Patents

Literature

94results about How to "Concentration maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

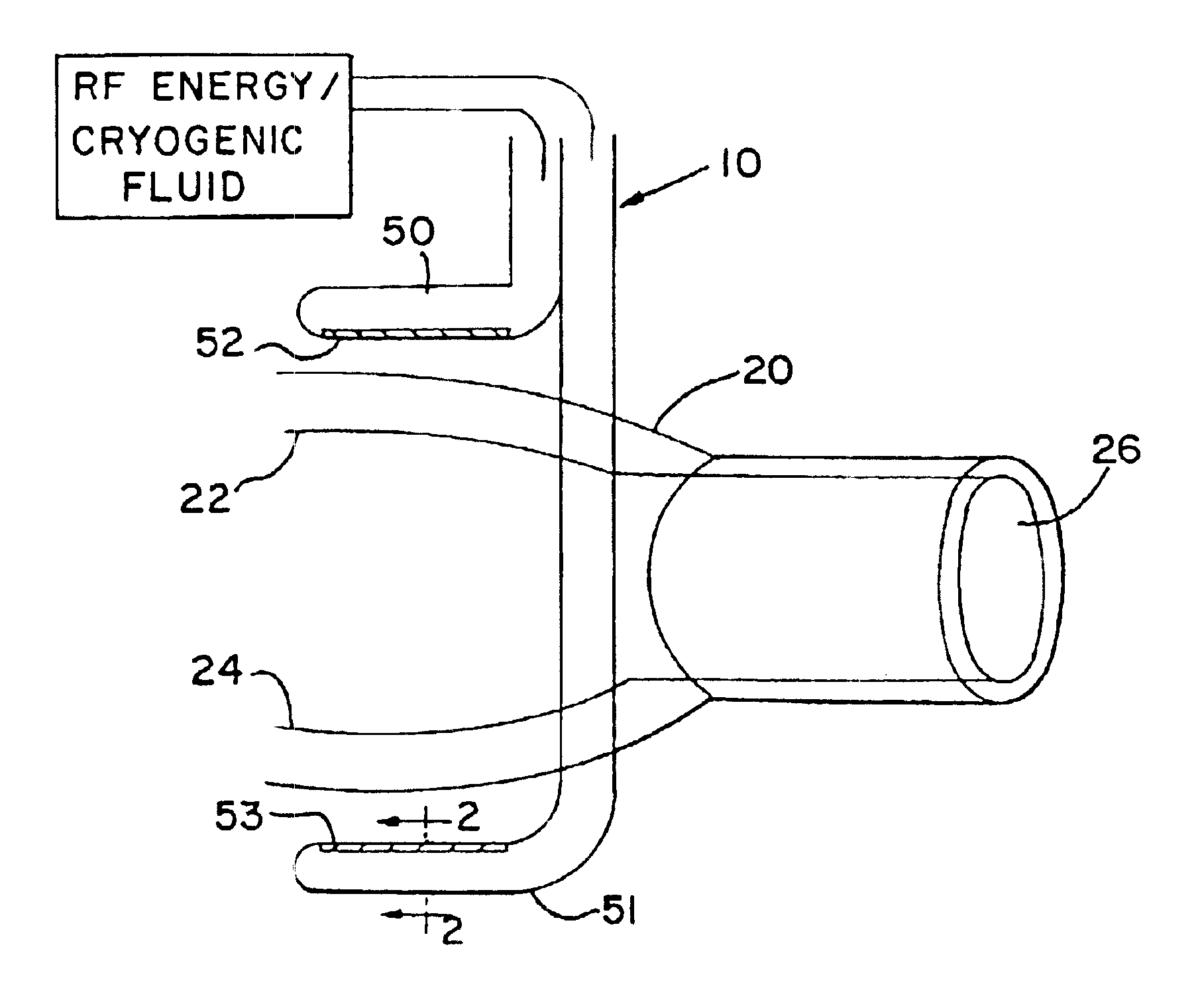

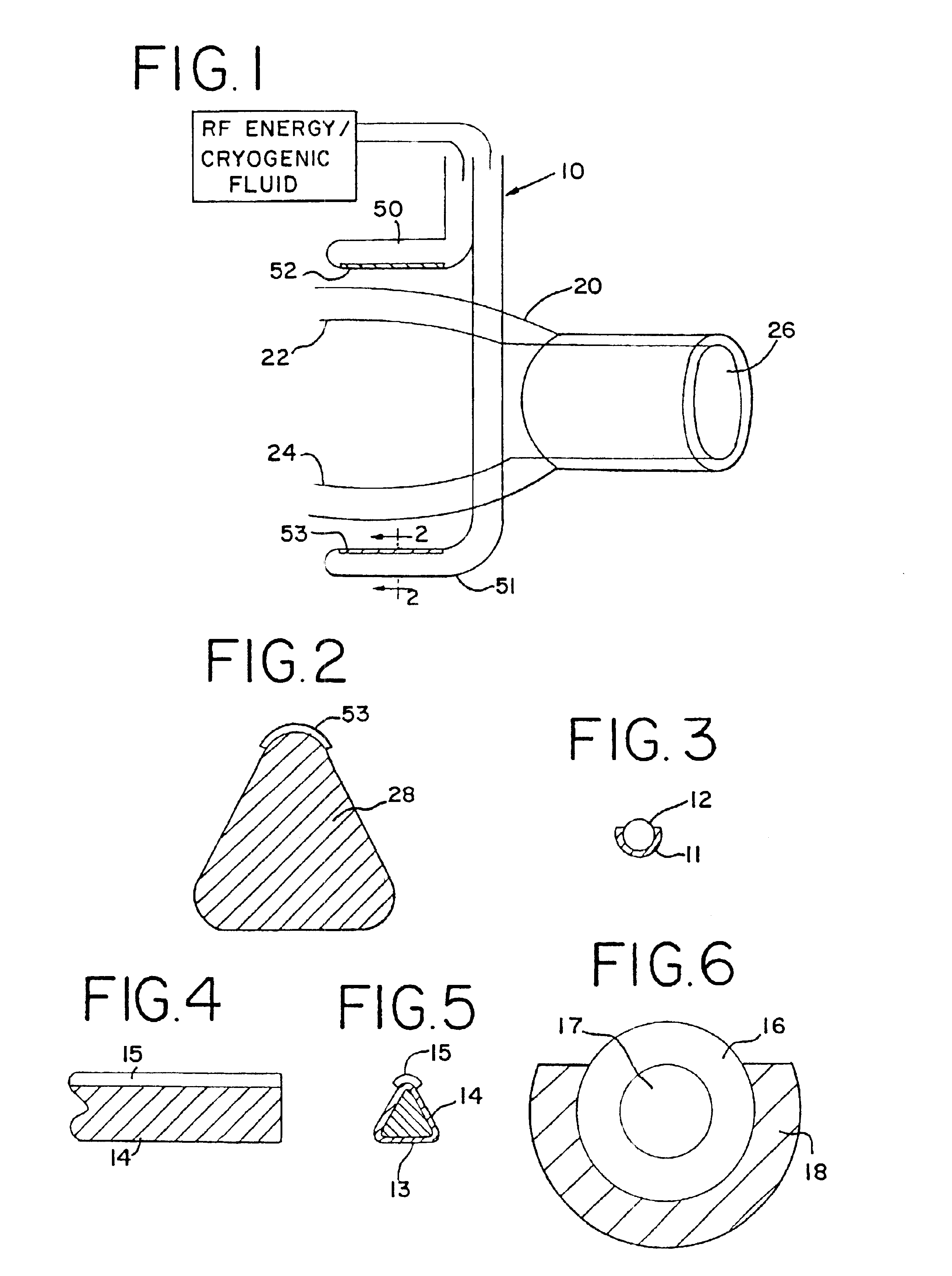

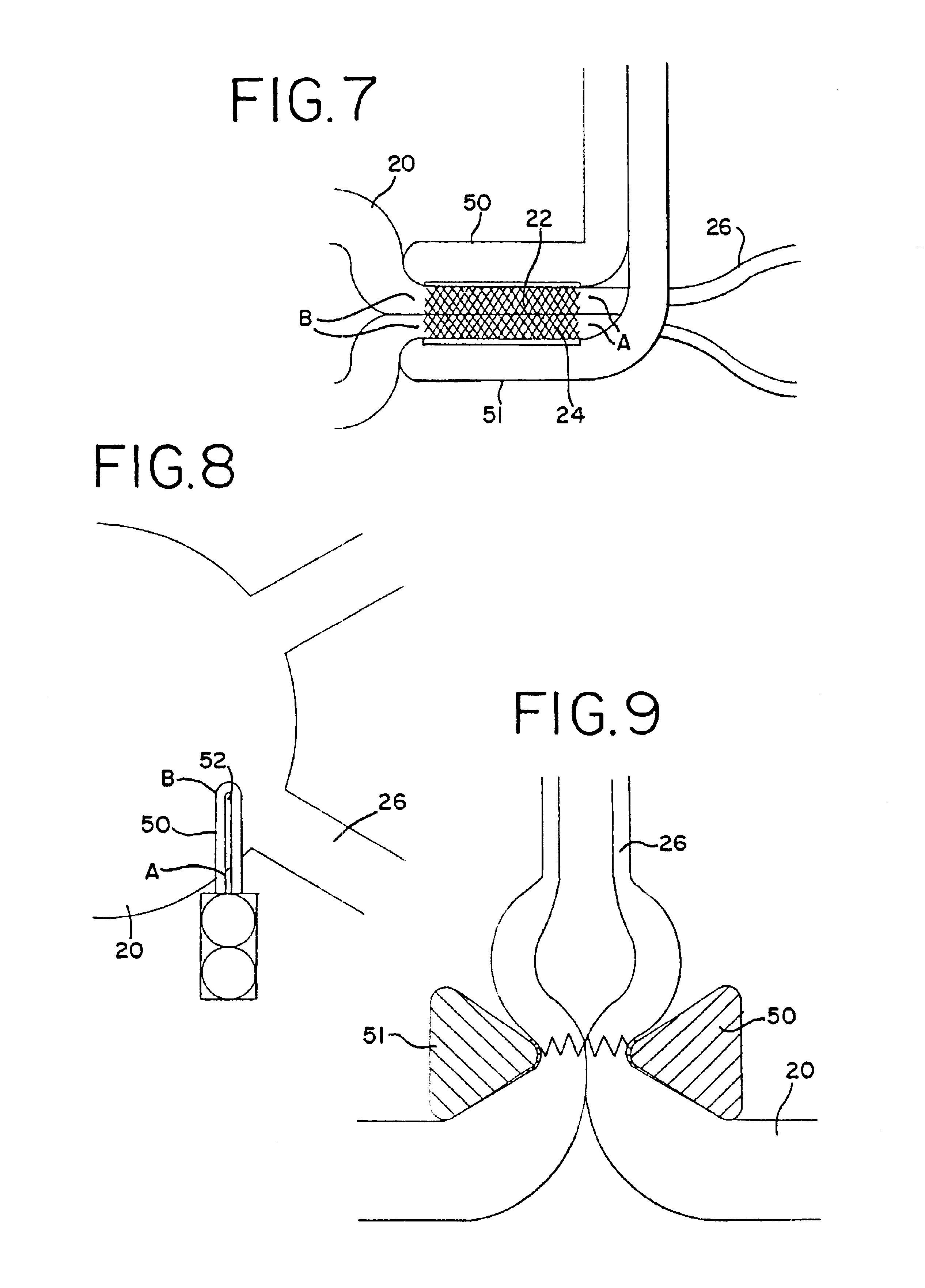

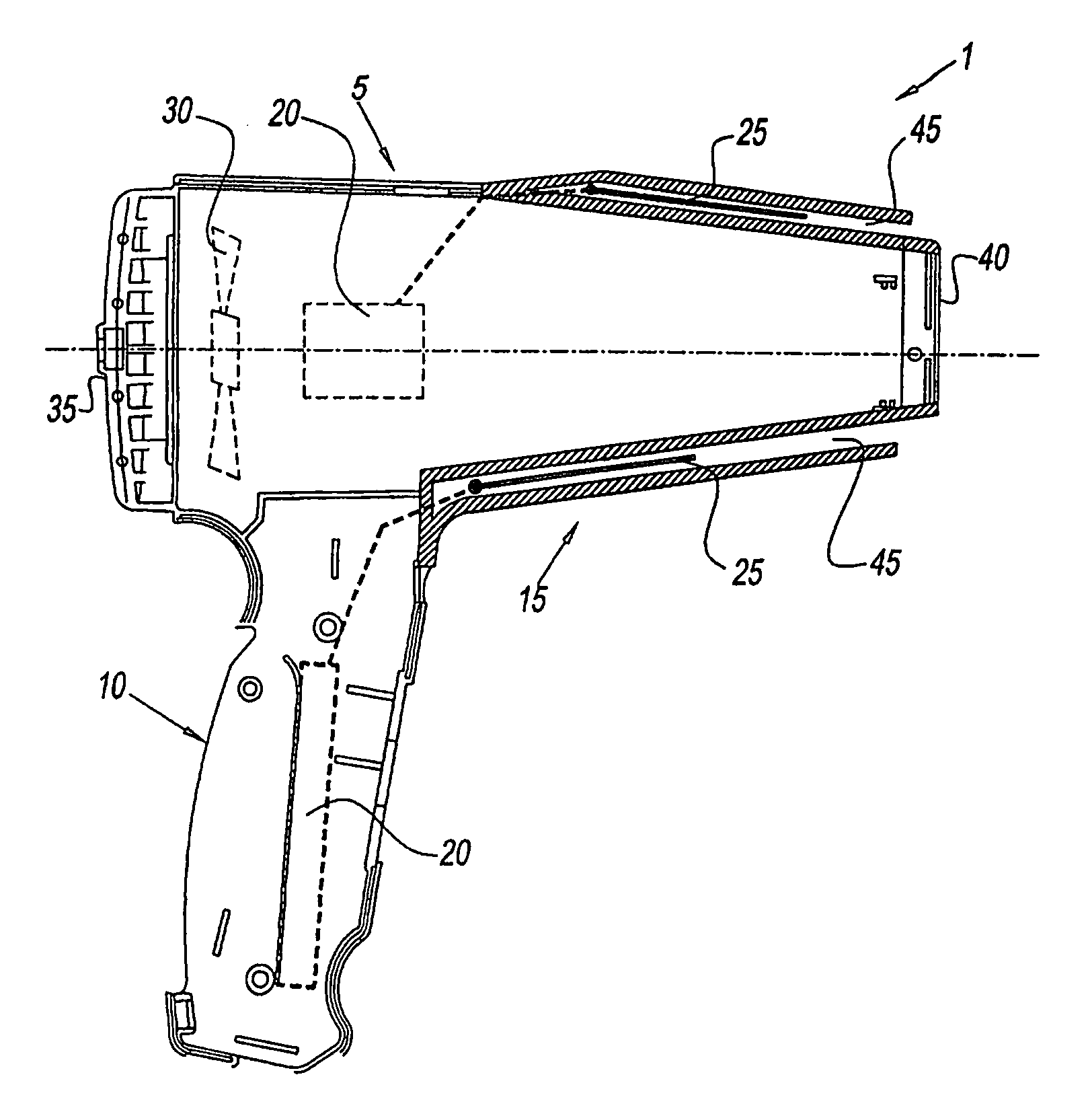

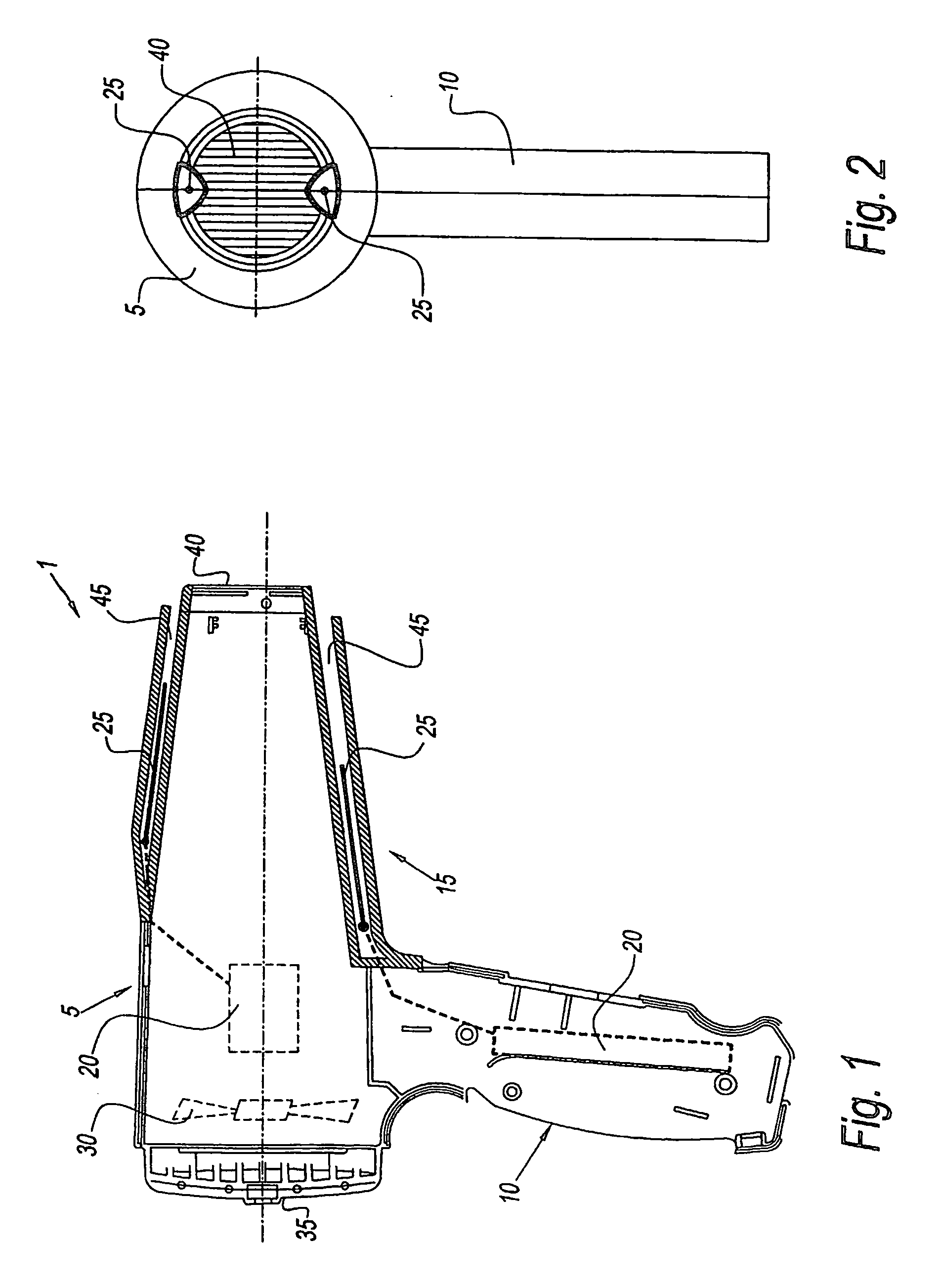

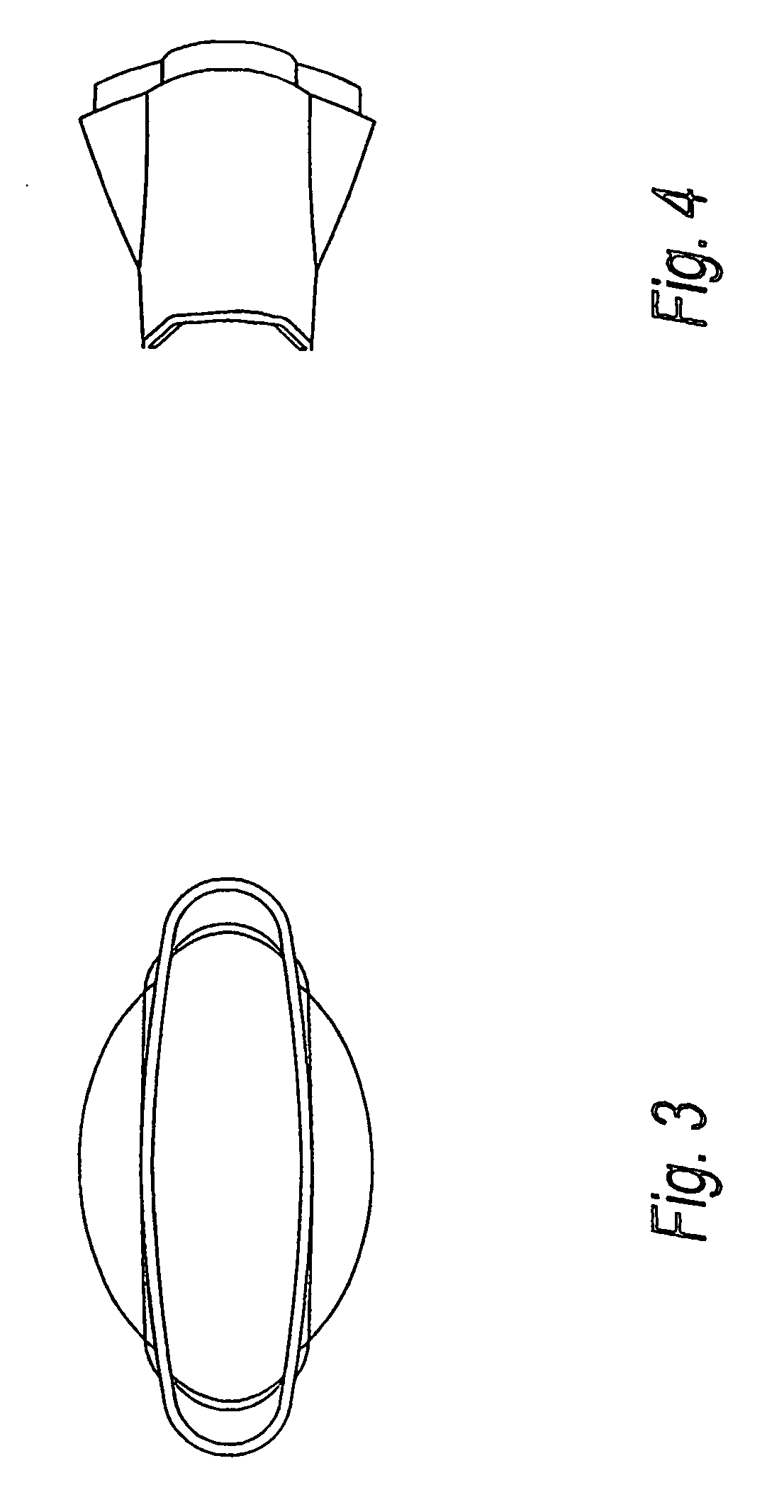

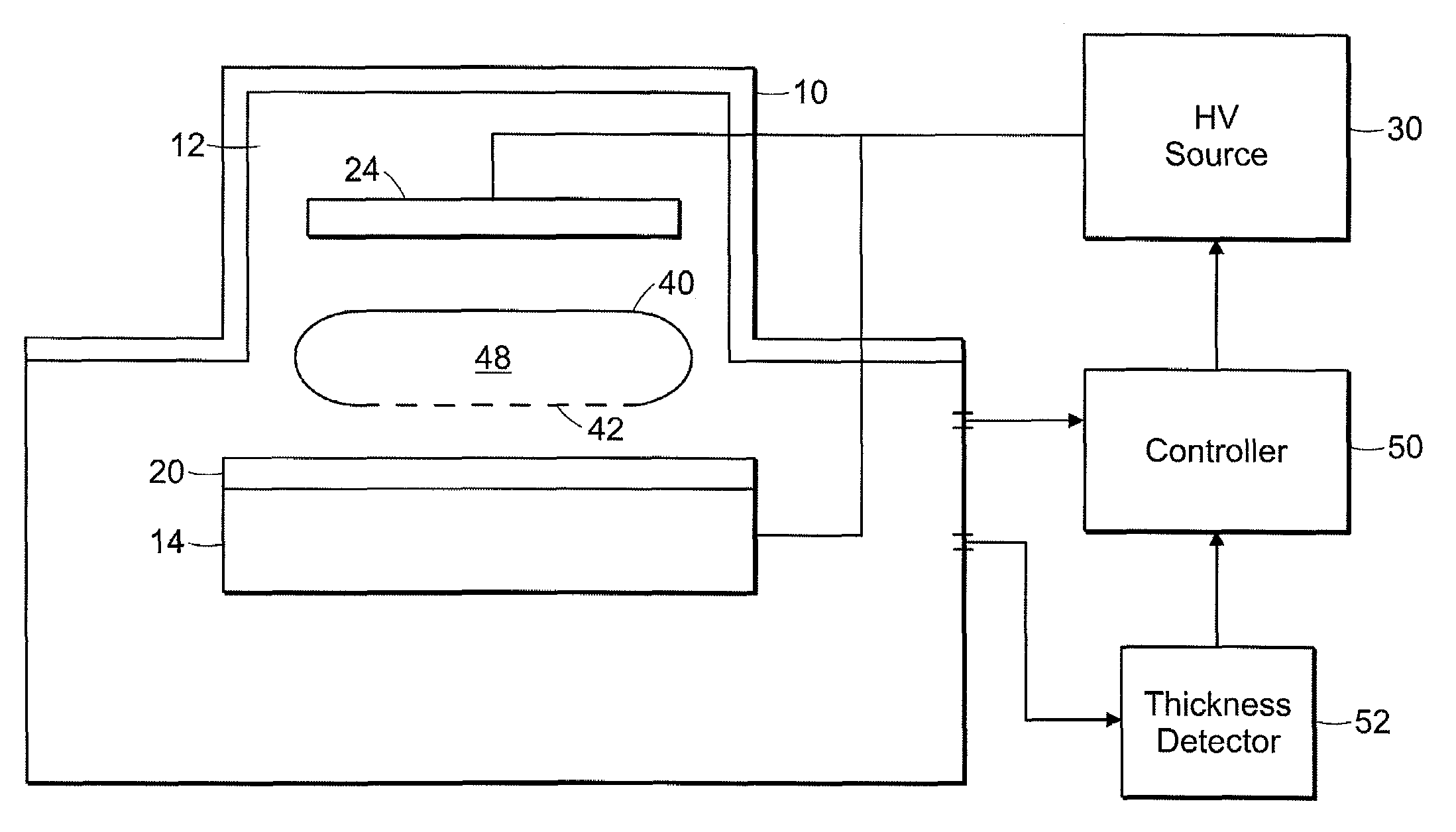

Method for transmural ablation

InactiveUS6896673B2Minimizes the tissue being ablatedVolume andDiagnostic recording/measuringSurgical instruments for heatingBiomedical engineeringOrgan of Corti

A method for transmural ablation using an instrument containing two electrodes or cryogenic probes. A clamping force is exerted on the two electrodes or probes such that the tissue of the hollow organ is clamped therebetween. Bipolar RF energy is then applied between the two electrodes, or the probes are cryogenically cooled, thus ablating the tissue therebetween. A monitoring device measures a suitable parameter, such as impedance or temperature, and indicates when the tissue between the electrodes has been fully ablated.

Owner:ATRICURE

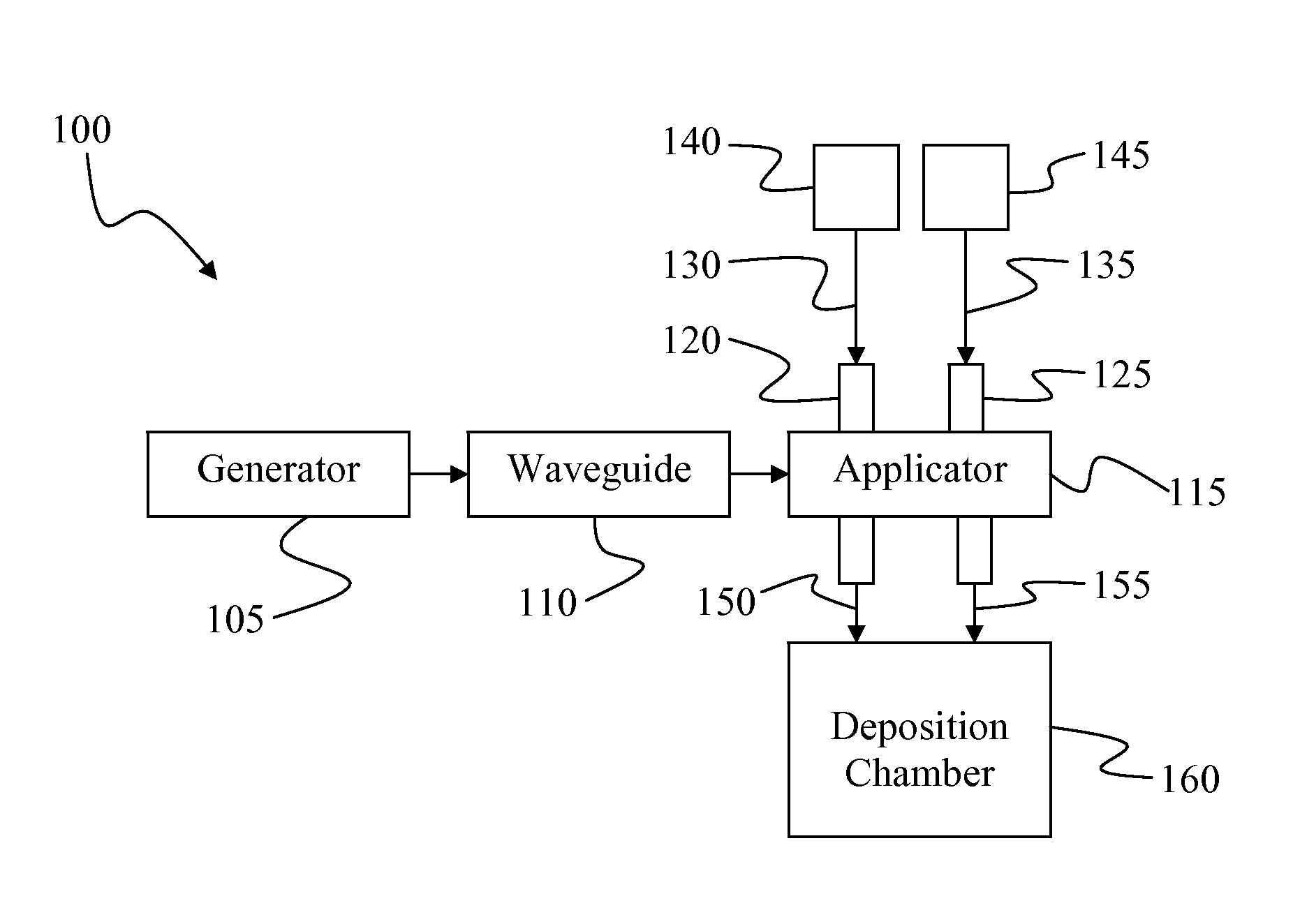

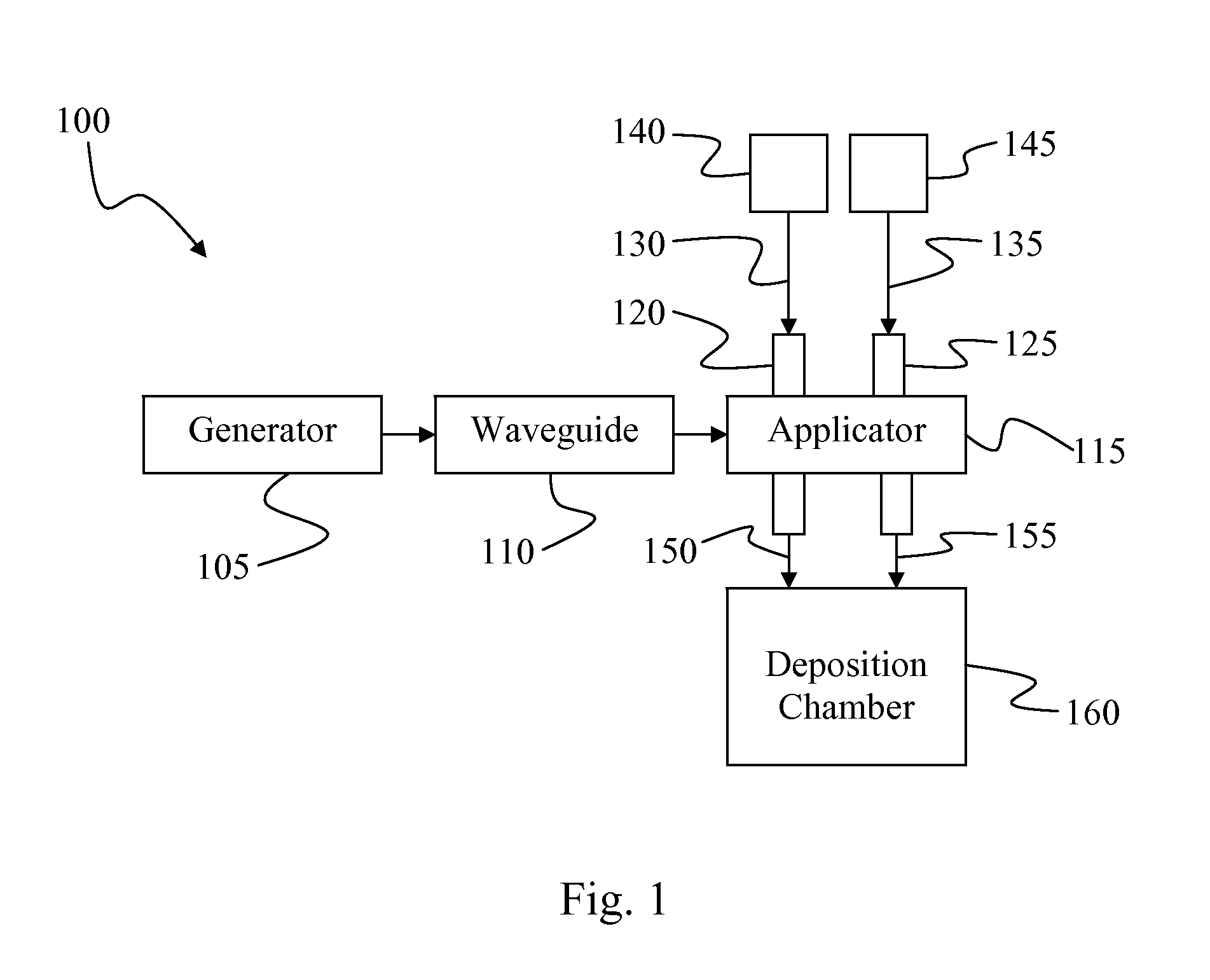

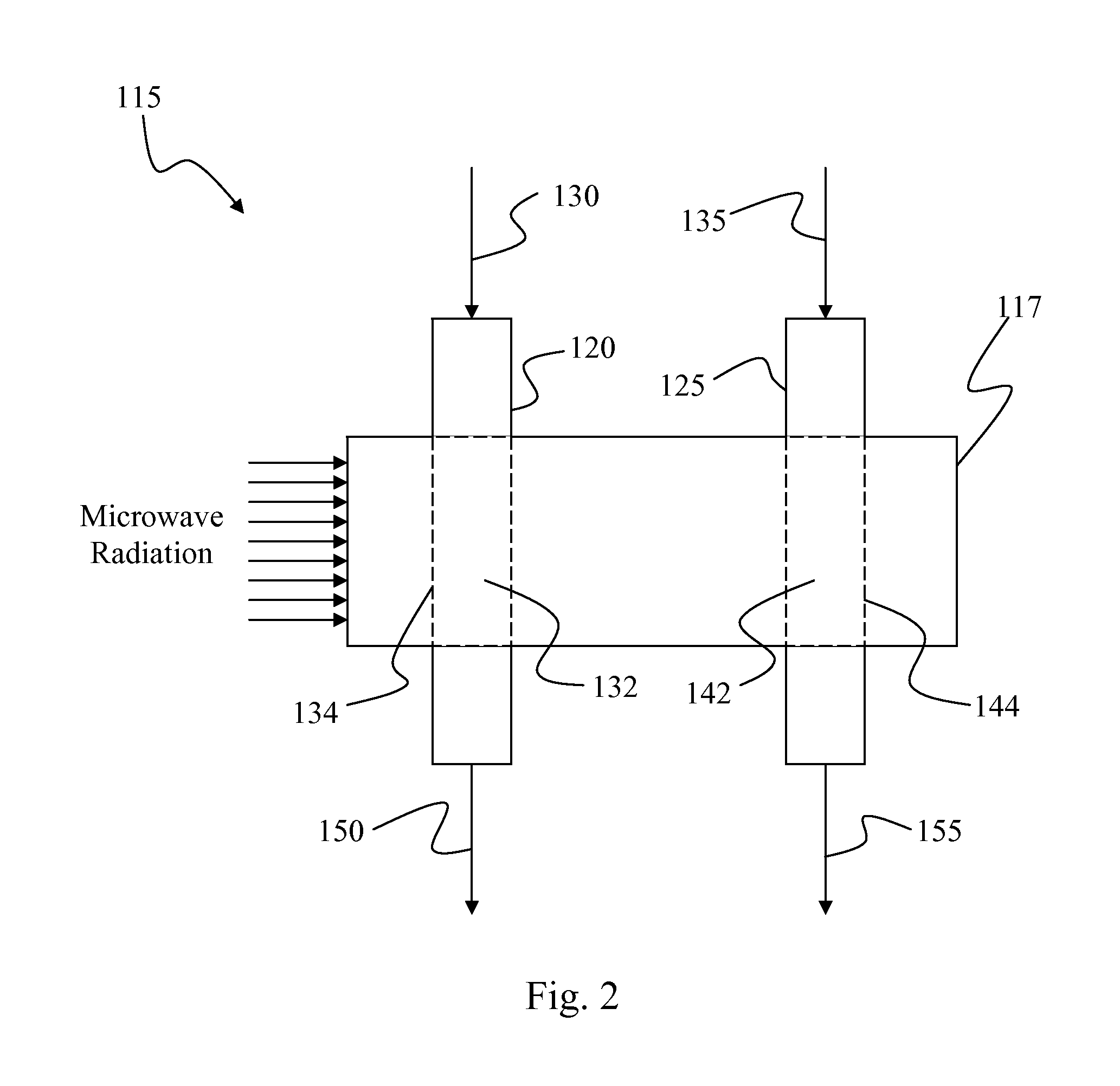

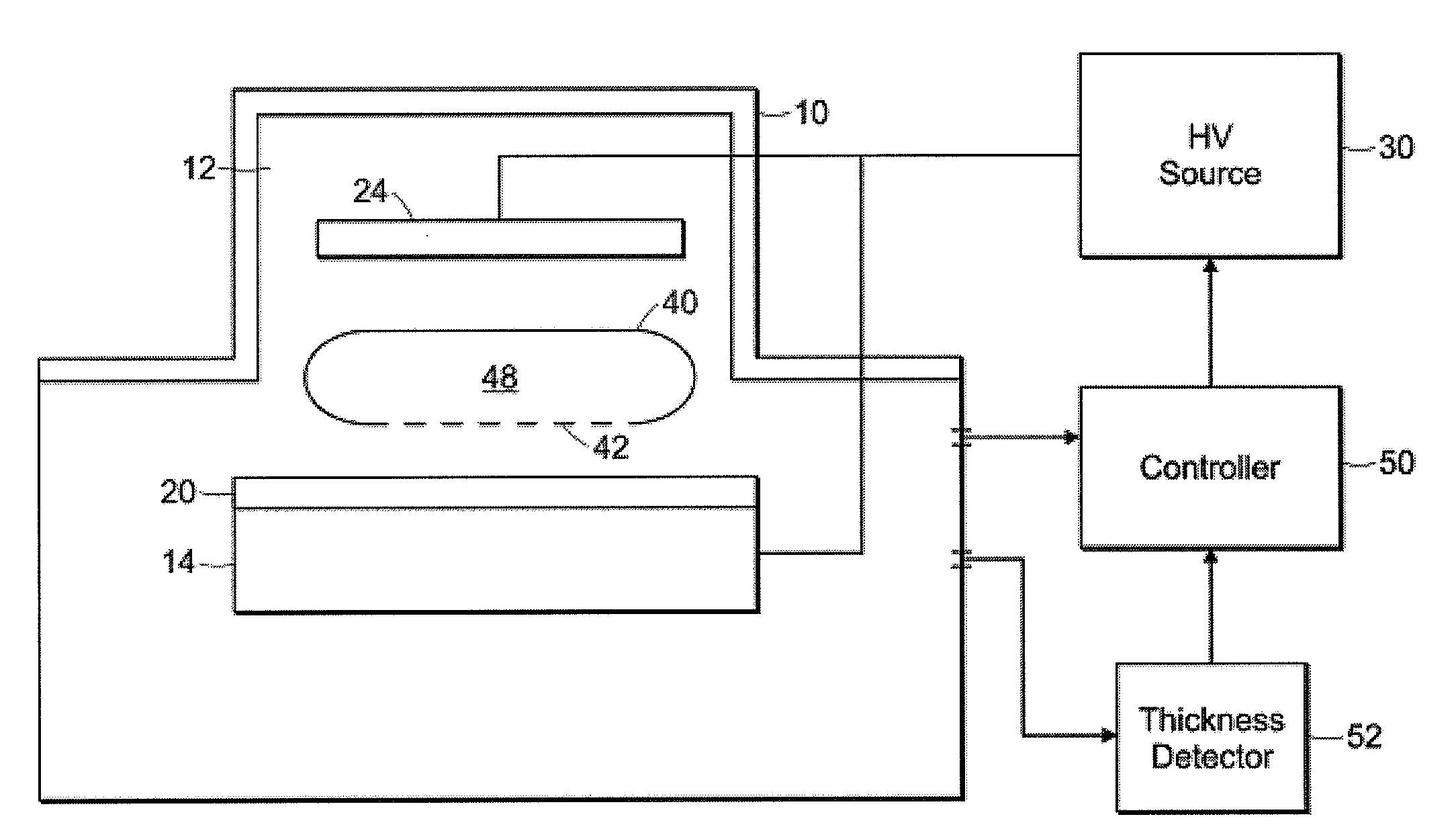

Plasma Deposition of Amorphous Semiconductors at Microwave Frequencies

InactiveUS20120040492A1Prevent and slow relaxationPrevent and slow and decayElectric discharge tubesFinal product manufacturePorosityPlasma deposition

