Patents

Literature

151 results about "Dual bus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

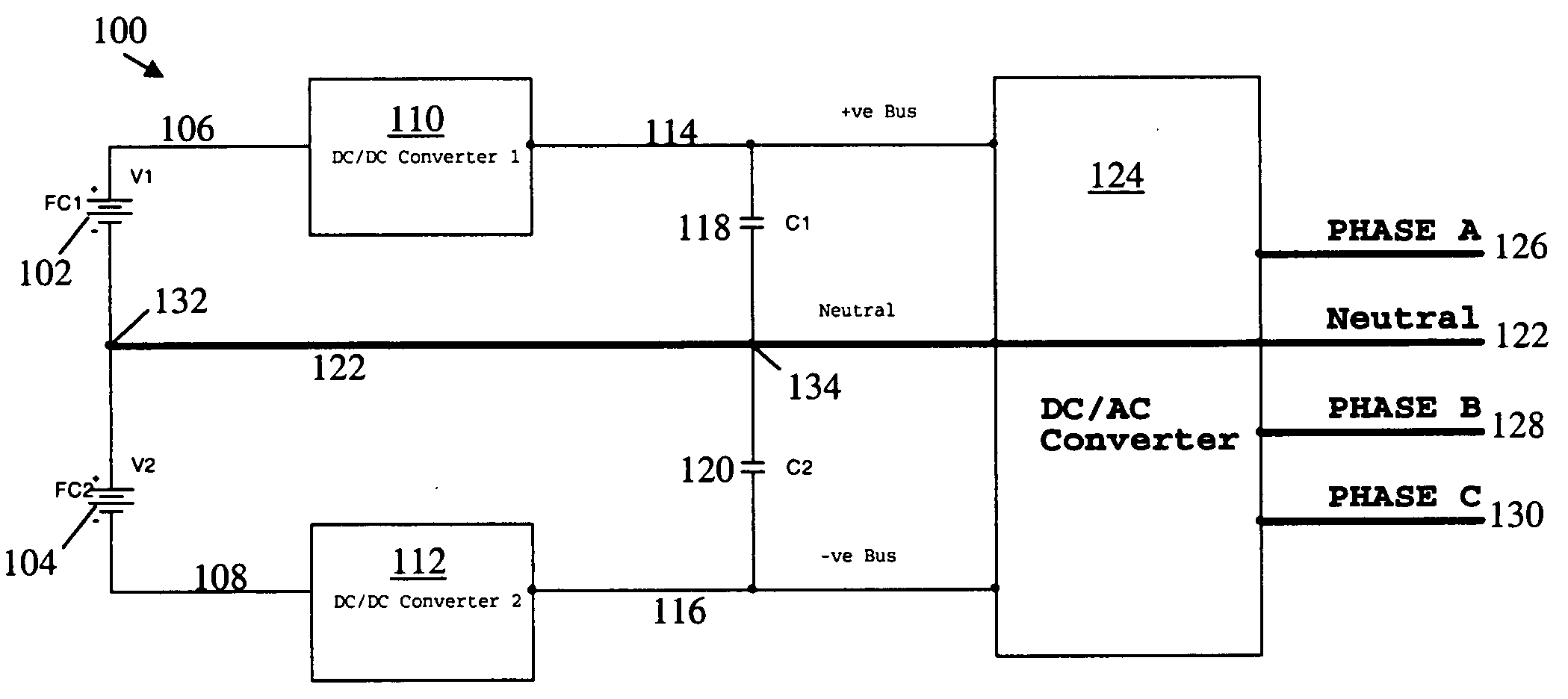

