Reflecting photonic concentrator

a technology of reflectors and concentrators, applied in the field of solar energy concentration, optics, power systems, etc., can solve the problems of not providing for the use of stationary reflectors, the time before investment in such technologies is returned, and the concentration of incident solar energy cannot be provided. achieve the effect of maximizing energy concentration, low architectural profile and optimizing device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0018] In a first embodiment, the present invention provides a reflective concentrator assembly that uses the Fresnel lens principle to describe the negative, inside profile of two refractive lenses that are superimposed, or interleaved, over one another. Where the first set of reflective surfaces are slopes having their own reflective target, the second set of reflective surfaces are reliefs that allow the first three slopes to be formed contiguously by a reflective material or substrate. Further, the relief surfaces do not interfere with the reflective pathway of photonic energy toward the target area when that photonic energy strikes the heliostatic array at an incident angle of 90 degrees. Because one embodiment of the concentrator assembly is symmetrical, the inverse is true where the second set of reflective surfaces are slopes having their own target, and the first set of reflective surfaces are reliefs.

second embodiment

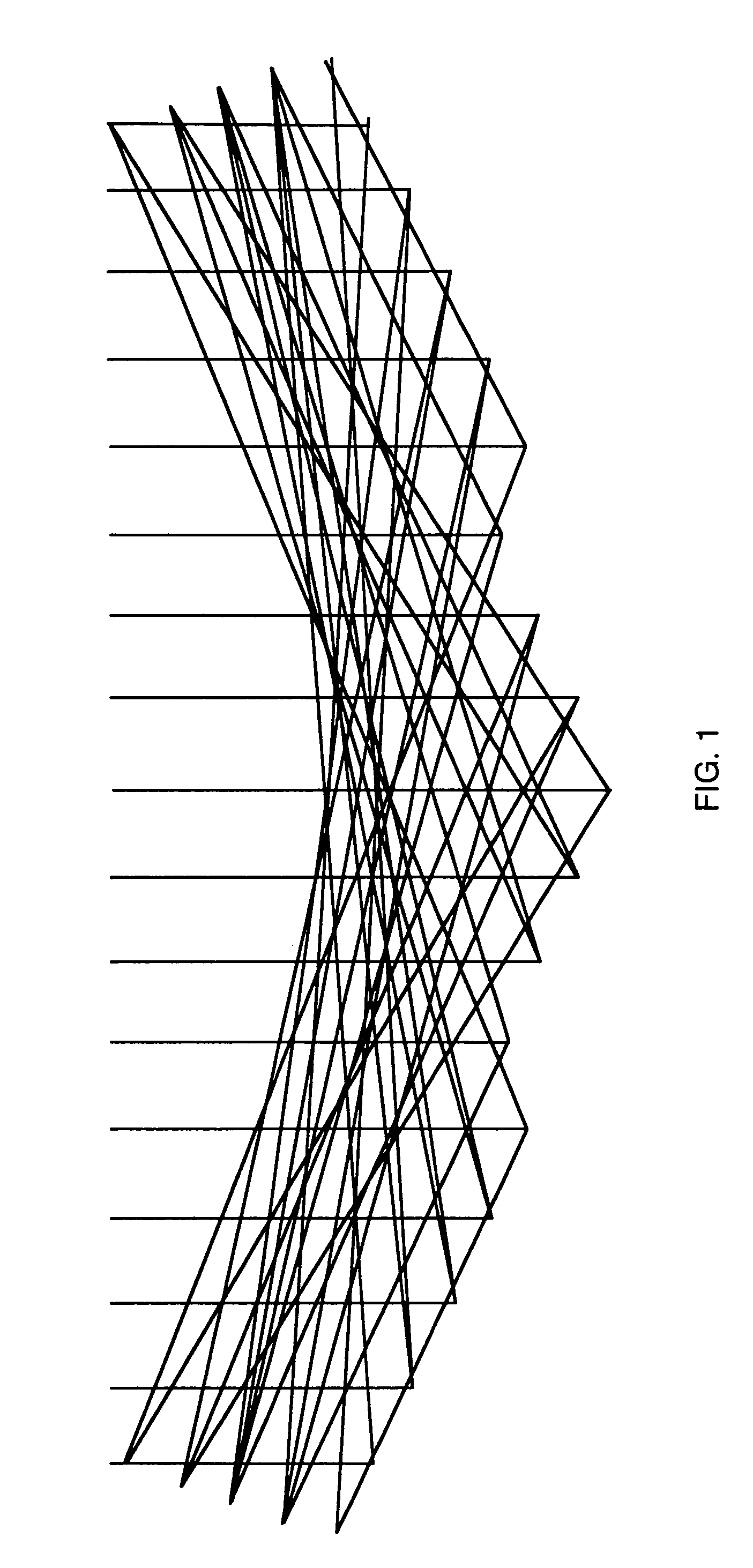

[0019]FIG. 1 shows the concentrator assembly of the present invention and depicts the reflective pathway of energy striking the heliostatic array at incident angle of 90 degrees and being reflected toward the two target areas. It is contemplated that these two target areas may comprise photonic transducers or receiving devices. In a second embodiment, a reflective projector may be used in conjunction with the heliostatic array. The reflective surface of the projector is designed to receive photonic energy arriving at a plurality of incident angles from the second set of reflective surfaces of the concentrator, and to evenly reflect and distribute that energy to the first target area described above.

