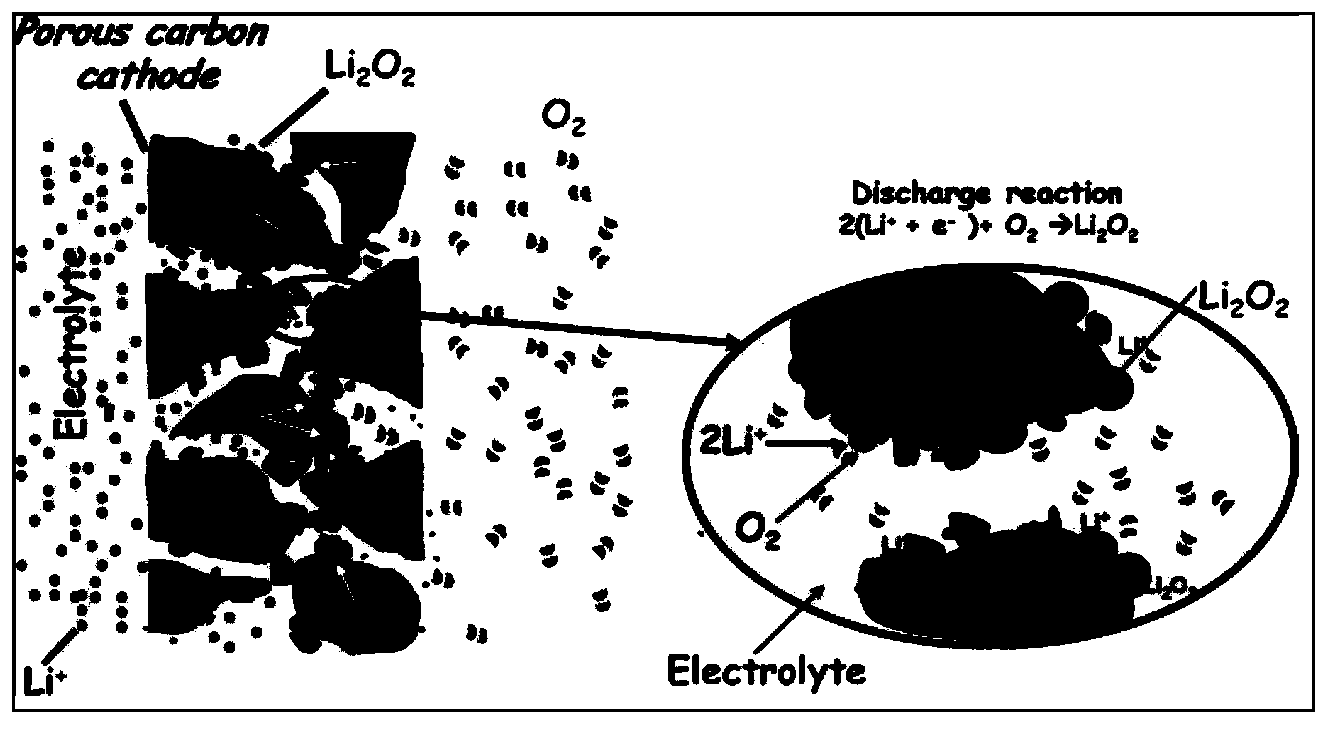

Nitrogen-doped porous carbon material used for anode of lithium-air cell

A porous carbon material and air battery technology, which is applied in battery electrodes, fuel cell-type half-cells, secondary battery-type half-cells, circuits, etc., can solve the unfavorable large-scale commercial preparation and application, and cannot meet the needs of lithium-air batteries. Requirements, high experimental conditions and other issues, to achieve the effect of promoting commercial applications, improving space utilization, and a wide range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared by sol-gel method combined with template method. Dissolve 6.16g resorcinol in 10mL deionized water to form a transparent solution; take 1g SiO 2 Add the sol to the above transparent solution, mix and dissolve evenly to obtain a solution; add dropwise 9.08g of formaldehyde solution to the above stirring solution, stir and mix evenly, and continue stirring at 20°C until the reaction forms a gel; the gel Transfer to a vacuum drying oven, vacuum dry and age at 70°C for 7 days, take it out, crush and grind to obtain a solid powder; put the solid powder in NH 3 Treat at 850°C for 3 hours in the atmosphere, wash off SiO with 1M HF solution 2 , after filtering and drying, the carbon material is obtained.