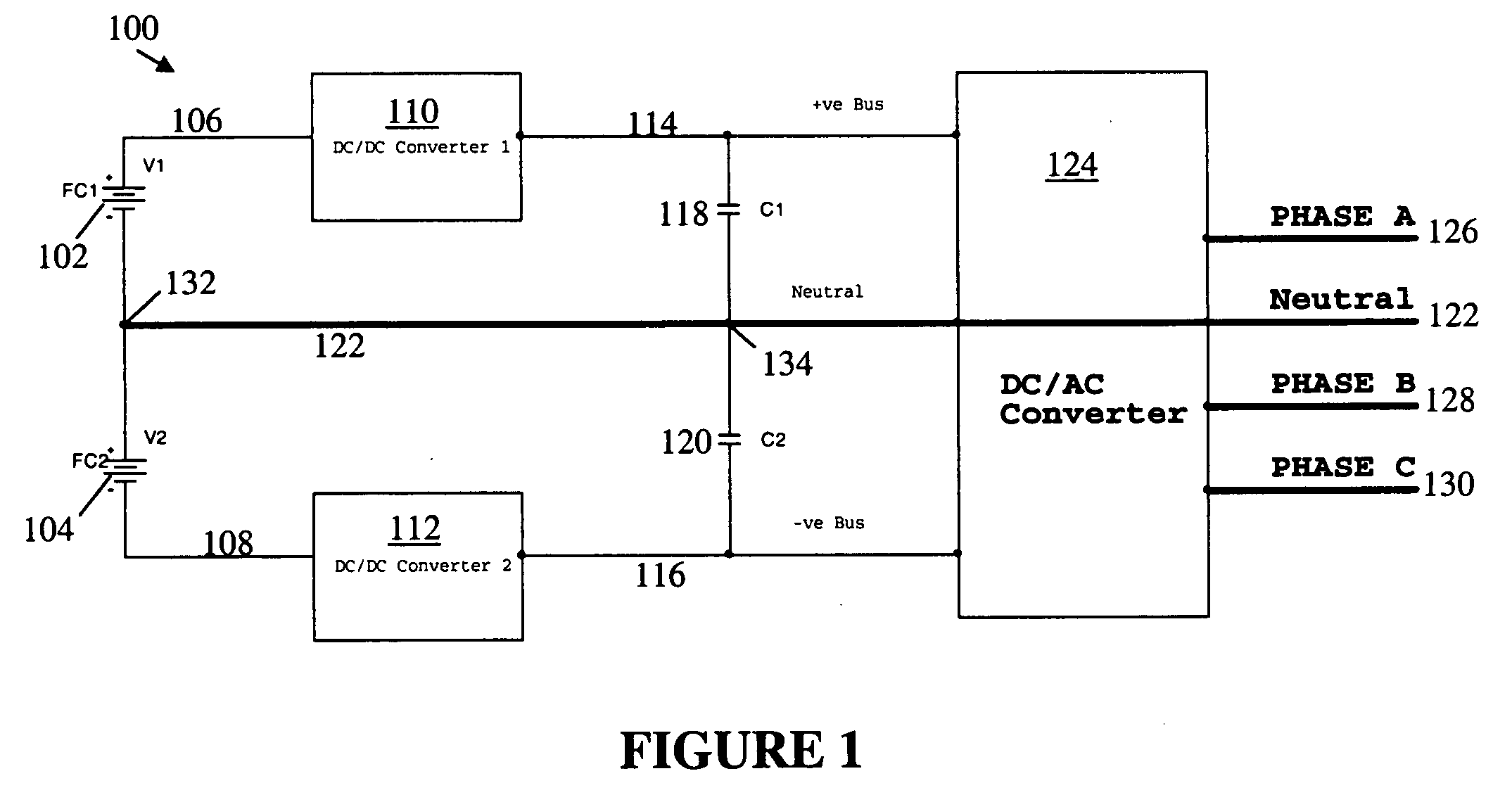

Integral stack columns

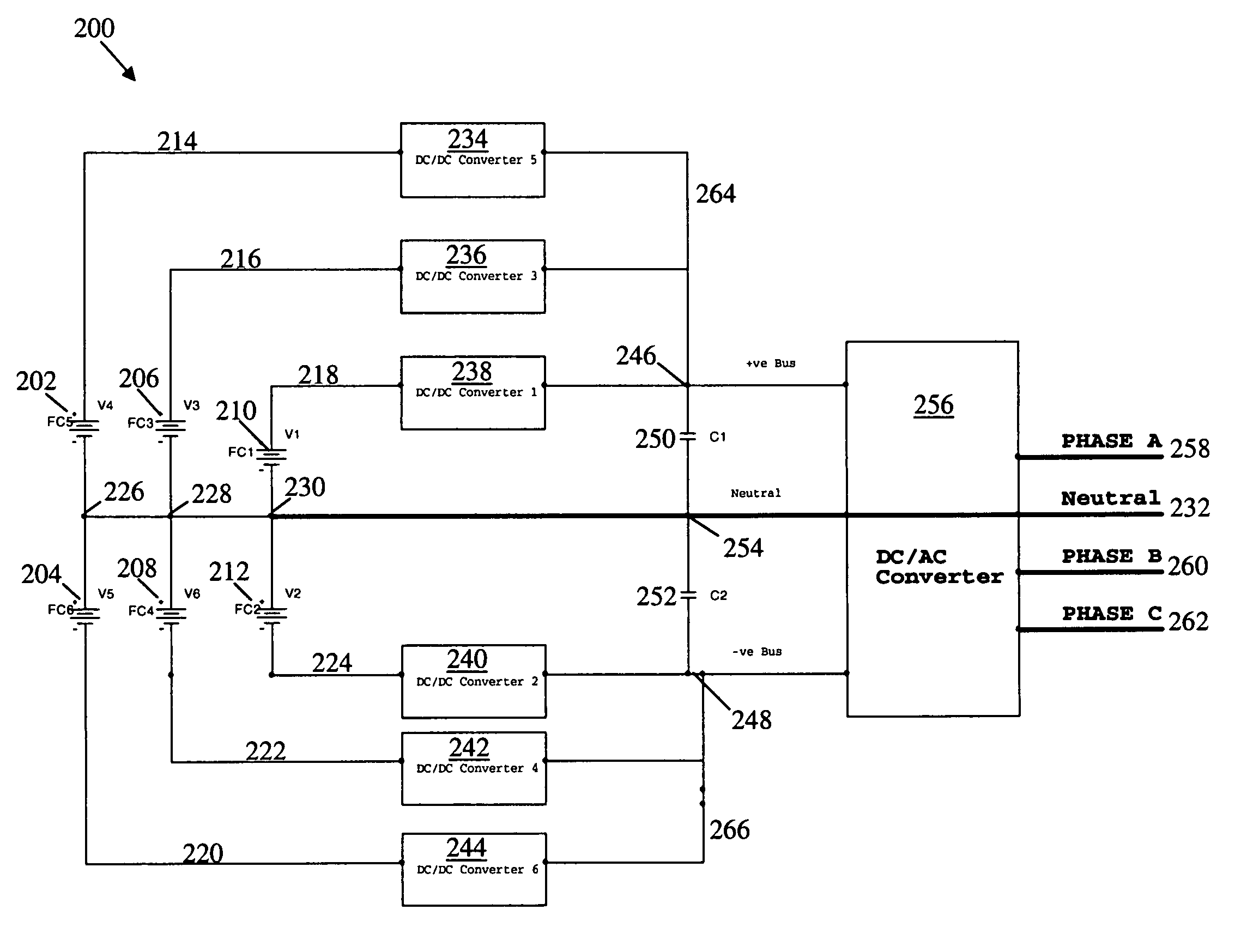

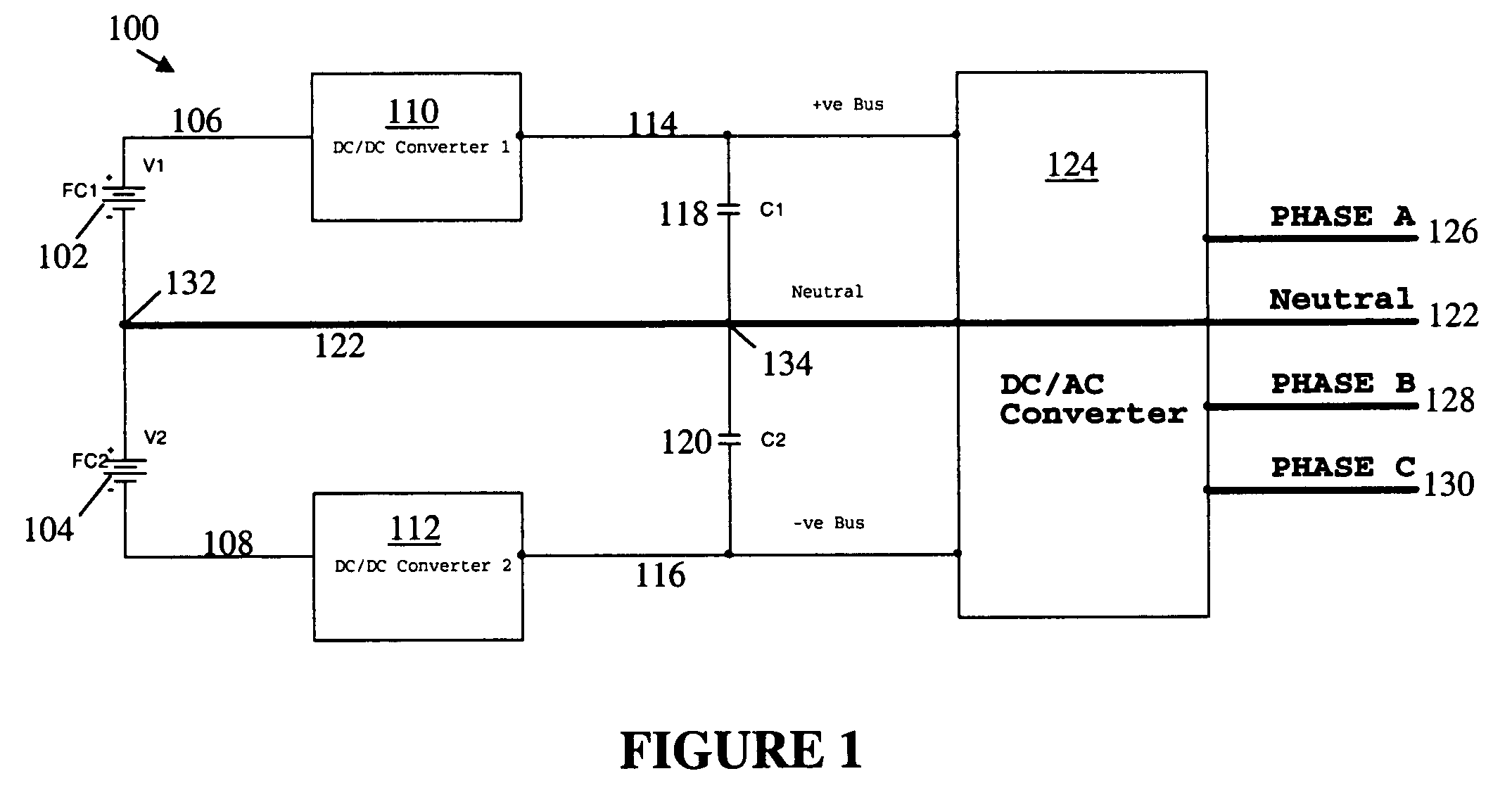