Apparatus and method for plasma deposition of thin film photovoltaic materials at microwave frequencies. The apparatus avoids unintended deposition on windows or other microwave transmission elements that couple microwave energy to deposition species. The apparatus includes a microwave applicator with conduits passing therethrough that carry deposition species. The applicator transfers microwave energy to the deposition species to activate or energize them to a reactive state conducive to formation of a thin film material. The conduits physically isolate deposition species that would react or otherwise combine to form a thin film material at the point of microwave power transfer. The deposition species are separately energized and swept away from the point of power transfer to prevent thin film deposition. Suitable deposition species include precursors that contain silicon, germanium, fluorine, and / or hydrogen. The invention allows for the ultrafast formation of silicon-containing amorphous semiconductors that exhibit high mobility, low porosity, little or no Staebler-Wronski degradation, and low defect concentration.

Owner:OVSHINSKY TECH

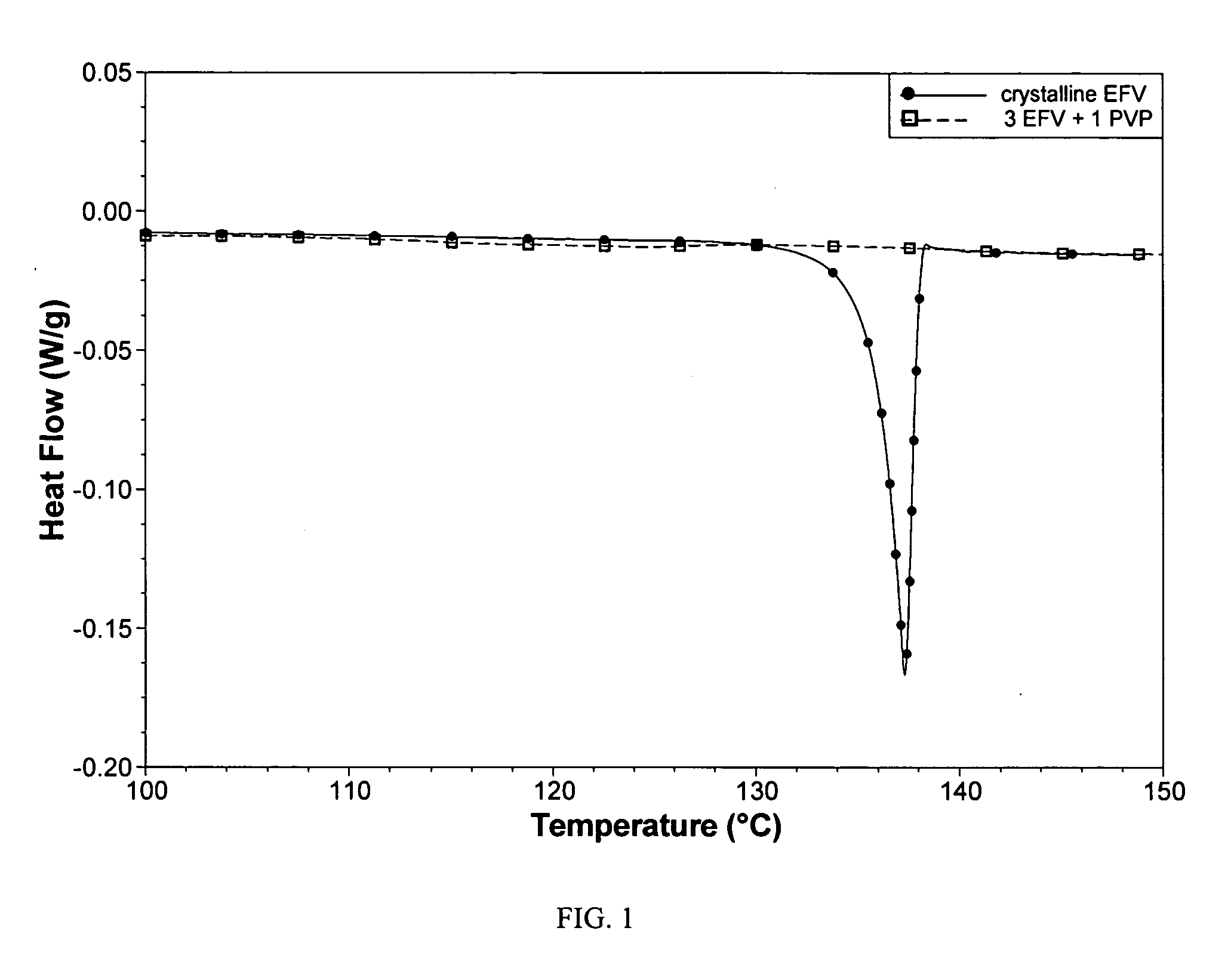

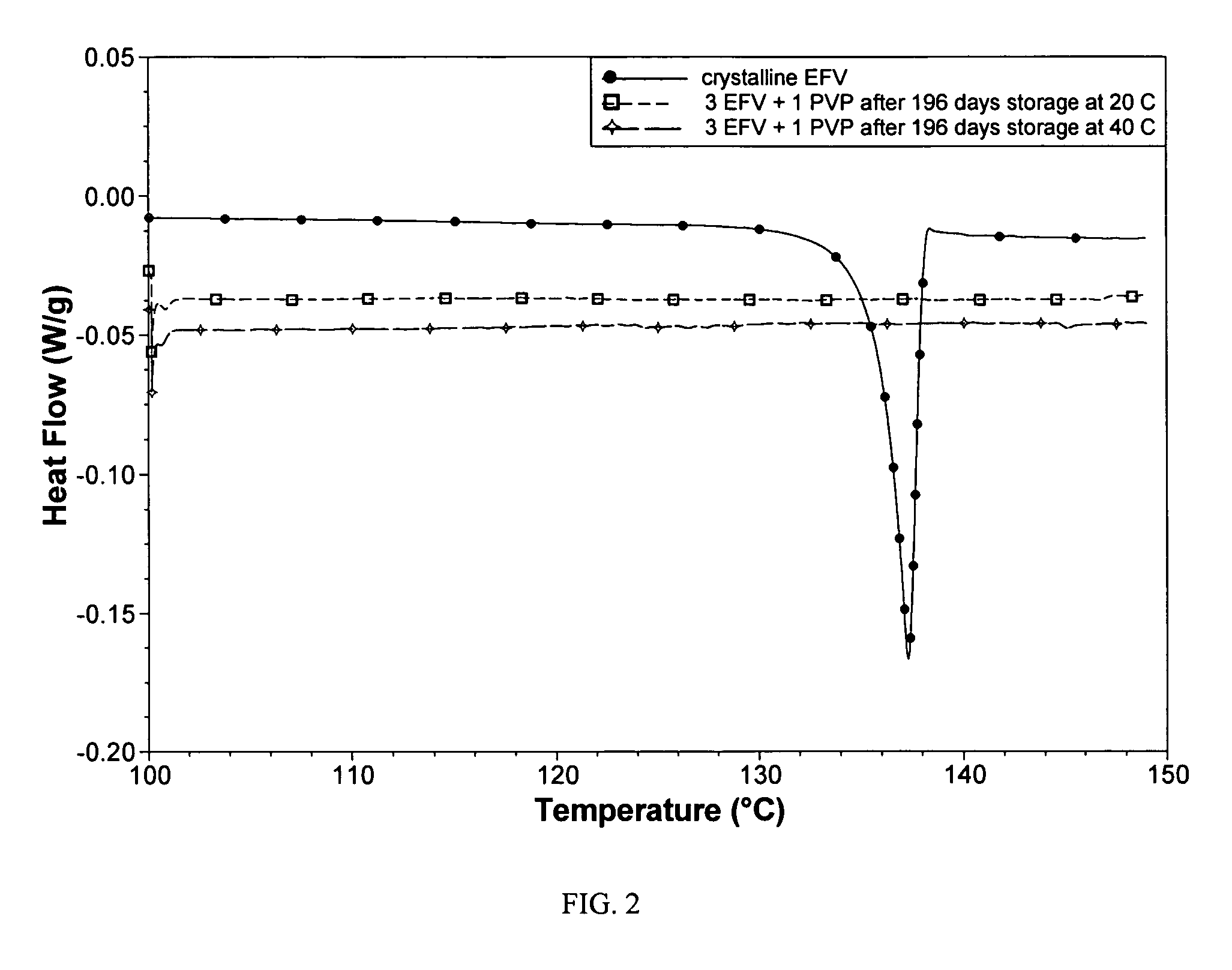

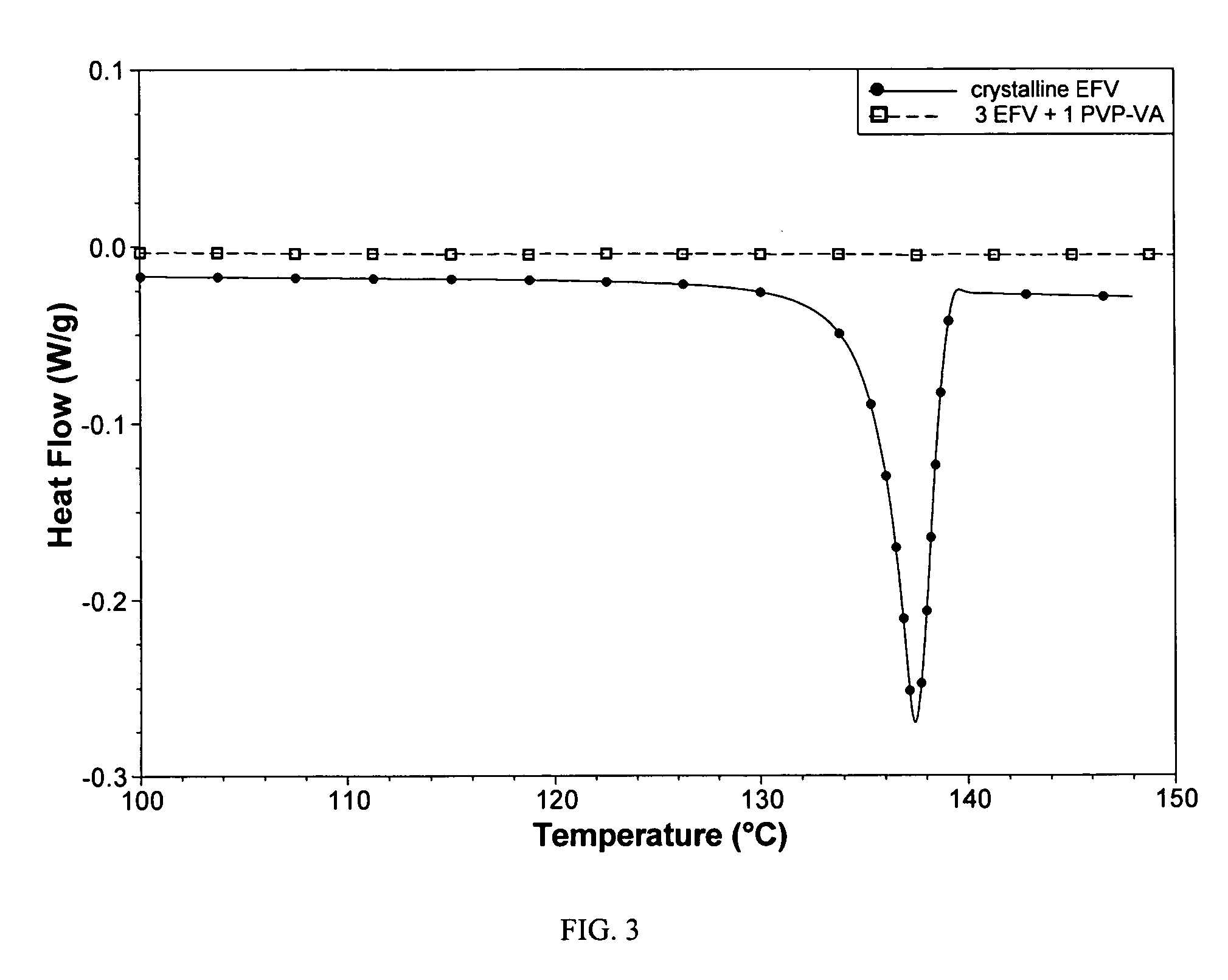

Amorphous efavirenz and the production thereof

InactiveUS20070026073A1Reducing residual solvent contentIncrease in bulk powder densityOrganic active ingredientsPowder deliverySolubilityPolymer chemistry

Efavirenz compositions of enhanced bioavailability are described that contain efavirenz with at least one solubility-enhancing polymer. Described methods to produce the bioenhanced products comprise solvent spray drying. One aspect of the method includes the steps of providing a mixture comprising efavirenz, a solubility-enhancing polymer and a single solvent, a solvent blend or solvent / non-solvent blend removing and then evaporating the mixture to form amorphous efavirenz.

Owner:ISP INVESTMENTS INC

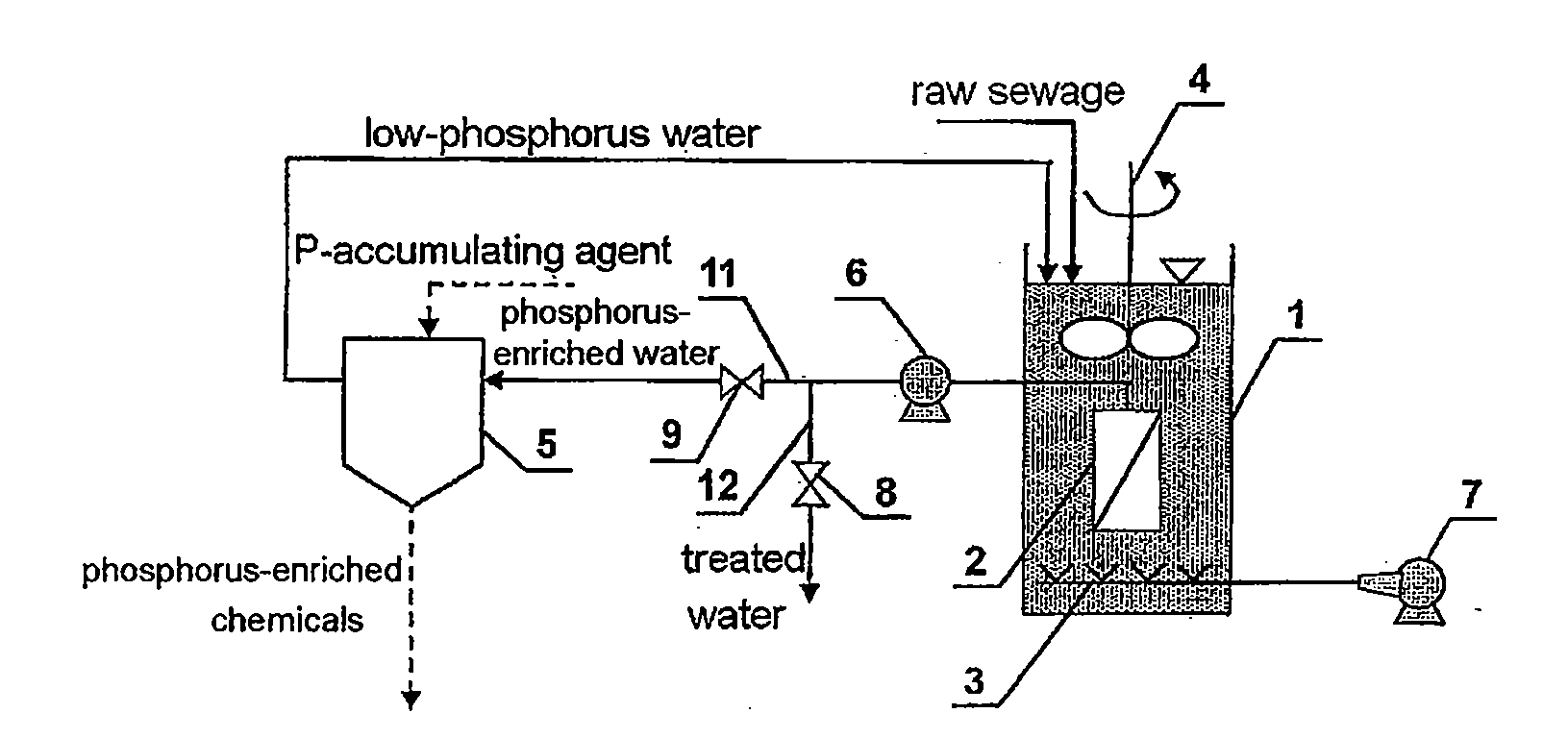

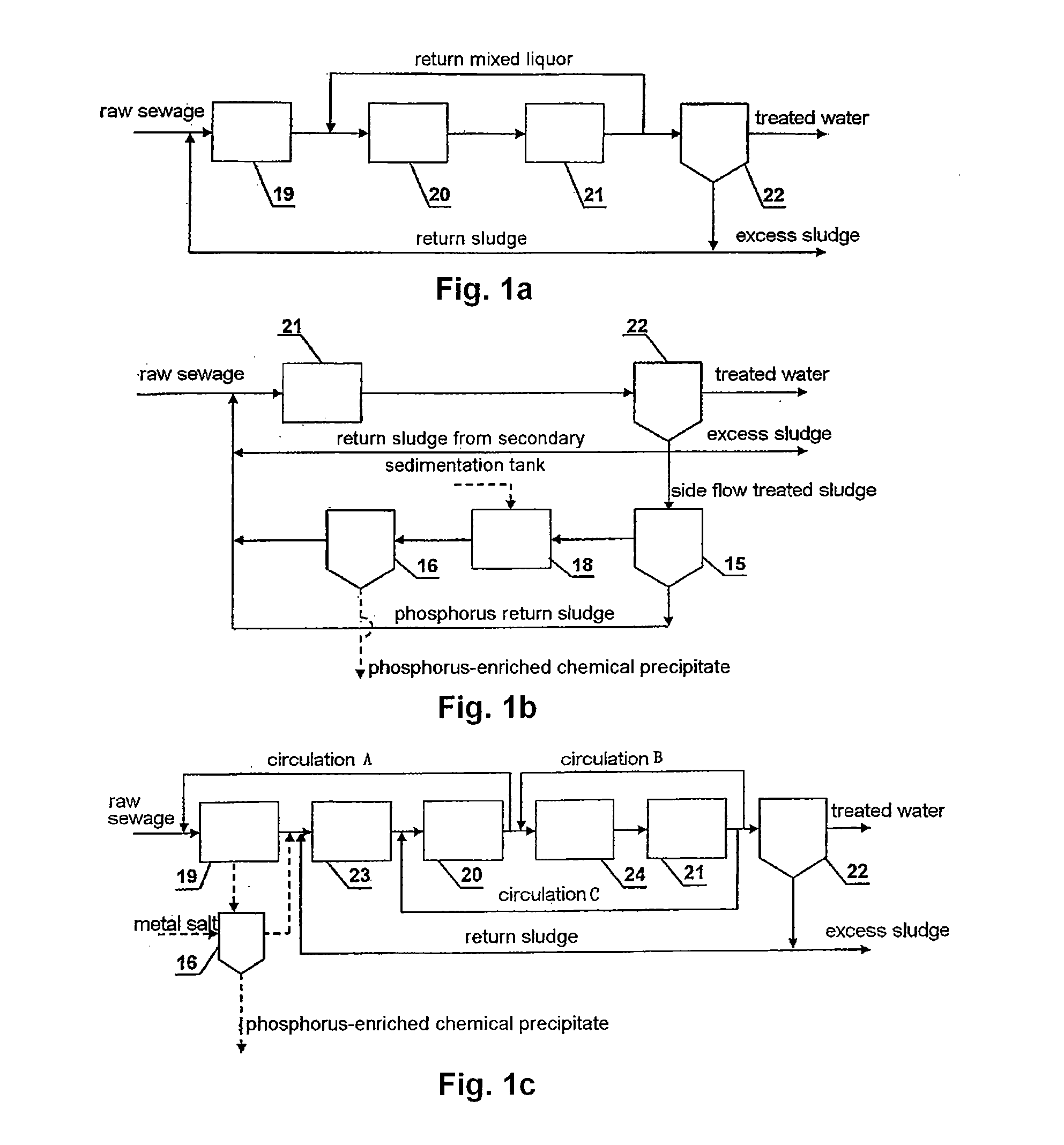

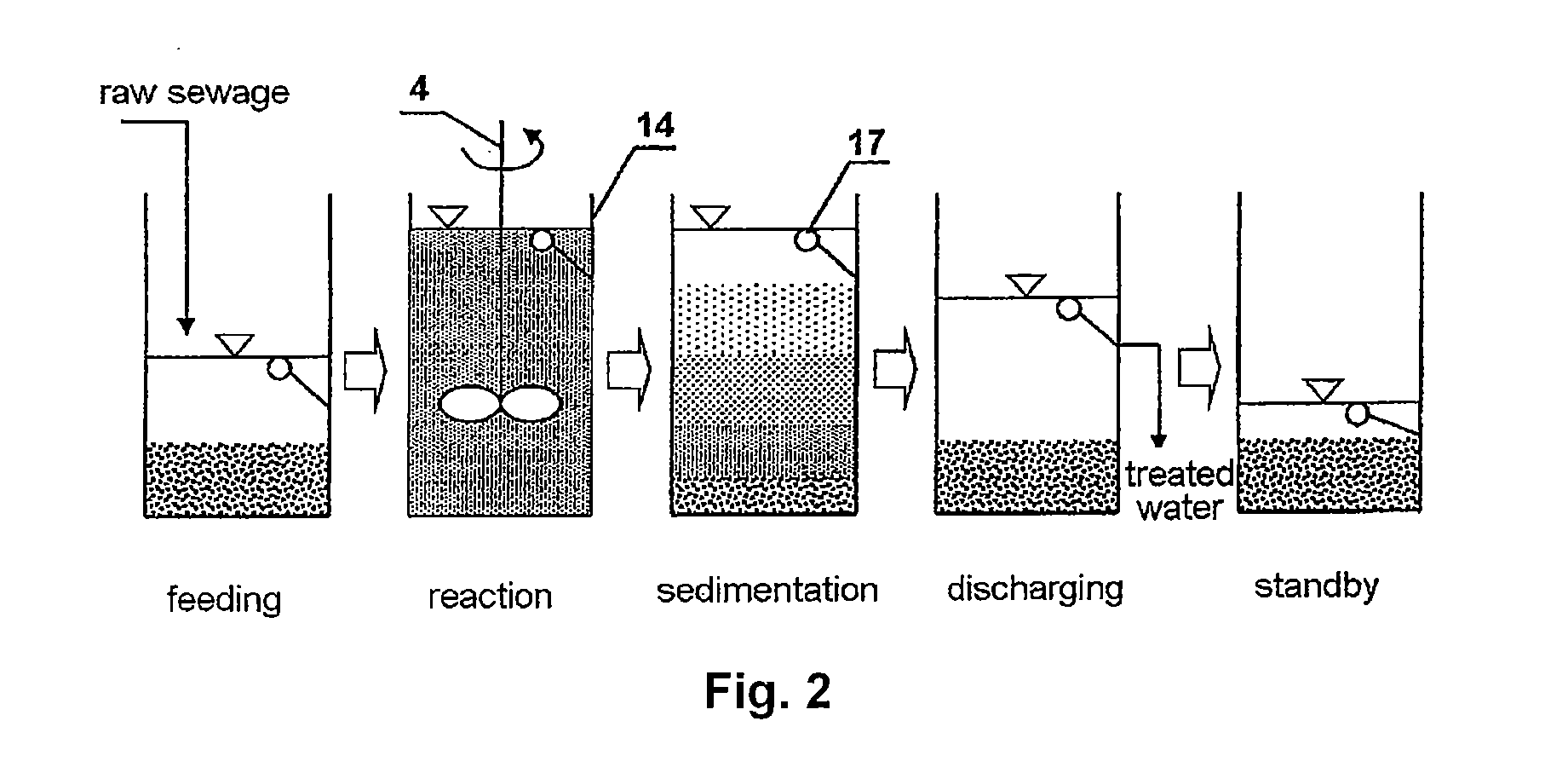

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

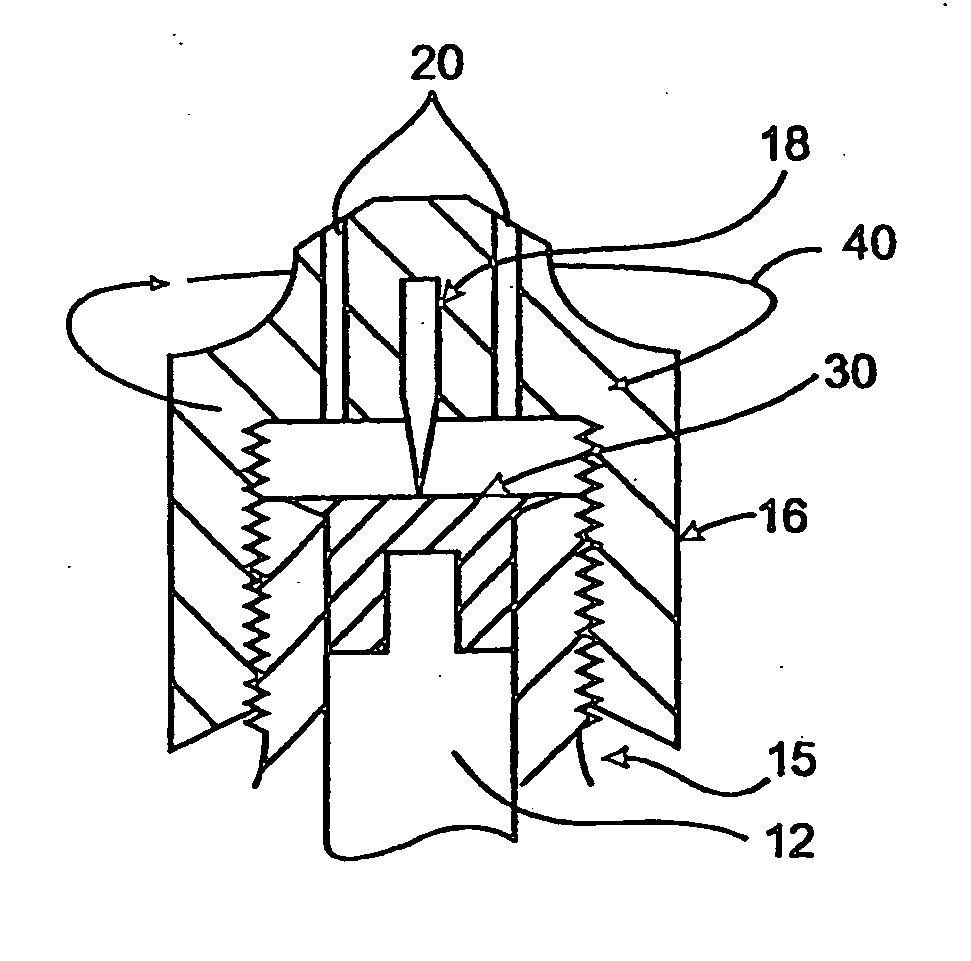

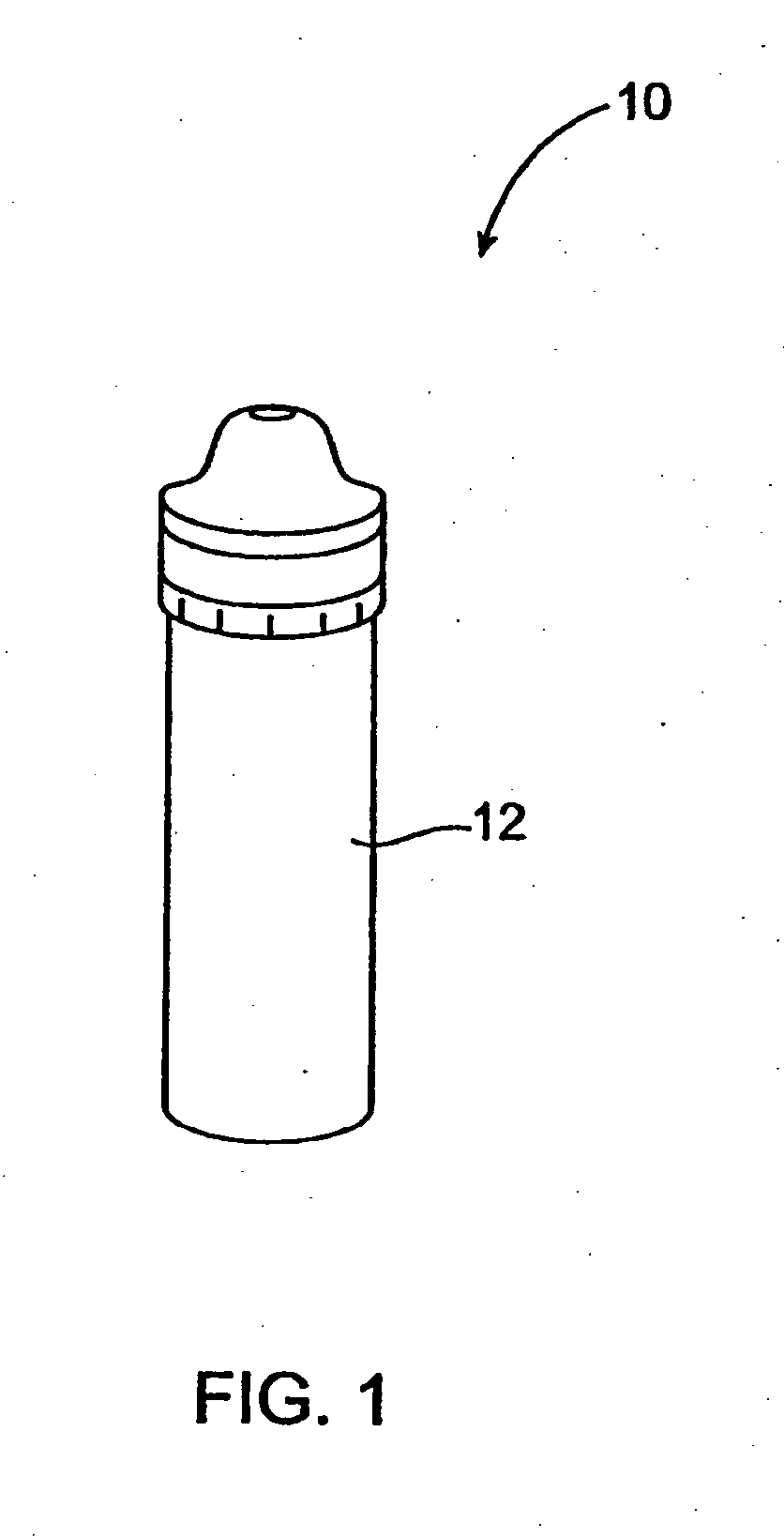

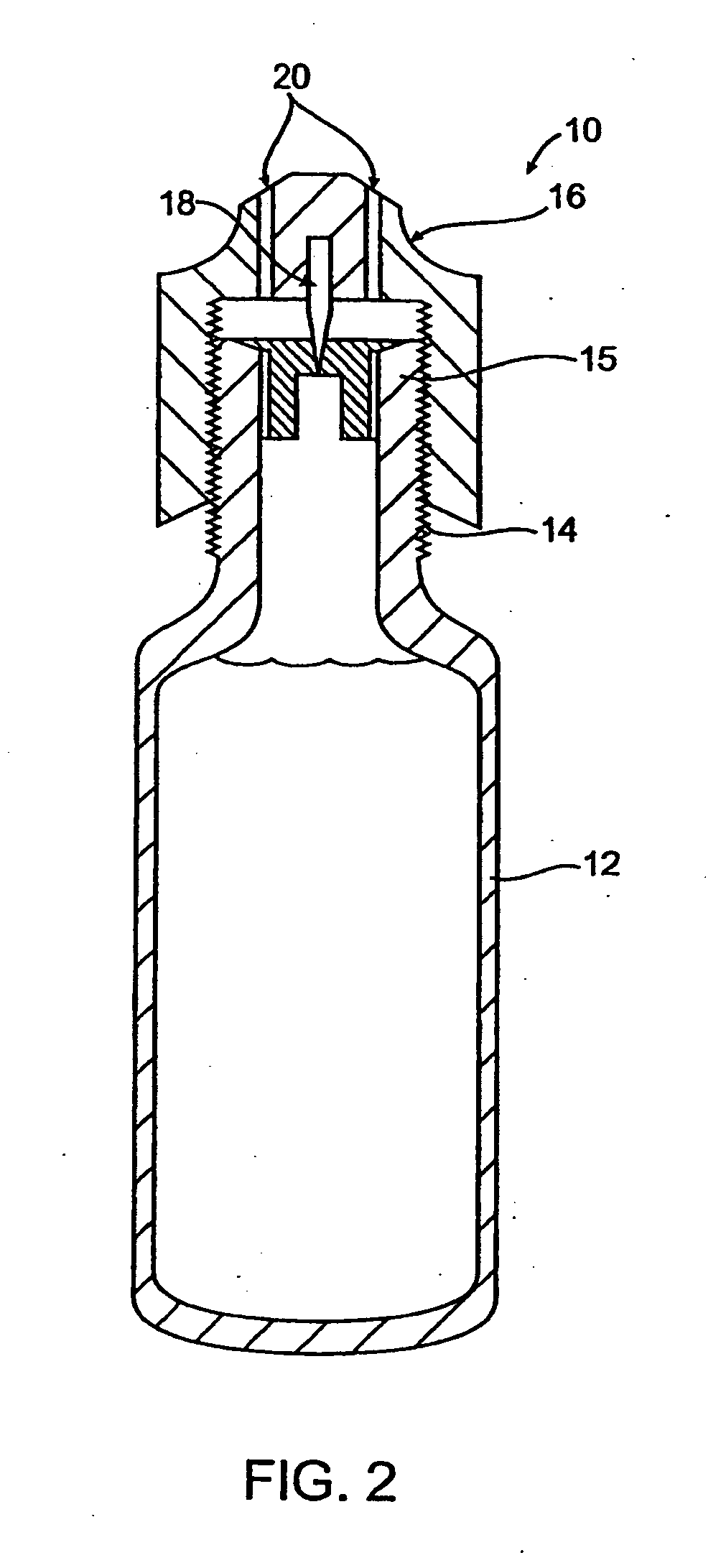

Methods and apparatus for relieving headaches, rhinitis and other common ailments

InactiveUS20050279350A1Relieve symptomsQuick reliefOrganic active ingredientsSenses disorderHigh concentrationDisease

Apparatus, methods, and kits for treating symptoms associated with common ailments, such as headaches, rhinitis, asthma, epilepsy, nervous disorders and the like, are provided. The apparatus comprises dispensers for carbon dioxide and other therapeutic gases. The methods comprise delivering small volumes of these gases to patients in a manner where the gas infuses into a body region in order to bathe the mucous membranes therein. It has been found that even very short exposure of patients to small volumes and high concentrations of such gases can provide significant relief from symptoms.

