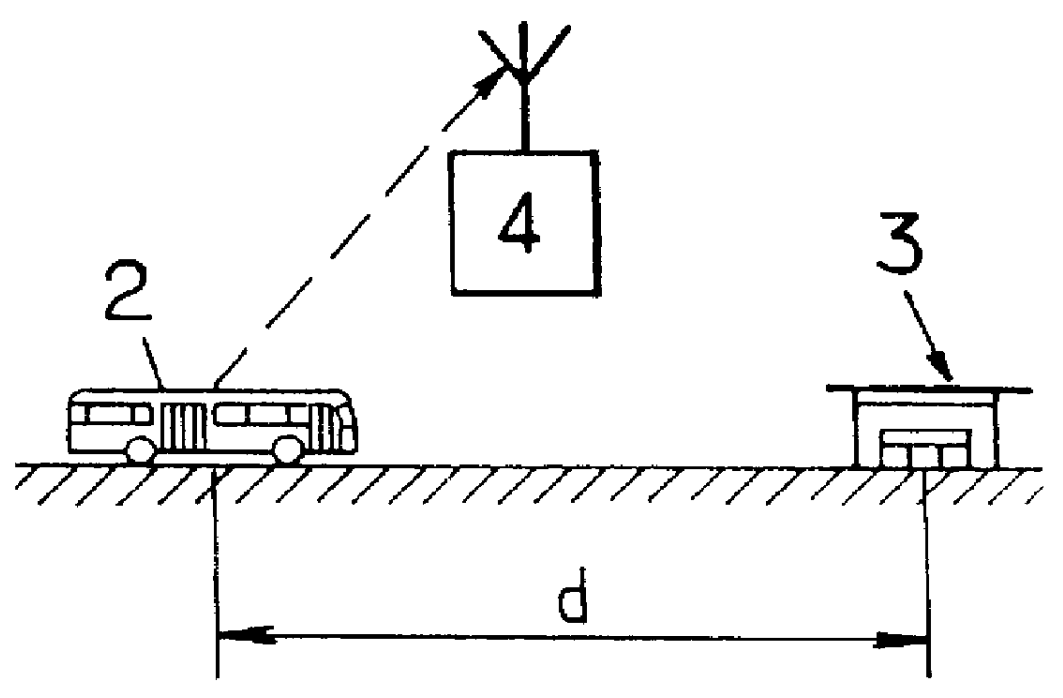

Portable appliance for informing the users of a bus network about waiting times at stops in the network

InactiveUS6097317AAnalogue computers for vehiclesAnalogue computers for trafficRadio receiverRadio reception

The portable appliance informs users about waiting times at stops in a bus network, the appliance comprising a radio receiver to receive data enabling waiting times to be determined, an interrogation keypad, a central unit for evaluating the estimated time of arrival of the next bus at a particular stop, a screen for displaying the waiting time for said bus, and a sound emitter. The central unit is designed to update cyclically the estimated time of arrival for the next bus and to actuate the sound emitter when said estimated time of arrival differs excessively from the time of arrival initially estimated the last time the appliance was interrogated by the user.

Owner:JCDECAUX

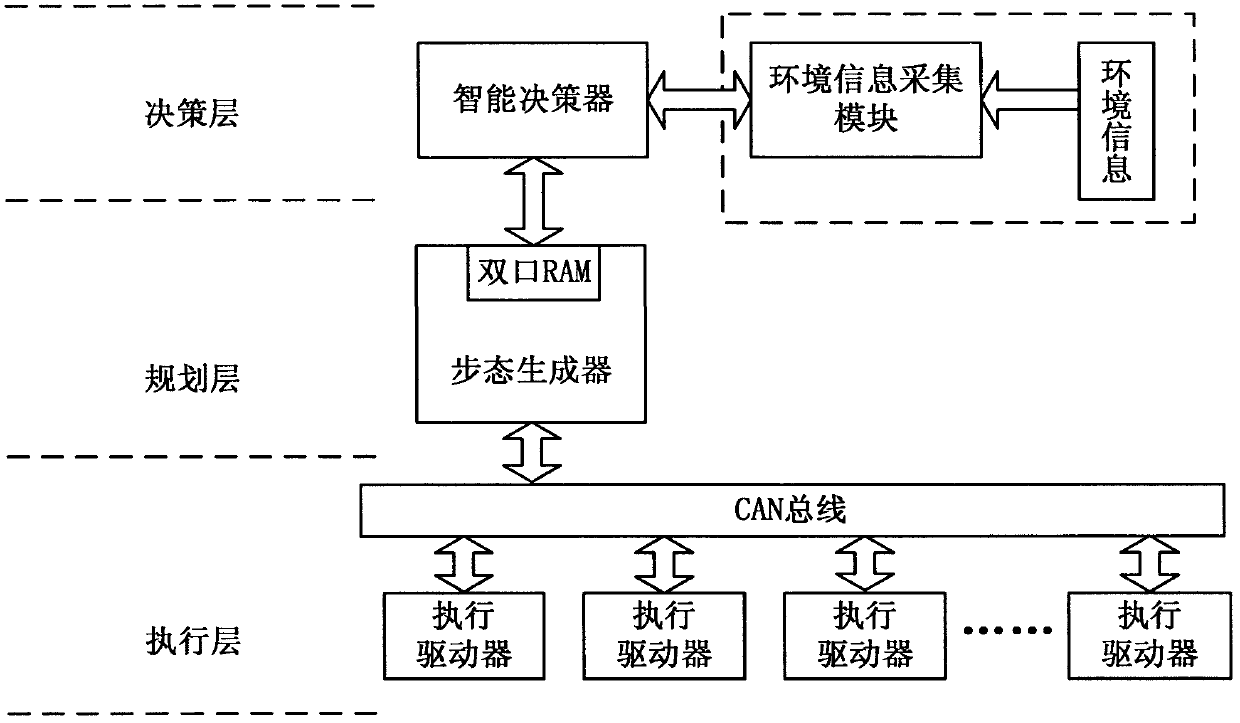

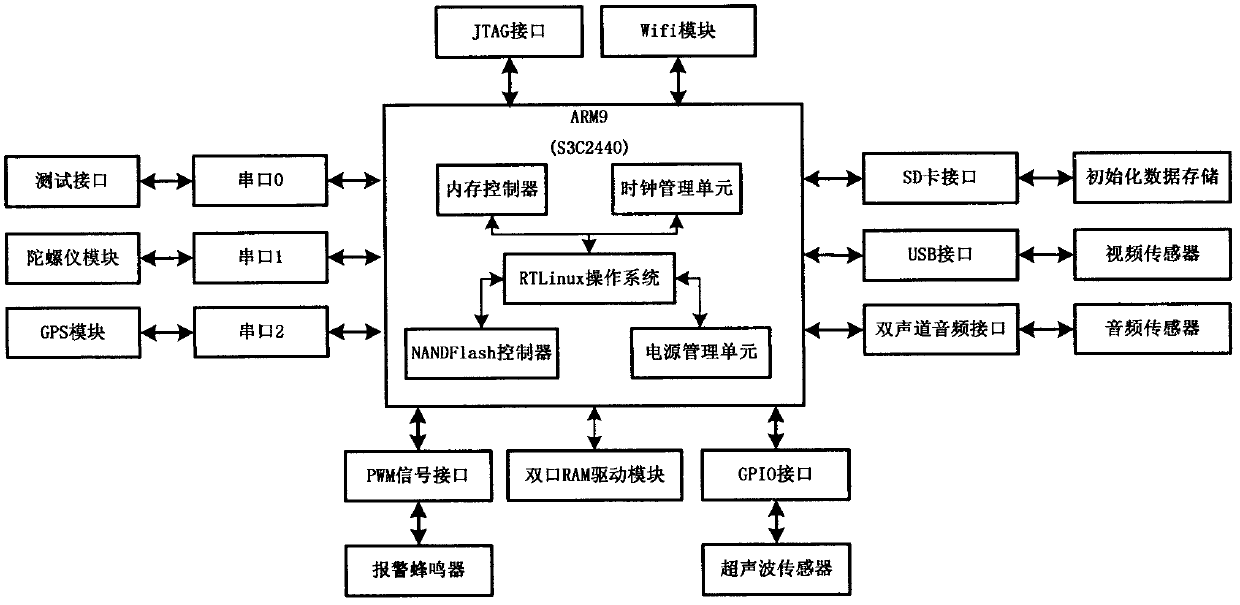

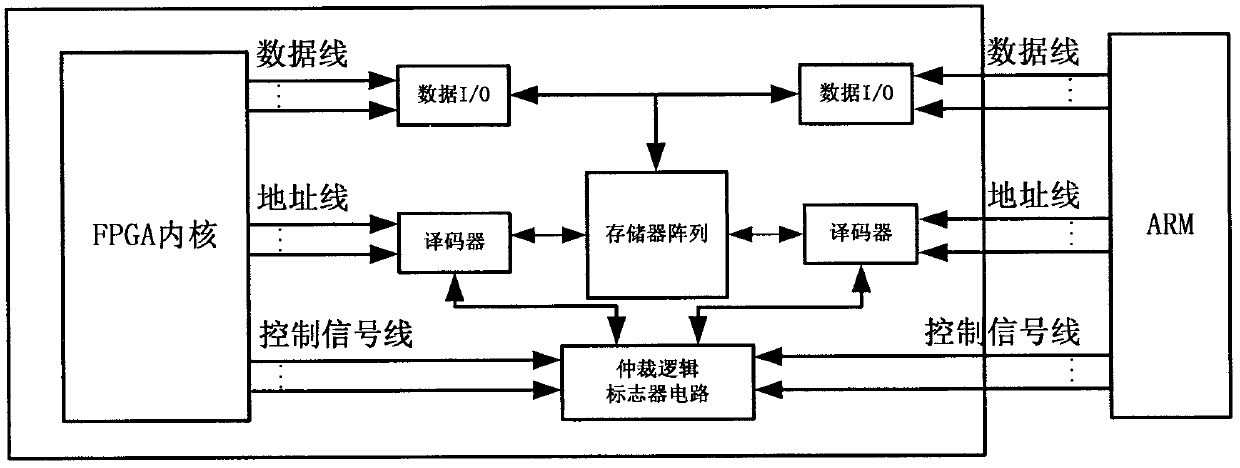

Combined type bionic quadruped robot controller

InactiveCN102637036AIntegrity guaranteedImprove adaptabilityPosition/course control in two dimensionsOperational systemNervous system

The invention relates to a combined type bionic quadruped robot controller, which is in a structure similar to a vertebrate nervous system, wherein the controller is divided into a decision layer, a planning layer and an execution layer which respectively correspond to a higher nervous center, a lower nervous center and a motor nerve of an animal. The decision layer for realizing that the robot senses the working environment and generates corresponding motion decision instructions consists of an ARM9 (advanced RISC (reduced instruction-set computer) machine 9) and an environmental information acquisition system, and a real-time operating system is embedded in the ARM9. The core of the planning layer is a walking pattern generator, and is used for planning and solving the motion parameters of each joint according to the decision instructions from the upper layer. The execution layer for controlling the current, the position and the speed of a driving motor in three closed loops consists of a motor controller using a digital signal processor as the core. Data can be effectively transmitted among the three layers in real time through a dual-port RAM (random-access memory) and a CAN (controller area network) bus network. The combined type bionic quadruped robot controller disclosed by the invention has the characteristics of high reliability, high flexibility, extension easiness and maintenance easiness, and has a broad application prospect in the technical field of bionic legged robots.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

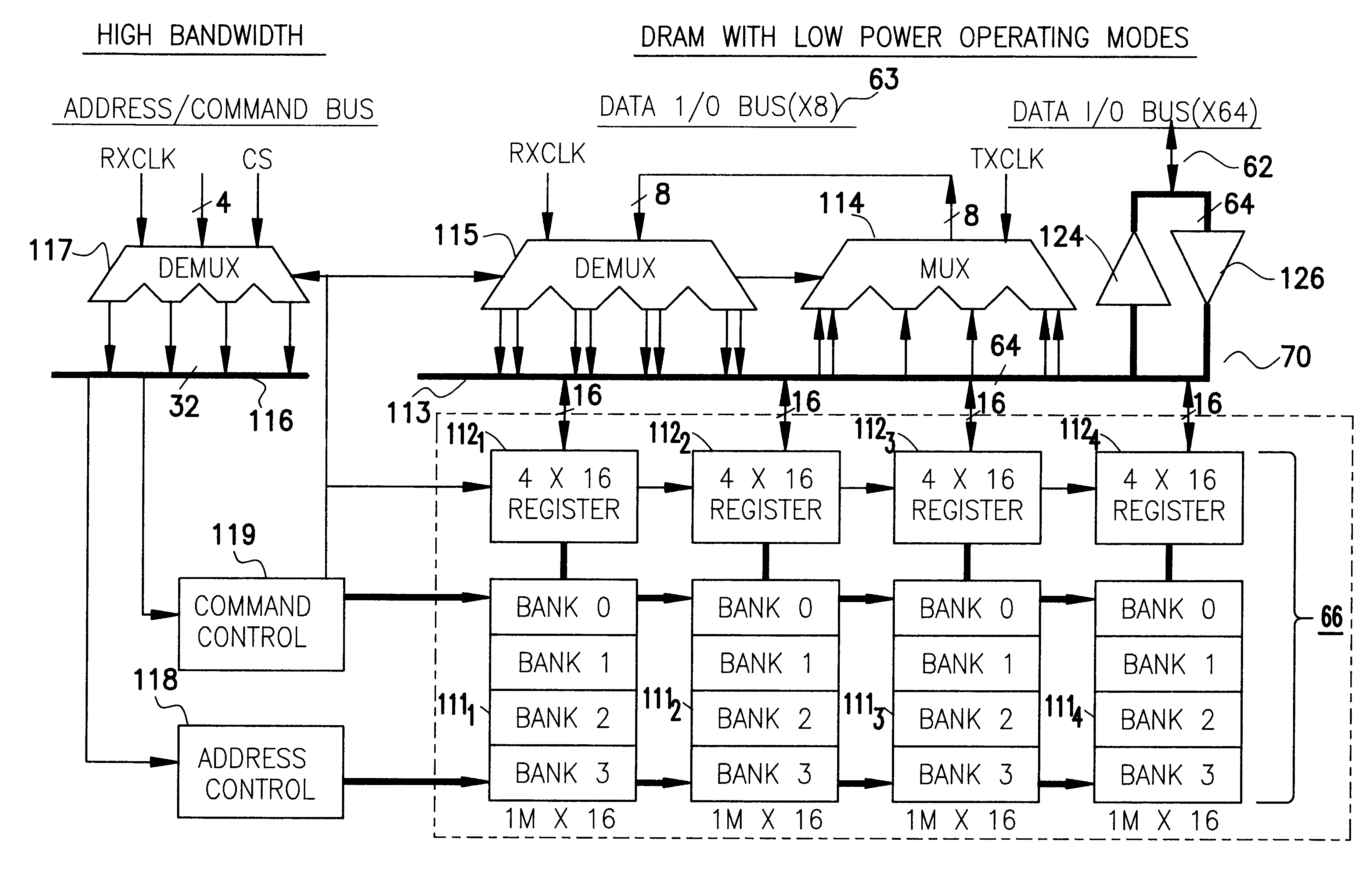

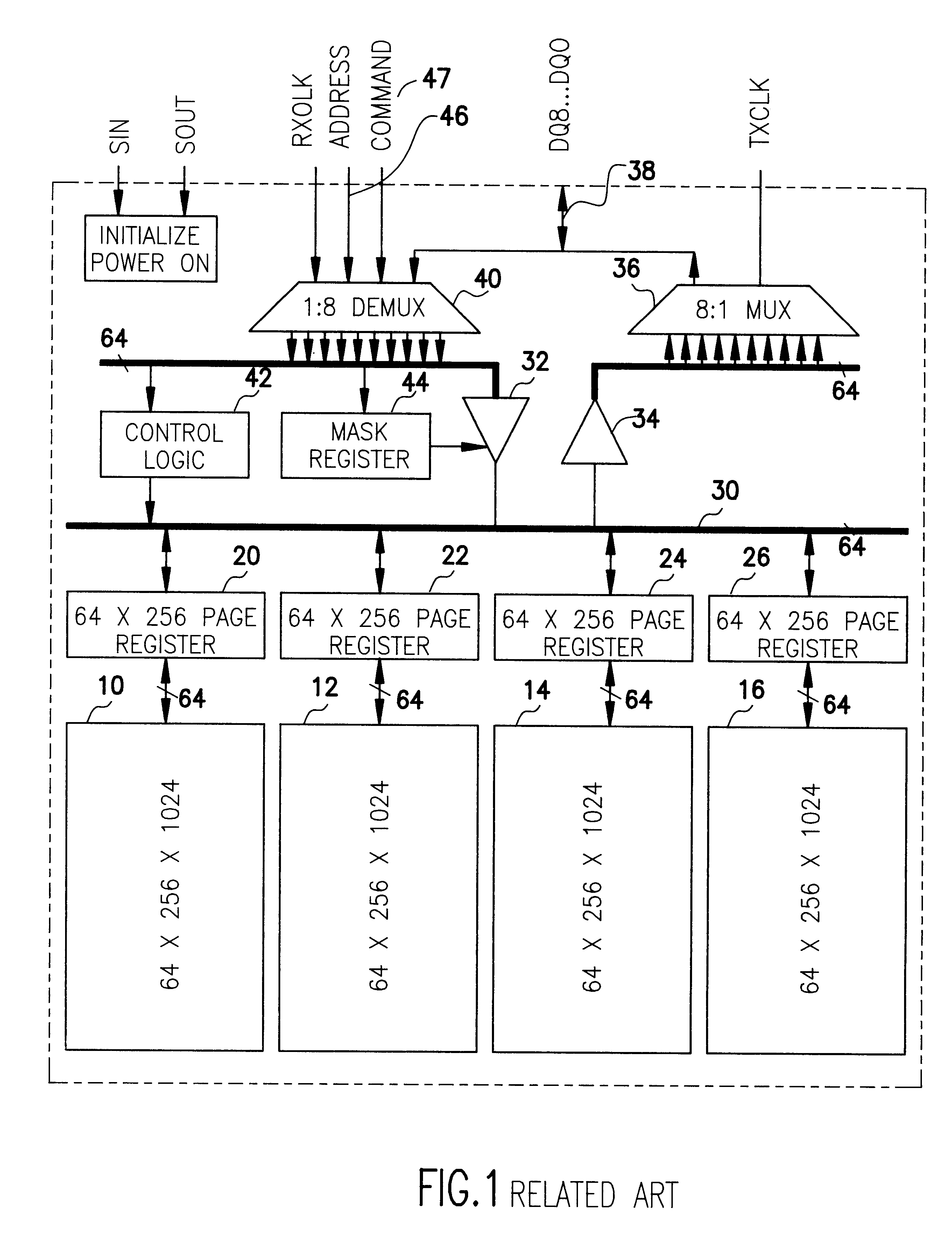

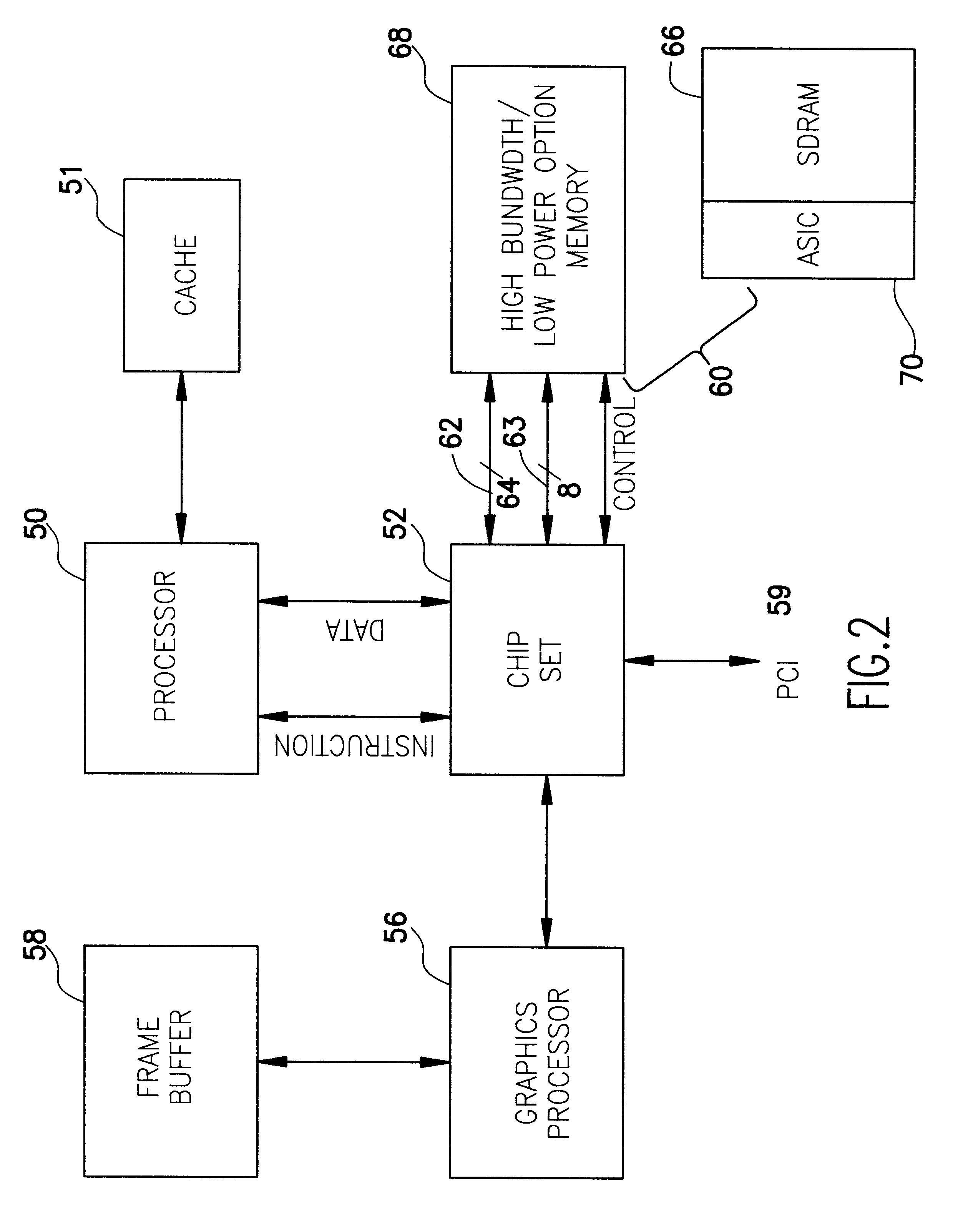

High bandwidth DRAM with low operating power modes

InactiveUS6178517B1Adjustable speedEnergy efficient ICTDigital data processing detailsPower modeGraphics

A high bandwidth DRAM is provided with two separate bus networks connecting the DRAM to a processor. One bus network is a high speed (e.g., 500 MHZ) 8:1 or 16:1 multiplexed I / O bus and the second is a slower (e.g., 64-bit) bus. The high-speed bus is used for example for graphic intensive applications which require fast access to large numbers of bits in the DRAM memory array. This of course results in higher power requirements. Since, not all applications require such large amounts of data to be transferred between the DRAM and the processor, the slower bus is provided for these less demanding applications such as word processors, spreadsheets, and the like. The slower bus requires less power to operate and therefore results in a power saving mode which, among other things, facilitates longer battery life.

Owner:MARVELL ASIA PTE LTD

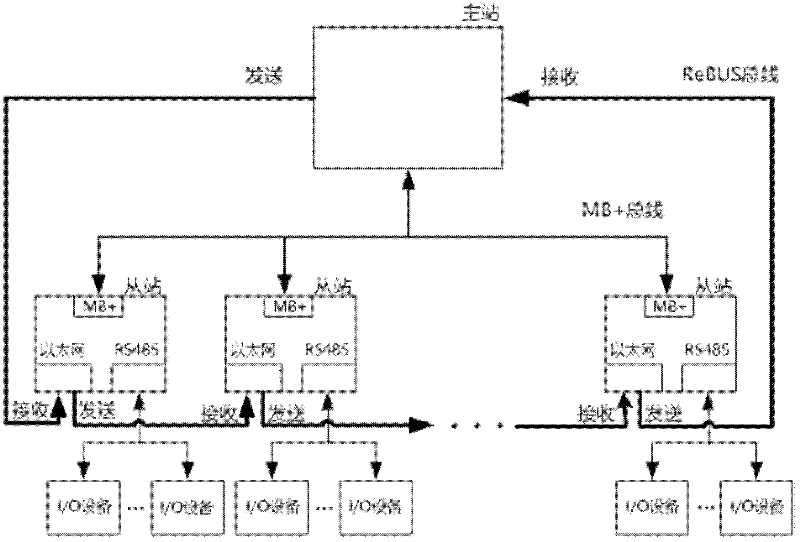

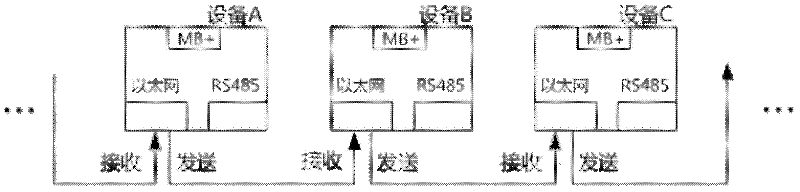

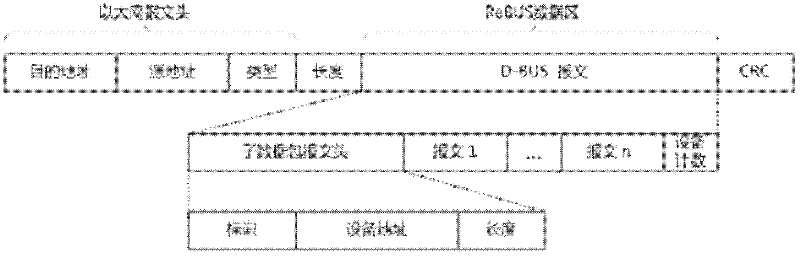

D-BUS high-speed bus technology based on ring type Ethernet and auxiliary network

InactiveCN102347879ASimple wayEasy wiringLoop networksBus networksStructure of Management InformationEmbedded system

The invention provides a D-BUS high-speed bus technology based on a ring type Ethernet and an auxiliary network, which belongs to the technical field of industrial control. The D-BUS high-speed bus technology is characterized in that a D-BUS (Dual-BUS) high-speed bus network consists of a high-speed ring type Ethernet ReBUS and an auxiliary network MB+, wherein the ReBUS bus utilizes the physical layer specification of Ethernet IEEE802.3, a main station is connected with slave stations in series to form a ring type topological structure, the wiring mode for the main station and the slave stations is same with that of the slave stations with the slave stations, a receiving terminal of each equipment is connected with a transmitting terminal of the former equipment, the transmitting terminal of the equipment is connected with a receiving end of a latter terminal, the receiving terminals are sequentially connected with the transmitting terminals in the mode to form a ring type network structure, I / O equipment are connected with the slave stations through RS485 serial ports and serve as the expansion I / O of the slave stations, and failure detection comprising failure diagnosis, failure location and communication redundancy is realized by the MB+ bus. The invention has the beneficial effects that the ring type wiring cost is low, the data exchange of all network nodes is realized by one message, the communication efficiency is high, a failure detection and failure recovery mechanism is provided, and the reliability is high.