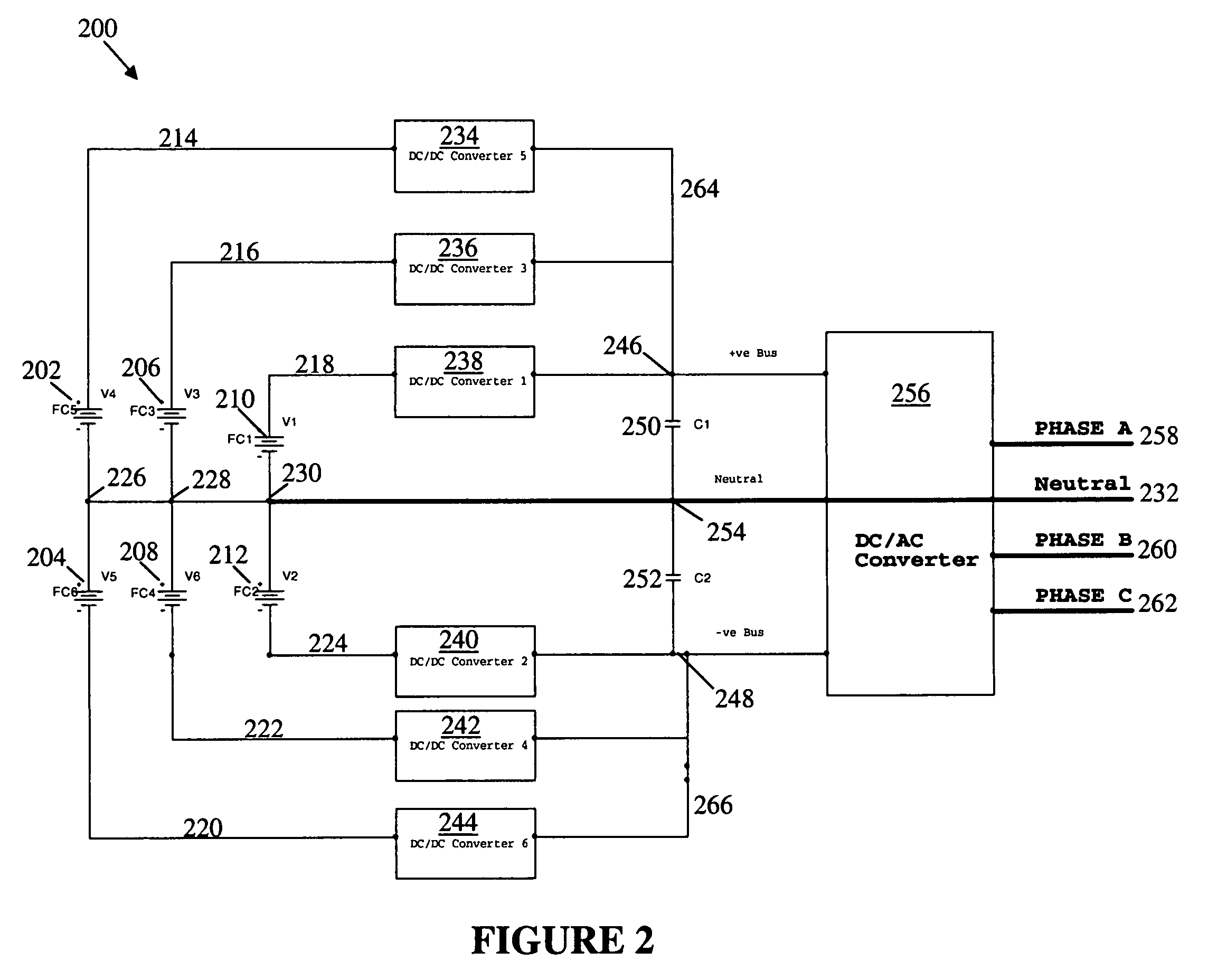

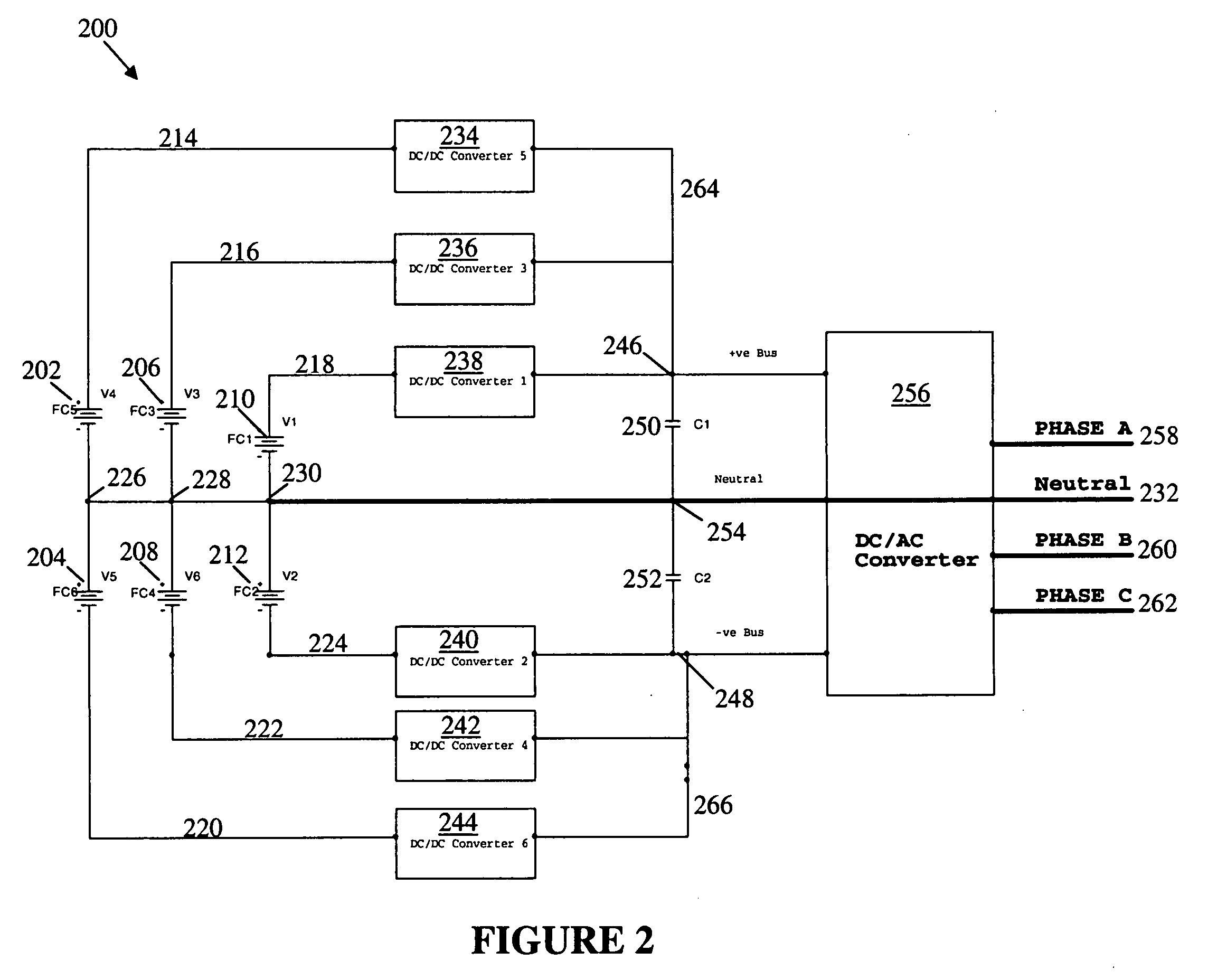

Systems and methods for power conversion are illustrated. Power conversion architecture for fuel cell systems in particular are described that use dual bus architectures having stack segment pairs and a center-tapped neutral line, and / or an architecture employing integer multiple of three DC / DC converter branches.