Owner:CAPNIA INC

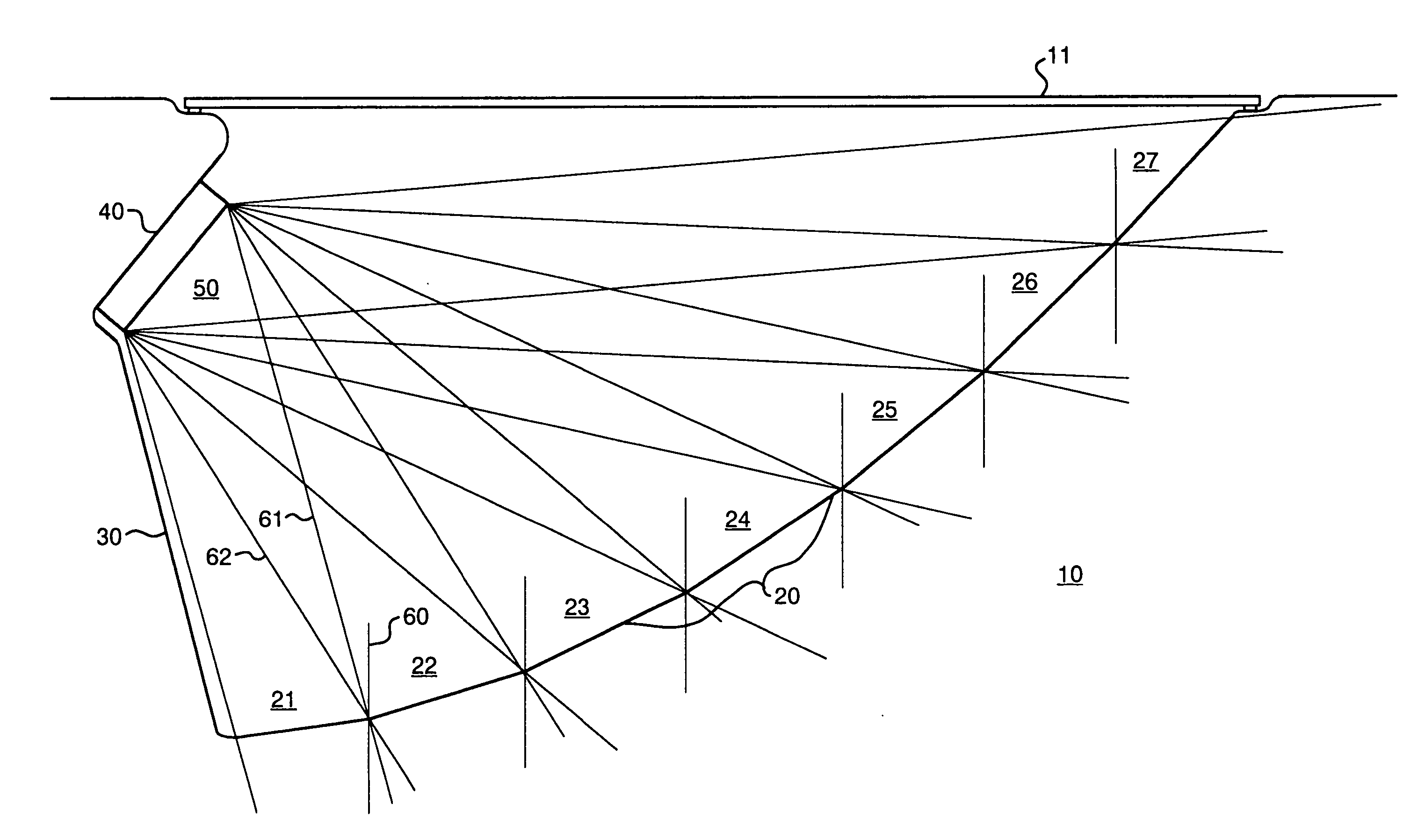

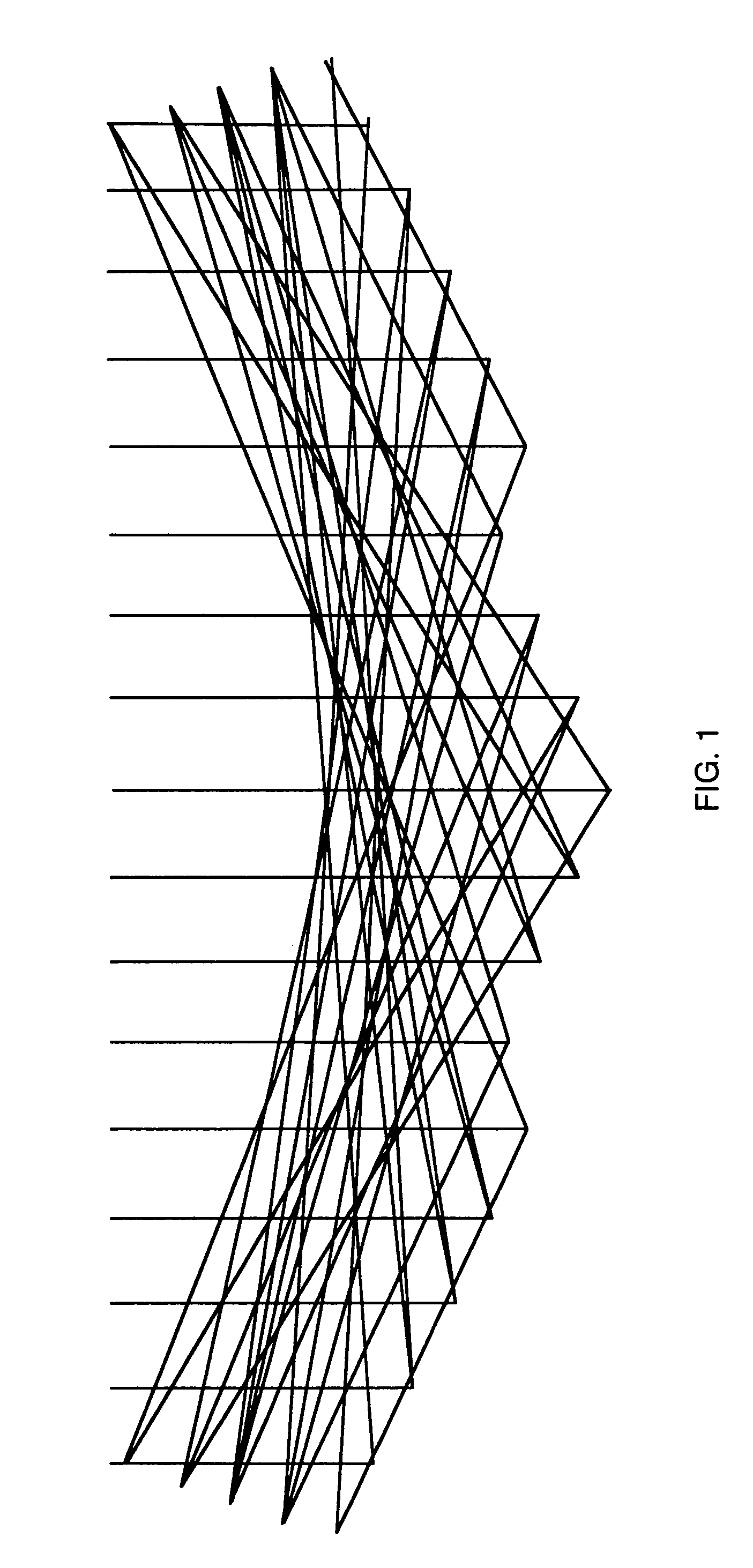

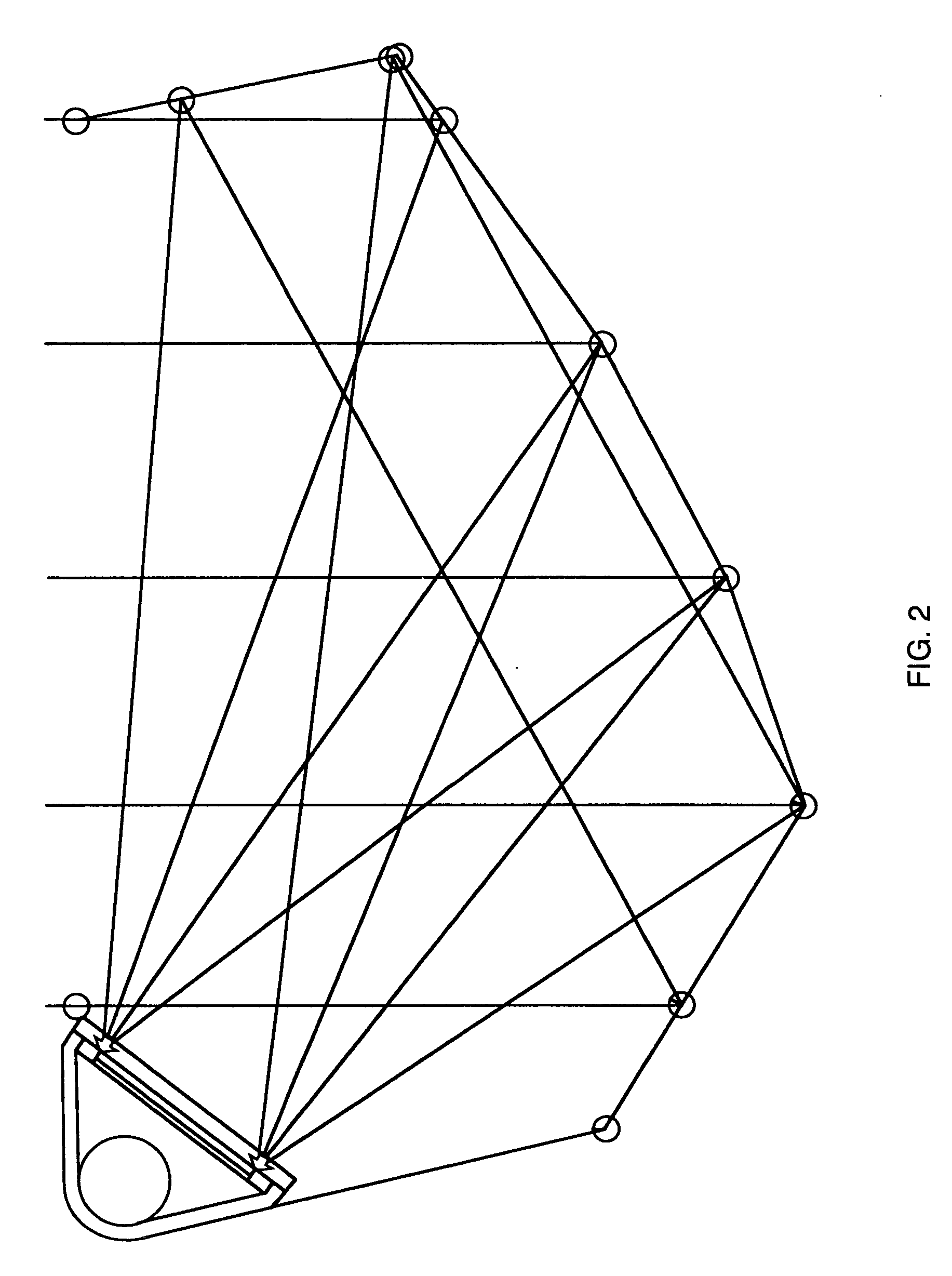

Reflecting photonic concentrator

InactiveUS20060249143A1Improve device efficiencyCompetitive costSolar heating energySolar heat collector controllersFresnel lensHigh concentration

A linearly reflecting trough concentrator that receives spectral energy, preferably visible and near-infrared solar energy spectra, and linearly reflects that energy onto a smaller area on one side of the device, thereby concentrating the energy. The linearly reflecting trough concentrator has the geometry of a single slope-relief interval in a Fresnel lens, and in preferred embodiment comprises an array of heliostatic facets connected continuously to form the base of the trough, a non-imaging focal point where a photonic receiver is located, and a relief surface to connect the heliostatic array to the receiver location. When spectral energy enters the trough at an angle normal to the array's horizontal reference, the concentrator linearly reflects energy to one side of the device where an energy receiver is mounted. The concentrator comprises an array of heliostats oriented according to the negative profile of two interleaved linear Fresnel lens, where the slope of one is the relief of the other. The concentrator reflects energy above and to each side of the device. Optionally using a reflecting projector on one side of the device, energy is then doubly concentrated to the other side. The device offers higher concentration ratios with an equivalent trough depth than prior art reflective trough concentrators. The device requires less depth and offers a lower-profile than prior art reflecting concentrators with the same degree of concentration.

