Liquid forging device of multisection mold surface for universal oil hydraulic press

A liquid die forging and hydraulic press technology, which is applied in the field of metal processing, can solve the problems of complicated control of die structure and movement, large work surface, etc., and achieve the effects of good movement synchronization, fewer parts, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

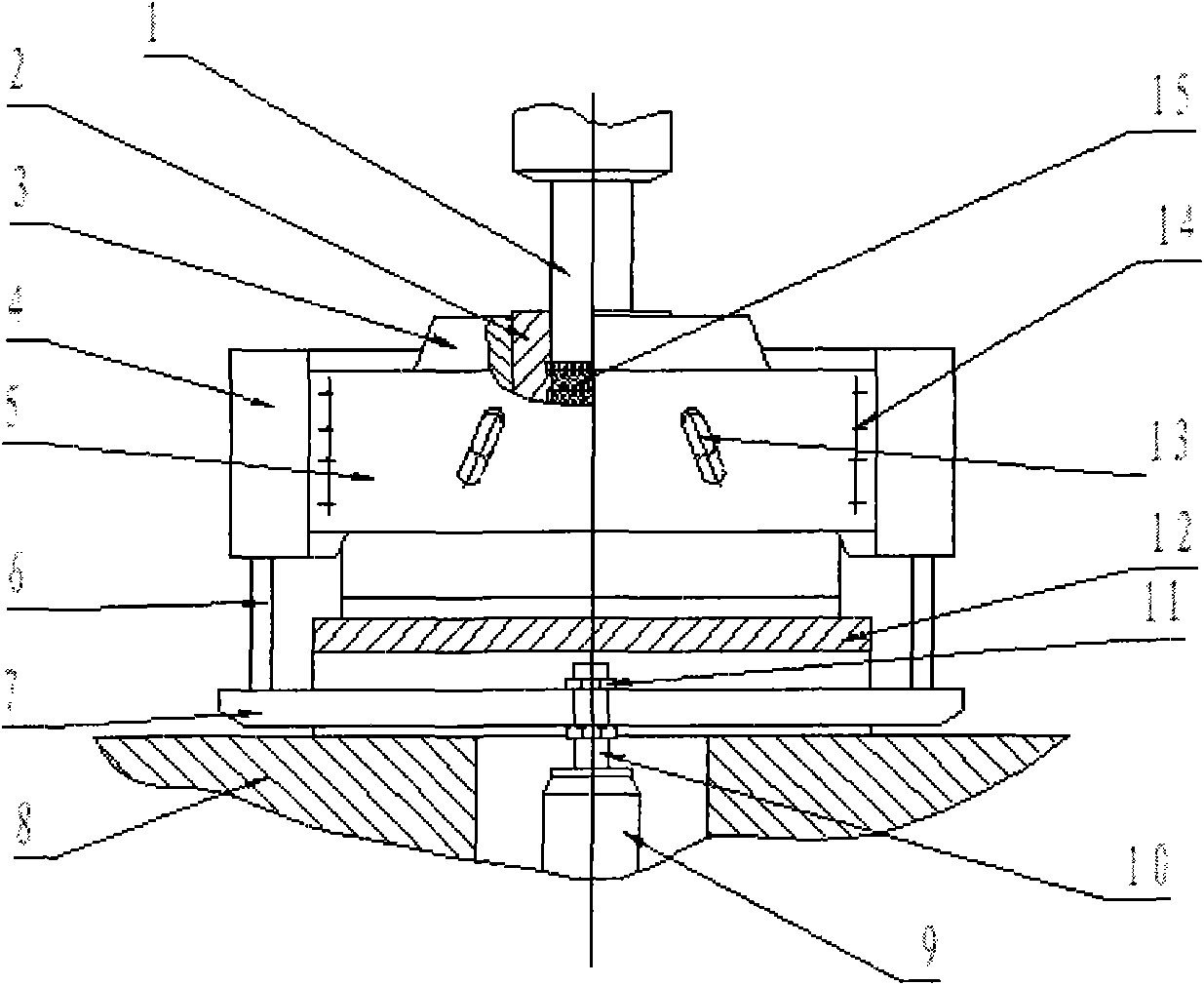

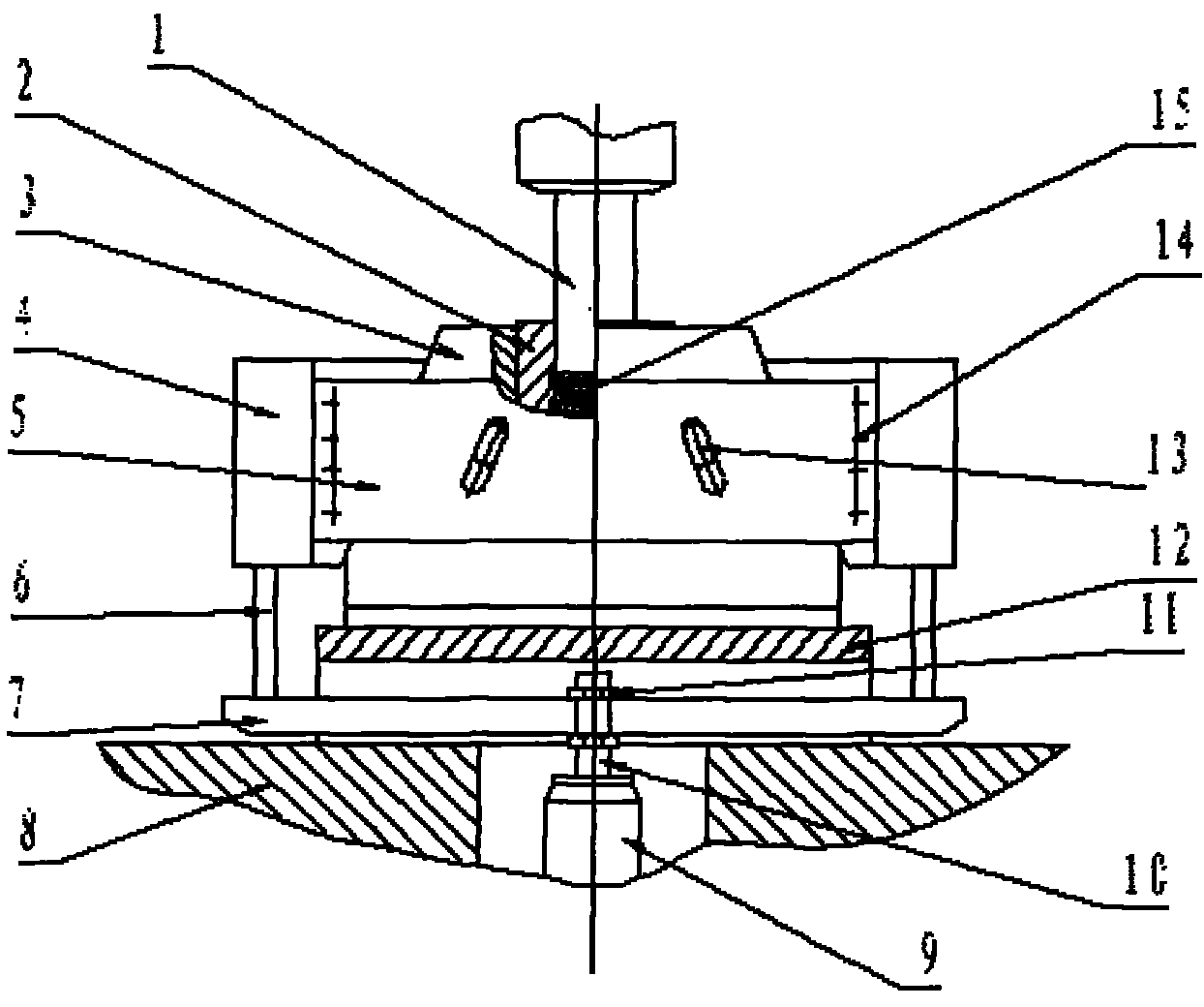

[0014] The present invention relates to a tool suitable for metal liquid die forging on a general-purpose hydraulic press, which is characterized in that the lower oil cylinder of the hydraulic press is used as the power source, and the opening of the horizontal and vertical two-parting surface molds is realized through a mechanical system. action. The closing action of the mold is realized by driving the inclined wedge to press down through the force transmission beam and the pull rod when the lower cylinder returns, forcing the movable module to move to the center under the push of the inclined force; The pull rod makes the wedge rise, and the movable module is separated under the drive of the side of the sliding pin hole on the side plate, so as to realize the mold opening. The specific movement process is as follows: when the plunger rod 10 of the lower oil cylinder 9 returns, the force transmission beam 7 fastened to the plunger pulls down the wedge 4 through the pull rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com