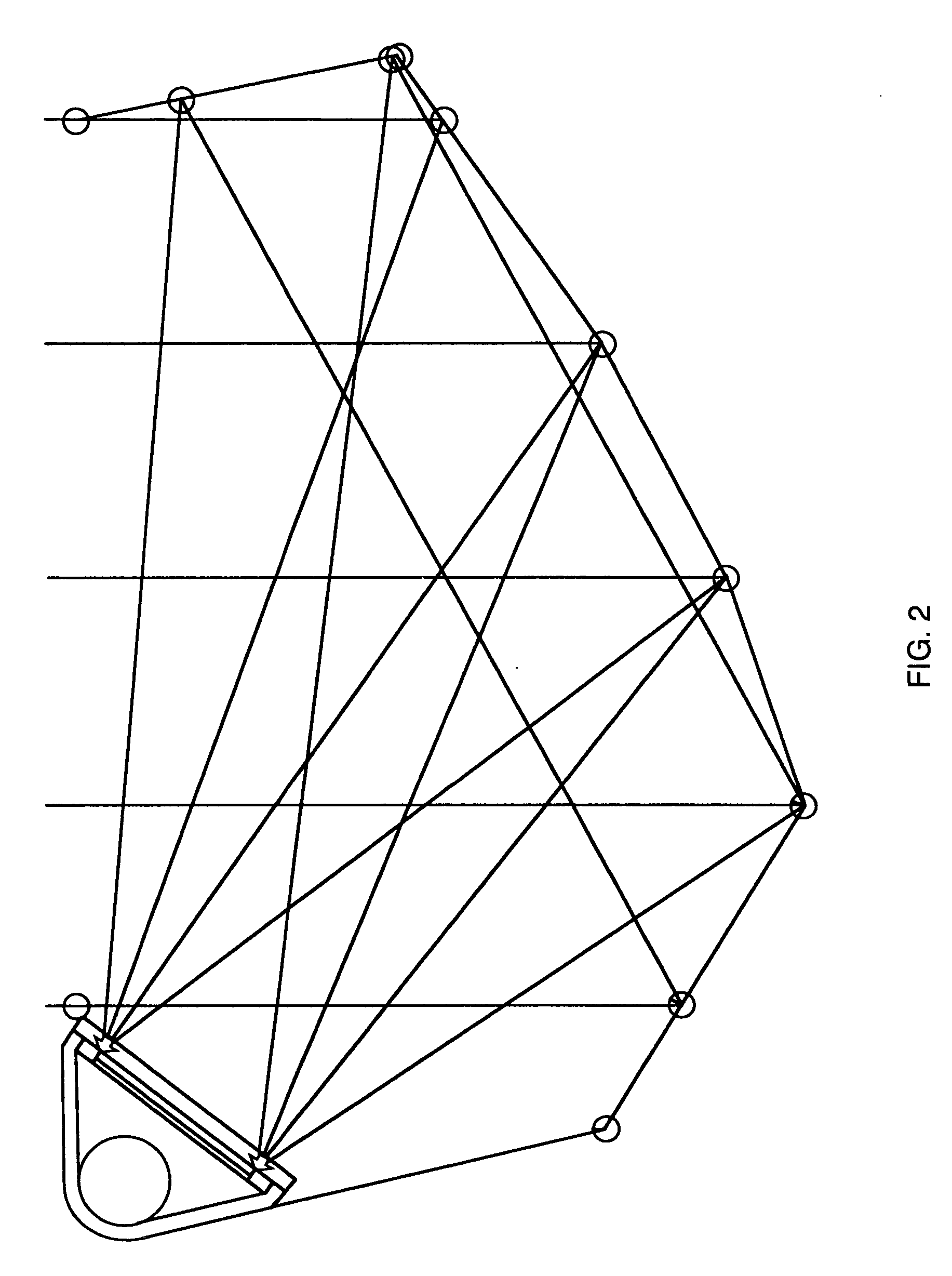

[0020]FIG. 2 represents the concentrator assembly with the reflective projector attached to the right side of the heliostatic array and depicts the path of photonic energy striking the heliostatic array at incident angle of 90 degrees. While a first set of light rays strike the first set ...