Owner:大连爱智控制系统有限公司

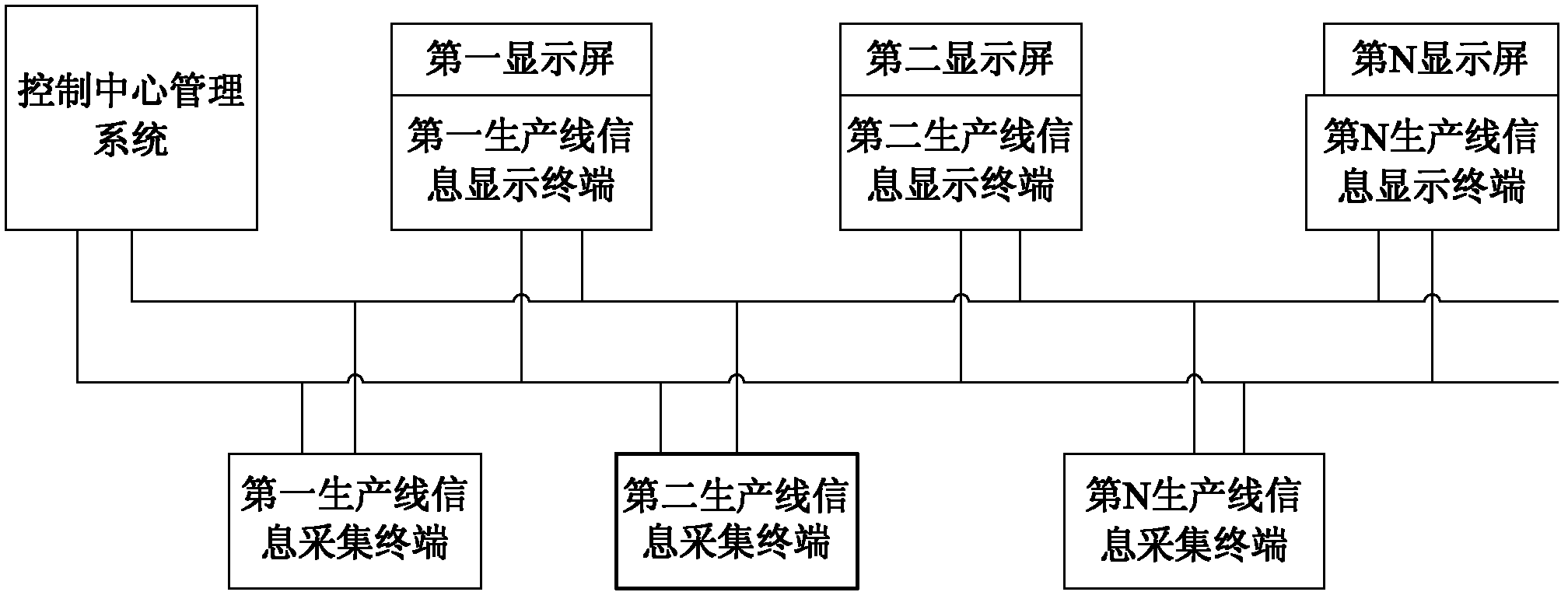

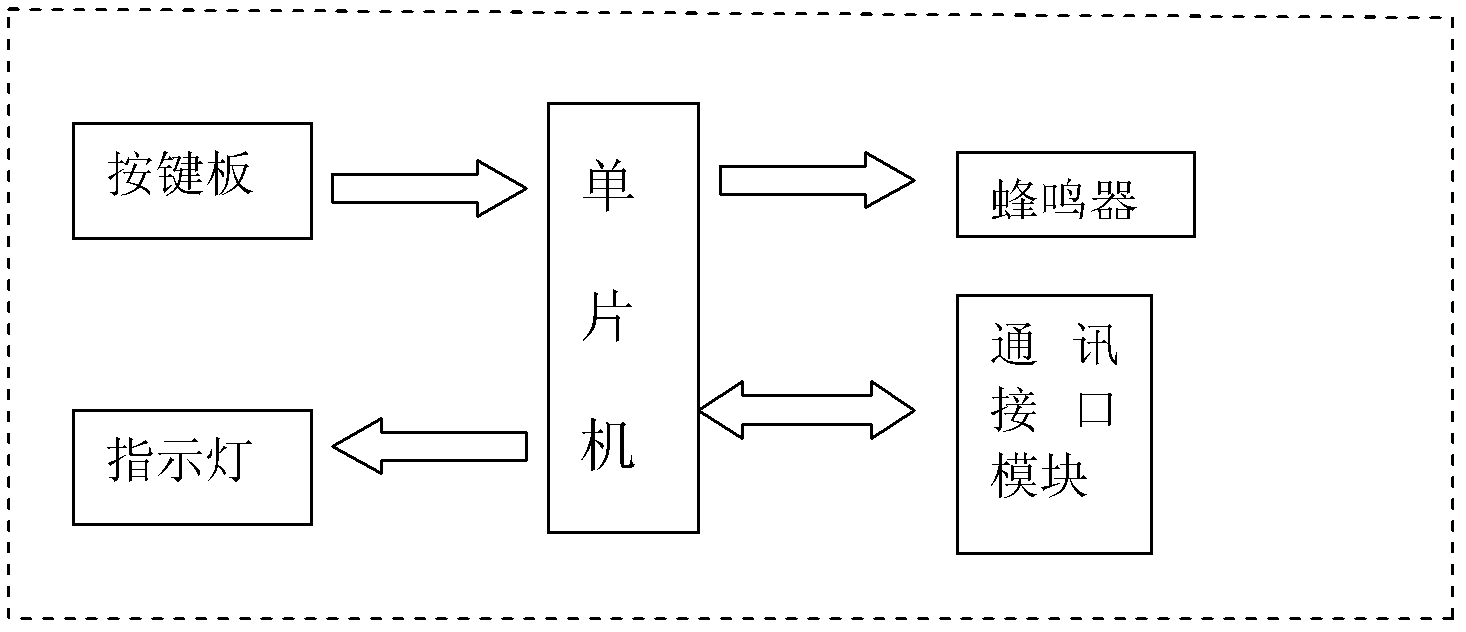

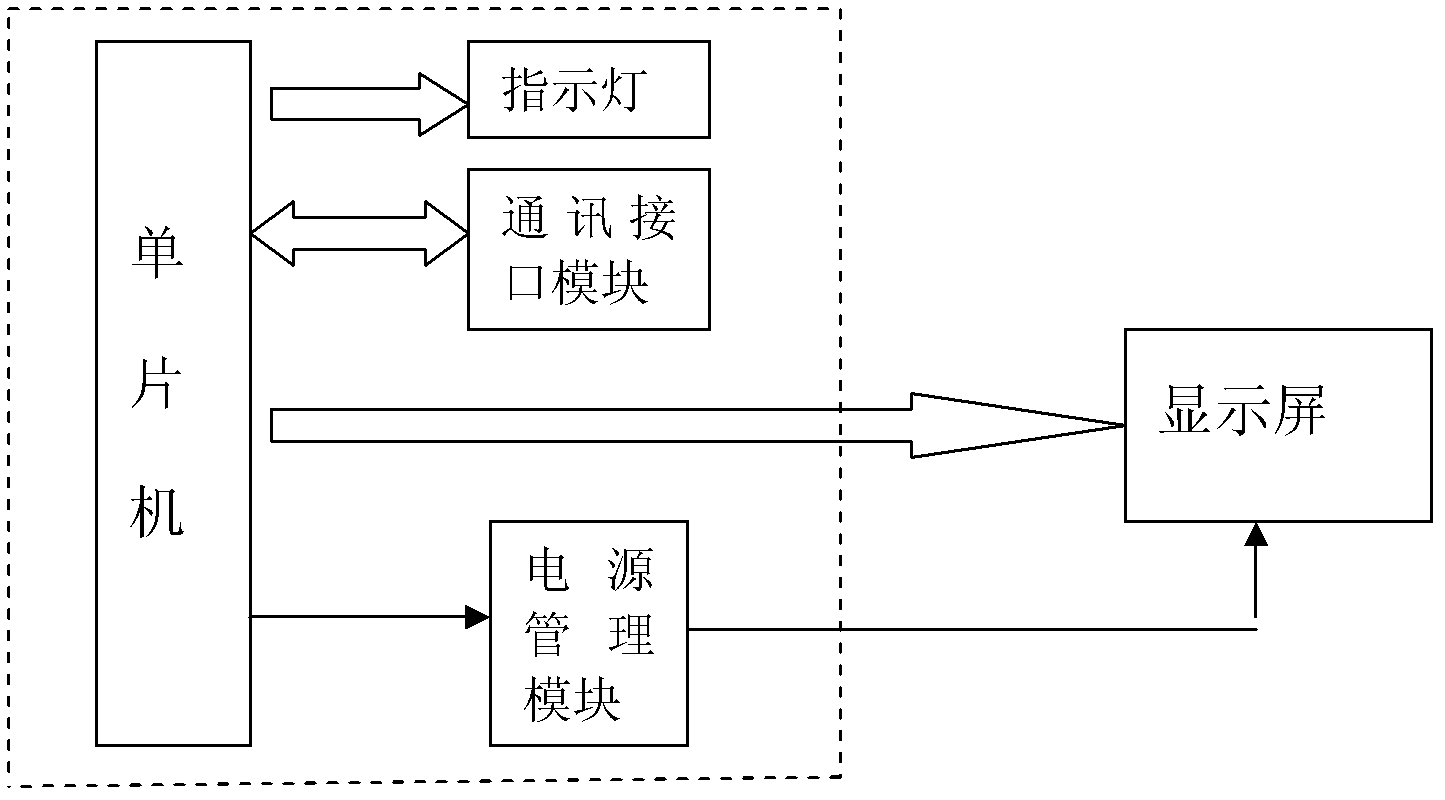

Data acquisition and information management system and acquisition method for production line

InactiveCN102436238ASimple structureFlexible layoutTotal factory controlProgramme total factory controlProduction lineData acquisition

The invention relates to a data acquisition and information management system and an acquisition method for a production line. The system comprises a plurality of production line information acquisition terminals, a plurality of production line information display terminals and a control center management system, wherein the production line information acquisition terminals are used for receiving a command of the control center management system and uploading the acquired data to the control center management system; the production line information display terminals are used for receiving a command issued by the control center management system and controlling the display effect of a display screen; the control center management system is used for performing communication with each acquisition terminal and display terminal to perform information interaction, saving information received from each acquisition terminal, and displaying the production line state in the form of diagram; and the plurality of acquisition terminals, the plurality of display terminals and the control center management system constitute a serial bus network. According to the system and the method, production line information can be acquired in real time, data can be analyzed and processed in real time, simultaneous delivery of a plurality of products is supported, a communication network is established in an economical and reliable industrial bus mode, and the quantity of the terminals can be increased flexibly according to the enterprise requirement and the production line layout.

Owner:GUANGDONG IND TECHN COLLEGE

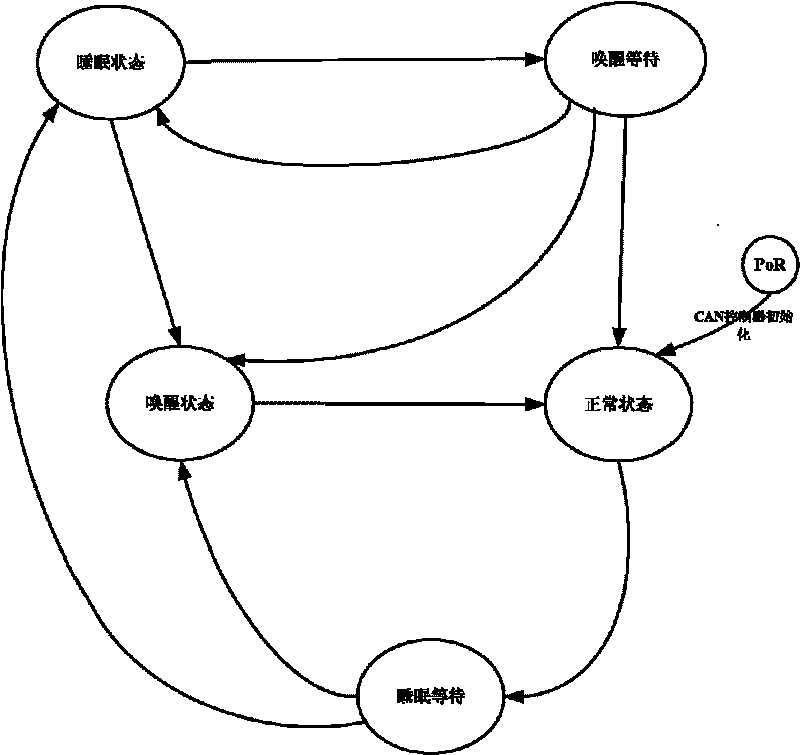

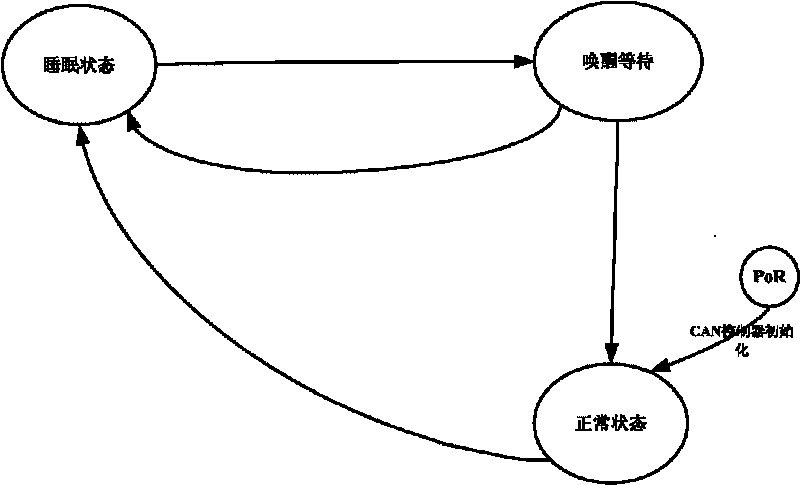

Electricity-saving method of vehicle-mounted CAN bus network

ActiveCN101700762AGuaranteed stabilityAvoid frequent switching transitionsElectric/fluid circuitBus networksElectricityOperational requirements

The invention provides an electricity-saving method of vehicle-mounted CAN bus network, belonging to the electronic technical field. The method solves the problem that electric energy is transported to existing automobile electric equipment no matter the equipment works or not to cause electric energy waste. The electricity-saving method of the vehicle-mounted CAN bus network is as follows: a CAN bus is provided with controller modules used as nodes, and the method can lead the control modules to enter a low power consumption mode in the case of no operational requirement under program setting, can switch each controller module among various states, thereby achieving the electricity-saving purpose when the controller modules are in the low power consumption state in the case of no tasks required to be processed.

Owner:南通迈程汽车技术有限公司

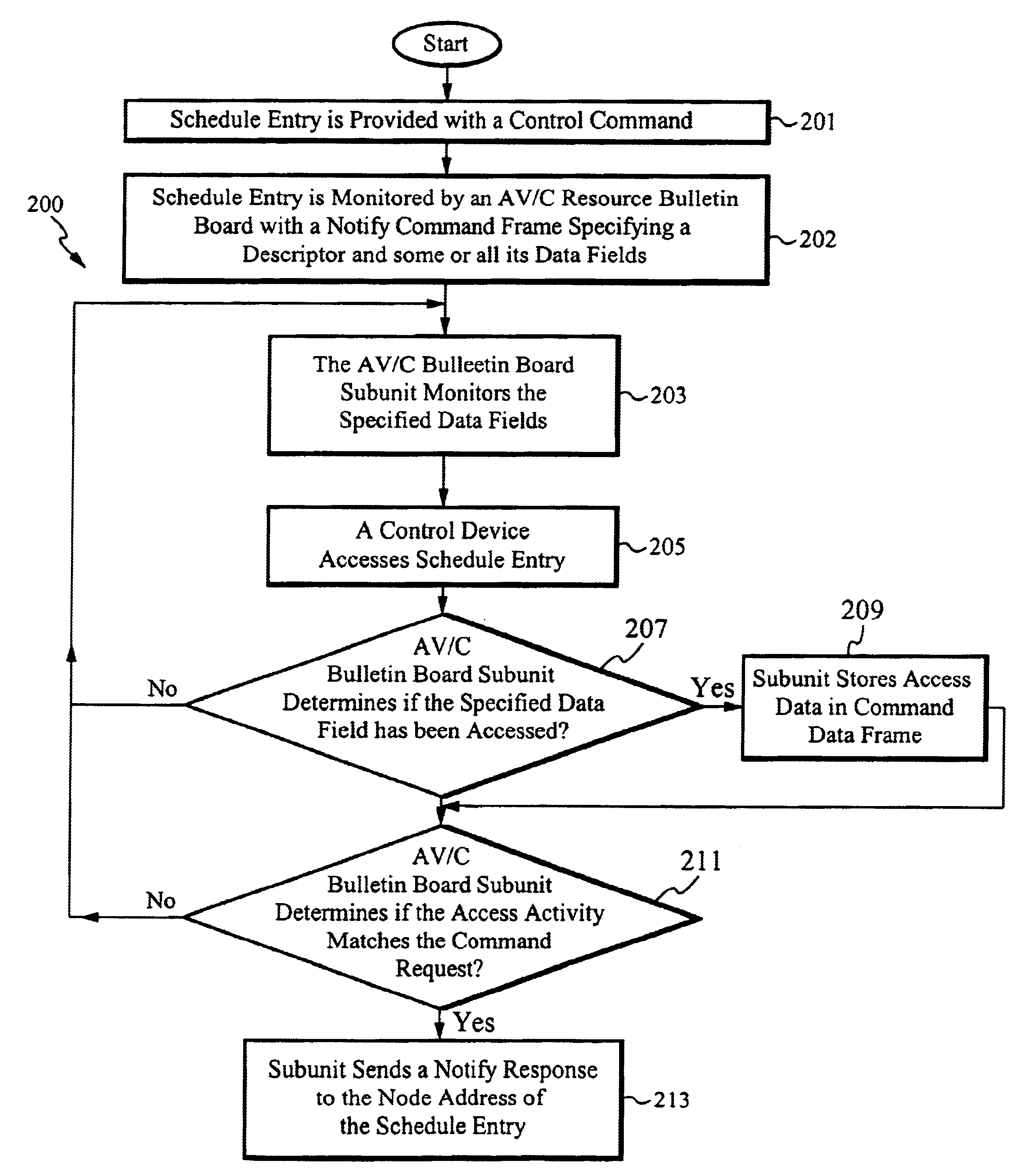

Method of and apparatus for communicating data structures between devices in a networking environment

An architecture, a system and a method monitors data structures over an IEEE 1394-1995 serial bus network. The data structures are portions of entries posted and stored to a descriptor mechanism. A resource request is submitted by a requesting control device to an AV / C resource schedule bulletin board subunit, where request data is stored and posted. The requesting control device submits a corresponding notify command data frame to the AV / C bulletin board subunit. When a competing control device performs a specified type of access activity on a specified data structure, the bulletin board subunit sends a notify response frame to the original requesting control device. The notify response frame provides an alert to the original requesting control device that the specified access activity has been performed on the specified data structure by a competing control device.

Owner:SONY CORP +1

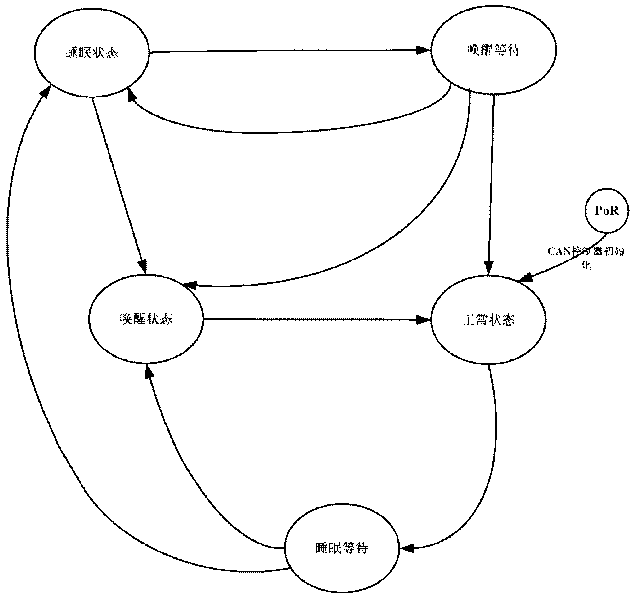

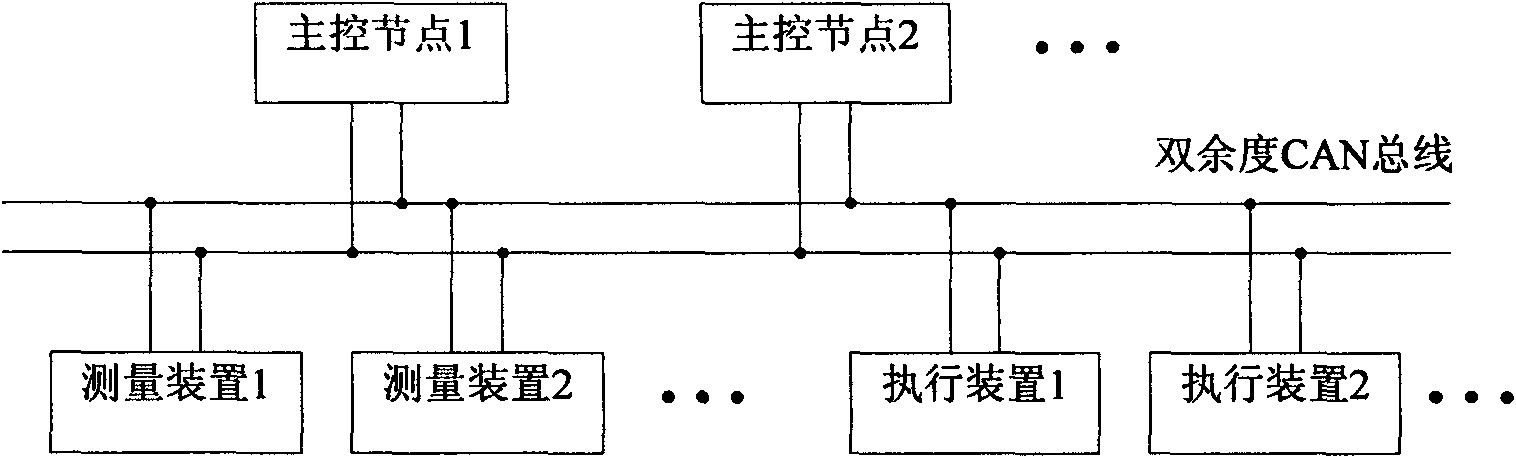

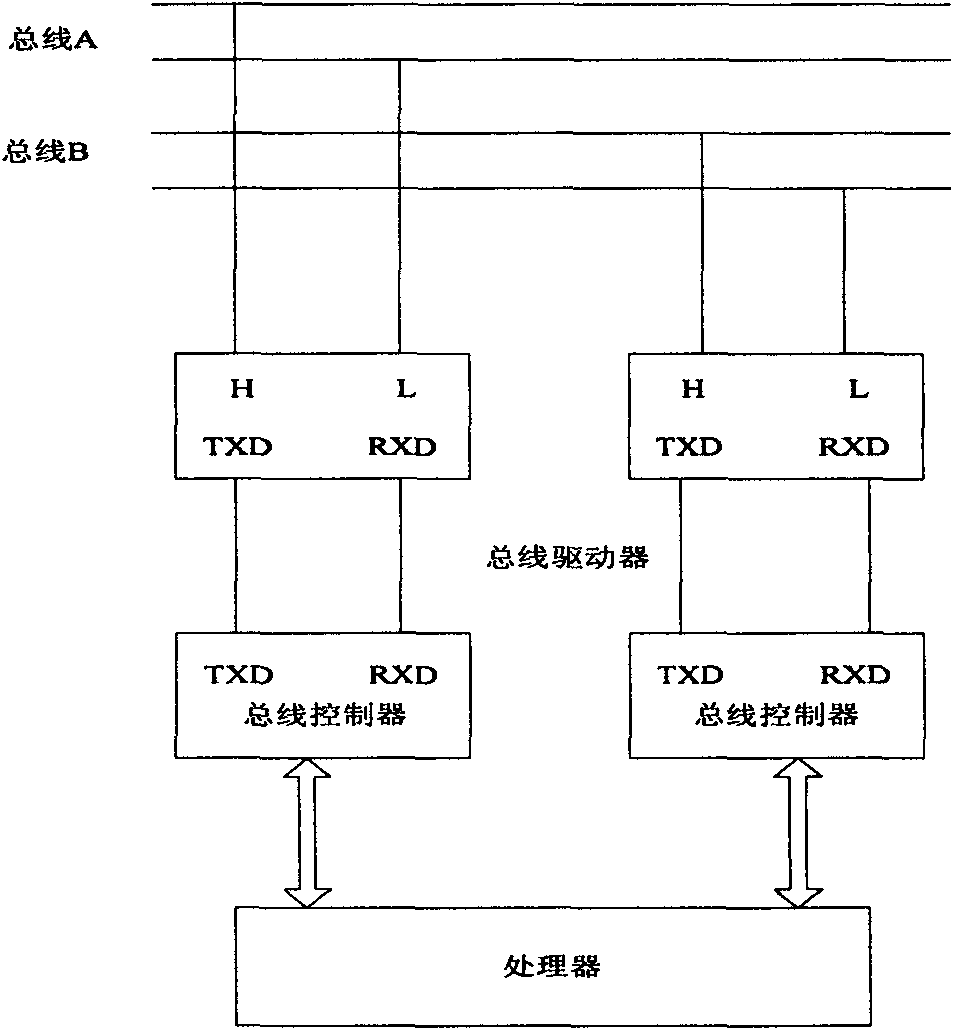

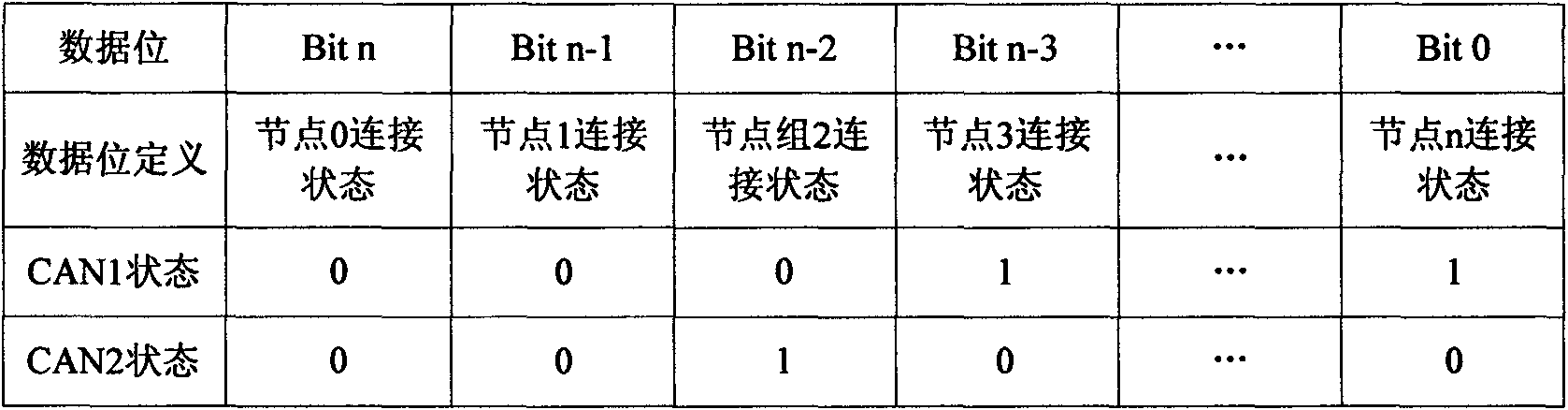

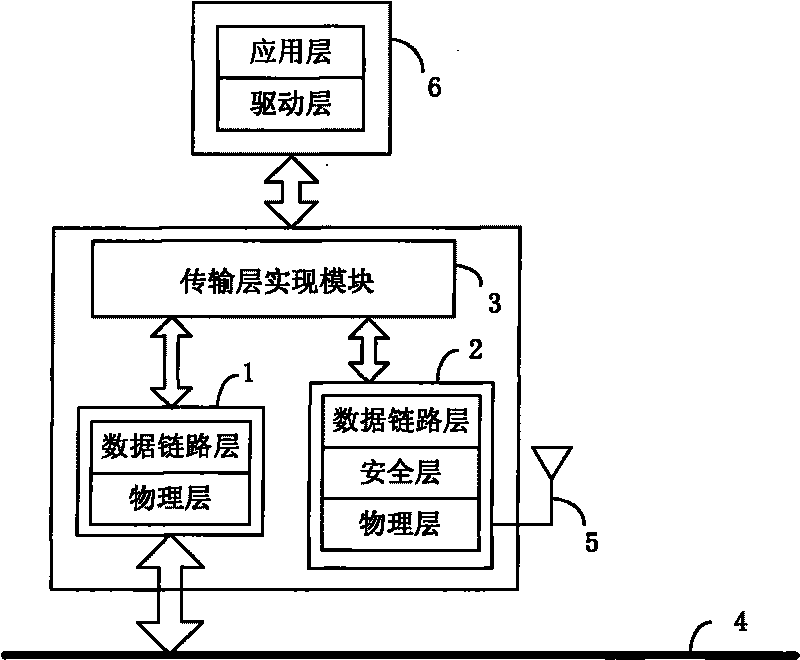

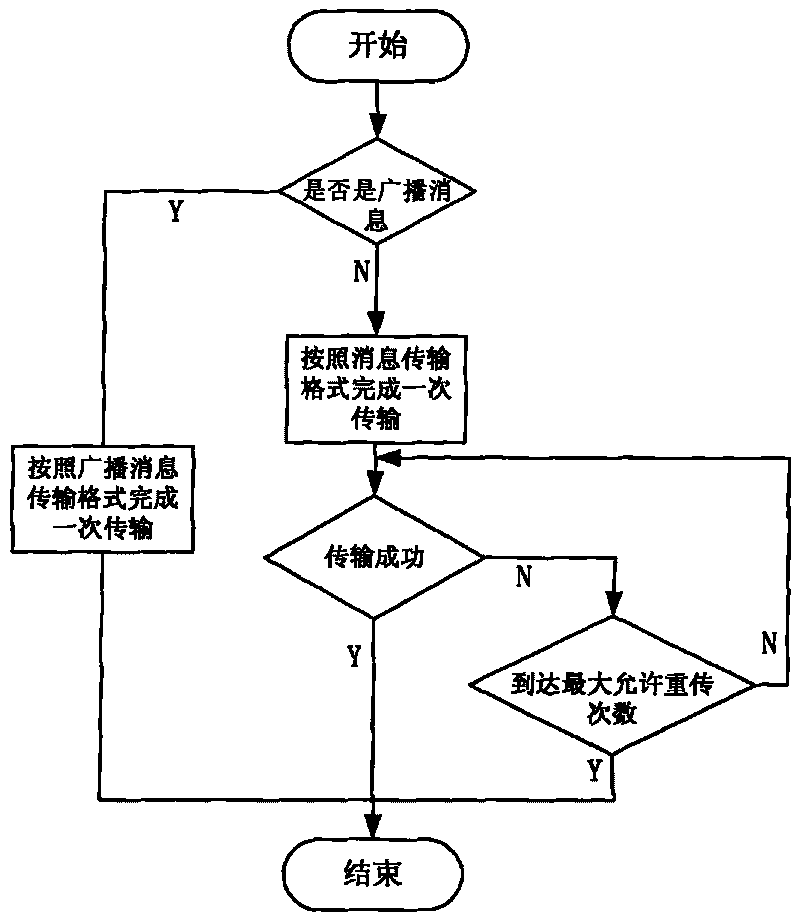

Network control method of dual-redundancy CAN bus

ActiveCN101631057AImprove fault toleranceEasy programmingError preventionBus networksElectricityMain channel

The invention provides a network control method of a dual-redundancy CAN bus, which comprises five major steps: step 1: switching on a system and carrying out node initialization; step 2: detecting the initialization of the system; step 3: carrying out normal work and cycle detection; step 4: carrying out treatment of abnormality during the operation of the system; and step 5: carrying out the treatment after switching over a main channel and a standby channel. The method fully utilizes a mature CAN device for constructing a dual-redundancy bus network, carries out error detection and specifies control authorities of different nodes through application software, realizes a network control strategy of distributed monitoring and centralized management, simultaneously provides a detailed fault detection method of the CAN bus system and carries out classification on different errors, thereby being easy to realize programming and having strong universality. The network control method improves the fault-tolerant capacity of the CAN bus system and fully utilizes the redundancy mechanism to ensure the reliability of the system; and the network control method has wide practical value and application prospect in the field of mechanical and electrical control.

