Magnetic rolling processing device for inner surface of long round tube

A processing device and inner surface technology, applied in the field of rolling processing, can solve the problems of reducing the use value of long round pipes, achieve the effects of good motion synchronization and stability, ensure personal safety, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated by the following examples, but not limited to the following examples.

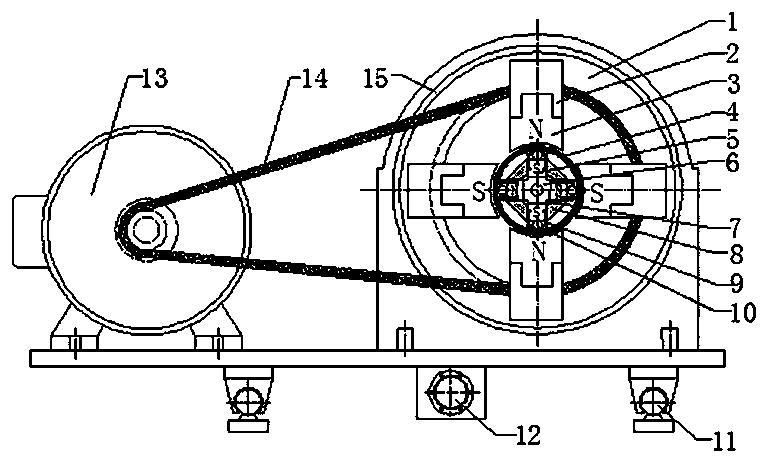

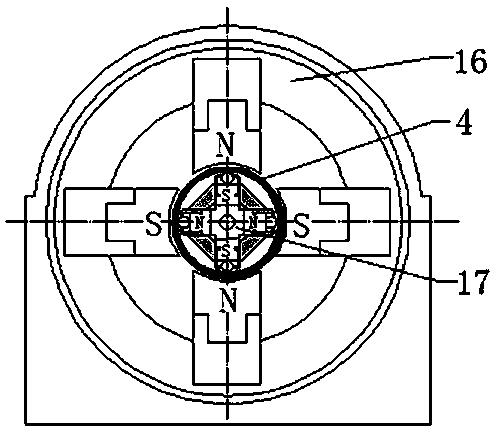

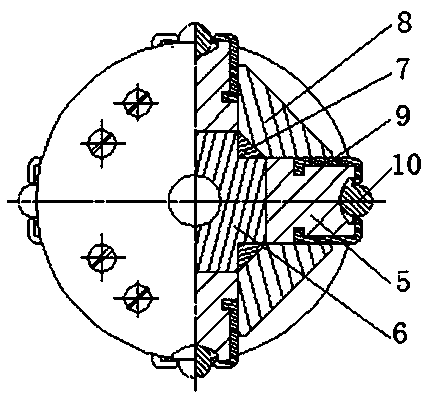

[0020] Such as figure 1 with figure 2 As shown, a magnetic rolling processing device for the inner surface of an oblong tube includes an external magnetic field generator and a magnetic rolling tool; the external magnetic field generator is driven to rotate by a motor and a conveyor belt to generate a spatial rotating magnetic field; two pairs of cuboids with the same size have The magnetic poles of the magnetic circuit are fixed on the 45 steel gaskets of the external magnetic circuit, and are connected together with the magnetic poles of the adjacent cuboid external magnetic circuit through the 45 steel auxiliary magnetic circuit of the external magnetic circuit to form an external magnetic circuit; the external magnetic circuits of two pairs of cuboids with the same size The magnetic poles of the magnetic circuit, the 45 steel gaskets of the external...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com