Owner:ASCENDANT ENERGY COMPANY

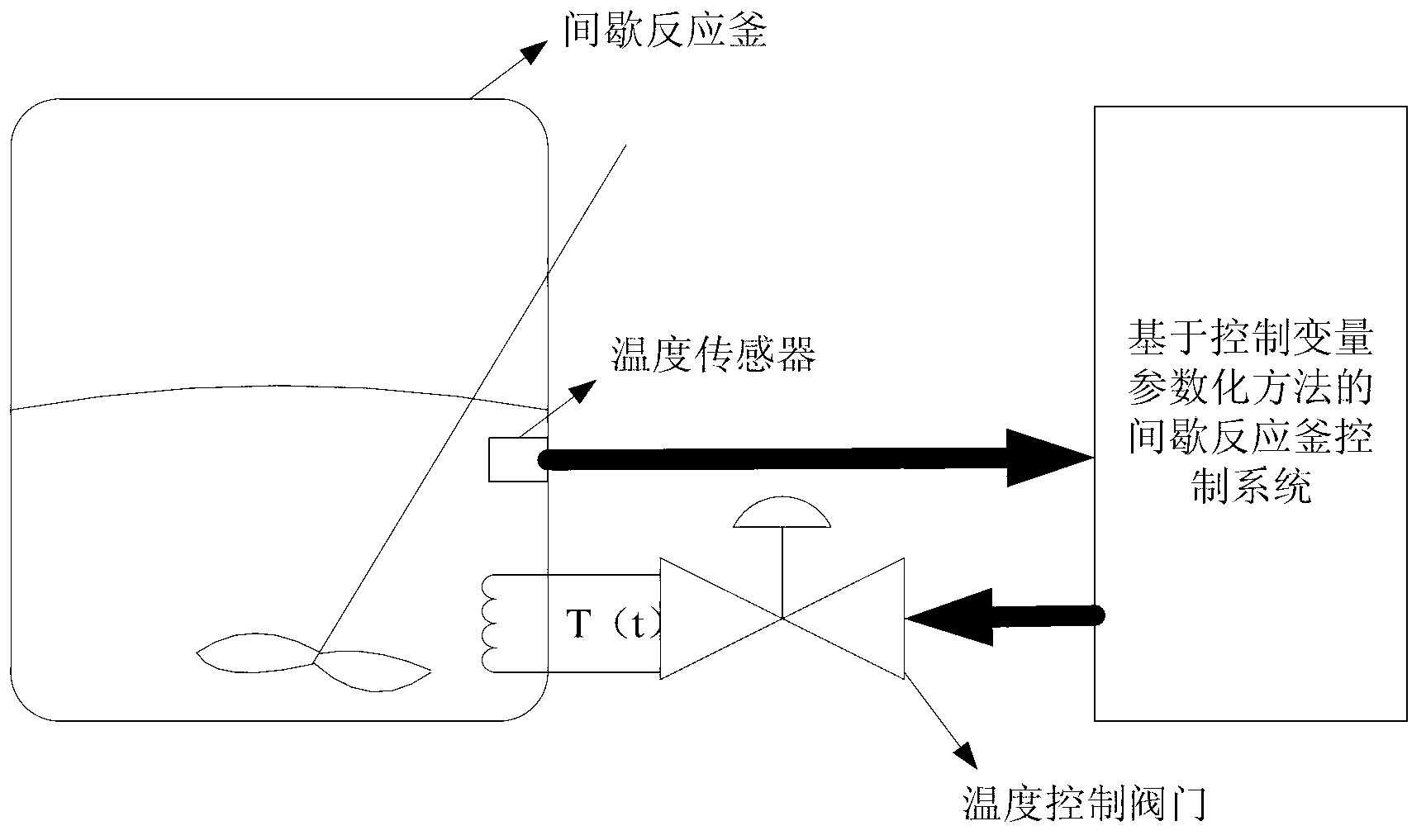

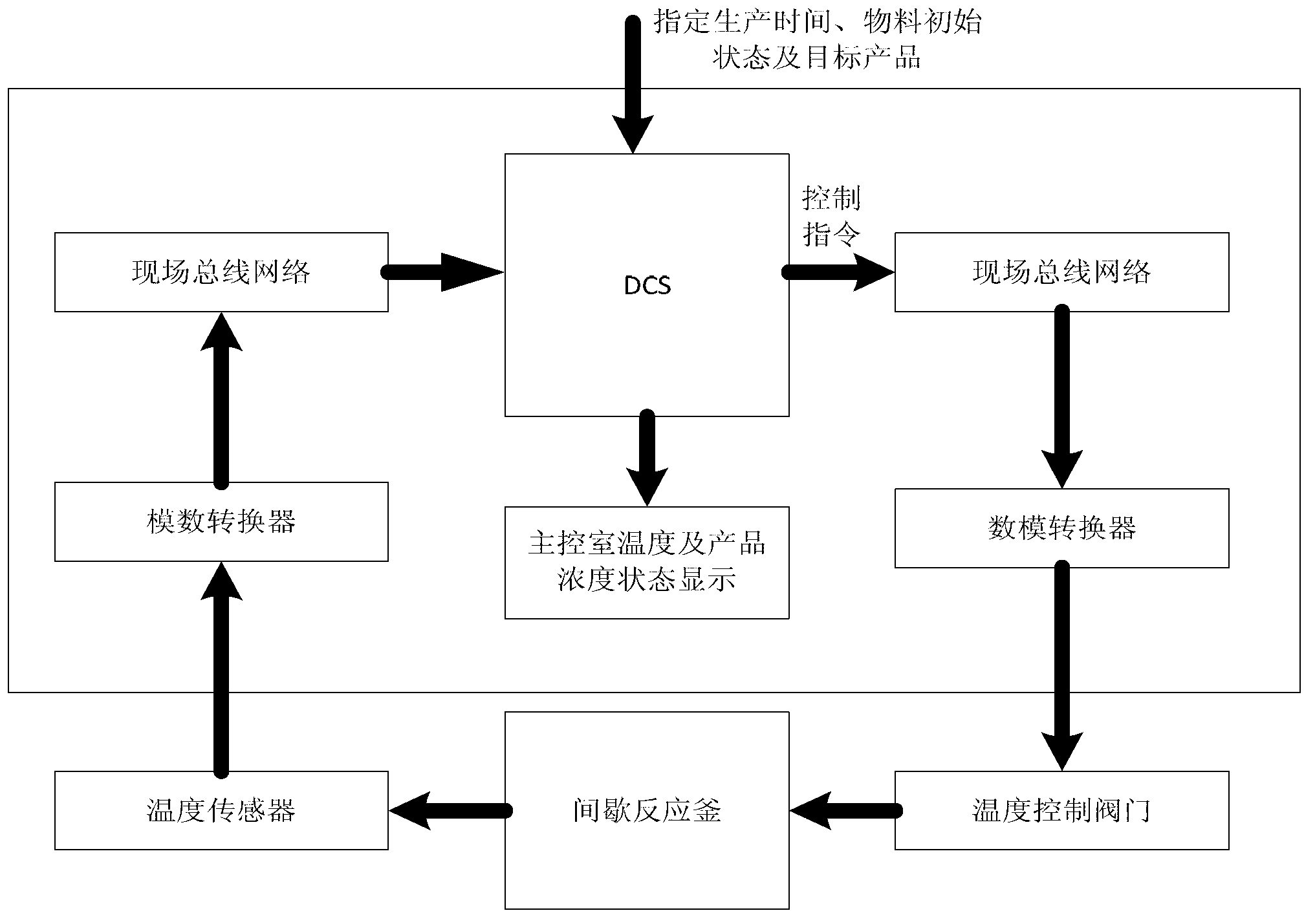

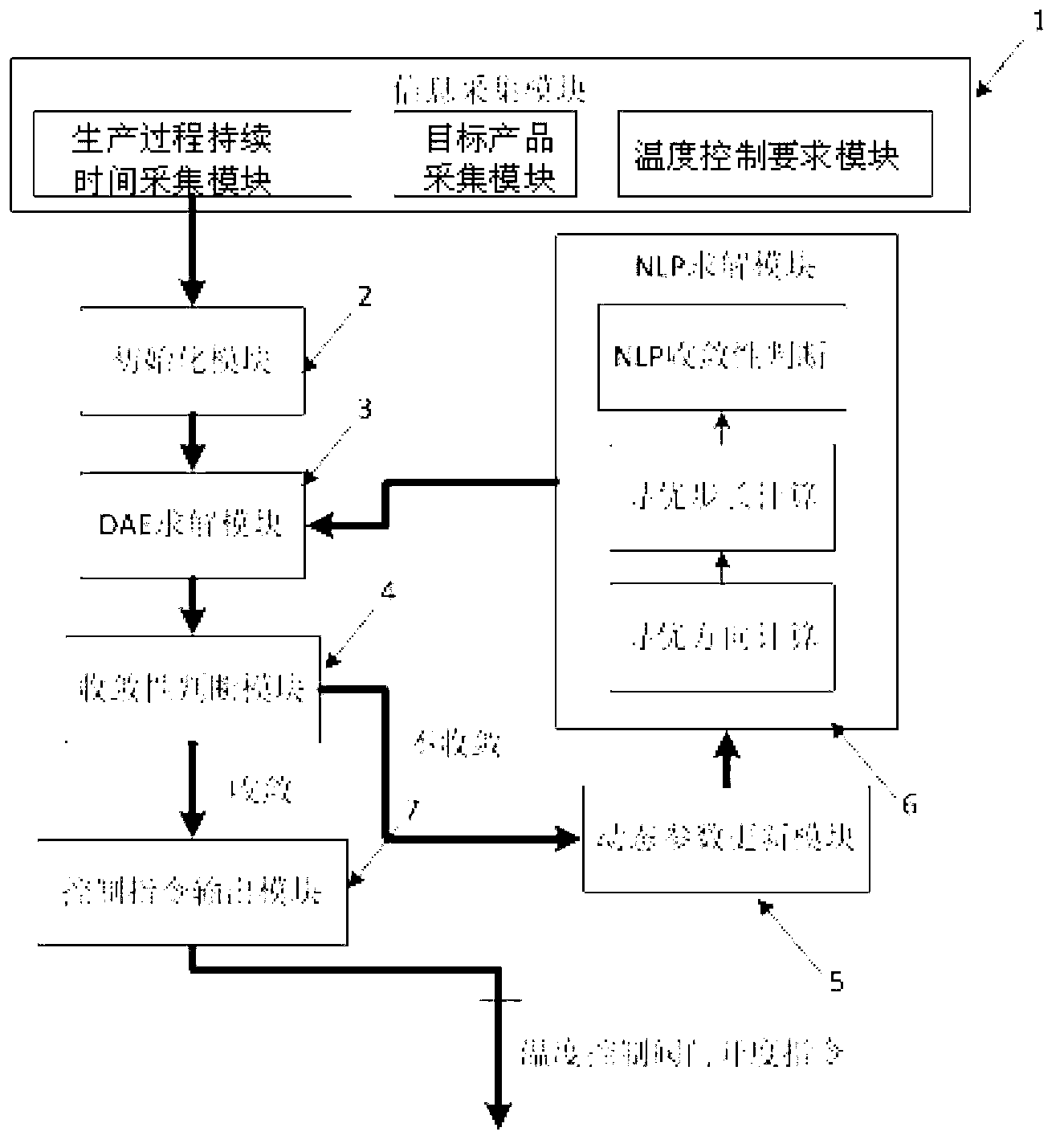

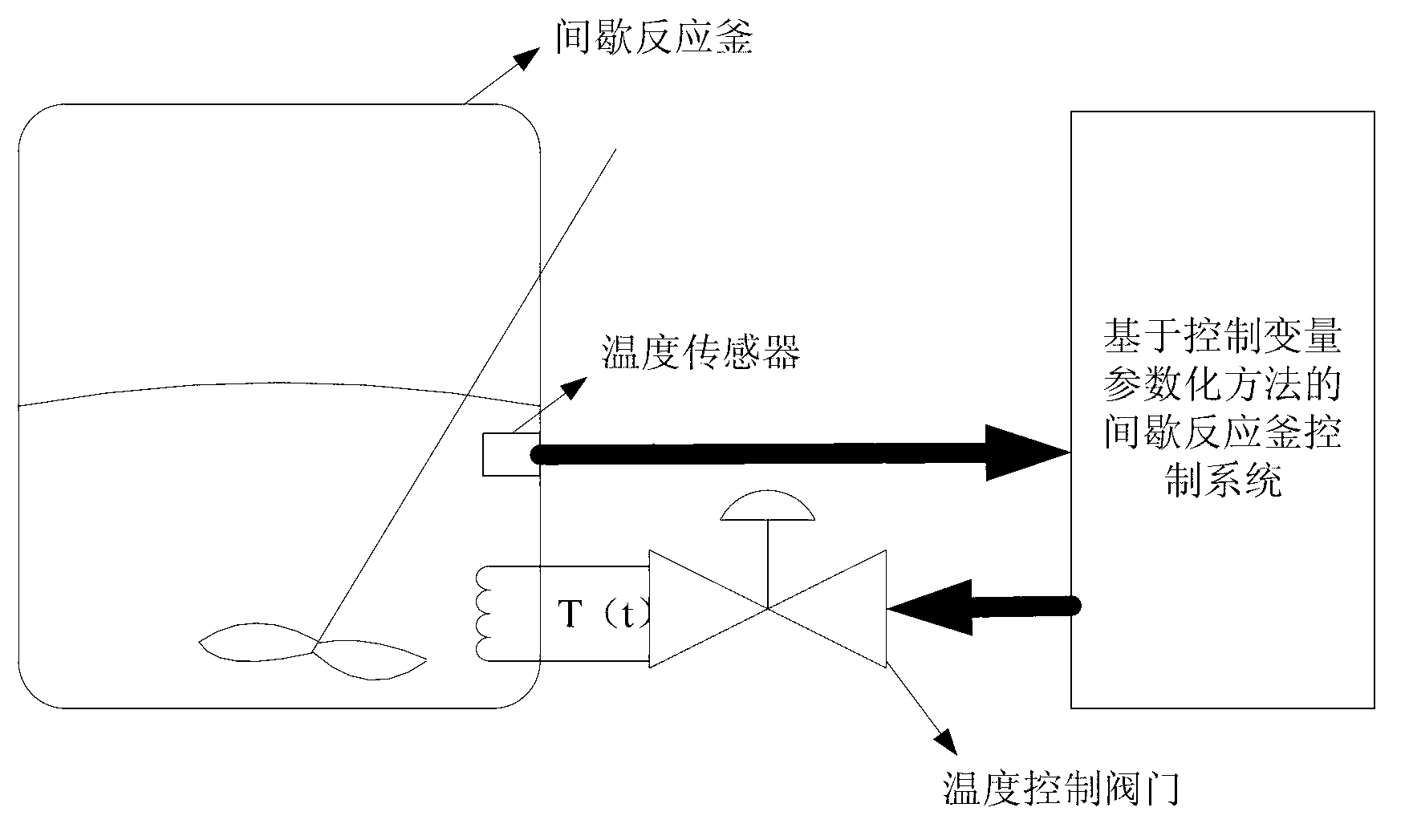

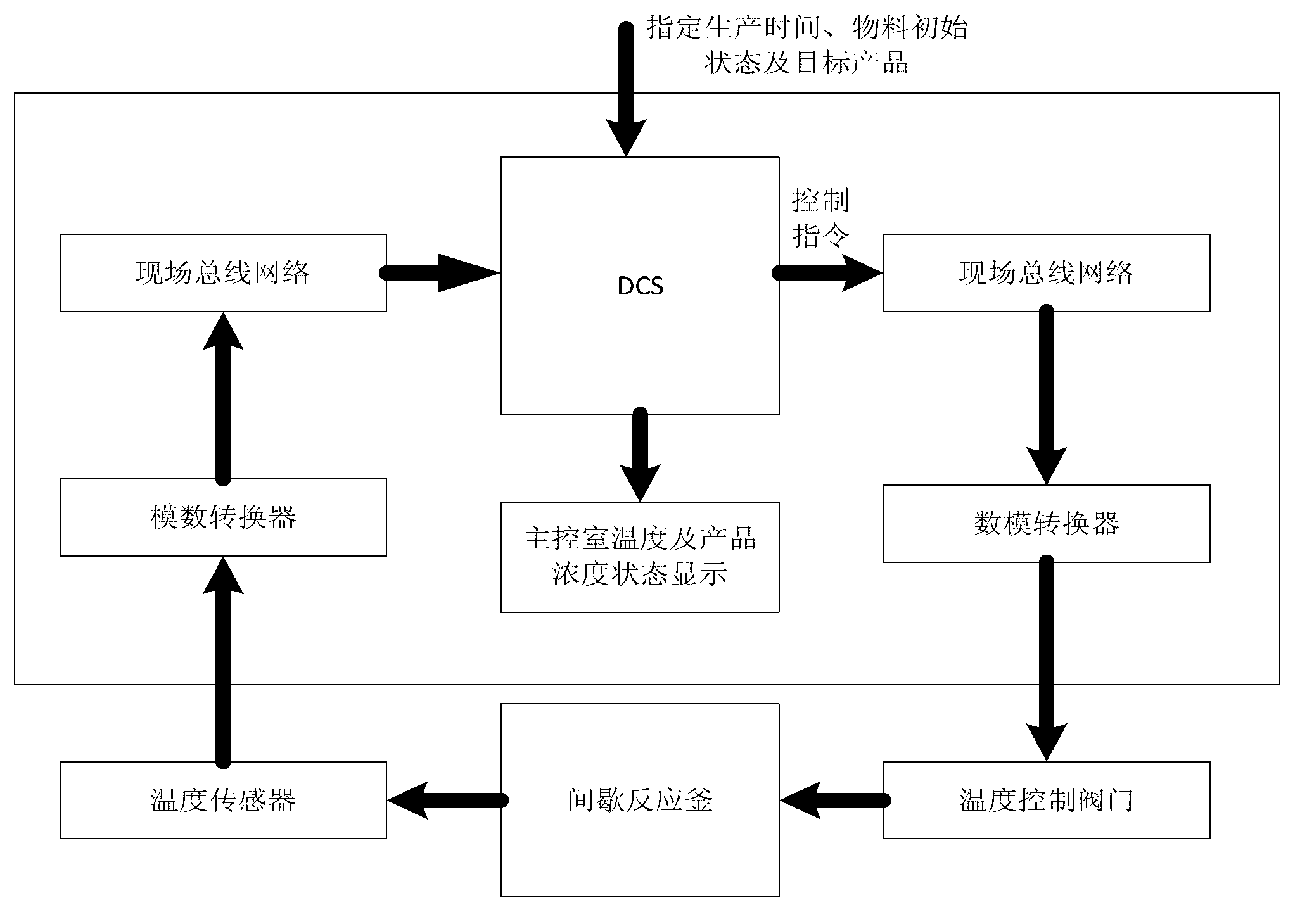

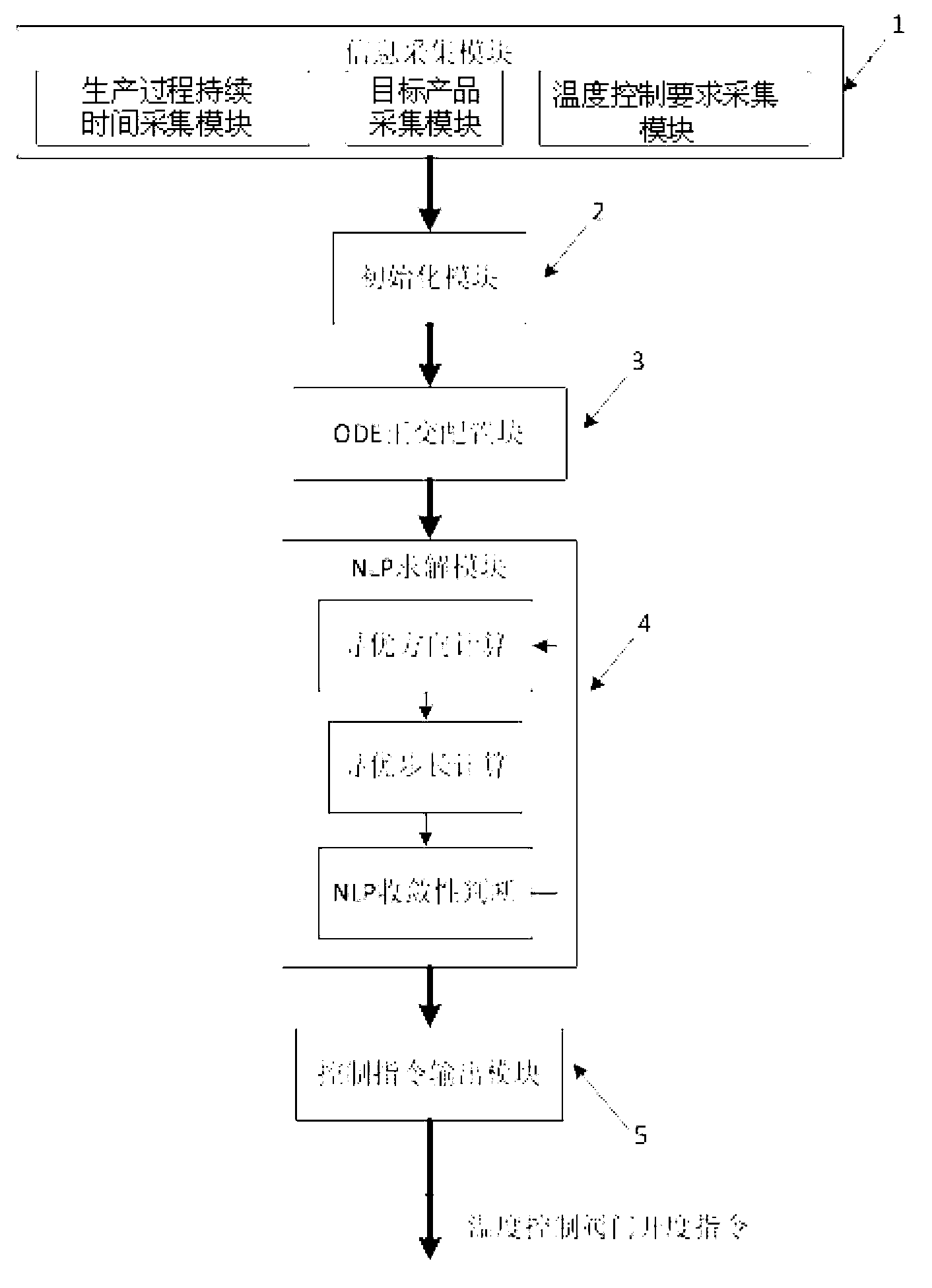

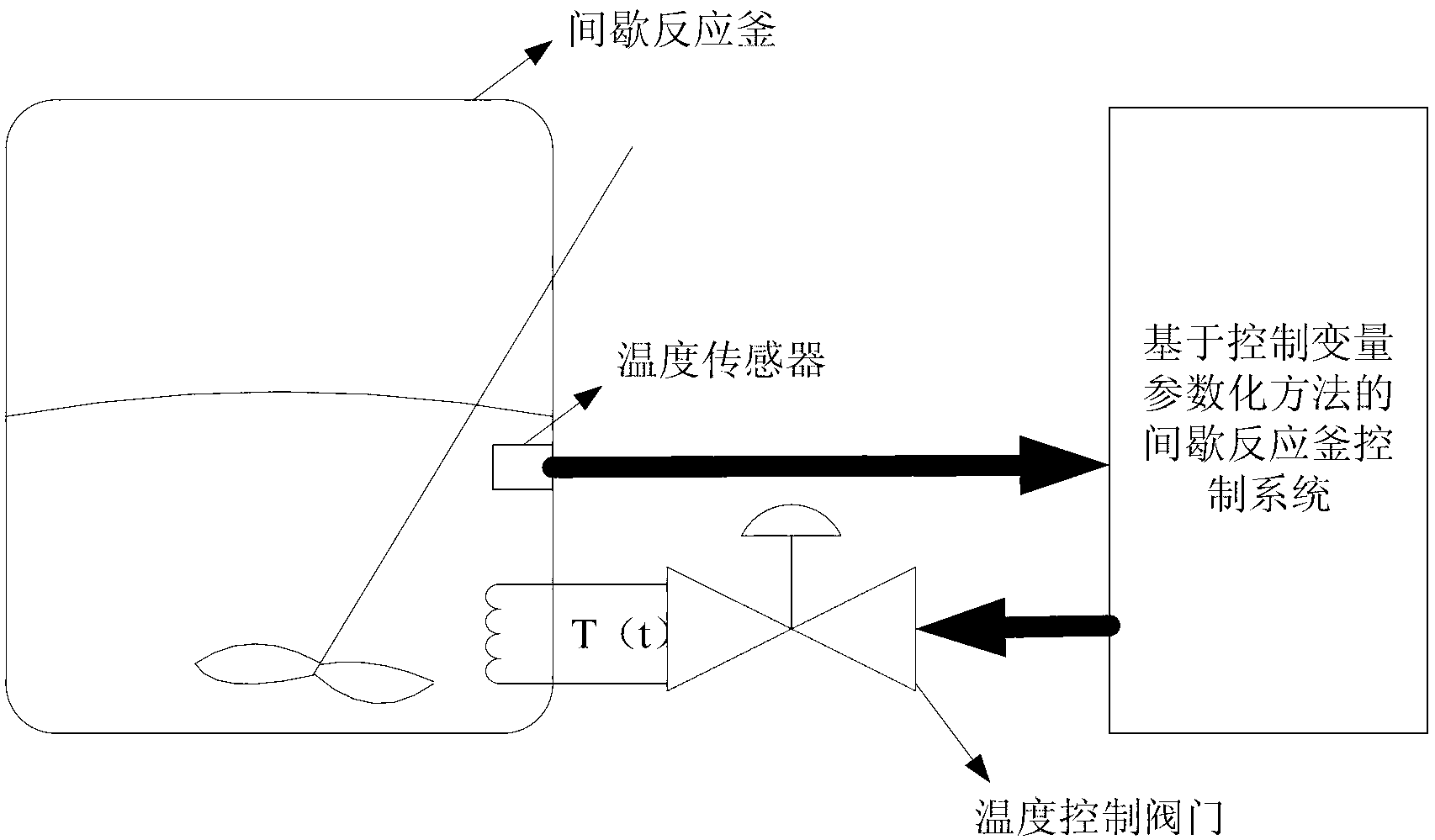

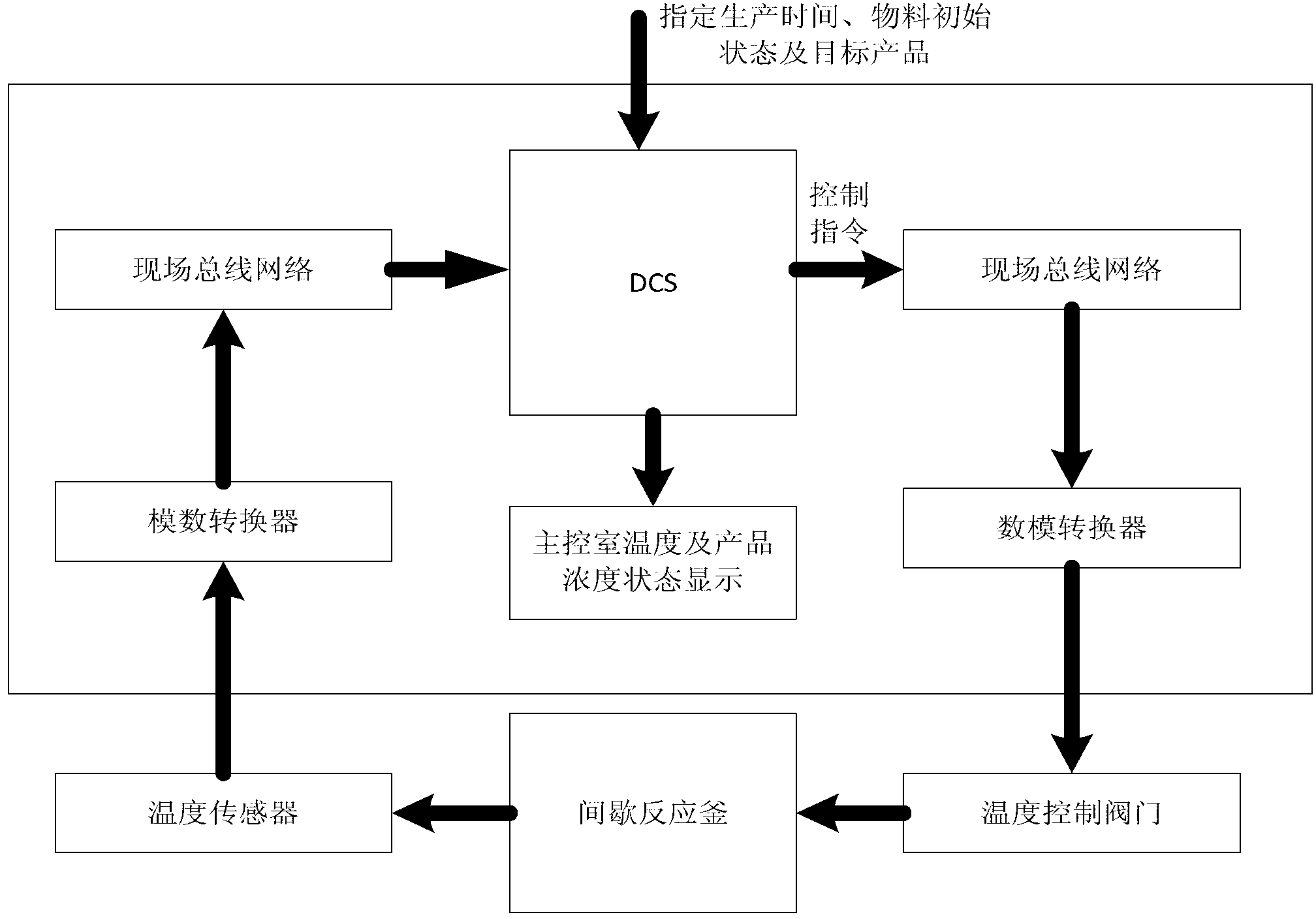

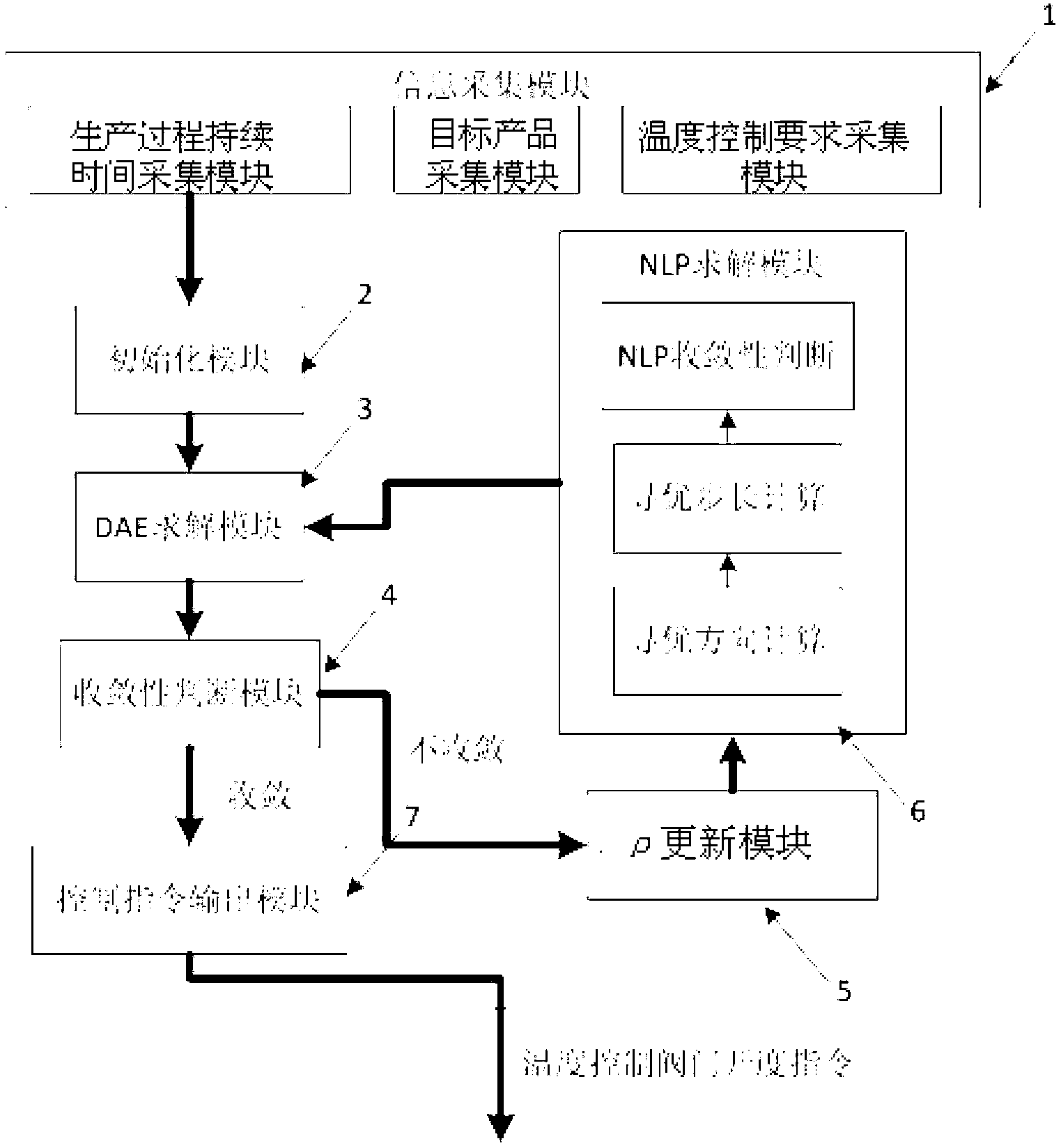

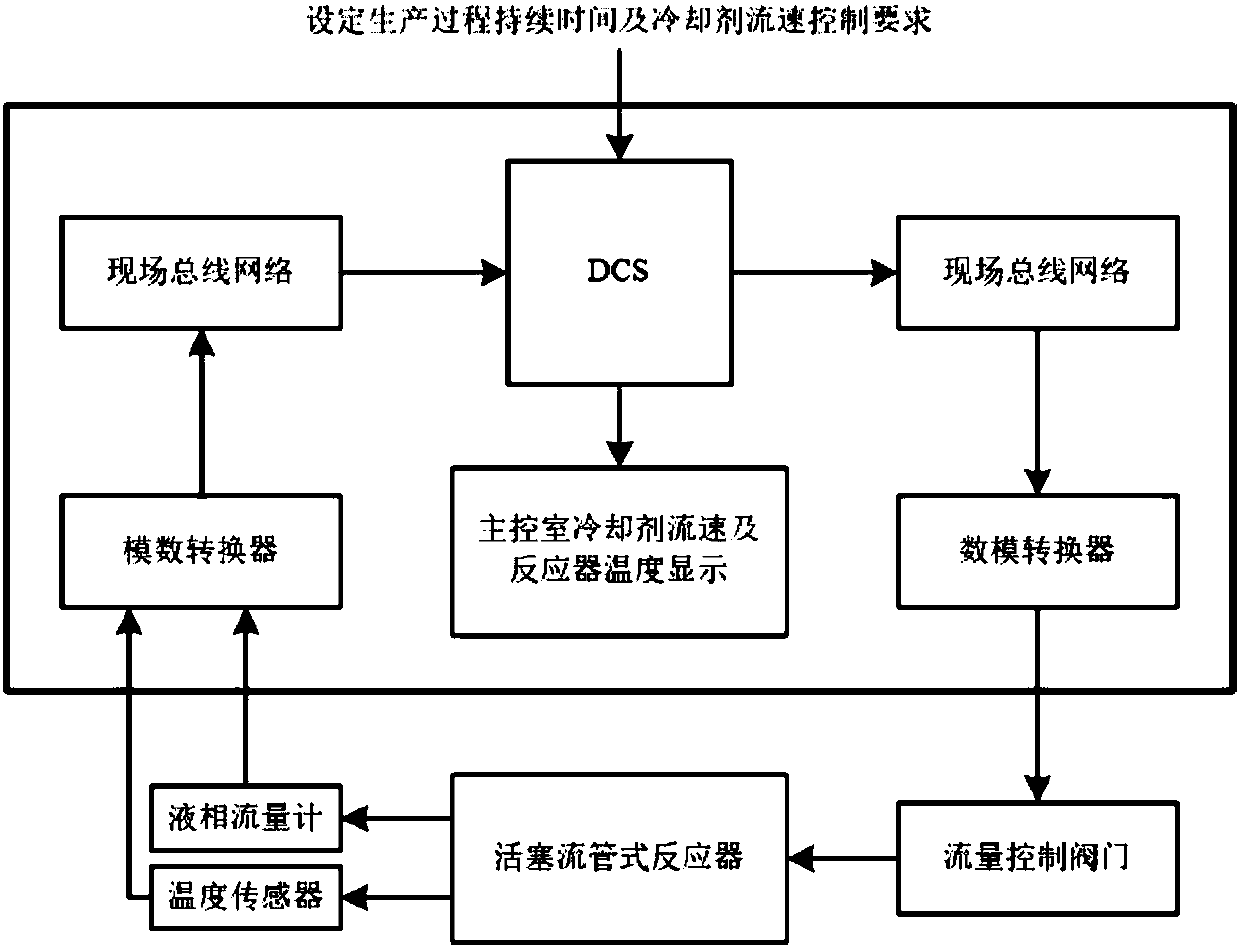

Intermittent reactor control system based on control variable parameterization method

InactiveCN103309371AConcentration maximizationRealize tapping potential and increasing efficiencyTemperature control using electric meansChemical/physical/physico-chemical processesTemperature controlDistributed control system

The invention discloses an intermittent reactor control system based on a control variable parameterization method. The system comprises an intermittent reactor, and a temperature sensor, an analog to digital converter, a site bus network, a DCS (distributed control system), a main control chamber and product concentration status display which are arranged at the end of the intermittent reactor, and a digital to analog converter and a temperature control valve which are arranged at the end of the intermittent reactor. After duration of production process, initial concentration status of materials in the reactor and a target product required to increase concentration are determined by an engineer in a control chamber, the DCS acquires a temperature control strategy to enable the target product concentration to be maximum, converts the temperature control strategy into an open command for a temperature control valve, transmits the open command to the digital to analog converter at the end of the intermittent reactor through the site bus network, and enables the temperature control valve to act according to received control commands. The temperature sensor collects the temperature of the reactor in real-time and returns to the DCS to enable the engineer in the control chamber to master the production process timely. By the aid of the intermittent reactor control system, concentration of the target product can be maximized, and potential synergies are realized.

Owner:ZHEJIANG UNIV

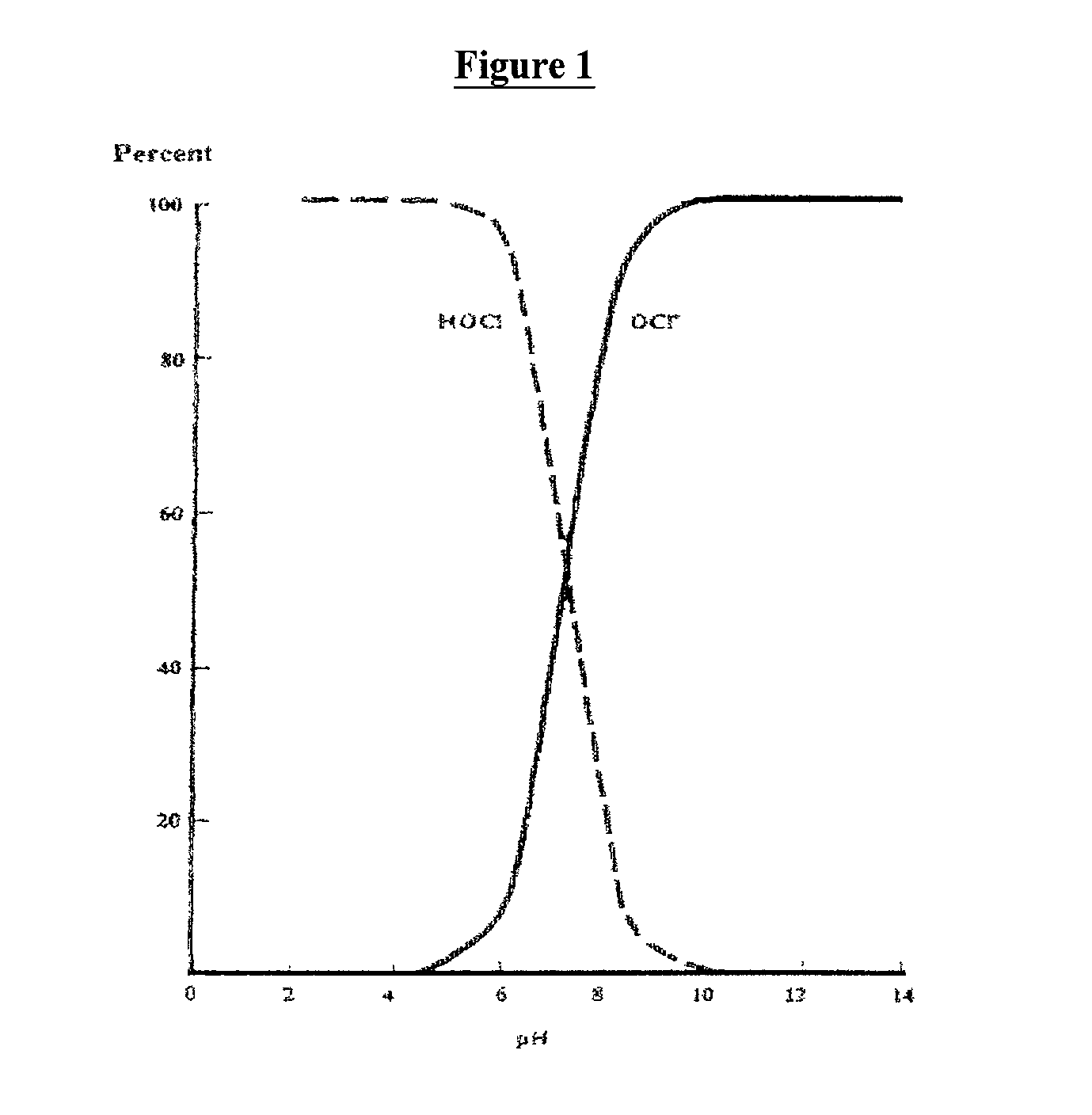

Color stable hypochlorous sanitizer and methods

InactiveUS20030059483A1Maximize activityReduce capacityBiocideOrganic chemistryHypochloritePotable water

Manual warewashing in common food service locations is typically performed in a multicompartment sink within three or more basins. In one basin the ware is contacted with an aqueous solution of a detergent composition. The ware is cleaned using mechanical action to remove soil. The cleaned ware is often rinsed in a subsequent sink in a potable water rinse and is then sanitized in a sanitizing solution in a subsequent basin, typically the third sink in sequence. The sanitizing solution can be rapidly depleted during periods of large volumes of hand washed ware. In order to monitor and control the concentration of the sanitizer in the sanitizer sink, we have found that even highly oxidizing hypochlorite bleaches, if adjusted to an appropriate pH, can maintain substantial sanitizing capacity while not decolorizing otherwise oxidatively sensitive dyes. In the method of the invention, the sanitizing solution adjusted to a pH of less than about 7 containing a dye can maintain a stable dye solution for a period of time greater than the time required to deplete 90% or more of the OCl-1 in solution. As a result, the hand washing staff can have a satisfactory indication of the existence of active sanitizer in the sanitizer step based on the presence of color in the aqueous solution.

Owner:KAY CHEM

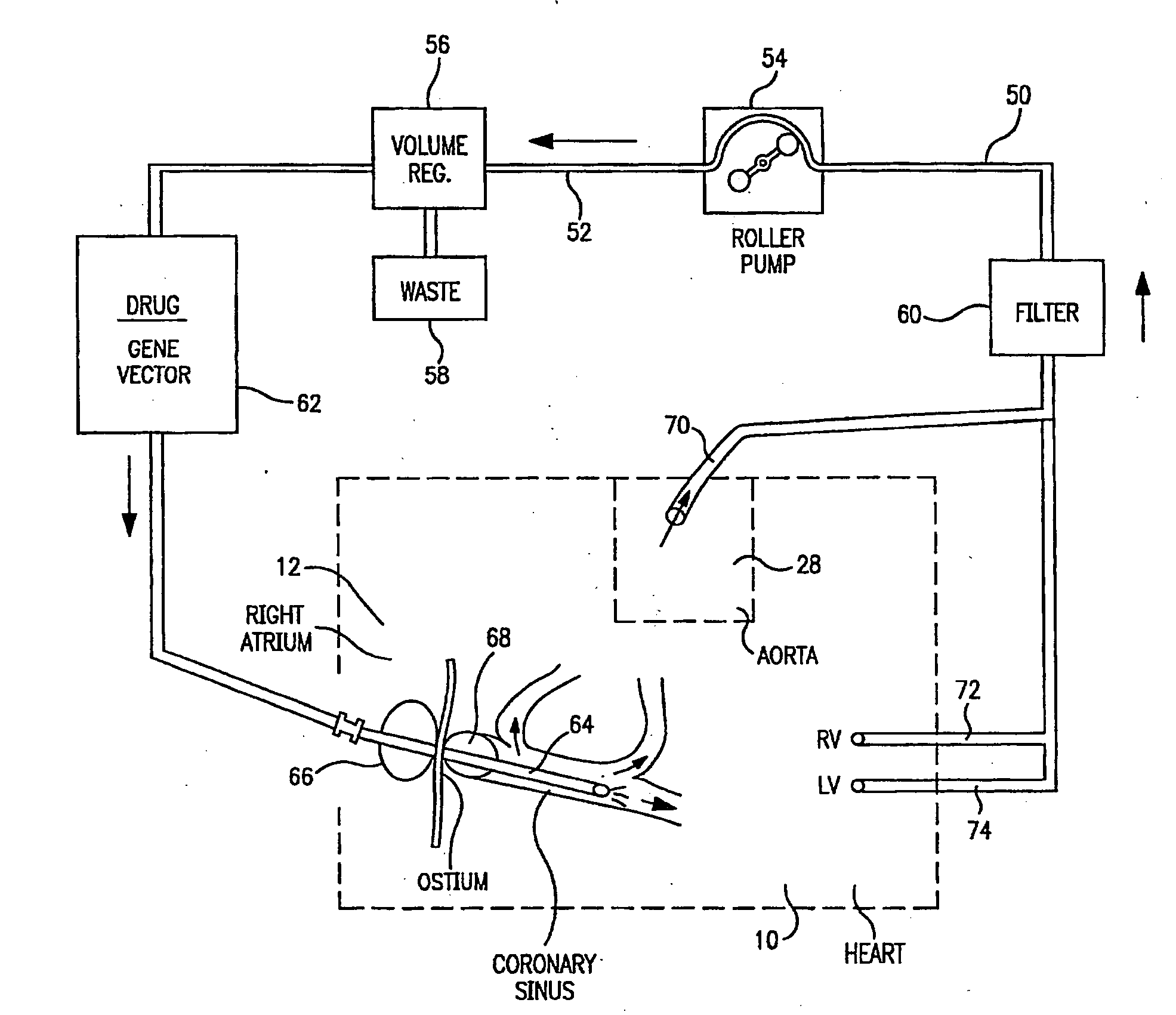

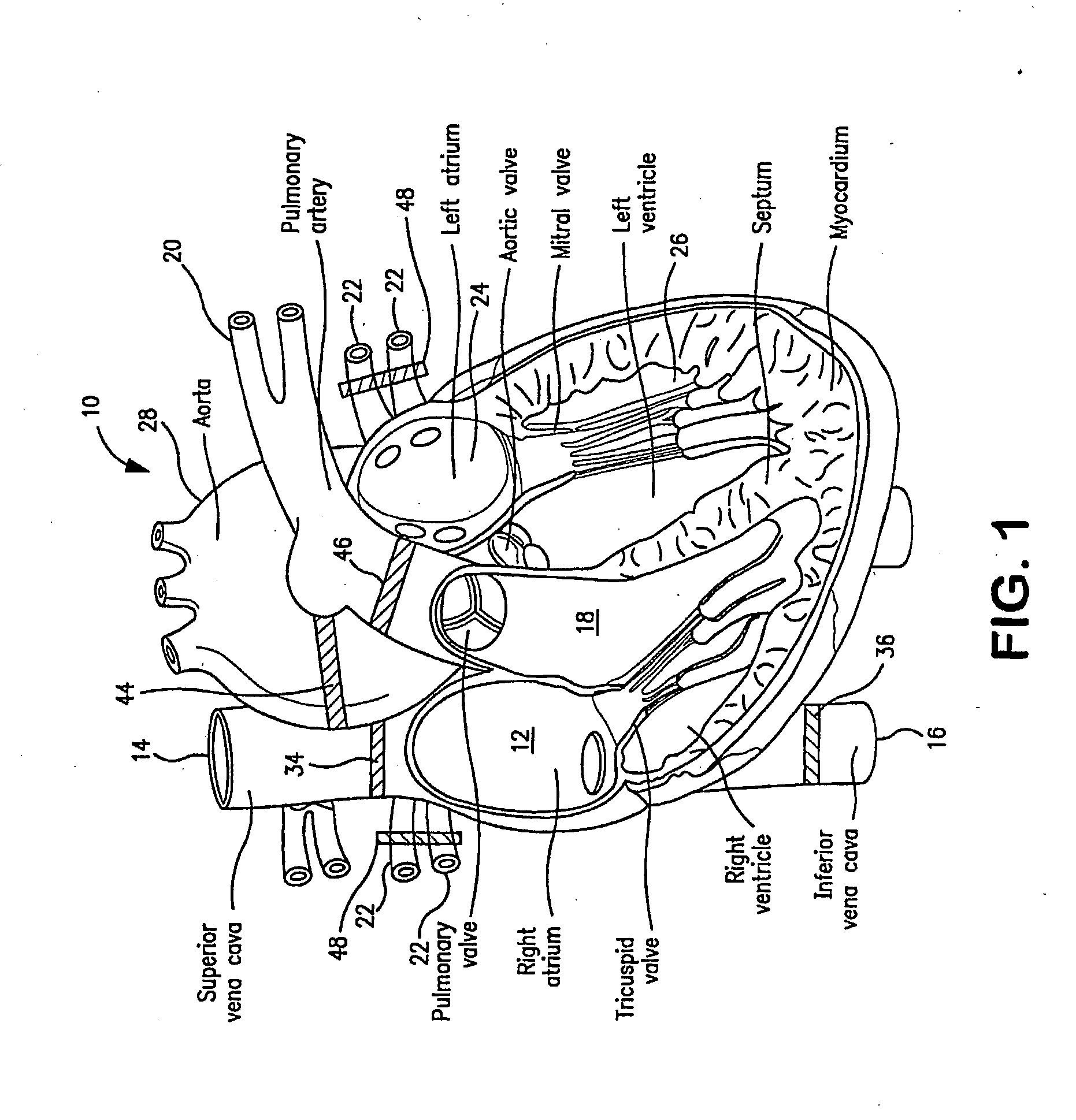

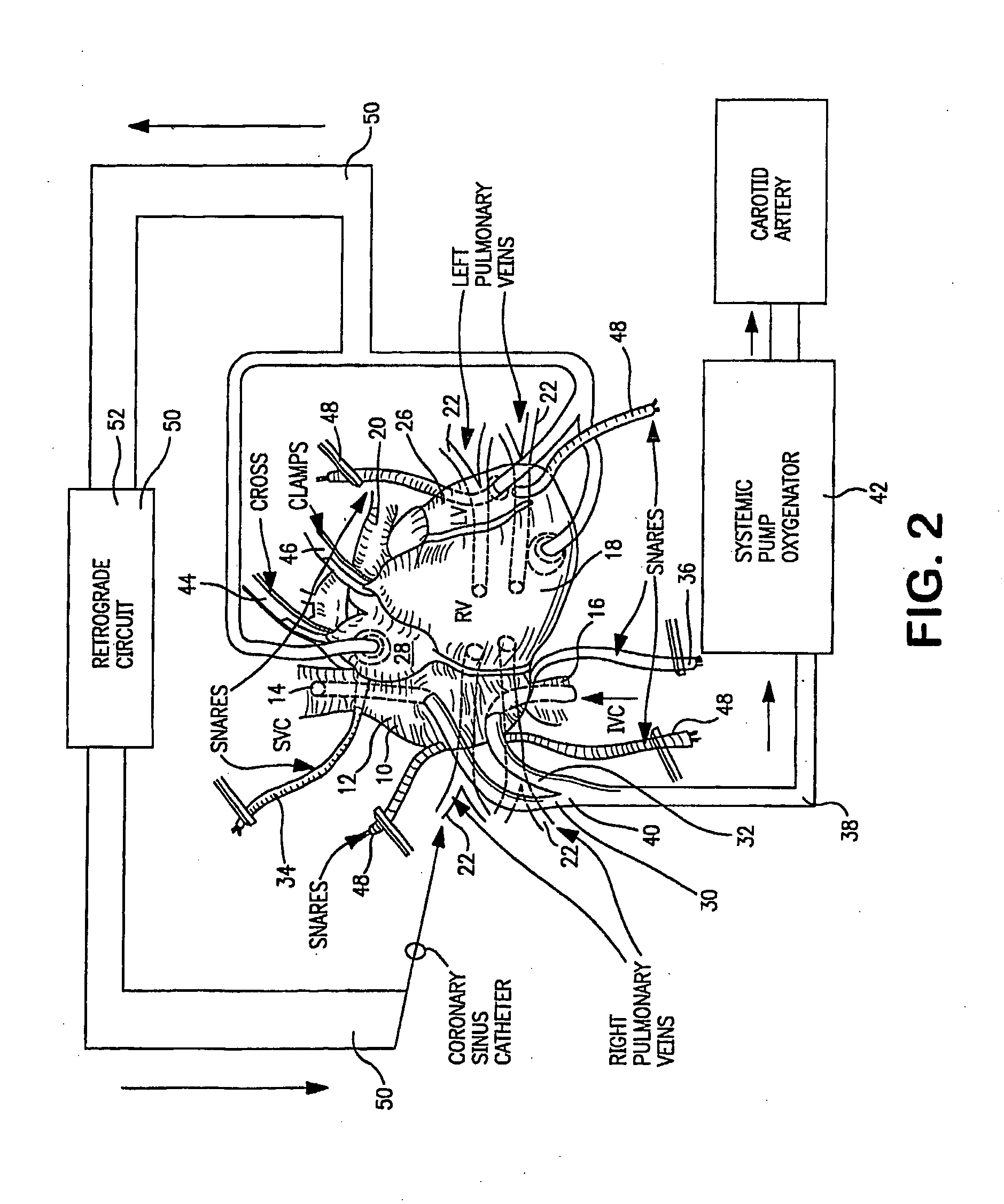

Perfusion circuit and use therein in targeted delivery of macromolecules

InactiveUS20090054823A1Efficient myocyte gene deliveryMaximize safetyDialysis systemsMedical devicesCardiopulmonary bypass surgeryIntensive care medicine

A perfusion circuit and a use thereof for delivering a substance to a subject's heart in situ during cardiopulmonary bypass surgery are provided. The perfusion circuit defines a path for re-circulating a solution containing a macromolecular complex through a coronary circulation circuit (50) through a subject's heart during a surgical procedure in which the substance is prevented from being delivered to the subject's other organs.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

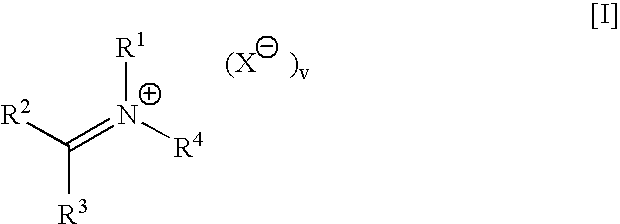

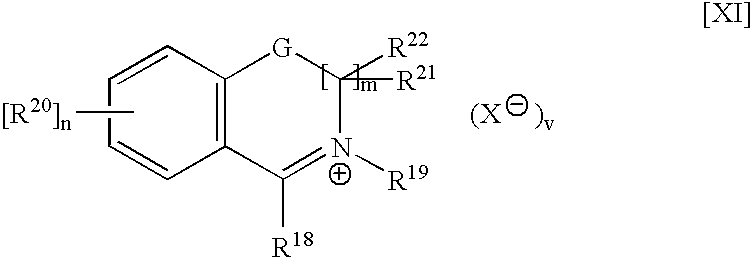

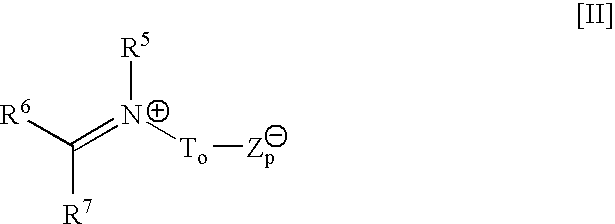

Ion generating device

InactiveUS20070085036A1Improved ion aeration effectImproved ionic aeration effectDrying solid materials with heatElectric discharge tubesMedicineElectrical polarity

There is provided a device for hair care having a housing with at least one aperture, one or more ion generators for selectively generating concentrations of ions having different combinations of intensity and polarity, and one or more ion emitters for selectively emitting concentrations of ions having different combinations of intensity and polarity. The device can be any device or combination of such devices, suitable for use with hair and for to optimize the known beneficial effects of ionization to hair of the user.