Owner:BEIHANG UNIV

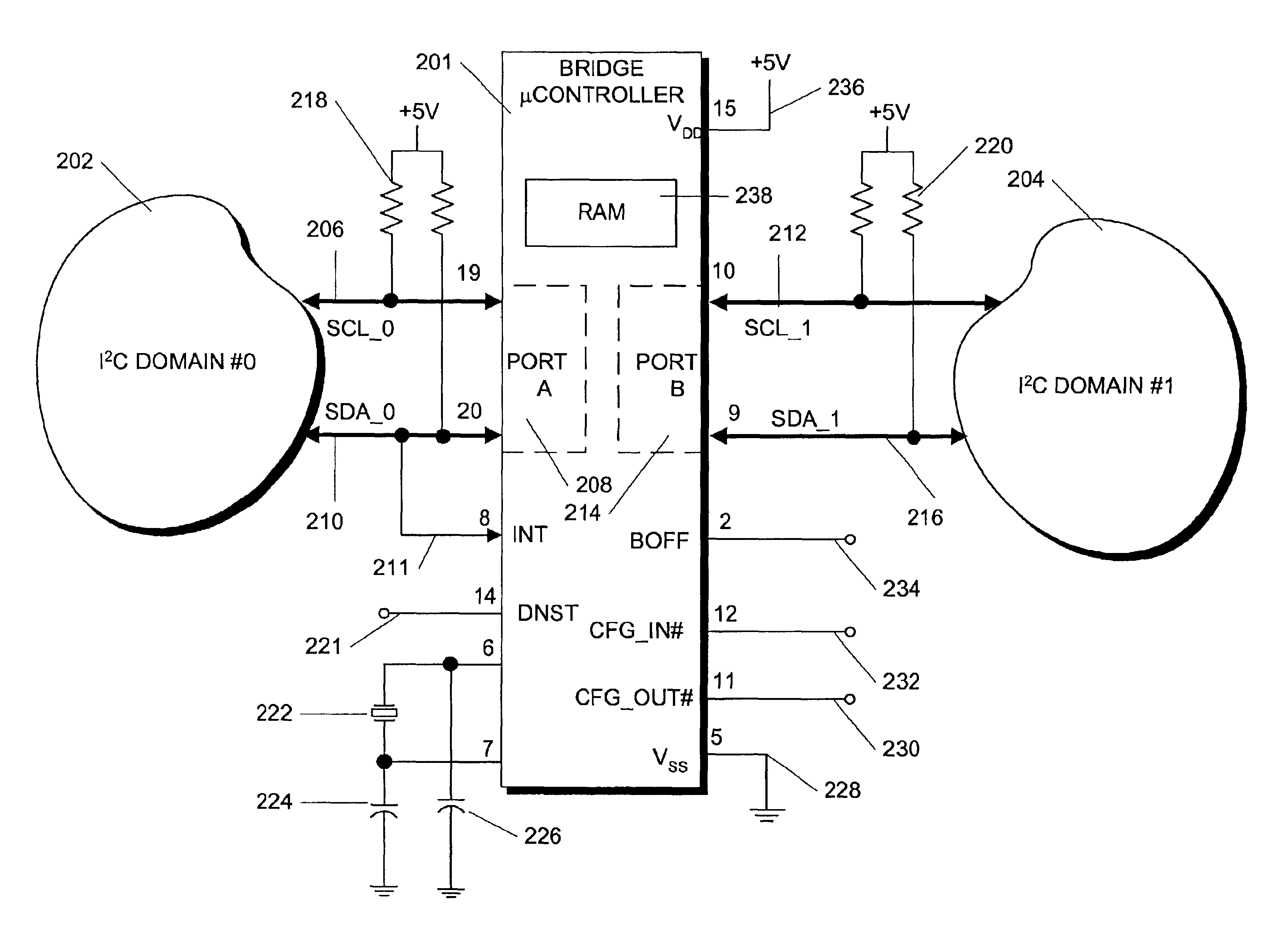

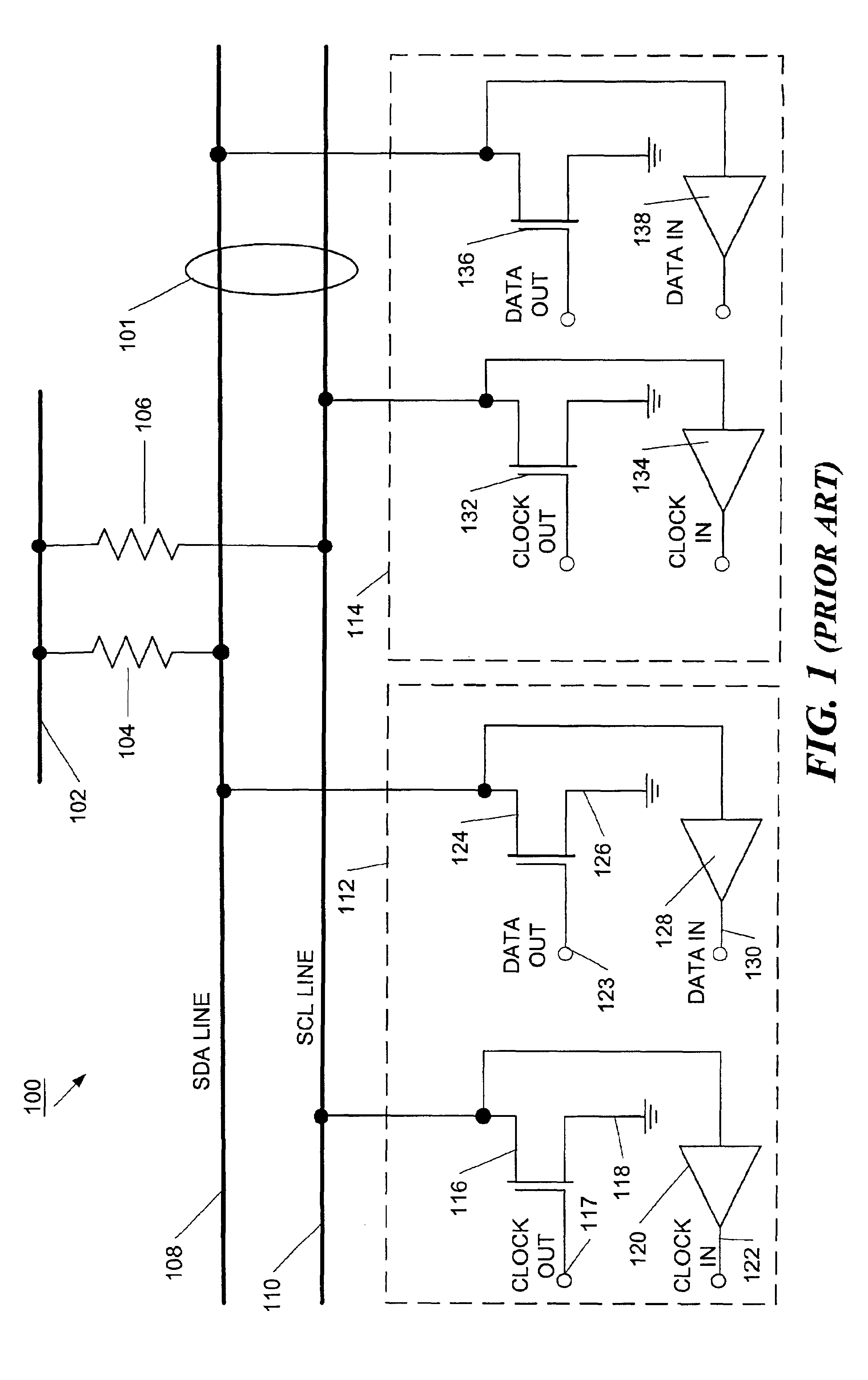

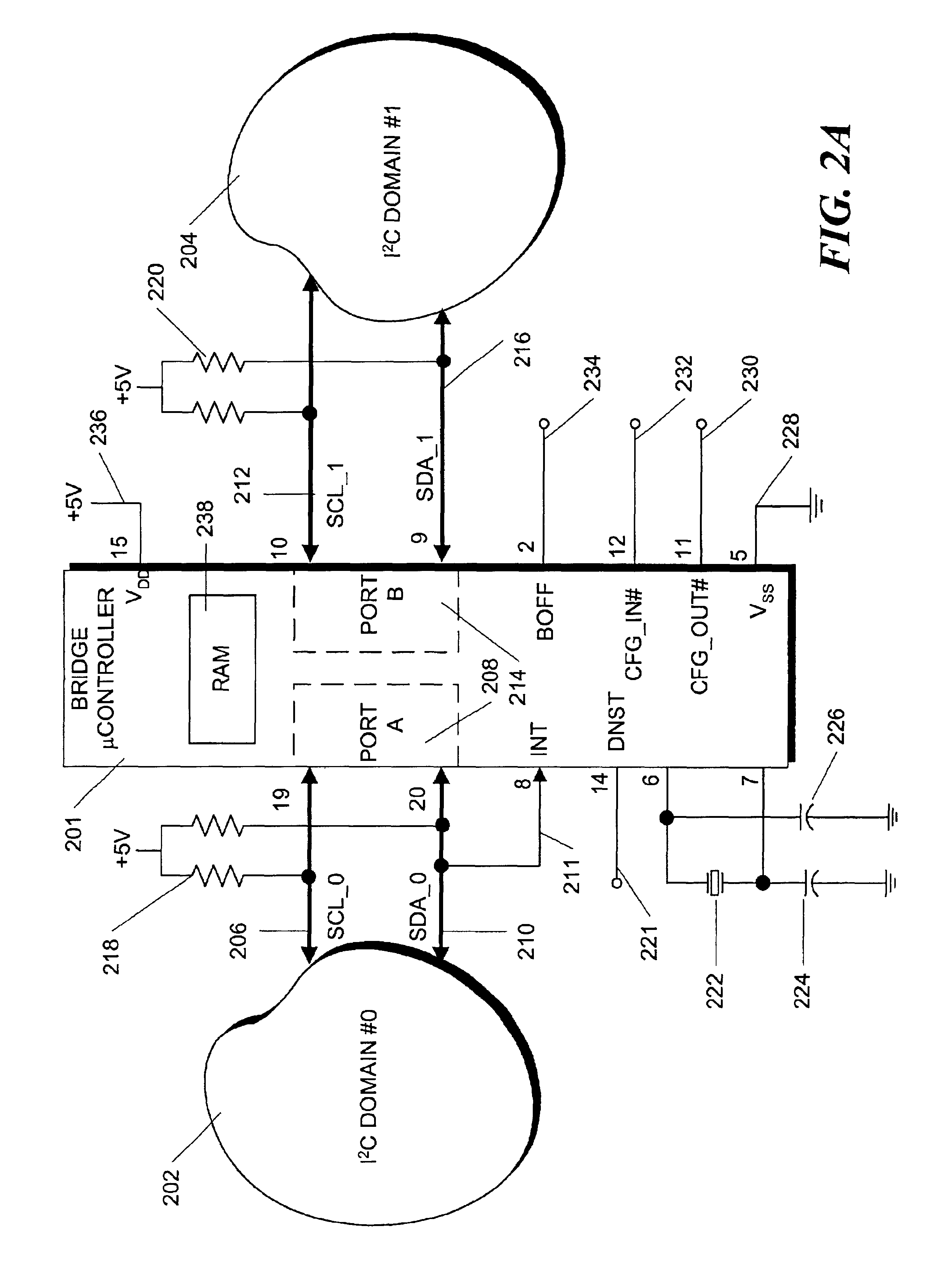

Method and apparatus for interconnecting wired-AND buses

InactiveUS6842806B2Maximizing abilityImprove abilitiesElectric digital data processingBitmapBus network

One or more bus bridges are used to partition a large I2C bus into smaller bus segments. By programming address bitmaps that are internal to each bridge, the various bus segments can be made to appear as one logical bus. In addition, the bus topology can be designed to maximize the ability to isolate faults within a given segment, thereby improving the ability of technicians to diagnose problems in very large I2C implementations. In one embodiment, the invention is a unidirectional bus bridge which is designed so that two such bridges can be used in parallel (facing in opposite directions) to implement a fully bi-directional bus bridge. In another embodiment, I2C slave addresses are replicated in a single logical I2C bus by addressing a tunnel command to a bridge, which command contains an address and causes the bridge to which it is addressed to forward the contained address.

Owner:ORACLE INT CORP

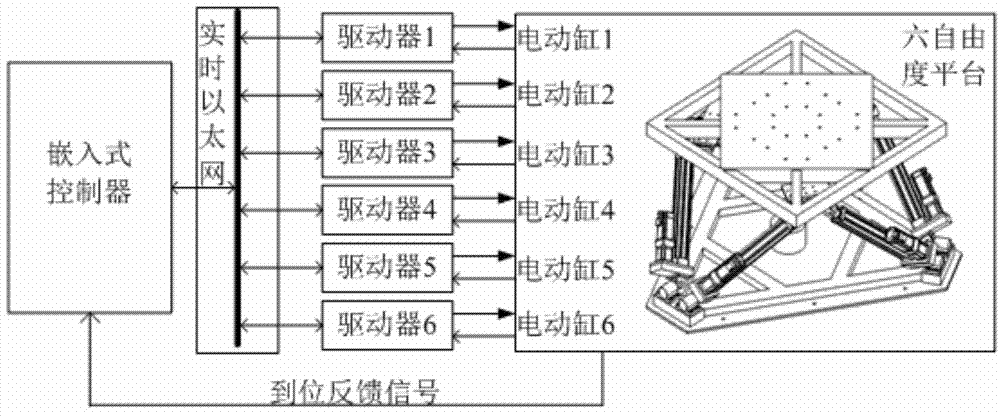

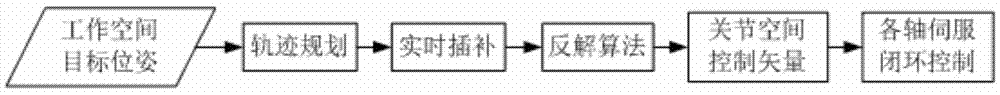

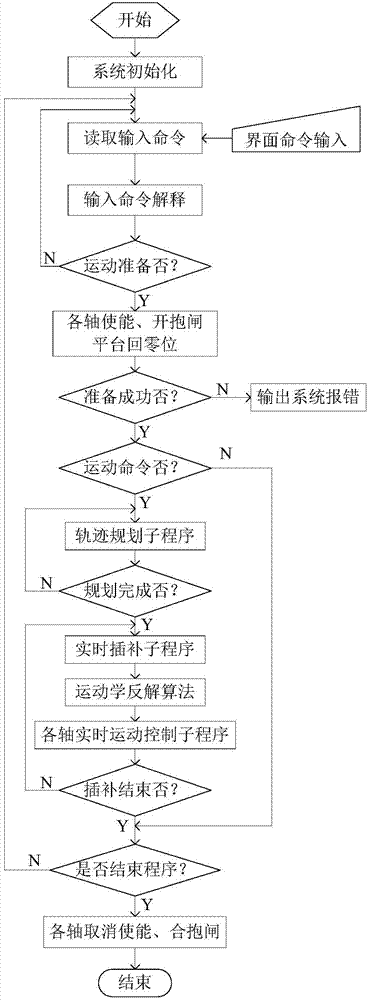

Power-driven six-degree of freedom motion platform high-precision control system and control method

ActiveCN104731107ASmooth and stable running trackGood movement synchronizationPosition/course control in three dimensionsMotor driveControl system

The invention belongs to the technical field of mechanical-electrical integration and drive control and discloses a power-driven six-degree of freedom motion platform high-precision control system and control method. The power-driven six-degree of freedom motion platform high-precision control system comprises an embedded controller, a real-time Ethernet bus network and a driver; the embedded controller transfers a control instruction to the driver through the real-time Ethernet bus network, a power-driven cylinder is connected with a servo motor, the driver drives the servo motor directly, the servo motor drives the power-driven cylinder to perform telescopic motion, and the motion of a six degrees of freedom motion platform is achieved. The power-driven six-degree of freedom motion platform high-precision control system and control method have the advantages of being high in control real-time performance, good in motion synchronism of all branches, high in reliability, simple in structure, flexible in extension and easy to maintain. Based on the flexible software design platform, not only can the motion simulation be achieved, but also the high-precision multi-degree of freedom location can be achieved.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

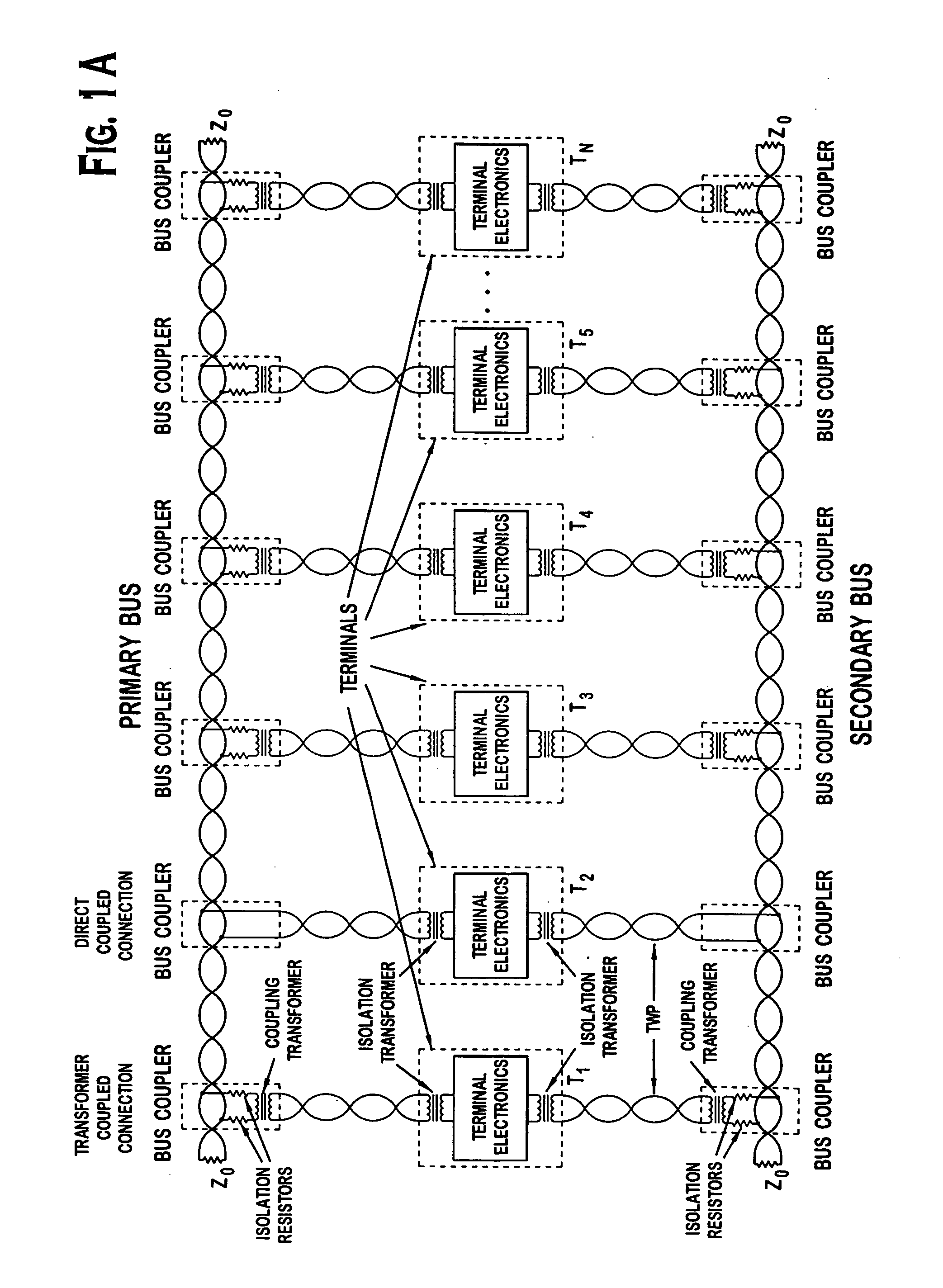

Dual speed/dual redundant bus system

InactiveUS20060101184A1Increase data rateDecreased SNRError detection/correctionData switching networksMultiplexingFault tolerance

Method and apparatus for use of the dual redundant bus network utilizing time and frequency multiplexing techniques to provide a high bit rate system that maintains a lower bit error rate with good fault tolerance by sending a low speed message on one bus and a high speed message on the remaining bus then operating at a dual bus mode and for reducing the speed of the high speed to aerate between the high speed and low speed message rates and multiplexing the low speed and reduced high speed messages when a fault condition is detected on one of the buses. Techniques are provided for continuously monitoring the buses to identify the least recently used (LRU) to facilitate bus selection and selection of one of the dual bus and concurrent modes for operation.

