Patents

Literature

37results about How to "Good movement synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

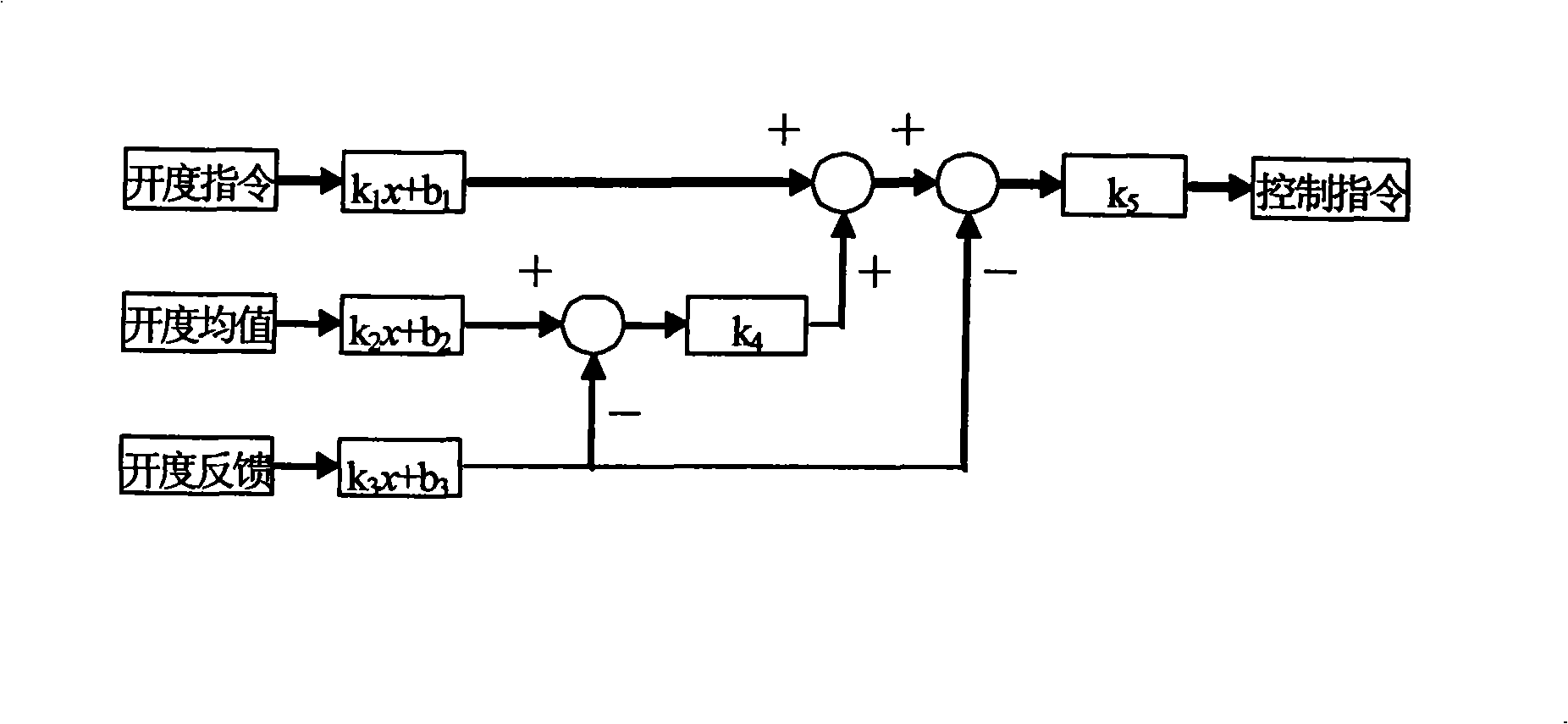

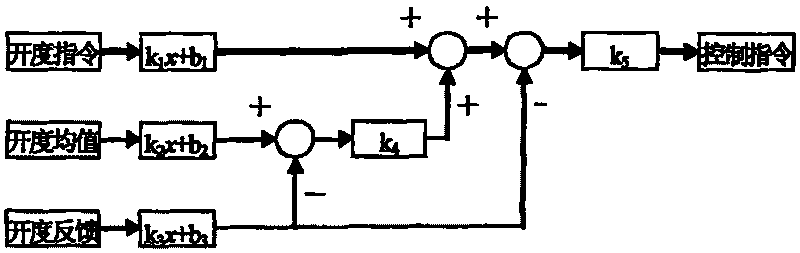

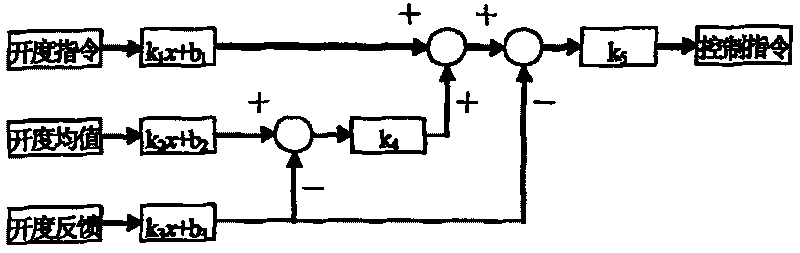

Large hydraulic turbines stationary guide blade synchronous regulation and control method

ActiveCN101260858AHigh control precisionSmall opening commandHydro energy generationMachines/enginesStart timeFull scale

The invention discloses an adjustment and control method for the synchronism of guide vanes of a large-scale water turbine, comprising the following steps: the resistance value of a drive coil of a servomotor is measured and then accurately defined in a single guide vane controller; the zero position and the full scale of a single guide vane instruction of the single guide vane controller are adjusted; a guide vane in the single guide vane controller synchronously controls adjustment of the zero position and the full scale of the instruction; the zero position and the full scale of a guide vane opening displacement sensor are adjusted; the vane mechanical bias voltage is measured and adjusted; the control parameter of the single guide vane is set; the synchronous control parameter of the guide vane is set; the starting time and the closing time of the guide vane are measured and adjusted; a single guide vane displacement transmitter gives a failure alarm; a single guide vane control loop gives an alarm; and an overall guide vane control loop gives an alarm. The adjustment and control method improves the control precision of guide vanes of a hydropower generating unit; the deviation of the opening instruction and the feedback is small; the action synchronism of the guide vane is good; both the starting time and the closing time of the guide vane meet the design requirements; the maximum deviation of the switching time is better than that of the standard requirement.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

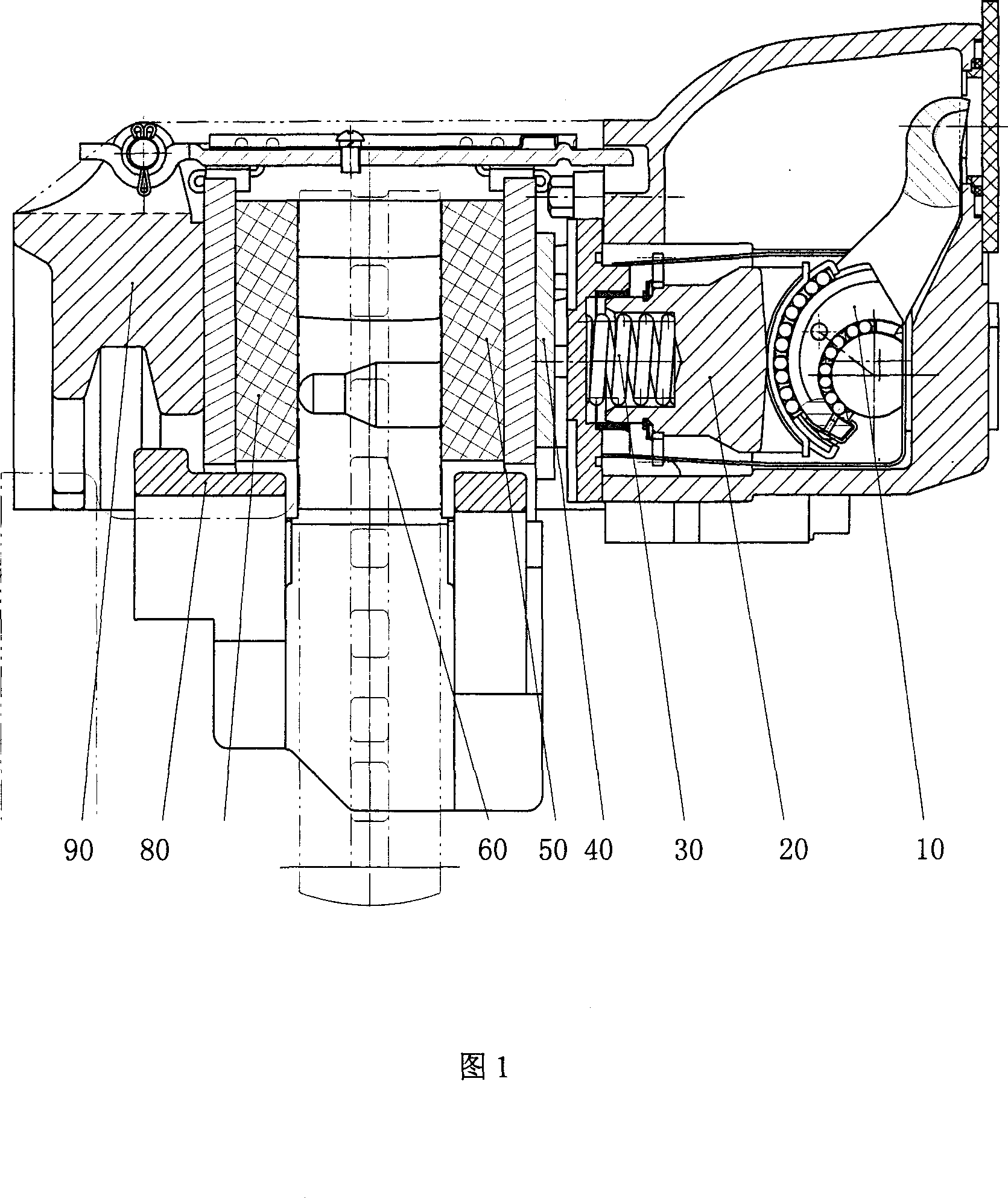

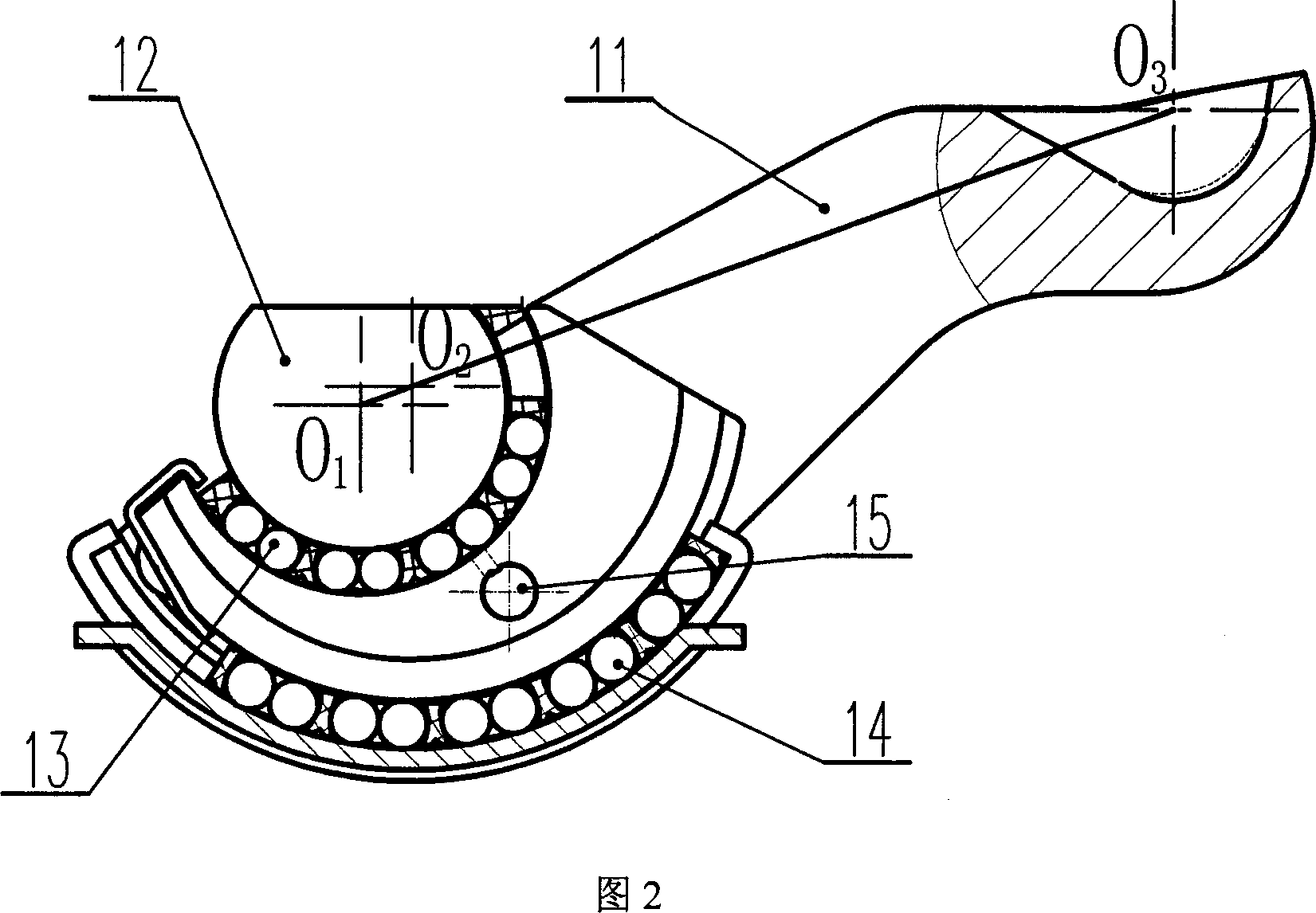

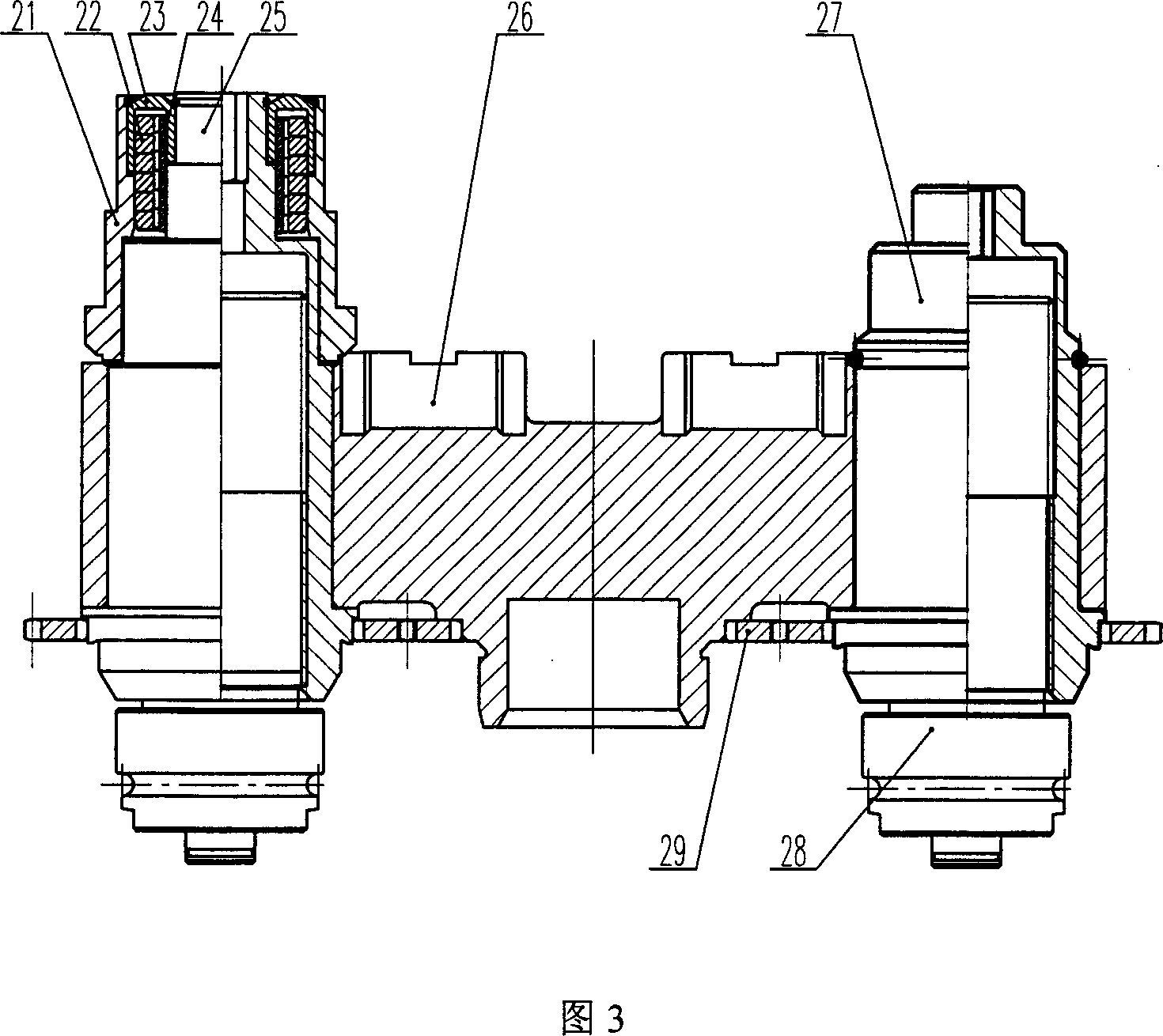

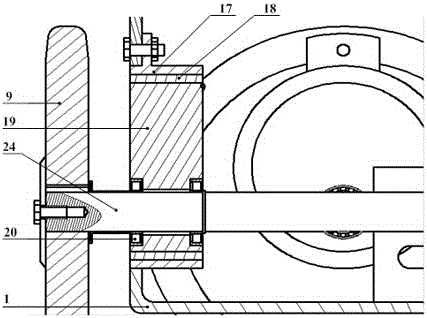

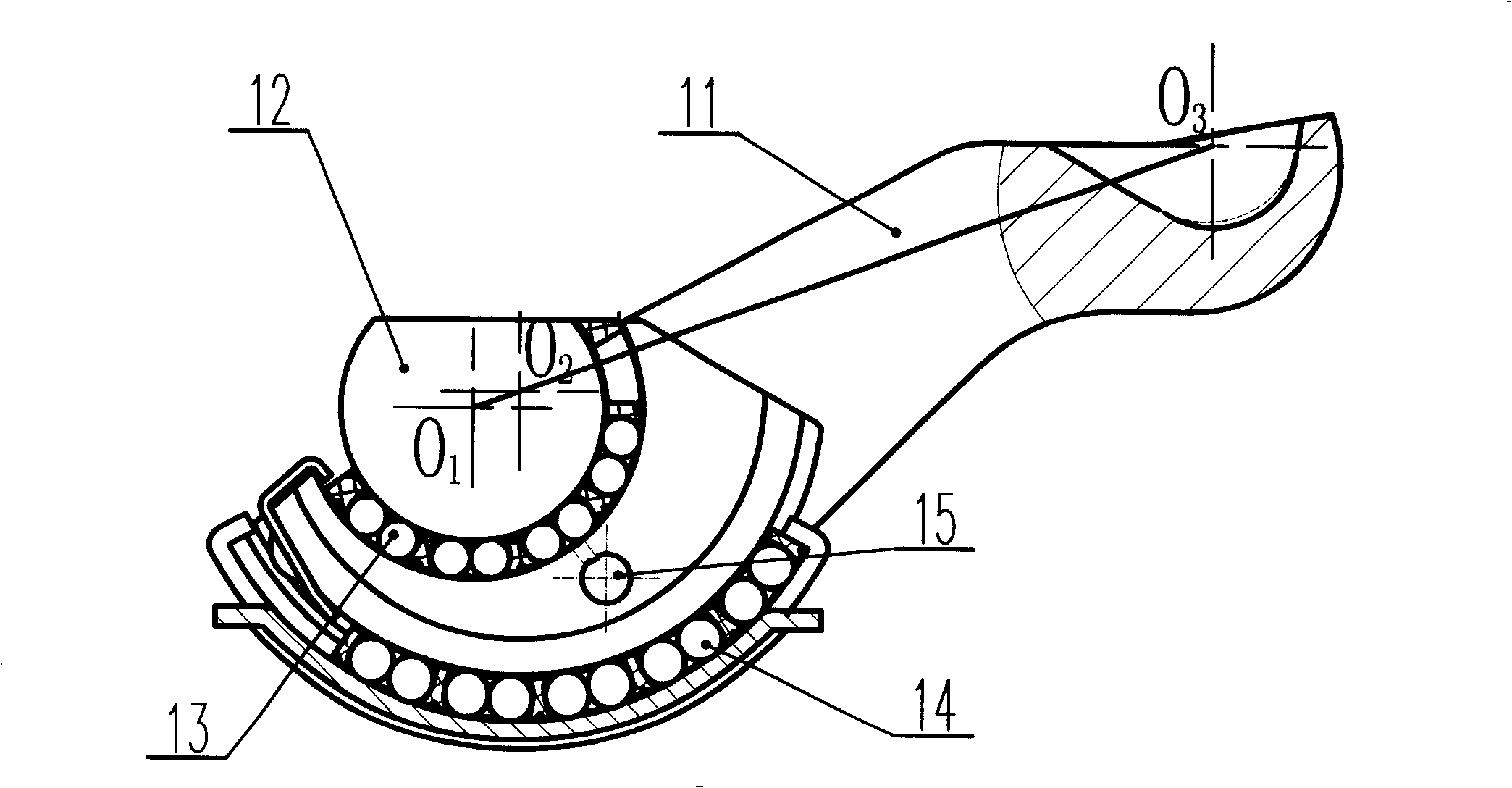

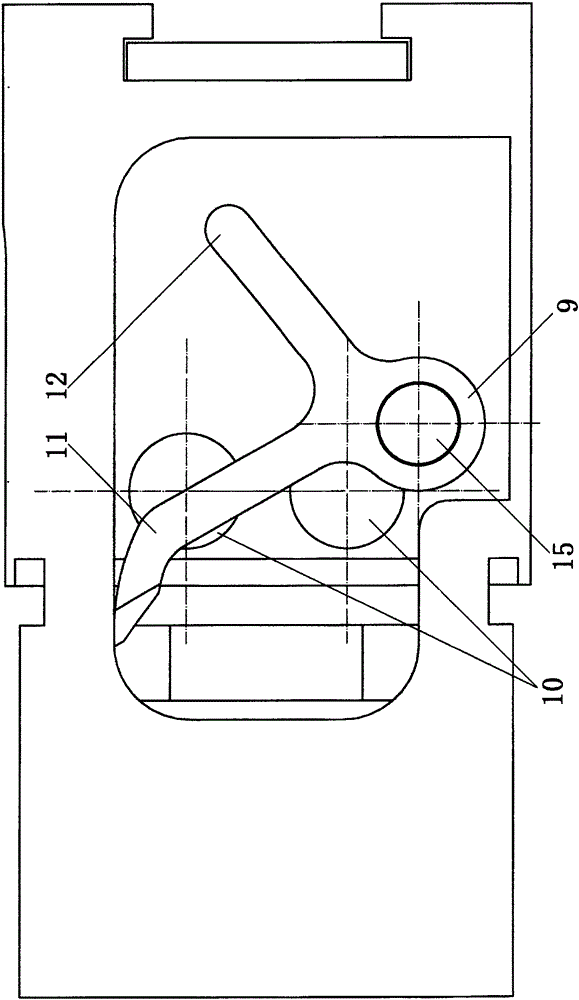

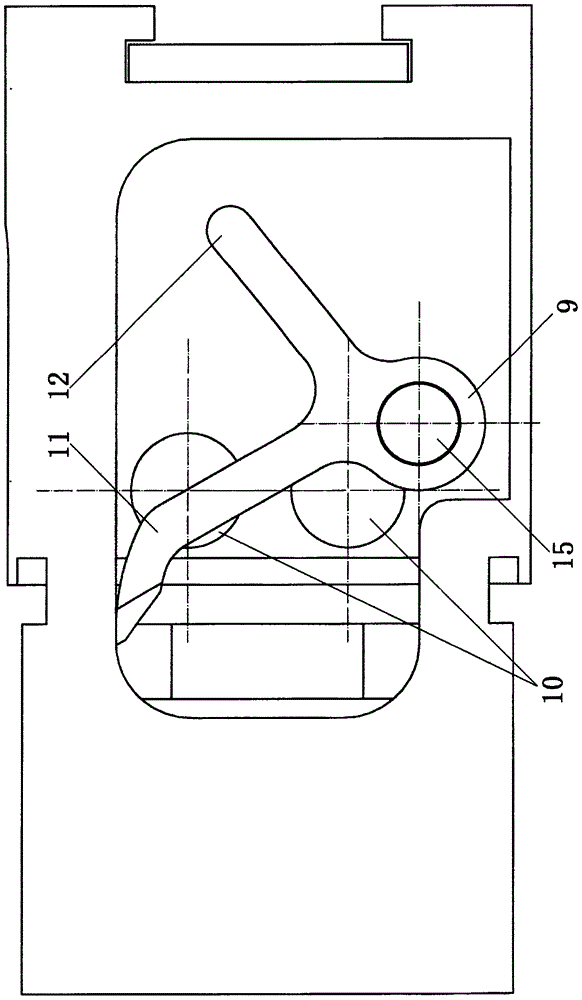

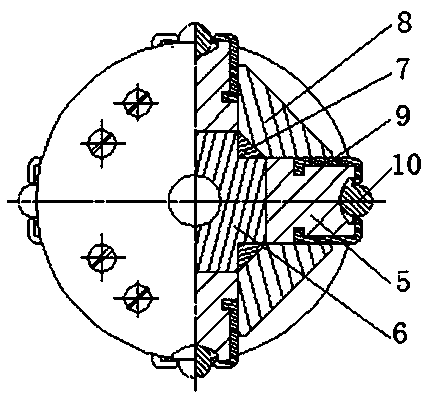

Floating tong type bipushing rod pneumatic disk brake based on rectangular torsional spring single dicrection clutch

ActiveCN1948778ALarge braking torqueConstant braking force ratioAxially engaging brakesBrake actuating mechanismsCalipersDisc brake

The invention comprises a pressure arm unit, a rotation shaft unit, a return spring, a push pedal, an internal friction plate, a brake, an external friction plate, a support and a caliper body arranged in order from right to left. Because of using the rectangular section torsional spring function, in a specific environment the invention can realize a one-way transmission of the torque and also can realize an overload protection effectively. The reasonable design of the pressure arm unit can supply the stable brake moment.