Owner:BLOOM ENERGY CORP

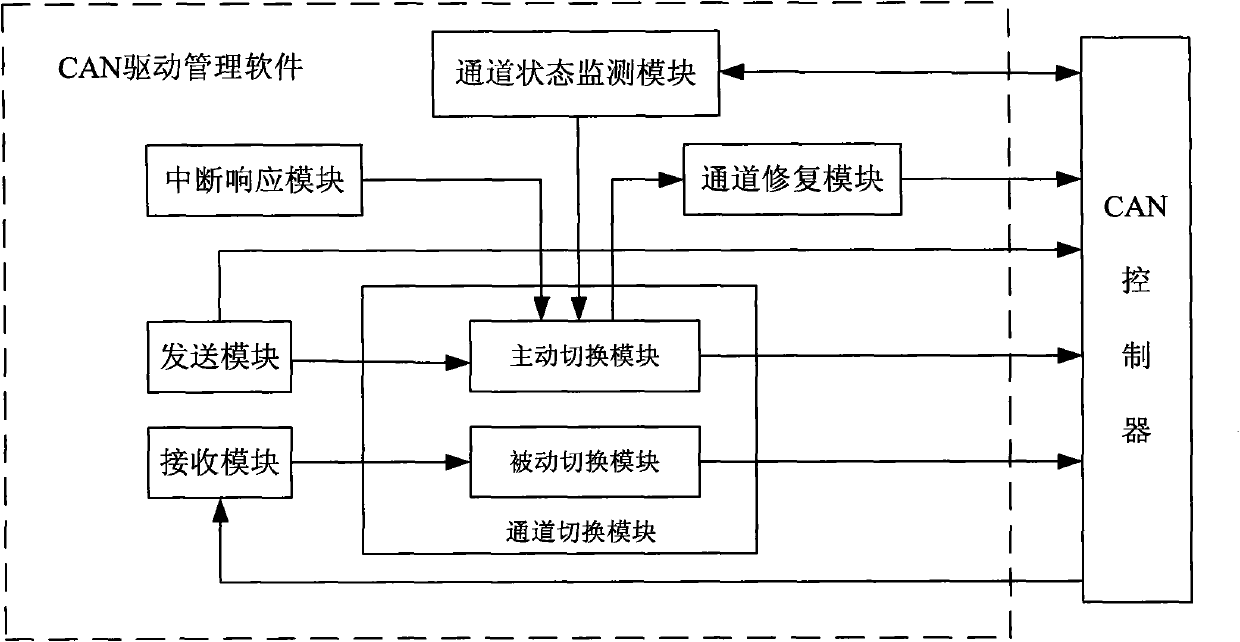

Heat switching system and heat switching method of dual-redundant CAN bus

ActiveCN101908974ASupport operationReduce the number of control nodesError preventionBus networksDual busQ-switching

