Novel chopping type straw super crusher

A pulverizer, straw technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of ineffective pulverization, affecting machine work, easy reamer, etc., to achieve high work efficiency, chopping effect and pulverizing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

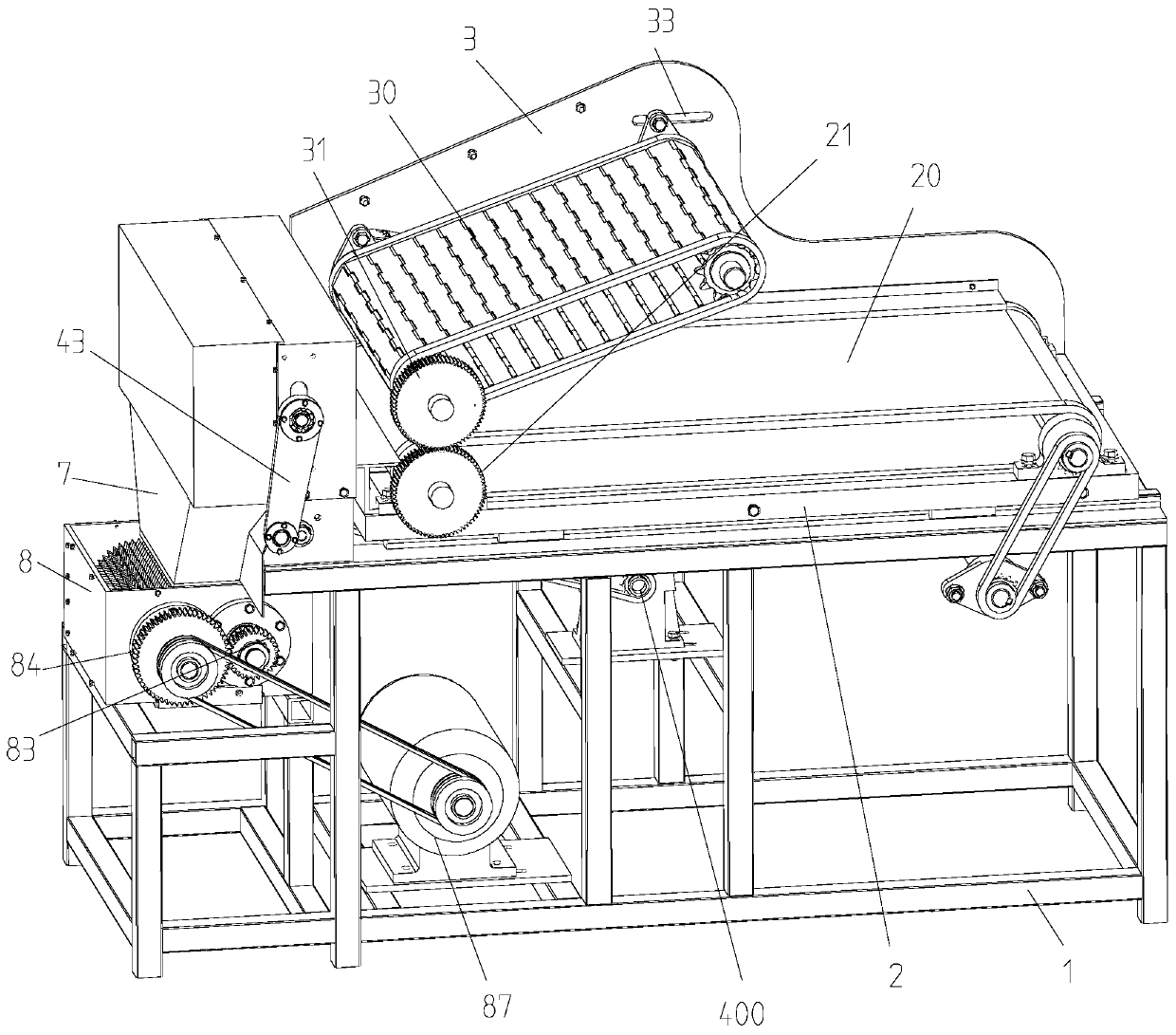

