Orthogonal collocation optimization based batch reactor control system

A technology of orthogonal configuration and reactor, applied in the field of batch reactor control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

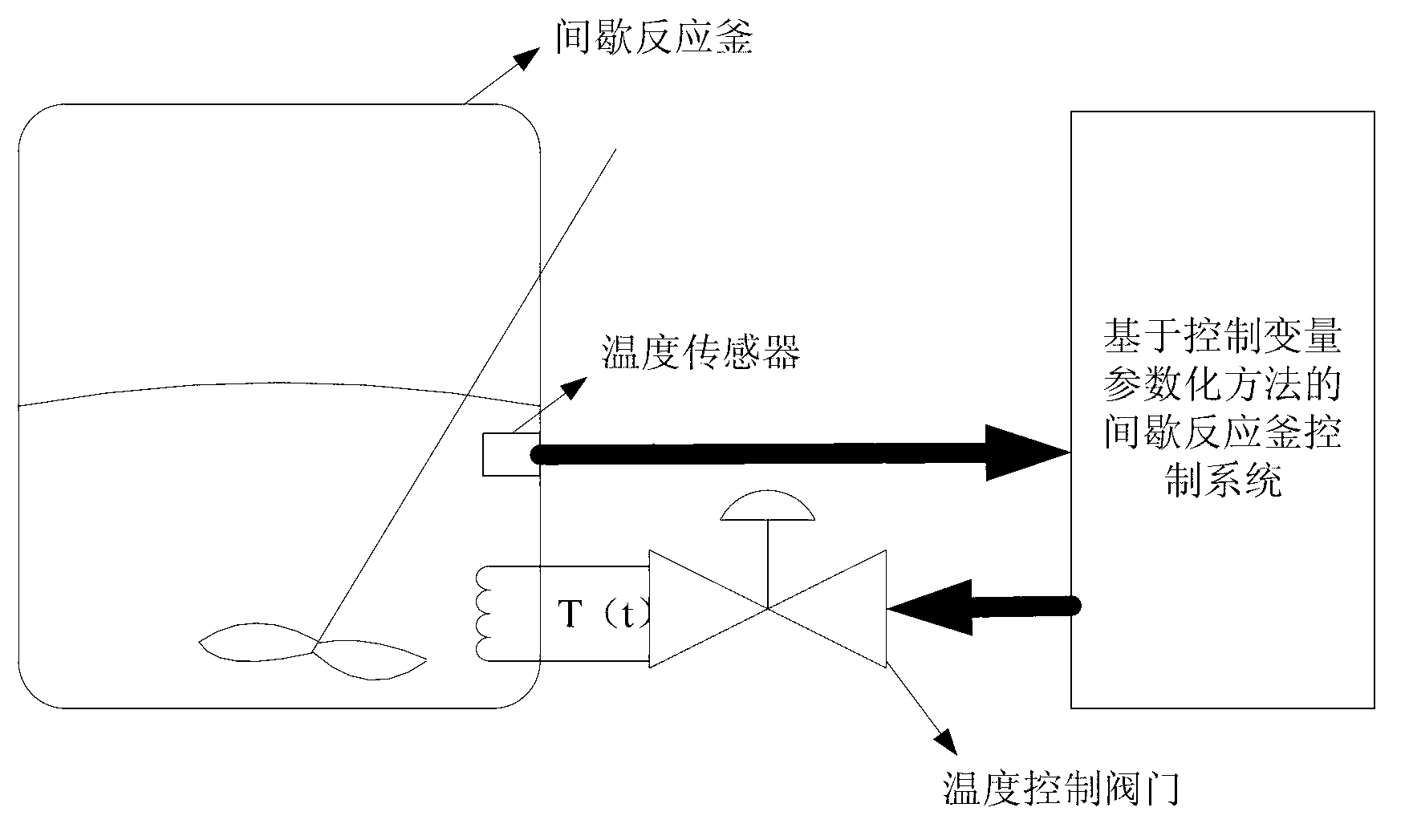

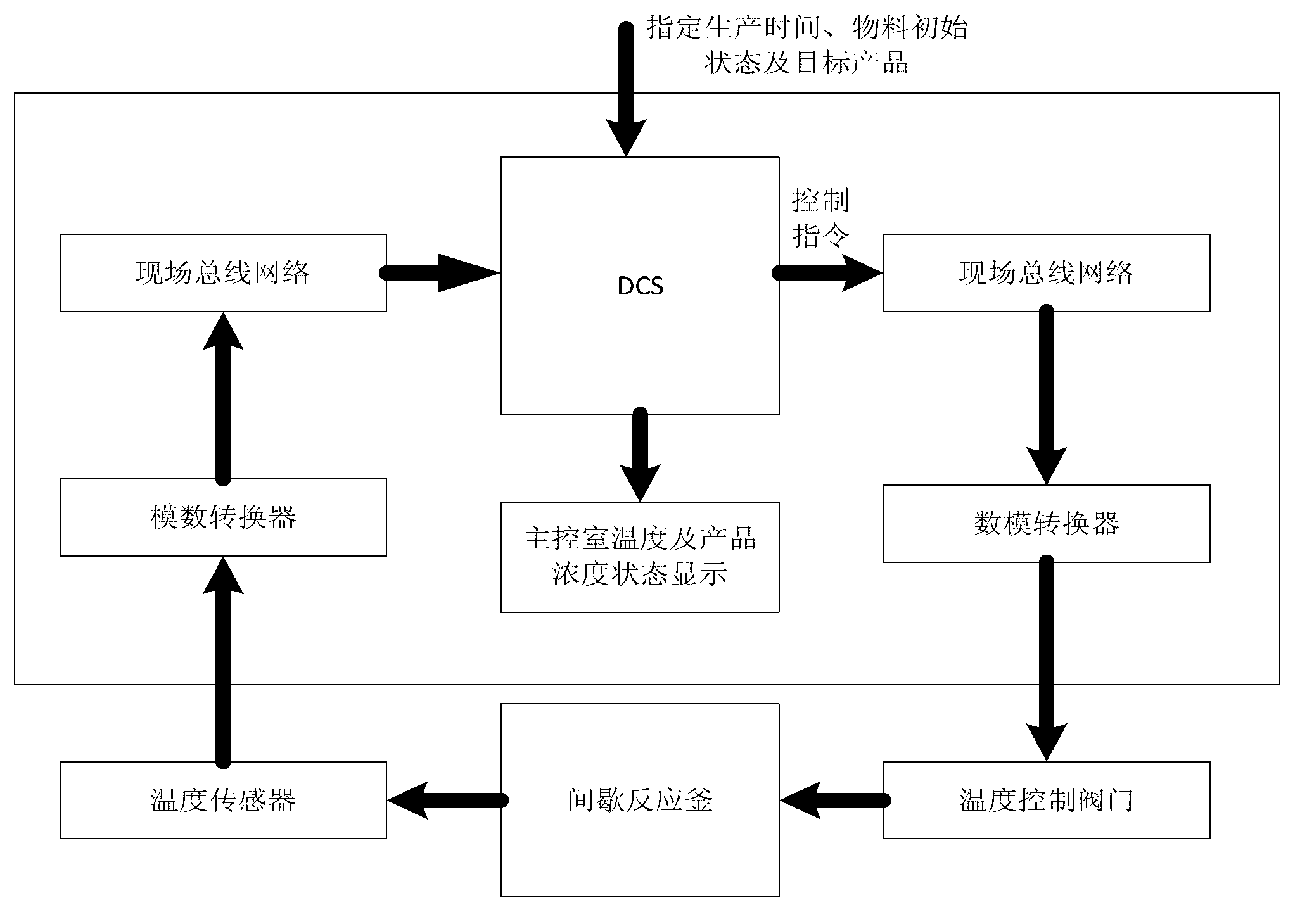

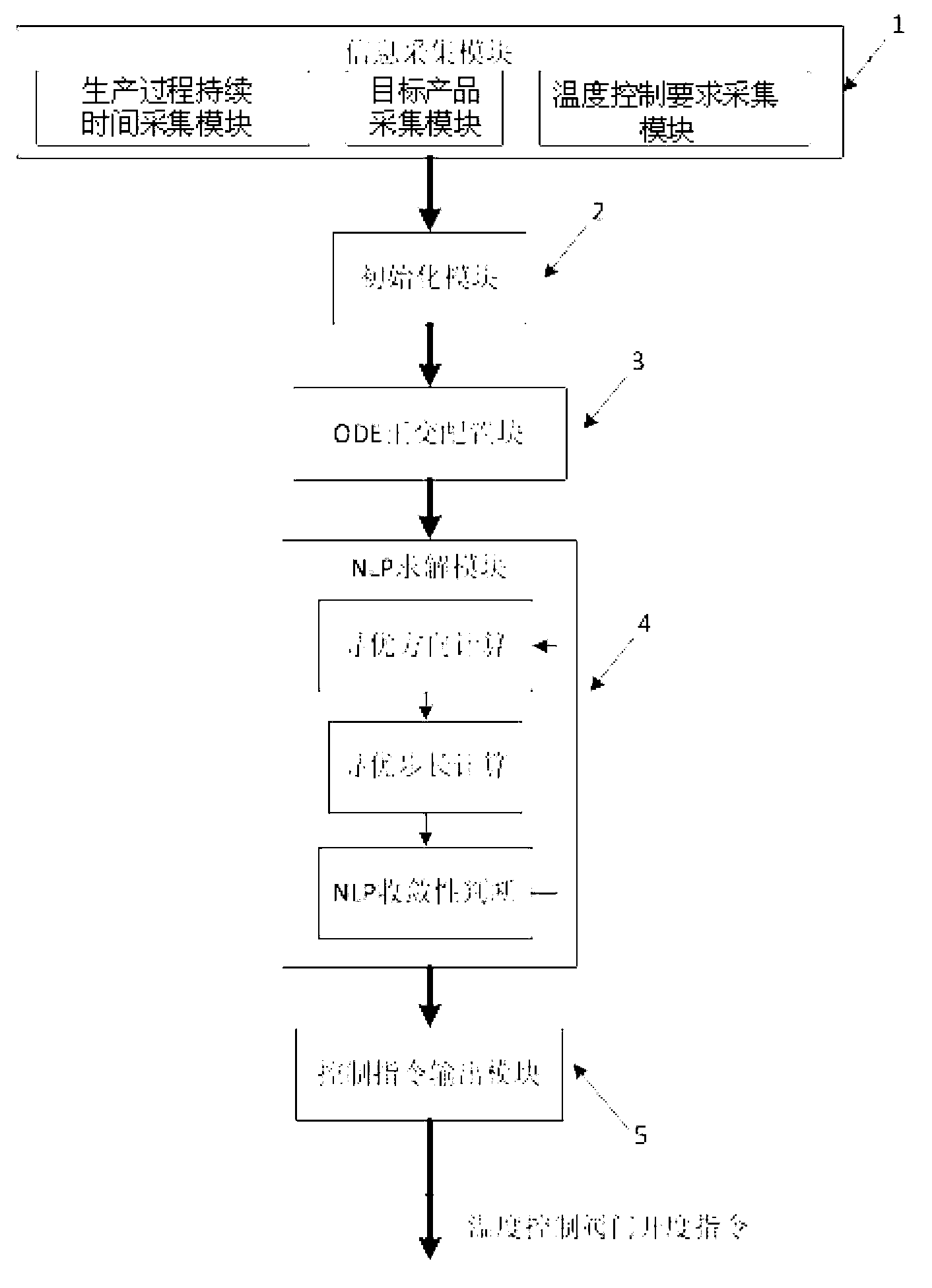

Image

Examples

Embodiment 1

[0047] The parallel irreversible reactions occurring in the batch reactor include: A→B and A→C, and the reaction rate constant is a function of temperature T(t), respectively

[0048] k 1 ( t ) = k 10 e - E 1 / R · T ( t )

[0049] k 2 ( t ) = k 20 e - E 2 / R · T ( t ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com