Owner:WUHAN YOUFIN AUTOPARTS

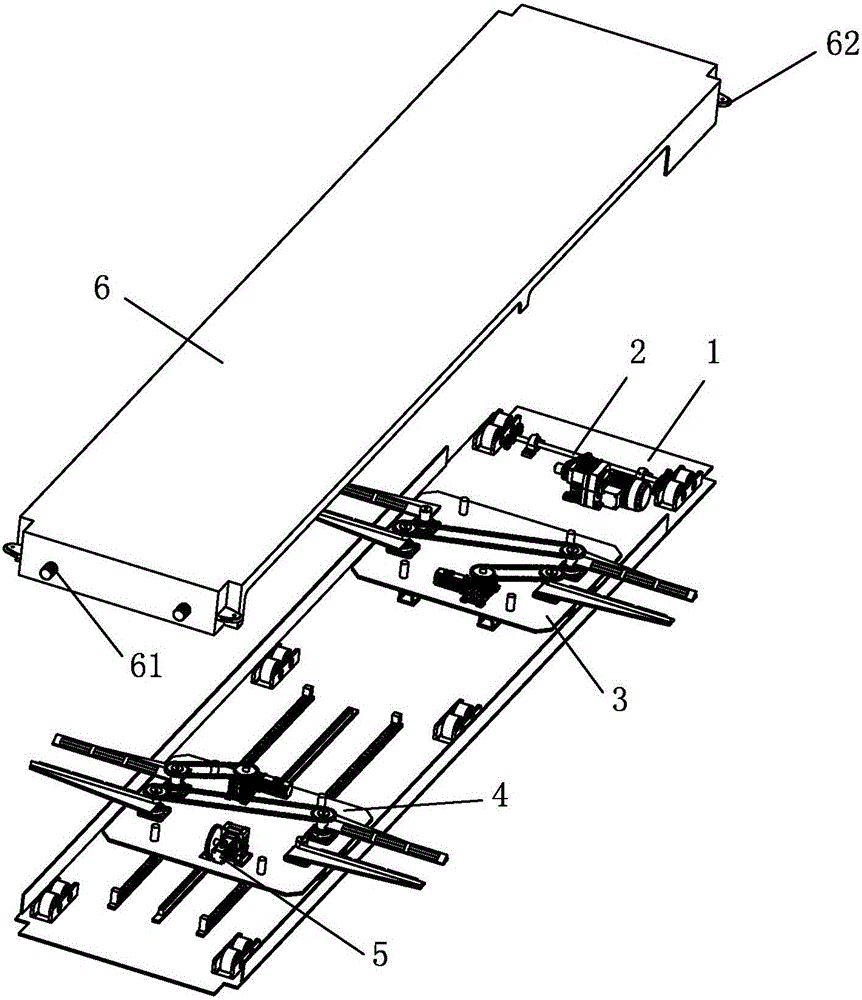

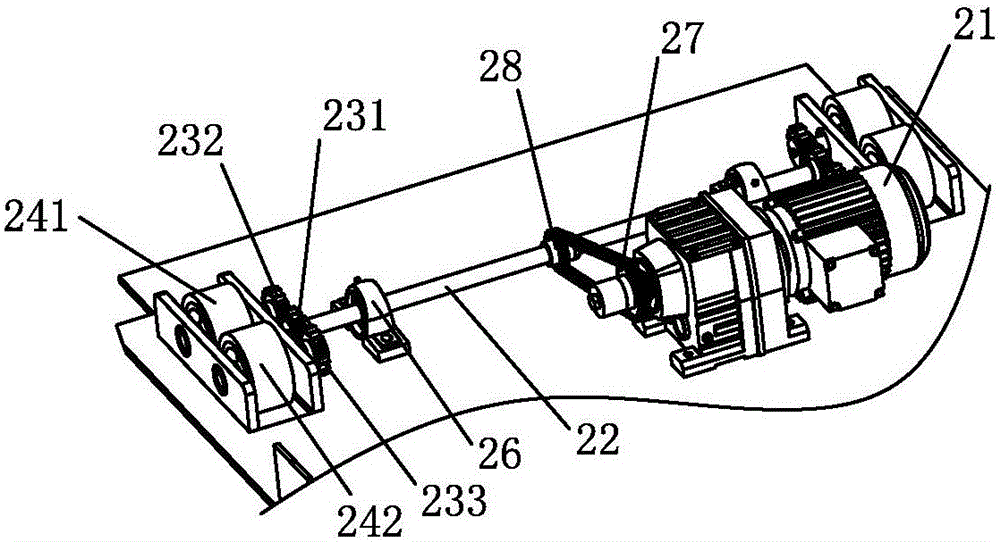

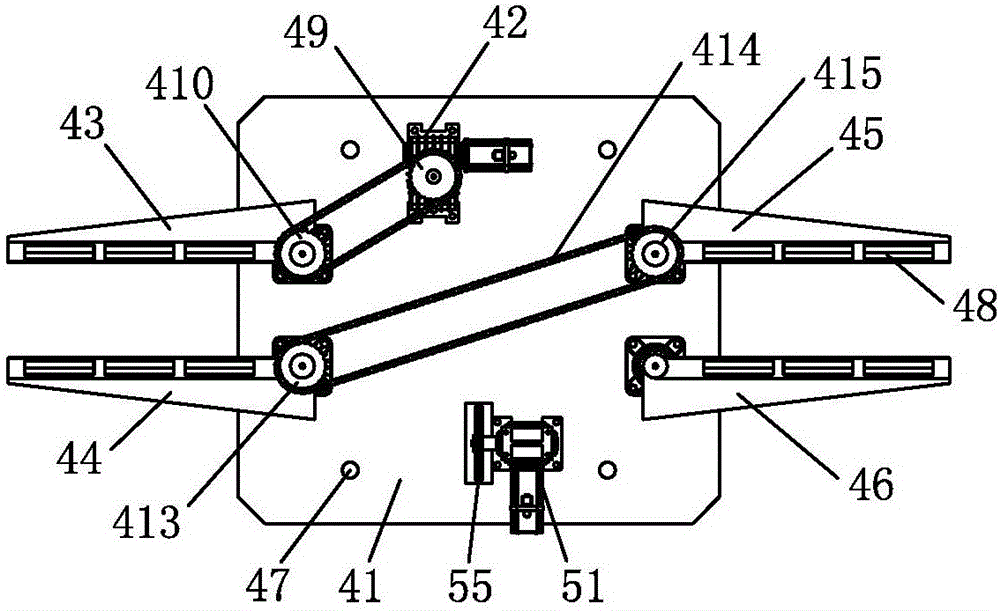

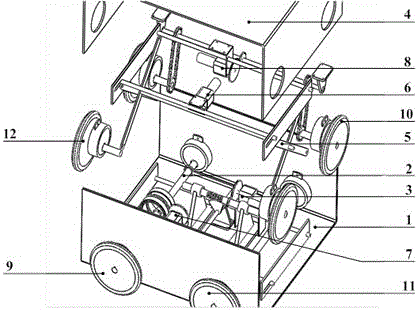

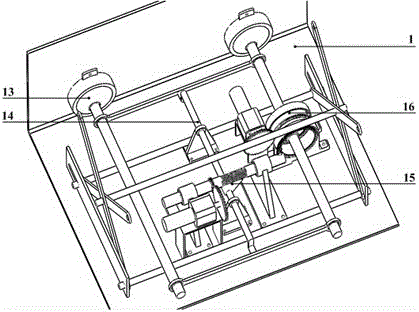

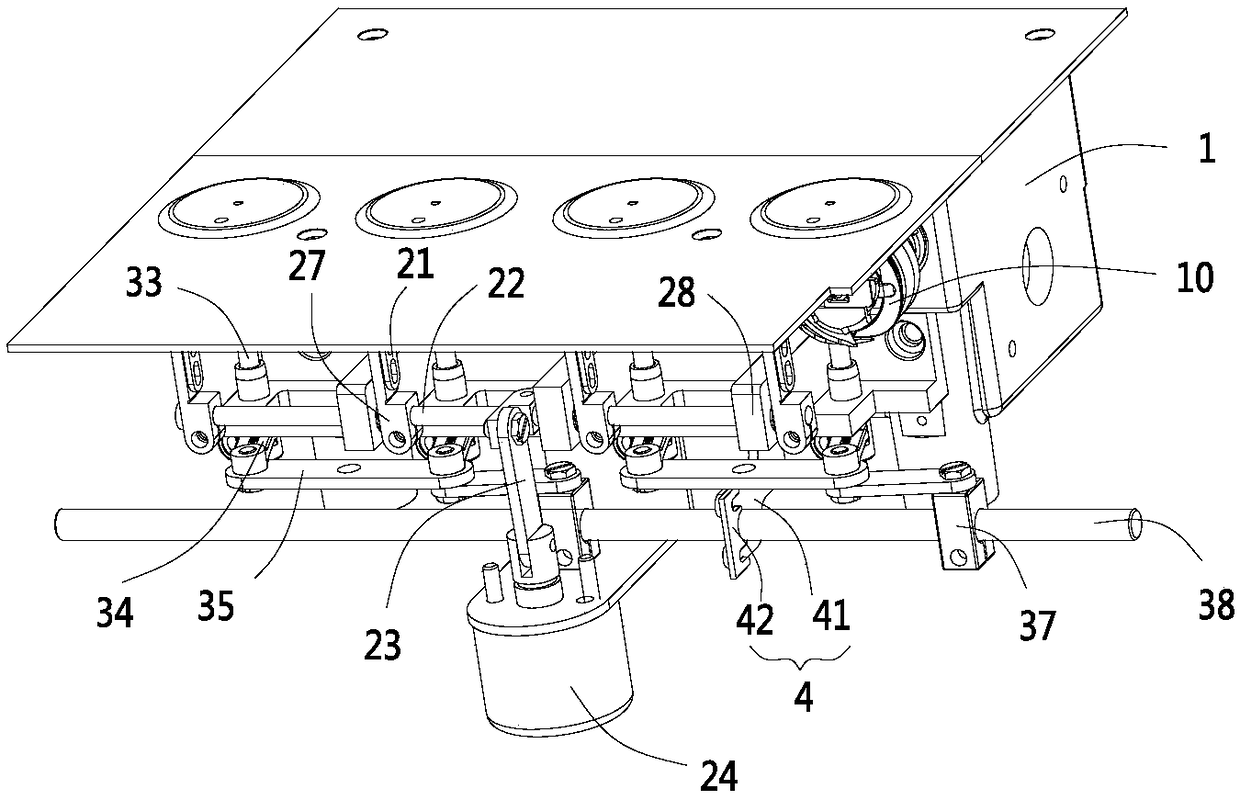

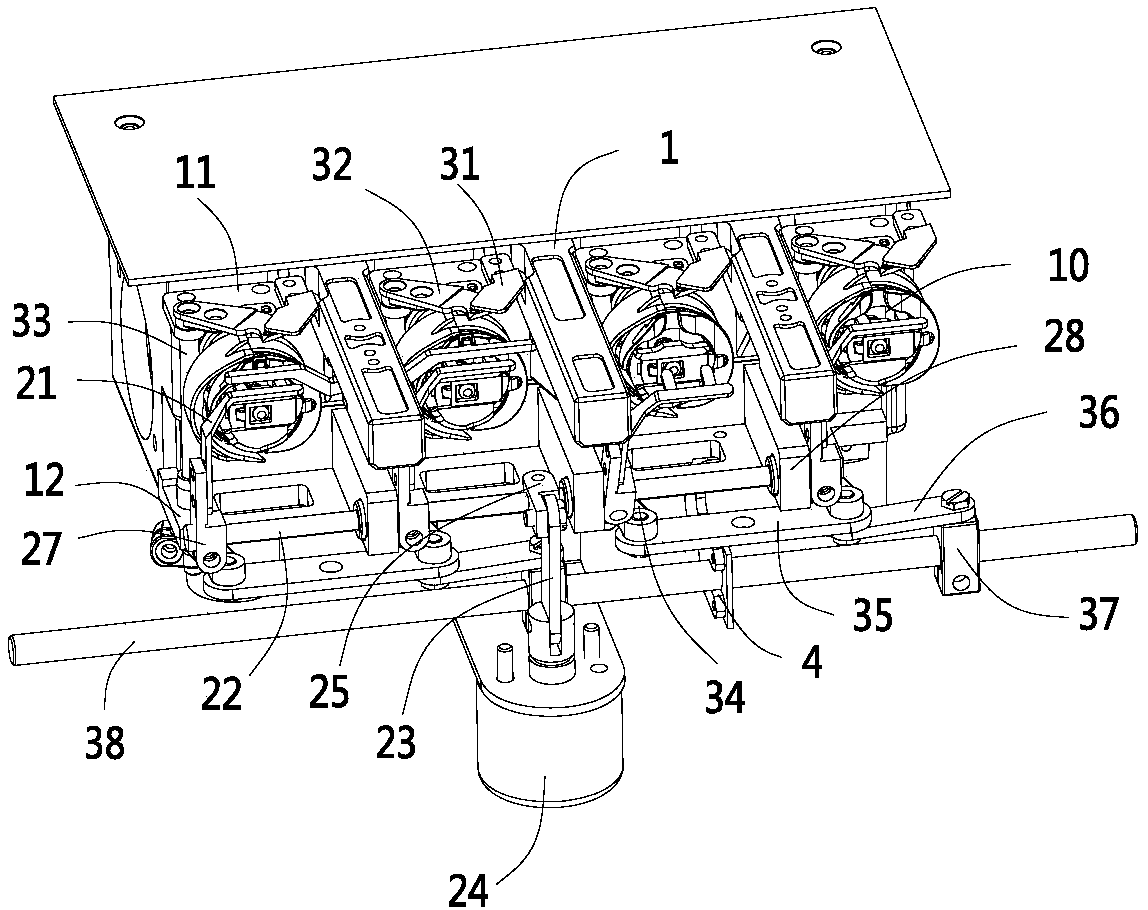

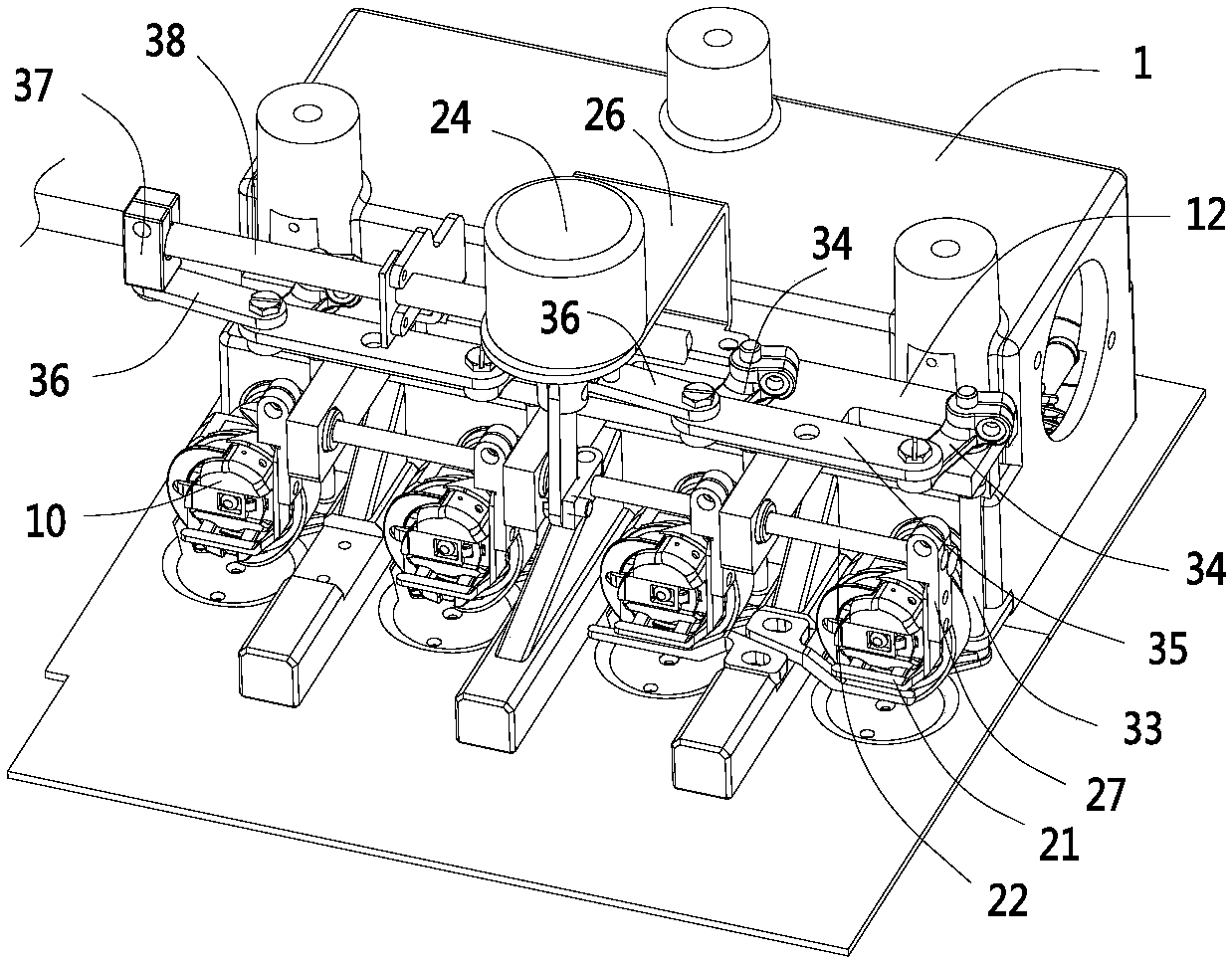

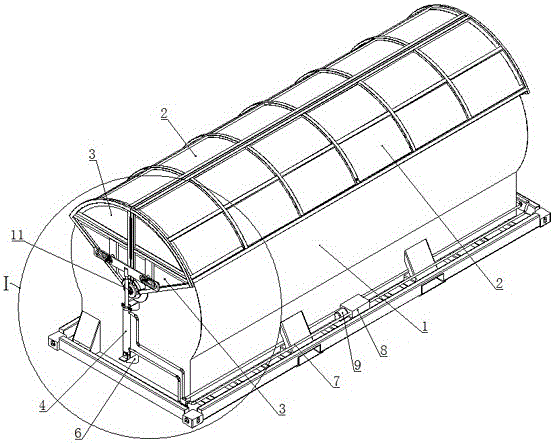

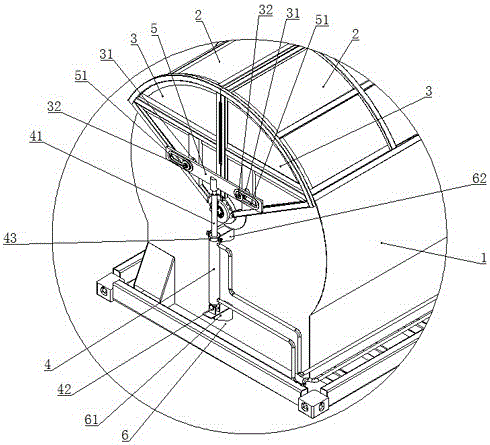

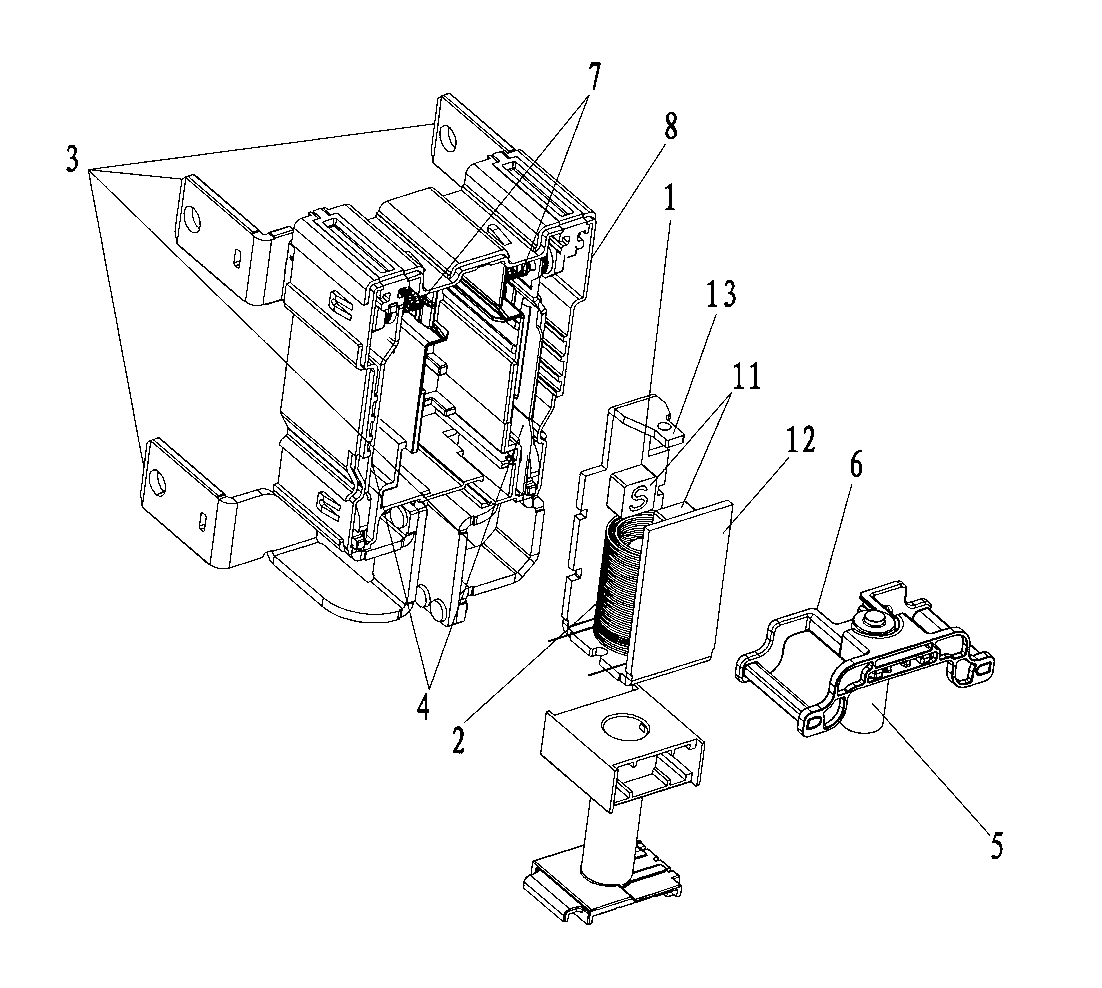

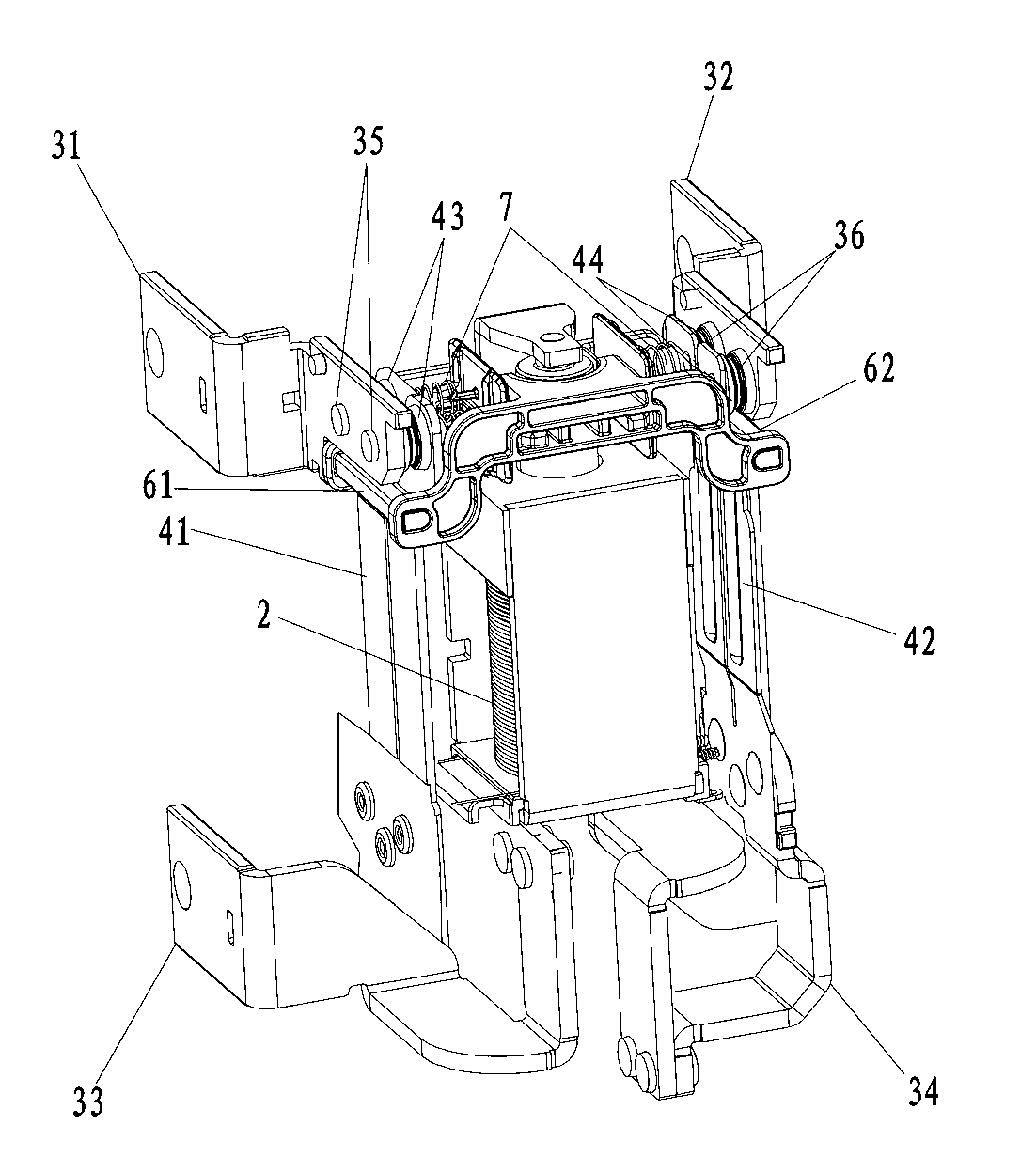

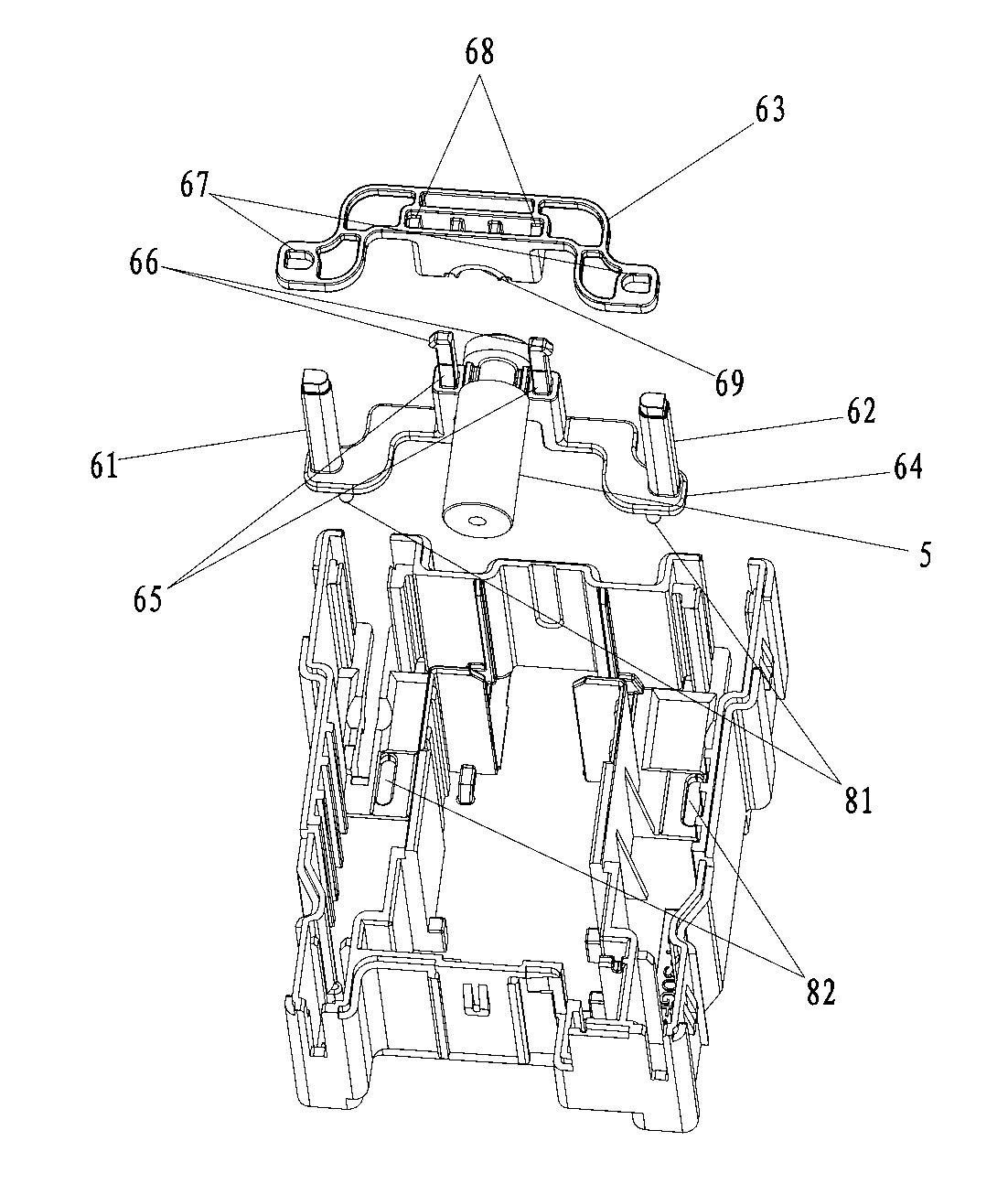

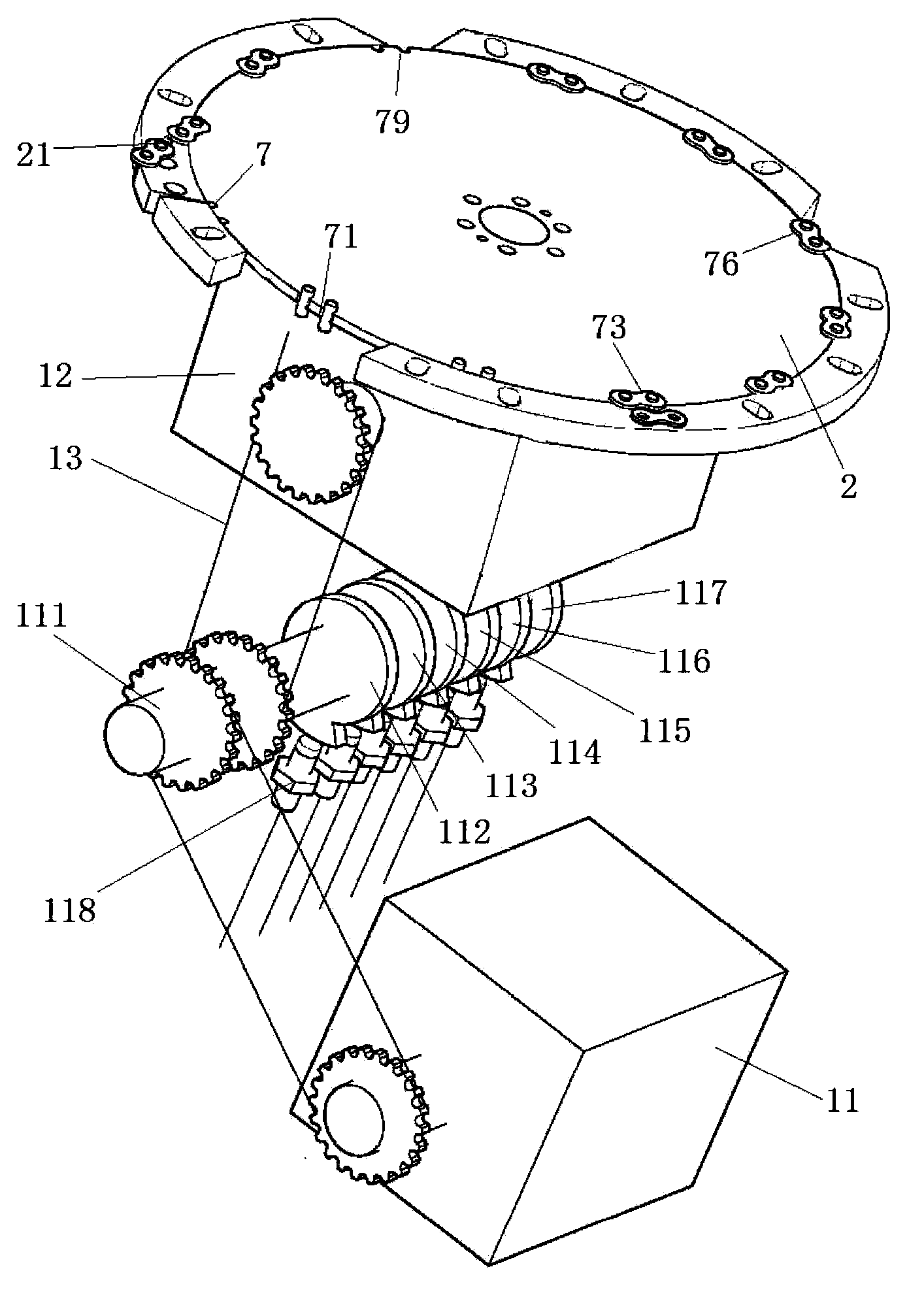

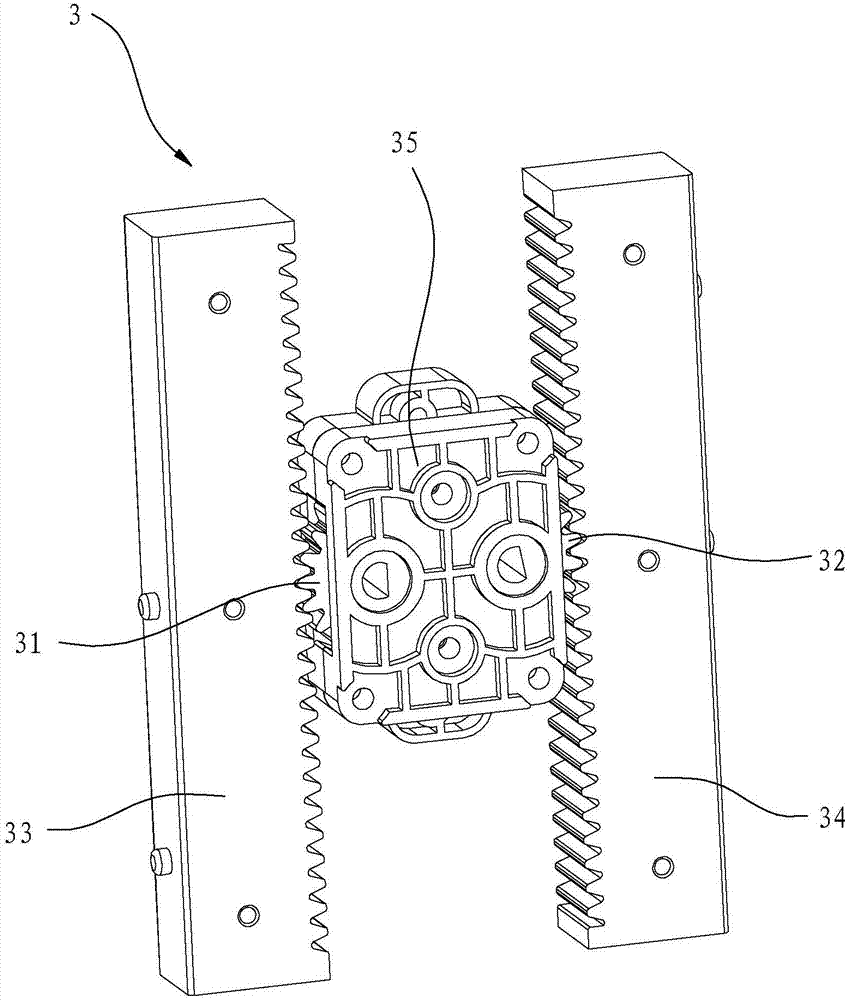

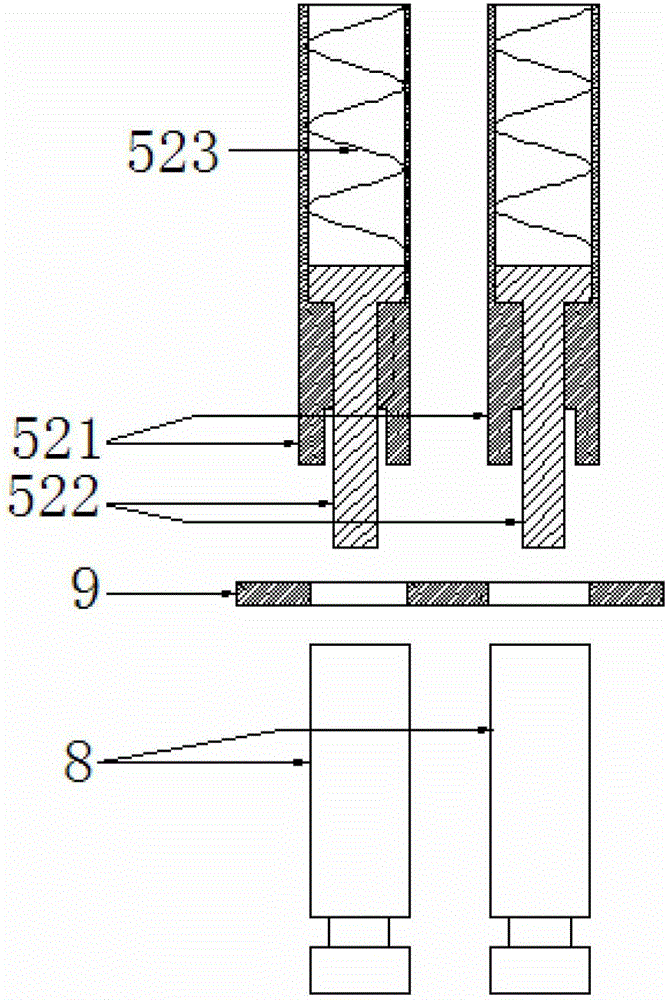

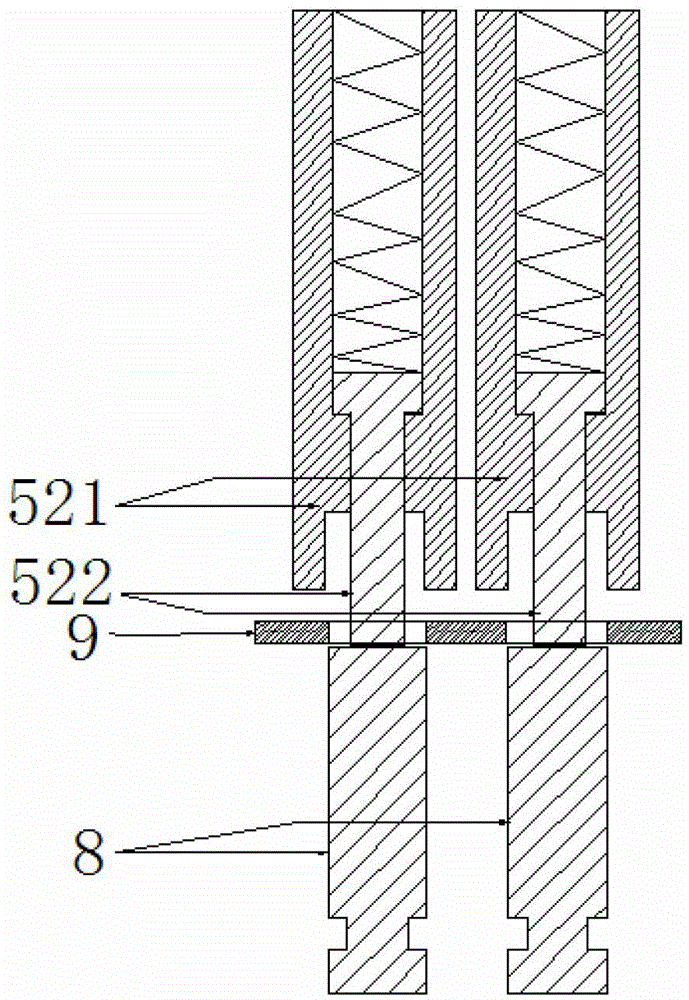

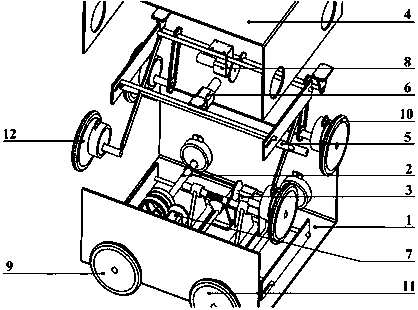

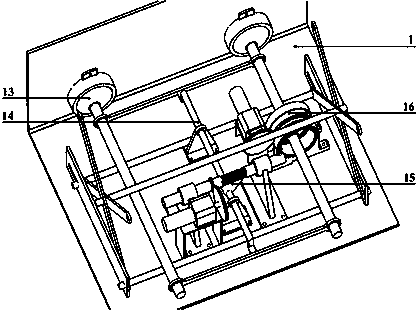

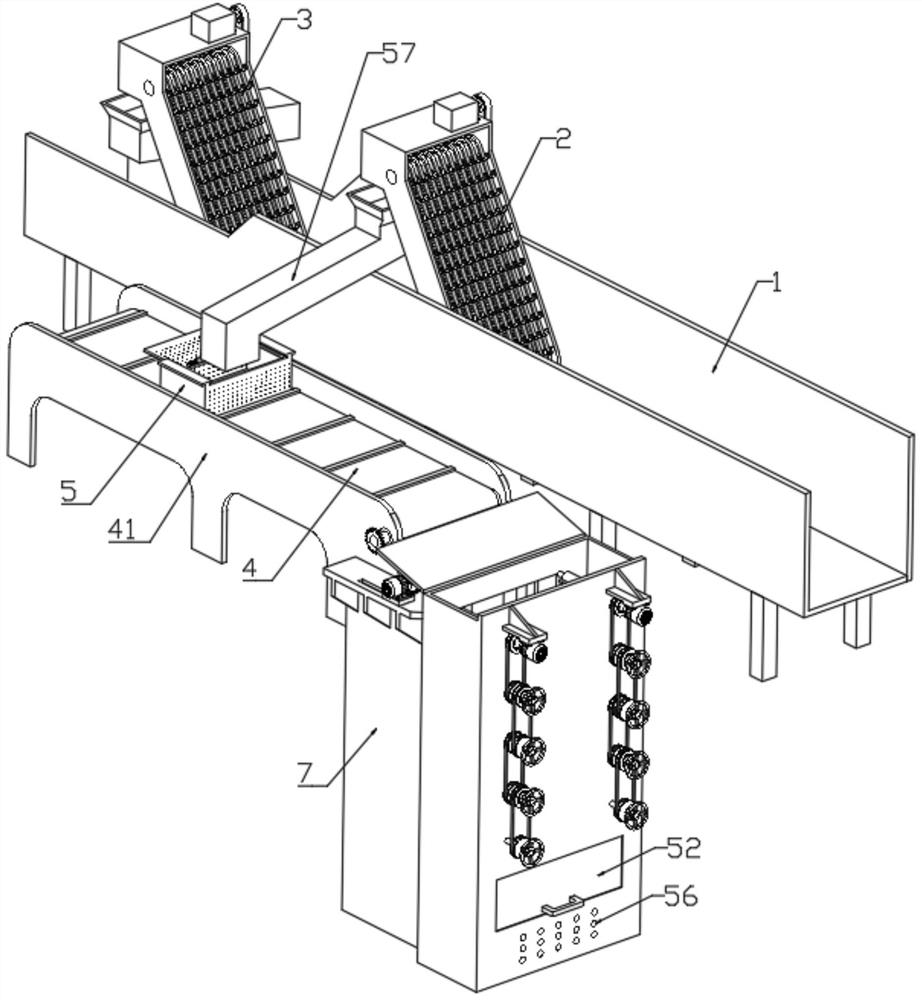

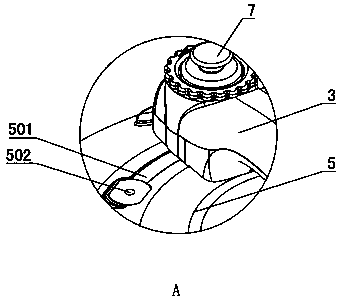

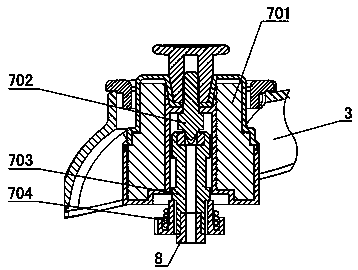

Tire-holding automobile carrier

ActiveCN105822117AGood movement synchronizationThe overall structure is simple and reliableParkingsGear wheelElectric machinery

The invention discloses a tire-holding automobile carrier. The tire-holding automobile carrier comprises a chassis for mounting various assemblies, wherein the chassis is provided with a walking mechanism for carrying an automobile to walk and clamping mechanisms for holding automobile tires; the clamping mechanisms comprises a first clamping mechanism and a second clamping mechanism which are the same in structures; the first clamping mechanism is fixedly arranged at one end of the chassis; the second clamping mechanism is arranged at the other end of the chassis in a sliding way through a wheel base adjusting mechanism. According to the tire-holding automobile carrier, a single automobile body structure is adopted, and one of the clamping mechanisms is arranged on the chassis in the sliding way through the wheel base adjusting mechanism in order to fit different wheel bases of different types of automobiles, so that the structure is simple and reliable, and is more stable than the conventional structure. Clamping arms of the clamping mechanisms on the same sides are meshed through synchronous gears, and diagonal clamping arms are in transmission through synchronous chains, so that a function that a single motor controls four clamping arms to rotate synchronously is realized, and higher action synchronism of the clamping arms is realized.

