Automatic langrage feeding device of nail shooting device

A nail shooter and automatic technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of large volume and weight, long time, high assembly accuracy, and achieve the effect of small size, light weight and good synchronization of actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

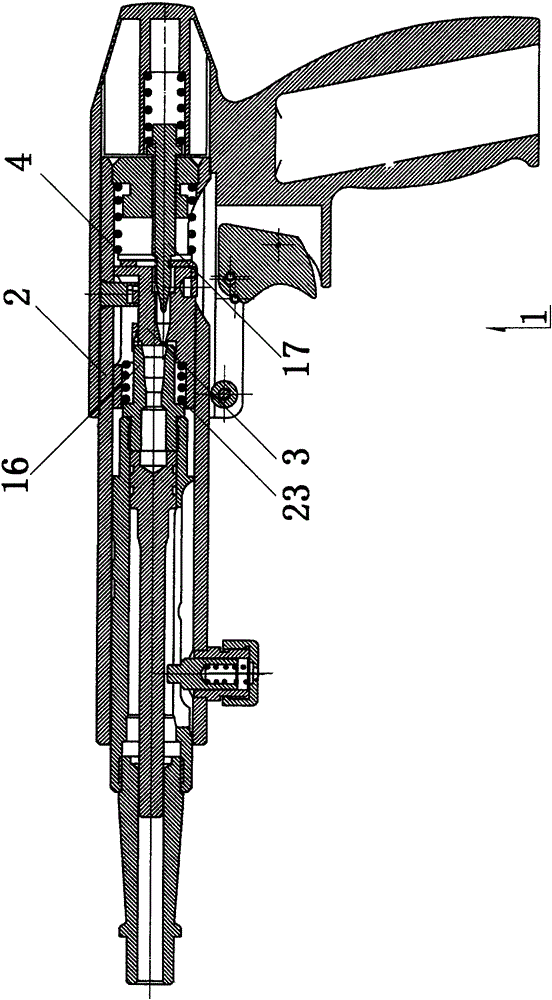

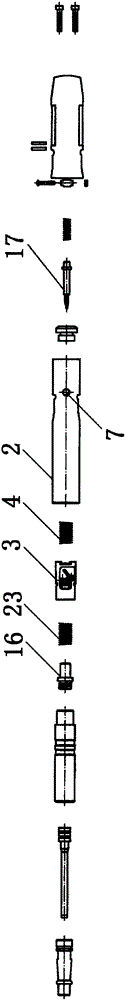

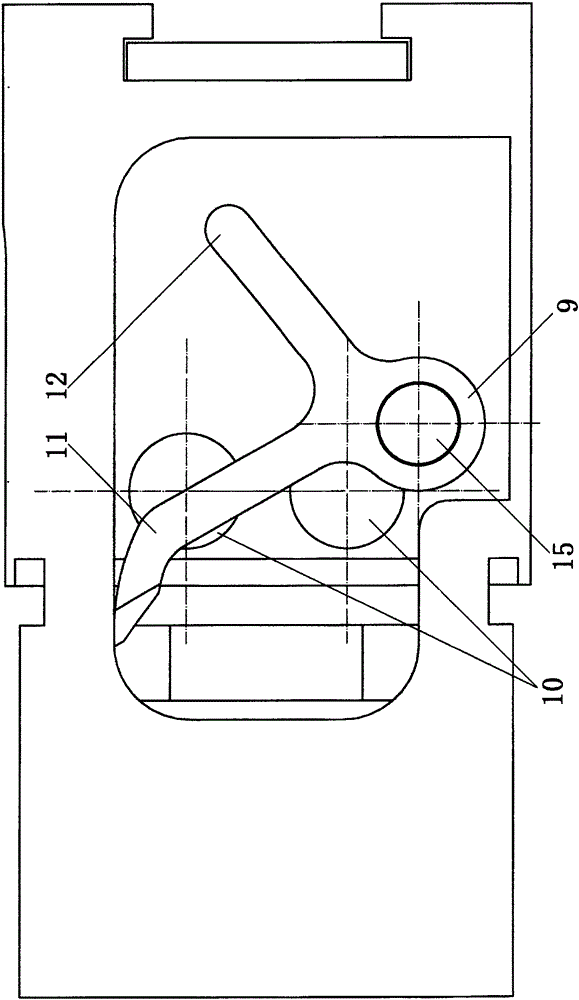

[0032] In the figure: 1 is the body, 2 is the shell, 3 is the firing pin seat, 4 is the return spring, 5 is the pop-up window, 6 is the hole, 7 is the pin, 8 is the mounting surface, 9 is the shift fork, 10 is the magnet, 11 is the front fork, 12 is the rear fork, 13 is the bevel, 14 is the gap, 15 is the bolt (also can be threaded pin or rivet), 16 is the chamber body, 17 is the firing pin, 18 is the belt, 19 is the dial Groove, 20 is bullet groove, and 21 is nail shooting bullet, and 22 is protrusion, and 23 is back-moving spring.

[0033] The firing pin seat 3 is a part that has always existed in the structure of the nail shooter. It is located between the chamber body 16 and the firing pin 17. It is used to guide the firing pin 17 so that the head of the firing pin 17 passes through the firing pin quickly. The hole inside the seat 3, and stretch out, accurately strikes the bottom shell of the nail-shooting projectile in the chamber body 16, reaches the purpose of explosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com