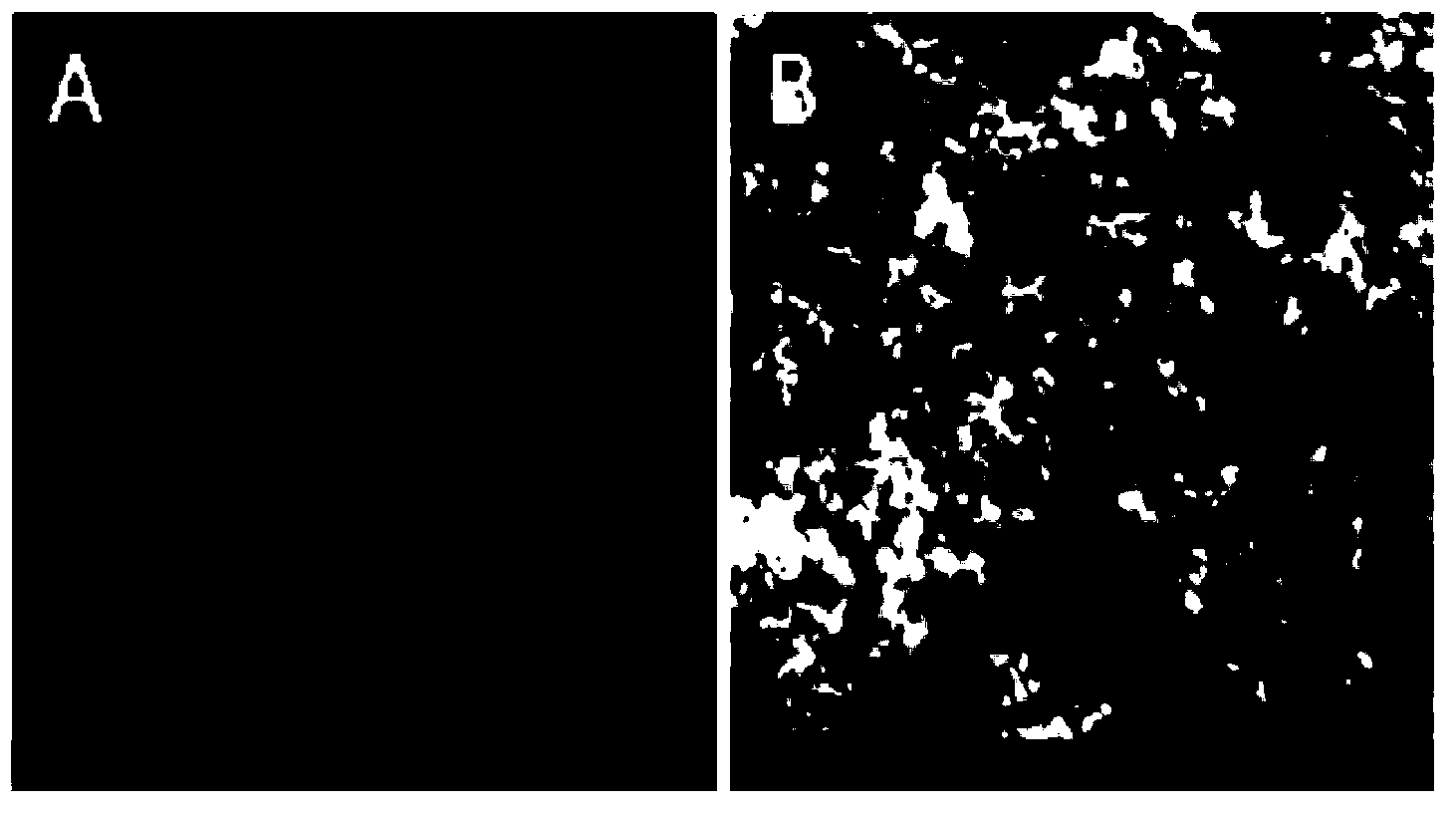

[0035] The positive electrode material structure prepared in Example 1 has a large number of deposition pores with a diameter of 10 to 40 nanometers, and graded pores with 1 to 2 micron-sc...

Embodiment 2

[0040] Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared by sol-gel method combined with template method. Dissolve 6.16g of resorcinol in 10mL of deionized water to form a transparent solution; add 2g of nickel hydroxide powder to the above transparent solution, mix and dissolve to obtain a uniform solution; add dropwise 9.08g of formaldehyde to the above stirring solution The solution was further stirred and mixed evenly, and continuously stirred in an environment of 20°C until the reaction formed a gel; the gel was transferred to a vacuum drying oven for 7 days of vacuum drying and aging treatment at 70°C, and then crushed and ground to obtain a solid powder; the solid Powder in NH 3 Treat at 900℃ for 3h, 1M HNO 3 The solution is washed to remove nickel oxide, filtered and dried to obtain the carbon material.

Embodiment 3

[0042] Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared by sol-gel method combined with template method. Dissolve 6.16g of resorcinol in 10mL of deionized water to form a transparent solution; take 4g of aluminum oxide powder and add it to the above transparent solution, mix and dissolve evenly to obtain a solution; add dropwise 9.08g of For the formaldehyde solution, stir and mix evenly, and continue to stir at 20°C until the reaction forms a gel; transfer the gel to a vacuum drying oven for 7 days of vacuum drying and aging treatment at 70°C, take it out, crush and grind it, and obtain a solid powder; Solid powder in NH 3 Treat at 800° C. for 5 hours, wash off Al2O3 with 2M HCl solution, and filter and dry to obtain the carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com