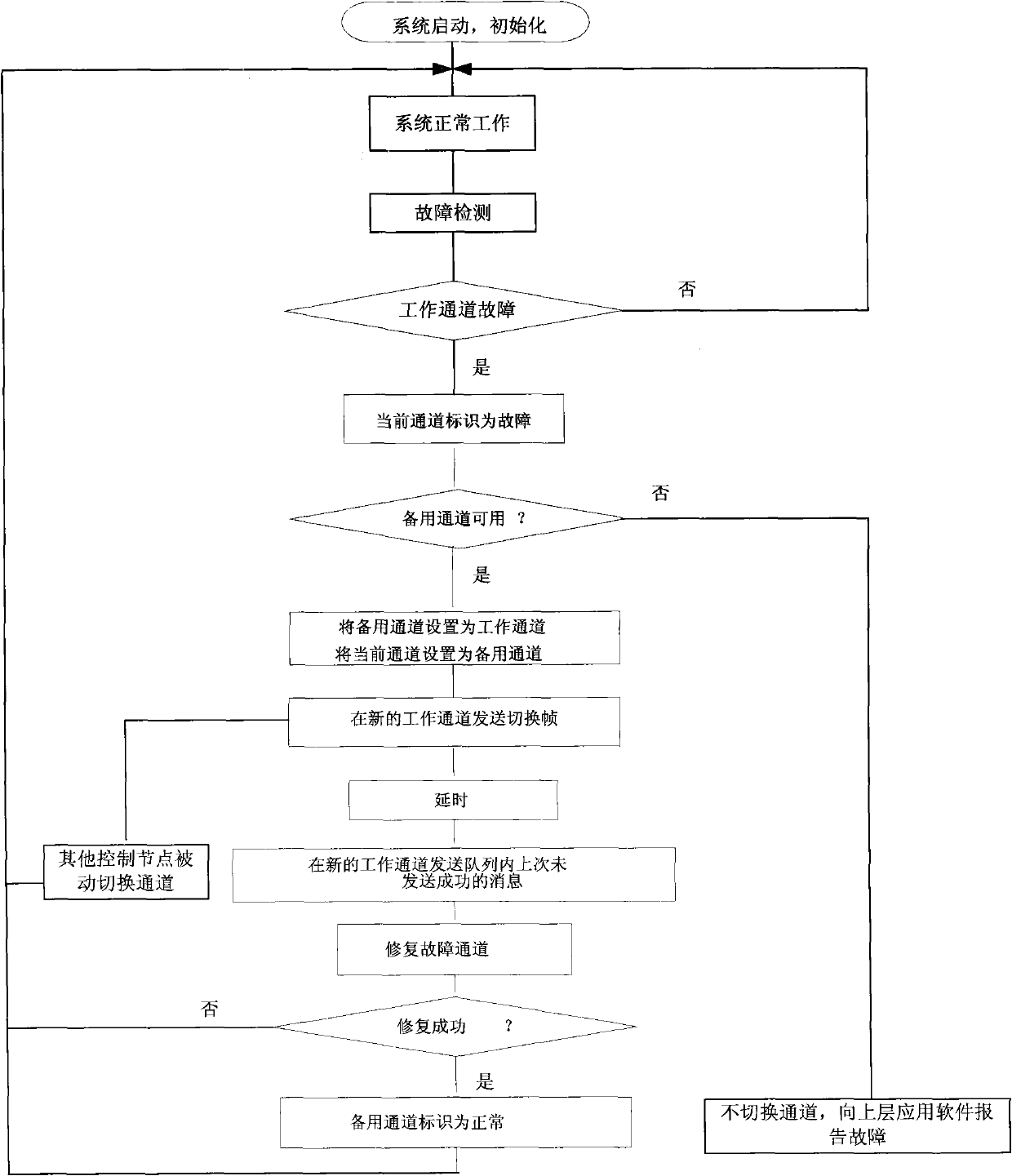

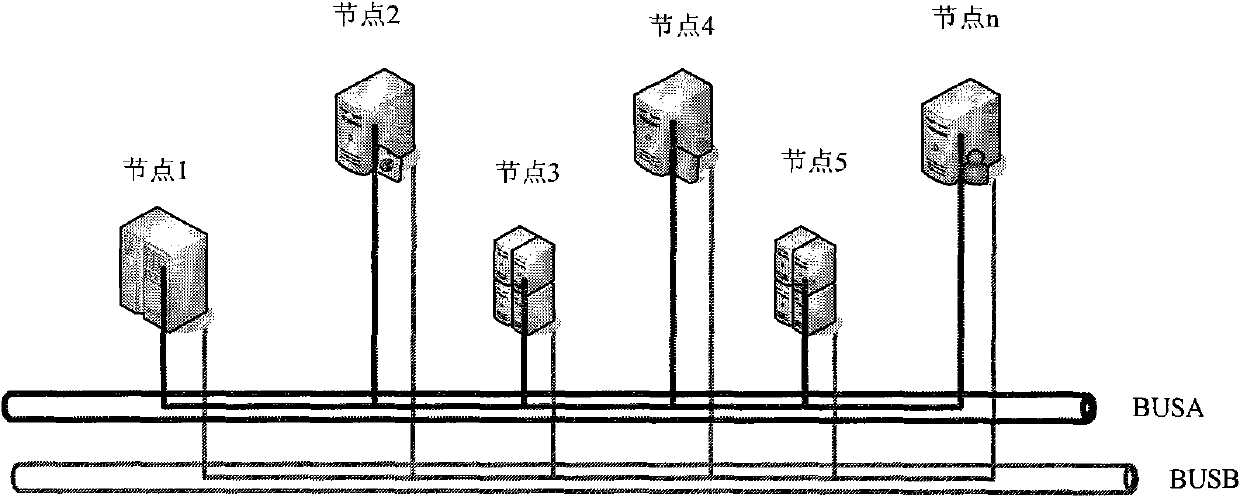

The invention relates to a heat switching system and a heat switching method of a dual-redundant CAN bus, and provides a networking mode of a dual-redundant CAN bus system and a dual-bus heat exchanging method. The networking mode of the dual-redundant CAN bus system is as follows: two bus cables are designed in network; each node unit comprises a microprocessor and two CAN controllers which are respectively connected with two bus cables to form two independent CAN channels. The dual-bus heat switching method is as follows: during operation, one of the channels is a working channel for receiving and transmitting messages and the other channel is used as a reserve channel for only receiving messages; and a CAN drive control software in the node monitors the channel state in real time, switches the reserve channel into a working channel when a fault occurs in the working channel and repairs the original working channel and sets the working channel to be a reserve channel.