Owner:DATA DEVICE CORP

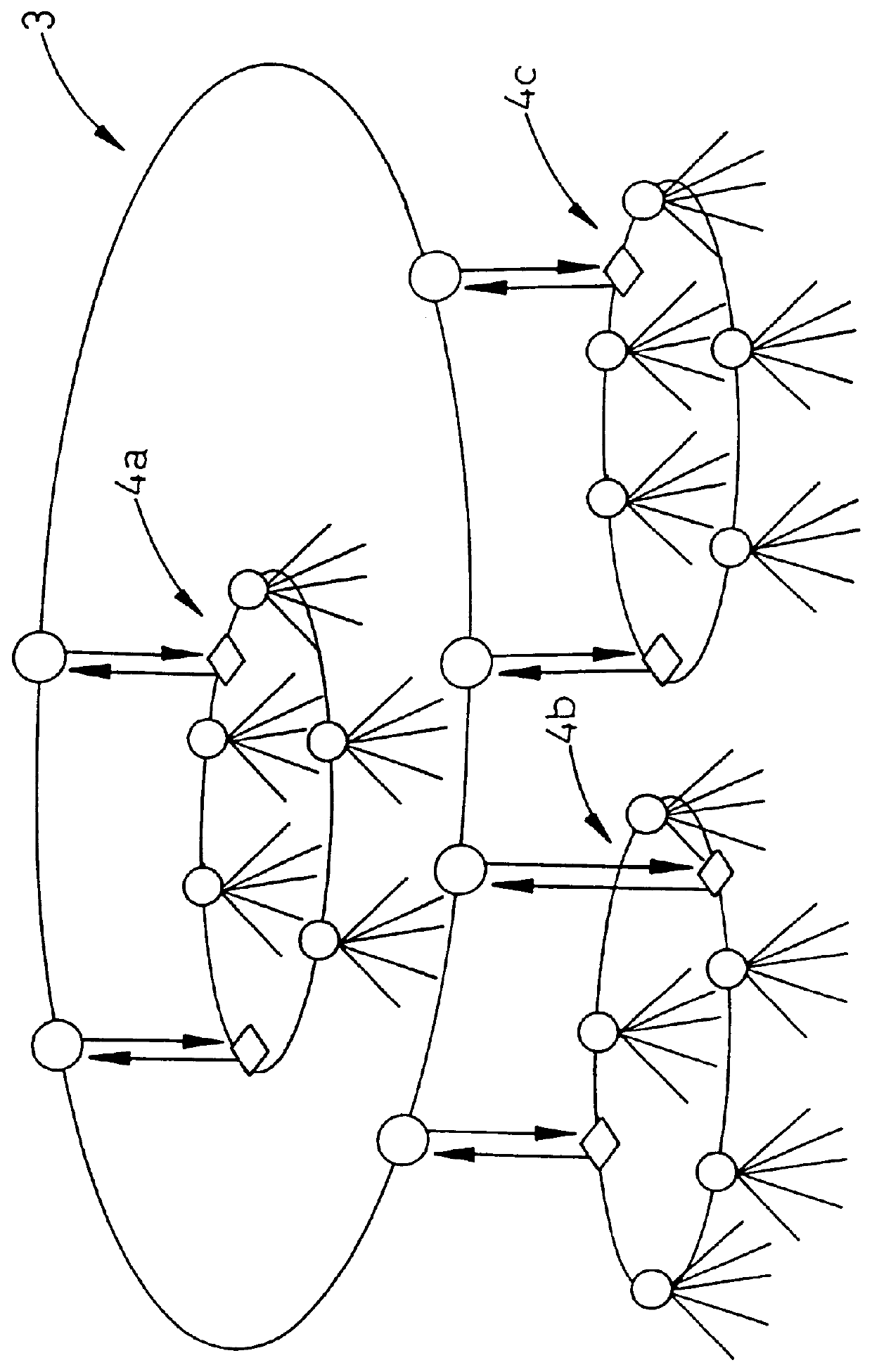

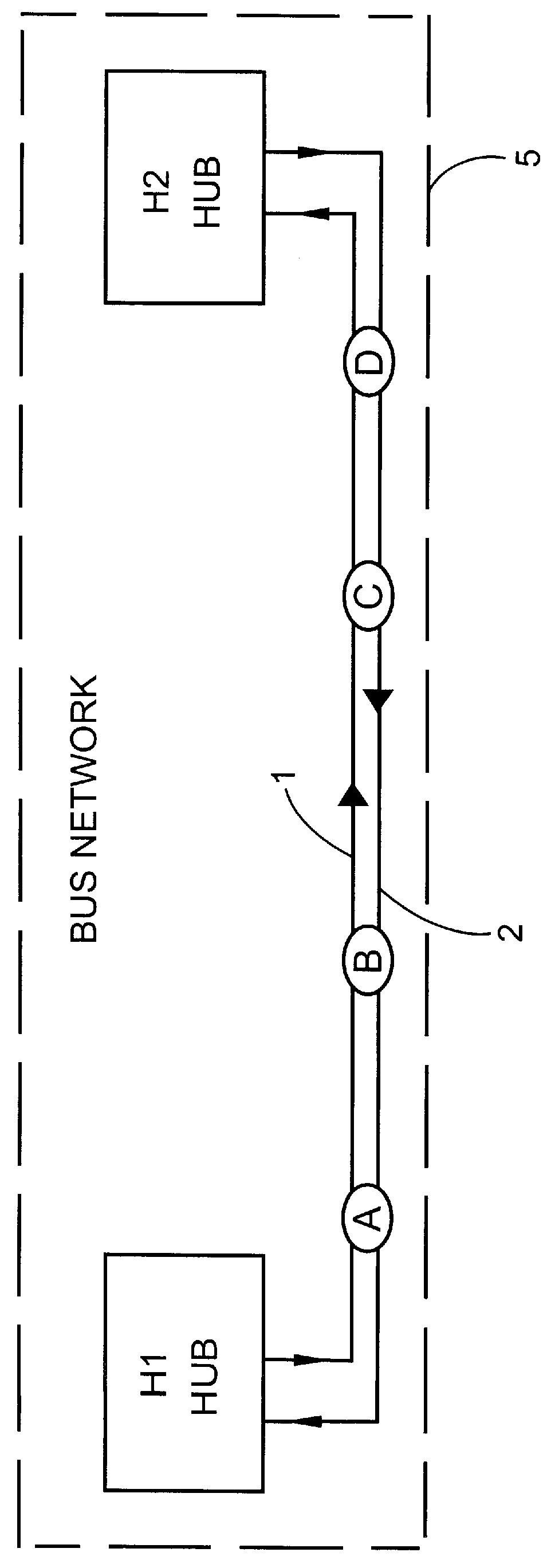

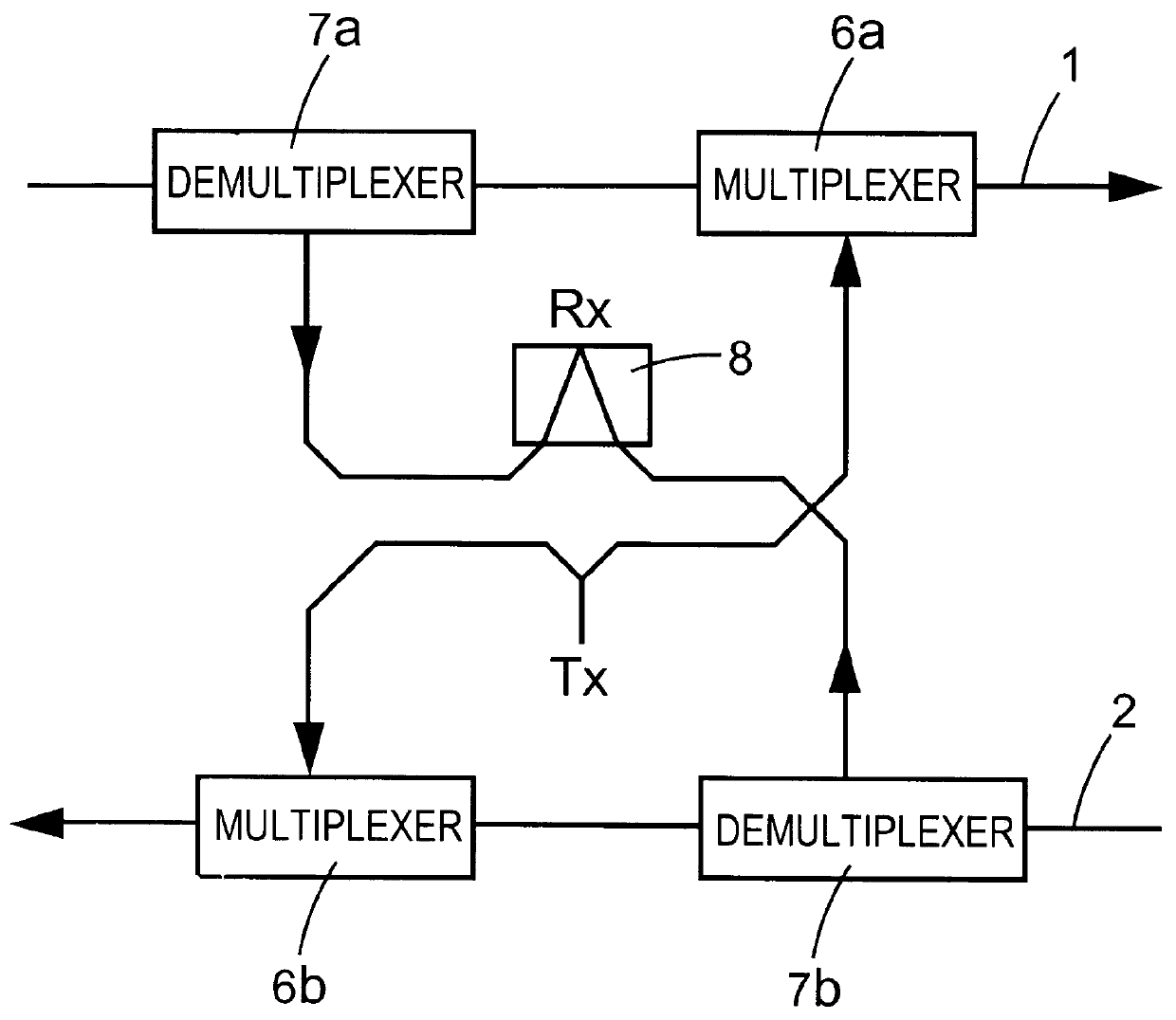

Optical network and arrangement and method in such network

PCT No. PCT / SE96 / 00374 Sec. 371 Date Dec. 29, 1997 Sec. 102(e) Date Dec. 29, 1997 PCT Filed Mar. 26, 1996 PCT Pub. No. WO96 / 31964 PCT Pub. Date Oct. 10, 1996An optical network which is arranged to ensure communication between nodes in a lower-order loop and a higher-order loop when there is an interruption in the lower-order loop or in the event of hub failure. Each lower-order loop consists of a bus network with hubs and one or a plurality of nodes. Two optical fibers connect the nodes in each bus network and are used for communication in opposite directions between the nodes. Each bus network comprises precisely two hubs of which the first closes the bus network end at the first end thereof and the second closes the bus network at the other end. The hubs connect the bus networks in a lower-order loop and join this loop to a higher-order loop. Each node in the bus network is arranged to communicate with each hub. Channel allocation can be carried out so that channels received in one node are re-used for transmission on the same fiber from the same node.

Owner:TELEFON AB LM ERICSSON (PUBL)

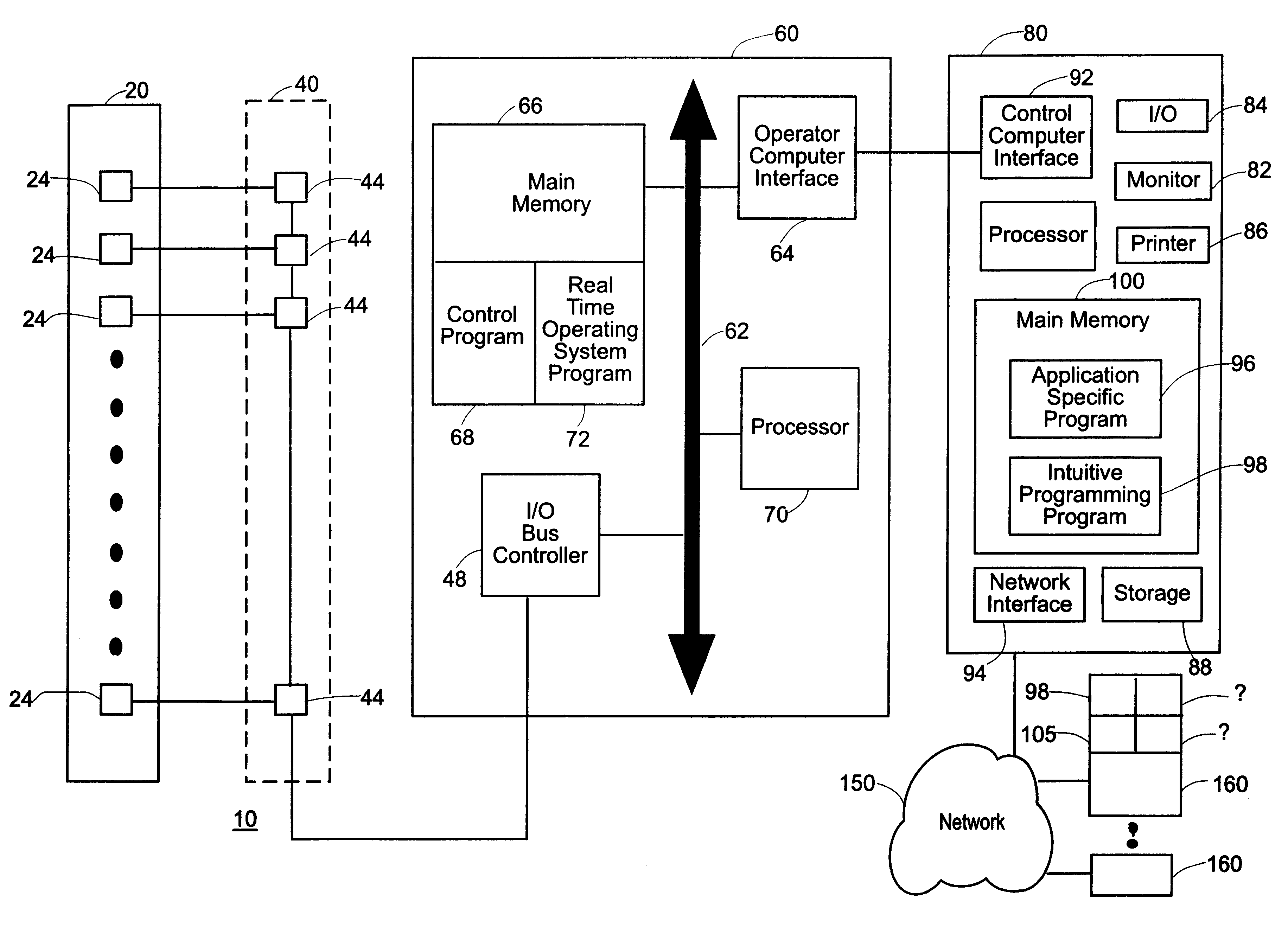

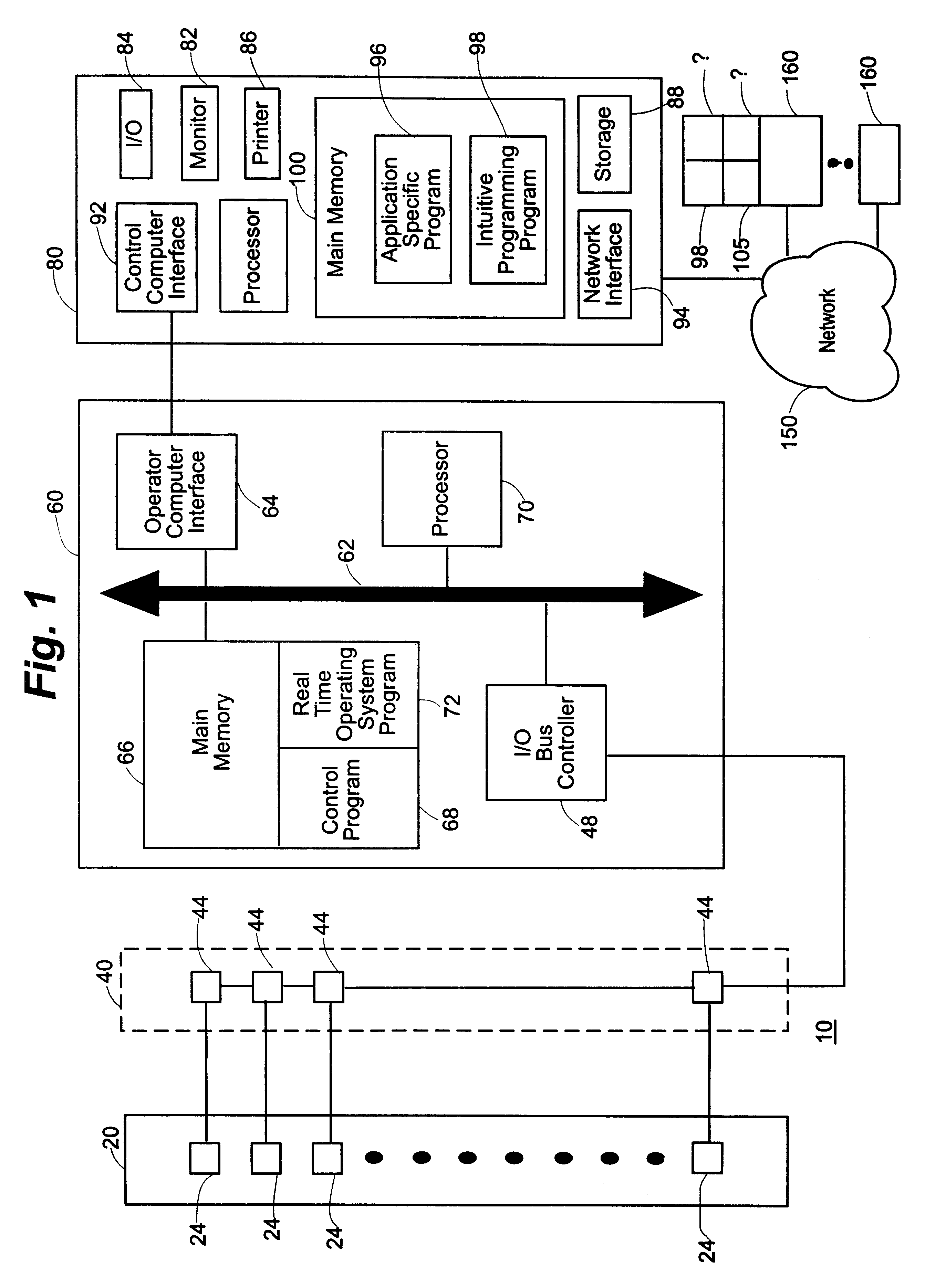

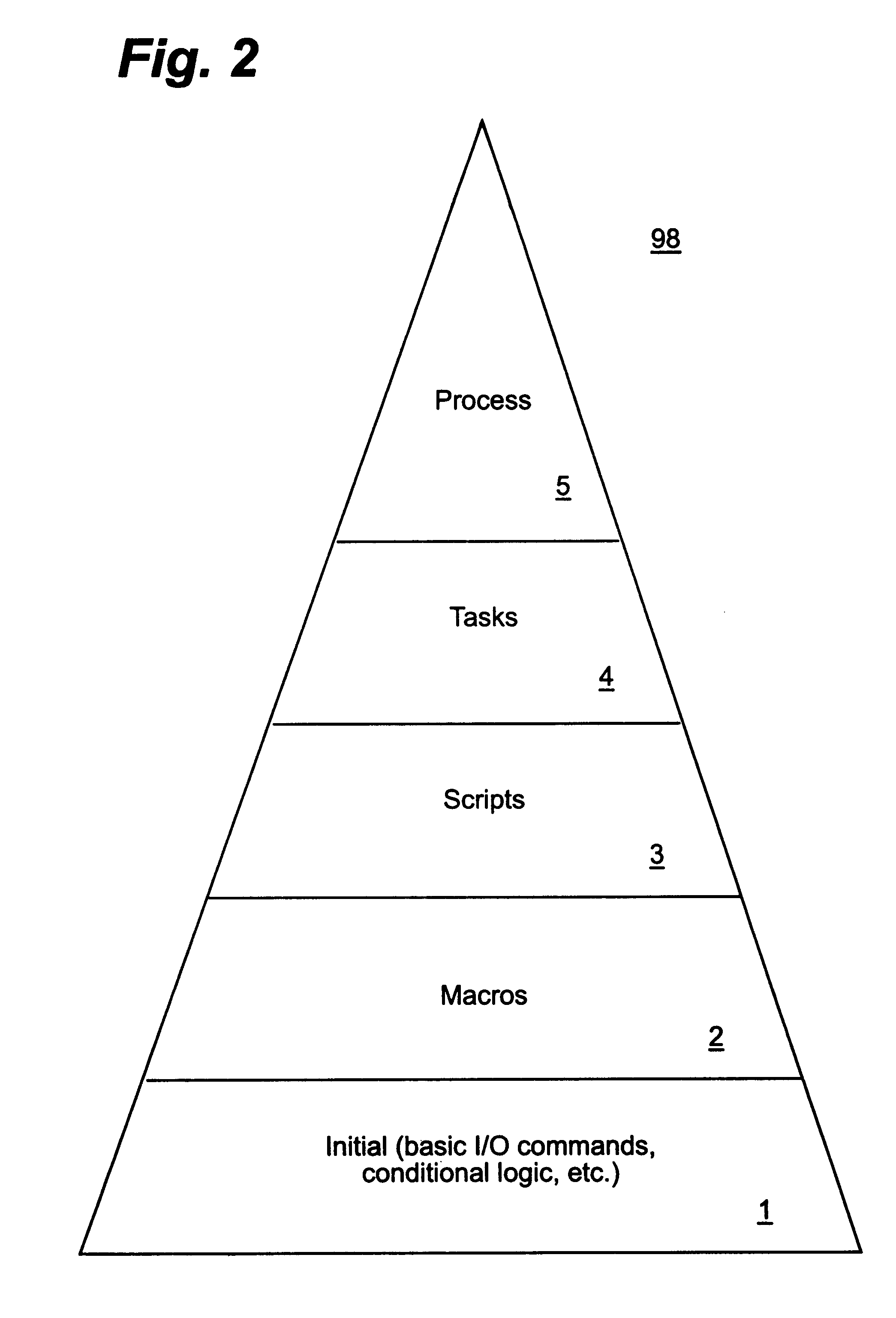

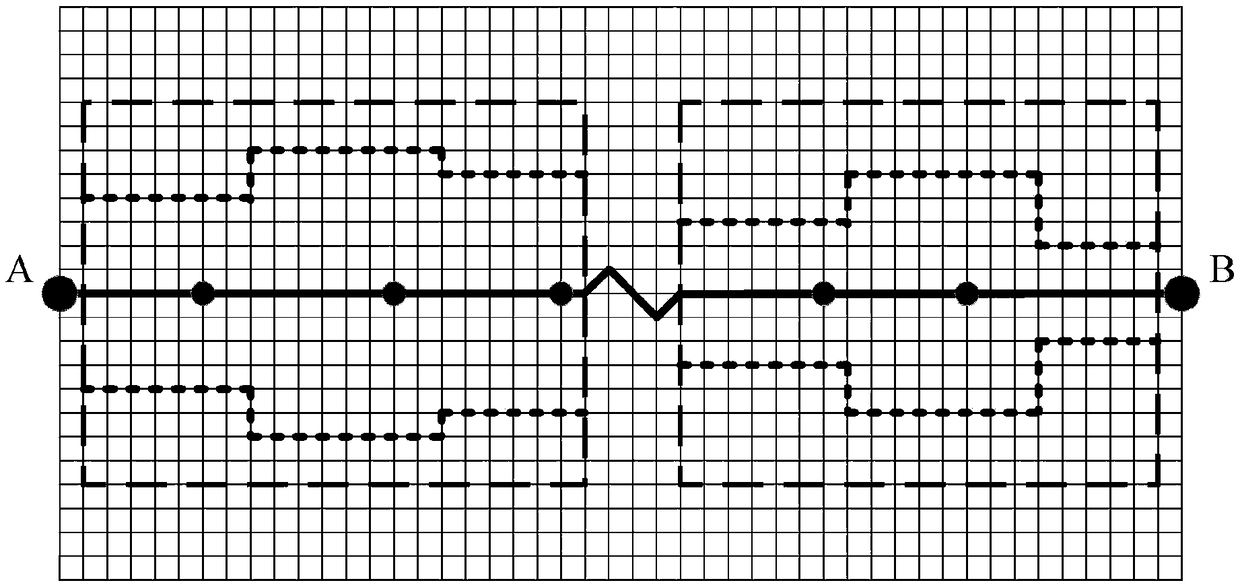

Processor-based process control system with intuitive programming capabilities

A system having a processor-based process control system for a plastic injection molding machine performing a plastic injection molding process having an I / O bus network containing a plurality of I / O modules operably connected to a corresponding I / O device associated with the plastic injection molding machine and a first computer having and I / O bus controller directly connected to the I / O bus network, a real-time operating system, and a first processor executing a plastic injection molding control program for controlling the plastic injection molding process.

Owner:HETTINGA SIEBOLT

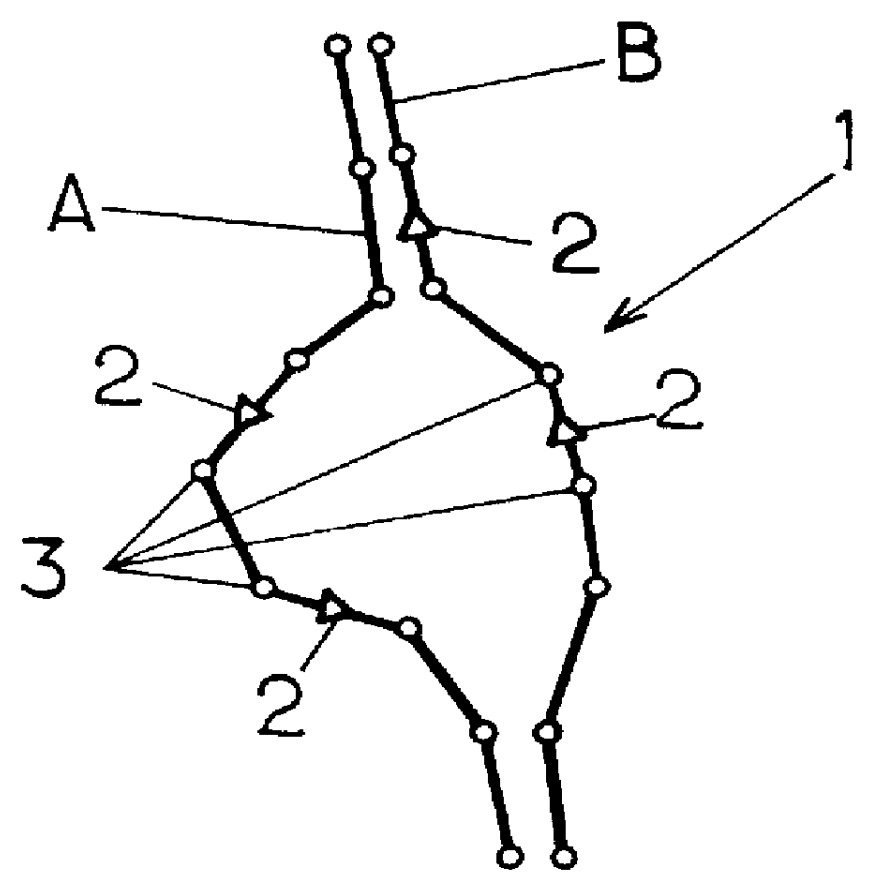

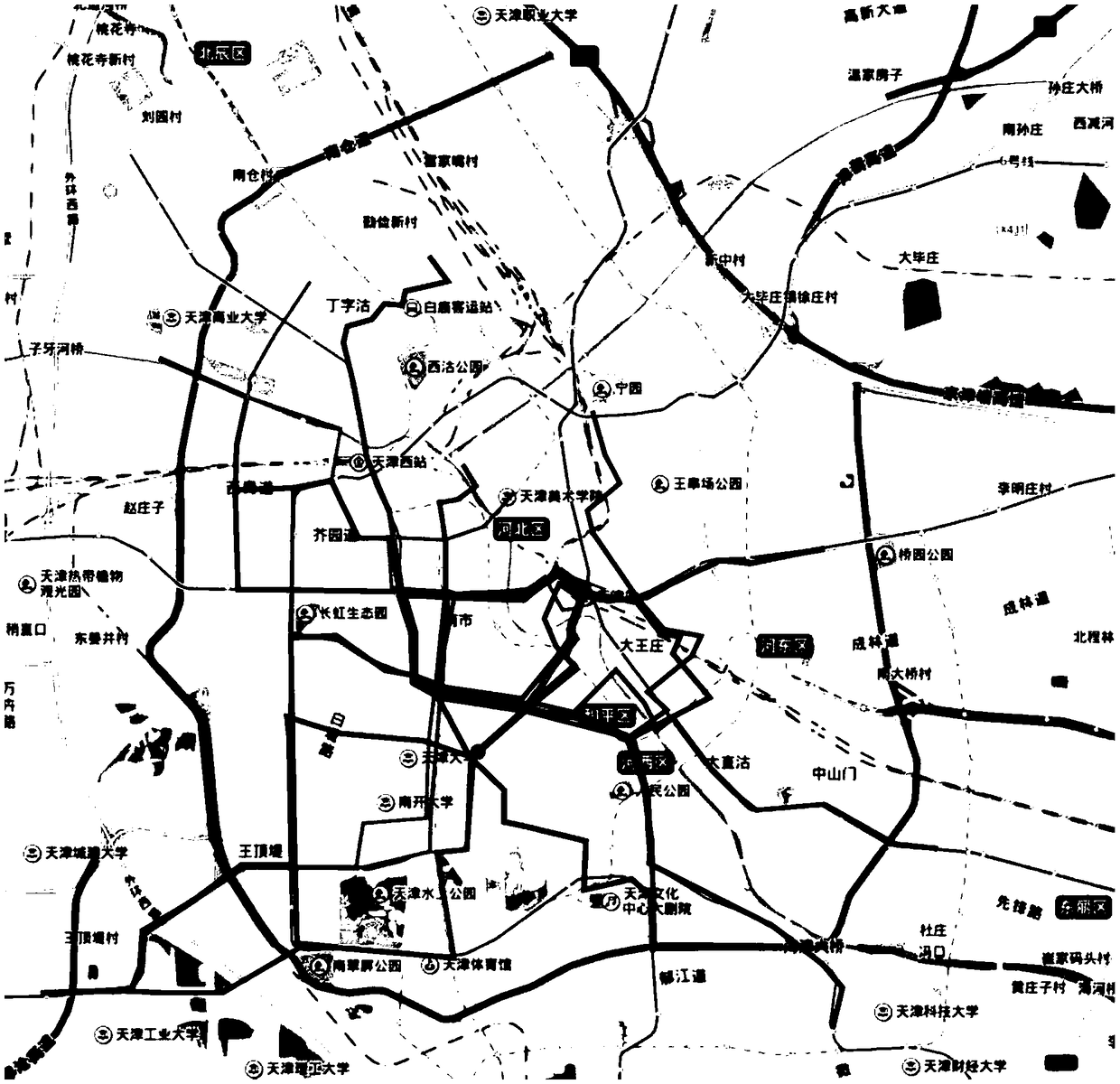

Customized bus route opening optimization method based on real-time demand

ActiveCN109409599AIncrease flexibilityImprove the status quo of low attendanceForecastingTravel modeRoad networks

The invention relates to a customized bus line opening optimization method based on real-time requirements, which comprises the following steps of: establishing a customized bus network system, comprising the selection of a network node, the determination of a network path and the selection of a parking node; customizing the bus line opening conditions, including: real-time demand user informationacquisition and demand response time determination; a method for customize a bus network model and passenger classification comprise that steps of: establishing a spatio-temporal road network, determining a spatio-temporal window of passengers and classify passengers; Initial customization of bus route generation model, including establishing a Route Optimization Model with Minimum Total passenger-Operator Cost; Initial customized bus route generation algorithm is to use column generation algorithm to determine the initial customized bus route; Optimize customized bus routes that have been opened. The invention can greatly improve the flexibility of the customized bus, so that the customized bus has more advantages in the travel mode selection, thereby improving the present situation of low seating rate of the customized bus, and finally improving the share rate of the customized bus travel mode.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

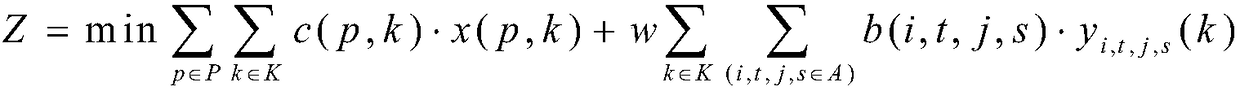

MIL-STD-1553B bus termination and redundancy backup method thereof

InactiveCN101707495ASustained Data Transmission CapabilityError preventionWired communicationThe Internet

The invention discloses an MIL-STD-1553B bus termination and a redundancy backup method thereof. The MIL-STD-1553B bus termination comprises a wire communication module, a transmission layer implementation module and a wireless communication module. The redundancy backup method is to use wireless communication for completing the task of message transmission when wire communication malfunctions. In the invention, when the failure of cables, couplers, or the termination causes the partial or total failure of the wire communication, the bus termination still guarantees sustaining data transmission capability, thus further enhancing the reliability of Internet. The wire communication module conforms to the existing 1553B bus norm and the wireless redundancy backup method is completely in linewith the upper-layer protocol used by the existing 1553B bus equipment. The bus termination can coexist with other equipment conforming with the 1553B norm in the same 1553B bus network.