Owner:CONAIR CORP

Method to improve characteristics of spray dried powders and granulated materials, and the products thereby produced

ActiveUS20070026083A1Reducing residual solvent contentIncrease in bulk powder densityOrganic active ingredientsPretreated surfacesNon solventAverage size

A method for preparing solid materials is described. One aspect of the method includes the steps of providing a mixture comprising an organic material in a blend of a solvent and non-solvent for the organic material, distributing the mixture into either droplets or granules, and evaporating the solvent and non-solvent mixture to form particles having an average size of from about 0.5 μm to about 5000 μm.

Owner:ISP INVESTMENTS LLC

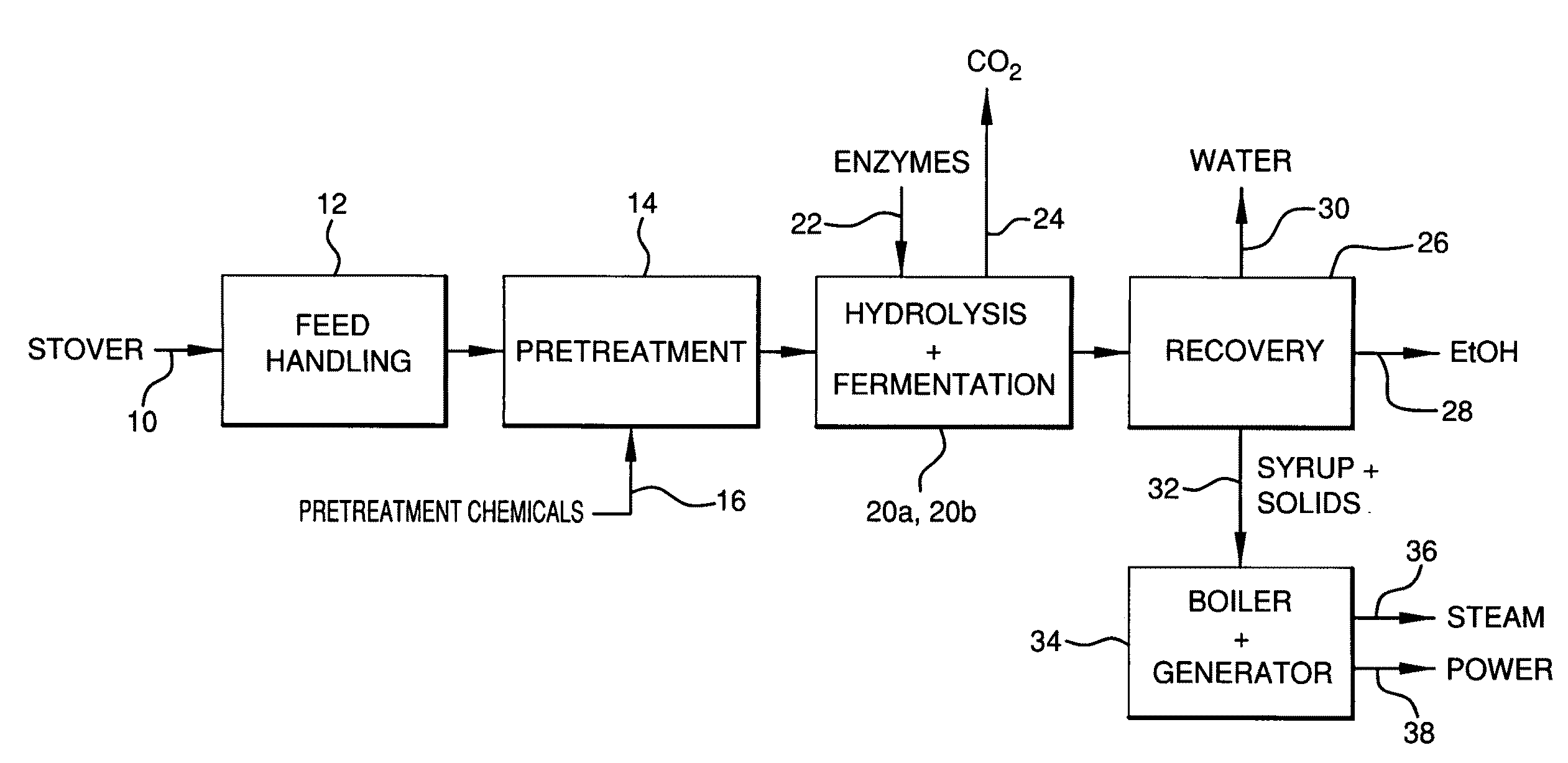

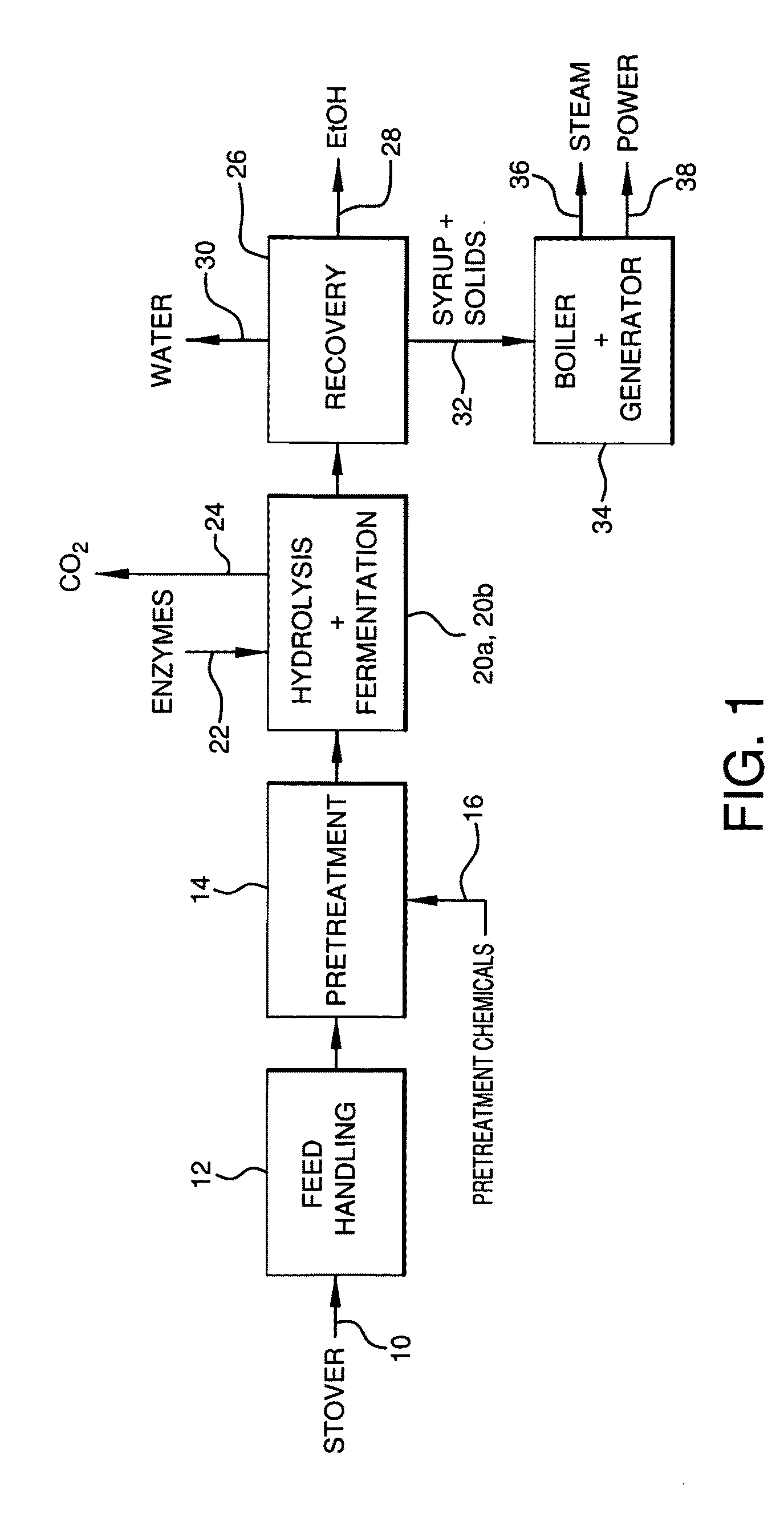

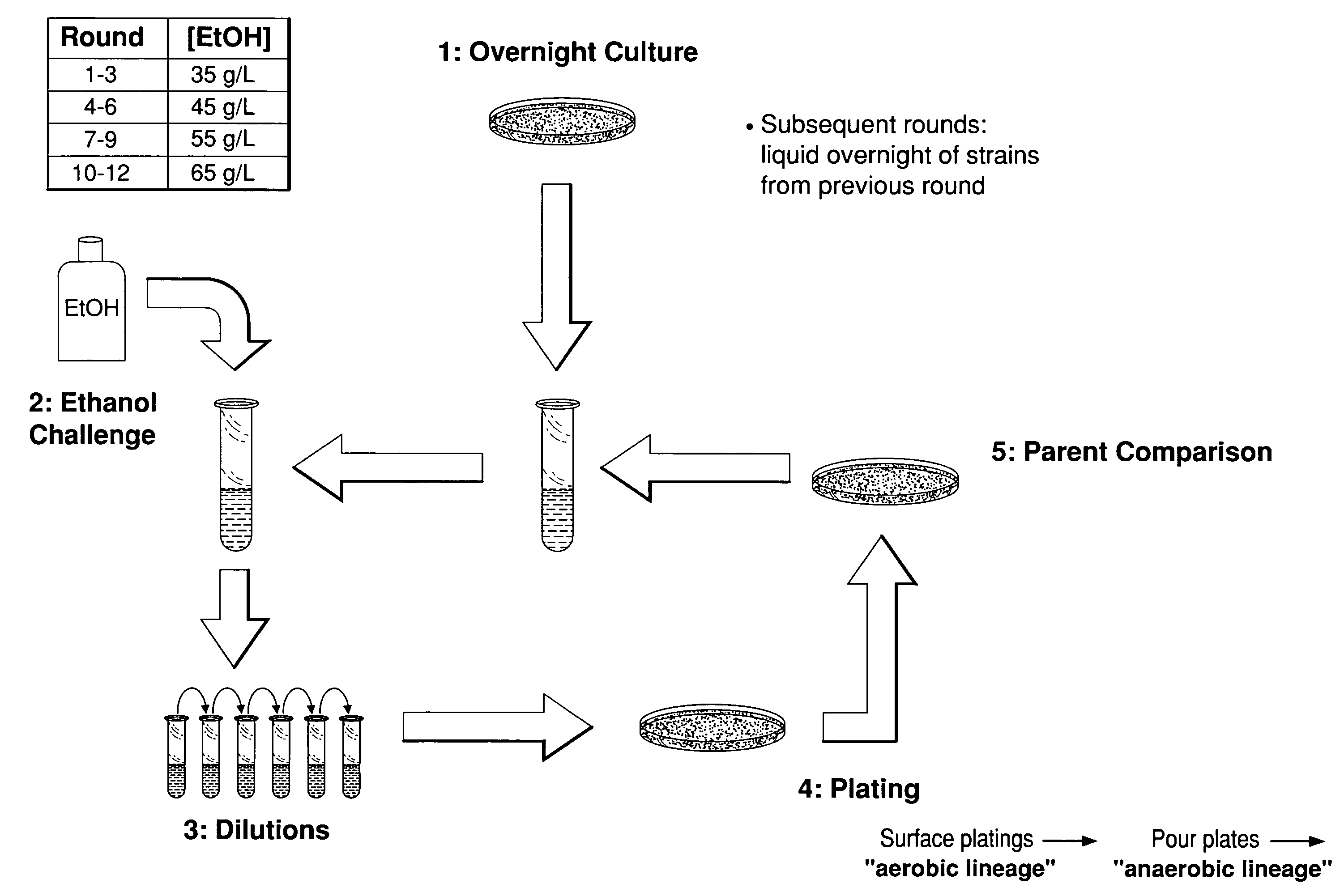

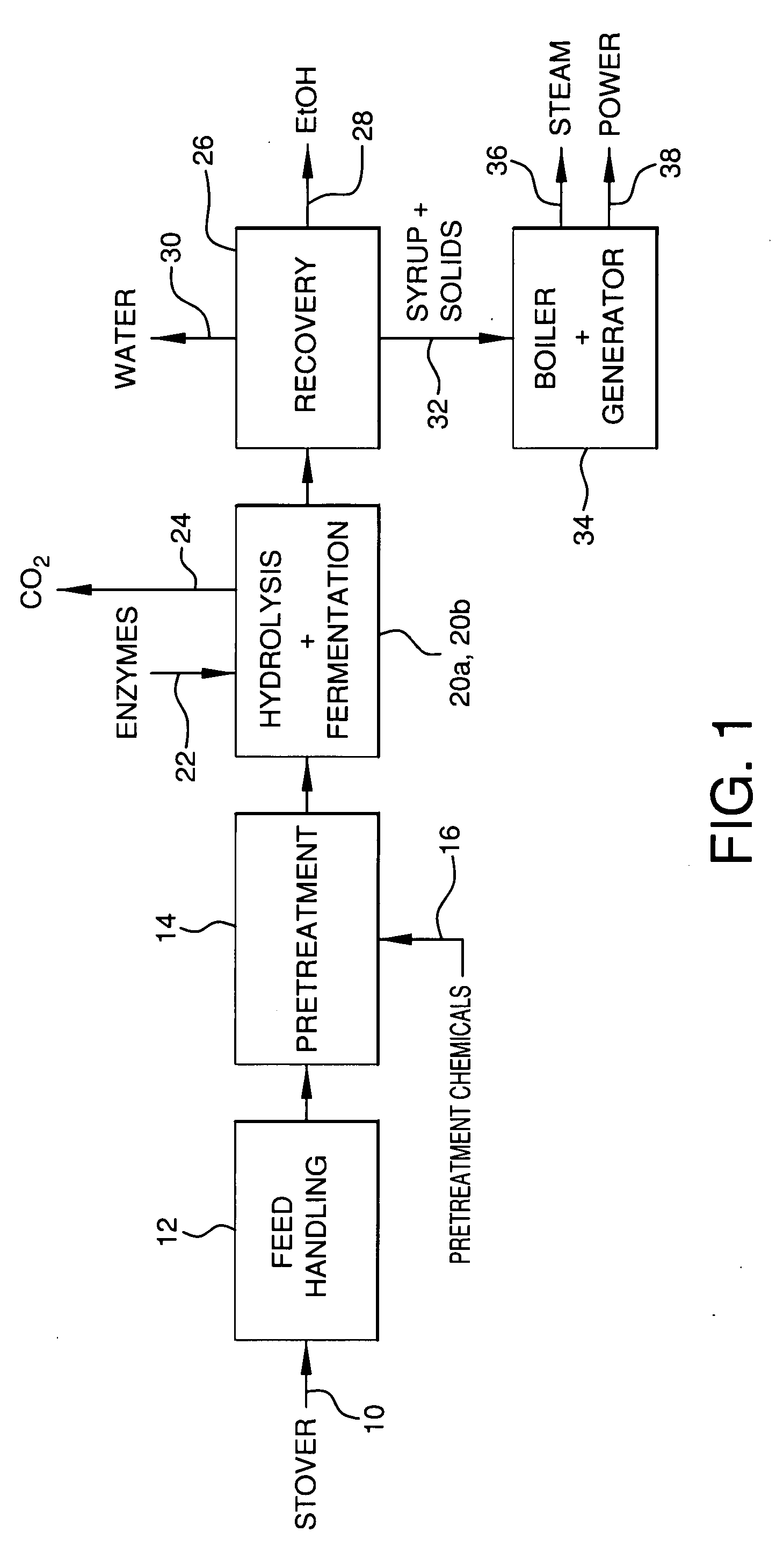

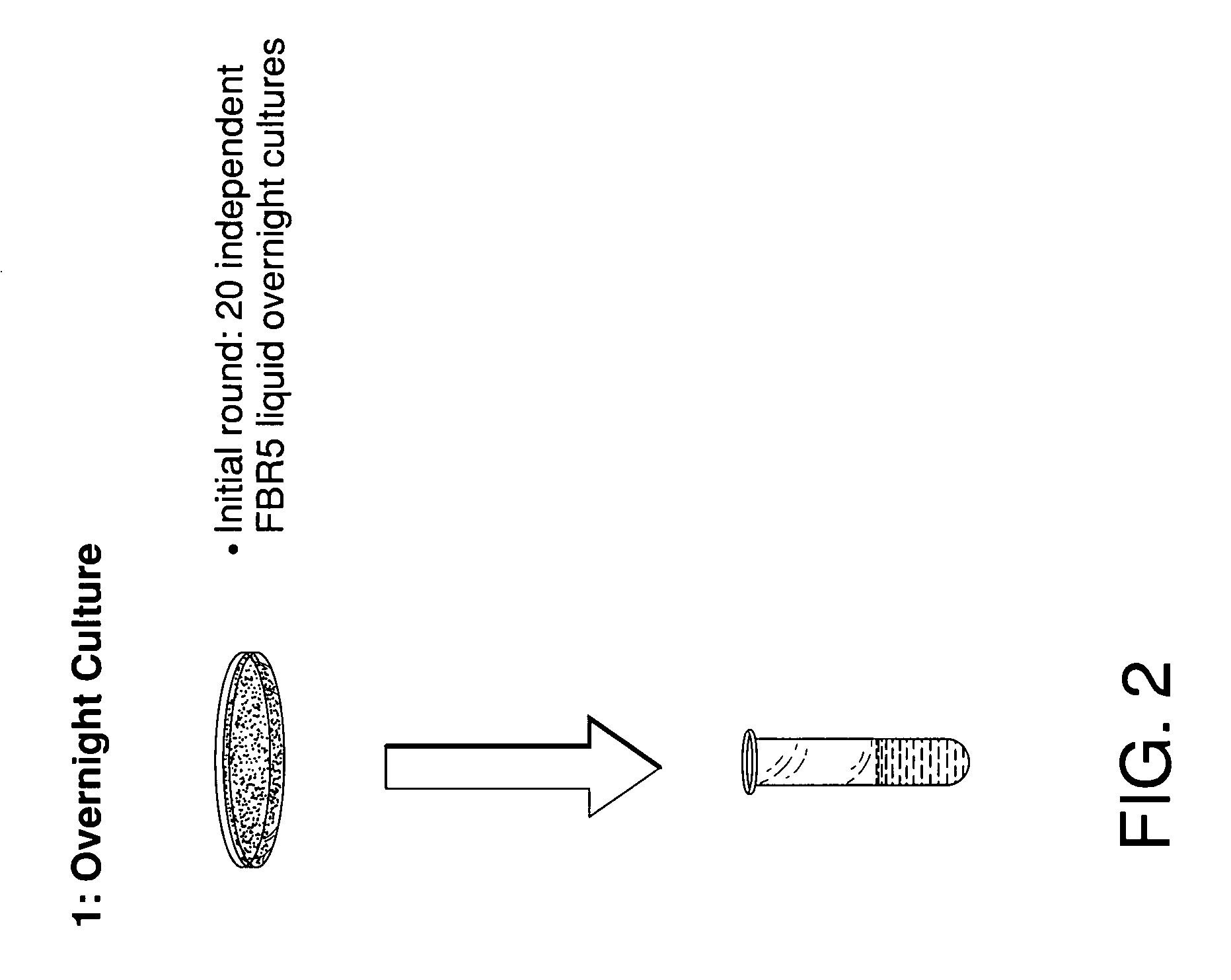

Ethanol resistant and furfural resistant strains of E. coli FBR5 for production of ethanol from cellulosic biomass

InactiveUS20090053793A1Concentration maximizationHigh yieldBacteriaBiofuelsCelluloseResistant strain

Owner:ROWAN UNIVERSITY

Orthogonal collocation optimization based batch reactor control system

InactiveCN103309234AConcentration maximizationRealize tapping potential and increasing efficiencyChemical/physical/physico-chemical stationary reactorsAdaptive controlTemperature controlDigital analog converter

The invention discloses an orthogonal collocation optimization based batch reactor control system. The orthogonal collocation optimization based batch reactor control system comprises a batch reactor body, a temperature sensor at the end of the batch reactor body, an analog to digital converter, field bus networks, a DCS (distributed control system), a main control room temperature and product concentration state displayer, an analog to digital converter at the end of a temperature control valve and the temperature control valve. After an engineer in a control room specifies duration of a production process, initial concentration states of materials in the batch reactor body and a target product needing concentration increasing, the DCS executes an internal orthogonal collocation optimization method to compute a temperature control strategy enabling the concentration of the target product to be maximum, the temperature control strategy is converted into an opening instruction of the temperature control valve, and the opening instruction is sent to the analog to digital converter at the end of the temperature control valve through the field bus networks so as to enable the temperature control valve to act correspondingly according to a received control instruction. By the system, the concentration of the target product can be maximized, and potential tapping and efficiency improvement are realized.

