Outlet housing for range hood

A technology for air outlet hoods and range hoods, which is applied in the direction of removing oil fumes, applications, household stoves, etc. It can solve the problems that the oil fume cannot be discharged normally, the opening and closing status of the valve cannot be detected in real time, and the oil fume is poured back, etc., to achieve conduction and isolation Easy to operate, easy to disassemble and replace, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

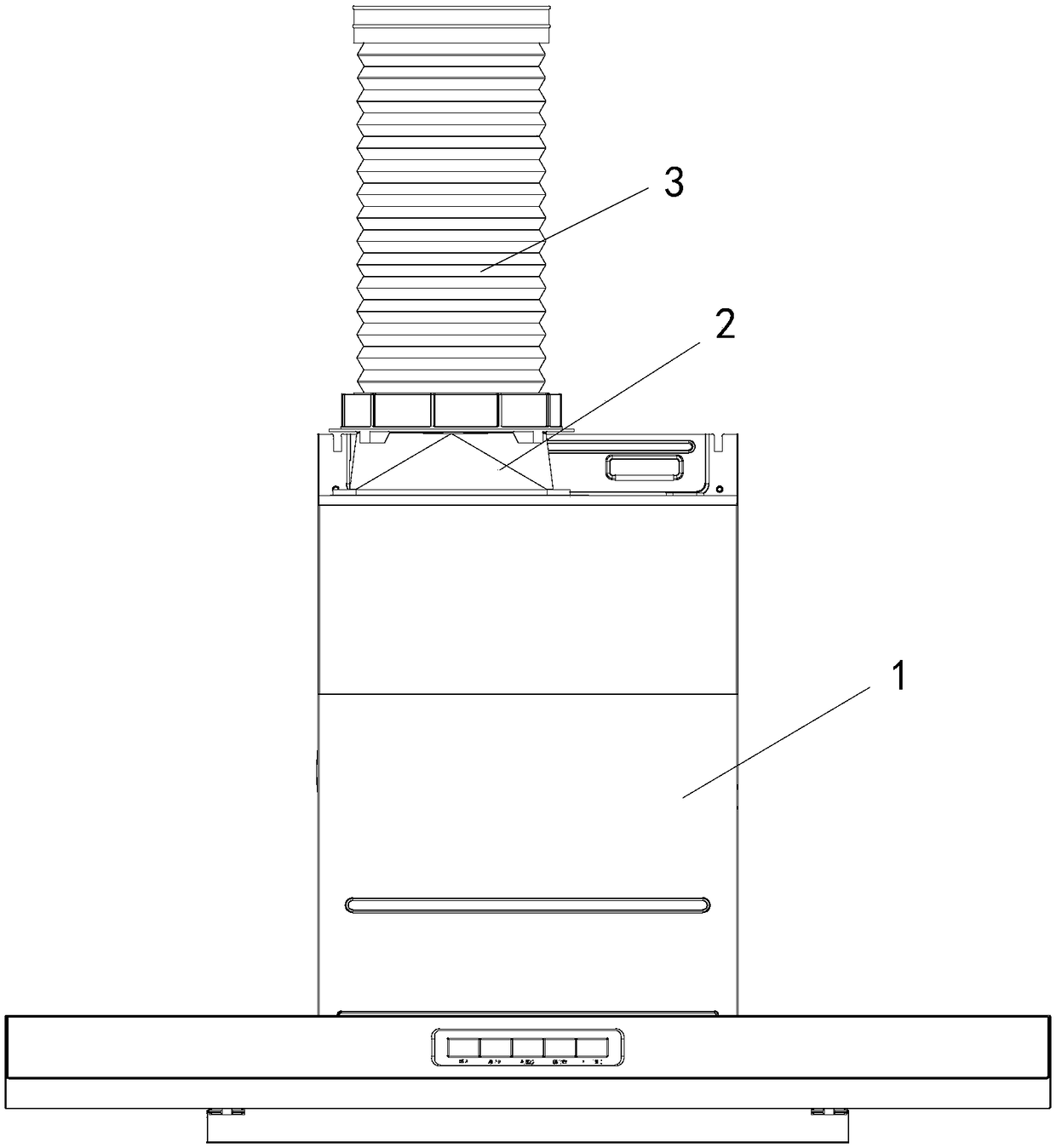

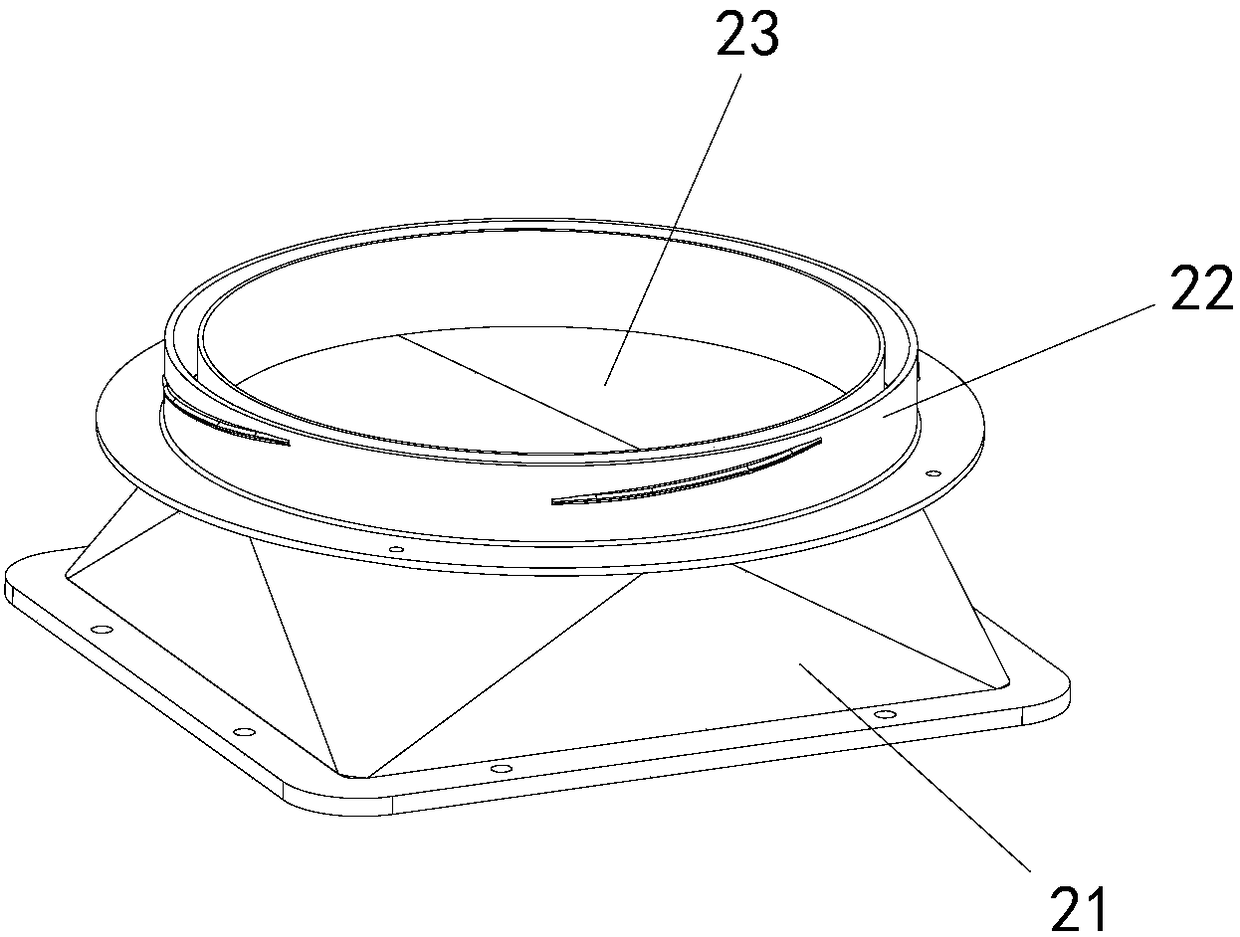

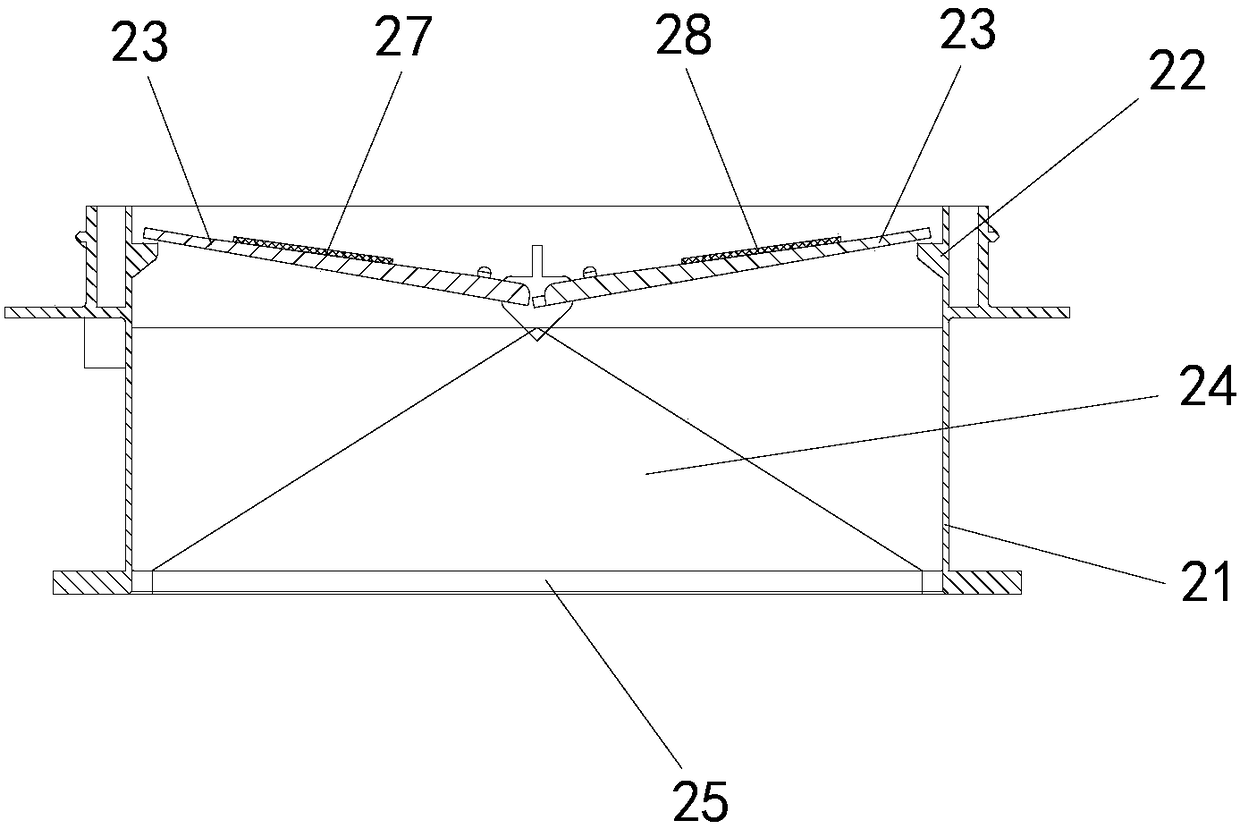

[0041] Such as Figure 1-5 As shown, the present embodiment provides an air outlet cover for a range hood. The air outlet cover 2 includes a lower cover 21 connected to the range hood 1, a mounting ring 22 connected to the air outlet pipe 3, and a stopper that can be turned over and opened. The valve leaf 23 of the return valve, the air outlet cavity 24 of the air outlet cover is formed in the lower cover 21 and the installation ring 22, the air inlet opening 25 of the air outlet cover 2 is formed at the bottom of the lower cover 21, and the installation ring The