Silica gel diaphragm and loudspeaker

A silicone diaphragm and speaker technology, applied in loudspeakers, sensors, electrical components, etc., can solve the problems of small material selection range, rolling vibration, and inconvenient adjustment of resonance frequency in the thickness adjustment range, so as to reduce extrusion deformation, The effect of reducing the difference and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

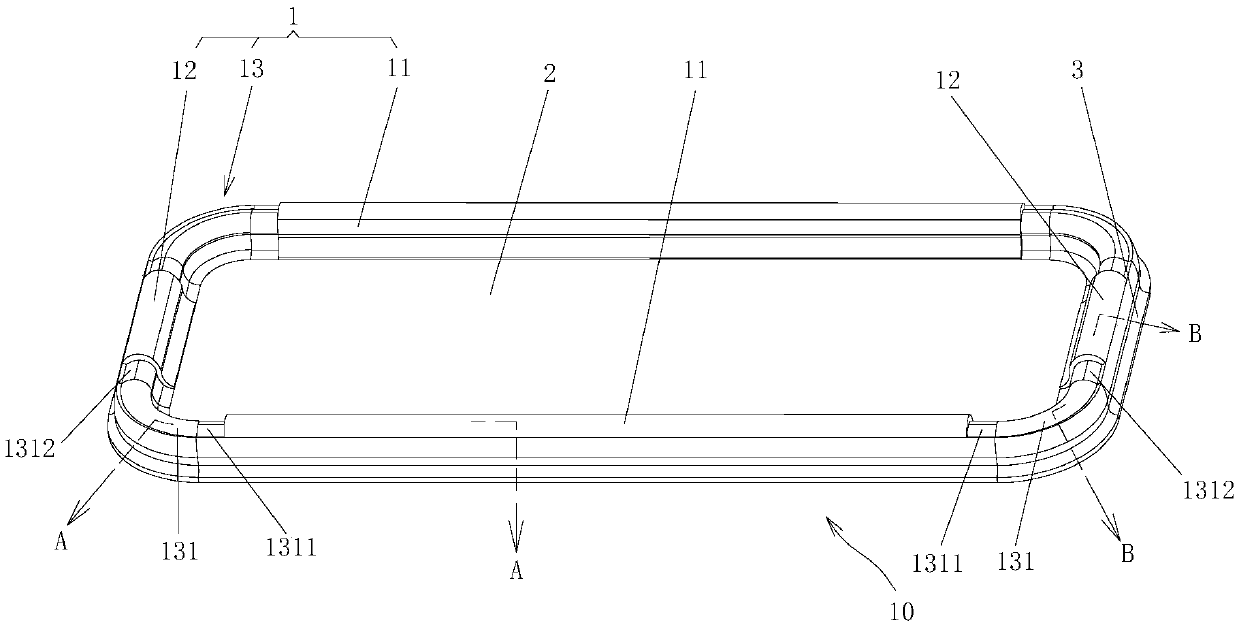

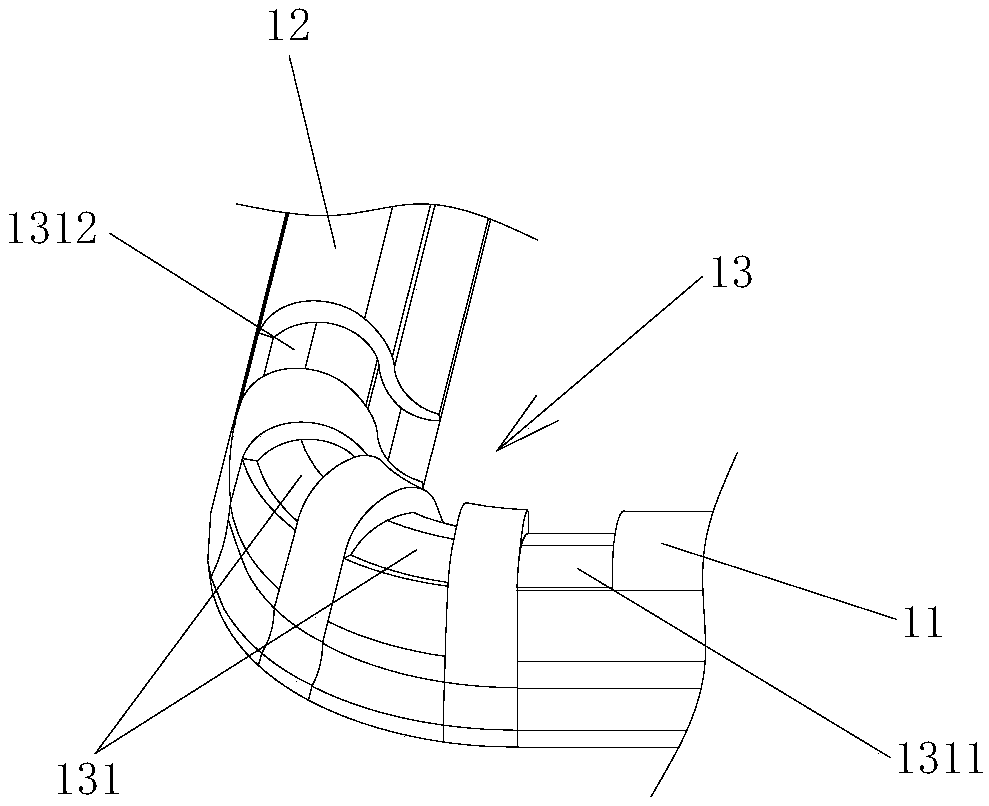

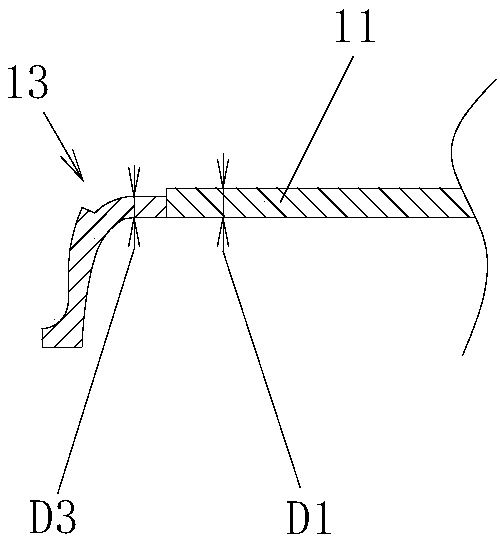

[0036] Such as Figure 1 to Figure 6 , Figure 7a , Figure 7b As shown, the present invention provides a silicone diaphragm 10, which has a rectangular ring portion 1 and a center sticking portion 2 connected to the inner peripheral edge of the ring portion 1, and the ring portion 1 is composed of two oppositely arranged One first flange edge 11 and two oppositely arranged second flange edges 12, the adjacent first flange edge 11 and the second flange edge 12 are connected with an edge corner. 13, wherein, each of the edge corners 13 of the ring has at least one thickness adjustment section 131, and the thickness D1 of the first ring edge 11 and the thickness D2 of the second ring edge 12 are respectively related to the thickness adjustment section 131. There is a first thickness difference D between the thicknesses D3 of the segments 131 .

[0037] Specifically, in this embodiment, the silica gel diaphragm 10 is substantially rectangular in shape, which includes a substan...

Embodiment approach 2

[0054] Such as Figure 1 to Figure 8 As shown, the present invention also provides a loudspeaker, which includes the silicone diaphragm 10 described in Embodiment 1. The structure, working principle and beneficial effects of the silica gel diaphragm 10 will not be repeated here.

[0055] The loudspeaker includes a magnetic circuit system 5, a basin frame 6 connected to the magnetic circuit system 5, and the silicone diaphragm 10 described in Embodiment 1, wherein a voice coil 7 is connected to the lower surface of the silicone diaphragm, and the voice coil 7 The lower end is inserted into the magnetic gap 51 of the magnetic circuit system 5 . Wherein, the magnetic circuit system 5 includes a magnetic bowl 52 , a central magnet 53 and a side magnet 54 , the side magnet 54 surrounds the outer periphery of the central magnet 53 , and a magnetic gap 51 is formed between the side magnet 54 and the central magnet 53 .

[0056] The loudspeaker of the present invention adopts the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com