Owner:ZHEJIANG UNIV

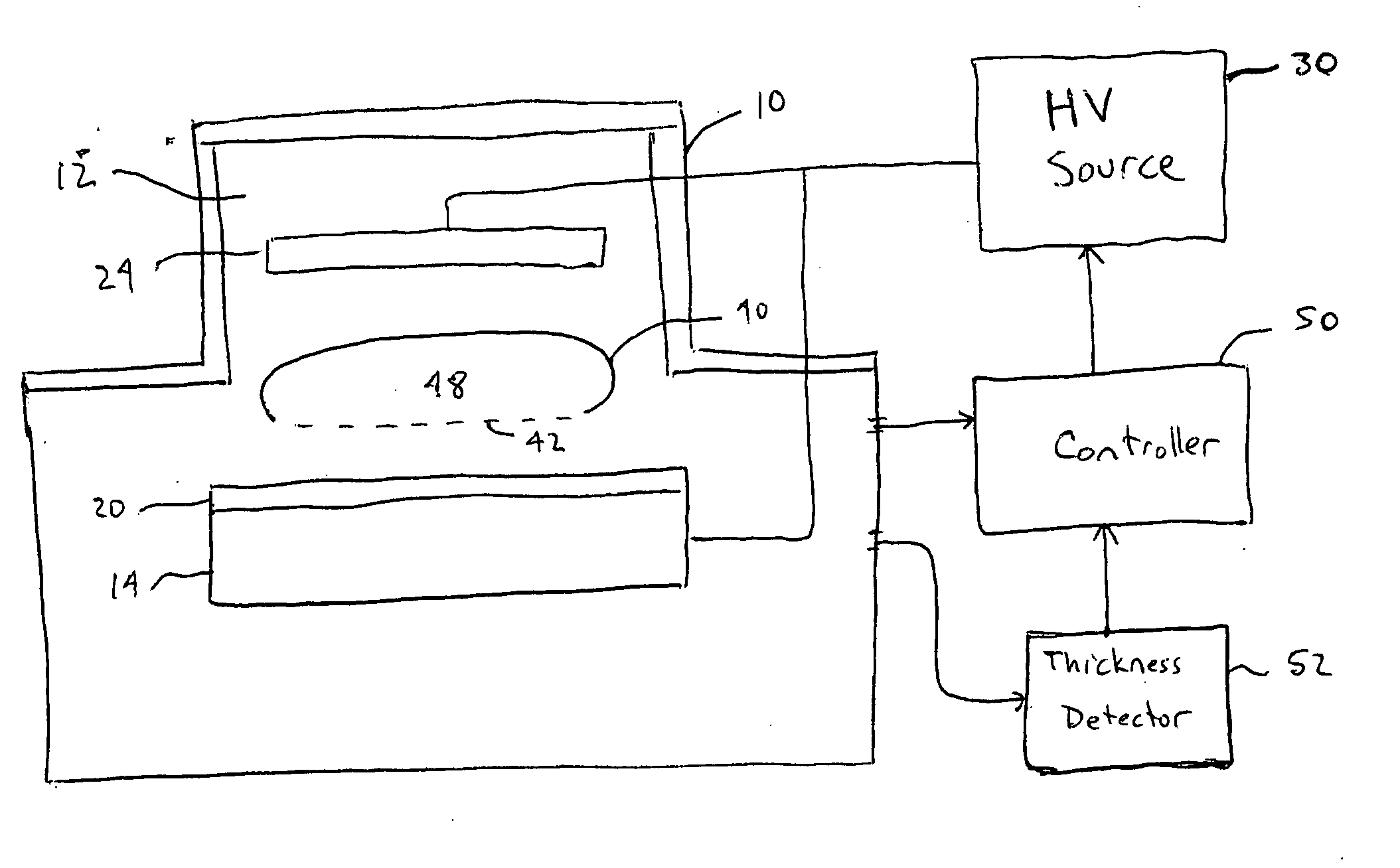

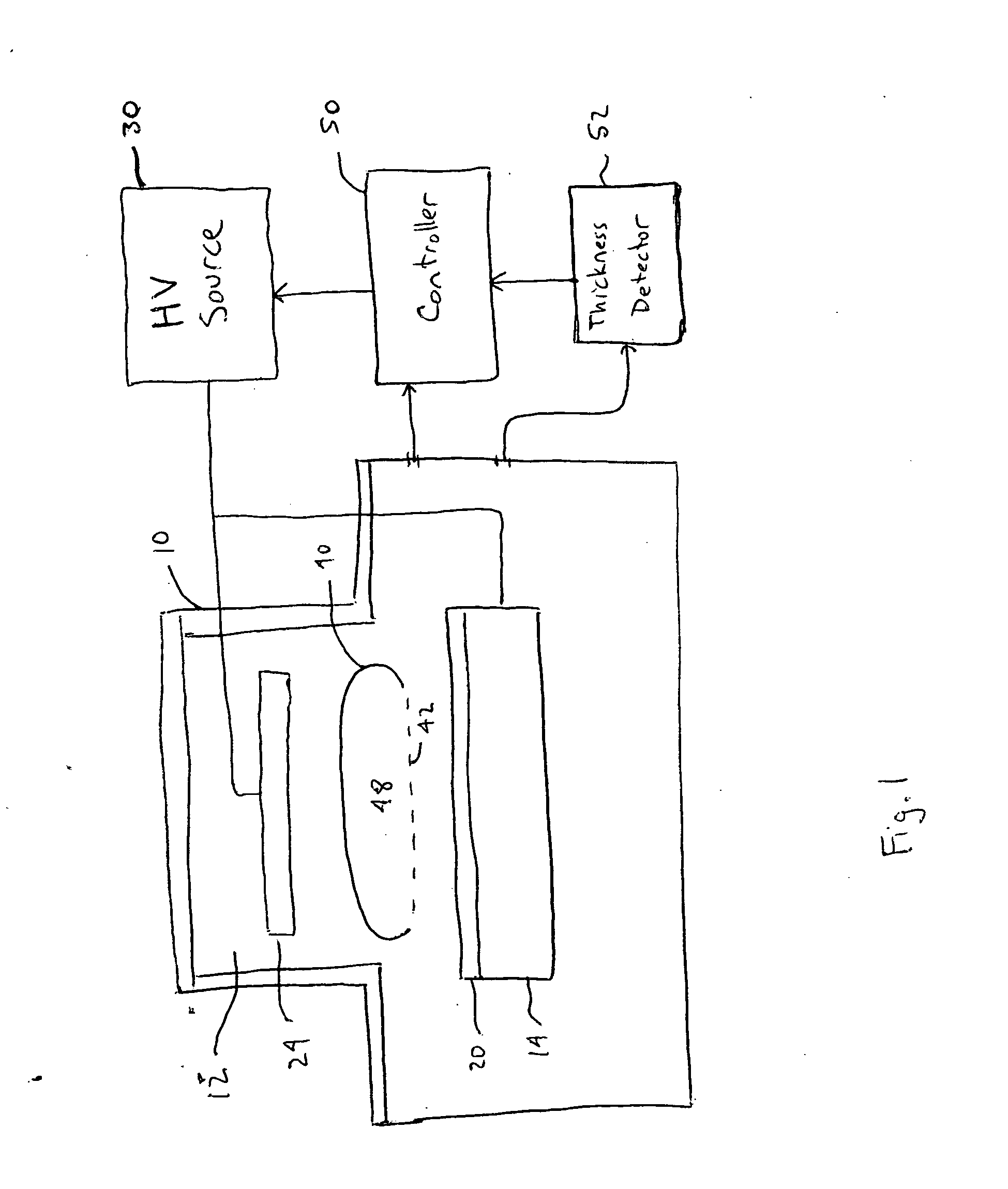

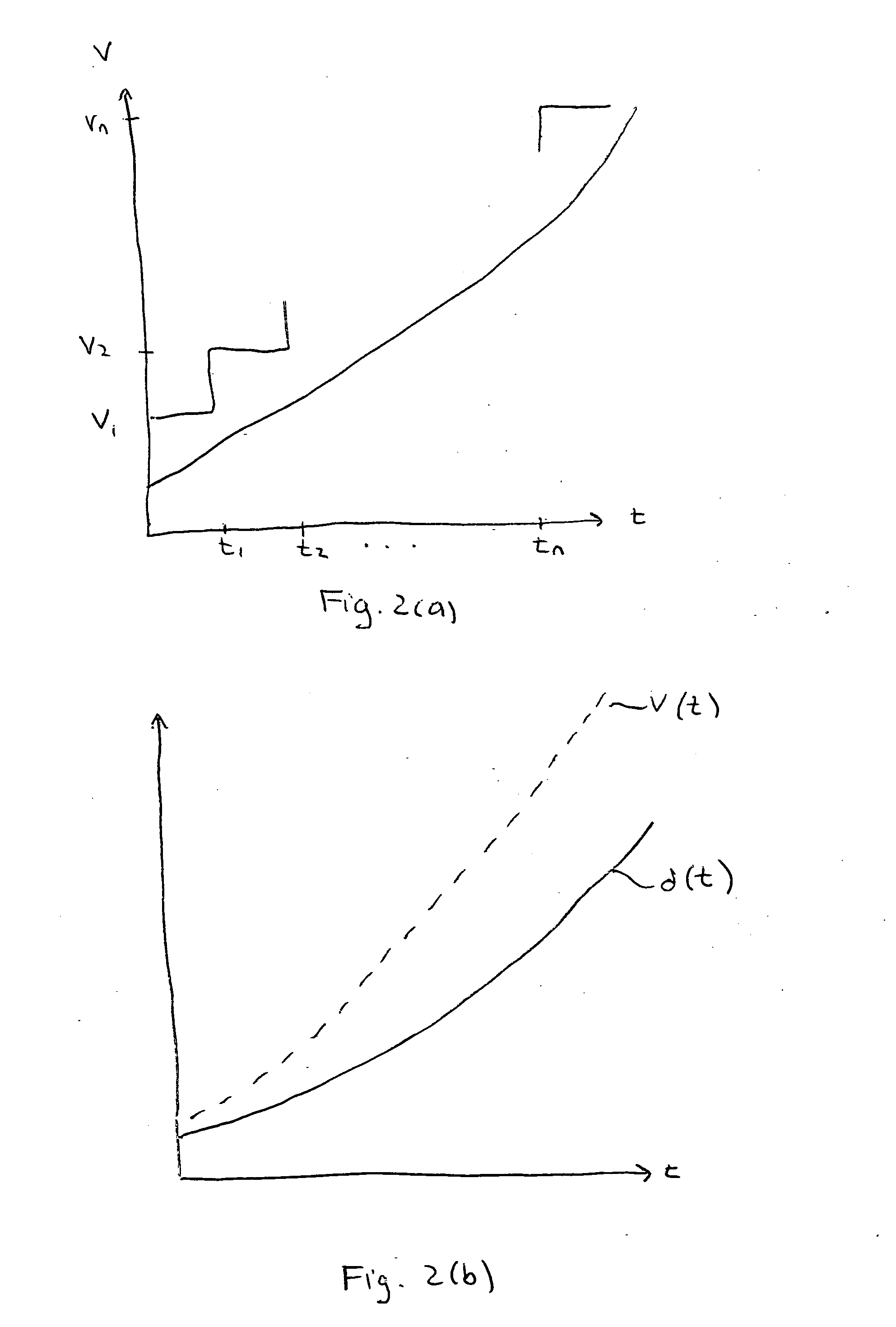

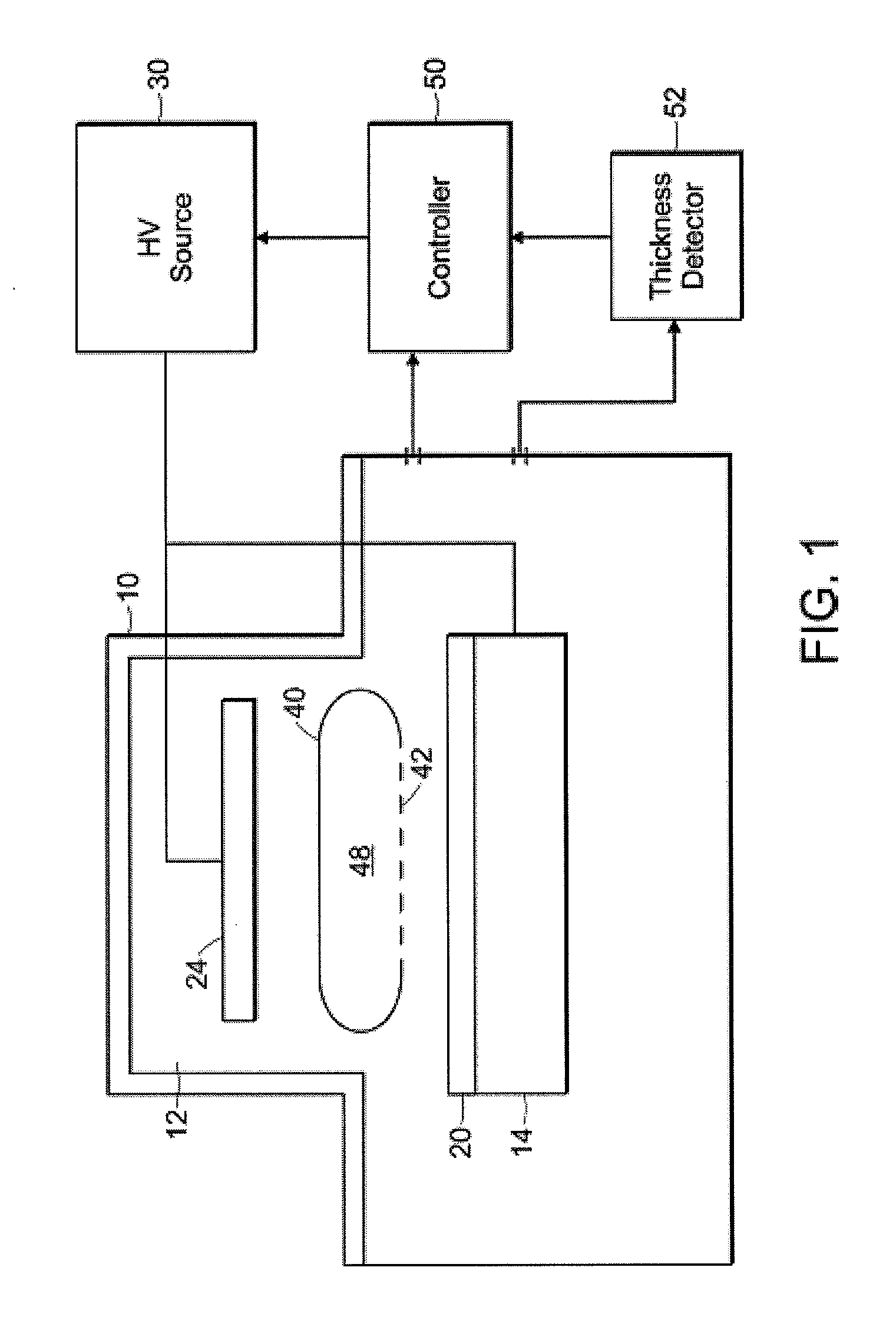

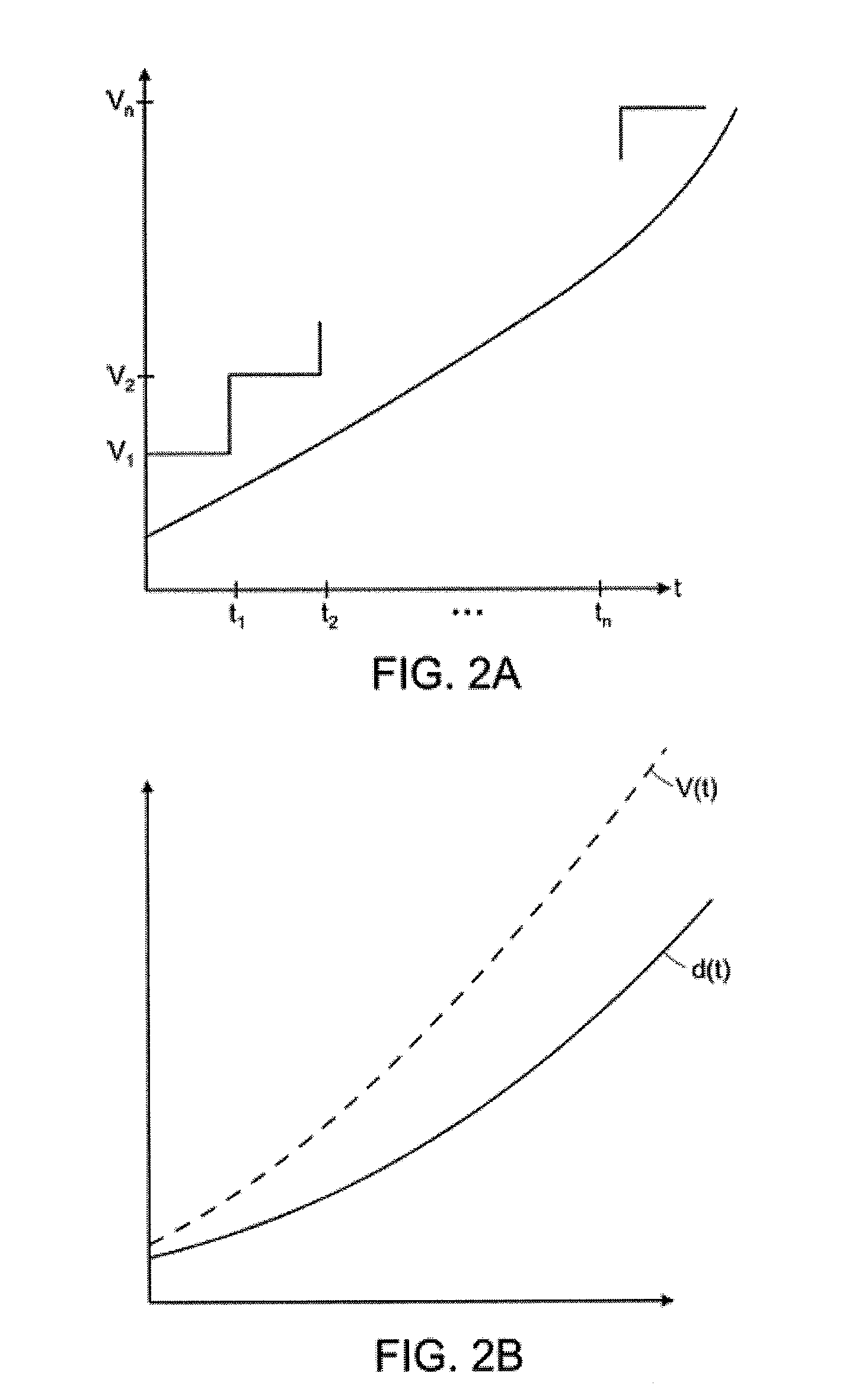

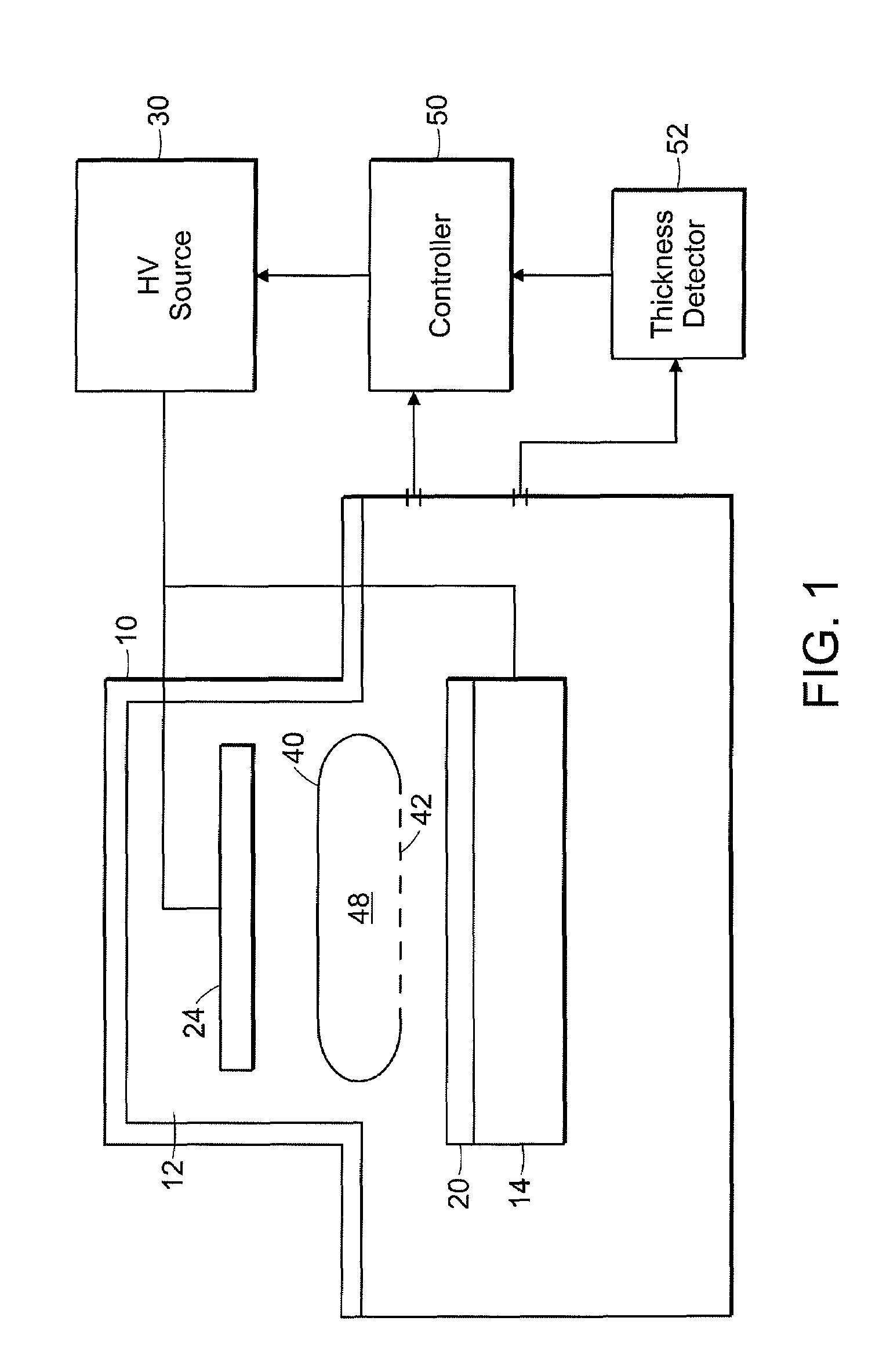

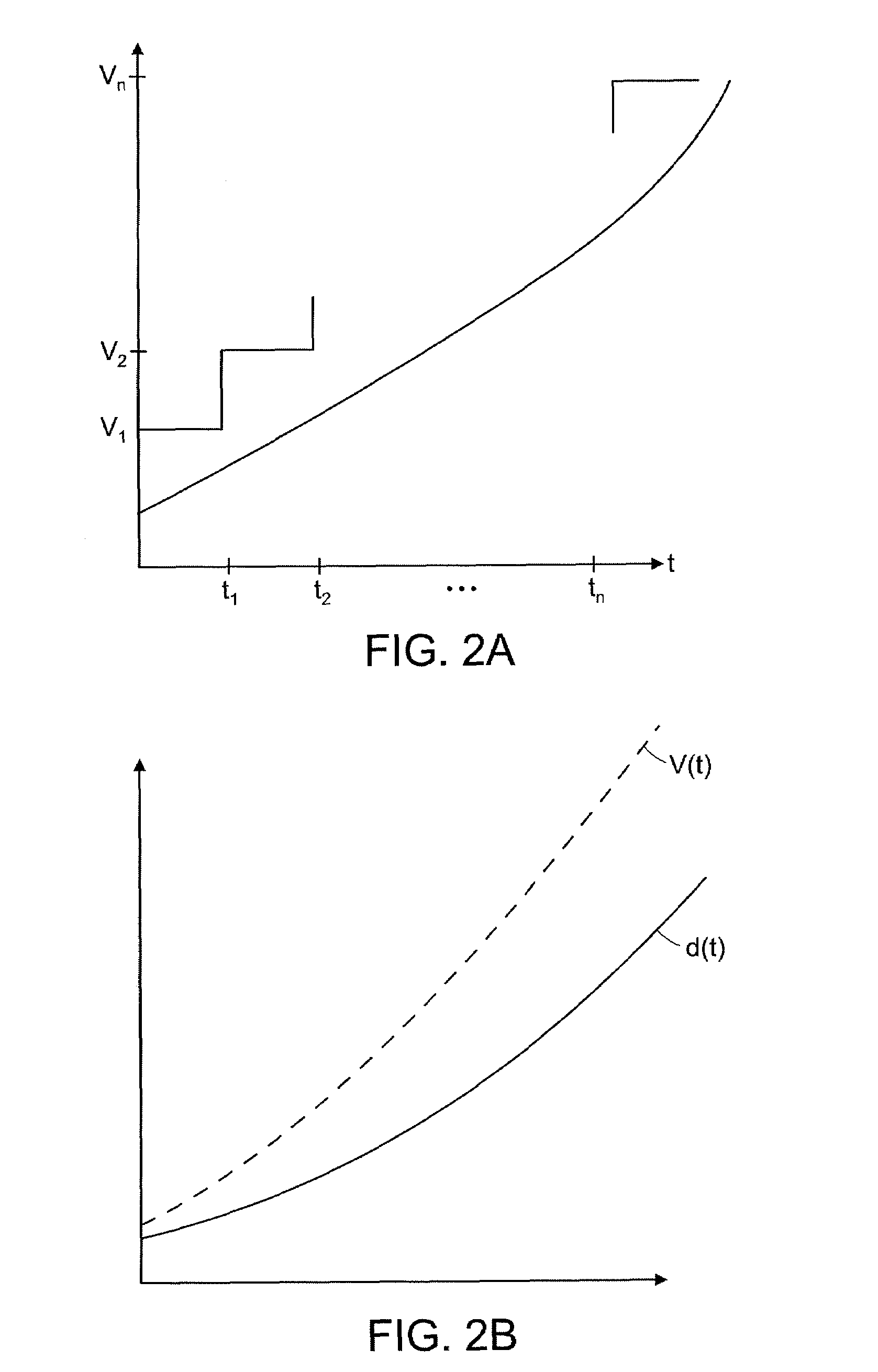

Profile adjustment in plasma ion implanter

ActiveUS20060289799A1Minimize spreadingConcentration maximizationElectric discharge tubesRadiation therapyIonEngineering

A method and apparatus are directed to providing a dopant profile adjustment solution in plasma doping systems for meeting both concentration and junction depth requirements. Bias ramping and bias ramp rate adjusting may be performed to achieve a desired dopant profile so that shallow and abrupt junctions in vertical and lateral directions are realized that are critical to device scaling in plasma doping systems.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Controlled availability of formulation components, compositions and laundry methods employing same

InactiveUS7109156B1Improve bleaching effectReducing organic catalyst decompositionNon-surface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsLaundryChemistry

The present invention relates to a method for the controlled availability formulation components, such as organic catalysts, into a wash solution. More particularly, the present invention relates to products and bleaching compositions containing such formulation components and laundry methods employing such formulation components.

Owner:THE PROCTER & GAMBLE COMPANY

Profile adjustment in plasma ion implanter

ActiveUS20090061605A1Maximize retained doseMaximize near surface concentrationElectric discharge tubesSemiconductor/solid-state device manufacturingDopantEngineering

A method to provide a dopant profile adjustment solution in plasma doping systems for meeting both concentration and junction depth requirements. Bias ramping and bias ramp rate adjusting may be performed to achieve a desired dopant profile so that surface peak dopant profiles and retrograde dopant profiles are realized. The method may include an amorphization step in one embodiment.

Owner:VARIAN SEMICON EQUIP ASSOC INC

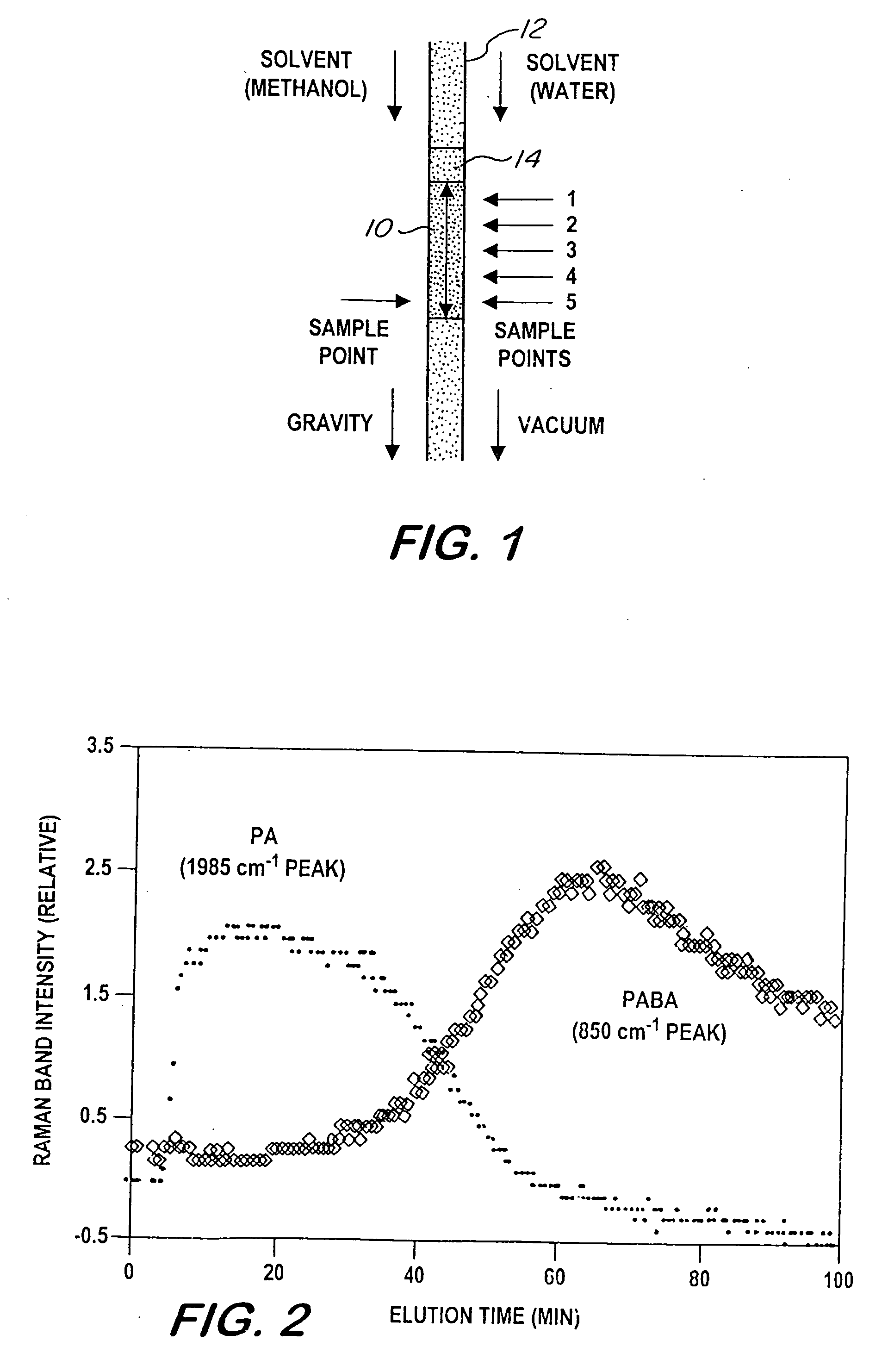

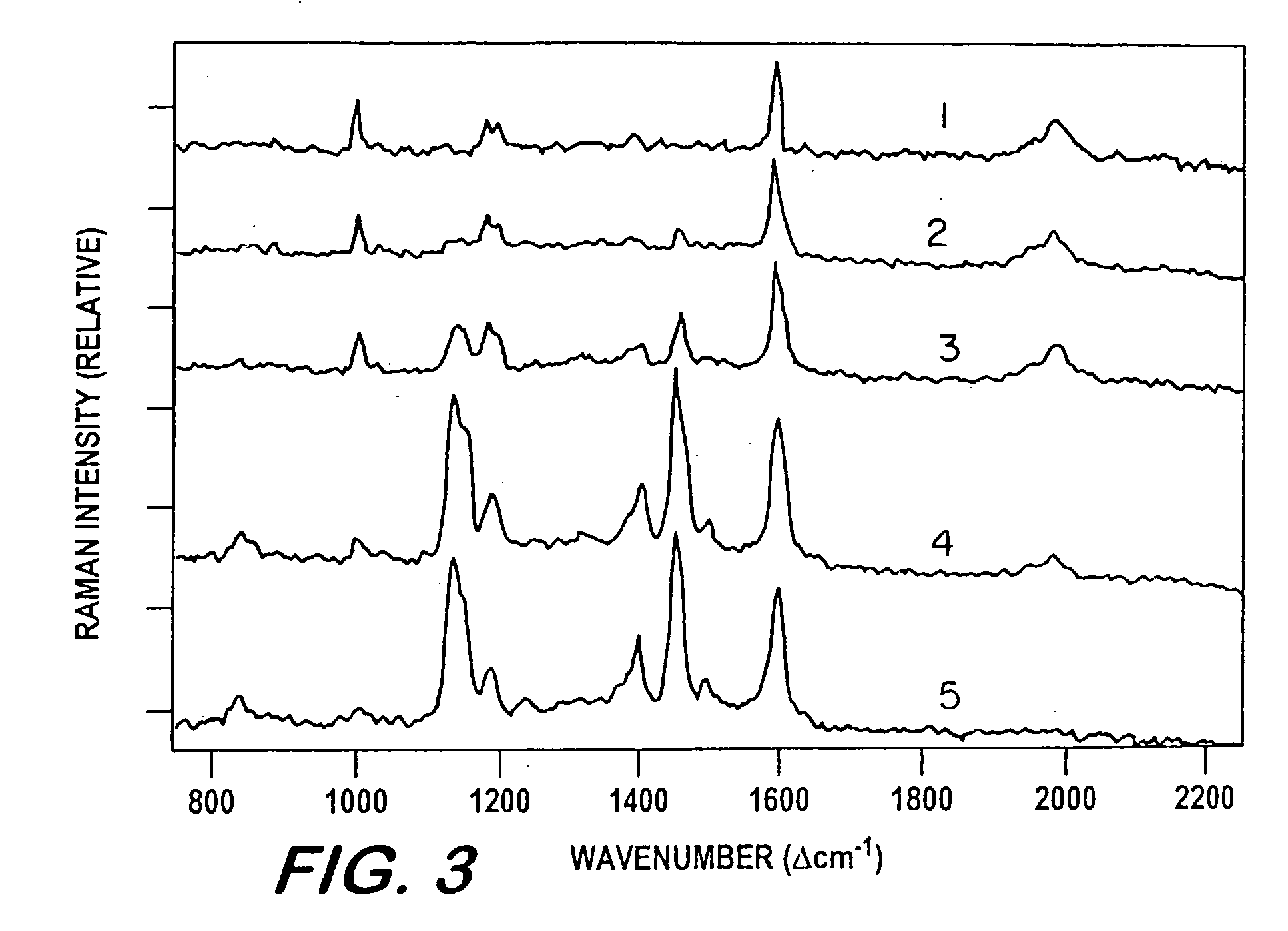

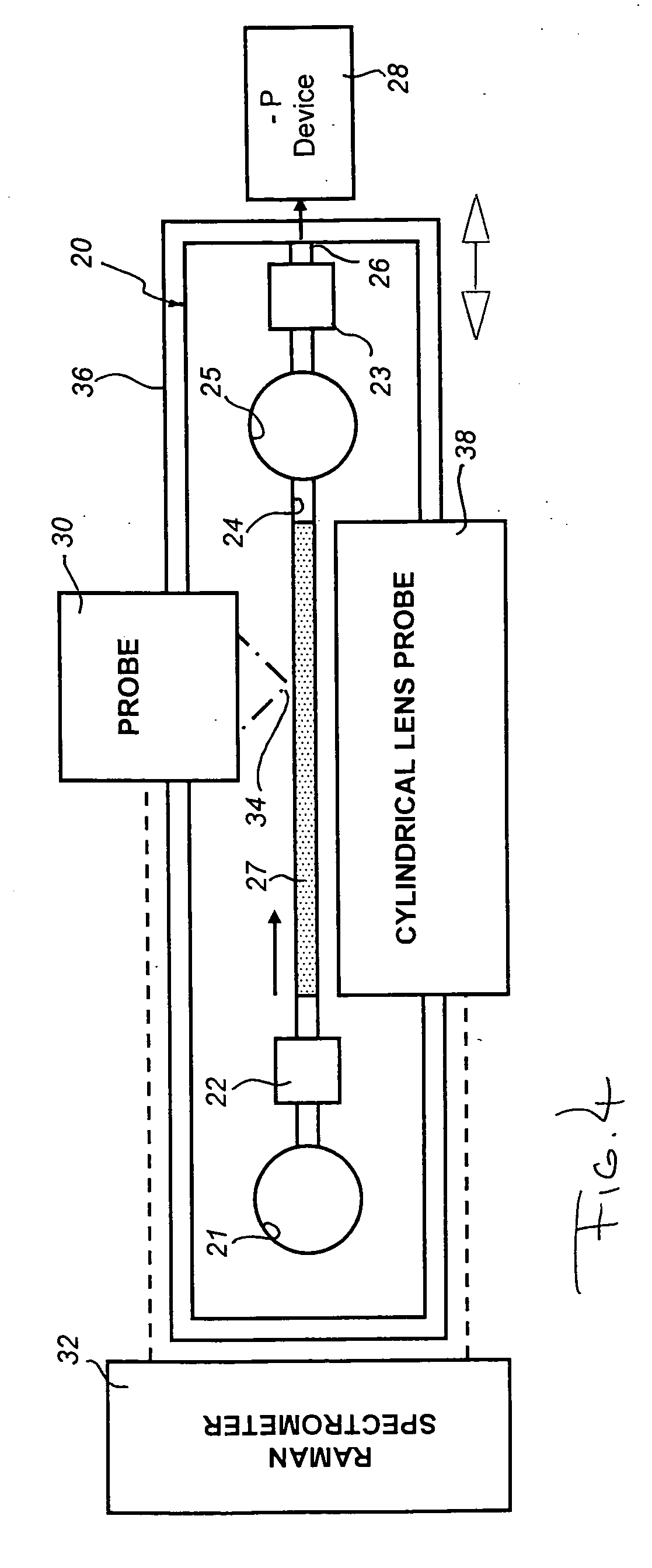

Analysis method effected with rapid analyte chemical separation and quick detection

InactiveUS20090168059A1Easy to separatePromote SER scattered radiationRadiation pyrometryComponent separationAnalyteChemical separation

A stationary medium is employed both to separate chemicals from a sample solution and also to generate surface-enhanced Raman scattering, so that spectral analysis of the separated analyte chemical can be performed. Applied driving force causes the sample to flow into the stationary medium and to distribute therethrough, thereby causing rapid separation of the analyte chemical, and surface-enhanced Raman scattered radiation is quickly detected, at a plurality of locations along a flow path defined by the stationary medium, for ultimate analysis.

Owner:REAL TIME ANALYZERS

Ethanol resistant and furfural resistant strains of E. coli FBR5 for production of ethanol from cellulosic biomass

InactiveUS20080090283A1Maximizing ethanol concentrationIncreased ethanol yieldBacteriaBiofuelsCelluloseResistant strain

Owner:ROWAN UNIVERSITY

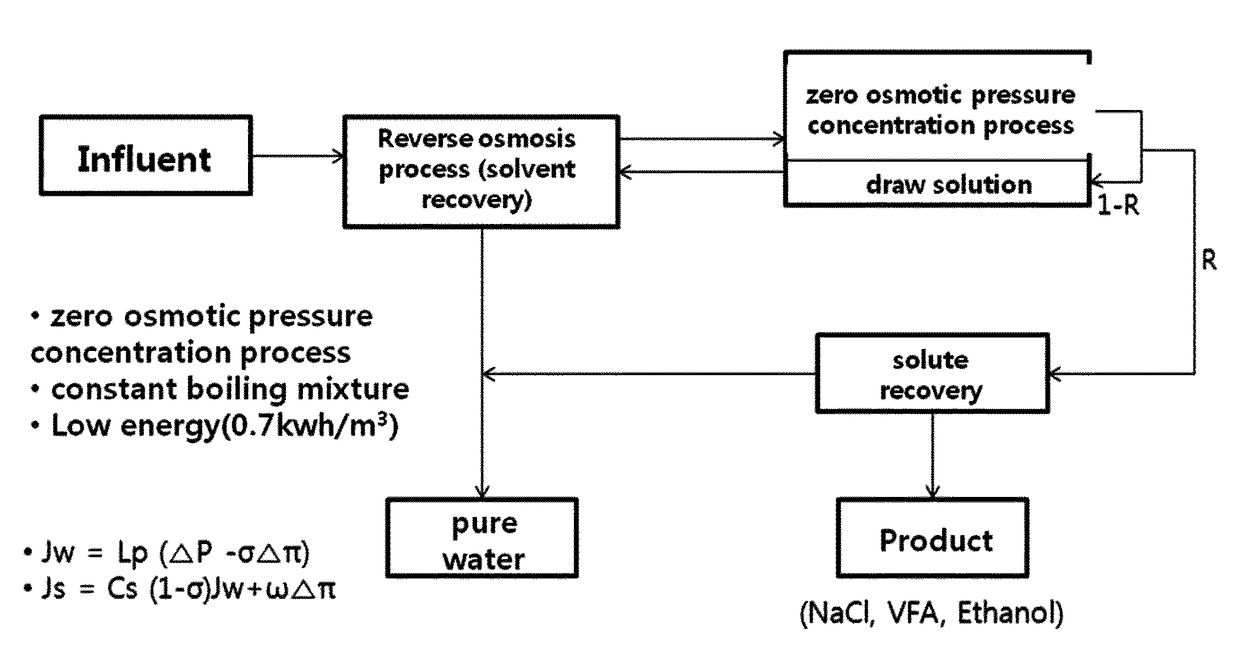

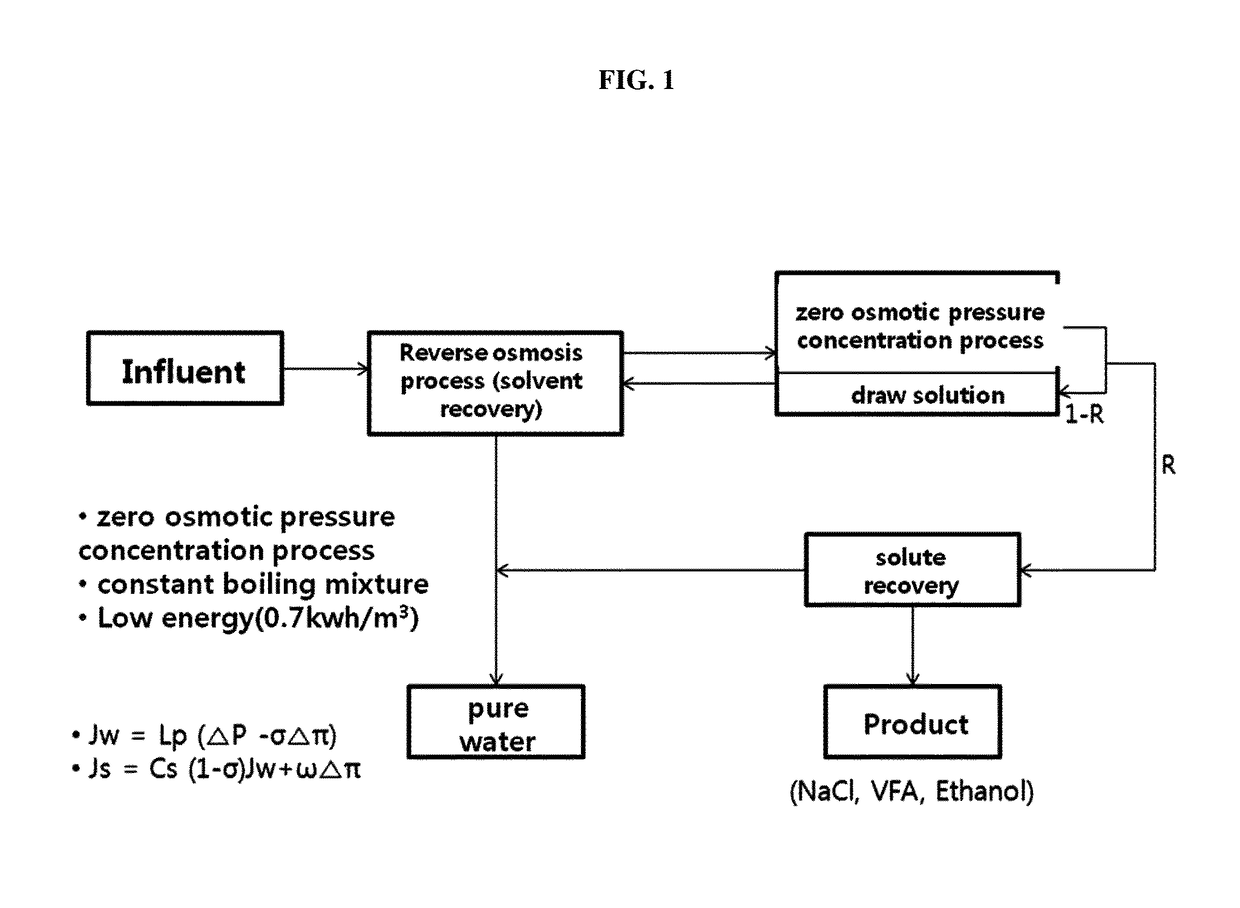

Method for concentrating aqueous containing solute into high concentration by hydraulic-membrane process under no difference in osmotic pressure

ActiveUS9950297B2Concentration maximizationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationSolvent

The present invention relates to a method of concentrating an aqueous solution at low pressure under a zero osmotic pressure difference condition, and more particularly, to a method of concentrating an aqueous solution containing a solute to be concentrated, at low pressure under a zero osmotic pressure difference condition. The method of the present invention comprises the steps of: (a) discharging water of a solute-containing aqueous solution to be concentrated, from a reverse osmosis separator to the outside, and transferring the concentrated aqueous solution to a zero osmotic pressure difference concentrator; (b) further concentrating the concentrated aqueous solution using the zero osmotic pressure difference concentrator comprising a feed chamber and a draw chamber, which are separated from each other by a reverse osmosis membrane or a forward osmosis membrane; and (c) recovering the solute and water from the aqueous solution further concentrated in the zero osmotic pressure difference concentrator. When the method of concentrating the aqueous solution at low pressure under the zero osmotic pressure difference condition is used, the aqueous solution can be concentrated to the maximum saturation concentration of a solute or a solution concentration of 100% using a reduced amount of energy without having to use an extraction solvent. In addition, there is an advantage in that a separate osmosis draw solution does not need to be used.

Owner:KOREA ADVANCED INST OF SCI & TECH

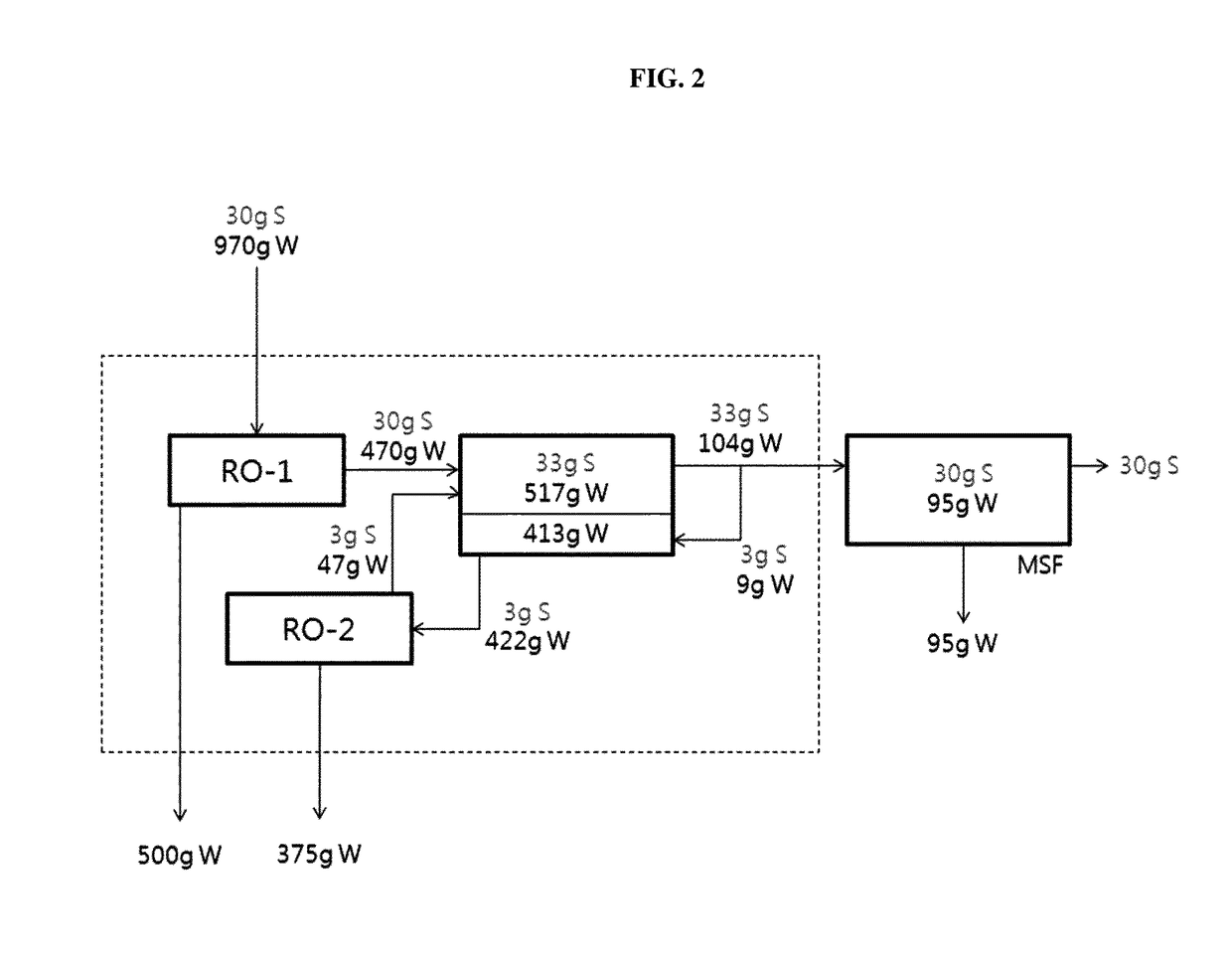

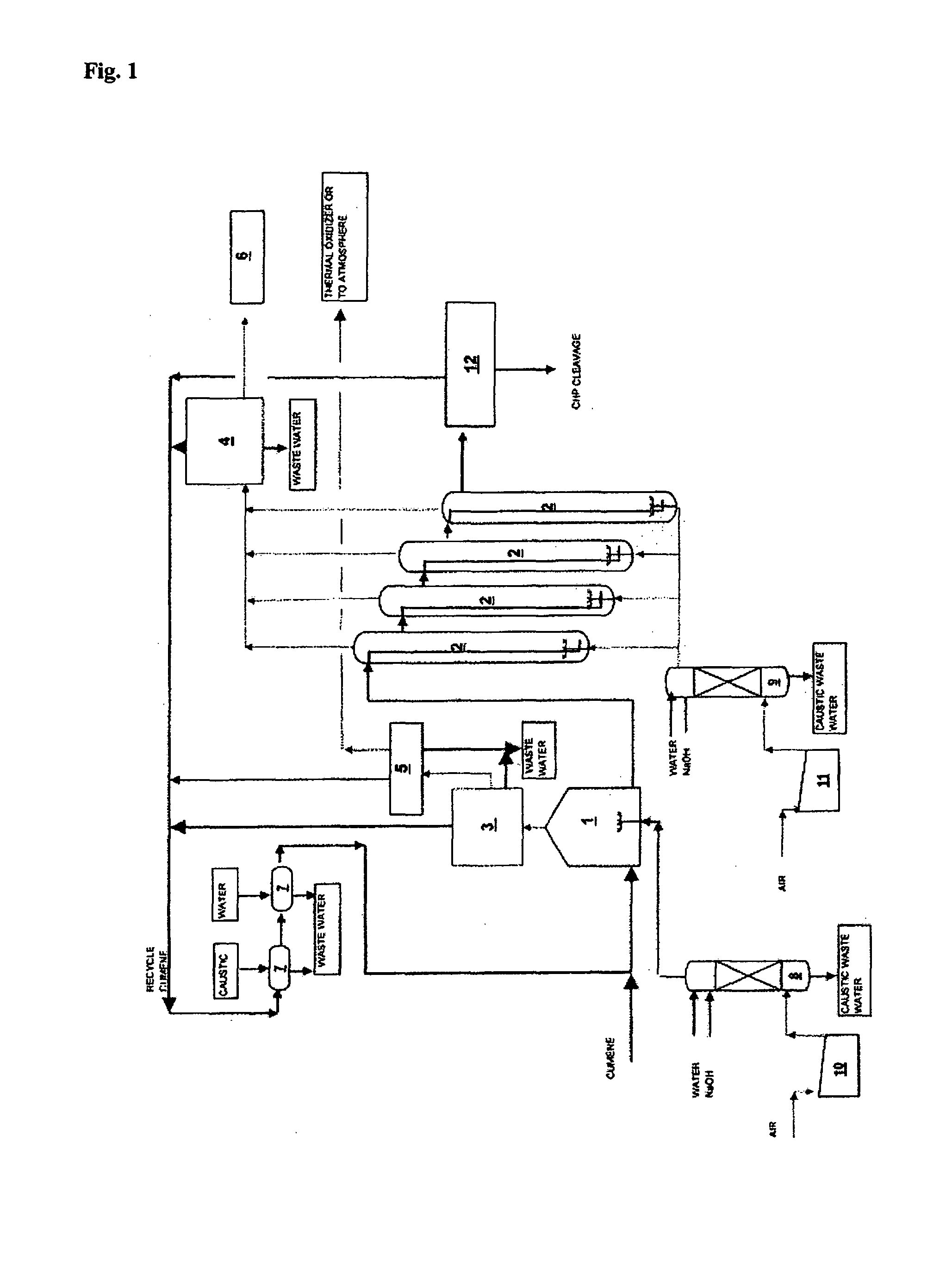

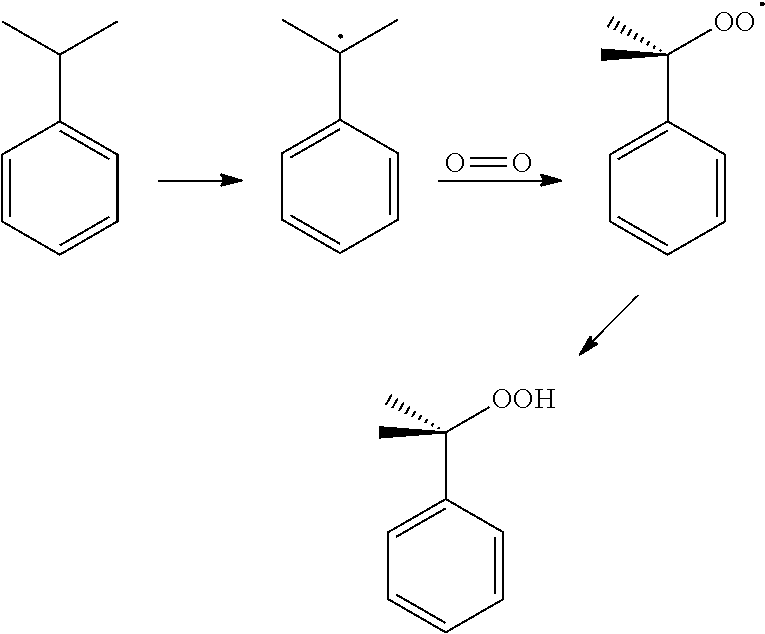

Multistage cumene oxidation

ActiveUS20110263905A1Maximize concentrationMinimize formationLiquid degasificationOrganic compound preparationCumene hydroperoxideChemistry

The present invention concerns a process for oxidizing cumene to cumene hydroperoxide using an oxygen containing gas, preferably air, which process comprises—conducting a cumene feed and an oxygen containing gas feed to at least the first oxidation reactor in a series of 3-8 reactors, thereby forming an oxidation mixture, and conducting the formed oxidation mixture from one reactor to the next, preferably after an oxidation reaction has taken place, wherein—the reactors comprise at least one lower pressure oxidizer (1) as the first reactor in the series and at least one higher pressure oxidizer (2) as the last reactor in the series; —any lower pressure oxidizer is operated at a pressure of at least atmospheric pressure and any higher pressure oxidizer is operated at a pressure of at least 0.5 bar higher than said at least one lower pressure oxidizer.

