Optimal control system for piston flow tube reactor based on adaptive optimization control node

A tubular reactor, optimized control technology, applied in the direction of adaptive control, control/regulation system, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

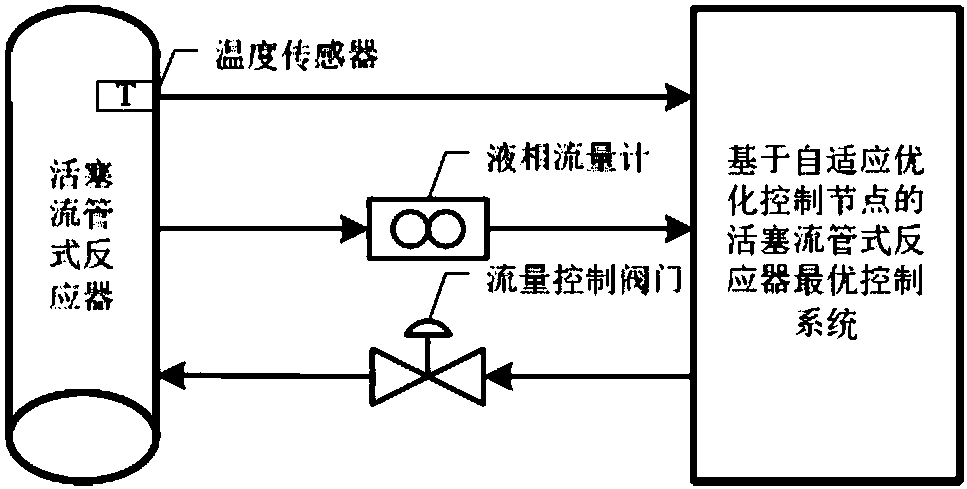

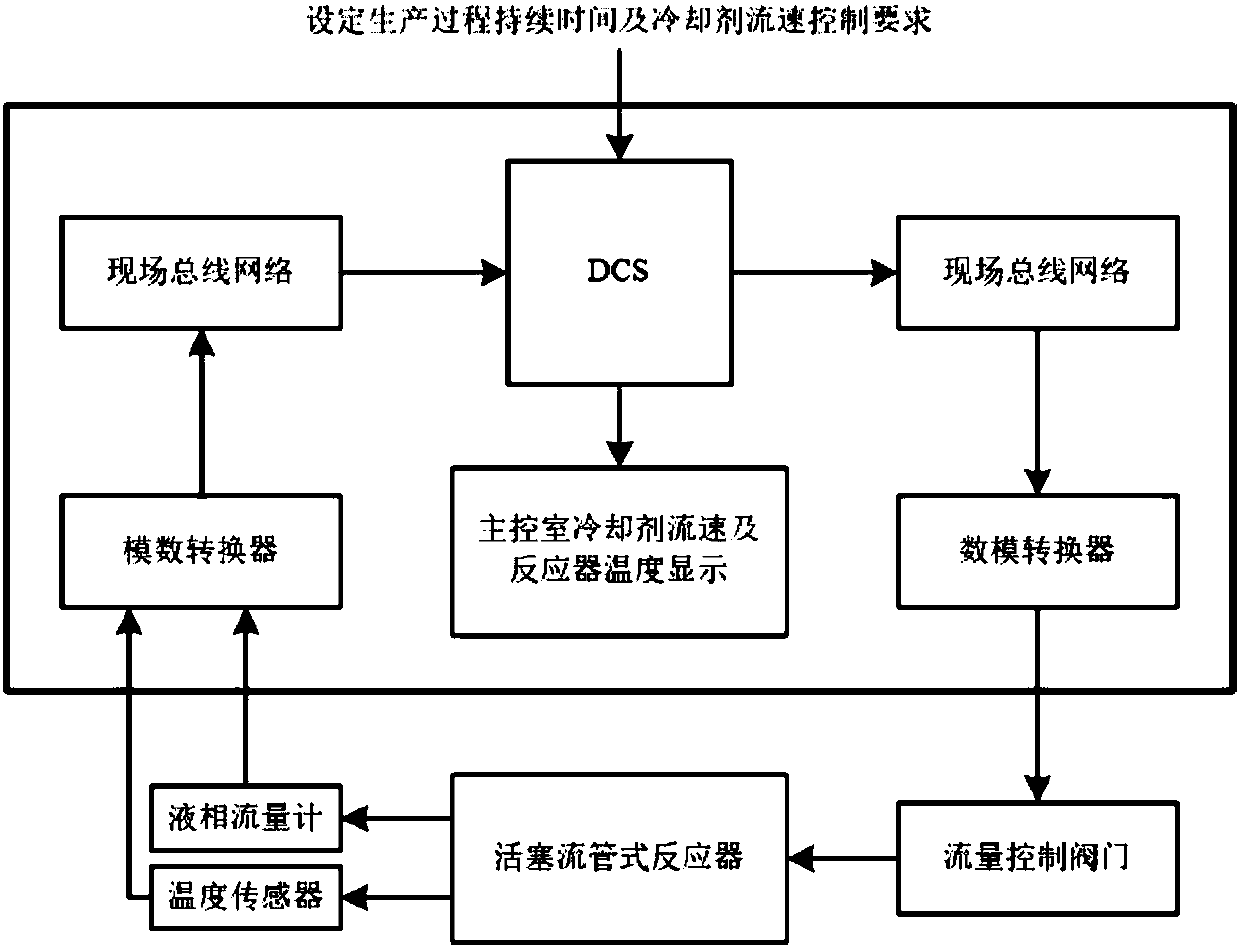

Method used

Image

Examples

Embodiment 1

[0188] A reversible exothermic reaction exists in a plug flow tubular reactor In order to maximize the concentration of product B, the optimal control strategy of the coolant flow rate needs to be studied. Its mathematical model is as follows:

