Mold locking device for plastic terminal bushing

A locking device and terminal sleeve technology, which is applied in the field of creation and belongs to the mechanical field, can solve the problems that two movable molds cannot be in place at the same time, poor synchronization of mold clamping actions, inconvenient disassembly, etc., and achieves reduction of maintenance costs, stable operation, disassembly and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The invention will be described in detail below with reference to the accompanying drawings and examples.

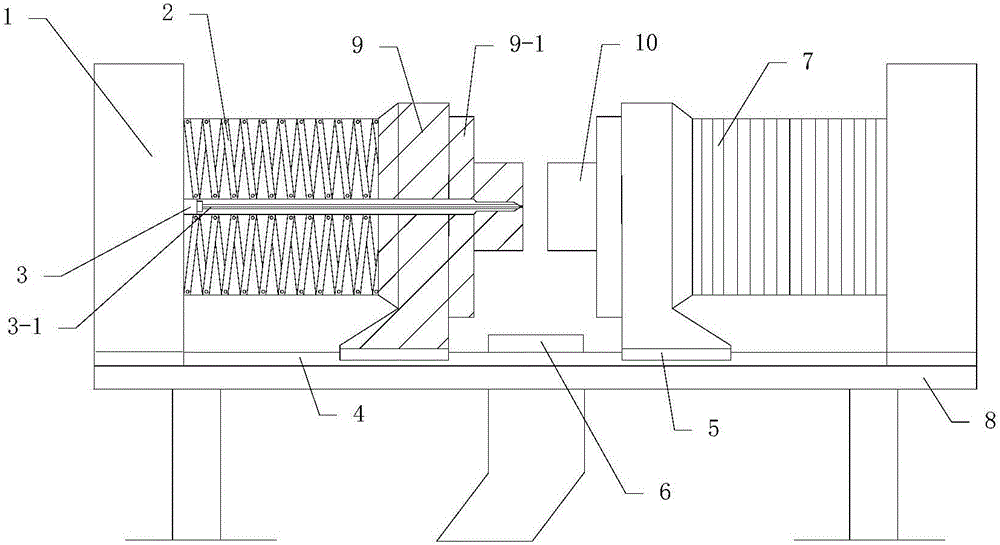

[0021] The mold locking device for plastic terminal sleeves includes a base 8, a mold clamping part and a blanking part. The mold clamping part includes a pressure operation box 1 vertically arranged at both ends of the base 8, and is installed on the pressure operation box 1 parallel to the base 8 The inner compression spring, the compression spring is provided with a telescopic rubber shell 7 on the periphery, and the mold mounting seat 9 is arranged at the end of the spring, and the mold mounting seat 9 is provided with a mounting seat card platform 9-1. Mounting holes are provided on the side surface of the card table 9-1, and the movable mold 10 is installed on the mounting seat card table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com