Owner:CHINA CONSTR UNDERGROUND SPACE

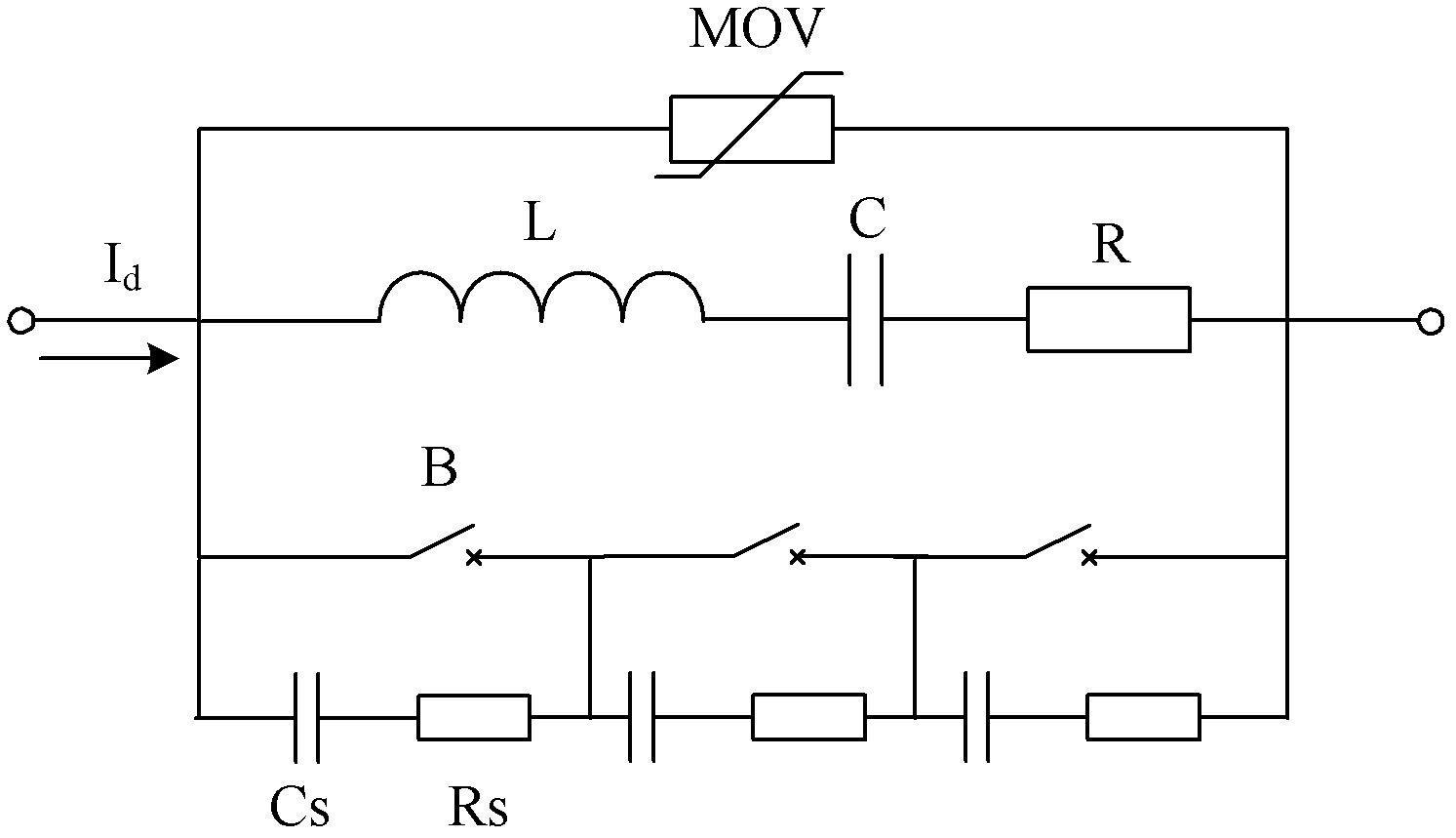

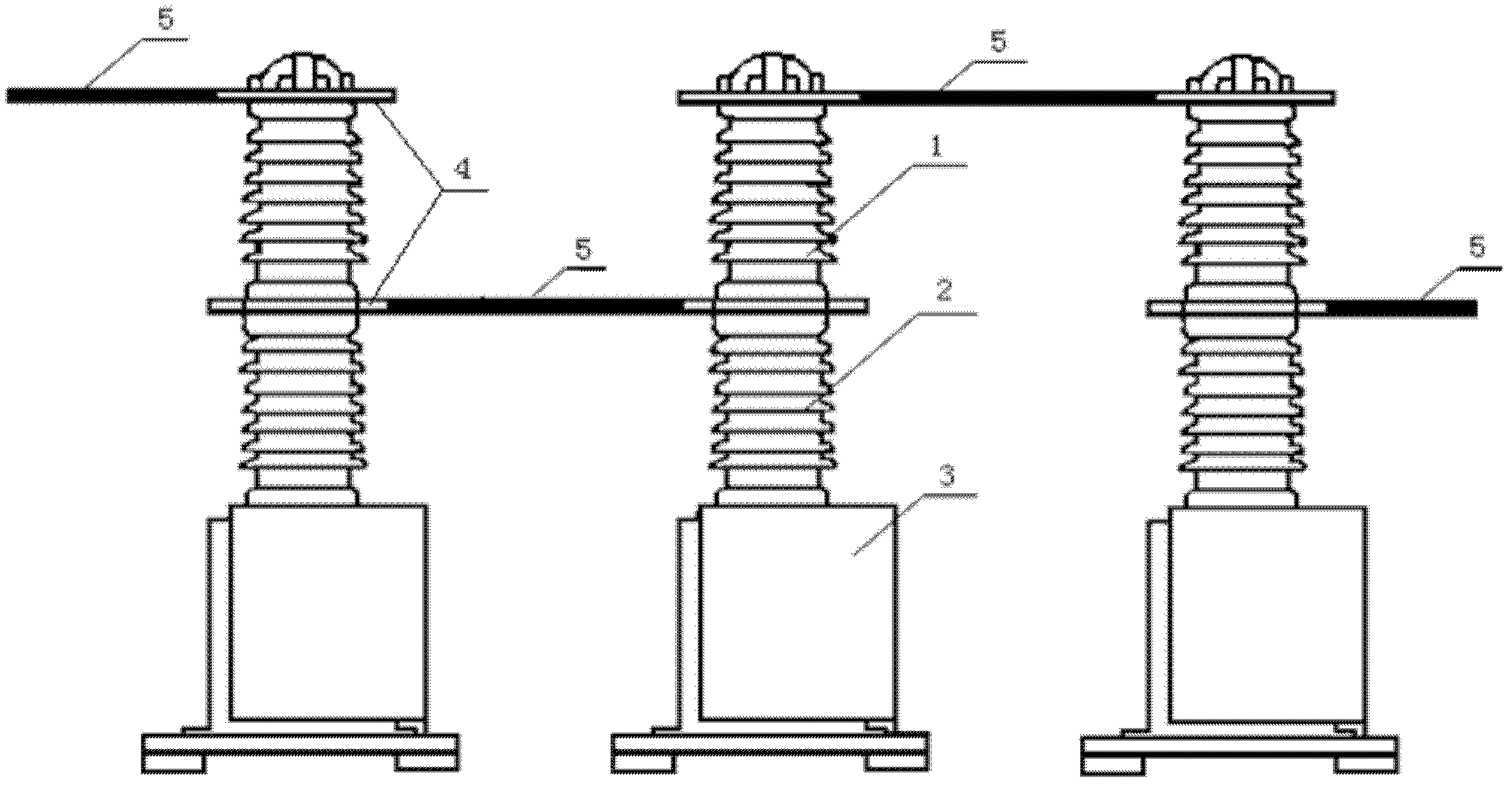

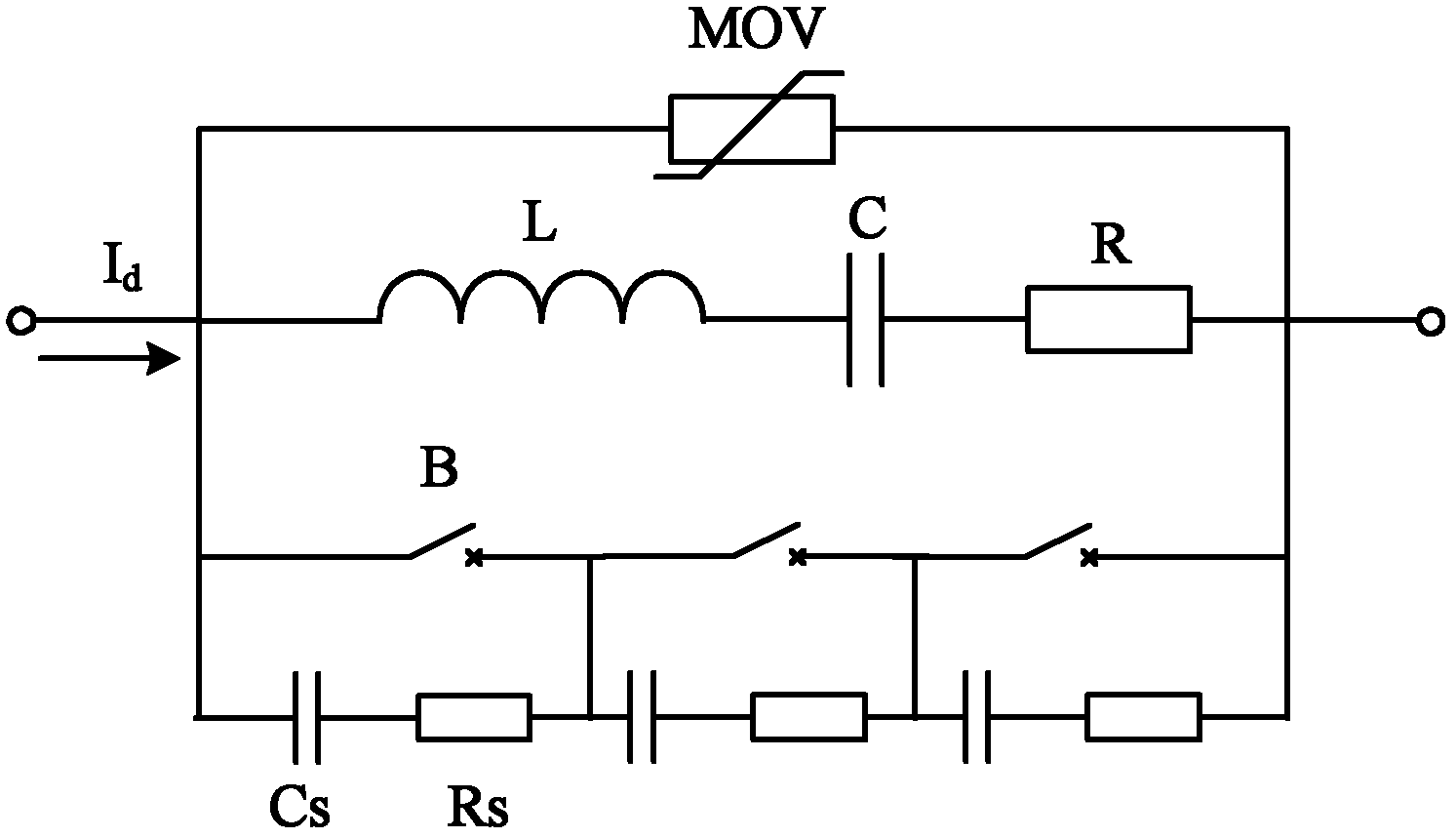

High voltage direct current breaker with multiple fractures and tandem type

InactiveCN102360991AImprove pressure equalizationHigh breaking voltageProtective switch detailsDc network circuit arrangementsOvervoltageUltra high voltage

The invention relates to a high voltage direct current breaker with multiple fractures and a tandem type. The breaker comprises a multi-fracture breaker, an oscillation loop and a dissipative element. The multi-fracture breaker includes a plurality of single-phase breakers and fractures of all the single-phase breaker are in series connection through connection buses; the multi-fracture breaker is respectively in parallel connection with the oscillation loop and the dissipative element through the connection buses; and a fracture of each the single-phase breaker is respectively in parallel connection with an RC equalizer circuit. According to the invention, fractures of a plurality of single-phase breakers are in series connection so as to form a multi-fracture tandem structure; effects of high drop-out voltage, heavy drop-put current and short drop-out time and the like are realized; and demands of ultra-high voltage and extra-high voltage direct current power transmission projects can be completely met. In addition, the oscillation loop in the invention is used for generating oscillation currents; the dissipative element is used for absorbing line energy and restricting overvoltages after currents are switched off; and the RC damping circuit is used for improving equalizing voltages between fractures of all the single-phase breakers.

Owner:CHINA ELECTRIC POWER RES INST +1

Variable-structure mobile robot capable of making orthogonal bidirectional movement and control method of variable-structure mobile robot

ActiveCN106003039AEnhanced mobilityIncrease flexibilityProgramme-controlled manipulatorDrive wheelEngineering

The invention discloses a variable-structure mobile robot capable of making orthogonal bidirectional movement and a control method of the variable-structure mobile robot. The variable-structure mobile robot capable of making orthogonal bidirectional movement comprises a chassis, a separation type variable-position driving mechanism, a variable-position motor, an integral variable-position driving mechanism, a variable-position electric push rod, a driving wheel motor A, a driving wheel motor B, a driving wheel A, a driving wheel B, a follower wheel A, a follower wheel B, a control device and a guiding sensor. The separation type variable-position driving mechanism is installed on the chassis, and the position, relative to the chassis, of the axis of the driving wheel A is changed while the position of the driving wheel motor A is kept unchanged. The integral variable-position driving mechanism is installed on a top cover, and the position, relative to the chassis, of the axis of the driving wheel B is changed by changing the height of the top cover. The axis of the driving wheel A is orthogonal with the driving wheel B, and the lowest position of the axis of the driving wheel A is the same as that of the driving wheel B. Orthogonal bidirectional movement of the mobile robot is achieved by changing the driving wheels making contact with the ground, the movement direction can be freely switched between orthogonal directions in the same plane, and the movement maneuverability and flexibility of the mobile robot are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

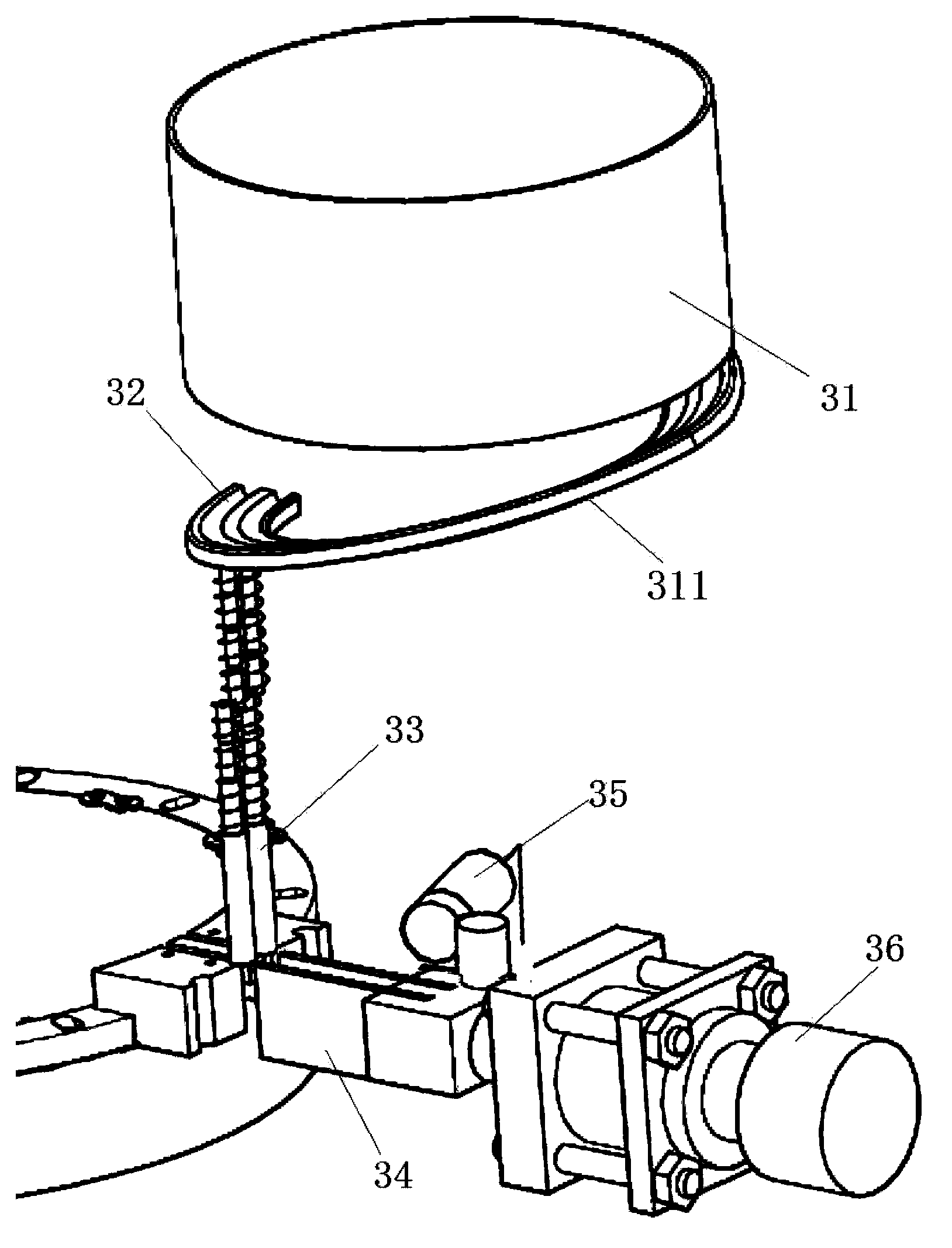

Embroidery machine

ActiveCN108221212ASave installation spaceGood synchronizationEmbroidering machines apparatusEngineeringMechanical engineering

The invention discloses an embroidery machine and belongs to the technical field of embroidery. The embroidery machine comprises an embroidery machine head, a shuttle box, a thread buckling device anda thread trimming device, wherein a rotating shuttle is arranged in the shuttle box; the thread buckling device comprises thread buckling parts which are movably arranged on the shuttle box and are used for buckling the rotating shuttle; the thread trimming device comprises a fixed cutter and moving cutters moving relatively to the fixed cutter. The embroidery machine is characterized in that thethread buckling device also comprises a driving rotation shaft rotatably arranged on the shuttle box; at least two thread buckling parts are connected with the driving rotation shaft simultaneously;the thread trimming device comprises a main driving connection rod and branched connection rods; at least two branched connection rods are arranged on the main driving connection rod simultaneously; each branched connection rod drives the moving cutters to move respectively; the driving rotation shaft is driven by a first driver and drives at least two thread buckling parts to work; the main driving connection rod is driven by a second driver and drives at least two moving cutters to move. The embroidery machine disclosed by the invention has the advantages that the structures of the thread buckling device and the thread trimming device are simplified, and the requirements of the installation space are reduced.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

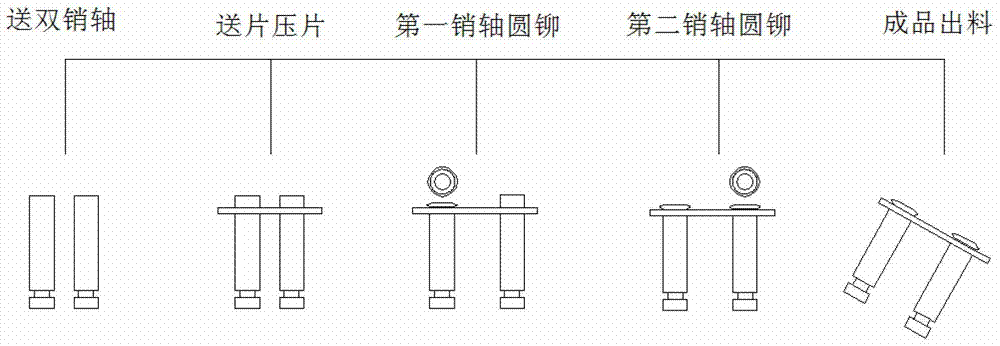

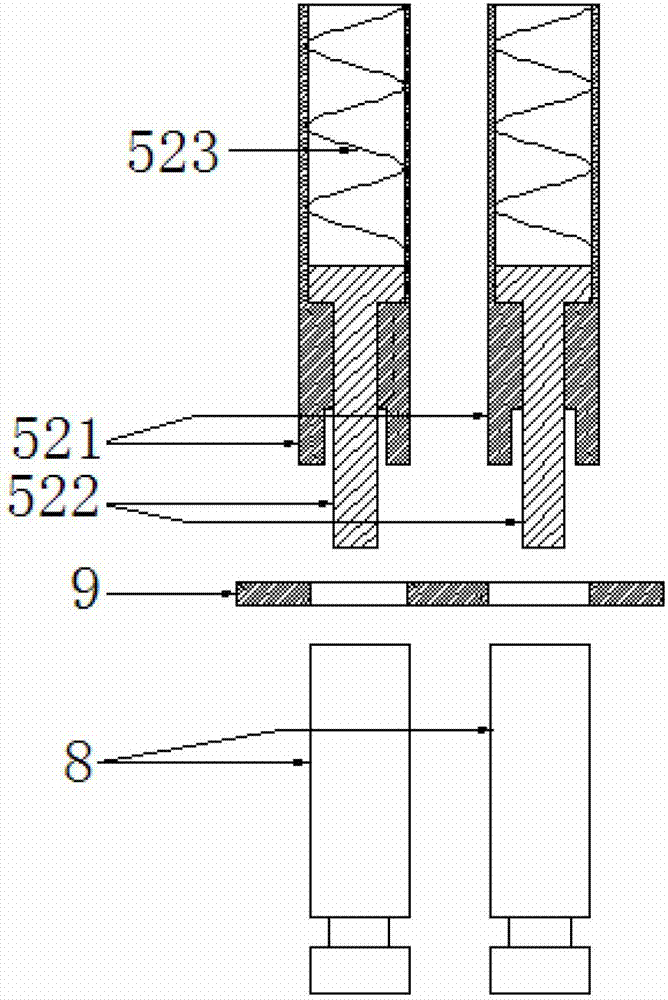

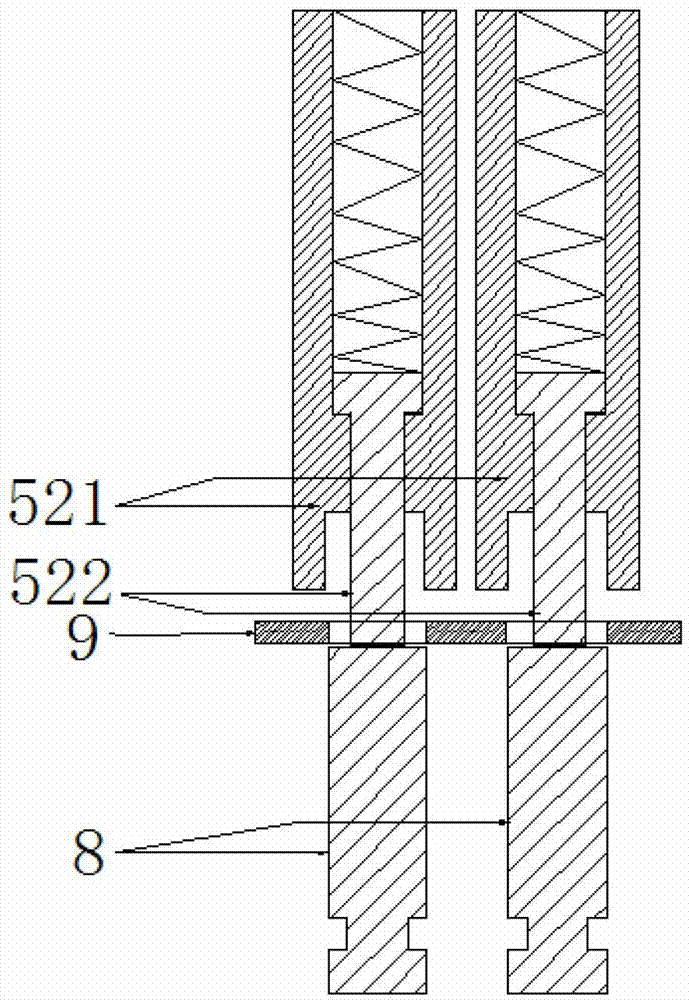

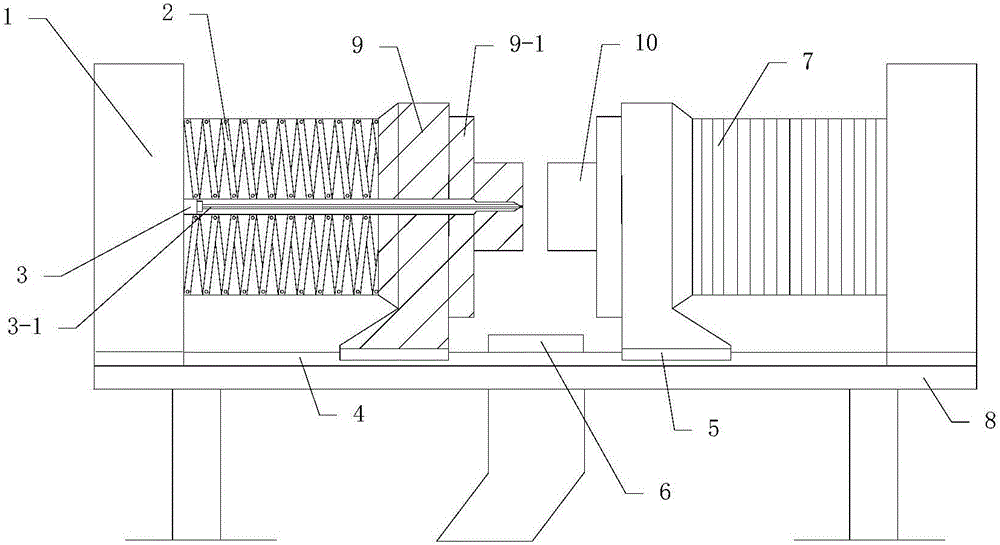

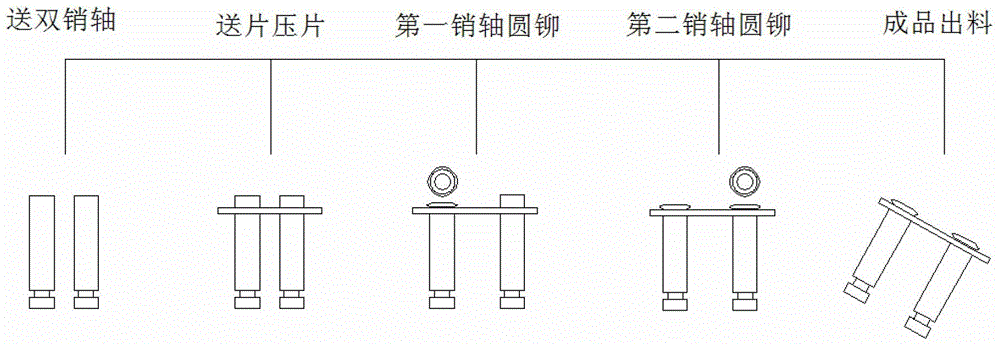

Chain joint assembling method

ActiveCN102873257AAvoid subsequent lossesHigh operational reliabilityMetal chainsEngineeringMechanical engineering

A chain joint assembling method includes step 1, providing a working rotary table; step 2, conveying pins; step 3, feeding outer links and assembling the same; step 4, primary round riveting; step 5, secondary round riveting. In the step 1, the working rotary table is connected with a driving device, 12 pairs of grooves are arranged on the outer side of the working rotary table uniformly, the driving device drives the working rotary table to rotate intermittently, and the rotation angle each time is 30 degrees. In the step 2, two pins are pushed into a first pair of grooves; In the step 3, the working rotary table rotates twice to push the links to the pins, the links are then assembled, and parts of the pins are protruded from the links. In the step 4, the working rotary table rotates three times continuously so that one of the pins with the links in the previous steps is subjected to round riveting. In the step 5, the working rotary table continues to rotate three times so that the other pin is subjected to round riveting. By the chain joint assembling method, reliability and action synchronism during production can be improved, loss in production is avoided, and production efficiency is improved.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

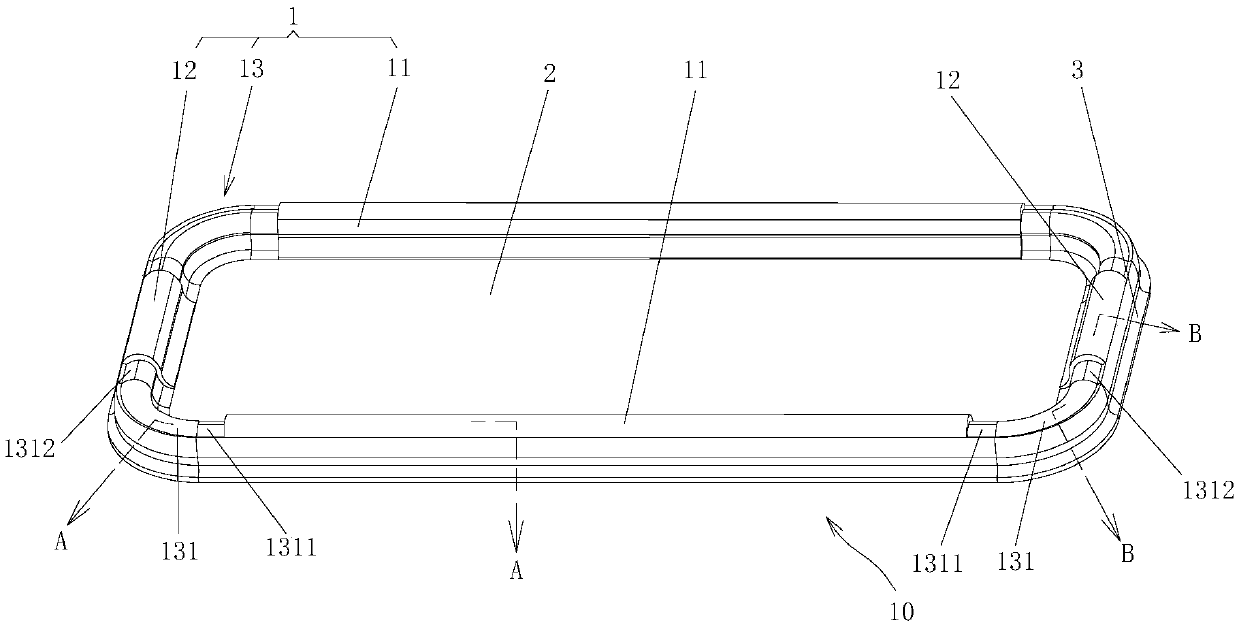

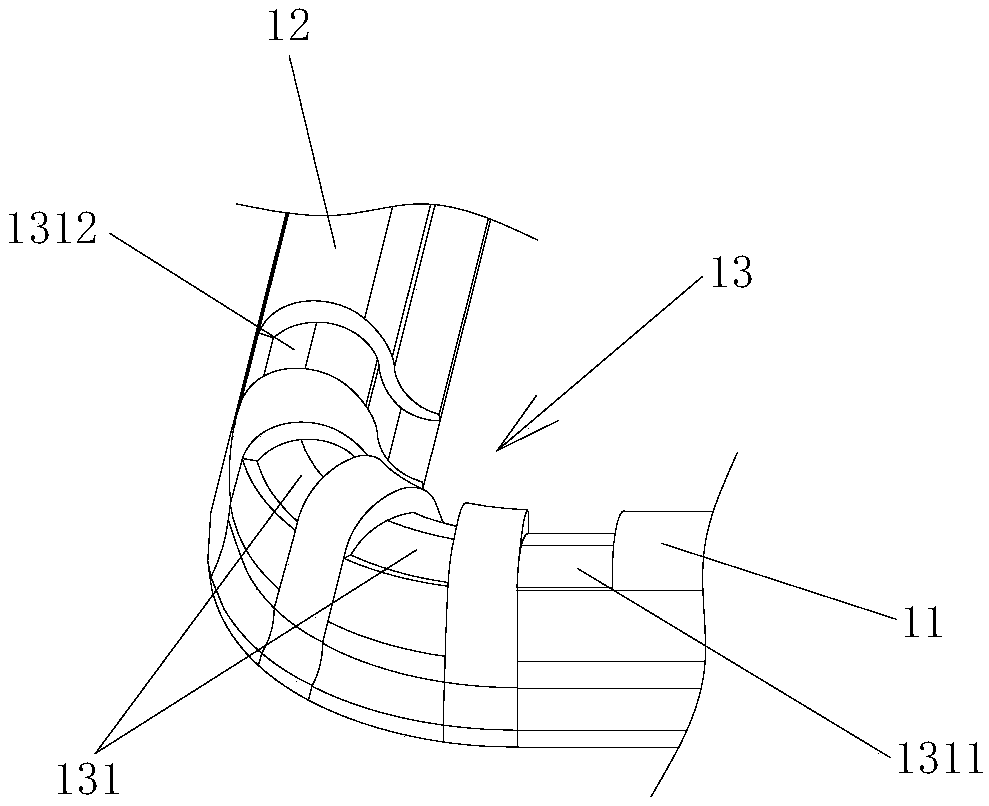

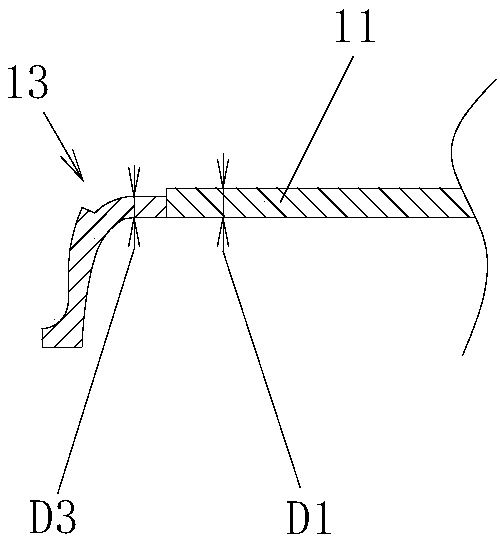

Silica gel diaphragm and loudspeaker

ActiveCN107948894AReduce stressUniform stress distributionElectrical transducersLoudspeakersEngineeringSilica gel

The invention provides silica gel diaphragm and a loudspeaker. The silica gel diaphragm has a rectangular folding ring part and a middle adhering part connected with the inner periphery of the foldingring part. The folding ring part is composed of two first folding ring sides which are set oppositely and two second folding ring sides which are set oppositely. A folding ring corner is connected between the adjacent first folding ring side and second folding ring side. Each folding ring corner is equipped with at least one thickness adjustment section. First thickness difference exists among the thickness of the first folding ring sides, the thickness of the second folding ring sides and the thickness of the thickness adjustment sections. According to the silica gel diaphragm and the loudspeaker provided by the invention, the stress at four corners of the silica gel diaphragm is reduced by changing the thickness of the thickness adjustment sections of the folding ring corners of the silica gel diaphragm, so the resonant frequency is reduced and the roll vibration is suppressed.