Owner:BEIHANG UNIV

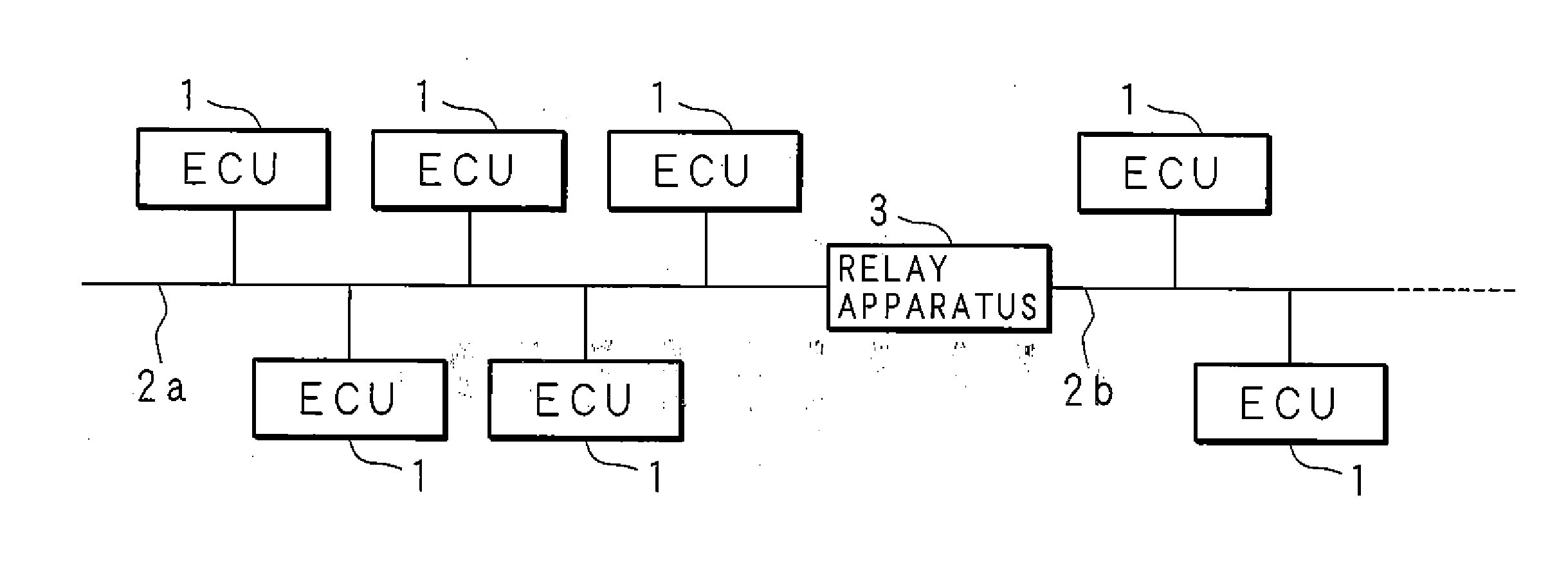

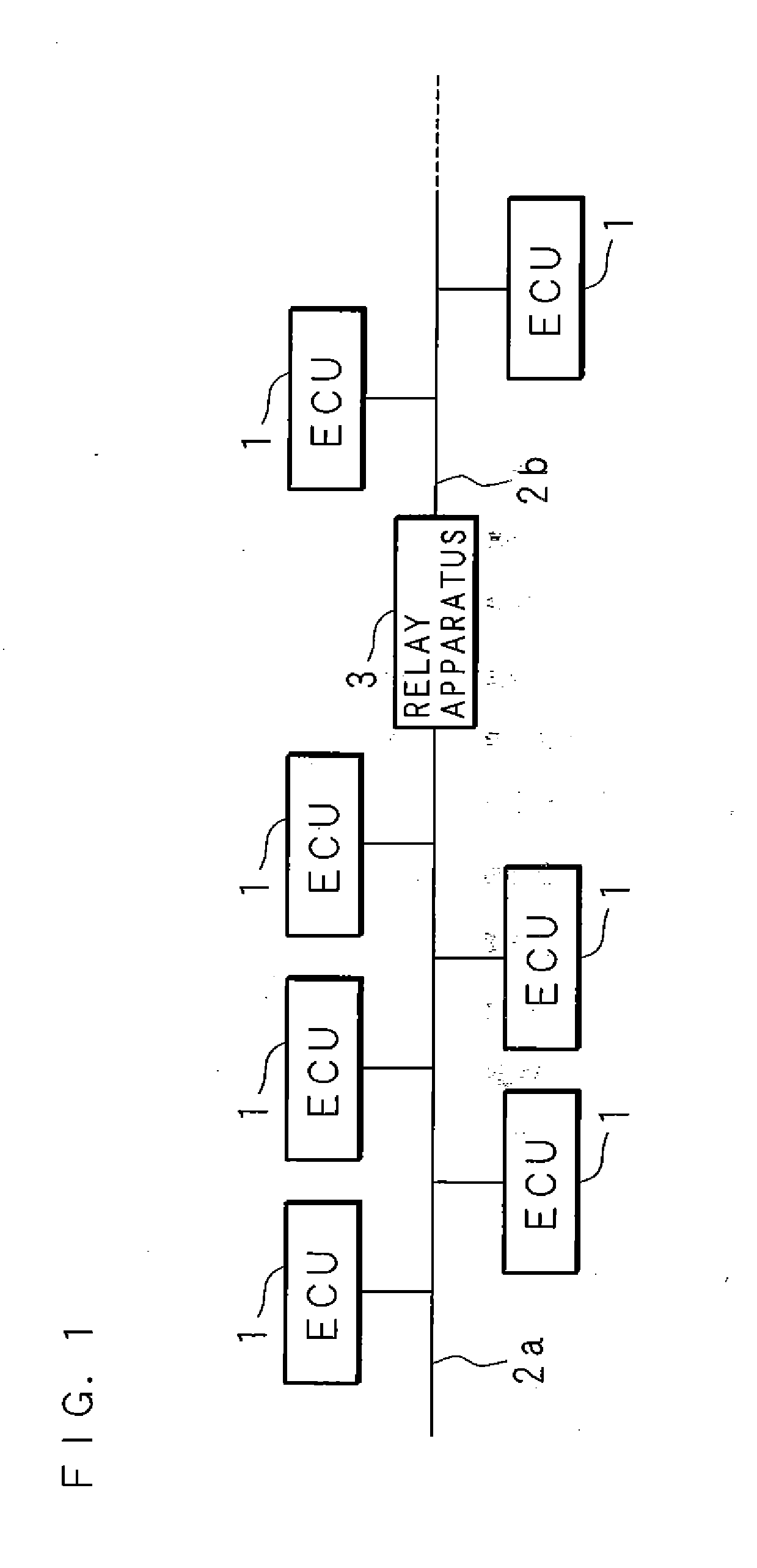

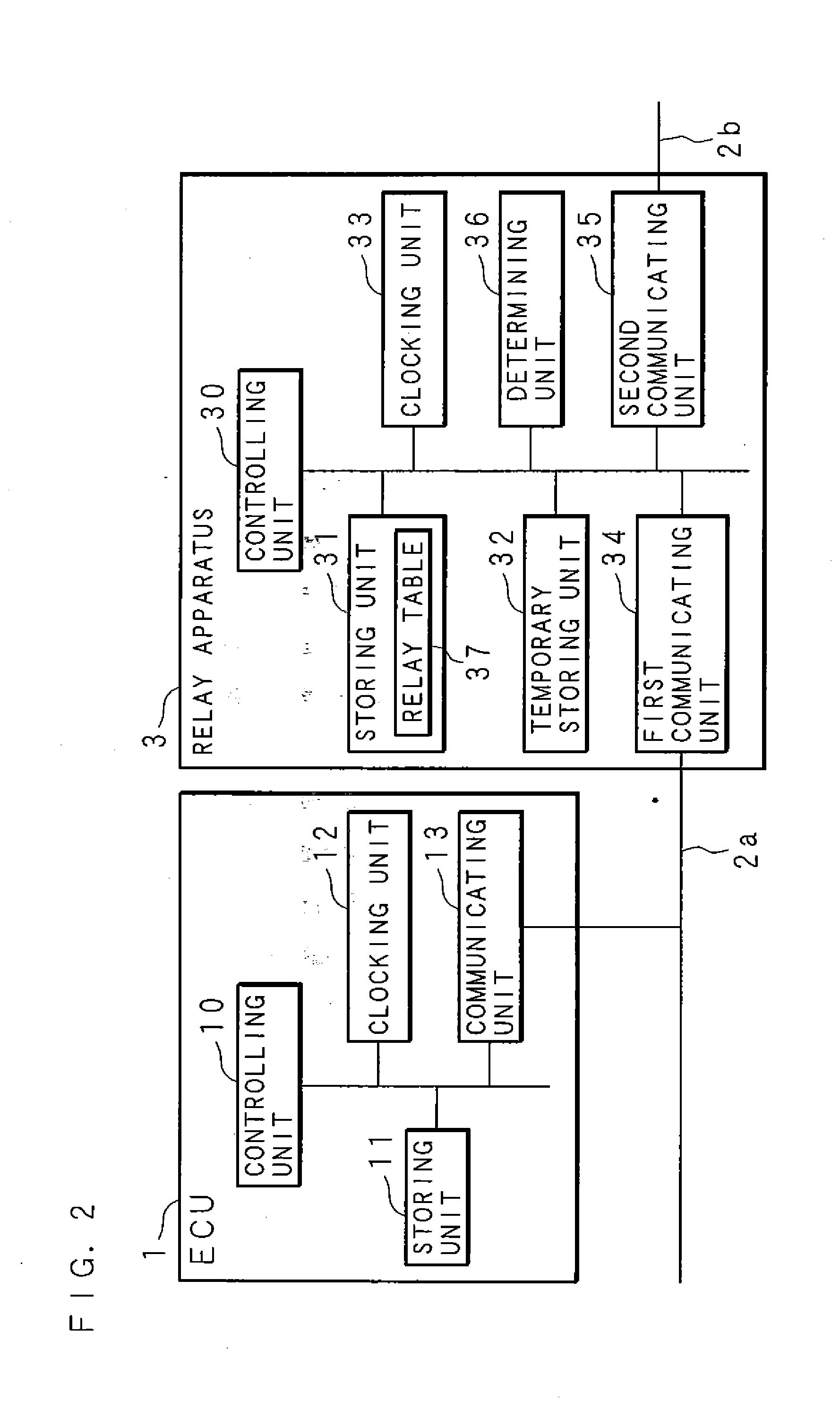

Communication apparatus, relay apparatus, communication system and communication method

InactiveUS20110208884A1Improve communication efficiencyPrevented from reachingData switching networksElectric digital data processingCommunications systemEngineering

It is expected to provide a communication apparatus, relay apparatus, communication system and communication method for effectively performing a communication timing adjustment when a collision has occurred on a communication line, efficiently reducing the communication collision with reducing processing loads on each apparatus, for making each apparatus effectively perform the transmission timing adjustment, and for improving the communication efficiency. ECUs are connected to communication lines with a bus topology. A relay apparatus is connected to the communication lines, obtains a time distribution based on a number of messages transmitted to the communication lines. When the bias occurs in the transmission timings, the relay apparatus transmits an instruction message that instructs to perform the timing adjustment for messages transmitted between the ECUs. In addition, it is determined whether a message to be relayed is held. When it is determined that such a message is held, the instruction message is transmitted.

Owner:AUTONETWORKS TECH LTD +2

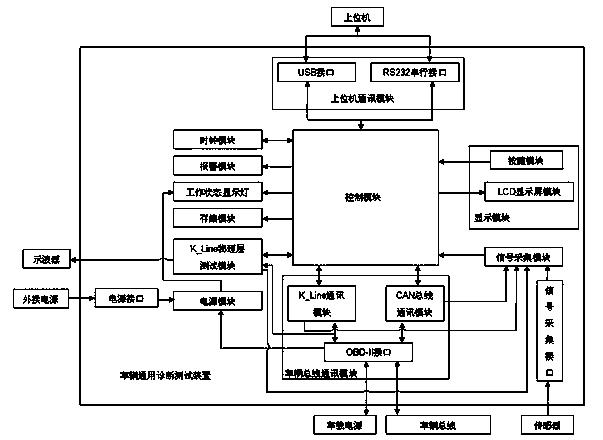

Commonly-used diagnostic test device for vehicle

ActiveCN103412562AImplement diagnosticsDiagnostic test implementationElectric testing/monitoringData switching networksComputer modulePhysical layer

The invention discloses a commonly-used diagnostic test device for a vehicle. The commonly-used diagnostic test device comprises a control module, a vehicle bus communication module, a K-Line physical layer test module, a display module, an upper computer communication module, a clock module, a signal acquisition module, a storage module, a working state display lamp, an alarm module and a power module. The control module is used for analyzing and processing data, the vehicle bus communication module is connected with the control module and conducts data exchange, the upper computer communication module and the clock module are connected with an upper computer, the signal acquisition module is connected with the control module and transmits data to the control module, the storage module, the working state display lamp and the alarm module are connected with the control module, and the power module supplies power to all the modules. According to the commonly-used diagnostic test device, a performance test, a functional test and a diagnostic test can be conducted on a finished vehicle vehicle-mounted control unit, a diagnostic function test based on a bus network can be achieved, and a bus communication protocol and a diagnostic protocol are tested. The commonly-used diagnostic test device is high in universality, various vehicle models can be diagnosed, cross-platform vehicle models can be diagnosed, and the finished vehicle bus network can be diagnosed.

Owner:CHINA FIRST AUTOMOBILE

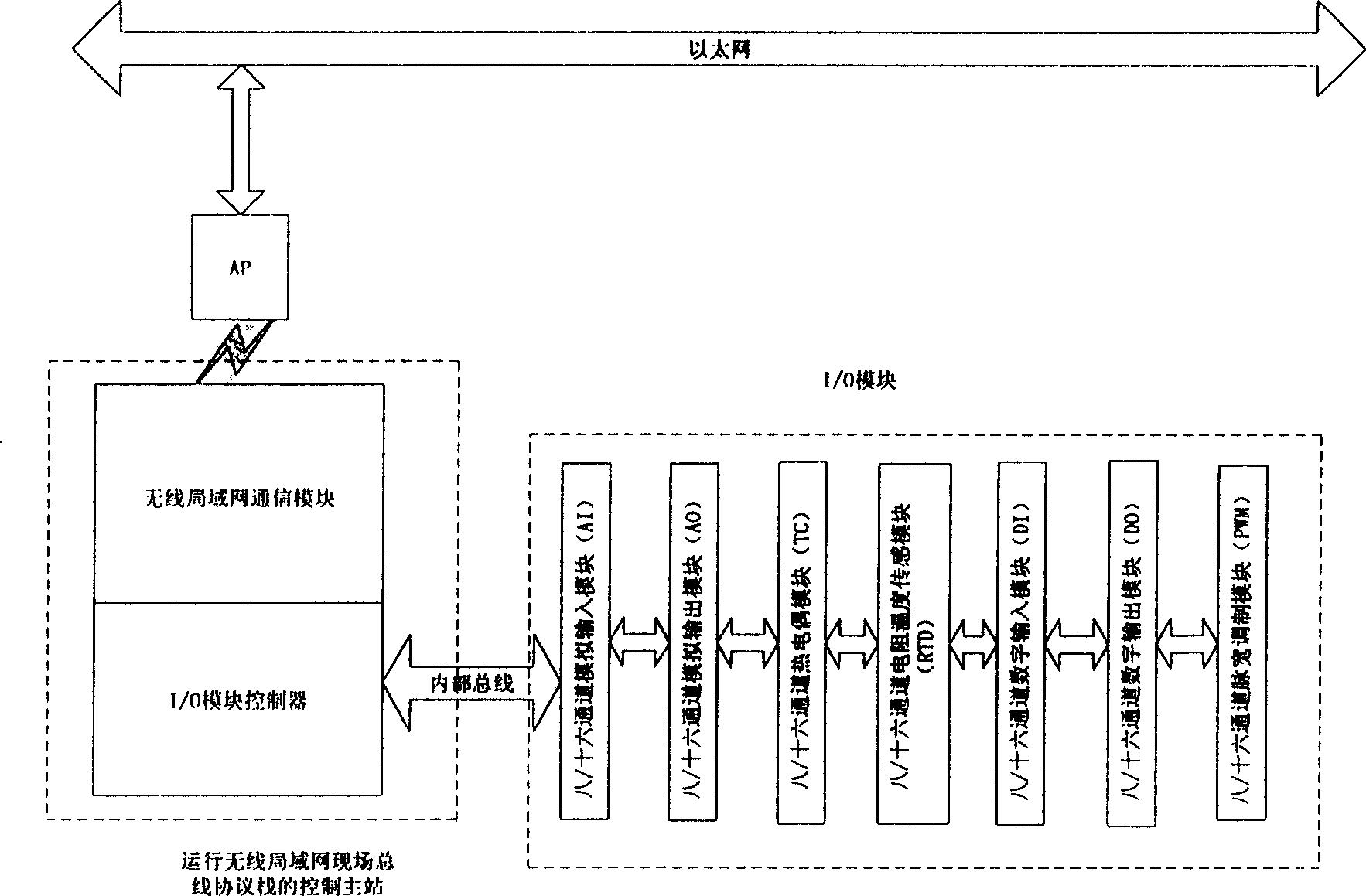

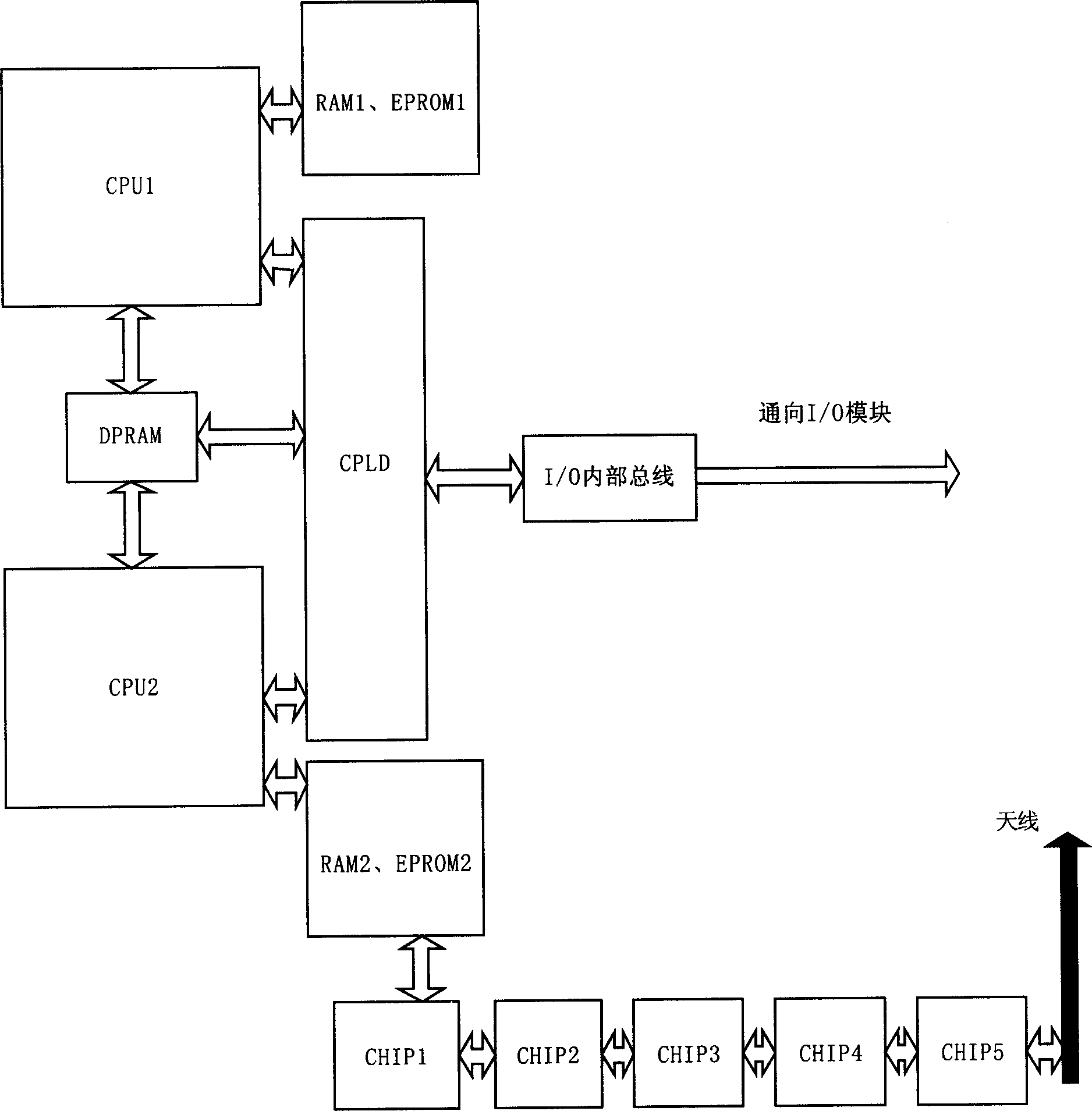

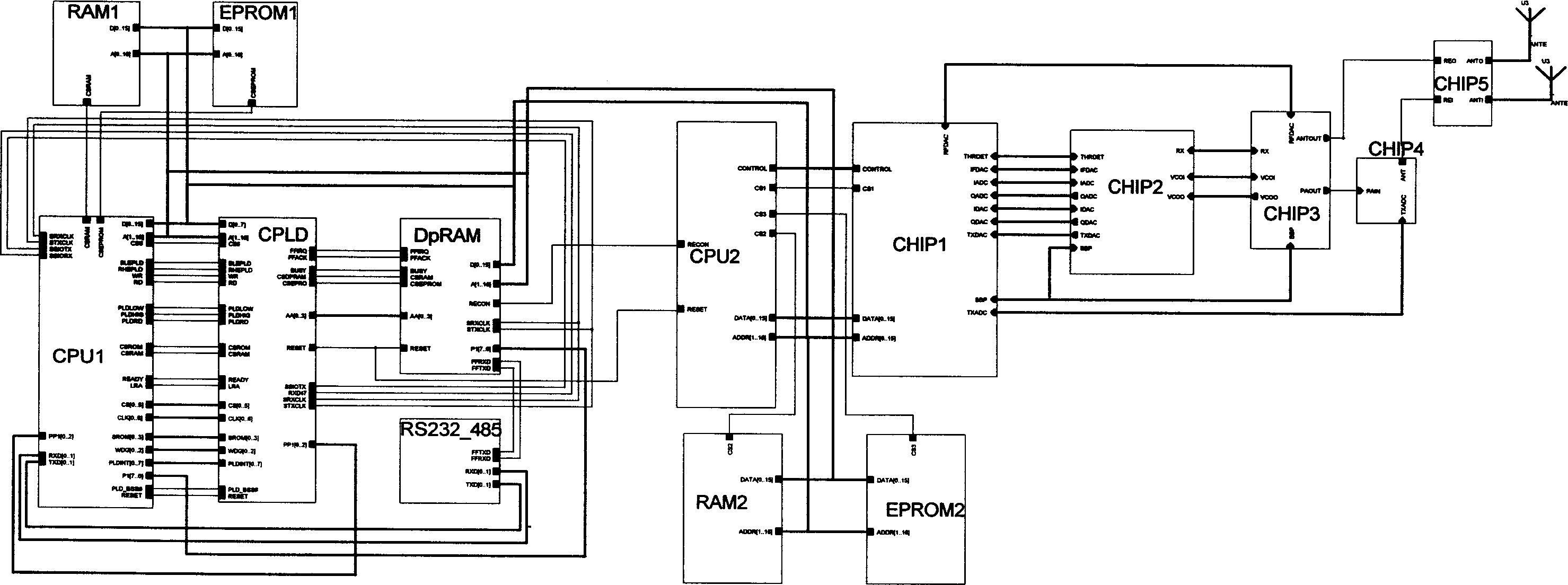

Wireless local area network on-site bus network control station

InactiveCN1567114ASupport hot swapSupport plug and play technologyTotal factory controlElectric digital data processingAutomatic controlDistributed structure

This invention relates to auto-control field, which in detail is used to a wireless LAN on-site bus net control station. It comprises main control station and I / O module, wherein, its main control station runs the wireless LAN on-site bus agreements and accomplishes the distribution I / O control through I / O module controller and receives and transmits data to Ethernet through wireless LAN transmission module. The I / O module is to accomplish the collection and conversion of the on-site signals. It is based on intelligence control device of the wireless Ethernet and turns the DCS total distributed system structure into new type of total distribution structure to completely distribute the control into the on site by network control station. This invention especially applies to old industry control system reconstruction to make it possible for old enterprises to enter the new time of on-site bus.