Owner:BOREALIS AG

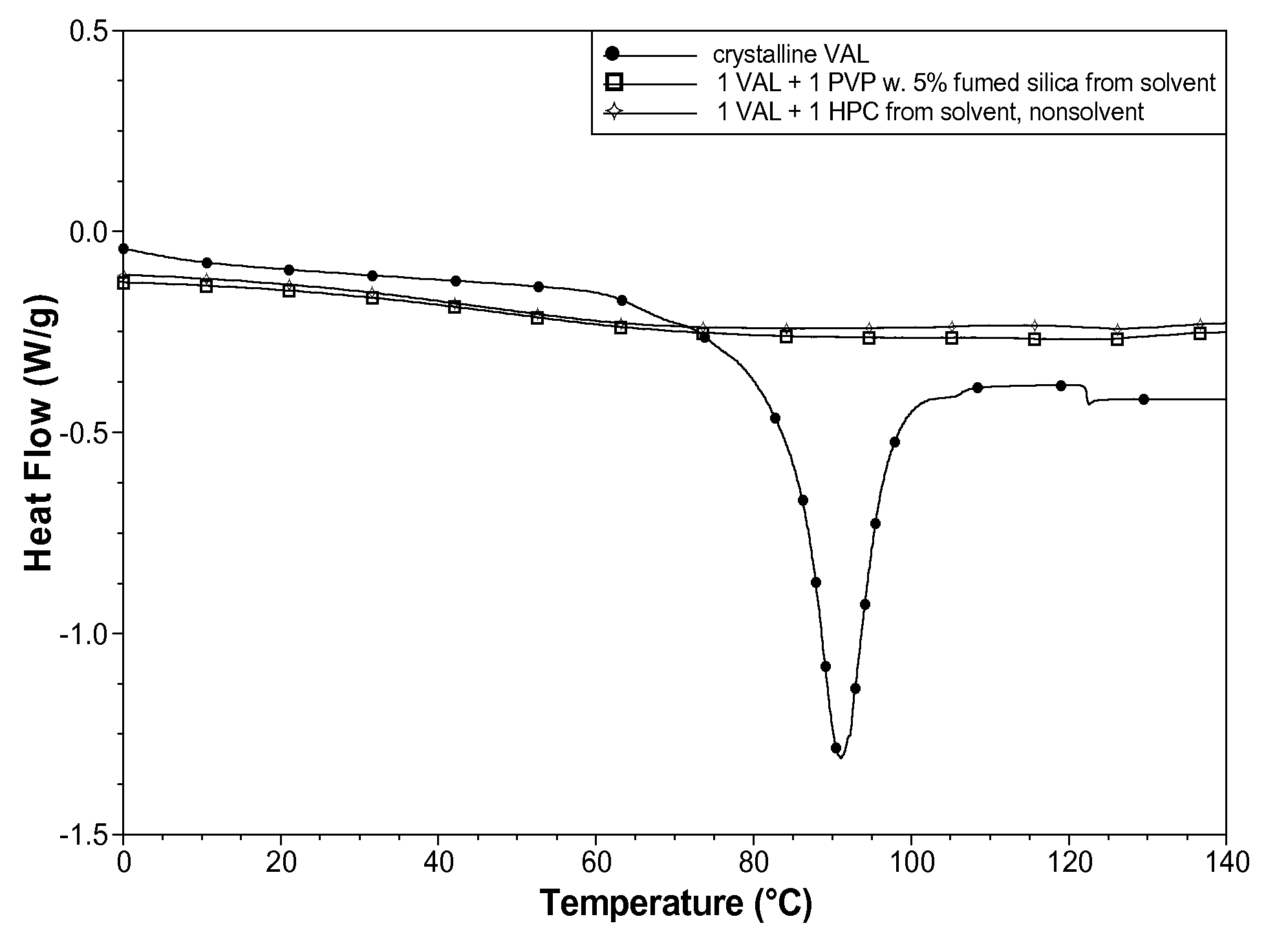

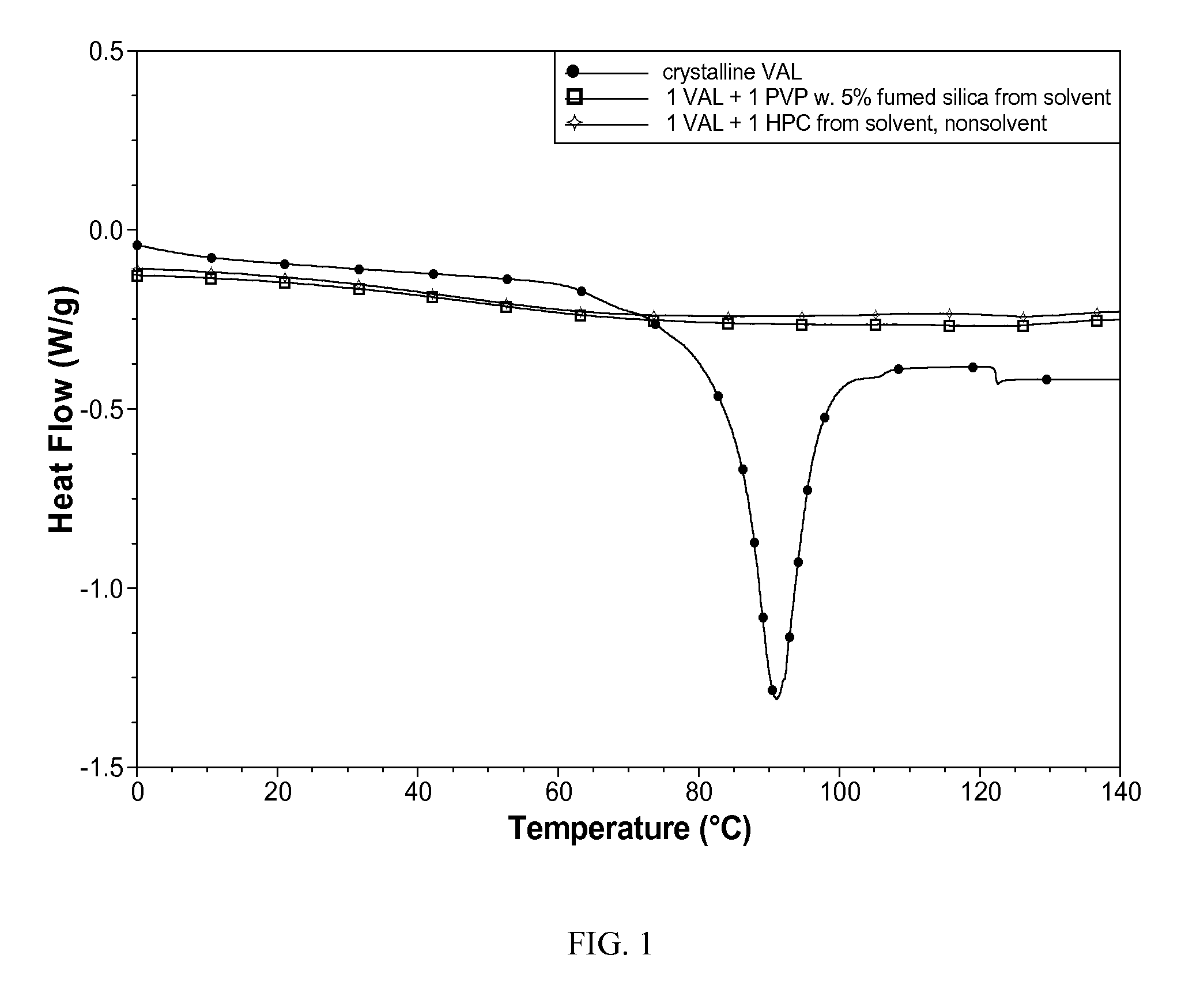

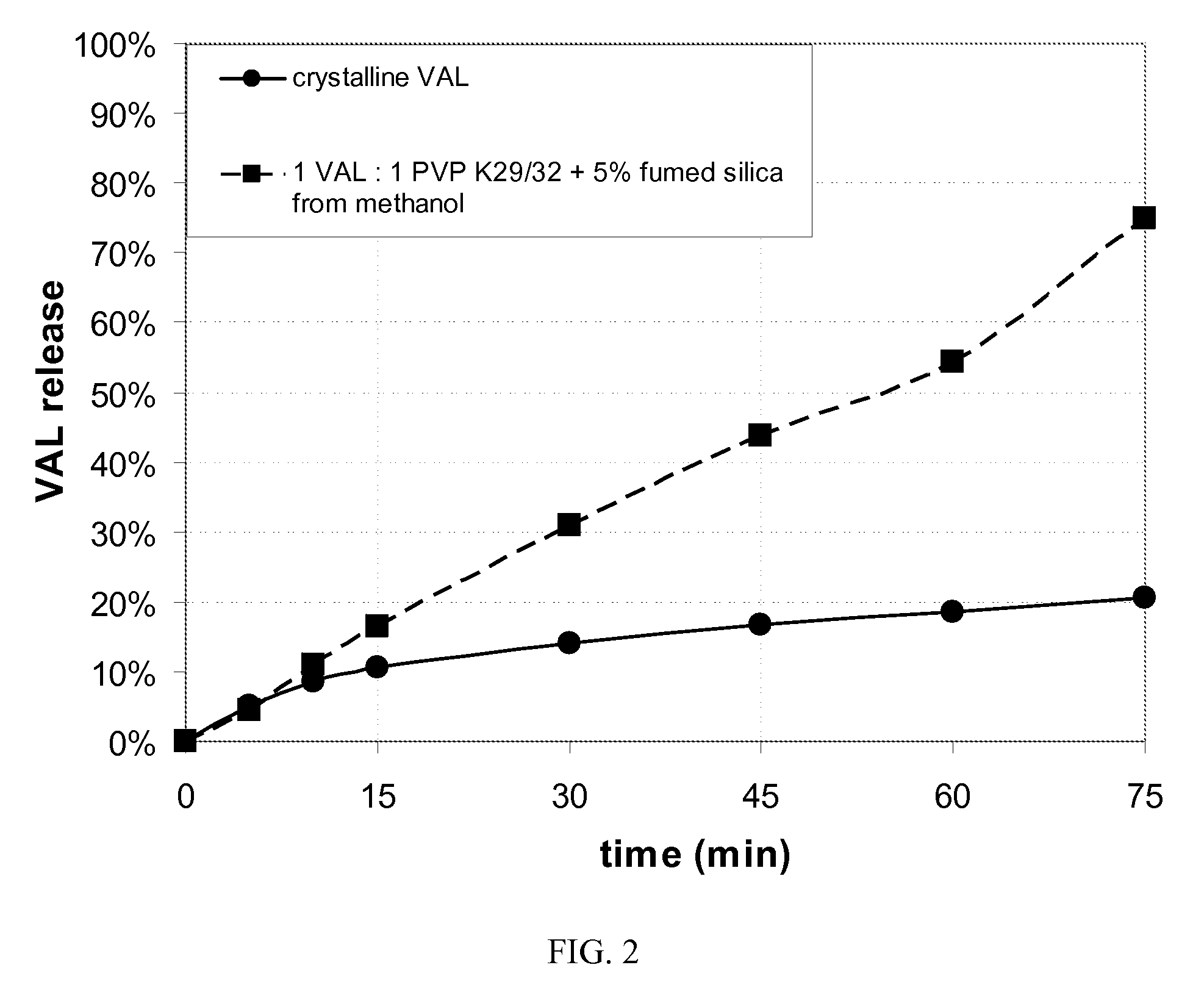

Amorphous valsartan and the production thereof

InactiveUS20080152717A1Reducing residual solvent contentIncrease in bulk powder densityBiocidePowder deliveryNon solventSolubility

Valsartan compositions of enhanced bioavailability are described that contain valsartan with at least one solubility-enhancing polymer. Described methods to produce the bioenhanced products comprise solvent spray drying. One aspect of the method includes the steps of providing a mixture comprising valsartan, a solubility-enhancing polymer and a single solvent, a solvent blend or solvent / non-solvent blend removing and then evaporating the mixture to form amorphous valsartan.

Owner:ISP INVESTMENTS INC

Batch reactor control system based on accurate punishment optimization

InactiveCN103324086AConcentration maximizationRealize tapping potential and increasing efficiencyChemical/physical/physico-chemical stationary reactorsAdaptive controlTemperature controlDigital analog converter

The invention discloses a batch reactor control system based on accurate punishment optimization. The batch reactor control system is formed by a batch reactor body, a temperature sensor at the end of the batch reactor body, an analog-digital converter, a field bus network, a DCS, a master-control room temperature and product concentration status displayer, a digital-analog converter at the end of a temperature control valve and the temperature control valve. After the duration time of the production process, the initial concentration state of materials in the reactor body and target products with concentration required to be improved are appointed by a control room engineer, the internal accurate punishment optimization method is implemented by the DCS, temperature control strategies which enable the concentration of the target products to be maximum are calculated and converted into opening instructions of the temperature control valve, the opening instructions are transmitted to the digital-analog converter at the end of the temperature control valve through the field bus network, and the temperature control valve executes corresponding motions. The temperature sensor at the end of the batch reactor body collects the temperature of the batch reactor body in real time, and therefore the control room engineer can master the production process at any time. The batch reactor control system enables the concentration of the target products to be maximum and achieves the aims of digging potential and improving efficiency.

Owner:ZHEJIANG UNIV

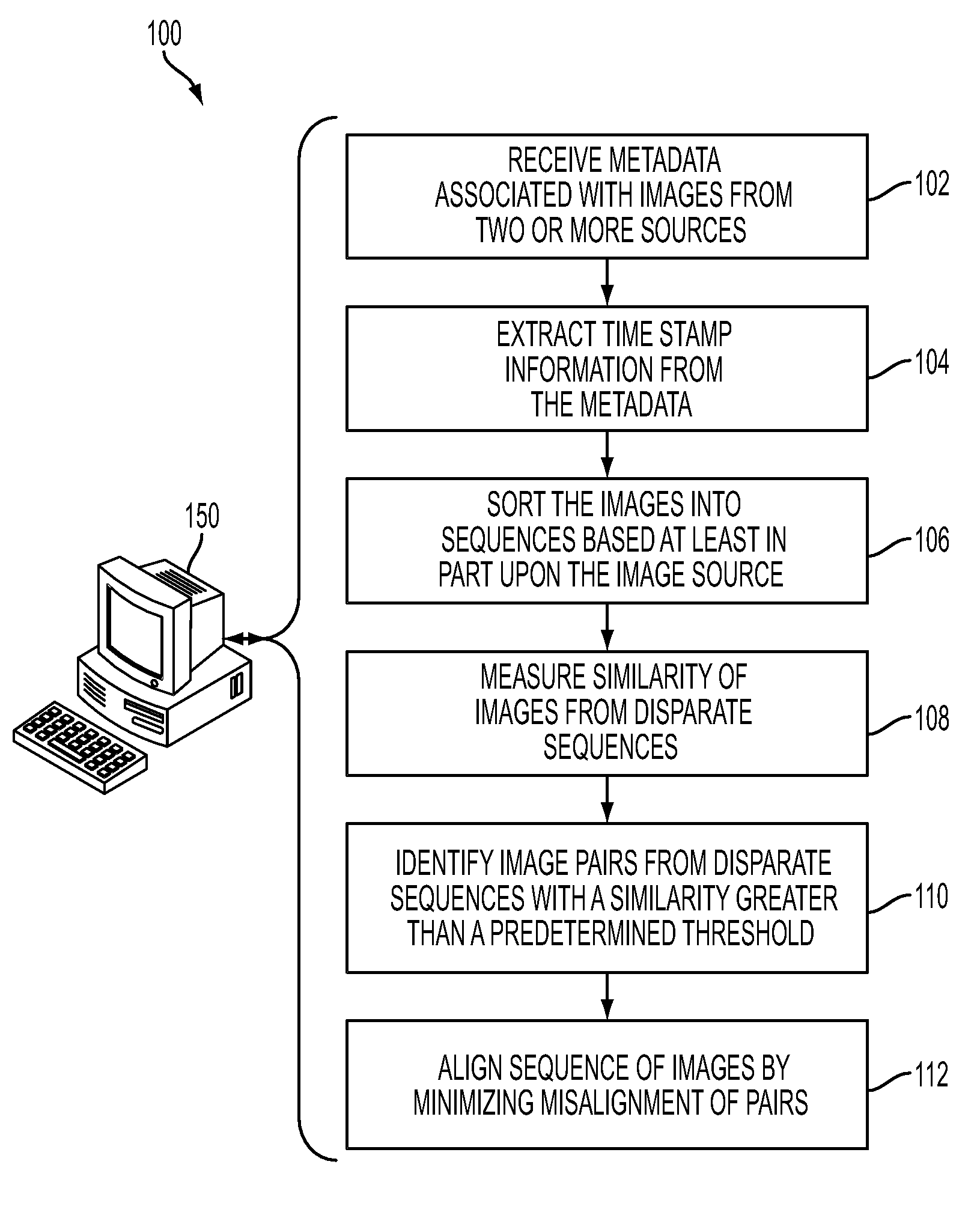

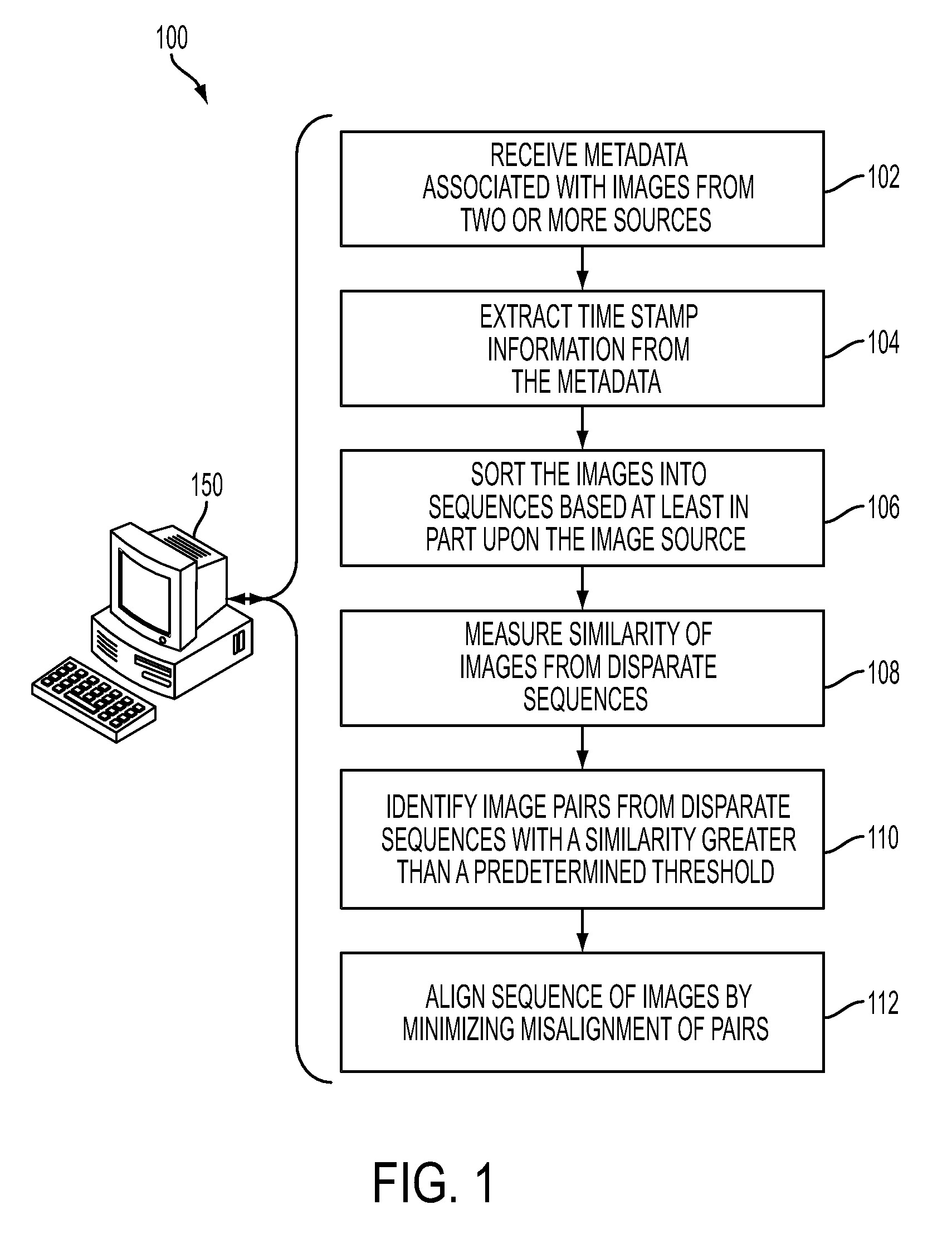

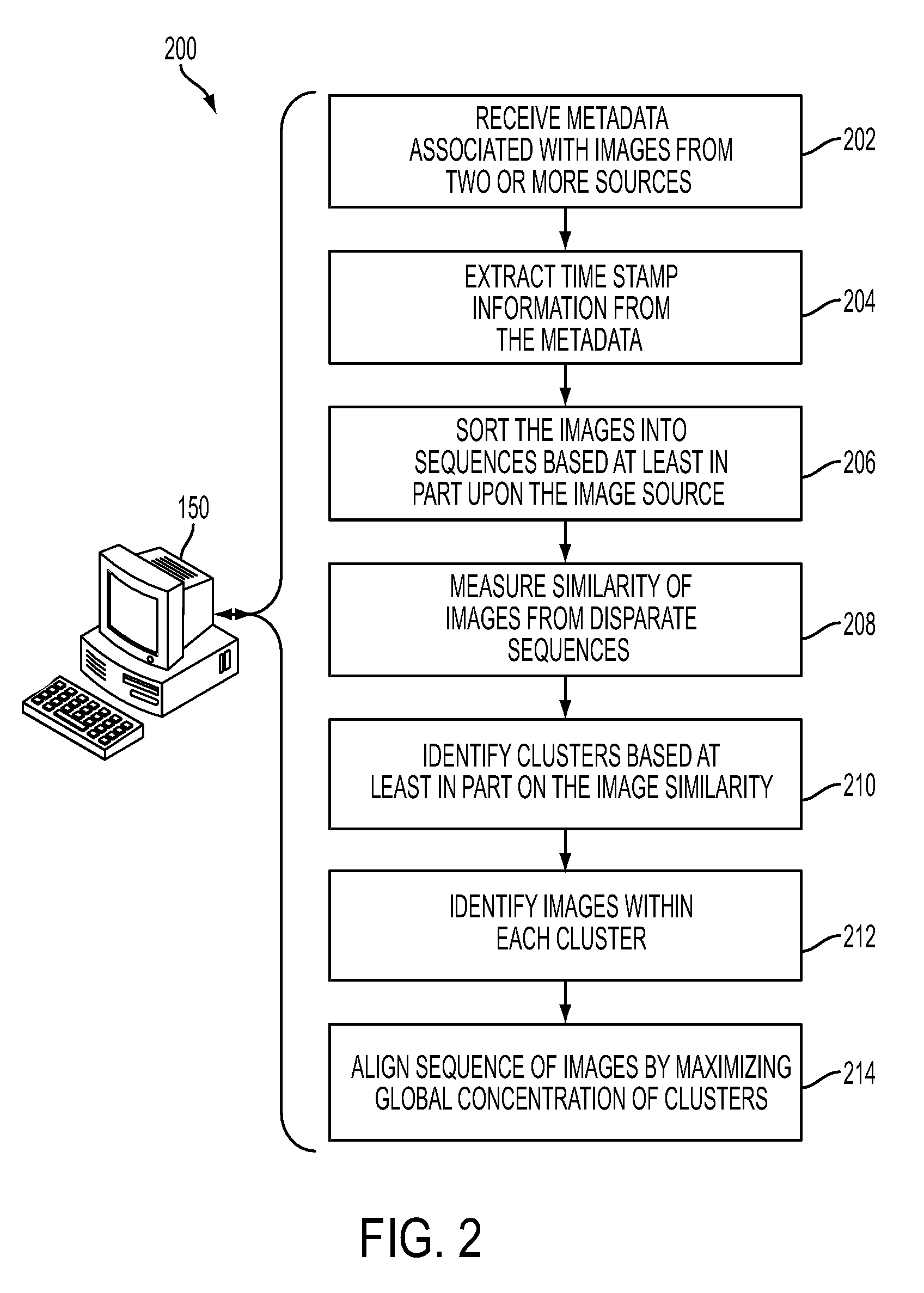

Synchronizing image sequences

InactiveUS8326087B2Minimize misalignmentConcentration maximizationCharacter and pattern recognitionMetadata still image retrievalPattern recognitionImage pair

As set forth herein, a computer-based method is employed to align a sequences of images. Metadata associated with images from two or more sources is received and a time stamp is extracted from the metadata. The images are sorted into sequences based at least in part upon the image source. The similarity of images from disparate sequences is measured and image pairs from disparate sequences with a similarity greater than a predetermined threshold are identified. A sequence of images is aligned by minimizing the misalignment of pairs.

Owner:XEROX CORP

Profile adjustment in plasma ion implanter

ActiveUS7528389B2Concentration maximizationMaximize doseElectric discharge tubesRadiation therapyDopantEngineering

A method and apparatus are directed to providing a dopant profile adjustment solution in plasma doping systems for meeting both concentration and junction depth requirements. Bias ramping and bias ramp rate adjusting may be performed to achieve a desired dopant profile so that shallow and abrupt junctions in vertical and lateral directions are realized that are critical to device scaling in plasma doping systems.

Owner:VARIAN SEMICON EQUIP ASSOC INC

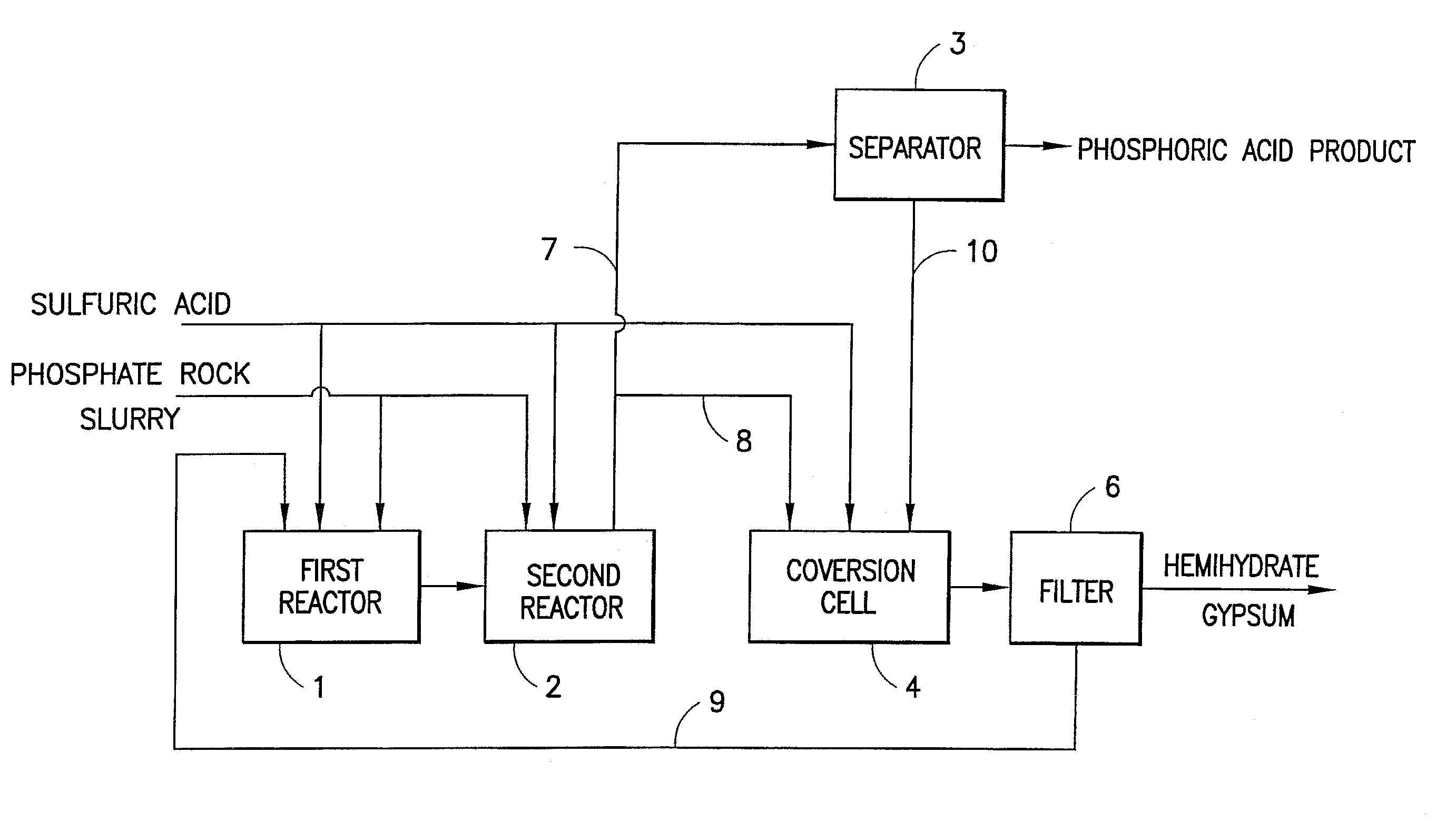

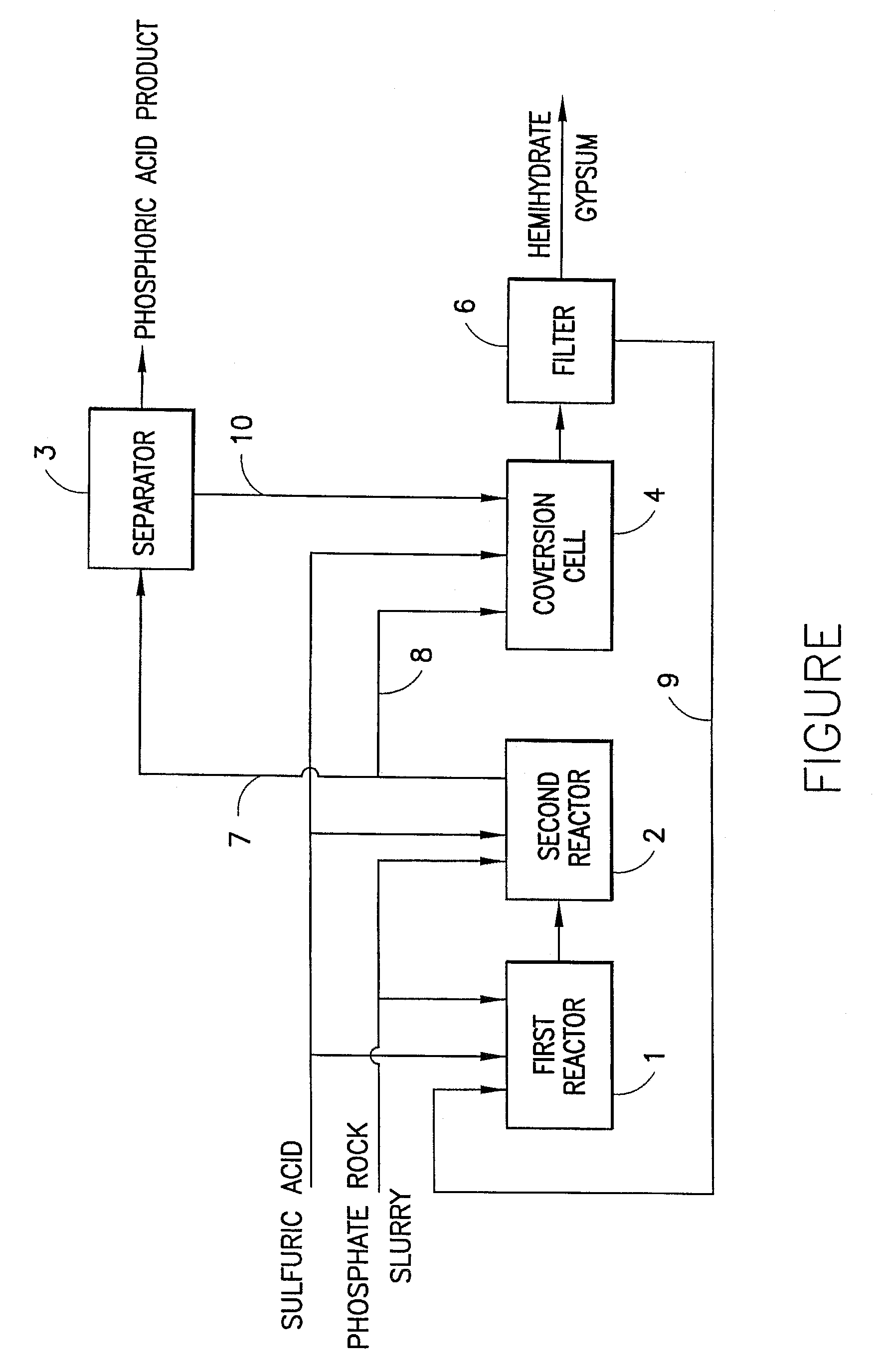

Method of preparing wet process phosphoric acid

InactiveUS7172742B2Concentration maximizationImprove crystallization conditionsCalcium/strontium/barium sulfatesPhosphorus oxyacidsFiltrationPhosphate