Owner:SSI NEW MATERIAL (ZHENJIANG) CO LTD

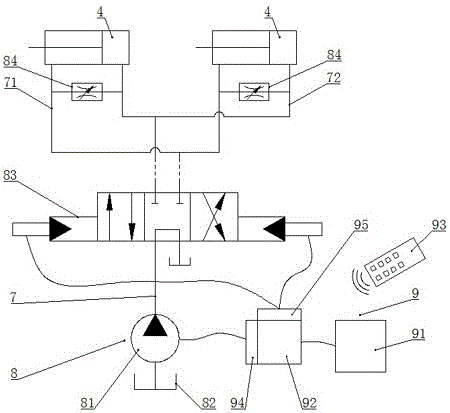

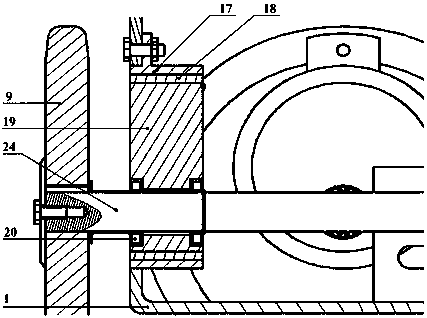

Cylindrical conveying box door opening and closing device

The invention discloses a cylindrical conveying box door opening and closing device. The problem that an existing box door opening and closing device is high in manufacturing cost, poor in action synchronism and not tight in closing of a box door. The cylindrical conveying box door opening and closing device comprises a cylindrical box body and two arc-shaped box doors, wherein connecting plates are respectively arranged at two ends of the box doors; and the box doors are respectively hinged to two ends of the box body coaxially via the connecting plates and articulated shafts. The cylindrical conveying box door opening and closing device is characterized in that two oil cylinders are vertically fixed on end surfaces of two ends of the box body respectively via fixing pieces, a push-and-pull arm is transversely arranged at an end of a piston rod of each oil cylinder, and two chutes are symmetrically formed in each push-and-pull arm; a hinge pin is correspondingly arranged on each connecting plate, and the hinge pins positioned at the same end of the box body are respectively matched with the insides of the chutes correspondingly; and the oil cylinders communicate with a hydraulic station via hydraulic tubes respectively, and the working state of the hydraulic station is controlled via a control device. The using frequency of the oil cylinders is low, and the manufacturing cost is low; the oil cylinders drive the box doors to open and close, the action synchronism is good, a driving force is sufficiently, and the box doors are closed tightly.

Owner:荣成中磊科技发展有限公司

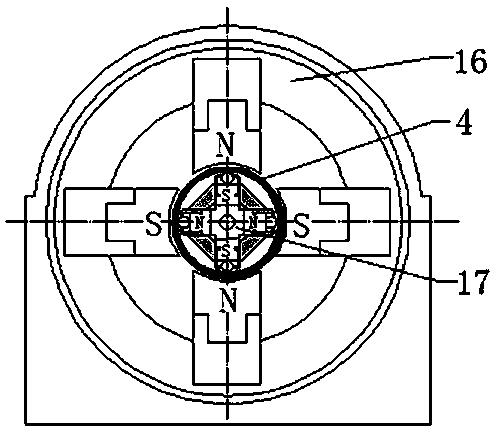

Combined push clamp duplex spring type magnetic latching relay

ActiveCN102709124AThere will be no side-to-side tiltGuaranteed positioningElectromagnetic relay detailsNon-polarised relaysSynchronismMagnet

The invention discloses a combined push clamp duplex spring type magnetic latching relay. The combined push clamp duplex spring type magnetic latching relay comprises a permanent magnet assembly, a coil assembly, a lead-out sheet group, a movable spring sheet group, an armature and a shell, wherein the permanent magnet assembly comprises two permanent magnets and a piece of yoke iron; the two permanent magnets are positioned on the upper part of the coil assembly and are opposite to each other; the piece of yoke iron is positioned outside the coil assembly; a yoke iron end extends out of the upper part of the coil assembly; the lead-out sheet group consists of an upper left lead-out sheet, an upper right lead-out sheet, a left lower lead-out sheet and a right lower lead-out sheet which are positioned at four corners of the permanent magnet assembly respectively; the upper left lead-out sheet is provided with two left static contacts; and the upper right lead-out sheet is provided with two right static contacts. The combined push clamp duplex spring type magnetic latching relay is novel and reasonable in structure, convenient to assemble and high in working reliability, the left and right movable spring sheets are high in action synchronism, and the movable and static contacts are stable in contact state or separation state.

Owner:SANYOU CORP LTD

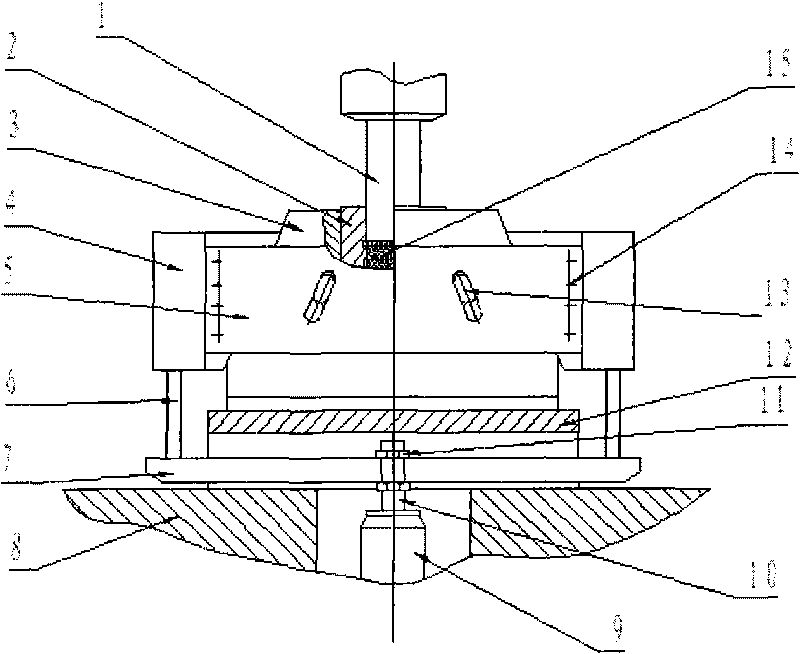

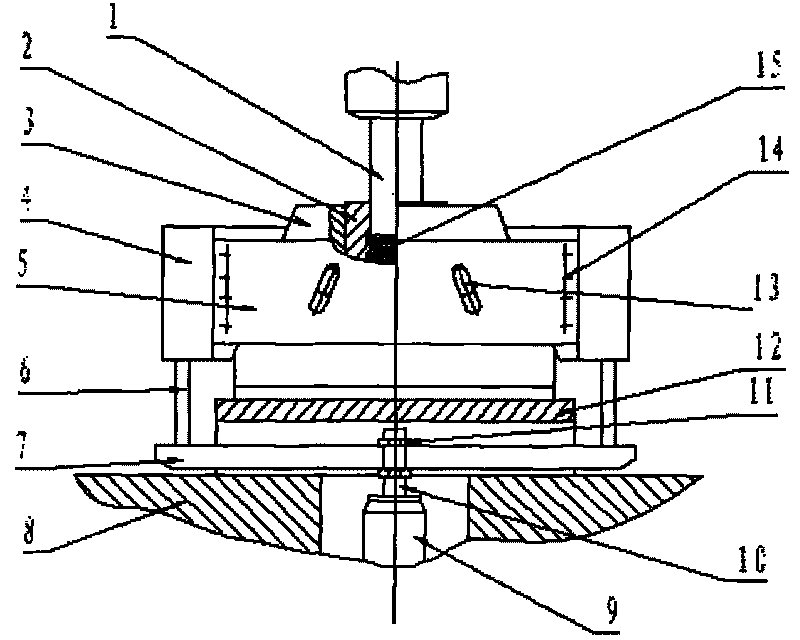

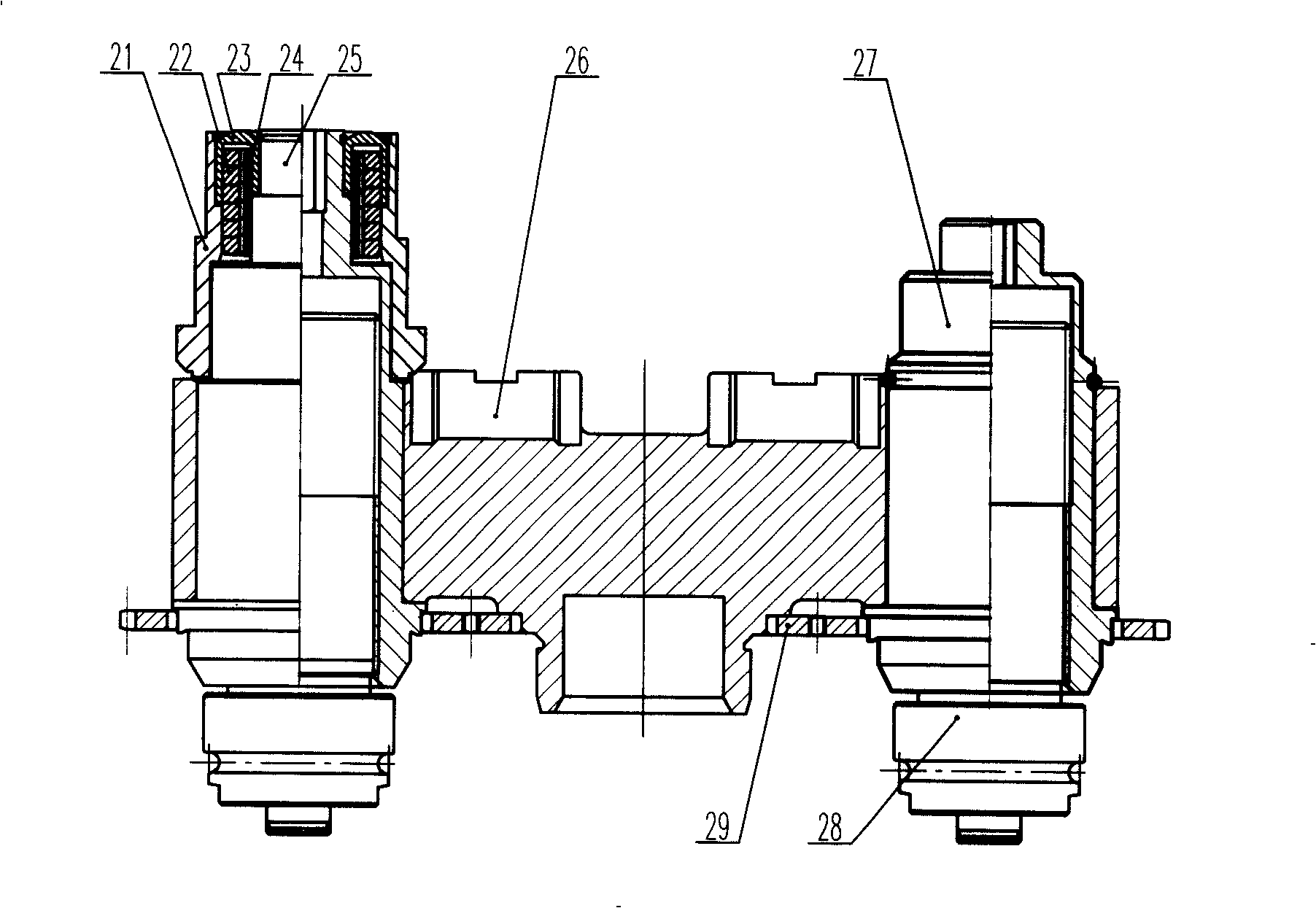

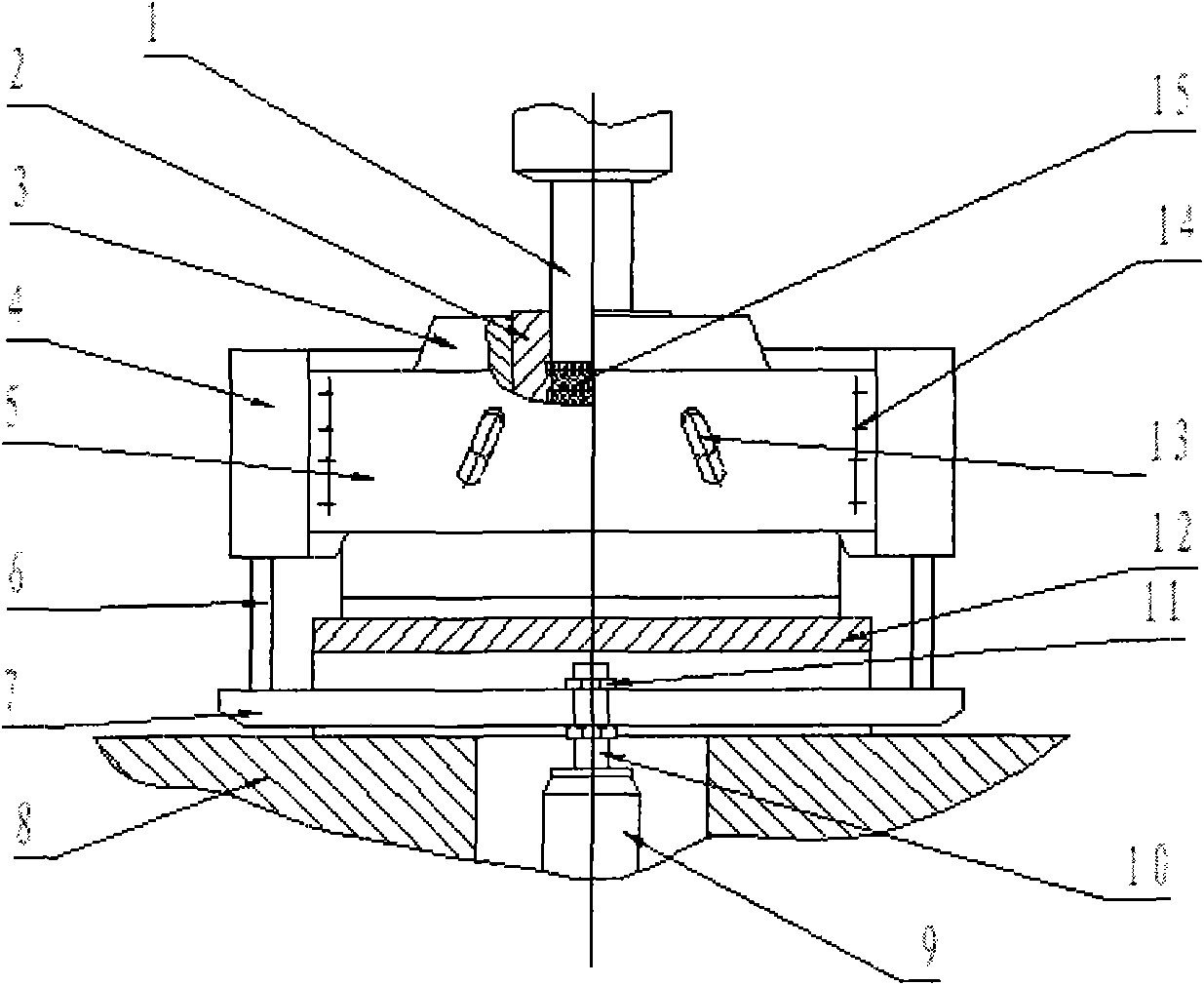

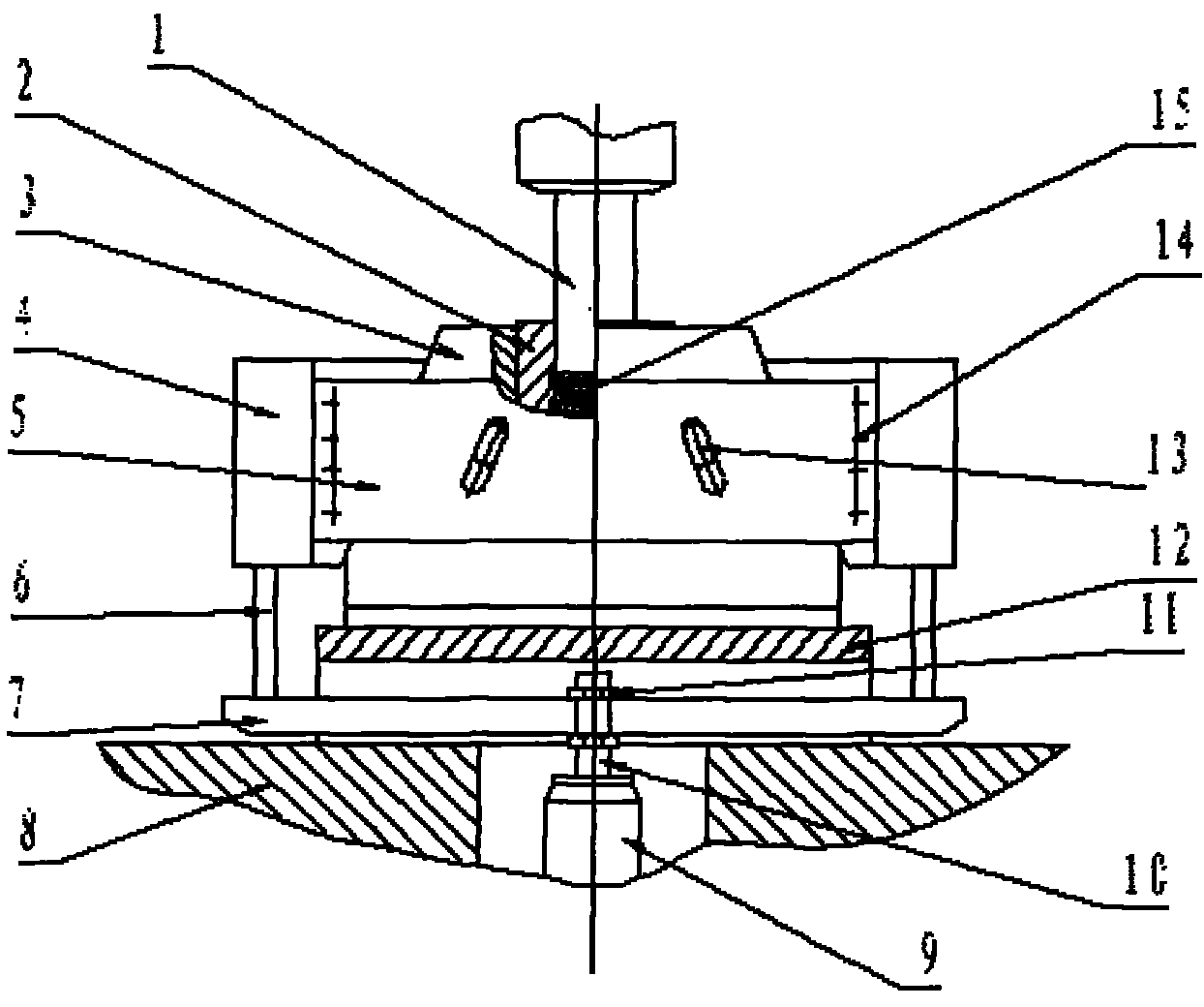

Liquid forging device of multisection mold surface for universal oil hydraulic press

The invention relates to a liquid forging device of a multisection mold surface for a universal oil hydraulic press, belonging to the technical field of metal processing and comprising movable modules, upper dies, a concave die insert, oblique wedges, a pull rod, side plates, sliding pins, a supporting block and a force transmission transverse beam, wherein the upper dies are positioned in cavities of the movable modules; the two movable modules are positioned on the supporting block of a workbench of the press and can move along a guiding groove on the supporting block left and right; the force transmission bevels of the left oblique wedge and the right oblique wedge respectively come into tight contact with bevels on the two movable modules; a plunger rod of an oil cylinder under the oil hydraulic press is fastened with the force transmission transverse beam in a hole of the supporting block and is respectively connected with the oblique wedges by the pull rod; the sliding pins on both sides of the movable modules are matched with holes of the sliding pins of the side plates; and the side plates are fastened on both sides of the oblique wedges and are connected with the oblique wedges into a whole. The liquid forging device can realize the liquid forging process of a horizontal mold surface forging and a vertical mold surface forging by the opening and the closing control dies of a lower topping cylinder of the universal oil hydraulic press.