Owner:无锡中科泛在信息技术研发中心有限公司

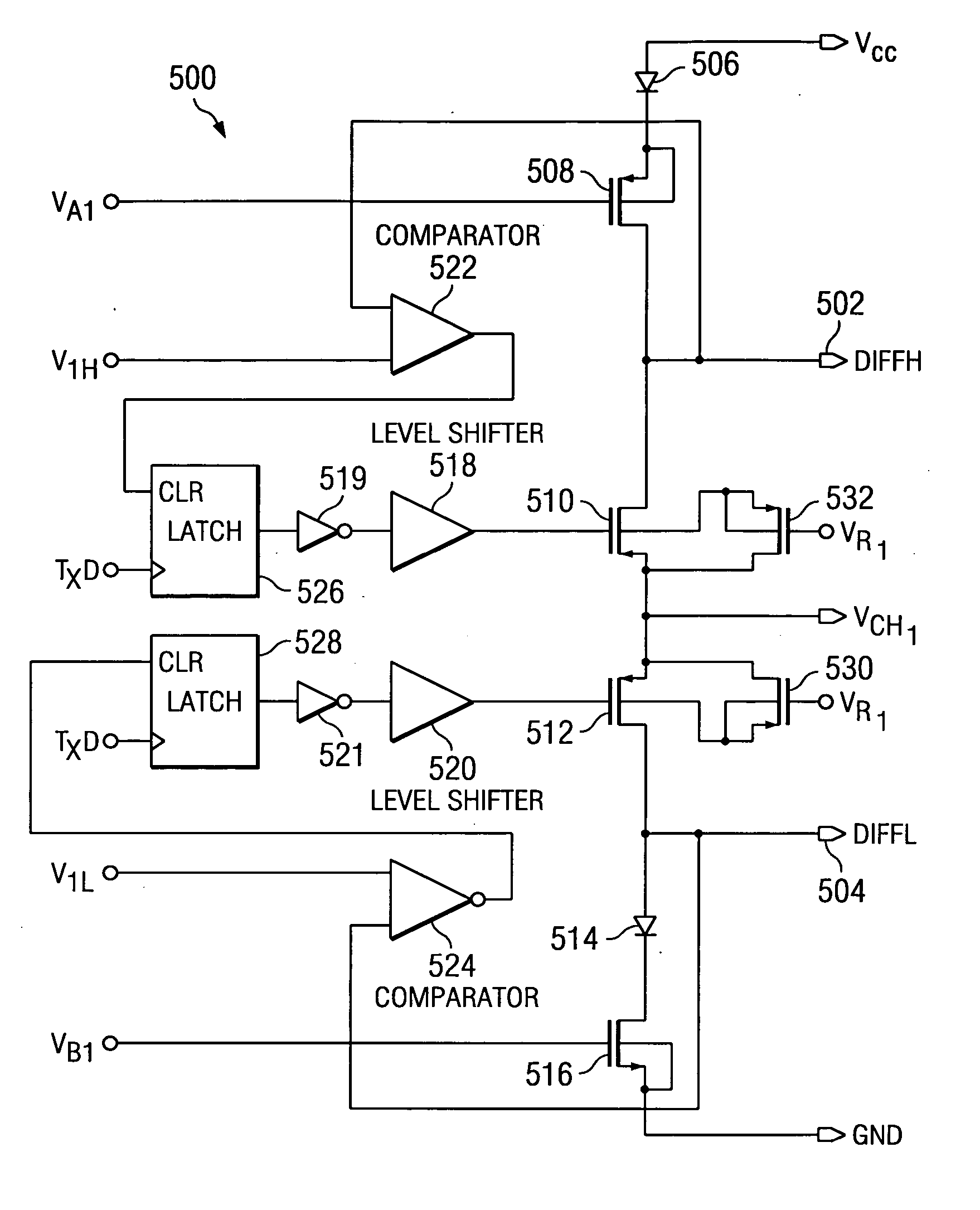

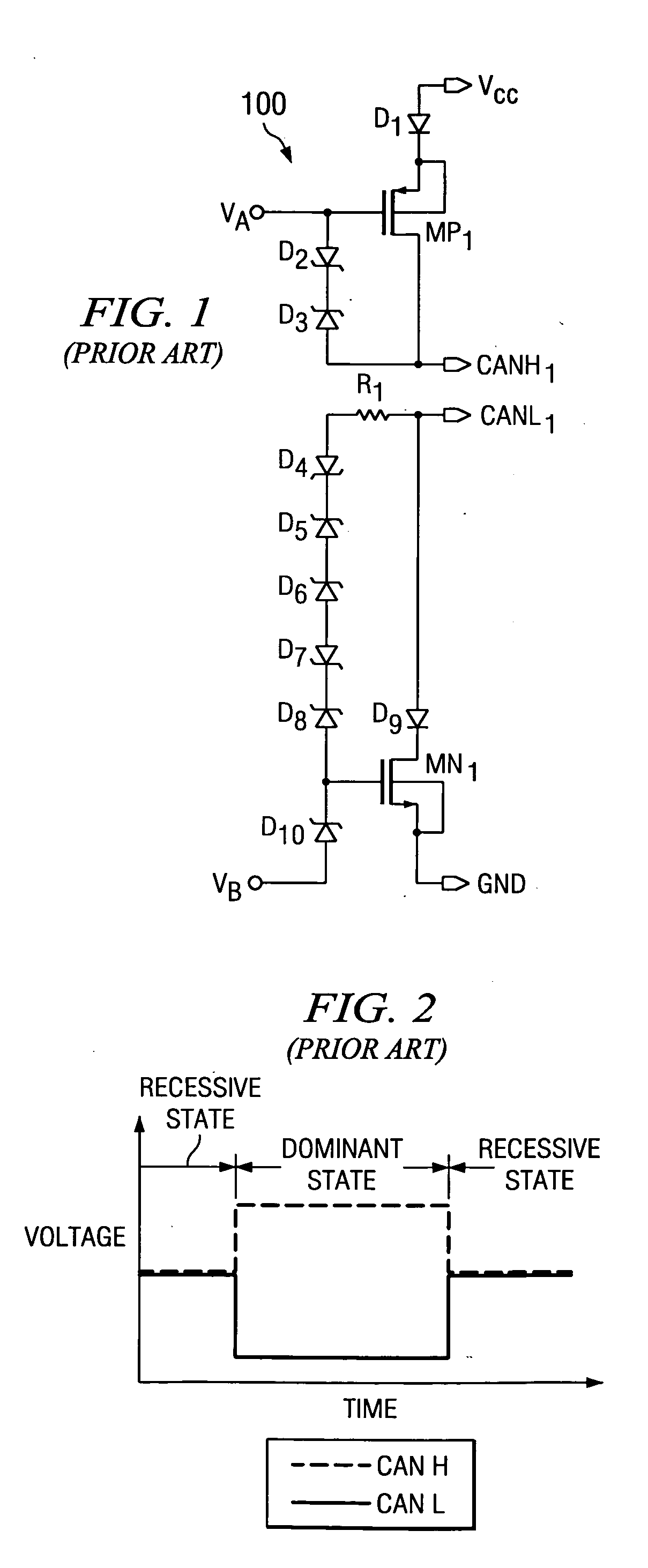

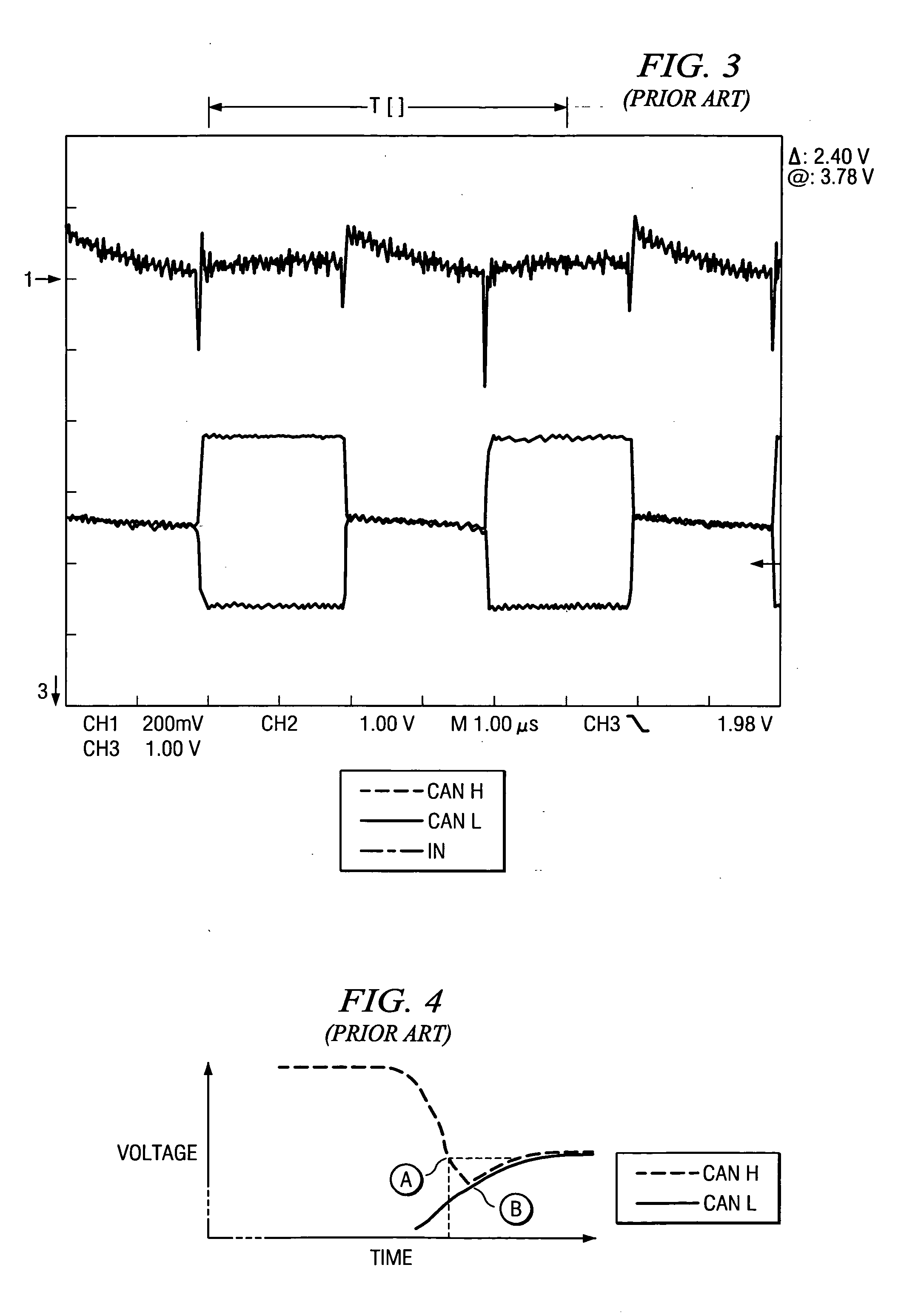

Common mode stabilization circuit for differential bus networks

ActiveUS20060091915A1Minimizes common-modeGood symmetryElectronic switchingElectric pulse generatorArea networkLow voltage

A differential bus network, in general, or a controller area network (CAN) driver, in particular, controls and minimizes the variation on the common-mode signal of the CAN bus. This CAN driver also provides improved symmetry between its differential output signals, CANH and CANL, and provides protection for its low voltage devices from voltage transients occurring on its output lines. The common-mode signal is sensed and buffered, then during the dominant to recessive transition, the bus signals are shorted to the buffered common mode voltage. Specifically, additional switches or transistors are used to pull the differential output signals, CANH and CANL, to the common mode signal VCM when the state of the CAN bus transitions from dominant to recessive. This improvement minimizes high frequency spikes in the common-mode signal and eliminates DC shifts during transitions of the state of the CAN bus. A driver system may include a plurality of CAN drivers are serially interconnected to form a driver system, wherein each downstream driver stage receives a time-delayed form of the digital input signal TxD, each stage providing a time-delayed contribution to the differential output signals of the overall driver system.

Owner:TEXAS INSTR INC

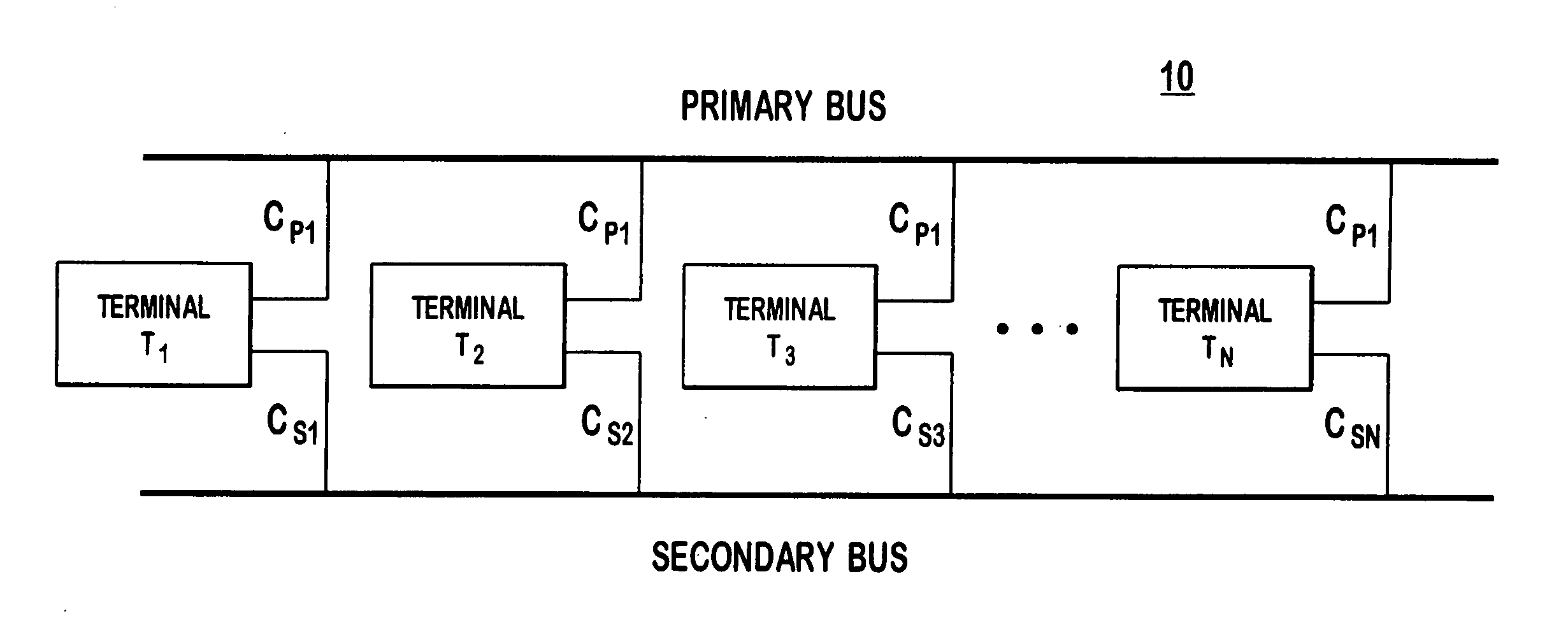

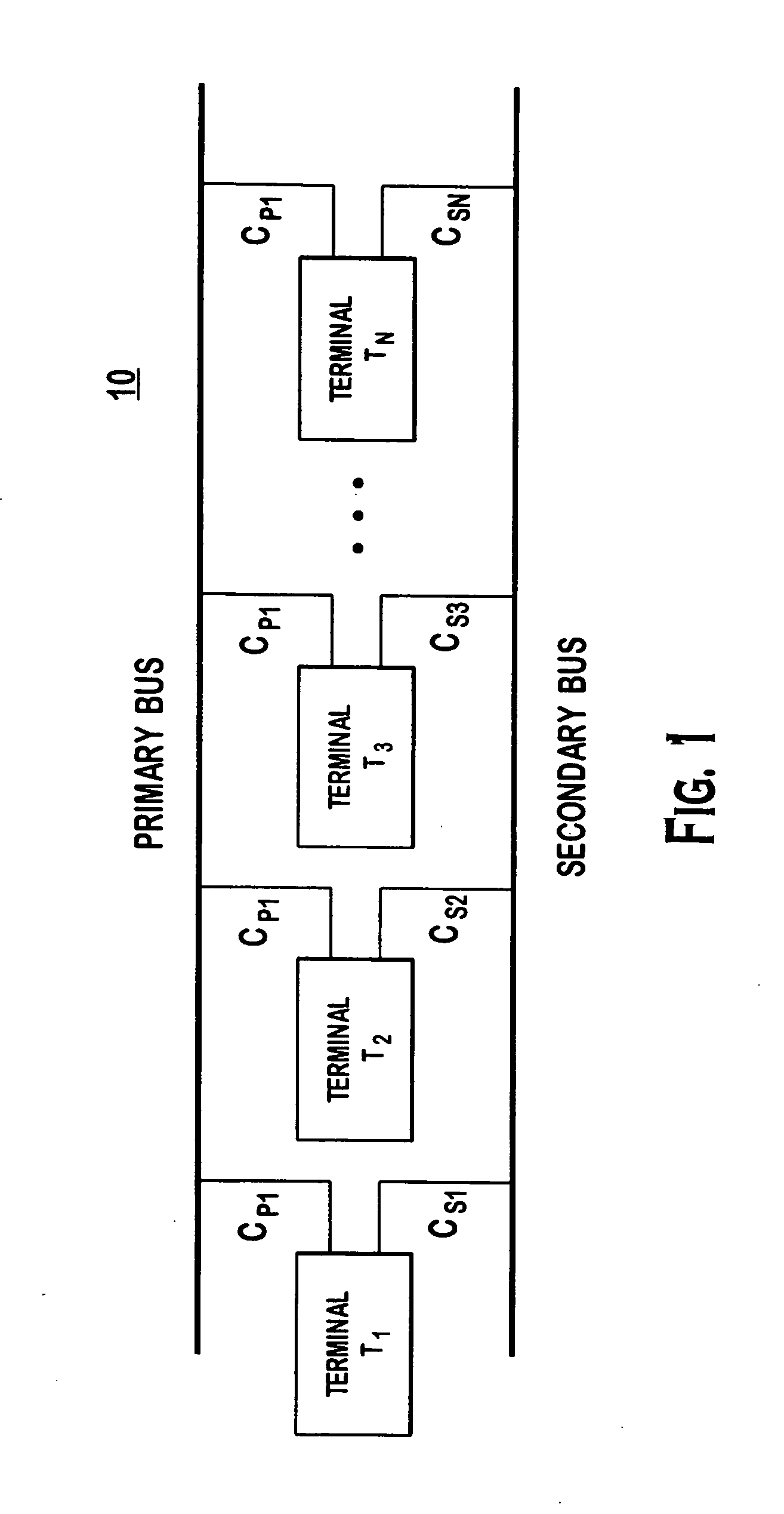

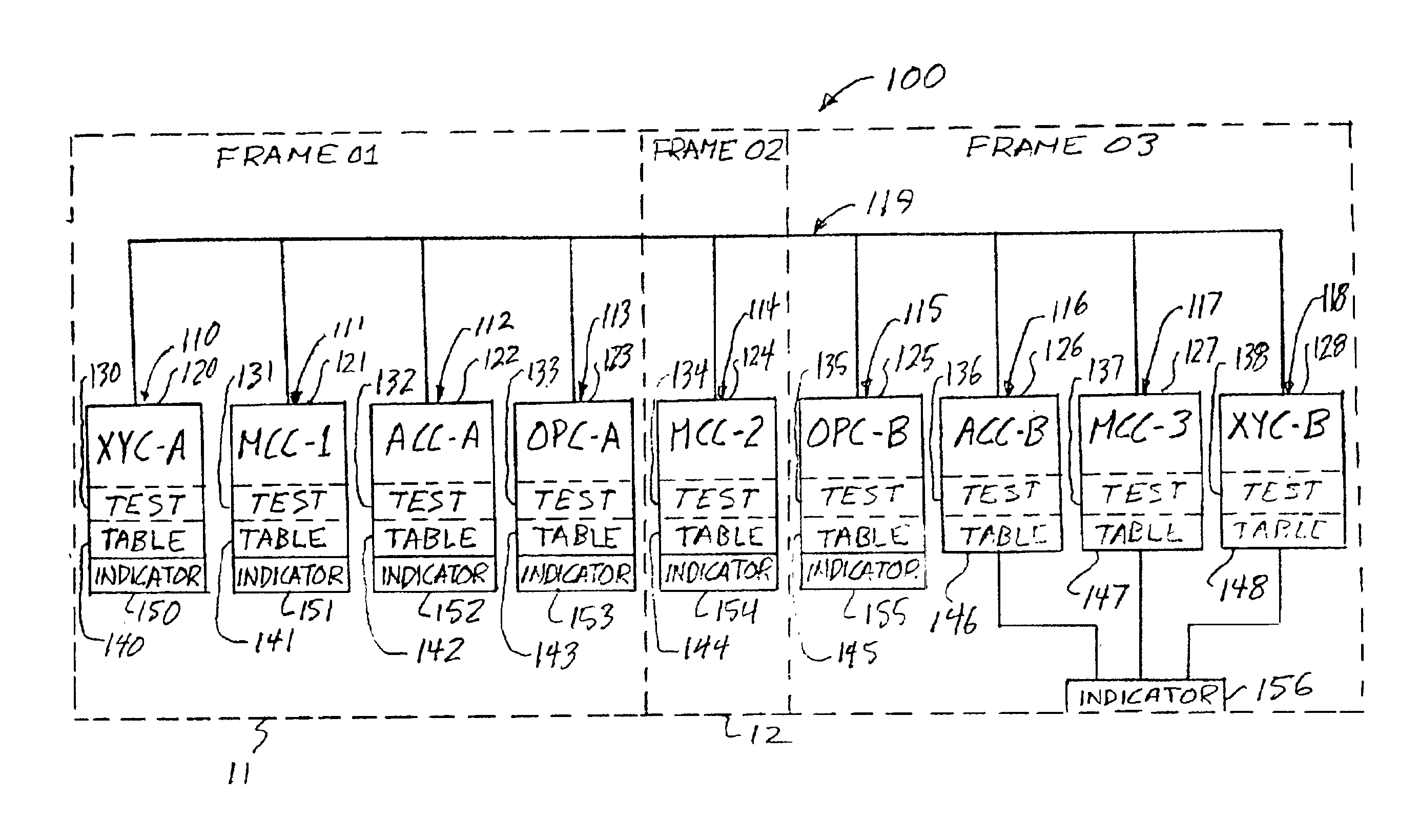

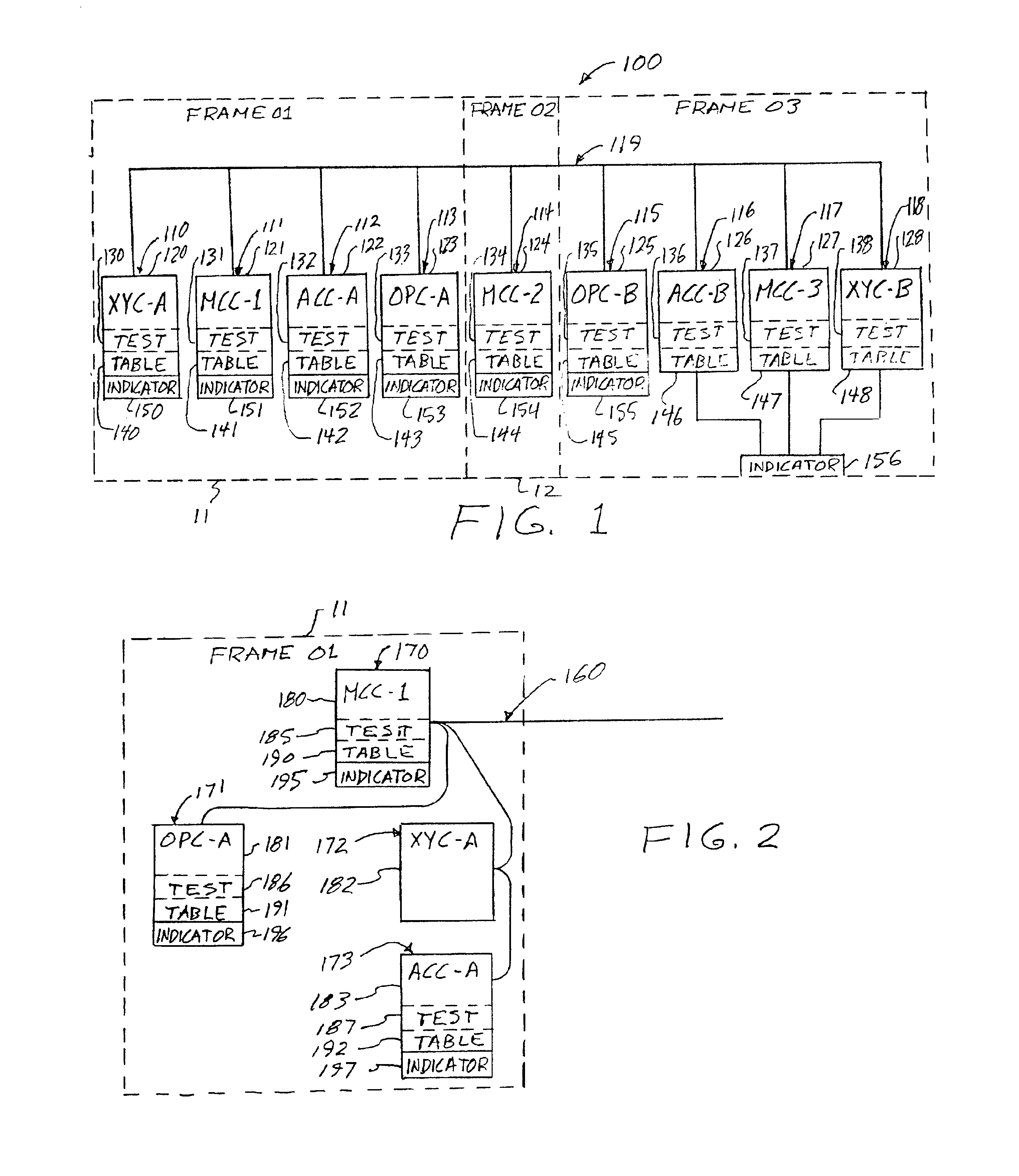

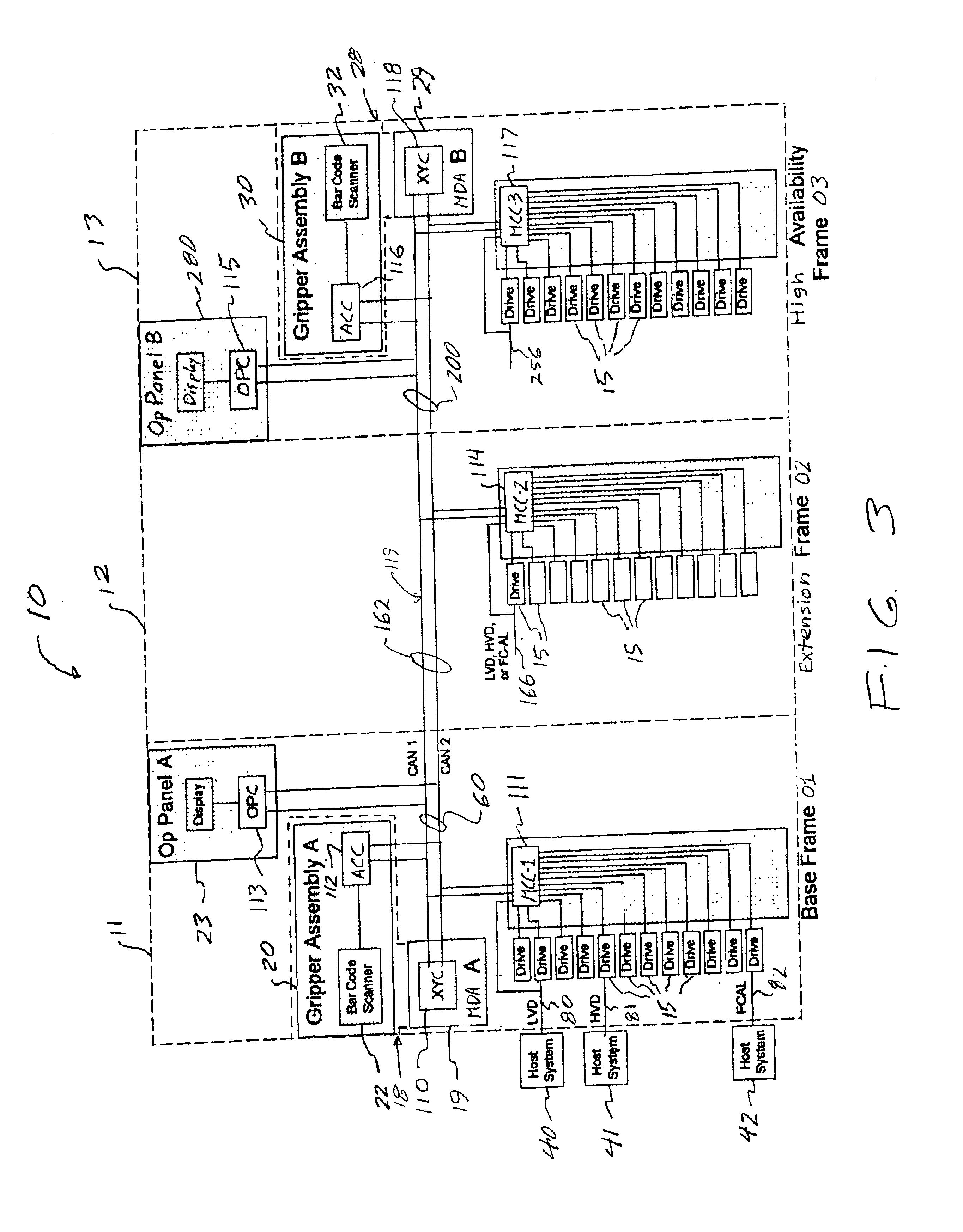

Failure isolation in a distributed processing system employing relative location information

InactiveUS6931564B2Multiple failureError preventionError detection/correctionMultidrop busProcessor node

Failure isolation in a distributed processing system of processor nodes coupled by a multi-drop bus network. The processor nodes have information of relative locations of the processor nodes on the network, and have an associated local error indicator, such as a character display. Each node independently tests access to other nodes on the network, and upon detecting a failure to access one or more nodes, determines, from the relative locations, the node having failed access which is closest. The failure detecting processor posts, at its associated local error indicator, an identifier of the closest failed access node. A user may inspect the local error indicators and thereby isolate the detected failure.