third embodiment

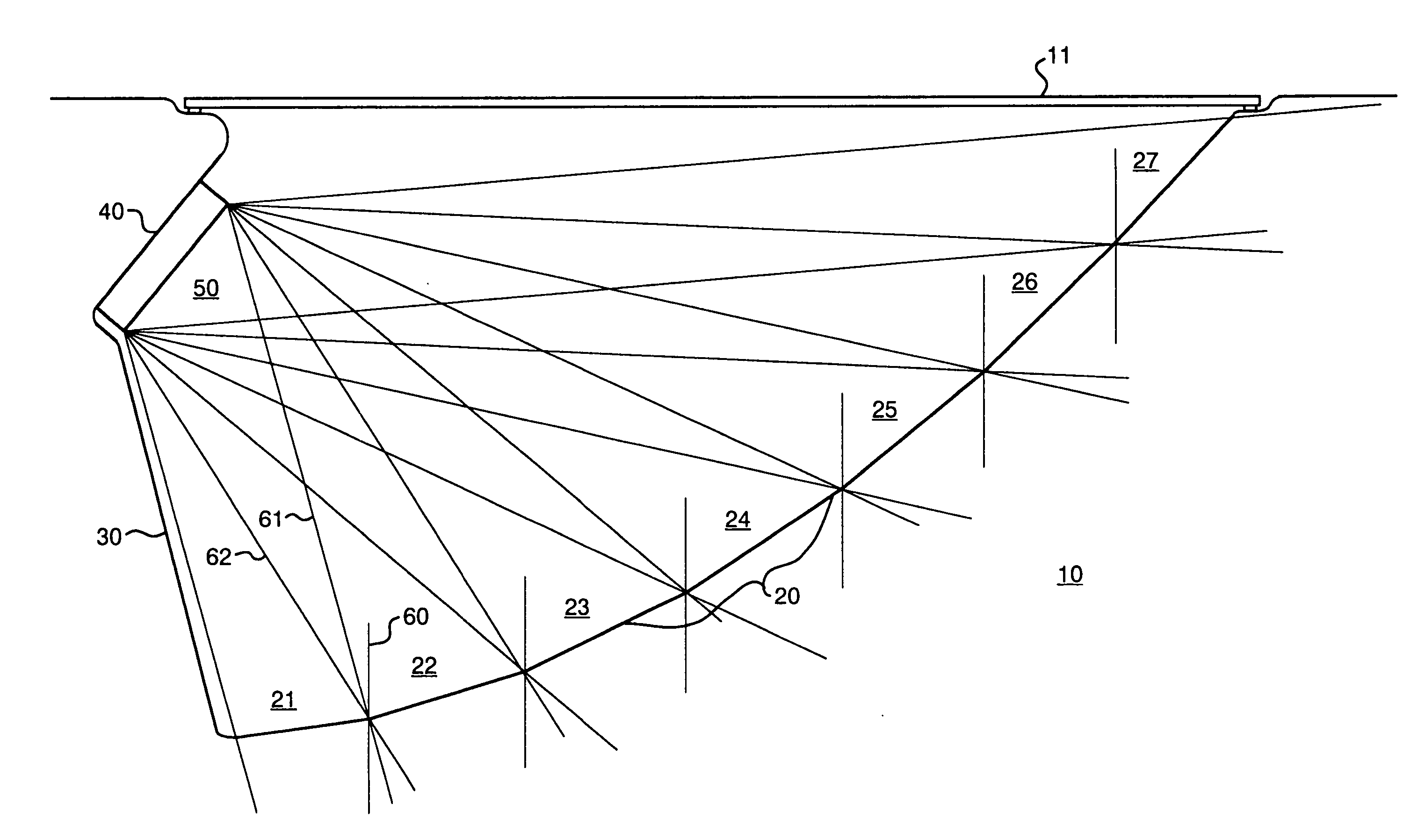

[0023] In the present invention, shown in FIG. 3, concentrating reflector 10 comprises reflective surface area 20, relief plane 30, and vertically oriented sidewall 40 for mounting solar receiver 50. In a preferred embodiment, wherein reflective surface 20 is faceted and non-imaging, a parabolic shape is described having a curve formed of large intervals to form the single heliostat. When the profile of the single reflective surface 20 is joined to relief plane 30, the negative profile, i.e., the concave inside edge, is described for a single convex slope-relief Fresnel lens interval.

[0024] In a Fresnel lens, the convex thickness of a lens may be reduced by dividing the arc of the lens into segments and then flattening the top of each curved segments onto the same plane. The segment's curvature is the slope, and the interval segment necessary to eliminate thickness and join each slope is the relief. The preferred embodiment of the disclosed invention is derived from embodiments havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com