Owner:JIANGSU UNIV

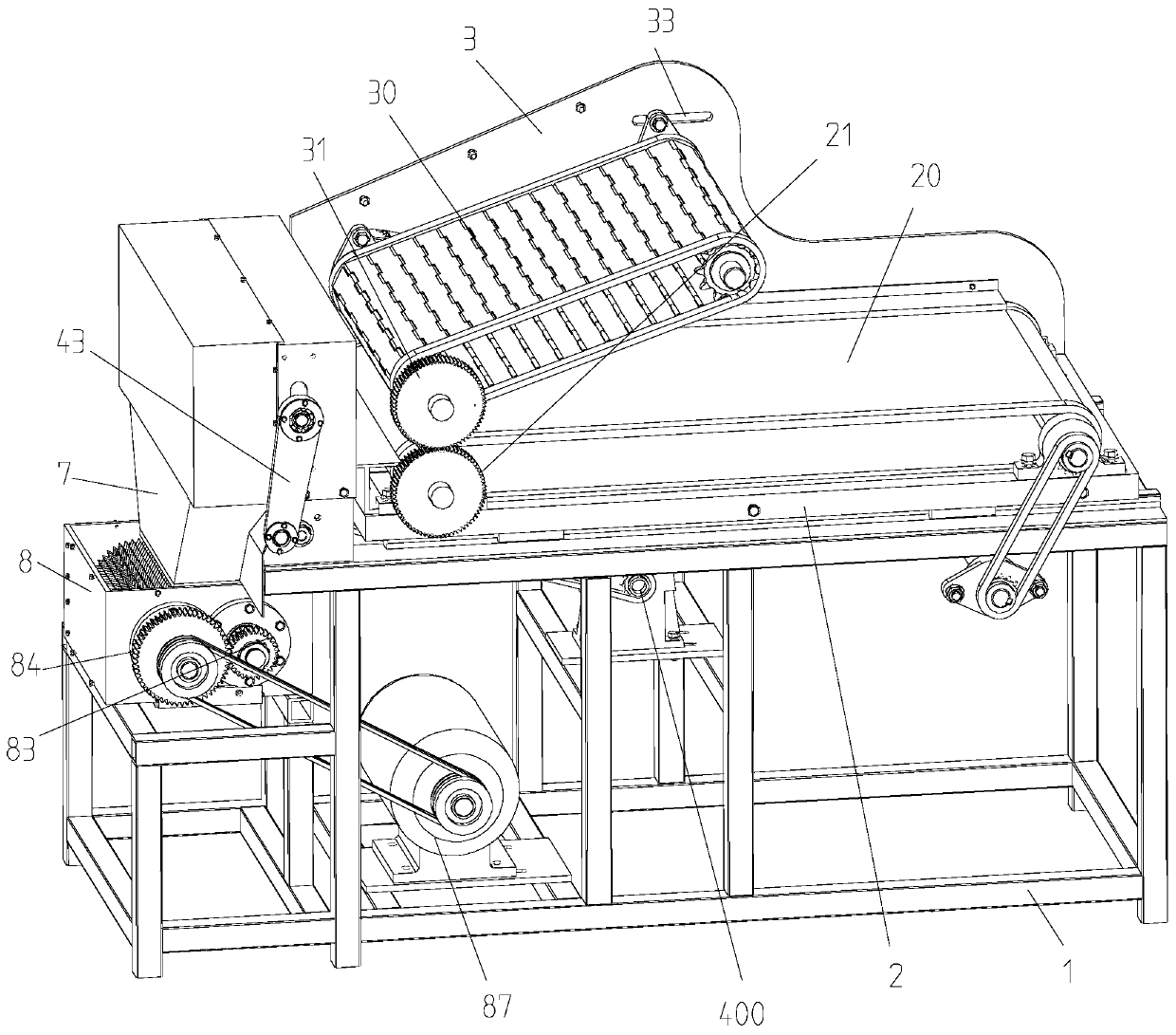

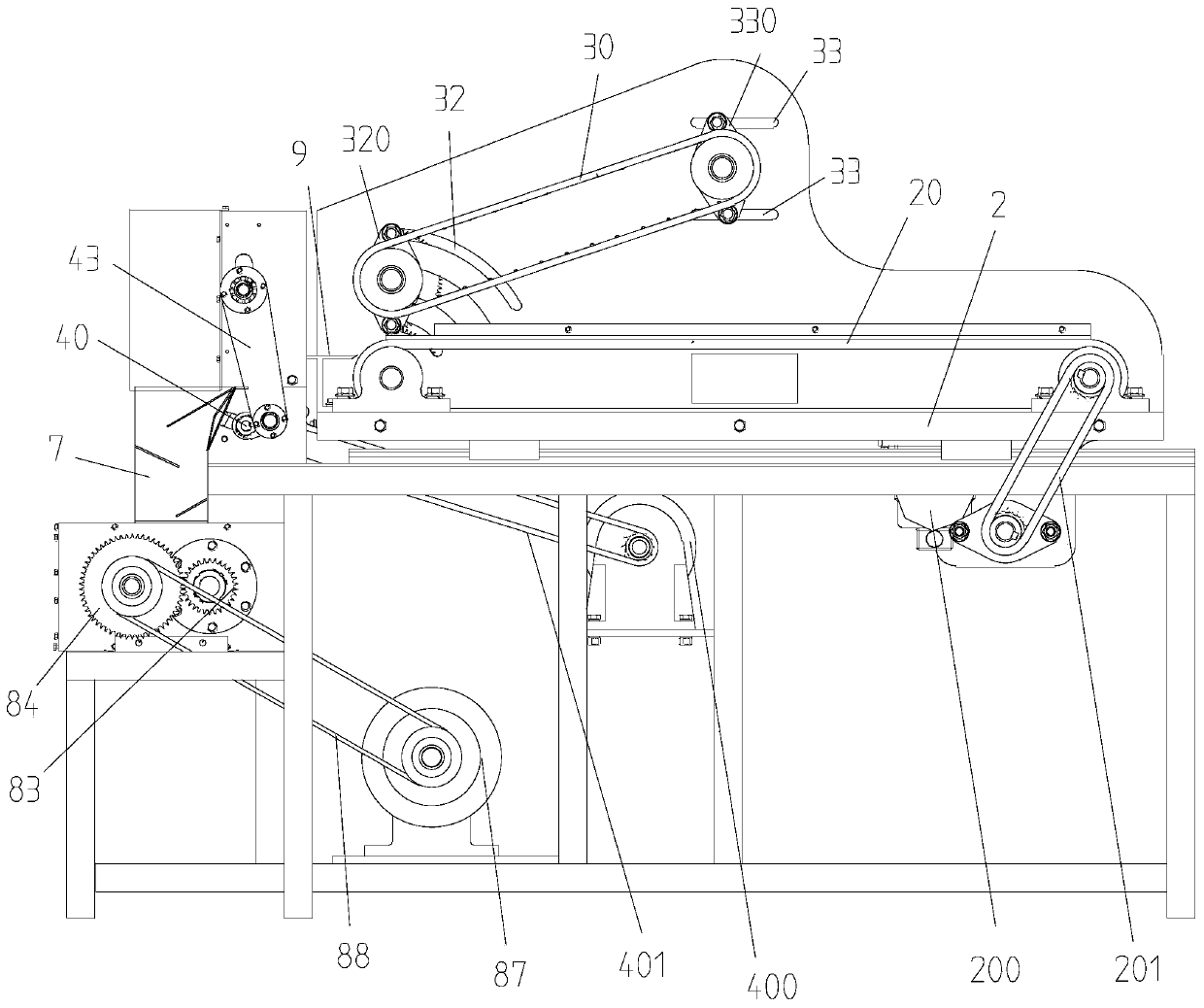

Novel chopping type straw super crusher

The invention discloses a novel chopping type straw super crusher, which comprises a frame, wherein the upper end of the frame is movably connected with a conveying base, two sides of the conveying base are respectively provided with side mounting plates, the upper end surface of the conveying base is provided with a lower conveyor belt, an upper conveyor belt is arranged between the two side mounting plates at a position right above the lower conveyor belt, the upper conveyor belt and the lower conveyor belt are arranged at an acute angle, lower gears are arranged at two ends of a front rotating shaft of the lower conveyor belt, upper gears are arranged at two ends of the front rotating shaft of the upper conveyor belt, and are meshed with the lower gears. A fixed chopping table is arranged at one end of the frame close to the lower gear, a lower chopping knife is arranged at the upper end of the fixed chopping table, a crankshaft penetrates through the fixed chopping table, the two ends of the crankshaft are respectively connected with the two ends of the chopping knife through a chopping connecting rod, and a conveying base is connected with the crankshaft through a base connecting rod. A funnel is arranged at the oblique lower position of the fixed chopping table, and a crushing device is arranged below the funnel.

Owner:NANCHANG INST OF TECH

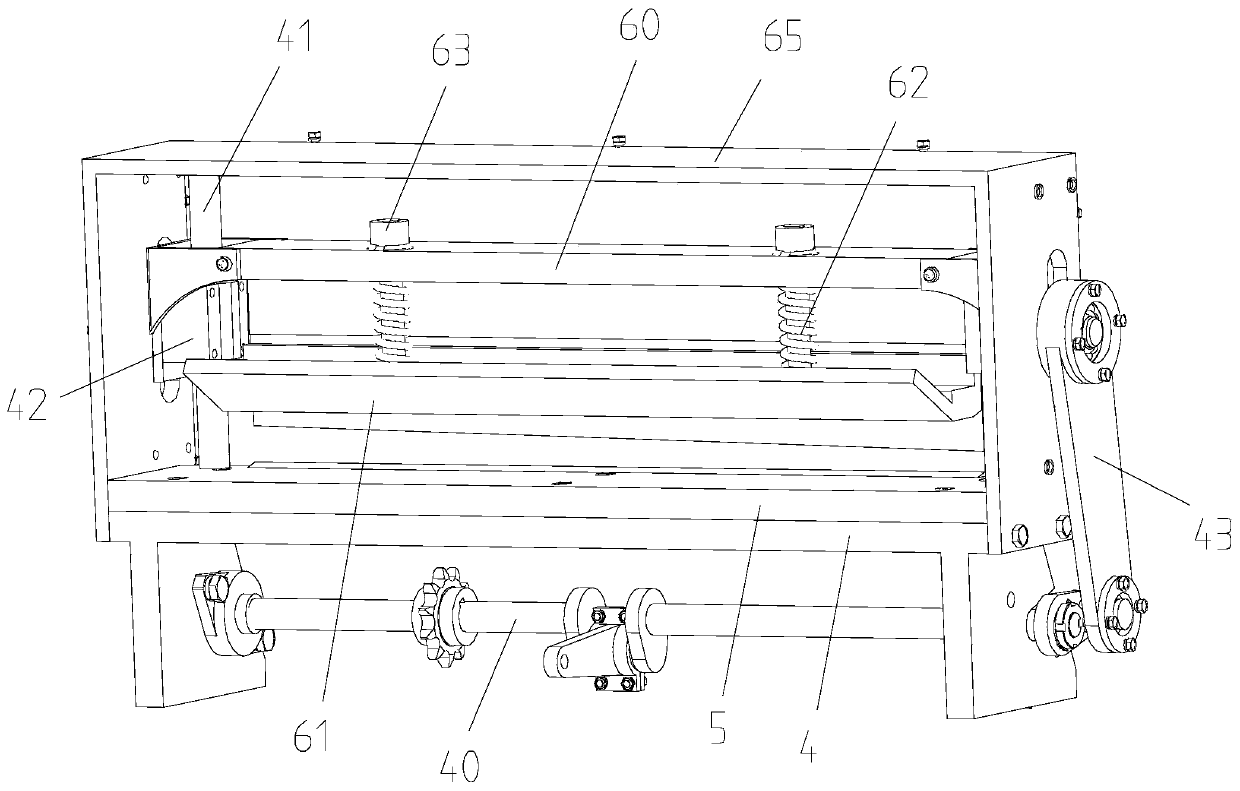

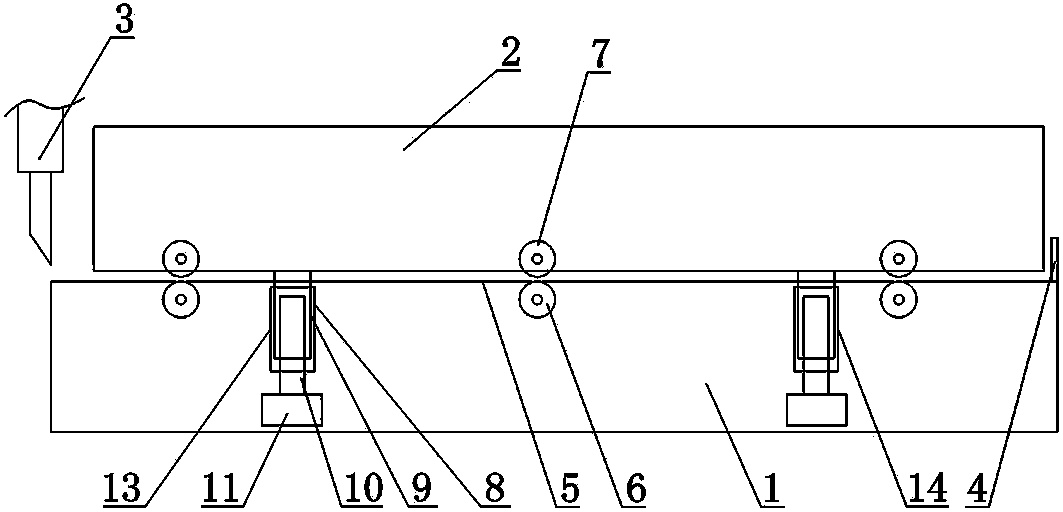

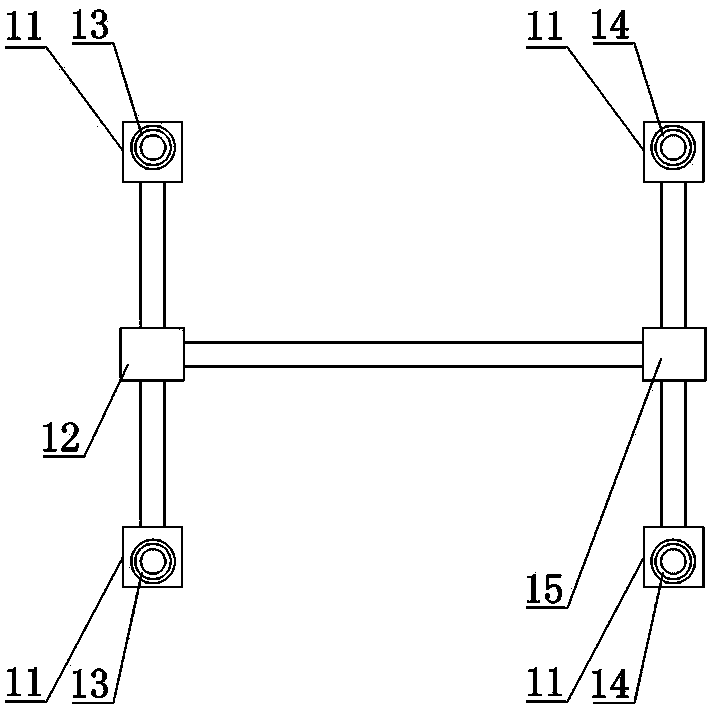

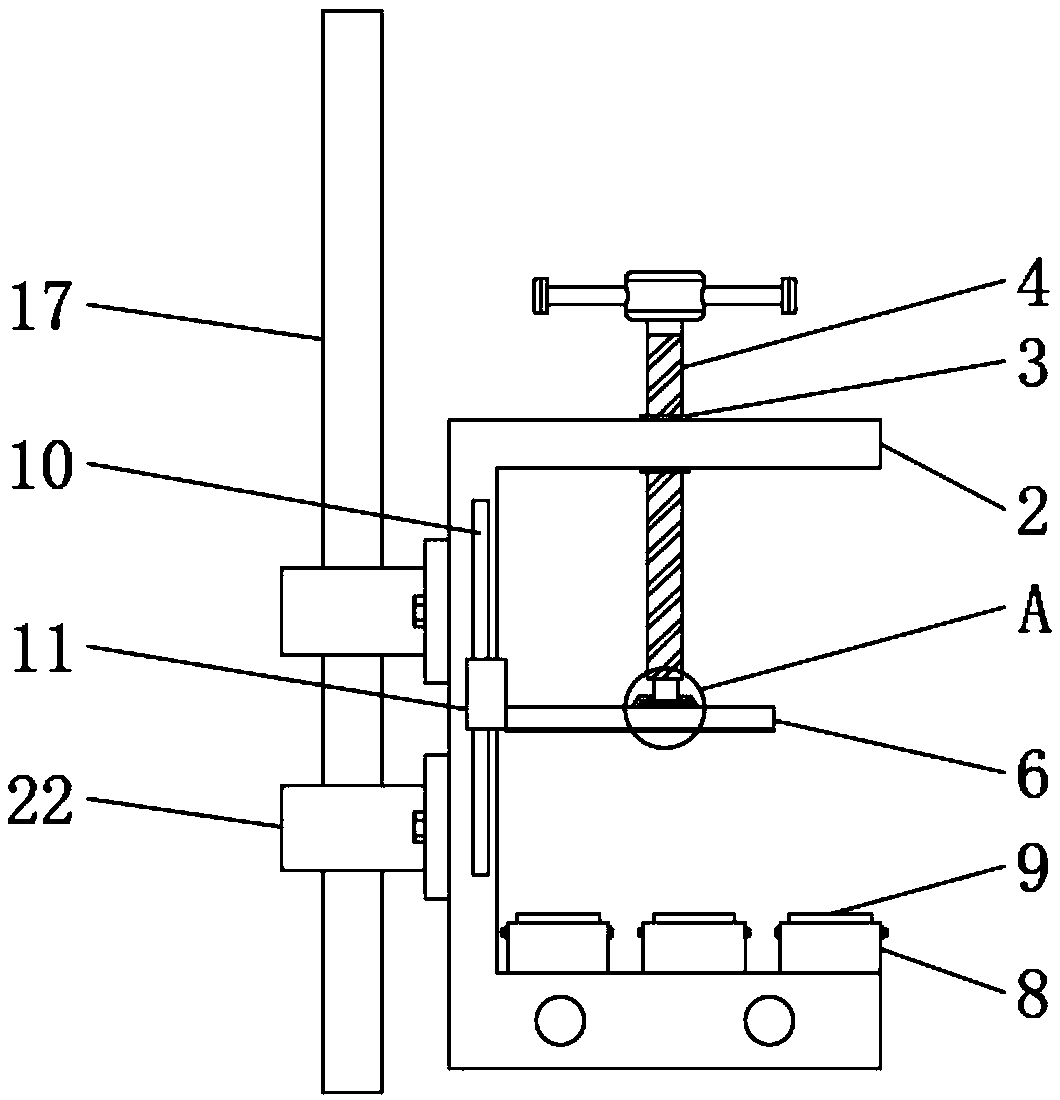

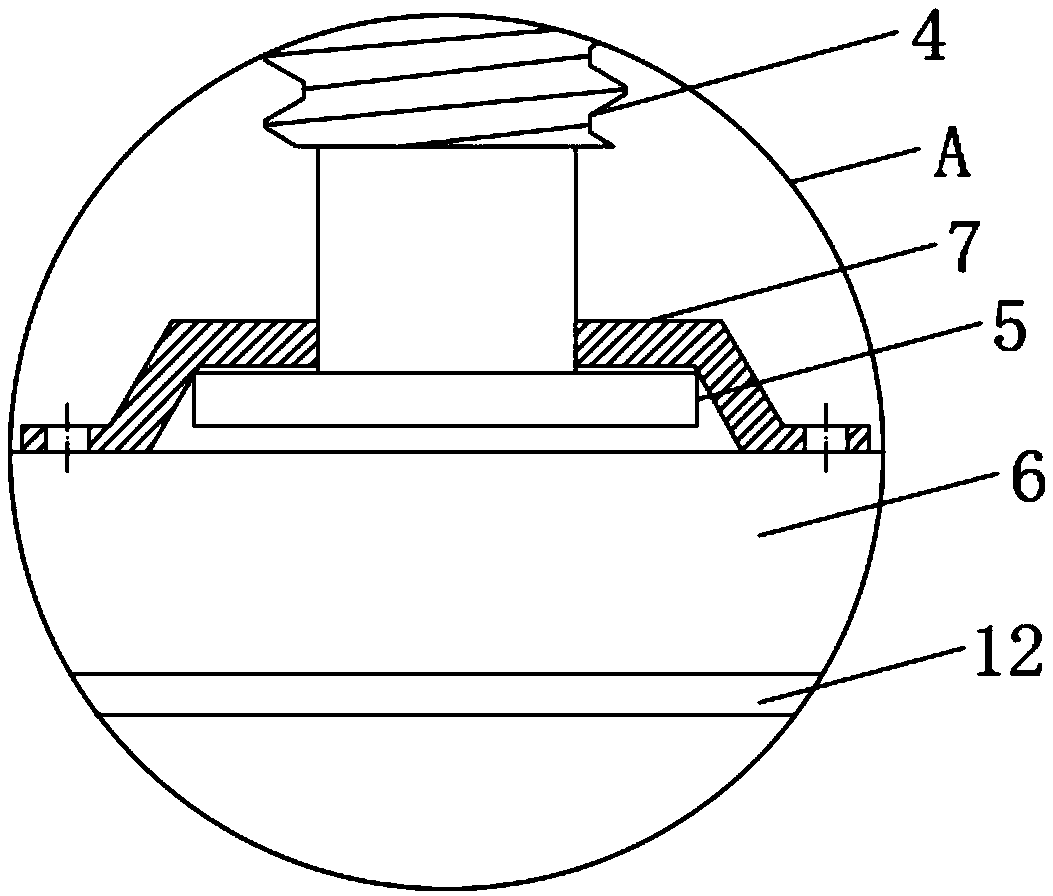

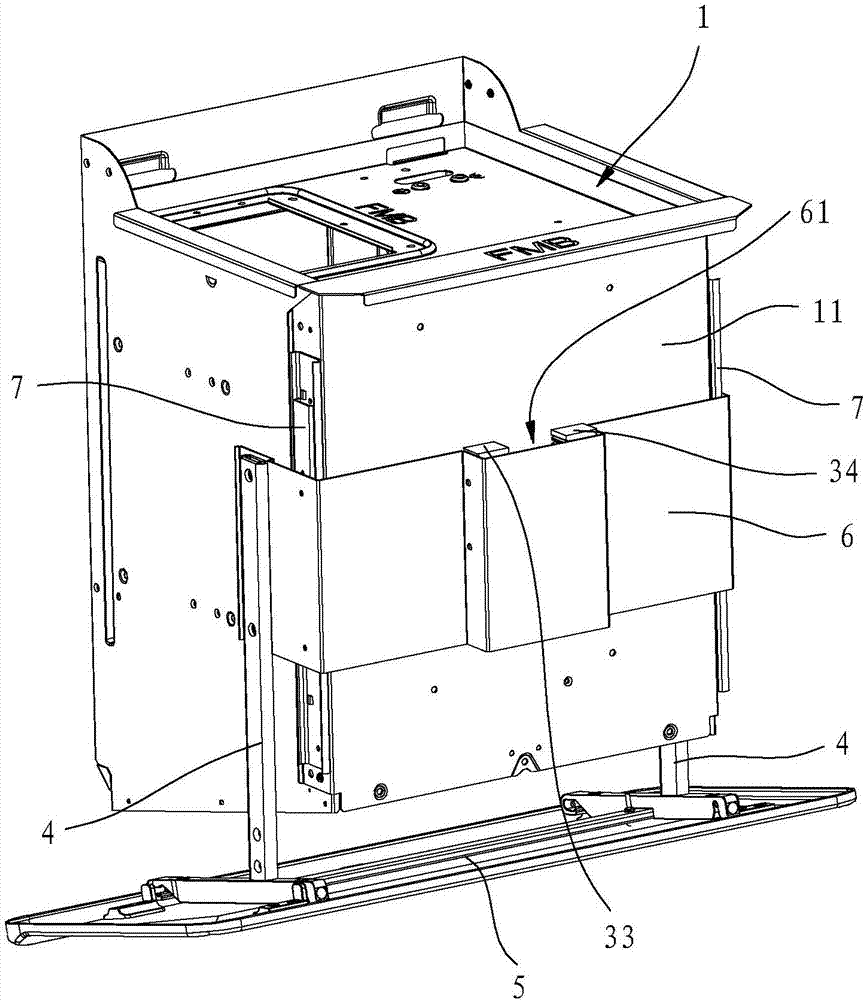

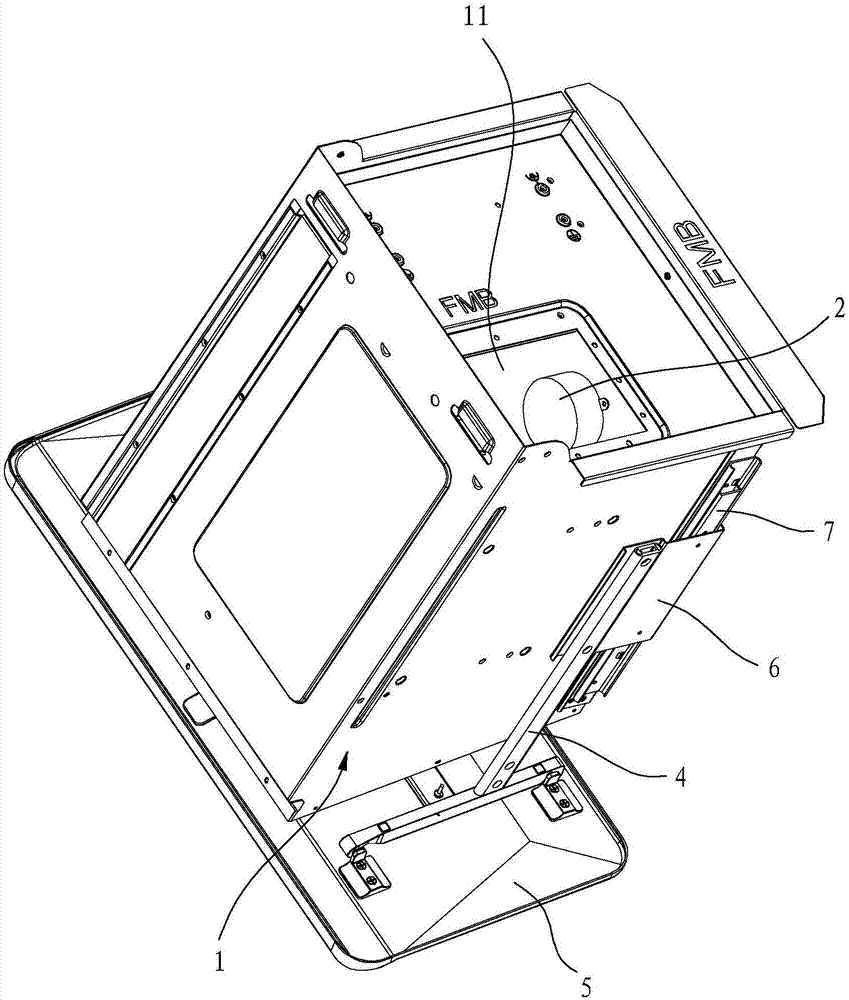

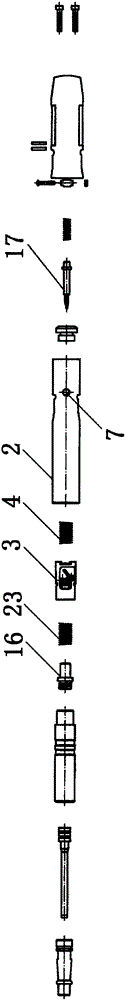

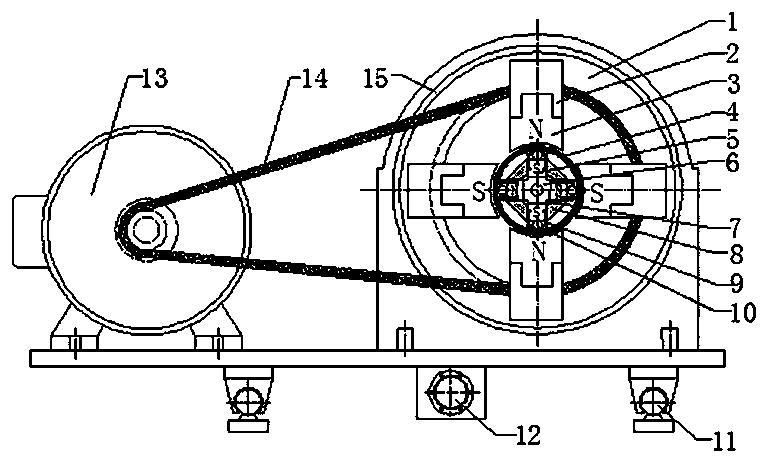

Plate shearing machine driven to rise and fall through single motor

InactiveCN103639520AGood movement synchronizationAchieve cutNibbling shearing machinesShearing machine accessoriesEngineeringMotor shaft

The invention discloses a plate shearing machine driven to rise and fall through a single motor. The plate shearing machine comprises a machine base (1) and a machine cover (2), lifting devices are arranged between the machine cover (2) and the machine base, the three-shaft motor (12) is arranged between the two symmetrically-arranged lifting devices A (13) located on the front portion, a double-output driver (15) is arranged between the two symmetrically-arranged lifting devices B (14) located on the rear portion, two motor shafts of the three-shaft motor (12) are connected with drivers (11) of the two lifting devices A (13) respectively, a third shaft of the three-shaft motor (12) is connected with the double-output driver (15), and two output shafts of an upper output driver (11) are connected with drivers (11) of the two lifting devices B (14) respectively. The plate shearing machine has the advantages that the application range of the device is broadened; the four lifting devices can be driven to rise and fall through one three-shaft motor, and the machine cover runs stably and reliably.