Owner:INTELLECTUAL DISCOVERY INC

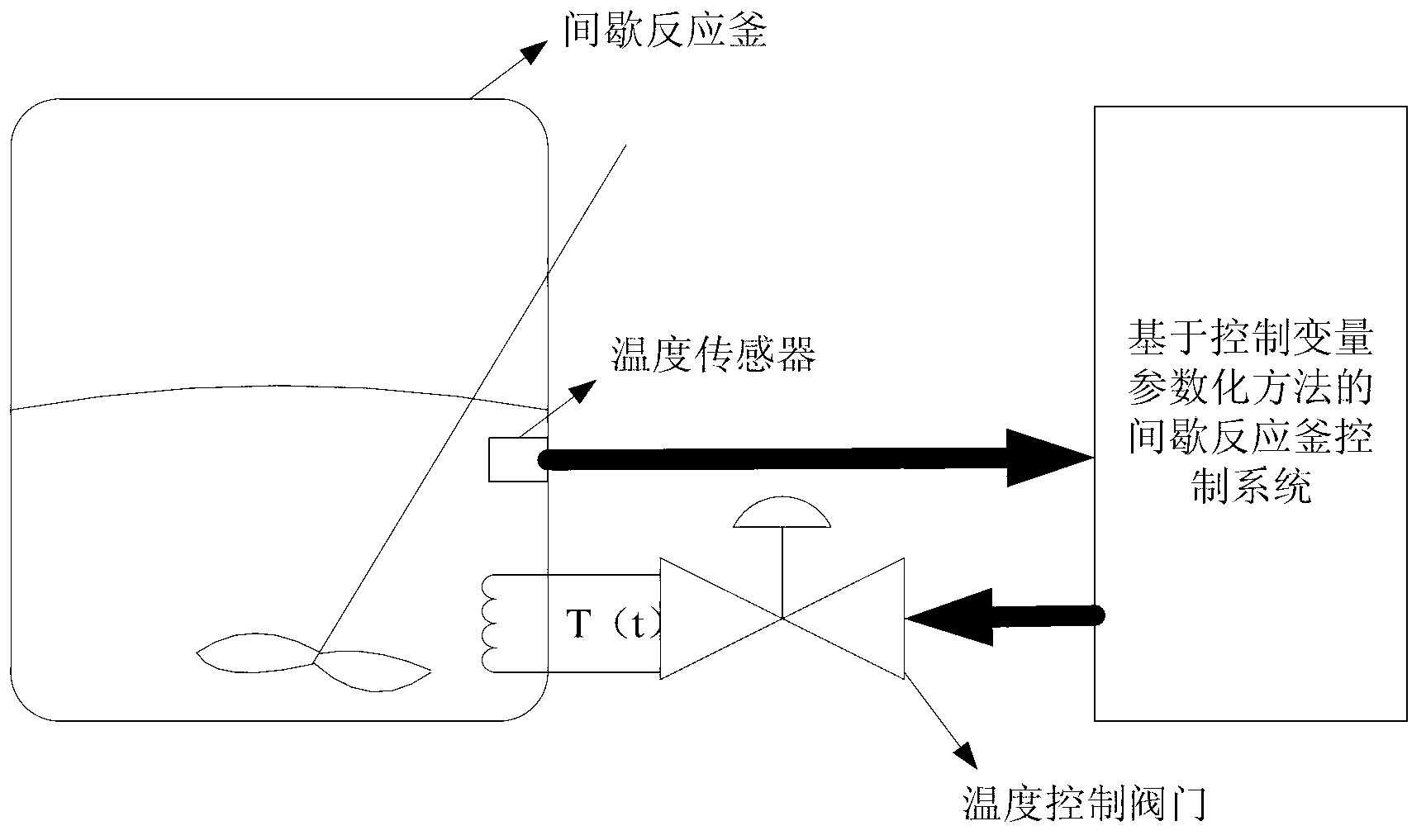

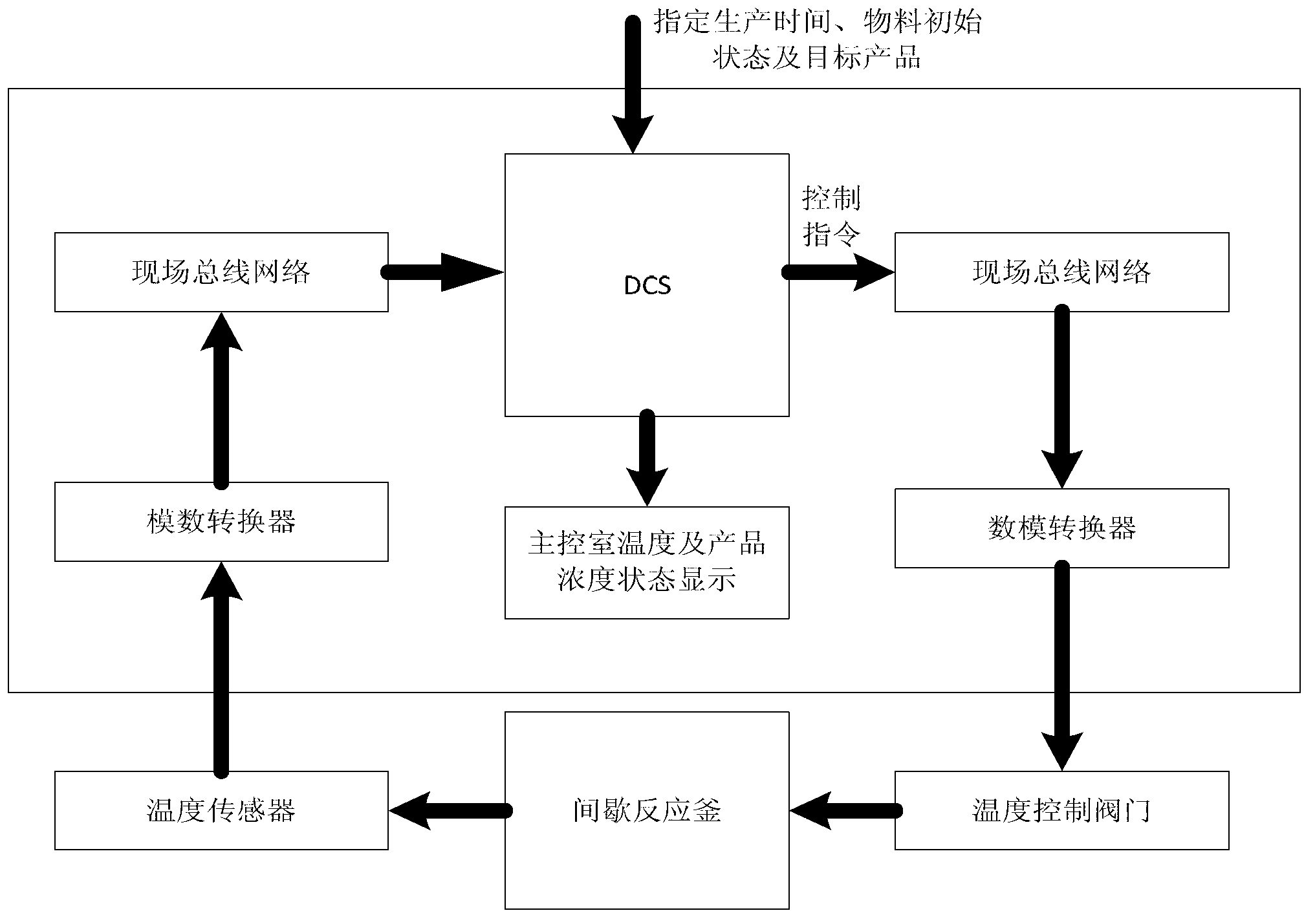

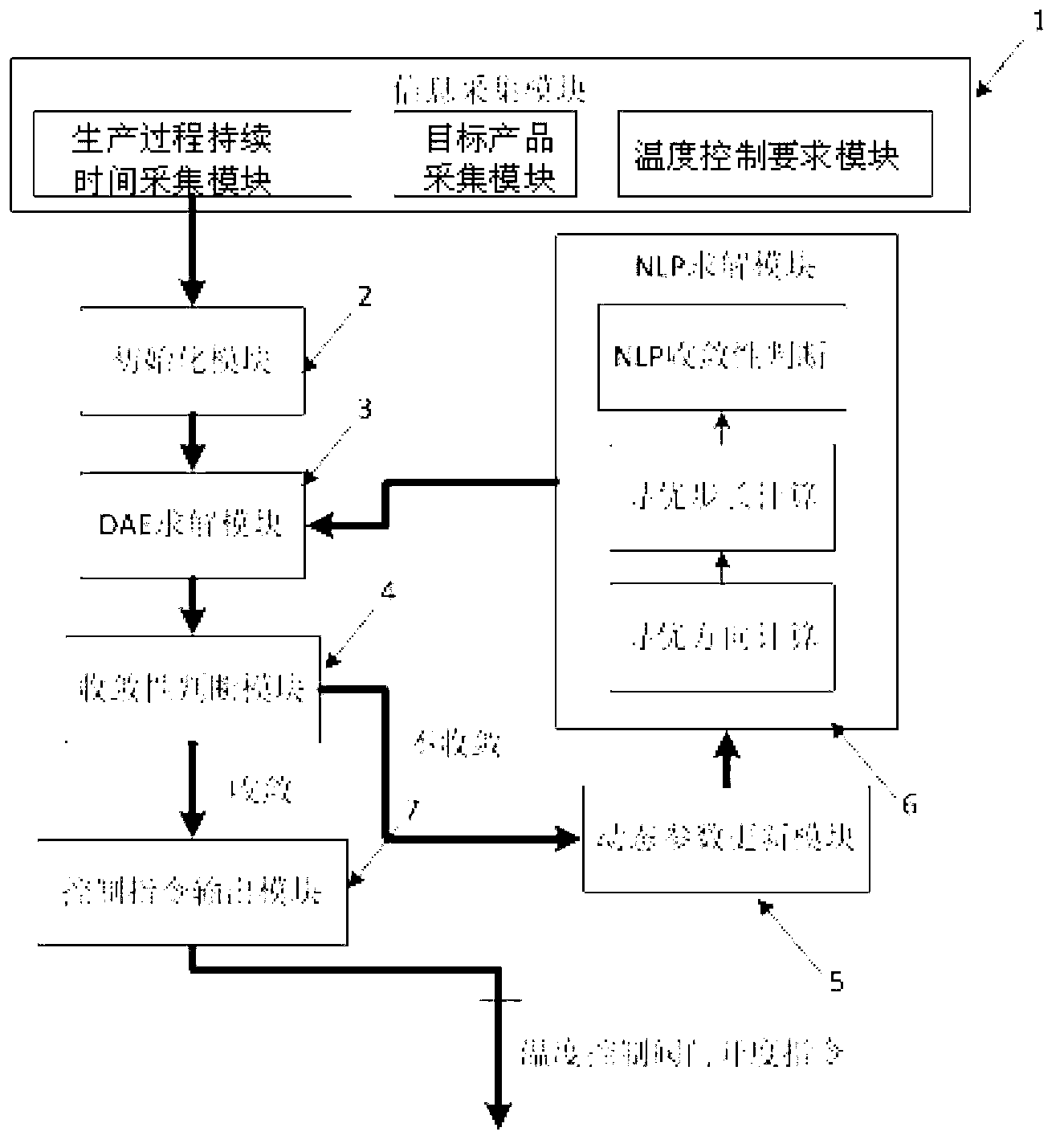

Intermittent reactor control system based on control variable parameterization method

InactiveCN103309371AConcentration maximizationRealize tapping potential and increasing efficiencyTemperature control using electric meansChemical/physical/physico-chemical processesTemperature controlDistributed control system

The invention discloses an intermittent reactor control system based on a control variable parameterization method. The system comprises an intermittent reactor, and a temperature sensor, an analog to digital converter, a site bus network, a DCS (distributed control system), a main control chamber and product concentration status display which are arranged at the end of the intermittent reactor, and a digital to analog converter and a temperature control valve which are arranged at the end of the intermittent reactor. After duration of production process, initial concentration status of materials in the reactor and a target product required to increase concentration are determined by an engineer in a control chamber, the DCS acquires a temperature control strategy to enable the target product concentration to be maximum, converts the temperature control strategy into an open command for a temperature control valve, transmits the open command to the digital to analog converter at the end of the intermittent reactor through the site bus network, and enables the temperature control valve to act according to received control commands. The temperature sensor collects the temperature of the reactor in real-time and returns to the DCS to enable the engineer in the control chamber to master the production process timely. By the aid of the intermittent reactor control system, concentration of the target product can be maximized, and potential synergies are realized.

Owner:ZHEJIANG UNIV

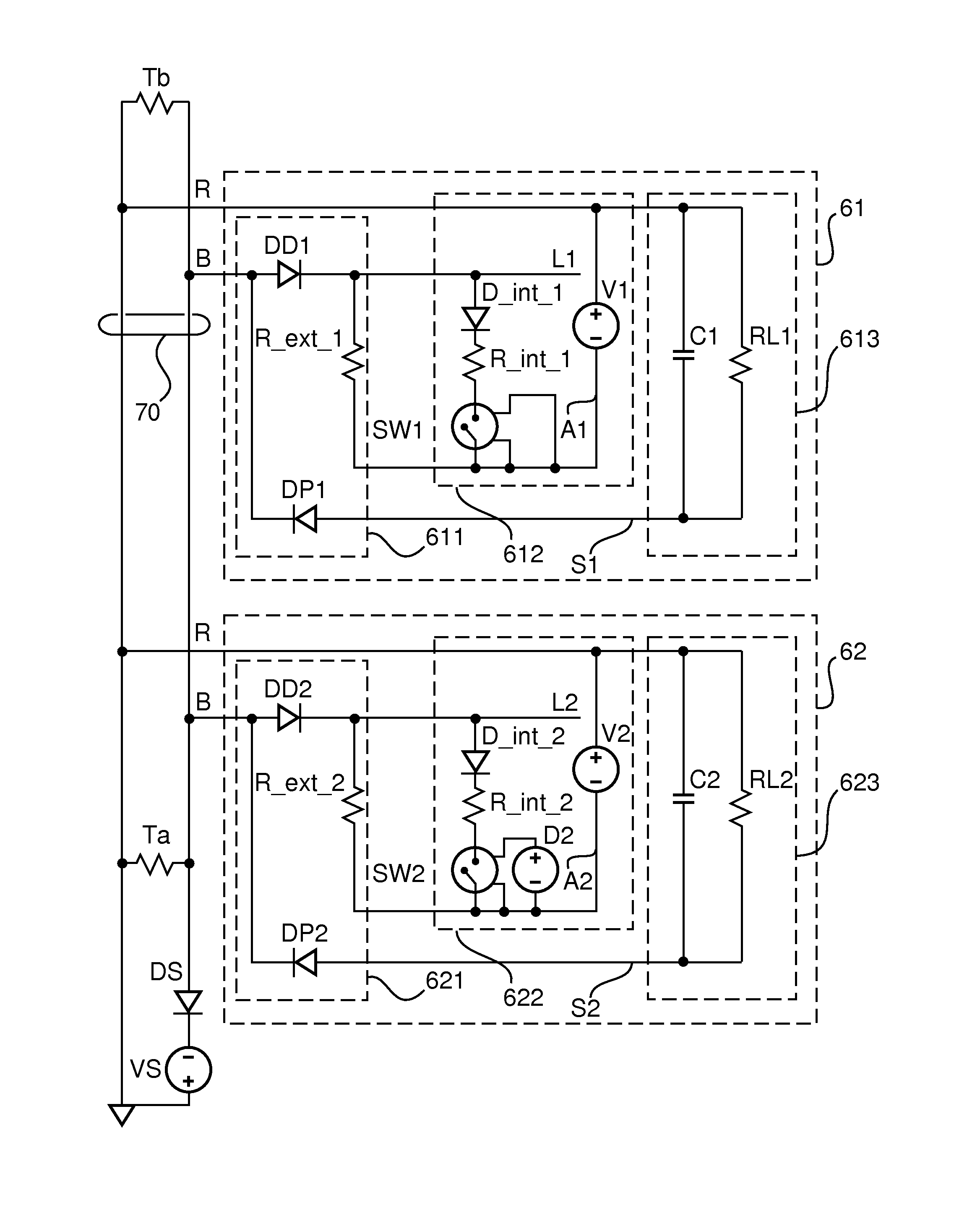

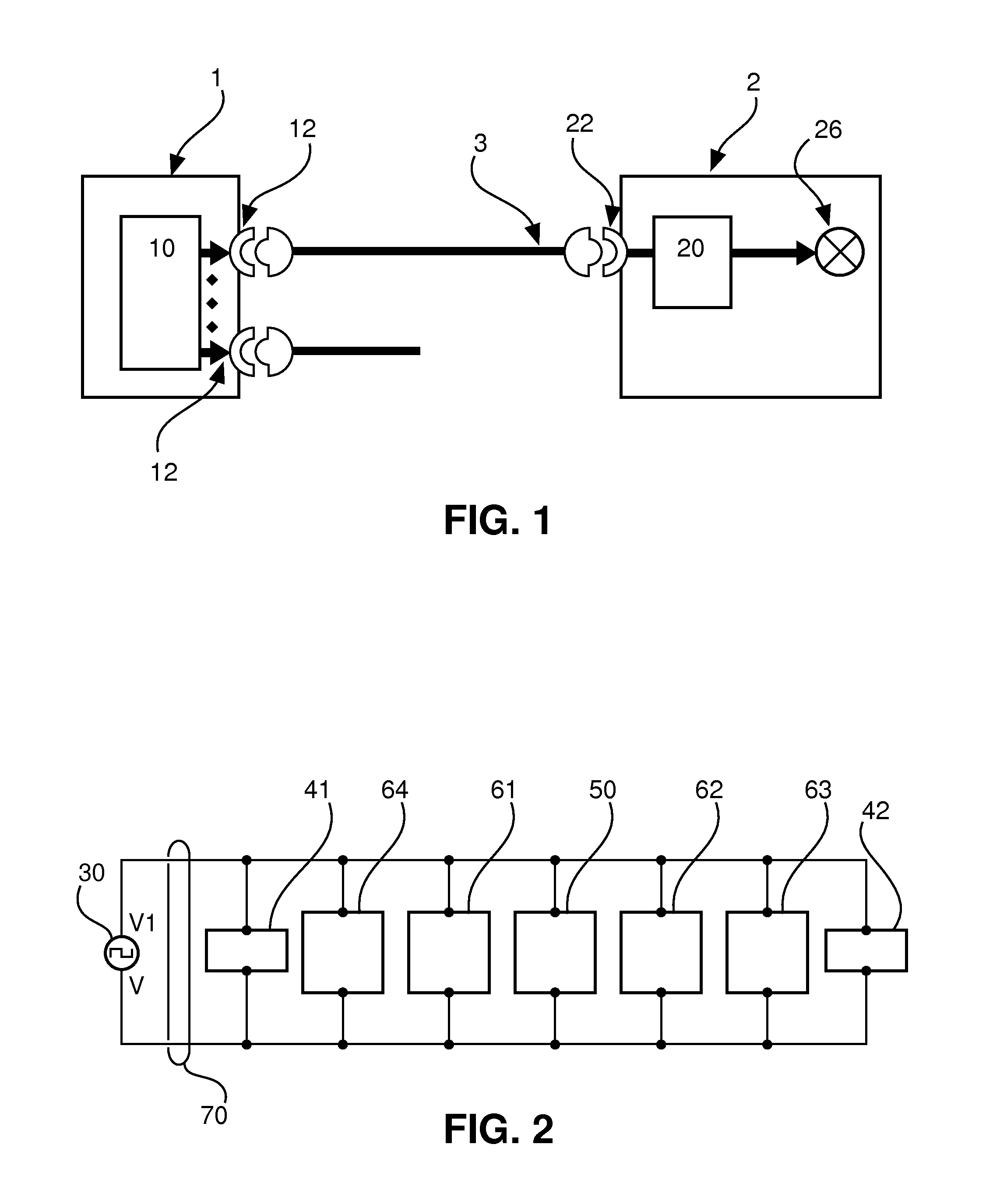

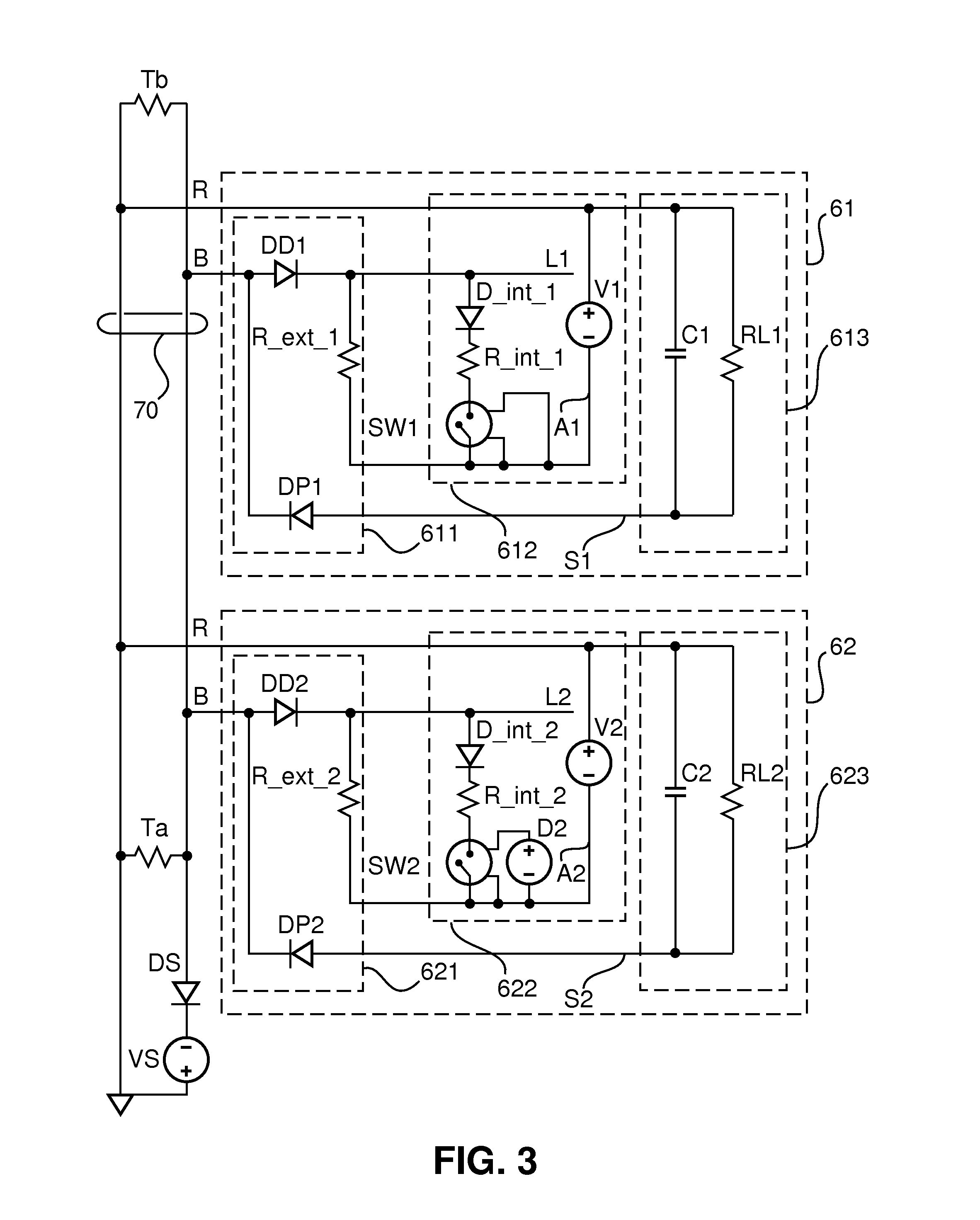

Method and apparatus for multiplexed power and data supply via a two-wire data communication cable

ActiveUS20150207317A1Efficiently powering loadEfficient loadingPower distribution line transmissionDigital data processing detailsMultiplexingCoaxial cable

The present invention relates to a method and apparatus for controlling data transfer and power supply to at least one load device (61-64) connected to a two-wire data communication cable (70) in a bus-type structure. Power supply and data transfer are multiplexed via the two-wire data communication cable so that a standard coaxial cable can be used for shared power and data transport, enabling the operation of lighting applications or other applications in retail and office, based on cheap, flexible, preconfigured cables in a bus topology and using known chipsets.

Owner:SIGNIFY HLDG BV

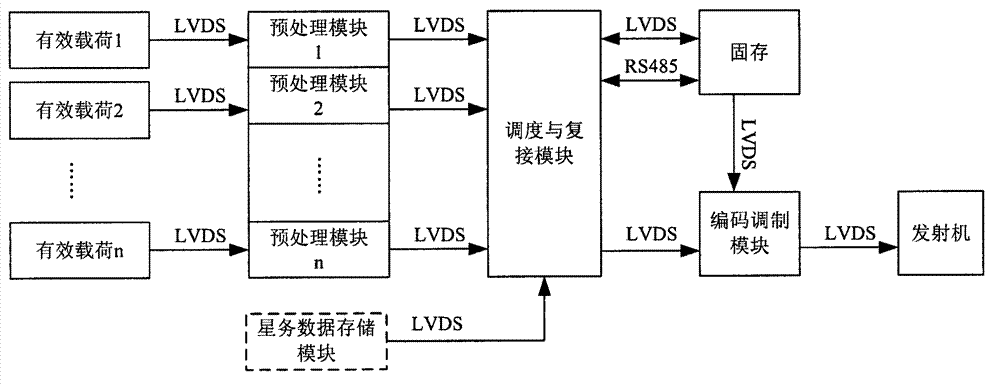

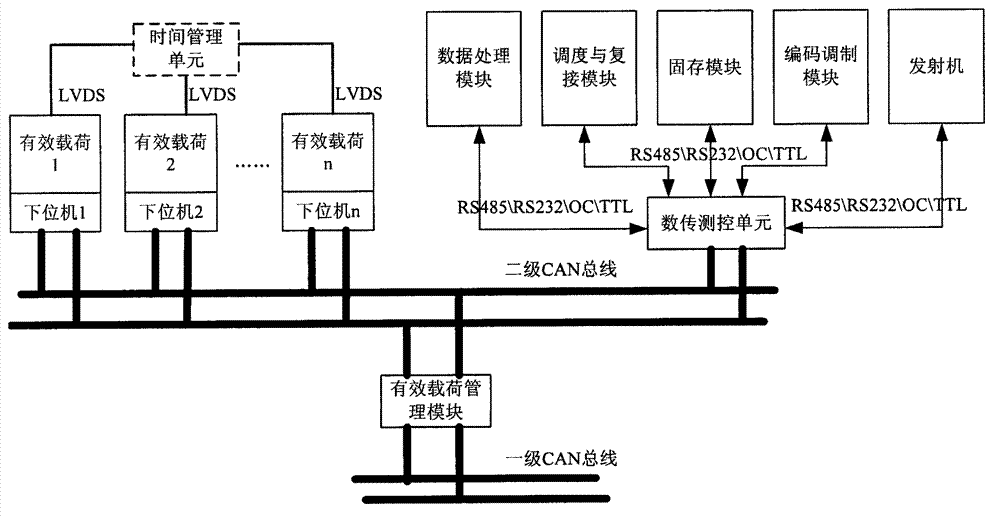

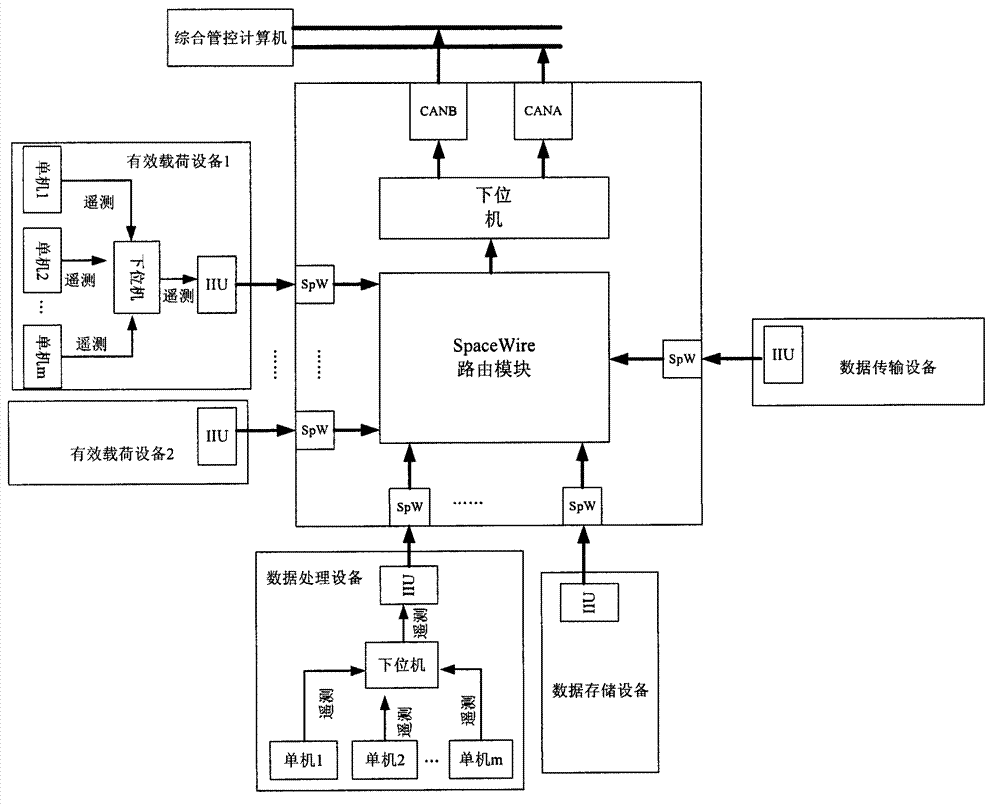

Management system for payload information of satellite based on intelligent high-speed router

The invention discloses a management system for payload information of a satellite based on an intelligent high-speed router. The management system comprises an intelligent high-speed router, a payload device, a data handling device, a data storage device and a data transmission device, wherein the intelligent high-speed router consists of a SpaceWire routing module, an intelligent control module and a SpaceWire standard bus interface; and the SpaceWire routing module is used for directly exchanging data from the payload device, the data handling device, the data storage device and the data transmission device, or used for outputting the data to a satellite payload low speed bus network by a CAN (Controller Area Network) interface of the intelligent control modular, and used for transmitting a remote control command from the satellite payload low speed bus network received by the intelligent control module to the payload device, the data handling device, the data storage device and the data transmission device. The system solves the problems that currently the interface of a satellite payload system and a data transmission system is complex, rapid assembly and testing are difficult, and the technology upgrade of a device is difficult.

