Large hydraulic turbines stationary guide blade synchronous regulation and control method

A control method and technology of water turbines, which are applied in the directions of hydropower generation, mechanical equipment, engine components, etc., to achieve the effect of saving debugging time, good synchronization and stable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

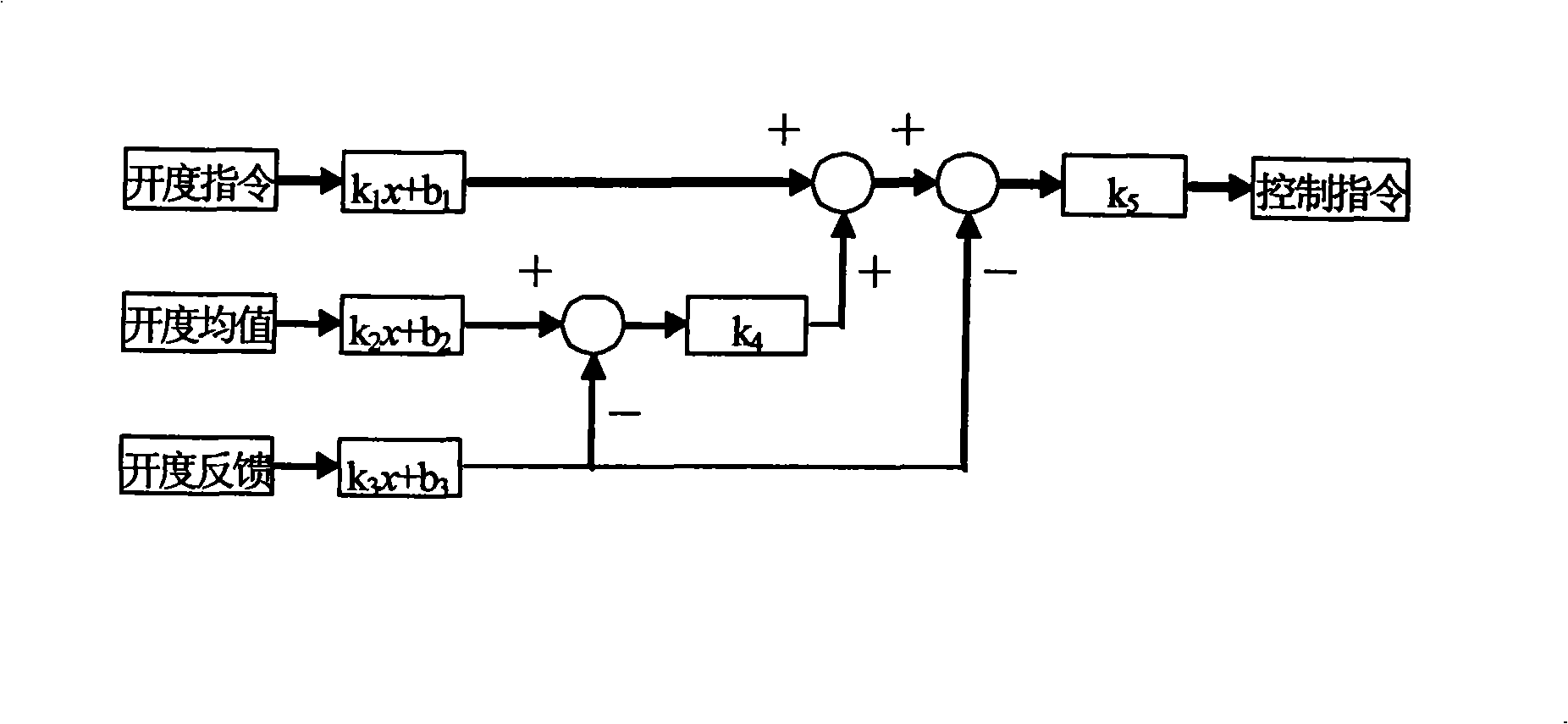

[0039] The method for adjusting and controlling the synchronization of guide vanes of a large water turbine according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] 1. Synchronization adjustment of guide vanes

[0041] 1.1. Measure the resistance value of the servomotor drive coil and accurately define it in the single guide vane controller;

[0042] At present, the servomotor controls are all current-driven, and its action rate is proportional to the driving current. Therefore, to ensure the synchronous control of the guide vanes, it is necessary to make the operating current of each servomotor consistent. The output command of the guide vane controller is a voltage signal. To obtain the same current signal, the load resistance of the servomotor must be known, and then defined in the software of the single guide vane controller.

[0043] 1.2 Adjustment of zero position and full scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com