Owner:SICHUAN GALAXY STEEL STRUCTURE ENG

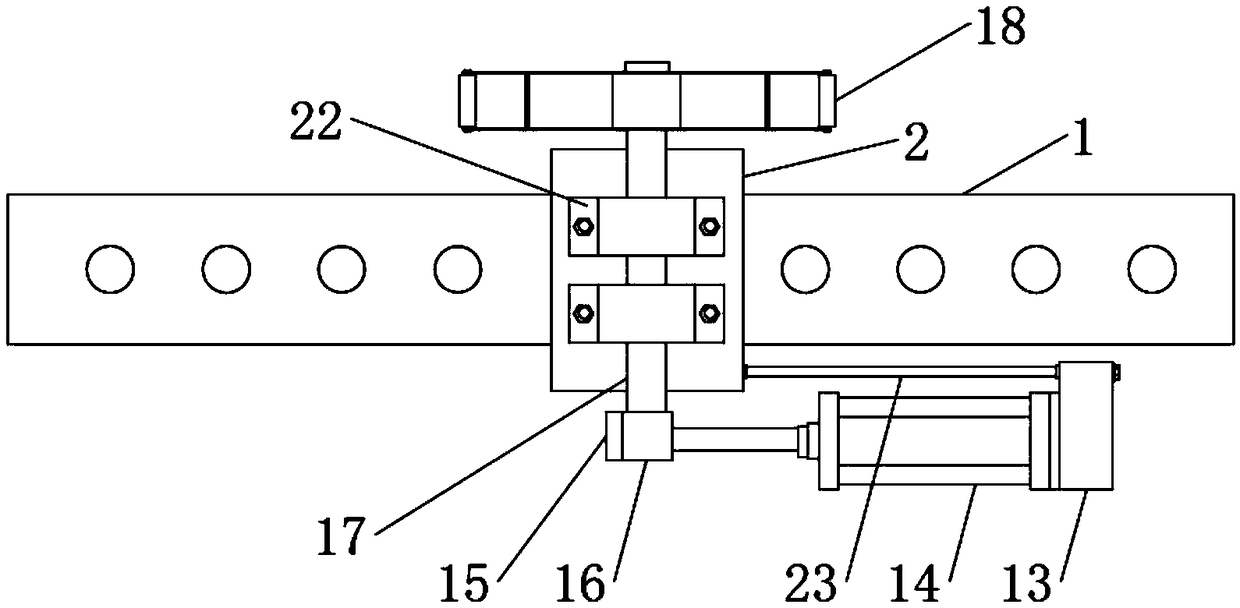

Movable motor vehicle tire alignment placement mechanism

InactiveCN109264349AGood movement synchronizationSimple structureConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a movable motor vehicle tire alignment placement mechanism. The mechanism comprises a conveying machine, a clamp mechanism and an alignment mechanism. The clamp mechanism comprises clamp bodies erected at the left and right sides of the conveying machine. Inner nut bushes are fixedly connected to the tops of the clamp bodies, the inner nut bushes are in threaded connectionwith rotating handle bolts, clamping bodies are arranged at the bottom ends of the rotating handle bolts, the clamping bodies and the clamp bodies clamp a rack of the conveying machine, the alignmentmechanism comprises a supporting plate, the supporting plate is fixedly connected with an end cover of a cylinder, an output rod of the cylinder is fixedly connected with a movable arm, the movable arm is hinged to one ends of two connecting rods separately, the other ends of the connecting rods are fixedly connected with a rotating shaft, the rotating shaft is fixedly connected with an alignmentplate, by adopting the cylinder, thrust is transmitted to the movable arm in a mechanical mode, the connecting rods hinged to the movable arm can drive the rotating shaft to rotate, the action synchronization of the two alignment plates is good, the alignment plates can push tires to the center line, and the mechanism is simple in structure and convenient to operate.

Owner:王少明

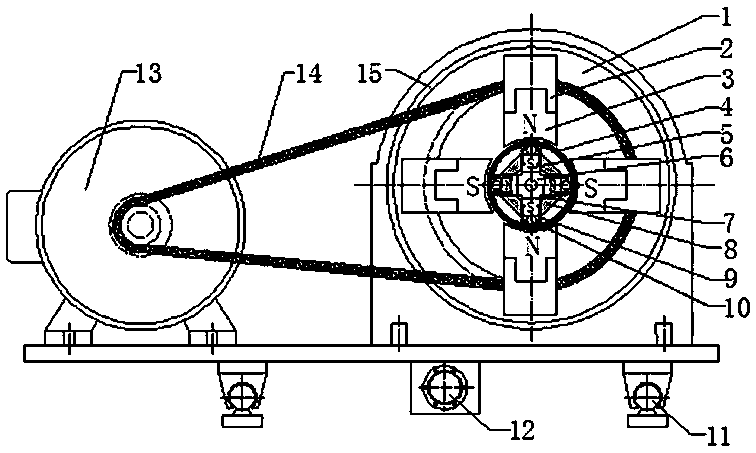

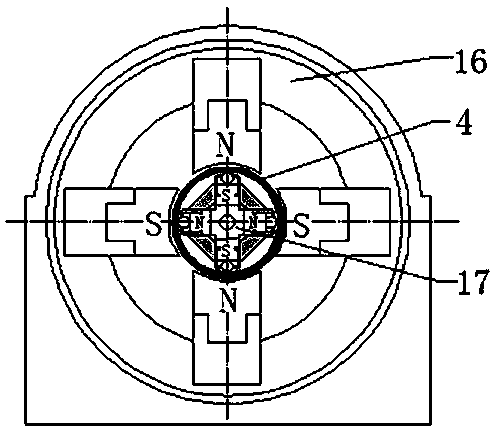

Magnetic rolling processing device for inner surface of long and circular tube

The invention combines a magnetic field control technology and a rolling technology, is applied to rolling processing of the inner surface of a long and circular tube, and belongs to the field of special processing. A magnetic rolling processing device for the inner surface of the long and circular tube comprises an external magnetic field generator located outside the long and circular tube and amagnetic rolling tool located inside the long and circular tube; the external magnetic field comprises external magnetic circuit magnetic poles; and the external magnetic circuit magnetic poles forma rotating magnetic field through circumferential rotation and perform axial feeding along the central axis of the long and circular tube to drive the rotating magnetic field to perform axial feeding.By the aid of the device, the problem that rolling processing of the inner surface of the long and circular tube cannot be completed through traditional rolling processing is solved.

Owner:WUXI WEIHAIDA MACHINERY MFG

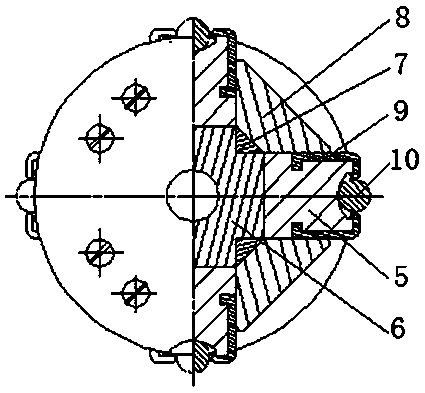

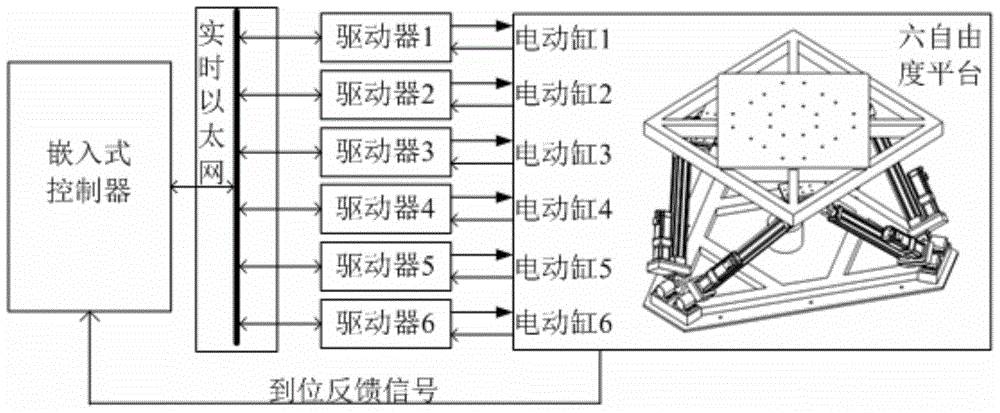

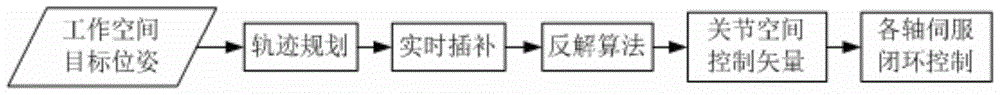

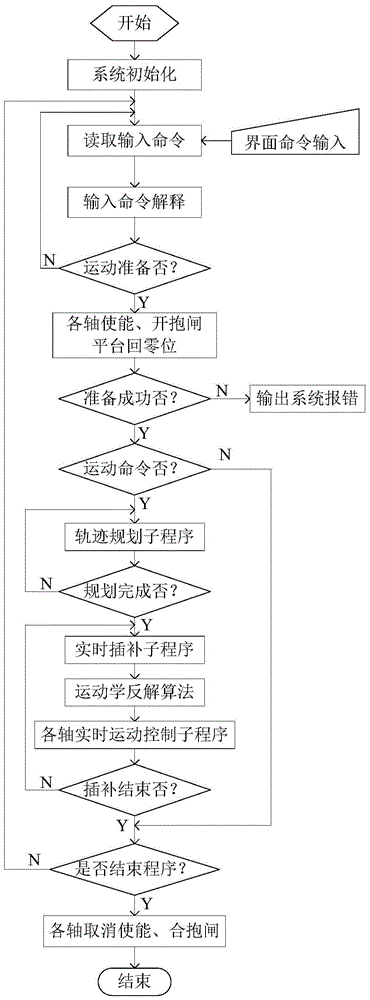

A high-precision control system and control method for an electric six-degree-of-freedom motion platform

ActiveCN104731107BSmooth and stable running trackGood movement synchronizationPosition/course control in three dimensionsSoftware designMotion simulation

Owner:BEIJING INST OF SPECIALIZED MACHINERY

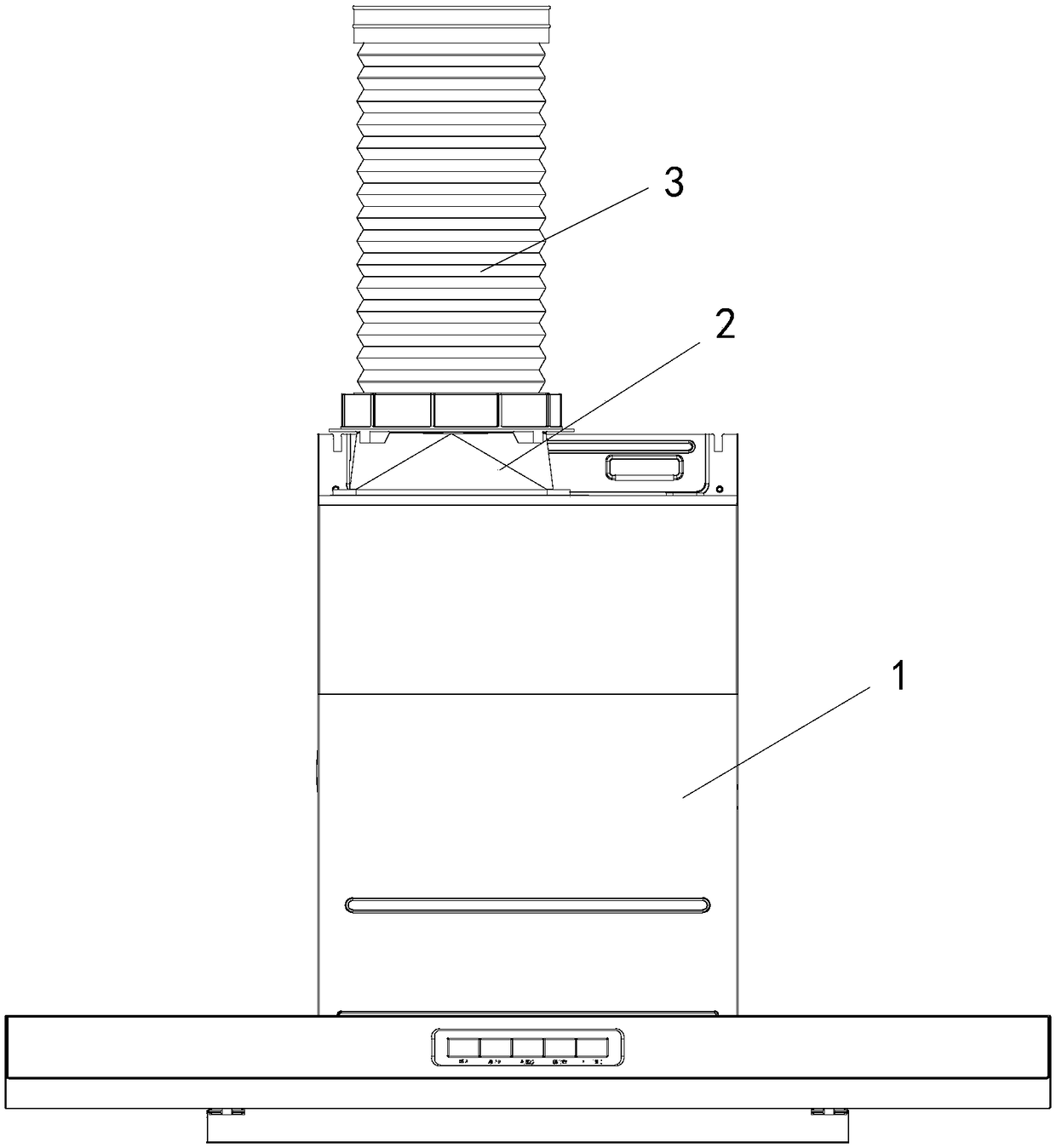

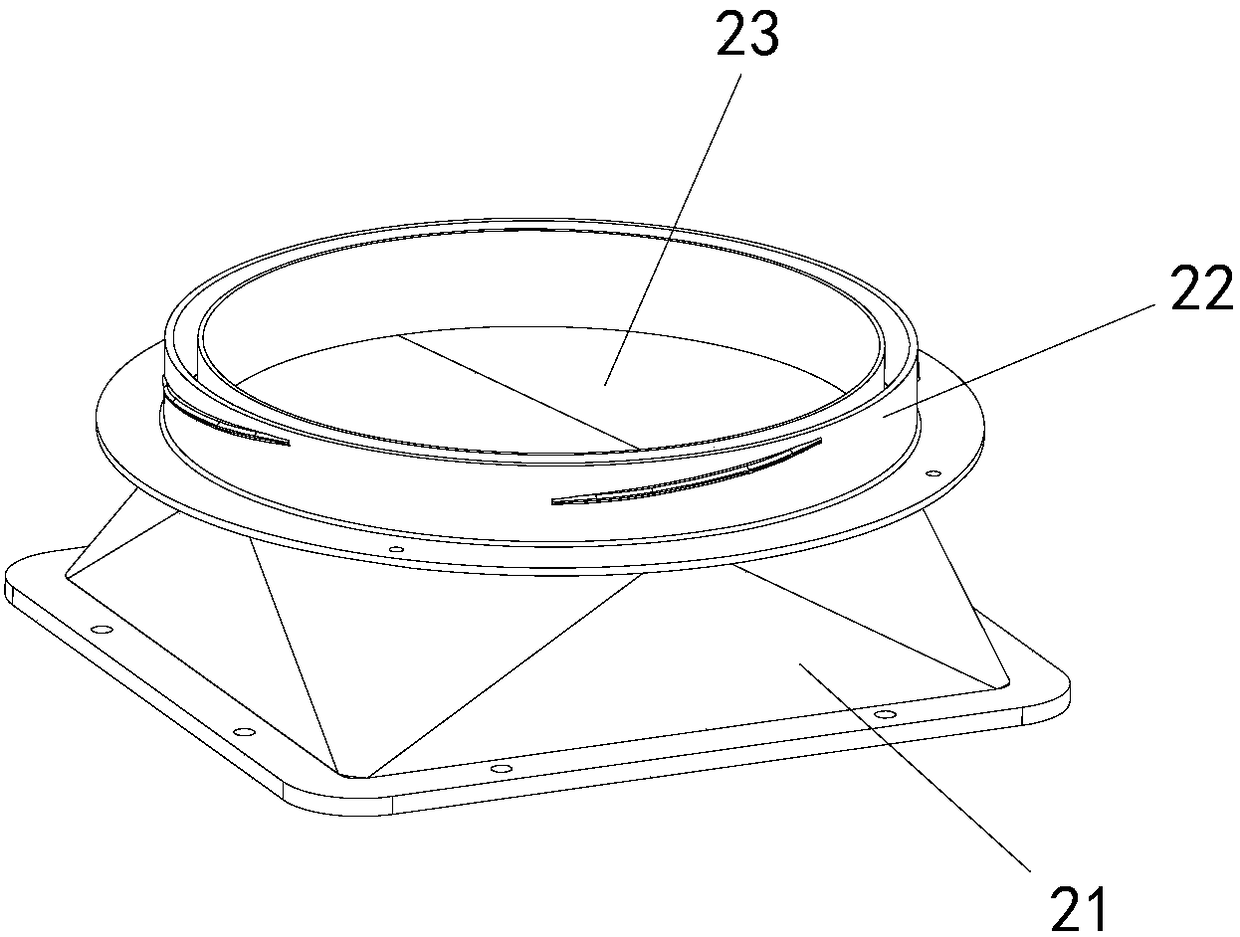

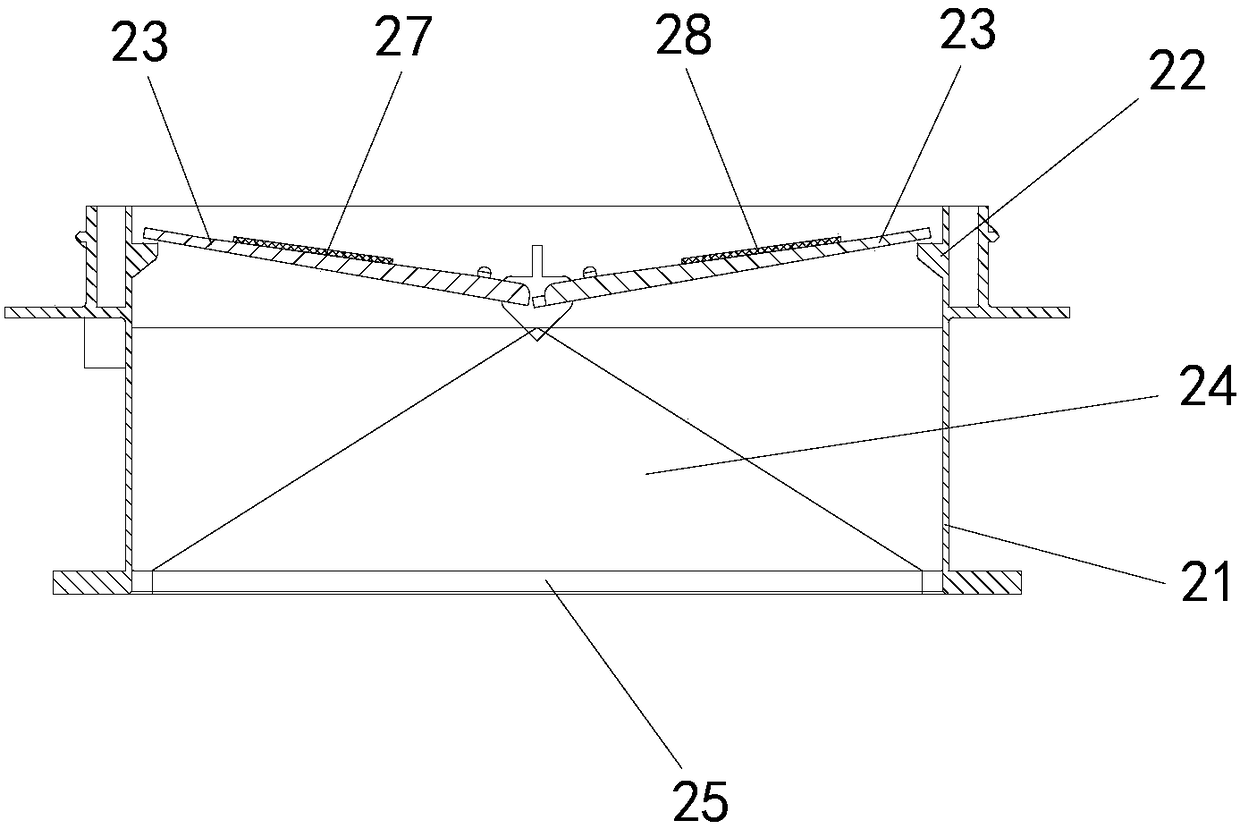

Outlet housing for range hood

ActiveCN108180518AEasy to operate on and offIn various waysDomestic stoves or rangesLighting and heating apparatusCapacitanceEngineering

The invention provides an outlet housing for a range hood. The outlet housing comprises a lower housing connected with the range hood, an installation ring connected with an air outlet pipe, and valveblades capable of being turned over to be opened. The lower housing and the installation ring form an air outlet cavity of the outlet housing; an air inlet opening of the outlet housing is formed inthe bottom part of the lower housing; an air outlet opening of the outlet housing is formed in the top part of the installation ring; the valve blades are two valve blades rotating oppositely; the twovalve blades are connected into the air outlet cavity through a rotary shaft, and can be turned over to be opened or closed so as to connect or disconnect the air inlet opening and the air outlet opening; the two valve blades can form an opposite valve blade included angle ranging from 0 degree to 180 degrees; and the outlet housing outputs a corresponding detection capacitance value according tothe valve blade included angle. The two valve blades with different polarities can form a variable capacitance device, the outlet housing outputs the corresponding detection capacitance value according to the valve blade included angle, and the range hood can judge an open-close state of the valve blades according to the capacitance value detected in real time.