Owner:AEROSPACE DONGFANGHONG SATELLITE

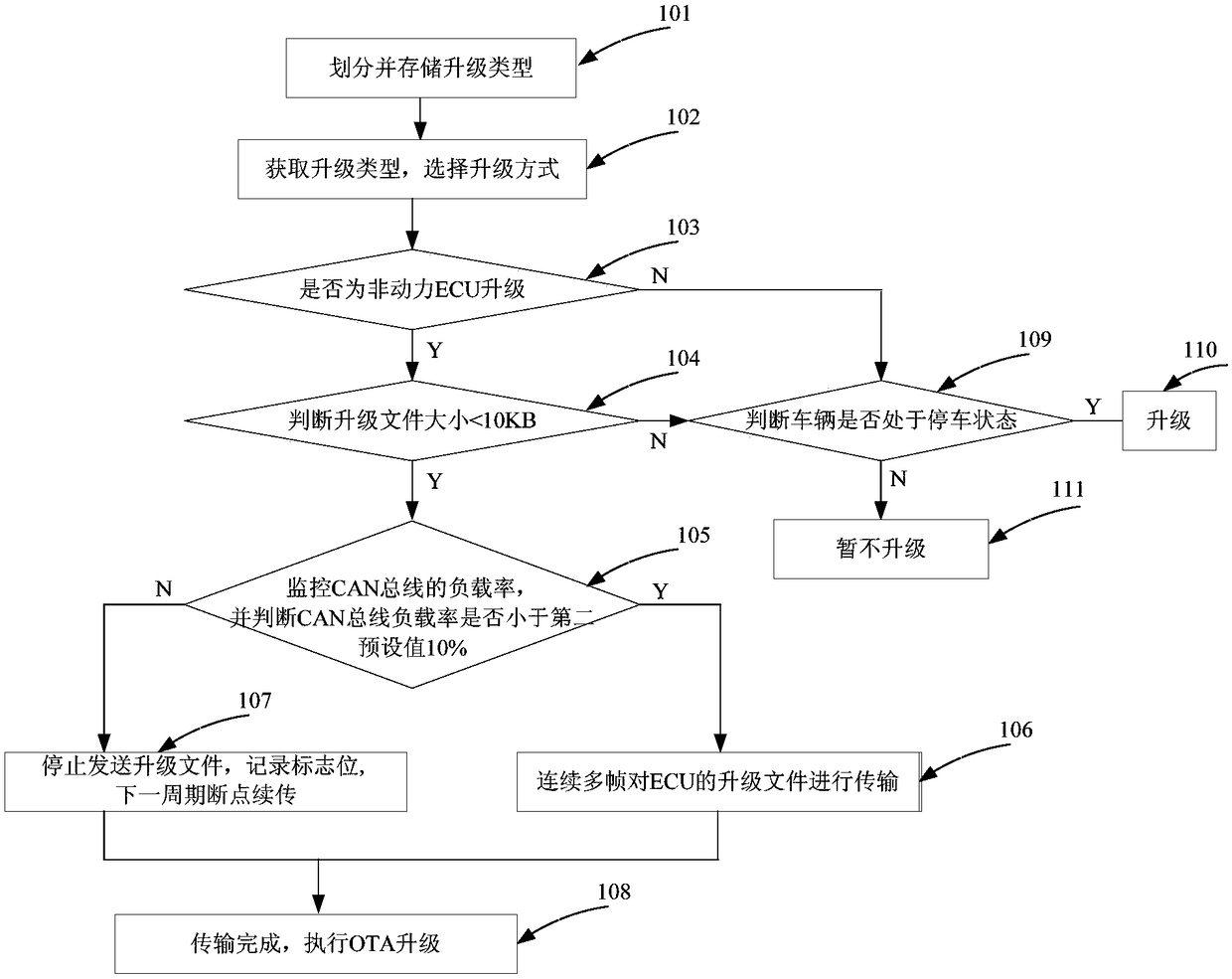

On-board OTA upgrading method based on CAN bus load monitoring

ActiveCN108282389ASimplify the upgrade processReduce lossSoftware deploymentBus networksOn boardComputer terminal

The invention discloses an on-board OTA upgrading method based on CAN bus load monitoring. The on-board OTA upgrading method comprises steps that all of internal electronic control units ECU are divided into different upgrading types according to function safety types, and are stored in a memory of an on-board OTA terminal in a form of data table; the on-board OTA terminal is used to receive the upgrading files and the upgrading types of the ECU, is used to search the data table in the memory, is used to select the upgrading types, and is used to determine whether the on-board OTA upgrading based on the CAN bus load monitoring is carried out or the upgrading is carried out during parking of a vehicle and in a dormant state of a vehicle bus network. The on-board OTA upgrading method based on the CAN bus load monitoring is advantageous in that by classifying the internal electronic units ECU, calculating a CAN bus network load rate, and determining an upgrading condition, an ECU upgrading process is simplified, internal bus network bandwidth is utilized in a maximized way, and loss of an on-board storage battery is reduced.

Owner:XIAMEN YAXON NETWORKS CO LTD

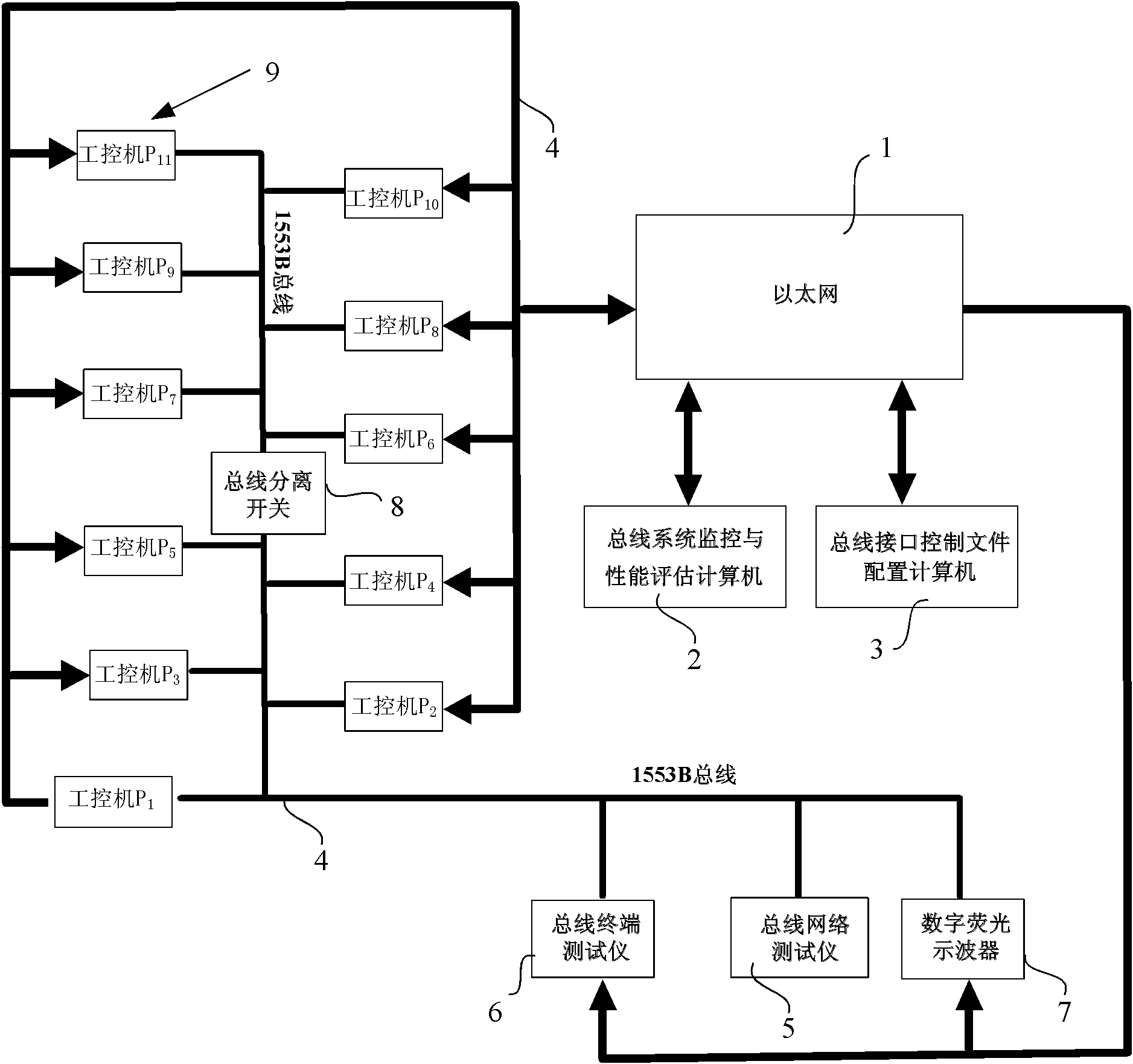

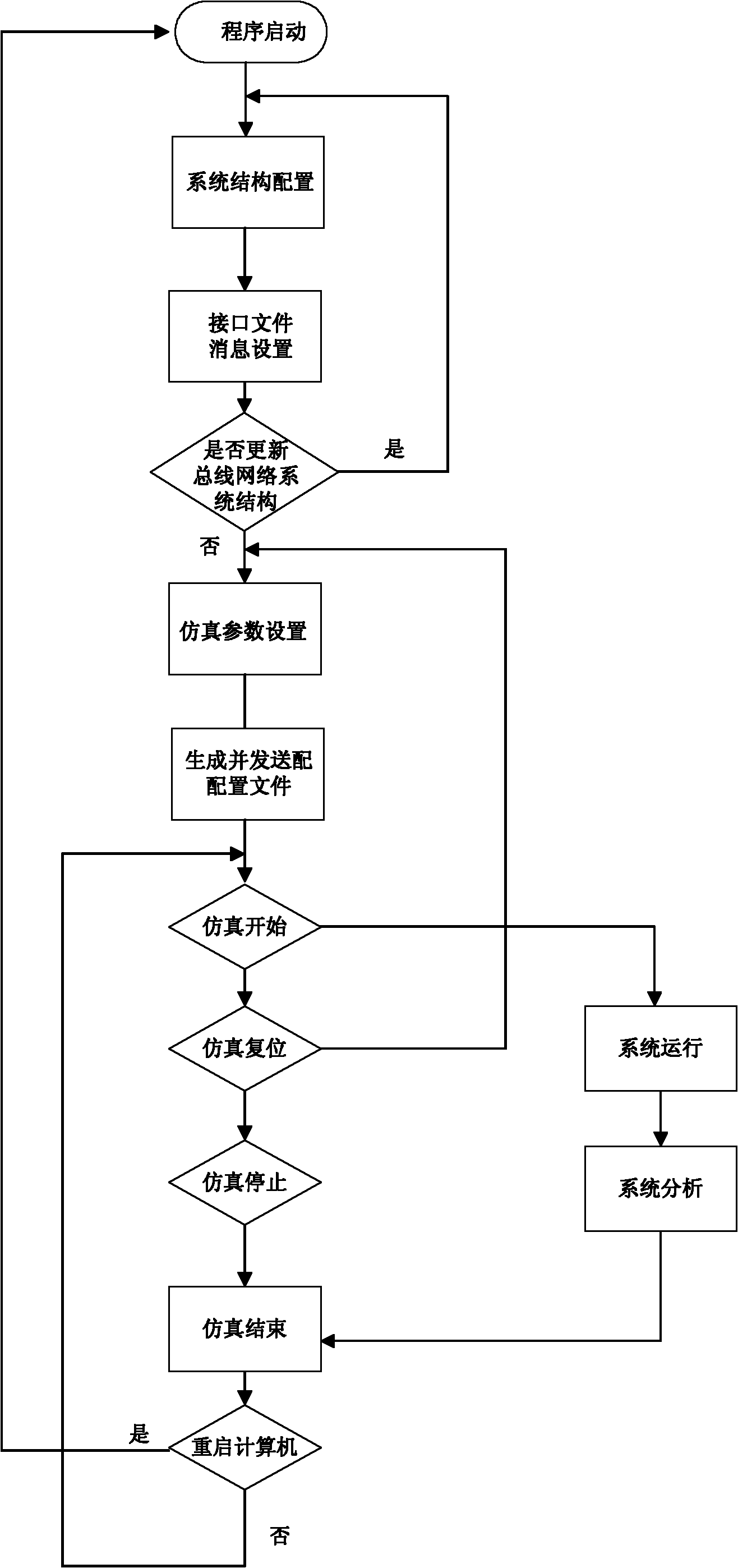

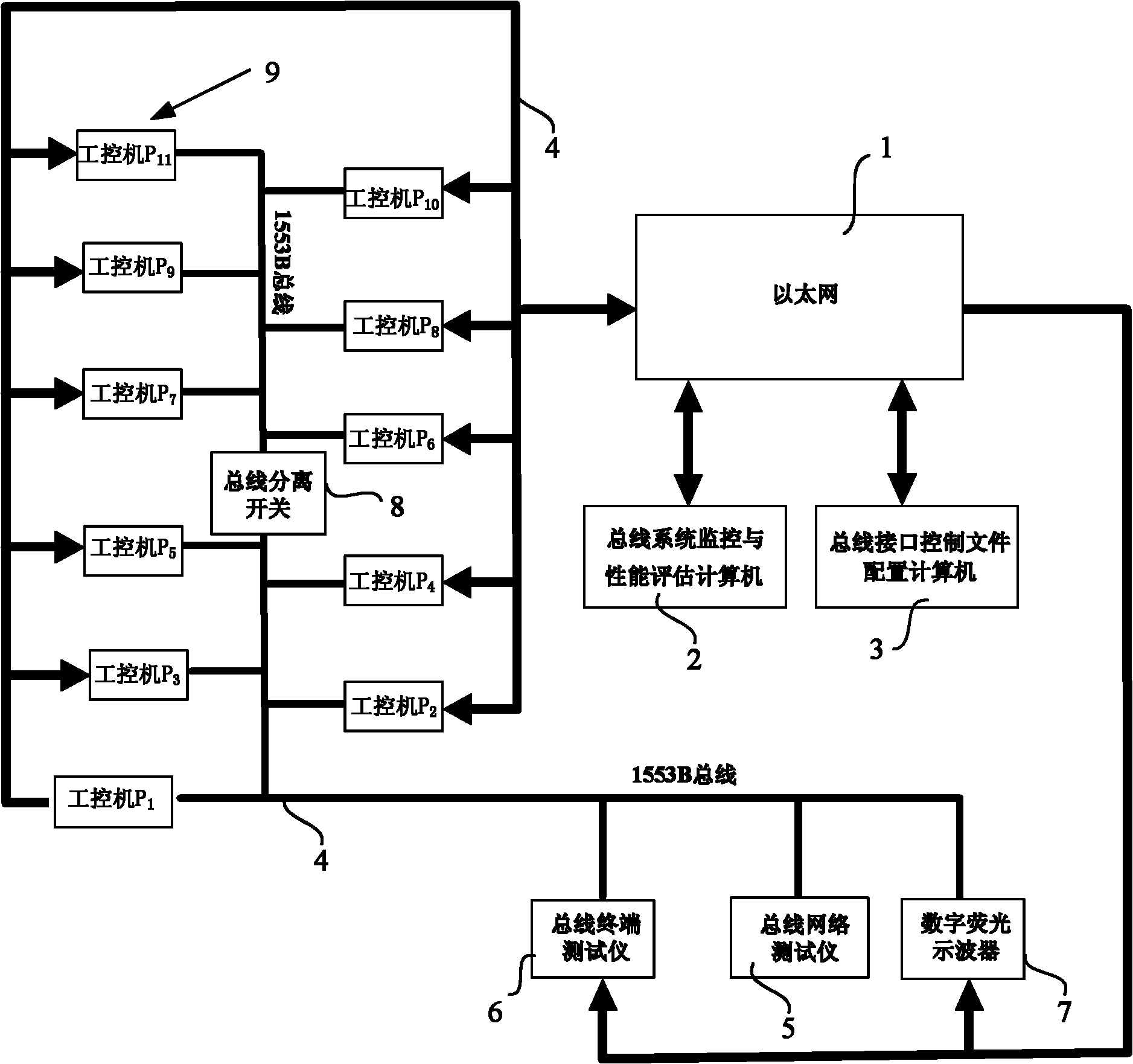

1553B bus network emulation system applied to spacecraft system

The invention discloses a 1553B bus network emulation system applied to a spacecraft system, which belongs to the field of aerospace and computer emulation. The 1553B bus network emulation system comprises a 1553B bus, the Ethernet, a bus network tester, a bus terminal tester, a digital phosphor oscilloscope, a bus separation switch, an emulation terminal, a bus system performance estimation computer and a bus interface control file configuration computer, and is used for emulating and analyzing the information transmission and system running of an actual spacecraft bus system. The 1553B bus network emulation system replaces conventional cable connection with a 1553B bus network, realizes the digitalized transmission and comprehensive utilization of network system information and improves the reliability and electromagnetic compatibility of the system by equipment with standard digital interfaces in combination with Ethernet communication, meets 1553B specifications, realizes coexistence in one network emulation system, can be used for a plurality of stages of analysis, development, test and the like of the spacecraft system and is of great importance to researches on the reliability of the actual spacecraft system.

Owner:BEIHANG UNIV

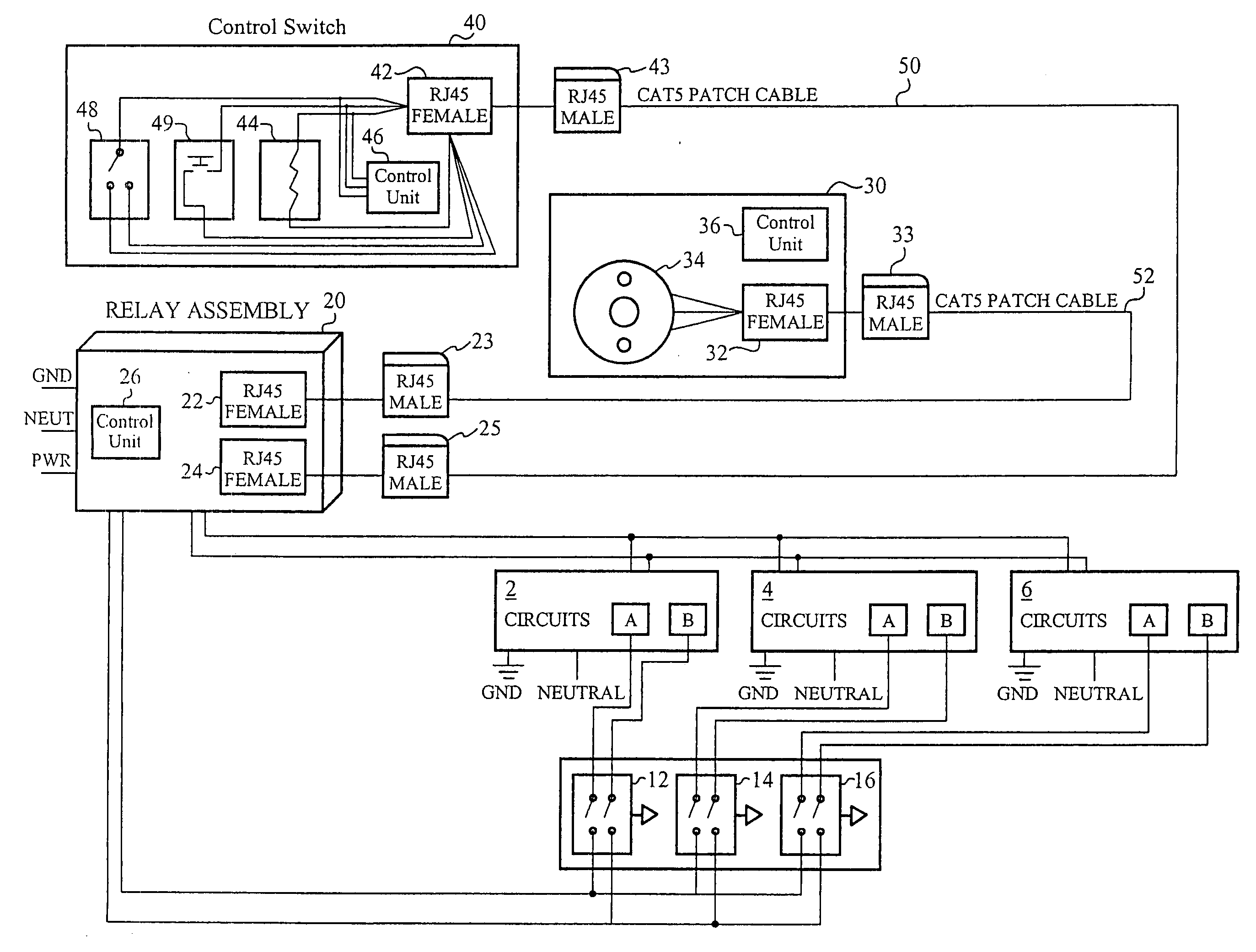

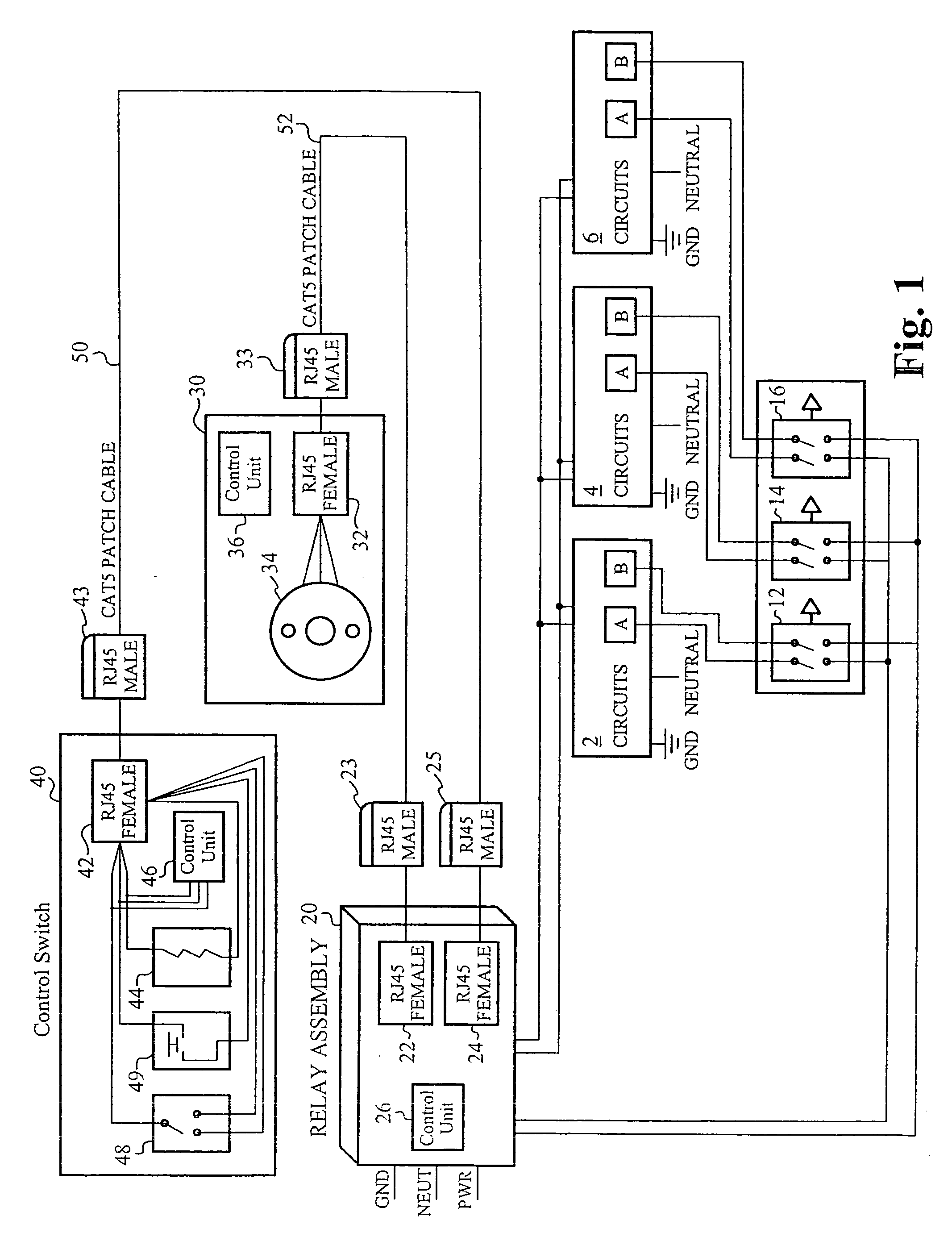

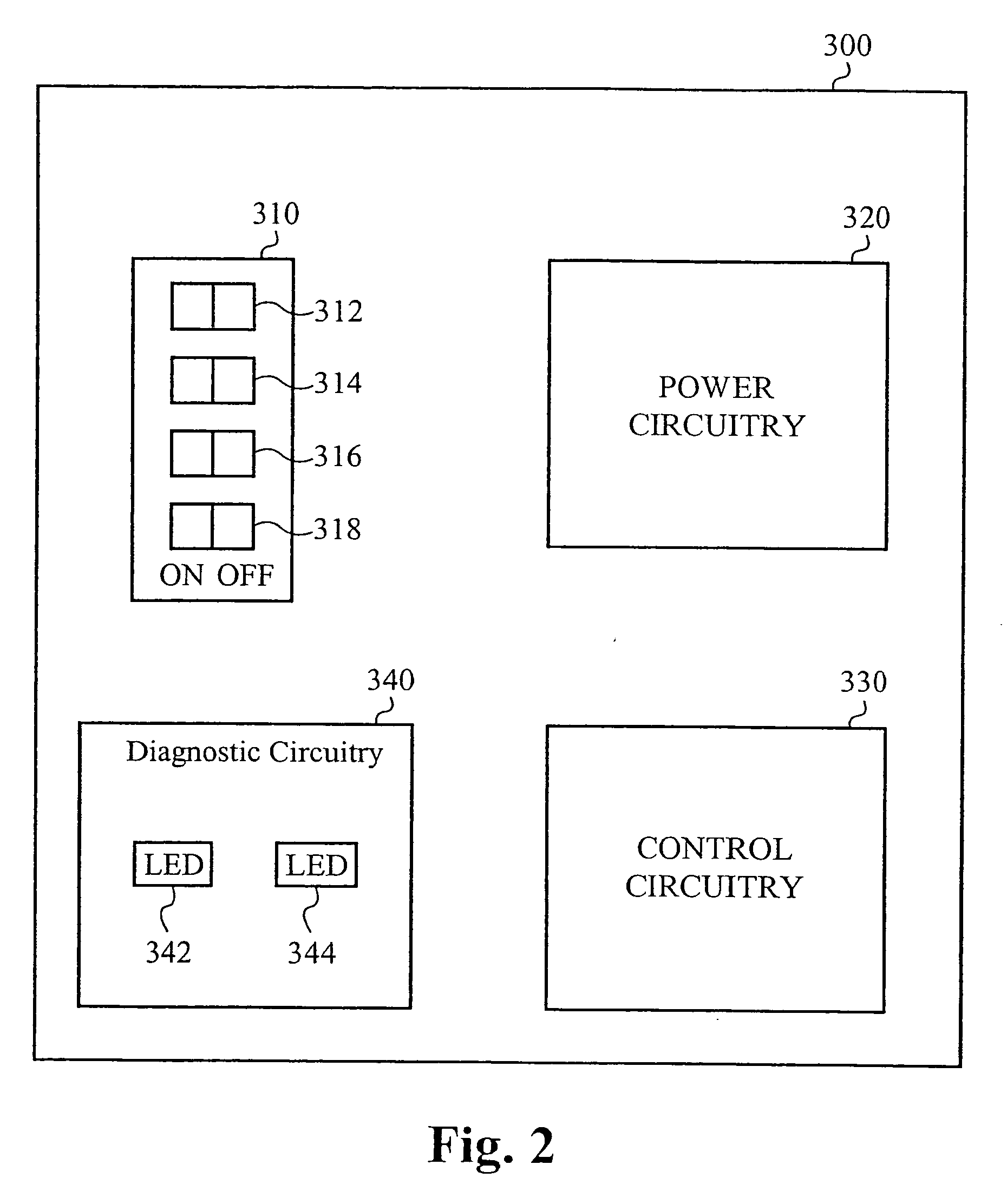

System and architecture for controlling lighting through a low-voltage bus

InactiveUS20070145826A1Dc network circuit arrangementsElectric light circuit arrangementLow voltageEffect light

A system and architecture for managing lighting through a seamless low-voltage bus network is disclosed. The system comprises a plurality of control units that serve as nodes for integrating devices, such as light fixtures, control switches and sensors into the bus. Each of the control units preferably includes a printed circuit board and node interconnects for assembling the low-voltage bus and for integrating the devices. Alternatively, the system comprises a central hub with a master printed circuit control board and a plurality of interconnects for assembling the bus and for integrating the devices.

Owner:FINELITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com