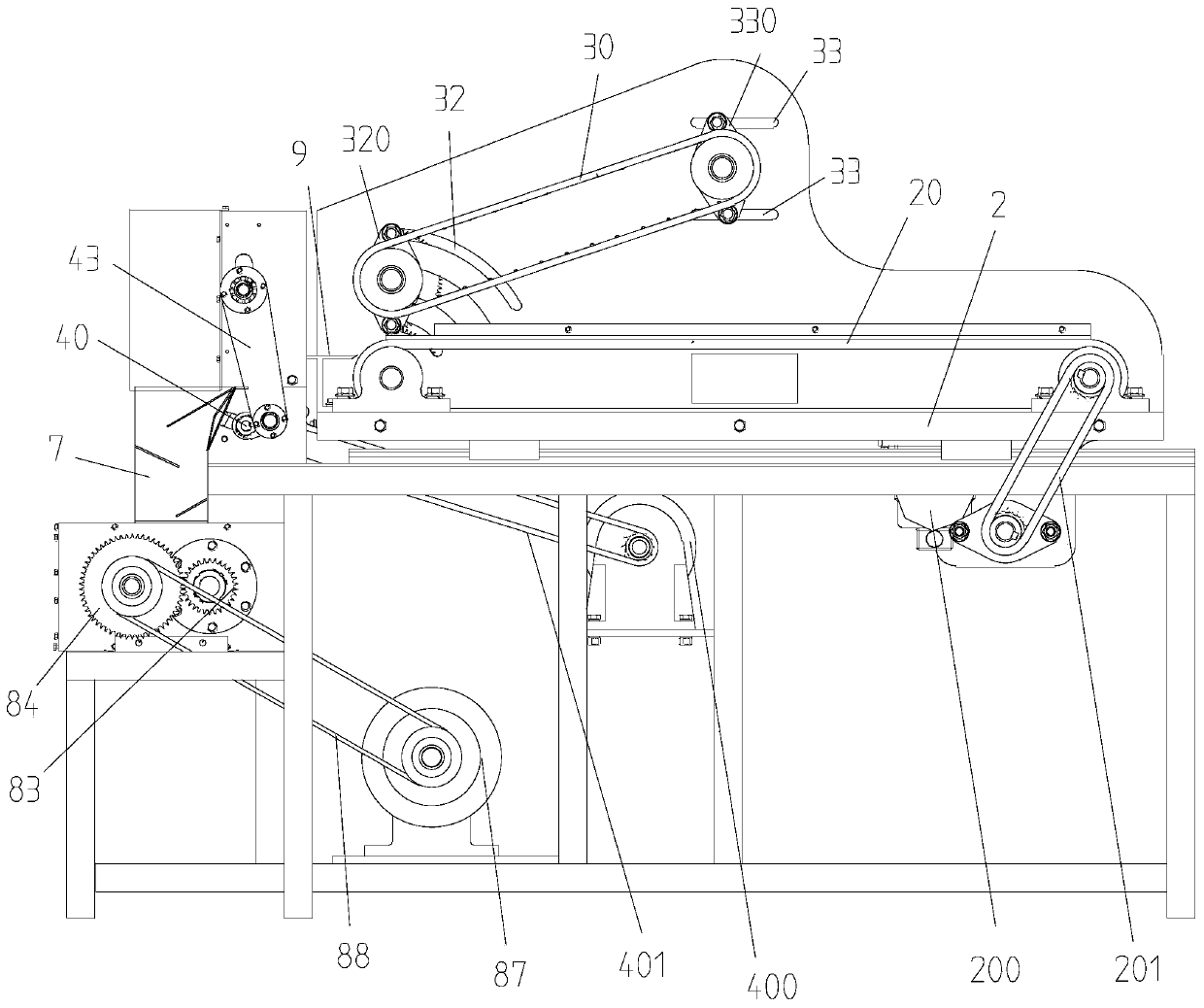

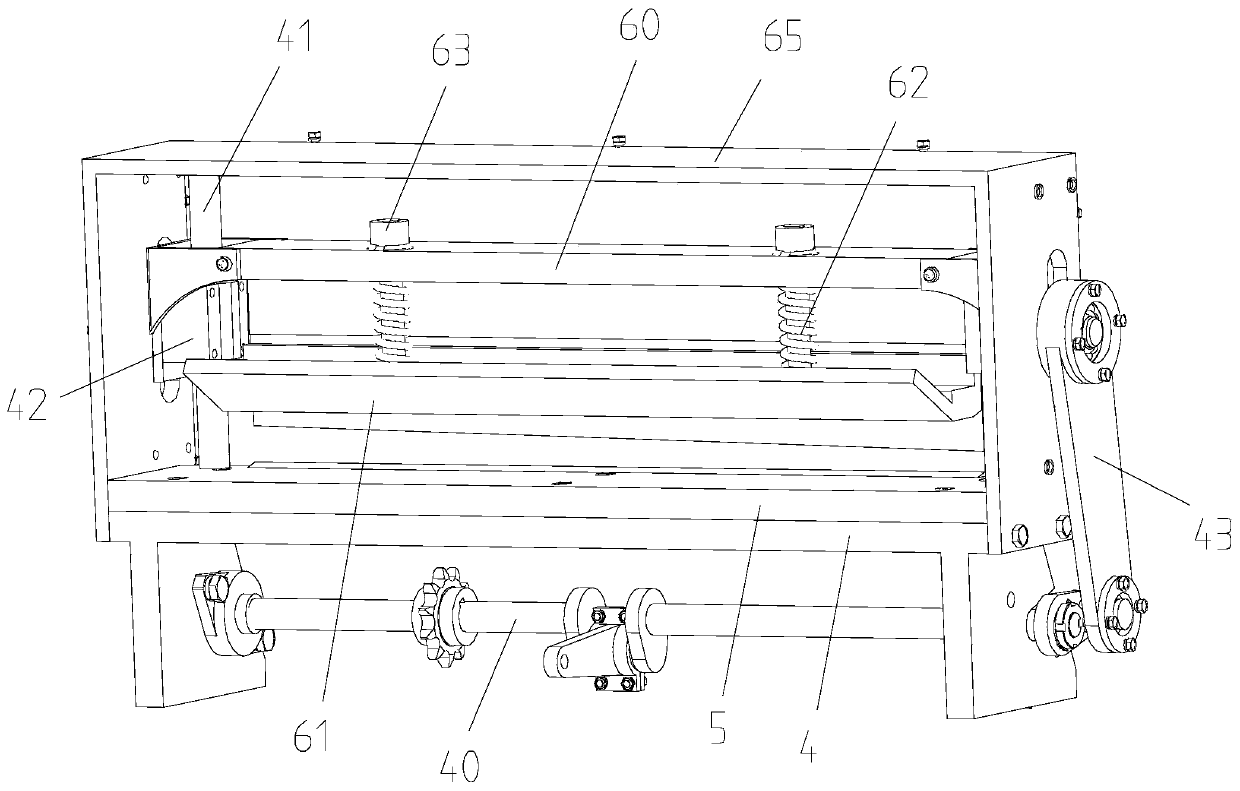

[0032] as attached figure 1 - attached Figure 6 The novel cutting type rice straw super pulverizer shown comprises frame 1, and frame 1 is a rectangular frame structure as a whole, and the upper end of this frame 1 is provided with slide rail along its length direction, and the lower end of conveying base 2 is provided with can A slider that moves back and forth along this rail. Both sides of the delivery base 2 are respectively provided with a side mounting plate 3 along the vertical direction, and the upper end surface of the delivery base 2 is provided with a lower conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com