Power-driven six-degree of freedom motion platform high-precision control system and control method

A motion platform and control system technology, applied in three-dimensional position/channel control and other directions, to achieve the effects of high real-time performance, simple structure, and flexible expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

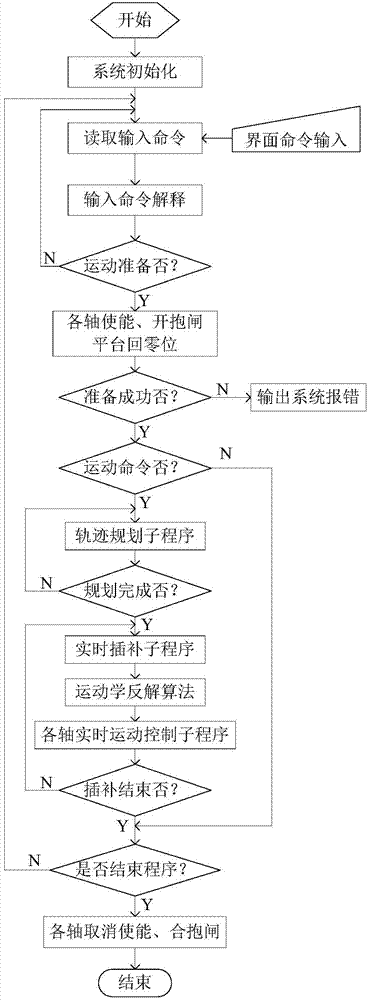

[0027] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

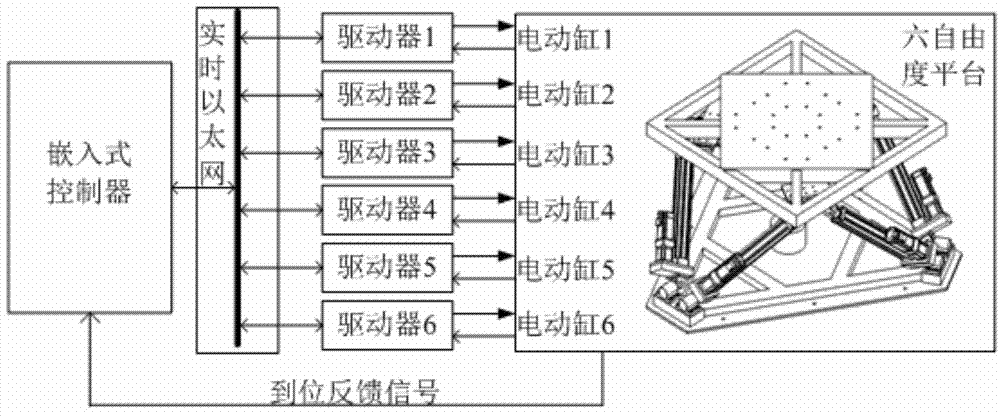

[0028] refer to figure 1 As shown, the six-degree-of-freedom motion platform body in this embodiment is a Stewart configuration parallel mechanism, which adopts an all-electric drive mode, including an upper platform, a lower platform, 6 electric cylinders, and a kinematic hinge connecting the upper and lower platforms.

[0029] Based on the structure of the above-mentioned six-degree-of-freedom motion platform, the hardware of the platform control system in this embodiment adopts a multi-axis servo system solution based on industrial real-time Ethernet. For the principle of hardware composition, see figure 1 As shown, specifically, the control system includes an embedded controller, a real-time Ethernet bus network and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com