The present invention relates to a method of preparing wet process phosphoric acid, which comprises: dividing raw materials which contain phosphate rock slurry and sulfuric acid into two parts, and then feeding these two parts into two reactors separately. In the first reactor, feeding 70–90 wt. % of the total amount of the slurry and sulfuric acid, in which the ratio of phosphate rock slurry to sulfuric acid to recycled phosphoric acid is set to be 1:0.6˜0.8:1.0˜2.5. 10˜30% of the reaction solution directly flows into conversion cell, participating in the conversion reaction of dihydrate gypsum. Thus resulted phosphoric acid concentration is 33˜39 wt. %. The recovery efficiency of P2O5 is 99% or more. When putting coke powders in the conversion solution as filter aid, the filtration efficiency can be improved by 10˜30%, and in so produced hemihydrate gypsum, P2O5 is 0.05˜0.2%, water of hydration is 4˜8%. The product can be used for producing sulfuric acid and cement without baking dry.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

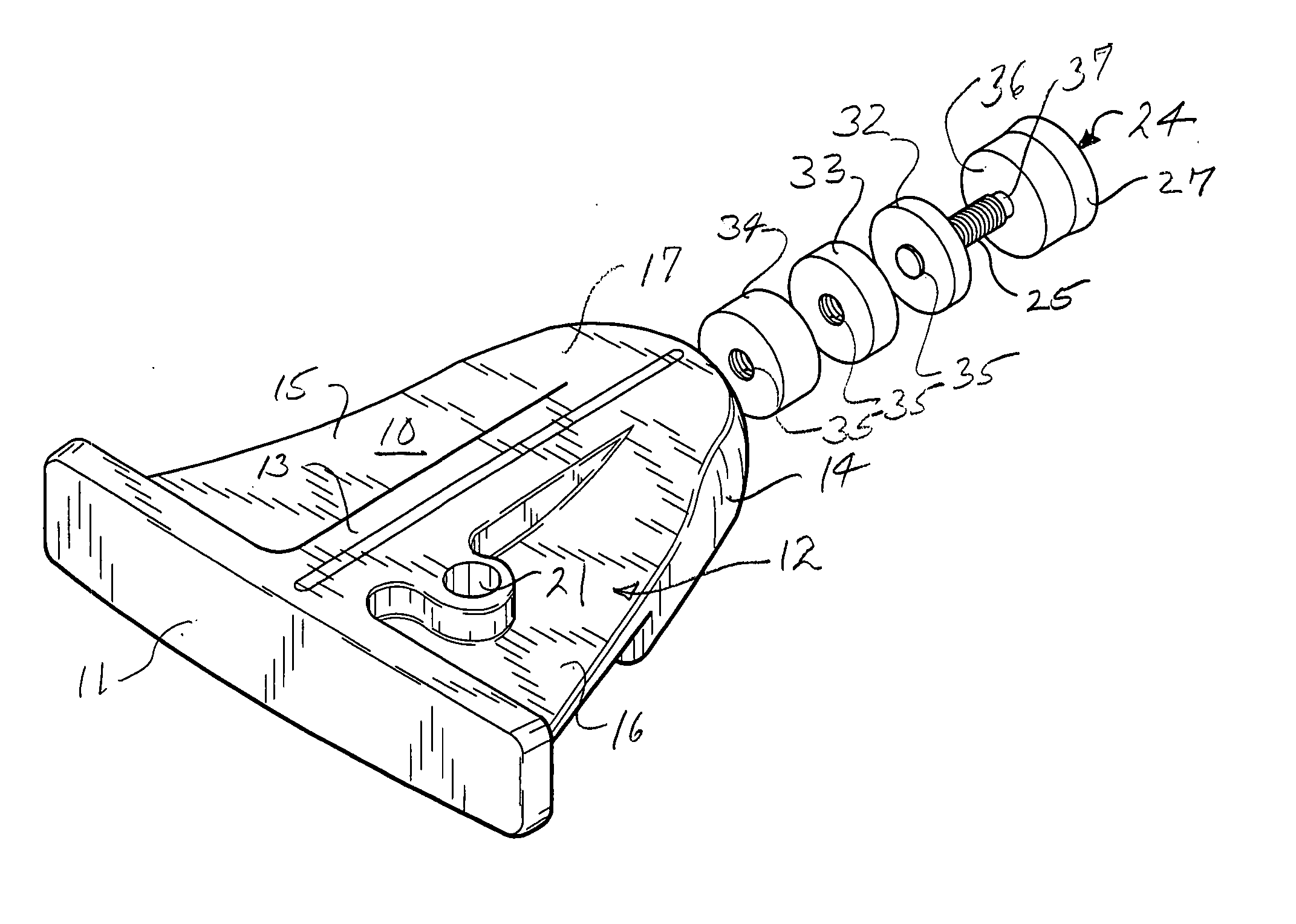

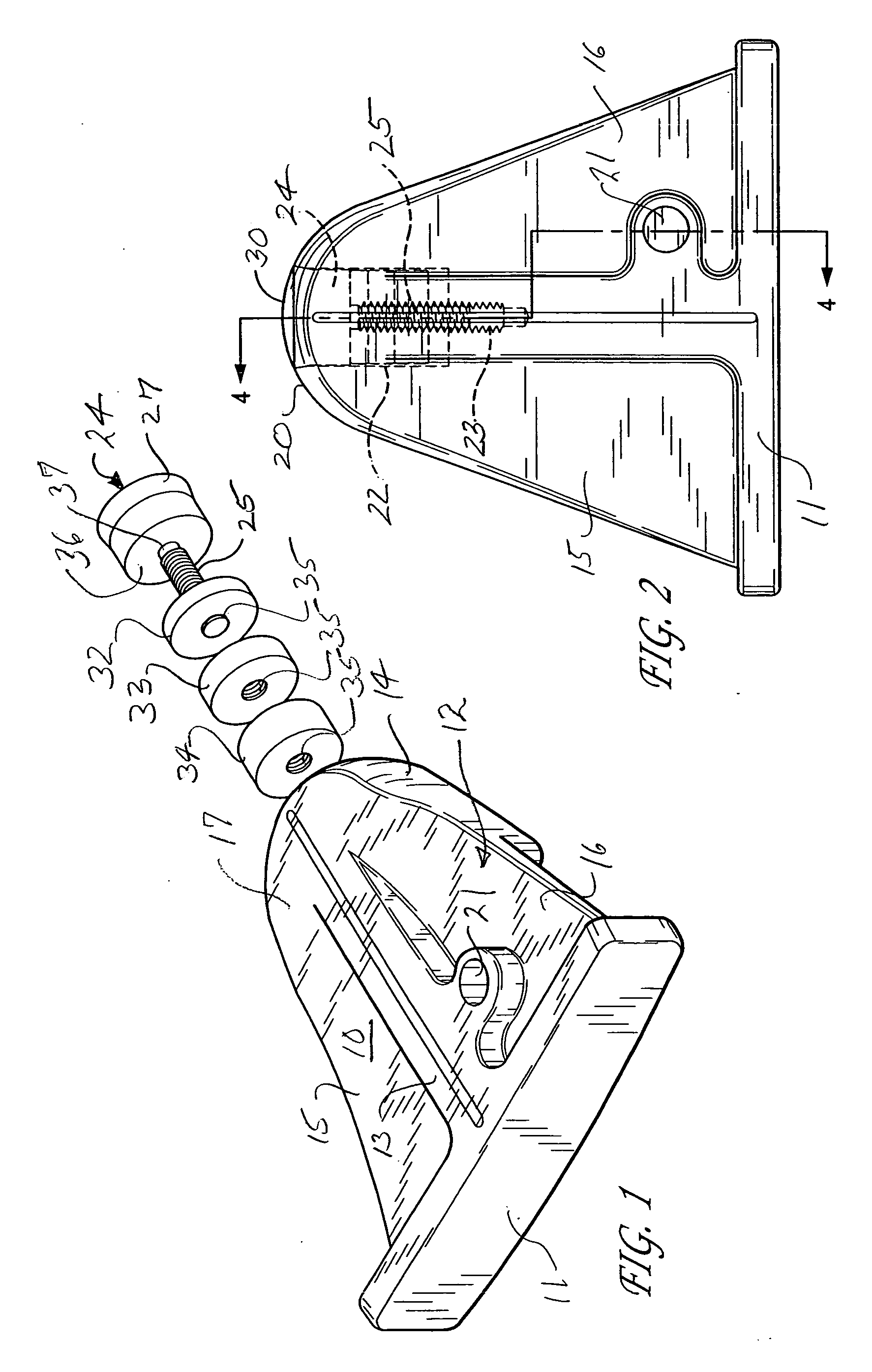

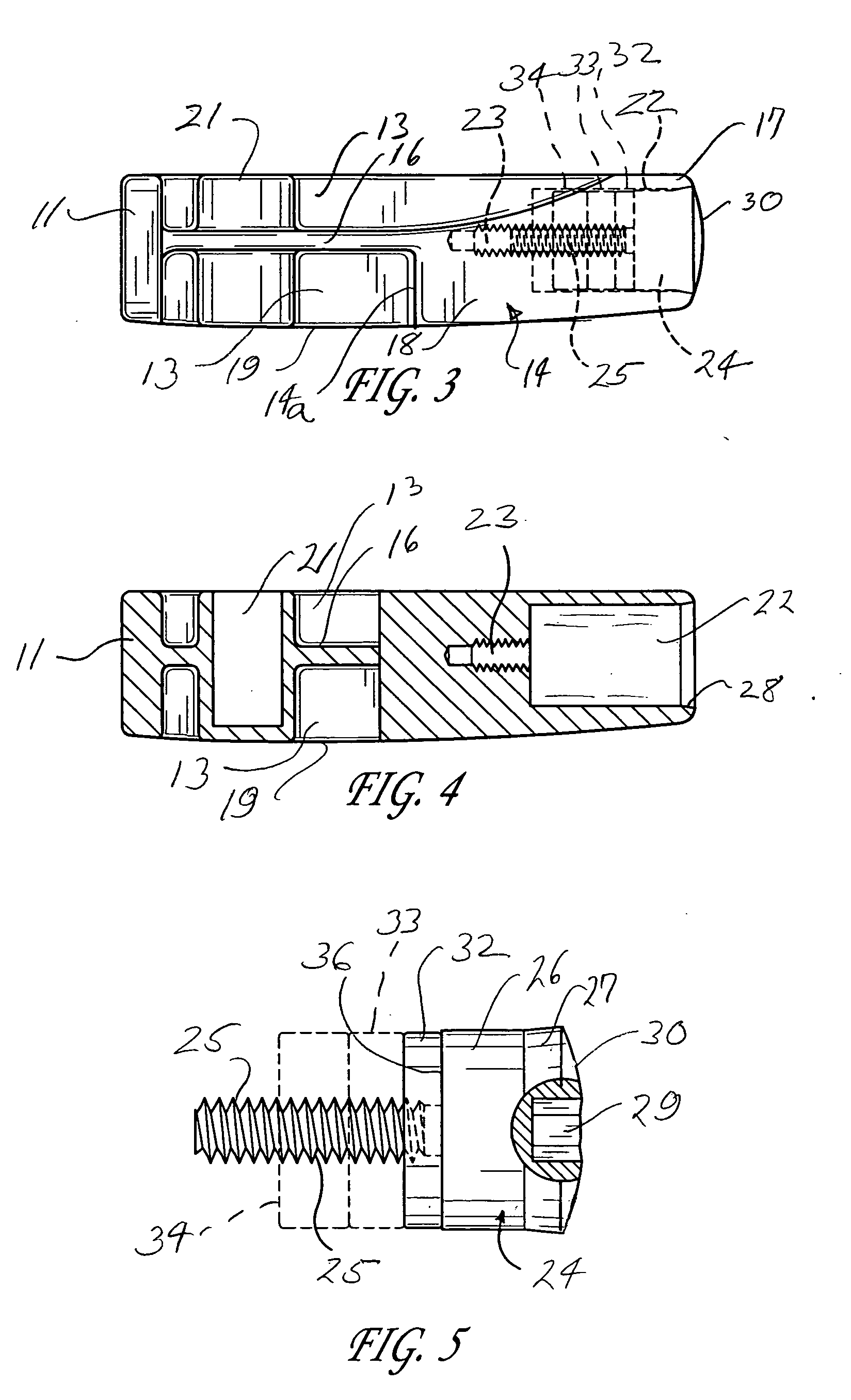

Adjustable weight putter

InactiveUS20060142095A1Easy to useOptimizes weight balanceGolf clubsRacket sportsSpecific gravityTungsten

An adjustable weight golf putter is provided with a body portion of a material of low specific gravity, for example aluminum, and a weighted cap, receivable in a longitudinal recess opening at the back extremity of the body portion. The weighted cap is formed of a material of high specific gravity, for example a tungsten-copper alloy, and has a weight which is at least more than 20%, and preferably more than 30% of the weight of the lighter body portion, concentrating the weight of the putter head toward the back and locating its center of gravity more than half way toward the back of the putter head. The weighted cap is secured by a threaded shaft engageable in a recess extension in the body. Optional weighted discs, of a high specific gravity material and each of a different weight, are threadedly engageable with the shaft and are usable in various combinations for optimal weight adjustment. The optional weights are applied in tight engagement with the weighted cap, to maintain weight concentration at the back.

Owner:CONNECTOR SET PARTNERSHIP

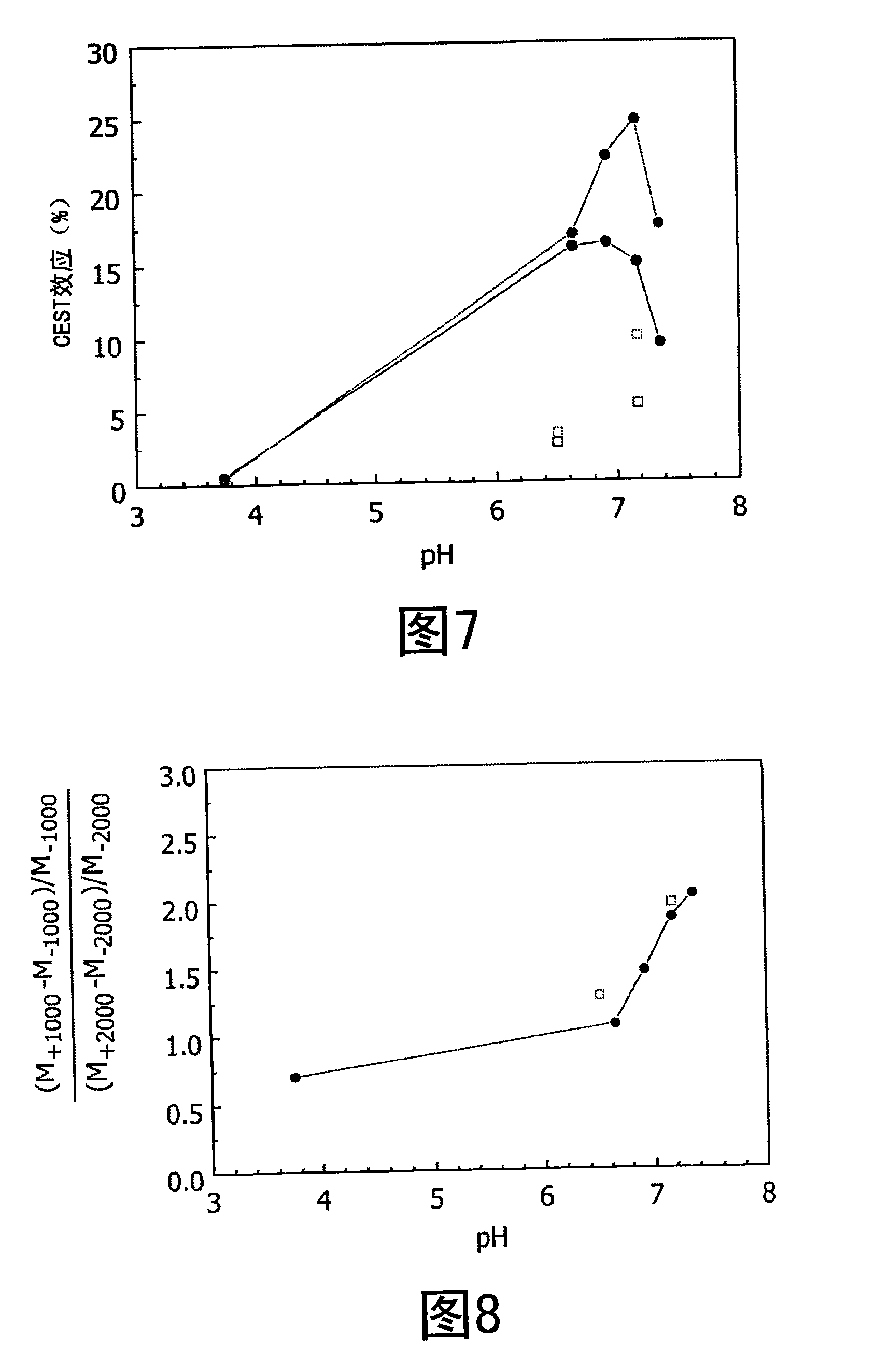

Method for using CEST contrast agents in MRI

InactiveCN101166987AEliminate dependenciesElimination of concentration dependenceMeasurements using NMR imaging systemsMagnetic variable regulationMedicineProton

The invention relates to a method for mapping of a physico-chemical parameter such as pH value, temperature, PO2 or metabolite concentration, using a chemical exchange saturation transfer contrast agent in Magnetic Resonance Imaging. This method may be used with agents having only one exchangeable entity pool, e.g. proton pool, by applying two different RF frequencies for pre-saturation of the contrast agent.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Viscosity index improver concentrates for lubricating oil compositions

ActiveUS20150184105A1Concentration maximizationLiquid carbonaceous fuelsBase-materialsPolymer scienceViscosity index

Concentrates of linear, block copolymers having a polymer block derived from a monoalkenyl arene, covalently linked to one or more blocks of a hydrogenated derivative of a conjugated diene copolymer, dissolved in highly saturated diluent oil, wherein the size of the monoalkenyl arene block is controlled to provide an optimized level of incompatibility of the block copolymer in the selected diluent.

Owner:INFINEUM INT LTD

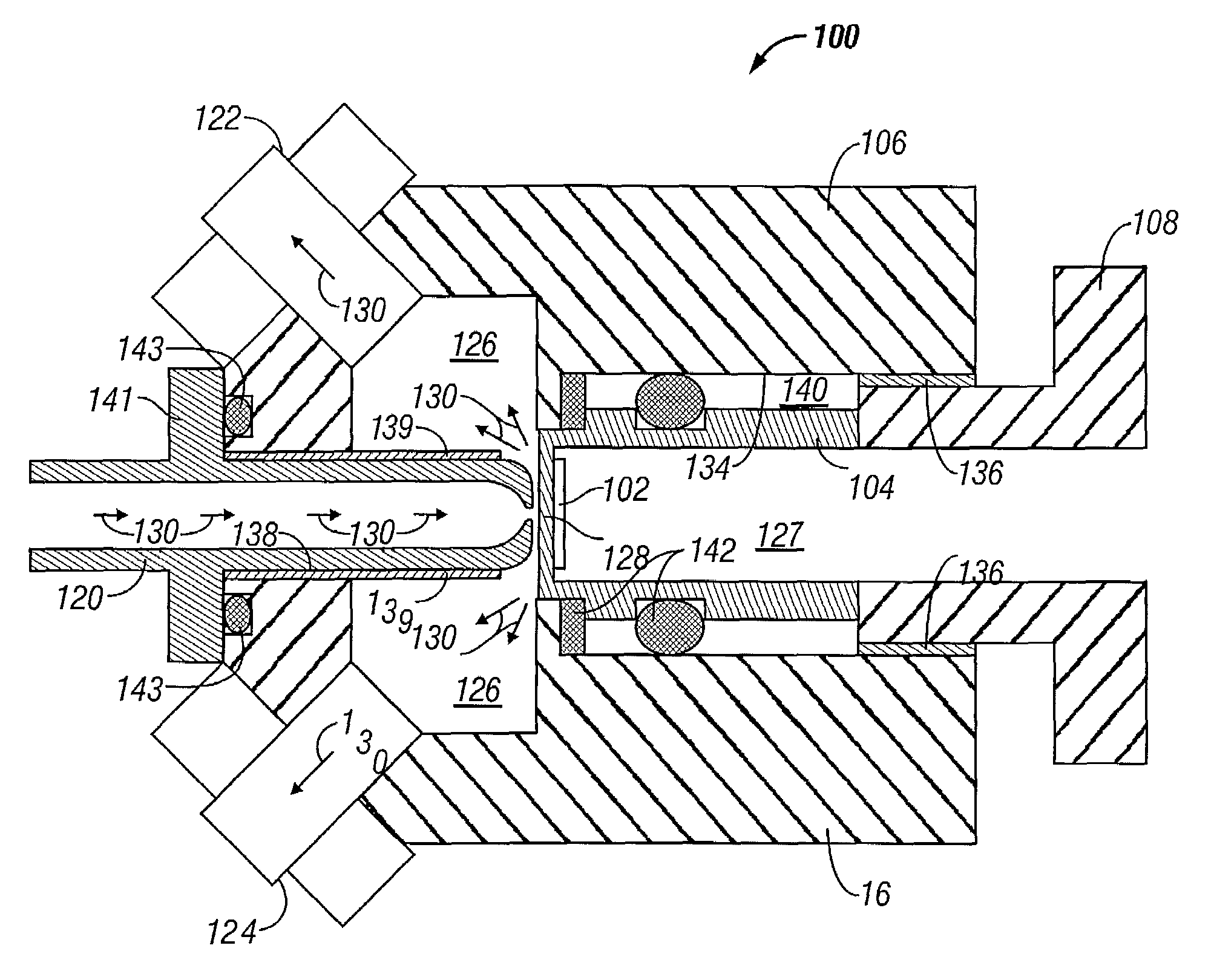

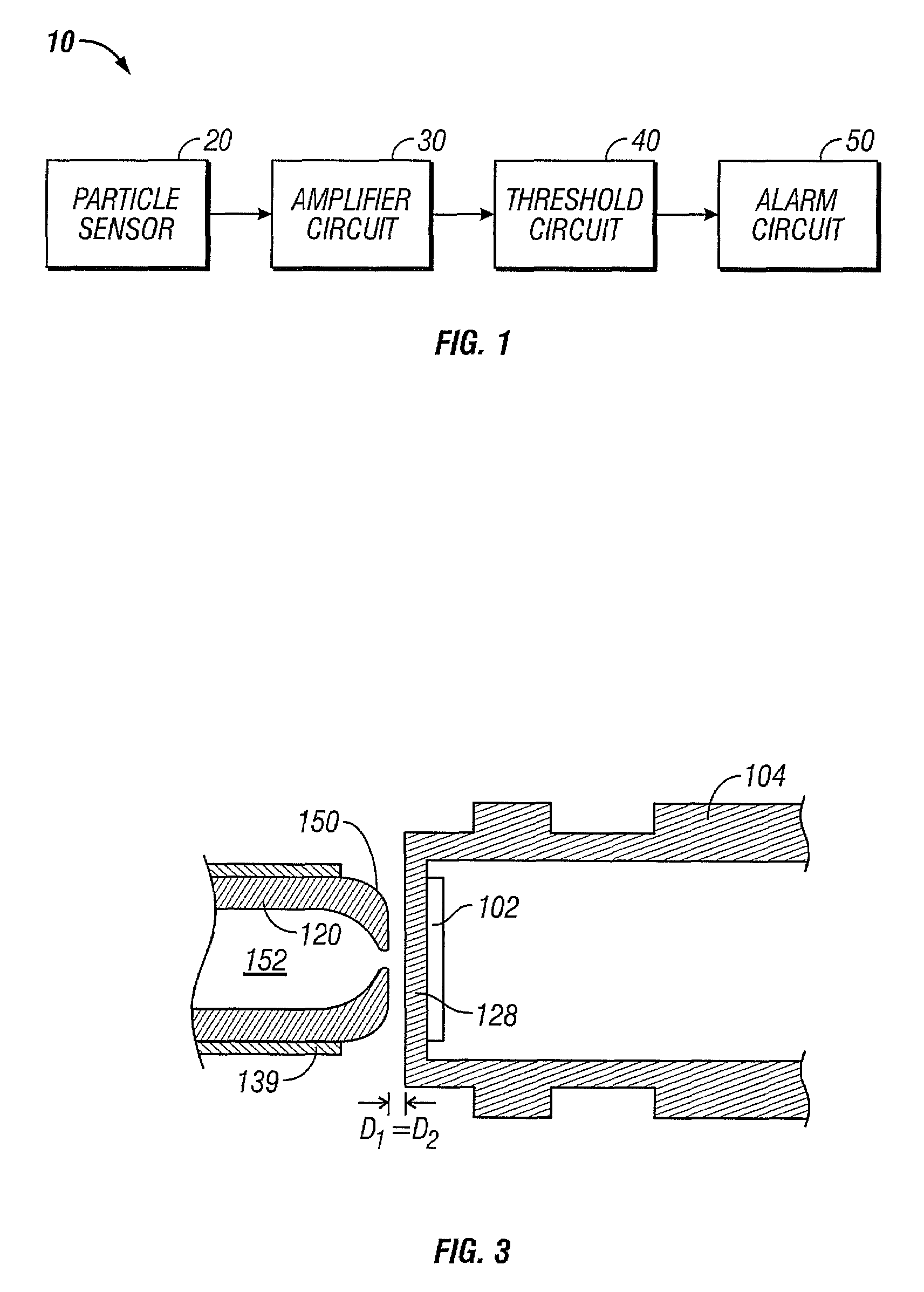

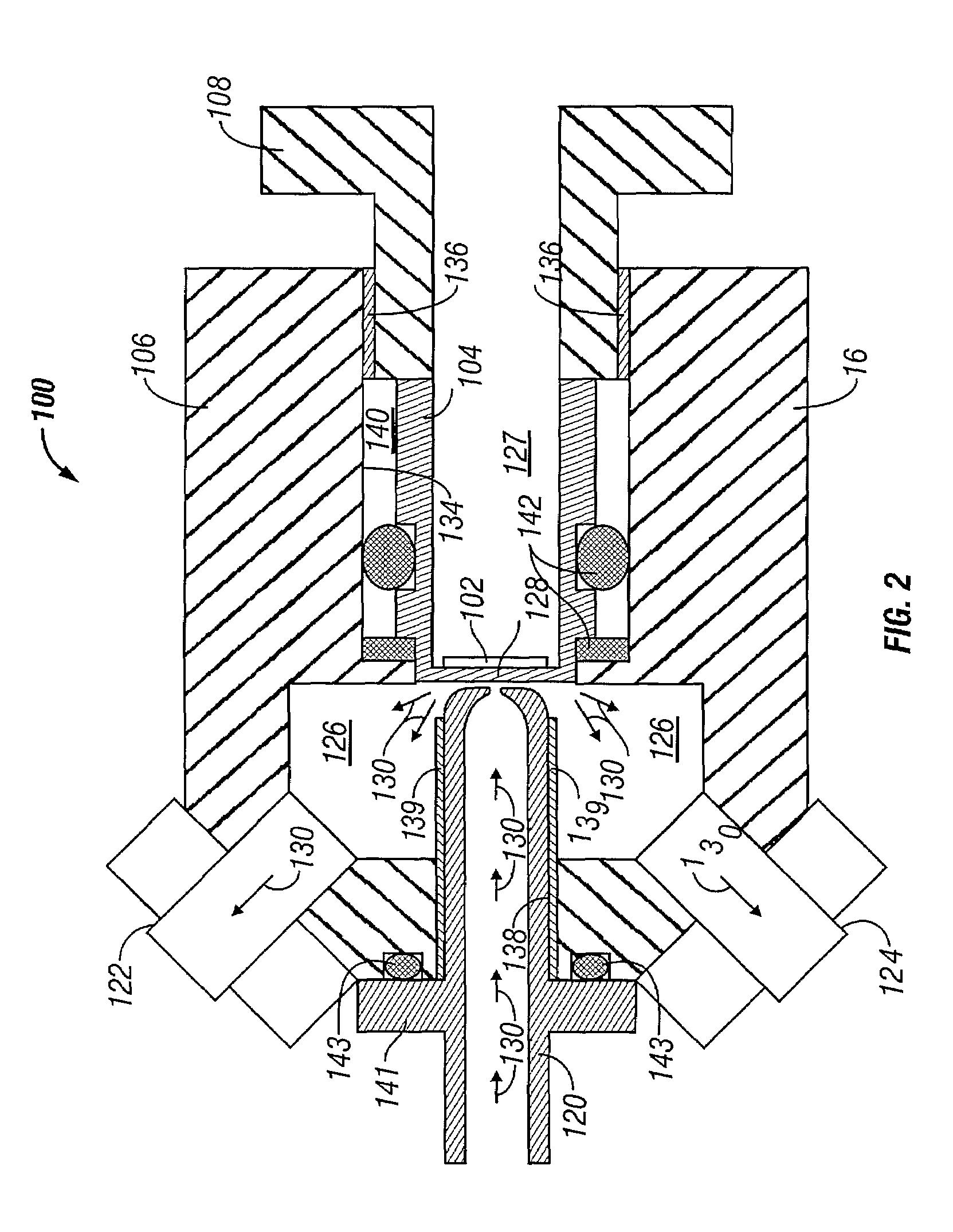

Acoustic particle alarm including particle sensor

InactiveUS7463158B2Reduce couplingReduce the amount requiredAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesMomentumAcoustics

The present invention provides an acoustic particle alarm comprising a particle sensor for indicating the concentration of particles exceeding a specified size and specified concentration, for particles entrained in a fluid flow impinging on a front face of the sensor, and a nozzle for directing the fluid flow such that the particles impact the sensor in a direction substantially normal to the front face of the sensor. Each particle impacting the front face of the sensor causes a response in an output of the sensor with amplitude that is monotonic in the momentum of the impinging particle.

Owner:LINEAR MEASUREMENTS

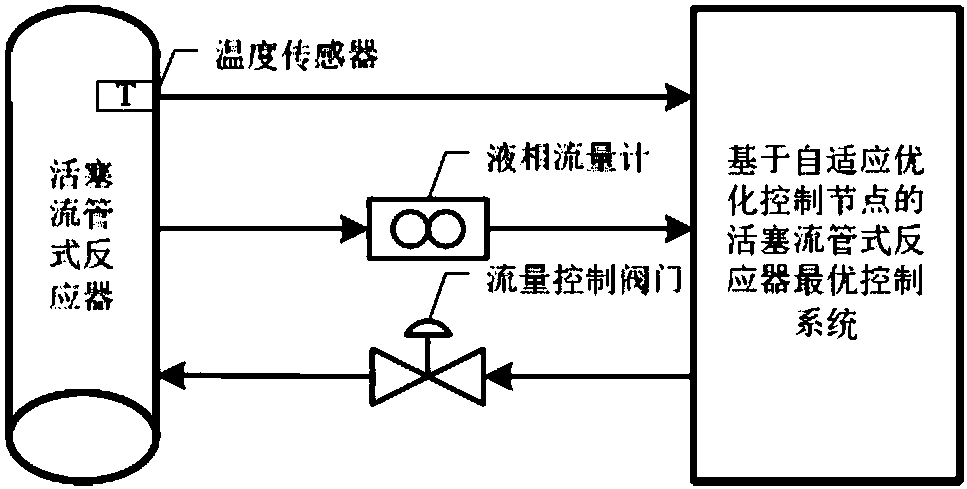

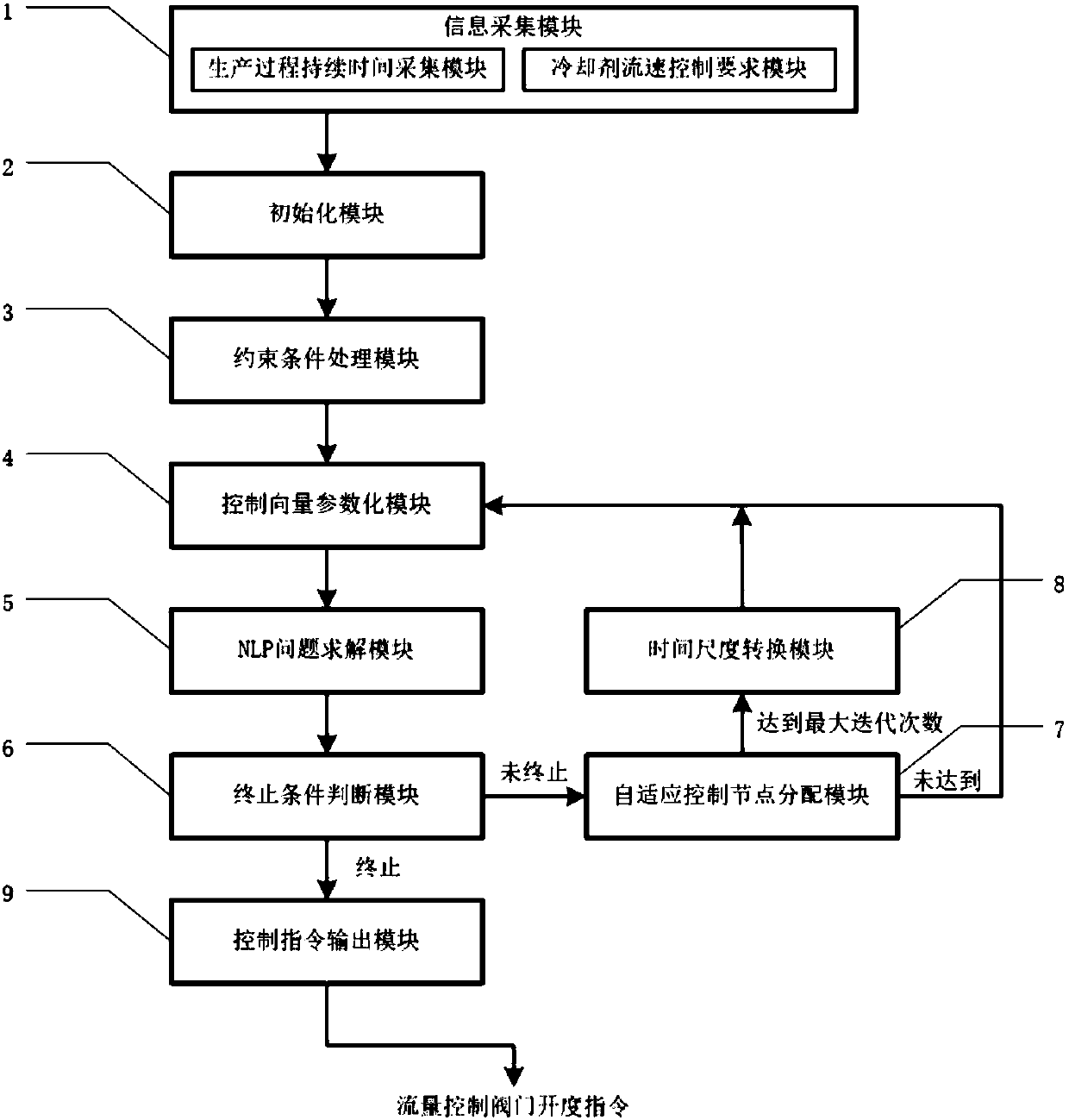

Optimal control system for piston flow tube reactor based on adaptive optimization control node

InactiveCN107807528AConcentration maximizationHigh precisionAdaptive controlAdaptive optimizationEngineering

The invention discloses an optimal control system for a piston flow tube reactor based on an adaptive optimization control node. The system is composed of a piston flow tube reactor body, a liquid flow meter and a temperature sensor at the piston flow tube reactor end, an analog-to-digital converter, a field bus network, a DCS, a main control chamber coolant flow rate and reactor temperature display, a digital-to-analog converter at the flow control valve end, and a flow control valve. After the duration of the production process and the coolant flow rate control requirement are specified, theDCS obtains a flow rate control strategy and converts the flow rate control strategy into an opening instruction of the flow control valve, the opening instruction is sent through the field bus network to the digital-to-analog converter at the flow control valve end, the flow control valve correspondingly acts according to the received control instruction, the liquid flow meter and the temperature sensor collect the coolant flow rate and temperature of the piston flow tube reactor in real time and send the coolant flow rate and temperature back to the DCS. The concentration of a target product in a piston flow tube reactor can be maximized, and potential tapping and efficiency increasing can be achieved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com