top of 22 forms the air outlet opening 26 of the air outlet cover 2, and the valve blades 23 are two valve blades that rotate relatively. The leaves 23 can be flipped open or closed respectively, so as to conduct or cut off the air inlet opening 25 and the air outlet opening 26, the two valve leaves 23 can form a relative valve leaf angle α, and the air outlet cover 2. Output the corresponding detection capacitance v...

Embodiment 2

[0052] The difference between the present embodiment and the first embodiment is that the positive and negative conductive electrode plates are glued and fixed to the valve leaf.

[0053] Such as Figure 6 As shown, the positive and negative conductive plates 27, 28 and their corresponding valve leaves 23 are fixed by gluing, and the two valve leaves 23 are respectively provided with overflowing glue that matches the positions of the positive and negative conductive plates 27, 28. Hole 5, this setting improves the uniformity of the glue overflow, and the thickness of the adhesive layer between the valve leaf 23 and the positive and negative conductive plates is uniform, which is conducive to the generation of capacitance between the positive and negative conductive plates, and is glued and fixed through the glue overflow hole 5 The valve leaf 23 and the conductive electrode plate enhance the installation reliability of the positive conductive electrode plate 27 and the negativ...

Embodiment 3

[0055] The difference between this embodiment and the first embodiment is that the positive and negative conductive plates are clipped and fixed with the valve leaf.

[0056] Such as Figure 7 As shown, the positive and negative conductive plates 27, 28 and their corresponding valve leaves 23 are fixed by clamping, and the two valve leaves 23 are respectively provided with card slots 6, and the positive and negative conductive plates 27, 28 Installed in the card slot 6, when installing, respectively install the positive conductive electrode plate 27 and the negative conductive electrode plate 28 into the card slot 6, and limit and fix the positions of the positive and negative conductive electrode plates and the positive and negative conductive electrode plates through the buckle 10 , so that the positive and negative conductive plates are firmly held in the slot 6 to prevent the plates from loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com