Owner:JOYOUNG CO LTD

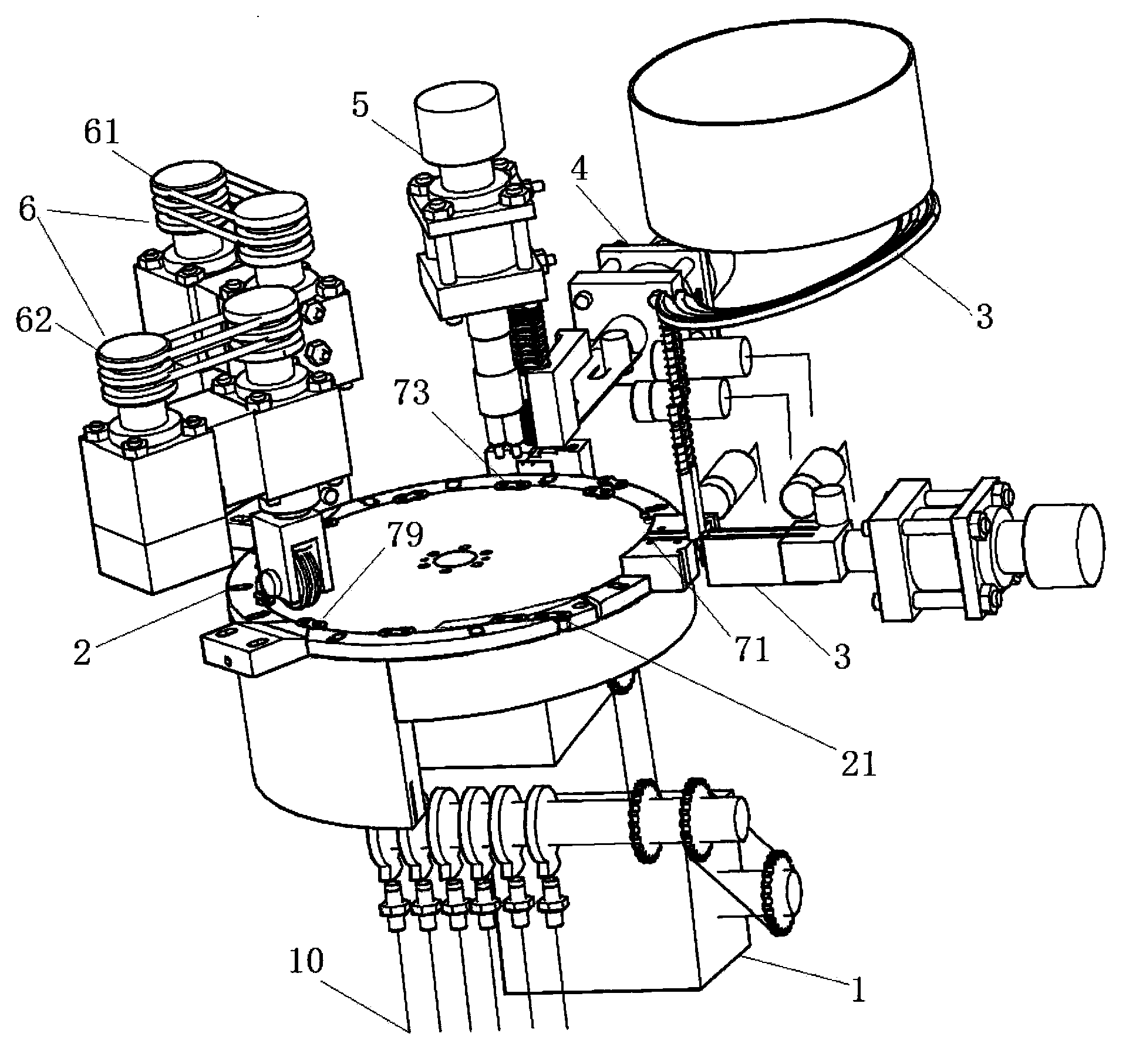

Chain connector assembly machine

ActiveCN102847867BAvoid subsequent lossesHigh operational reliabilityMetal chainsEngineeringAssembly machine

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

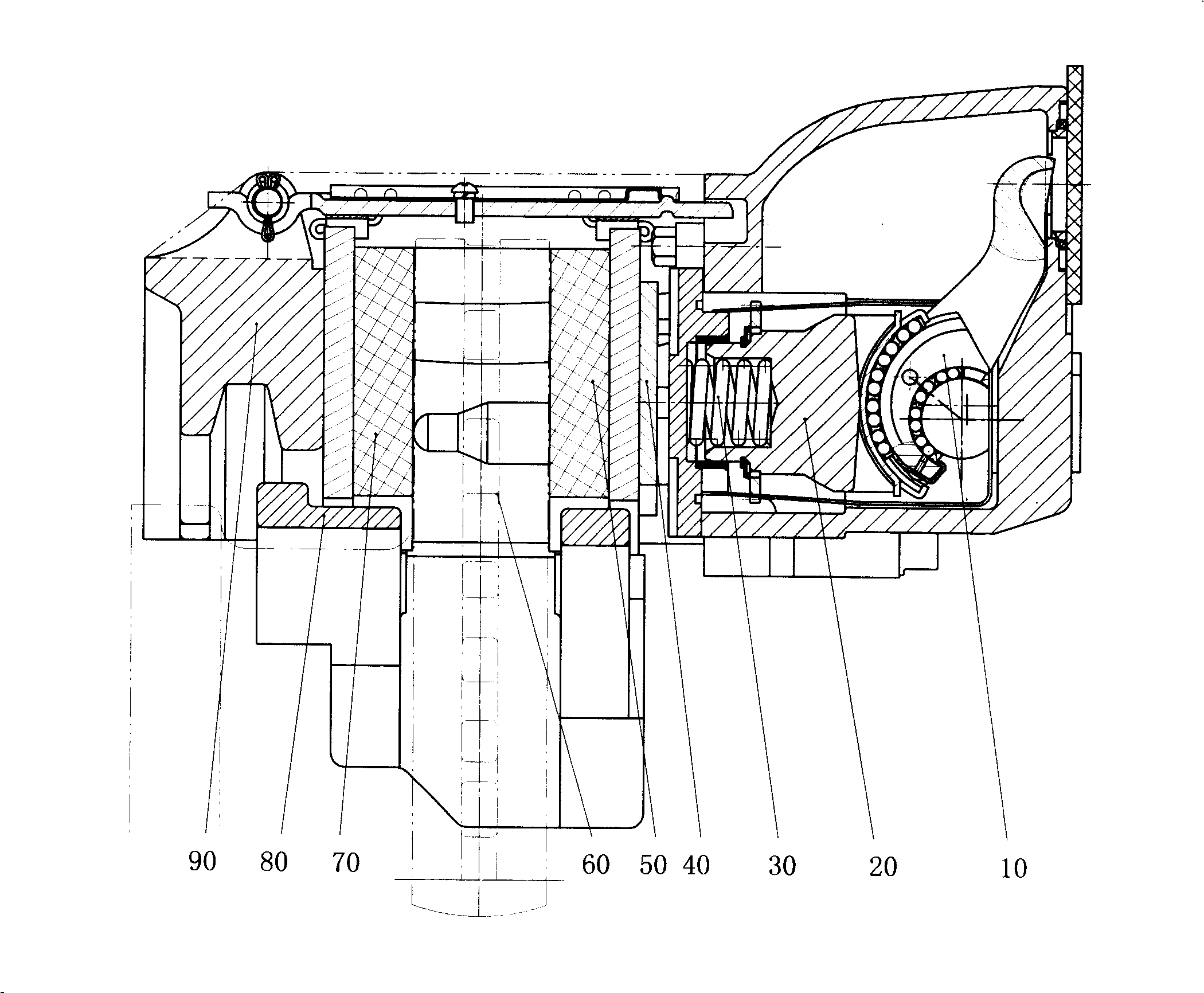

Smoke guide plate lifting mechanism of range hood

InactiveCN107289479ASmooth motionEven by forceDomestic stoves or rangesLighting and heating apparatusGear wheelDrive motor

The invention discloses a smoke guide plate lifting mechanism of a range hood. The mechanism comprises a mounting frame, a driving motor, a transmission mechanism, lifting rods and a smoke guide plate; the driving motor drives the lifting rods and the smoke guide plate to perform a lifting motion through the transmission mechanism; a driving gear and a driven gear of the transmission mechanism are horizontally arranged side by side and engaged with each other; a first rack is vertically arranged on the outer side of the driving gear and engaged with the driving gear; a second rack is vertically arranged on the outer side of the driven gear and engaged with the driven gear; the first rack and the second rack are connected with connecting plates; at least two lifting rods are provided and arranged on the left and right sides of the mounting frame; and the upper ends of the lifting rods are connected to the connecting plates. According to the smoke guide plate lifting mechanism, the transmission mechanism is designed as a double-gear structure; under driving by the driving motor, the first rack and the second rack can move up and down at the same time; the transmission mechanism cannot generate the tooth jump phenomenon and abnormal noise; uniform stress of the lifting rods on two sides is guaranteed; the motion synchronism is excellent; and the smoke guide plate can be kept in stable movement.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Floating tong type bipushing rod pneumatic disk brake based on rectangular torsional spring single dicrection clutch

ActiveCN100416128CRealize overload protectionReasonable designAxially engaging brakesBrake actuating mechanismsCalipersDisc brake

The invention comprises a pressure arm unit, a rotation shaft unit, a return spring, a push pedal, an internal friction plate, a brake, an external friction plate, a support and a caliper body arranged in order from right to left. Because of using the rectangular section torsional spring function, in a specific environment the invention can realize a one-way transmission of the torque and also can realize an overload protection effectively. The reasonable design of the pressure arm unit can supply the stable brake moment.

Owner:WUHAN YOUFIN AUTOPARTS

Large hydraulic turbines stationary guide blade synchronous regulation and control method

ActiveCN101260858BHigh control precisionGood movement synchronizationMachines/enginesSafety/regulatory devicesStart timeFull scale

The invention discloses an adjustment and control method for the synchronism of guide vanes of a large-scale water turbine, comprising the following steps: the resistance value of a drive coil of a servomotor is measured and then accurately defined in a single guide vane controller; the zero position and the full scale of a single guide vane instruction of the single guide vane controller are adjusted; a guide vane in the single guide vane controller synchronously controls adjustment of the zero position and the full scale of the instruction; the zero position and the full scale of a guide vane opening displacement sensor are adjusted; the vane mechanical bias voltage is measured and adjusted; the control parameter of the single guide vane is set; the synchronous control parameter of the guide vane is set; the starting time and the closing time of the guide vane are measured and adjusted; a single guide vane displacement transmitter gives a failure alarm; a single guide vane control loop gives an alarm; and an overall guide vane control loop gives an alarm. The adjustment and control method improves the control precision of guide vanes of a hydropower generating unit; the deviationof the opening instruction and the feedback is small; the action synchronism of the guide vane is good; both the starting time and the closing time of the guide vane meet the design requirements; themaximum deviation of the switching time is better than that of the standard requirement.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Mold locking device for plastic terminal bushing

The invention provides a mold locking device for a plastic terminal bushing. A mold mounting base is provided with a mounting base clamping table. A movable mold is mounted on the mounting base clamping table through a mounting hole. The mold locking device comprises the movable mold arranged in the mounting base, an ejector rod arranged in compression springs and an ejector pin mounted in the ejector rod and used for ejecting out a formed part, wherein the ejector rod and the ejector pin penetrate through the compression springs and the mold mounting base; a discharging hole formed in the center of a base is also provided. A plurality of sliding rails are arranged on the upper surface of the base, and sliding grooves matched with the sliding rails are formed in the fixed surface on the lower portion of the mold mounting base. According to the mold locking device, two-directional mold closing is adopted, action synchronism is good, operation is stable, the design is simple and reasonable, dismounting and operation are convenient, and repair cost is reduced.

Owner:TIANJIN DEHOU ELECTRONICS

Chain joint assembling method

ActiveCN102873257BAvoid subsequent lossesHigh operational reliabilityMetal chainsEngineeringMechanical engineering

A chain joint assembling method includes step 1, providing a working rotary table; step 2, conveying pins; step 3, feeding outer links and assembling the same; step 4, primary round riveting; step 5, secondary round riveting. In the step 1, the working rotary table is connected with a driving device, 12 pairs of grooves are arranged on the outer side of the working rotary table uniformly, the driving device drives the working rotary table to rotate intermittently, and the rotation angle each time is 30 degrees. In the step 2, two pins are pushed into a first pair of grooves; In the step 3, the working rotary table rotates twice to push the links to the pins, the links are then assembled, and parts of the pins are protruded from the links. In the step 4, the working rotary table rotates three times continuously so that one of the pins with the links in the previous steps is subjected to round riveting. In the step 5, the working rotary table continues to rotate three times so that the other pin is subjected to round riveting. By the chain joint assembling method, reliability and action synchronism during production can be improved, loss in production is avoided, and production efficiency is improved.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

Orthogonal two-way movement variable structure mobile robot and its control method

ActiveCN106003039BIncrease flexibilityImprove transmission efficiencyProgramme-controlled manipulatorDrive wheelEngineering

The invention discloses a variable-structure mobile robot capable of making orthogonal bidirectional movement and a control method of the variable-structure mobile robot. The variable-structure mobile robot capable of making orthogonal bidirectional movement comprises a chassis, a separation type variable-position driving mechanism, a variable-position motor, an integral variable-position driving mechanism, a variable-position electric push rod, a driving wheel motor A, a driving wheel motor B, a driving wheel A, a driving wheel B, a follower wheel A, a follower wheel B, a control device and a guiding sensor. The separation type variable-position driving mechanism is installed on the chassis, and the position, relative to the chassis, of the axis of the driving wheel A is changed while the position of the driving wheel motor A is kept unchanged. The integral variable-position driving mechanism is installed on a top cover, and the position, relative to the chassis, of the axis of the driving wheel B is changed by changing the height of the top cover. The axis of the driving wheel A is orthogonal with the driving wheel B, and the lowest position of the axis of the driving wheel A is the same as that of the driving wheel B. Orthogonal bidirectional movement of the mobile robot is achieved by changing the driving wheels making contact with the ground, the movement direction can be freely switched between orthogonal directions in the same plane, and the movement maneuverability and flexibility of the mobile robot are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

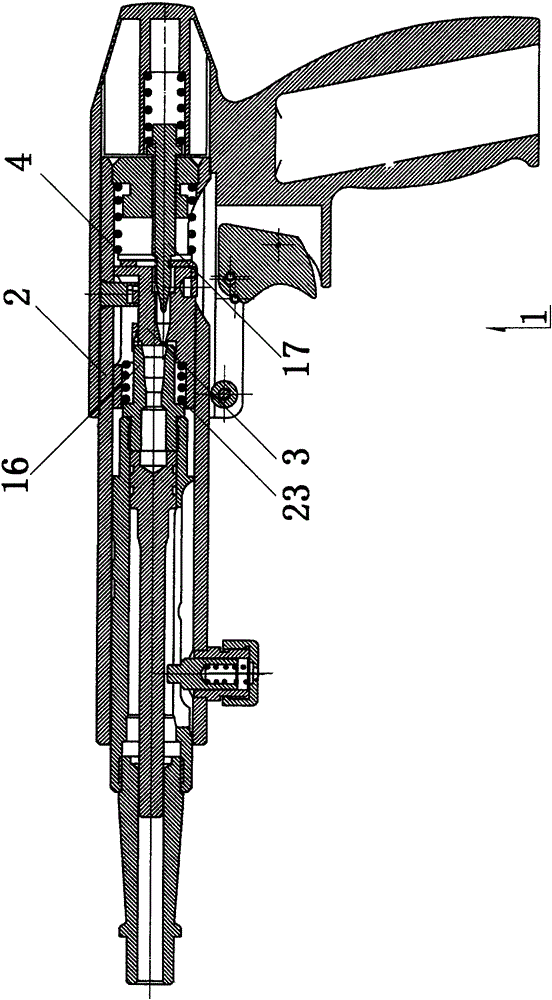

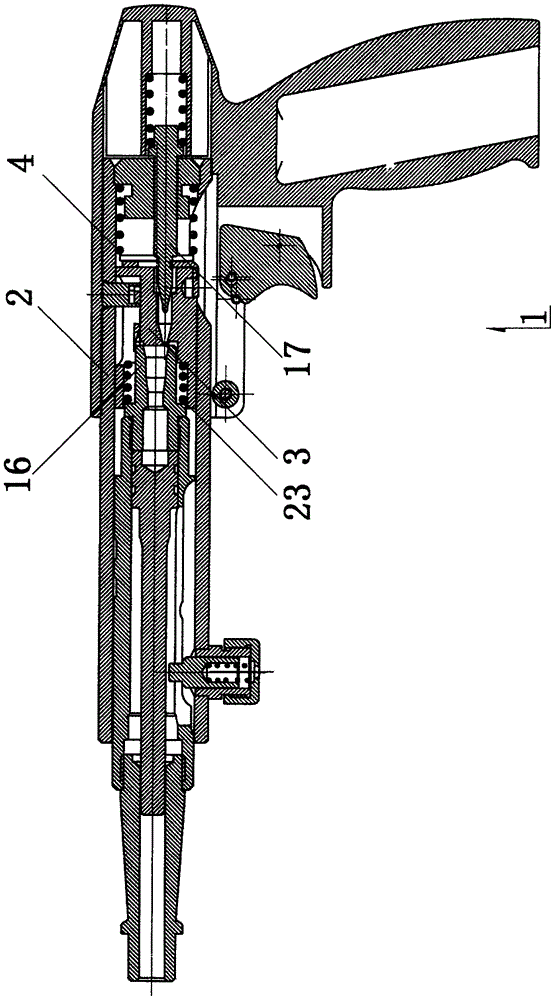

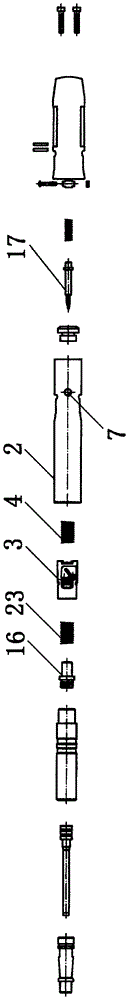

Automatic langrage feeding device of nail shooting device

ActiveCN105215939AGood movement synchronizationReduce volumeNailing toolsSynchronismContinuous operation

The invention relates to an automatic langrage feeding device of a nail shooting device. The automatic langrage feeding device comprises a body. The body comprises a shell and a firing pin base, a reset spring is arranged between the firing pin base and the shell, and the body is provided with a popup window. The body is provided with a hole, and a pin is arranged in the hole. A langrage groove is formed in the firing pin base. The firing pin base is provided with a mounting base, and a shifting fork and the mounting face are in rotary connection. Magnets are arranged on the mounting face. A front fork and a rear fork are arranged on the shifting fork. An overall lifting margin exists between the front fork and the mounting face. The rear fork and the pin match to achieve linkage. The automatic langrage feeding device has the beneficial effects that an original firing pin base structure is improved, the shifting fork is driven by power to alternately rotate through reciprocating motion of the reset spring, and therefore a langrage band is stirred to move, the action synchronism of a langrage shifting mechanism and the nail shooting device is good, and continuous operation can be achieved without human intervention. In addition, parts to which the improvement relates are small in size and light and are all internally arranged, the peripheral size of the whole nail shooting device cannot be increased, and added weight can be neglected.

Owner:YIBIN NANXI KECHENG ELECTROMECHANICAL FACTORY

Liquid forging device of multisection mold surface for universal oil hydraulic press

The invention relates to a liquid forging device of a multisection mold surface for a universal oil hydraulic press, belonging to the technical field of metal processing and comprising movable modules, upper dies, a concave die insert, oblique wedges, a pull rod, side plates, sliding pins, a supporting block and a force transmission transverse beam, wherein the upper dies are positioned in cavities of the movable modules; the two movable modules are positioned on the supporting block of a workbench of the press and can move along a guiding groove on the supporting block left and right; the force transmission bevels of the left oblique wedge and the right oblique wedge respectively come into tight contact with bevels on the two movable modules; a plunger rod of an oil cylinder under the oil hydraulic press is fastened with the force transmission transverse beam in a hole of the supporting block and is respectively connected with the oblique wedges by the pull rod; the sliding pins on both sides of the movable modules are matched with holes of the sliding pins of the side plates; and the side plates are fastened on both sides of the oblique wedges and are connected with the oblique wedges into a whole. The liquid forging device can realize the liquid forging process of a horizontal mold surface forging and a vertical mold surface forging by the opening and the closing control dies of a lower topping cylinder of the universal oil hydraulic press.

Owner:JIANGSU UNIV

Nail shooter automatic feeding device

ActiveCN105215939BReduce weightDoes not increase peripheral volumeNailing toolsReciprocating motionEngineering

The invention relates to an automatic langrage feeding device of a nail shooting device. The automatic langrage feeding device comprises a body. The body comprises a shell and a firing pin base, a reset spring is arranged between the firing pin base and the shell, and the body is provided with a popup window. The body is provided with a hole, and a pin is arranged in the hole. A langrage groove is formed in the firing pin base. The firing pin base is provided with a mounting base, and a shifting fork and the mounting face are in rotary connection. Magnets are arranged on the mounting face. A front fork and a rear fork are arranged on the shifting fork. An overall lifting margin exists between the front fork and the mounting face. The rear fork and the pin match to achieve linkage. The automatic langrage feeding device has the beneficial effects that an original firing pin base structure is improved, the shifting fork is driven by power to alternately rotate through reciprocating motion of the reset spring, and therefore a langrage band is stirred to move, the action synchronism of a langrage shifting mechanism and the nail shooting device is good, and continuous operation can be achieved without human intervention. In addition, parts to which the improvement relates are small in size and light and are all internally arranged, the peripheral size of the whole nail shooting device cannot be increased, and added weight can be neglected.

Owner:YIBIN NANXI KECHENG ELECTROMECHANICAL FACTORY

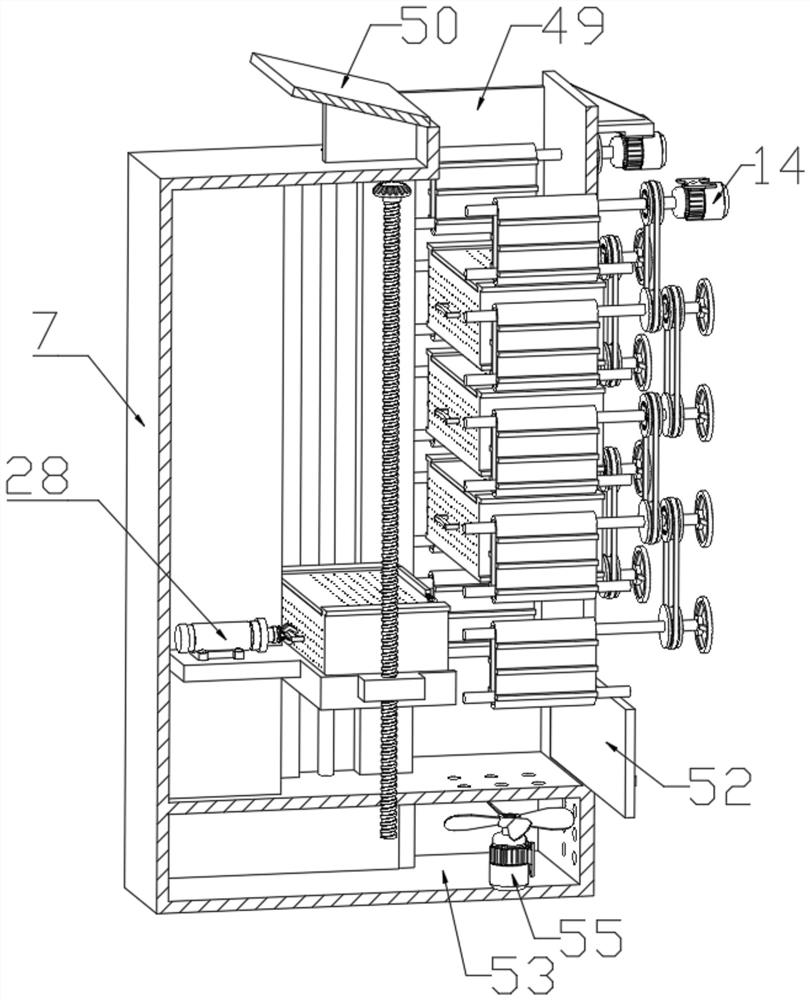

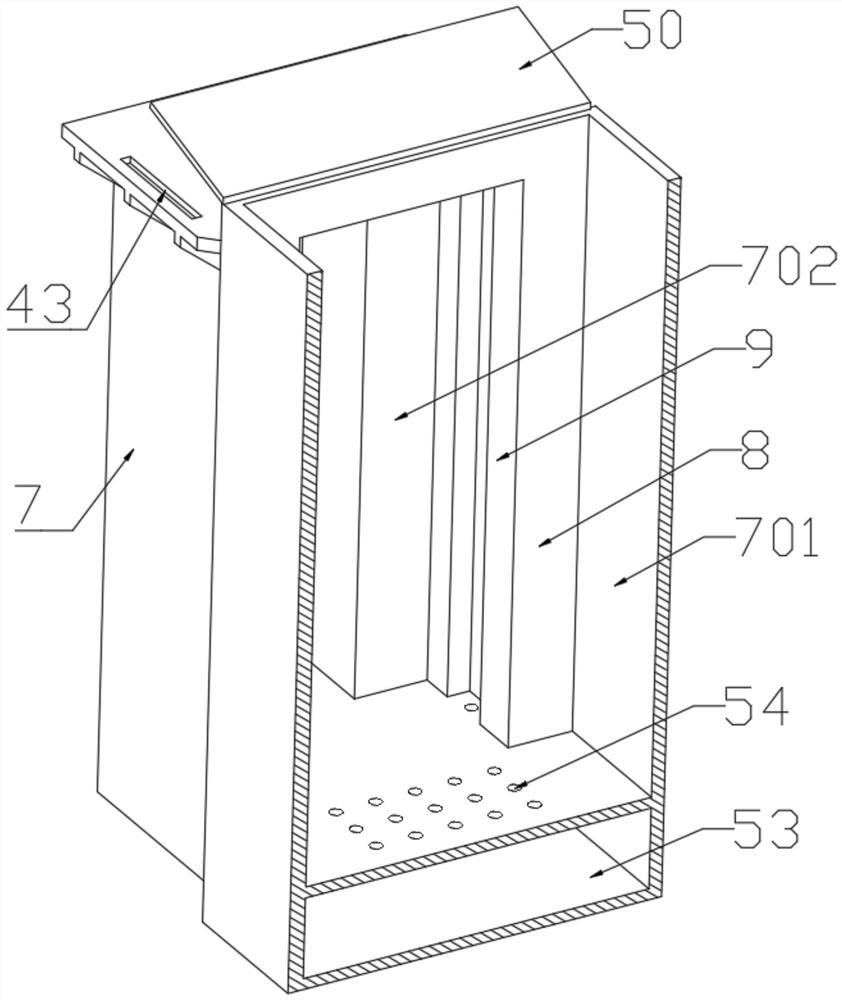

Switchable fermentation device for sewage treatment

ActiveCN113511927AReduce initial fermentation timeLow costBio-organic fraction processingClimate change adaptationProcess engineeringSewage

The invention provides a switchable fermentation device for sewage treatment. The switchable fermentation device comprises a sewage flow channel, a first grating, a second grating, a transmission unit, composting boxes and a fermentation unit, wherein the fermentation unit comprises a plurality of lifting module capable of vertically accommodating composting boxes and lifting the composting boxes and a sequence adjusting module for adjusting the vertical arrangement sequence of the composting boxes. According to the invention, the actions of discharging materials at a bottom layer everyday and adding new materials at an upper layer everyday in a dynamic intermittent composting process can be completed, and the sequential position of each composting box can be adjusted according to a composting fermentation condition, so it is guaranteed that the composting boxes which leave the fermentation unit are composting boxes having undergone thorough fermentation and can be discharged in sequence according to fermentation degrees.

Owner:ANHUI UNIV OF SCI & TECH GUOZHEN INFORMATION TECH CO LTD

Magnetic rolling processing device for inner surface of long round tube

ActiveCN107717326BSimple structureGood movement synchronizationMagnetic polesRotating magnetic field

Owner:WUXI WEIHAIDA MACHINERY MFG

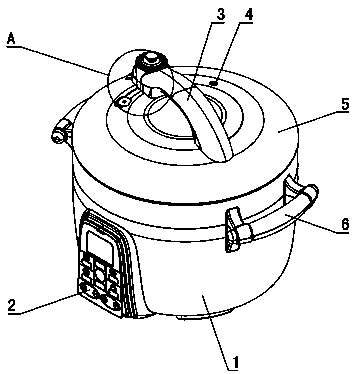

A kind of sealed electric rice cooker

ActiveCN105919411BEasy to useHeating evenlyCooking-vessel lids/coversWarming devicesLocking mechanismRice dishes

Provided is a sealed electric cooker, pertaining to the field of household cookers.The sealed electric cooker is characterized in that the position between a pot cover (5) and a pot body (1) is sealed; a retractable locking mechanism used for locking the pot cover (5) and the pot body (1) is arranged between the pot cover (5) and the pot body (1); the pot cover (5) is provided with an exhaust seal valve (4) communicating the pot body (1) with the air; the exhaust seal valve (4) is controlled by temperature so that exhaust is achieved; pressure can make the pot body (1) sealed when the pot body (1) reaches at certain temperature; ventilation is achieved when pressure of the pot body (1) is lower than the above pressure; and a safety valve (7) is arranged on the pot cover (5).The sealed electric cooker has following beneficial effects: air can be exhausted when water temperature increases to the boiling state; when saturated steam reaches certain pressure, the exhaust seal valve is sealed; when the saturated steam is condensed to water, the exhaust seal valve is opened; and by absorbing air in the pot, temperature for water, rice and saturated steam in the pot body can be up to 105-120 DEG C so that rice can be heated in an all-round way.

Owner:山东多星电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com