[0189]

[0190] where x 1 (t), x 2 (t) respectively represents the concentration of the standardized product B, temperature (K), and u(t) represents the normalized flow rate of the coolant.

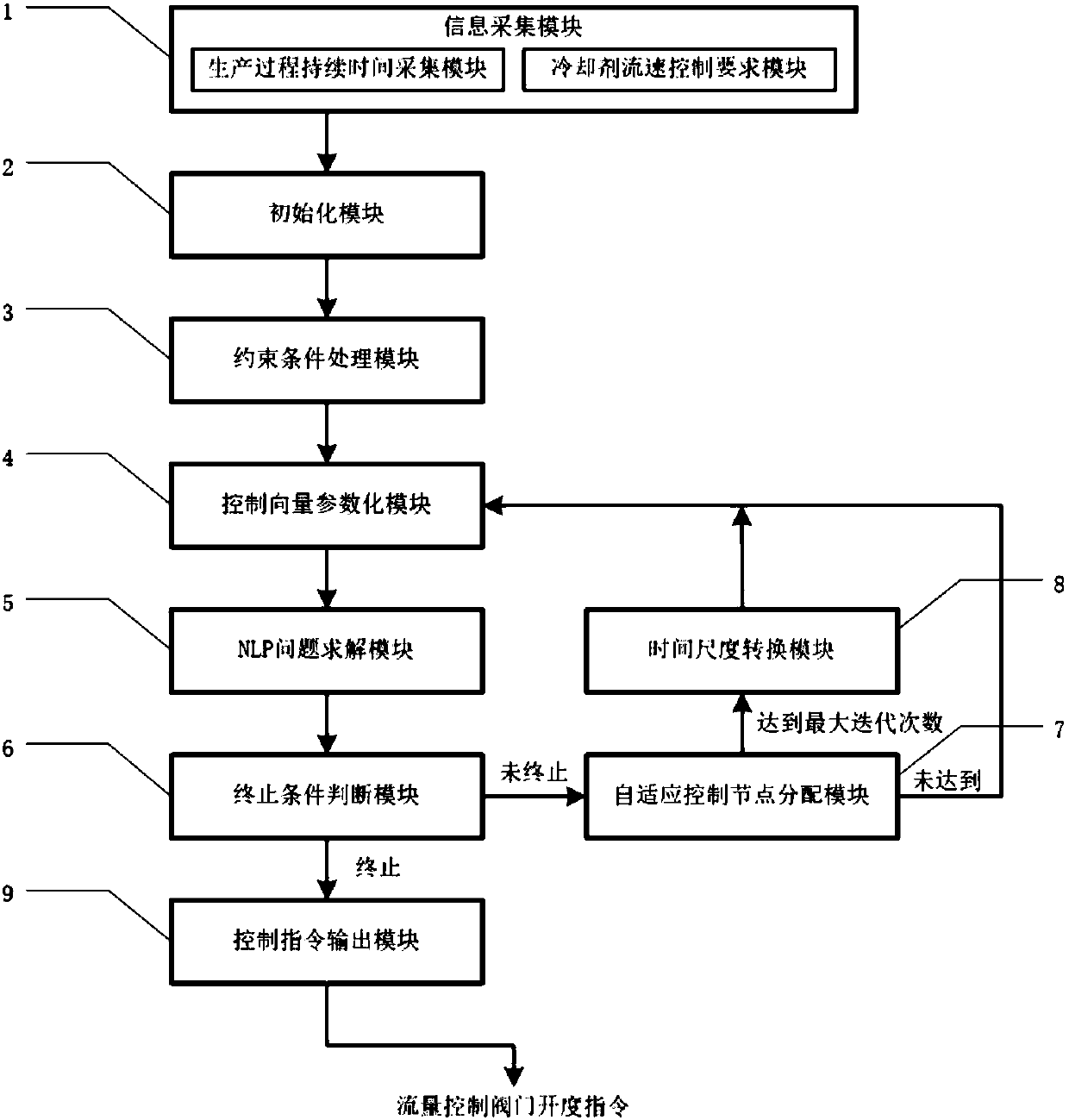

[0191] The control room engineer divides the duration of this production process t f =5min, the required information of coolant flow rate 0≤u(t)≤0.5 is input into the information collection module of DCS. The DCS immediately starts to run the optimal control method of the self-adaptive optimal control node, and its running process is as follows: image 3 Shown as:

[0192] Step E1: Initialize the operation of module 2, set the initial control grid number p=16, and the initial guess value of the coolant flow rate control strategy Set co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com