Owner:BEIJING INST OF SPACE LAUNCH TECH

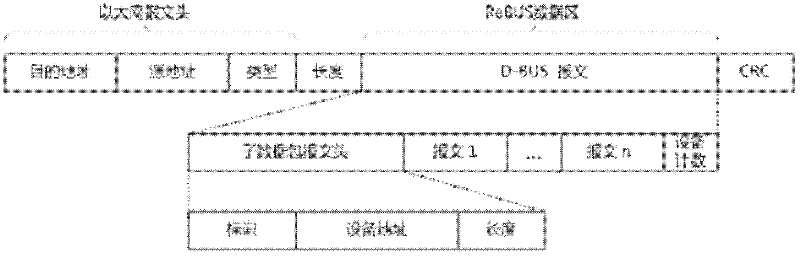

D-BUS high-speed bus technology based on ring type Ethernet and auxiliary network

InactiveCN102347879ASimple wayEasy wiringLoop networksBus networksStructure of Management InformationEmbedded system

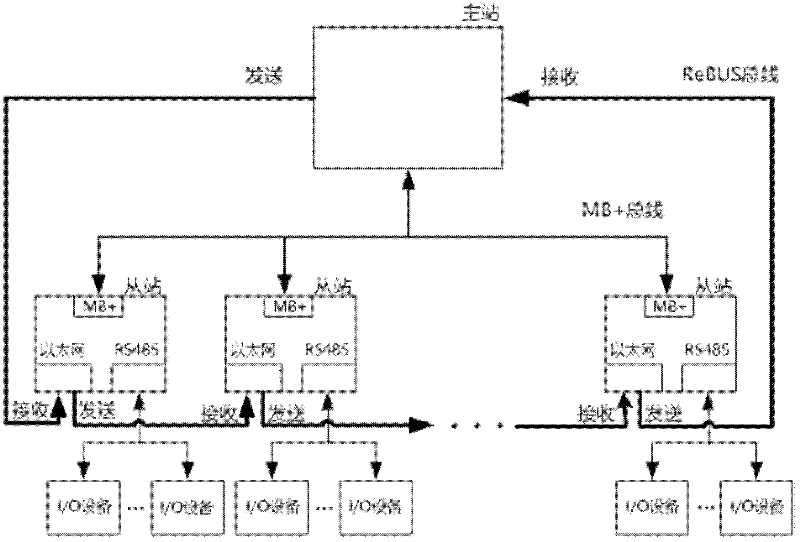

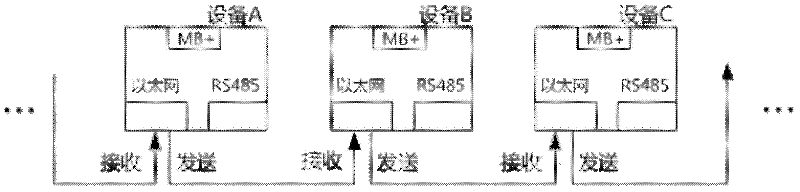

The invention provides a D-BUS high-speed bus technology based on a ring type Ethernet and an auxiliary network, which belongs to the technical field of industrial control. The D-BUS high-speed bus technology is characterized in that a D-BUS (Dual-BUS) high-speed bus network consists of a high-speed ring type Ethernet ReBUS and an auxiliary network MB+, wherein the ReBUS bus utilizes the physical layer specification of Ethernet IEEE802.3, a main station is connected with slave stations in series to form a ring type topological structure, the wiring mode for the main station and the slave stations is same with that of the slave stations with the slave stations, a receiving terminal of each equipment is connected with a transmitting terminal of the former equipment, the transmitting terminal of the equipment is connected with a receiving end of a latter terminal, the receiving terminals are sequentially connected with the transmitting terminals in the mode to form a ring type network structure, I / O equipment are connected with the slave stations through RS485 serial ports and serve as the expansion I / O of the slave stations, and failure detection comprising failure diagnosis, failure location and communication redundancy is realized by the MB+ bus. The invention has the beneficial effects that the ring type wiring cost is low, the data exchange of all network nodes is realized by one message, the communication efficiency is high, a failure detection and failure recovery mechanism is provided, and the reliability is high.

Owner:大连爱智控制系统有限公司

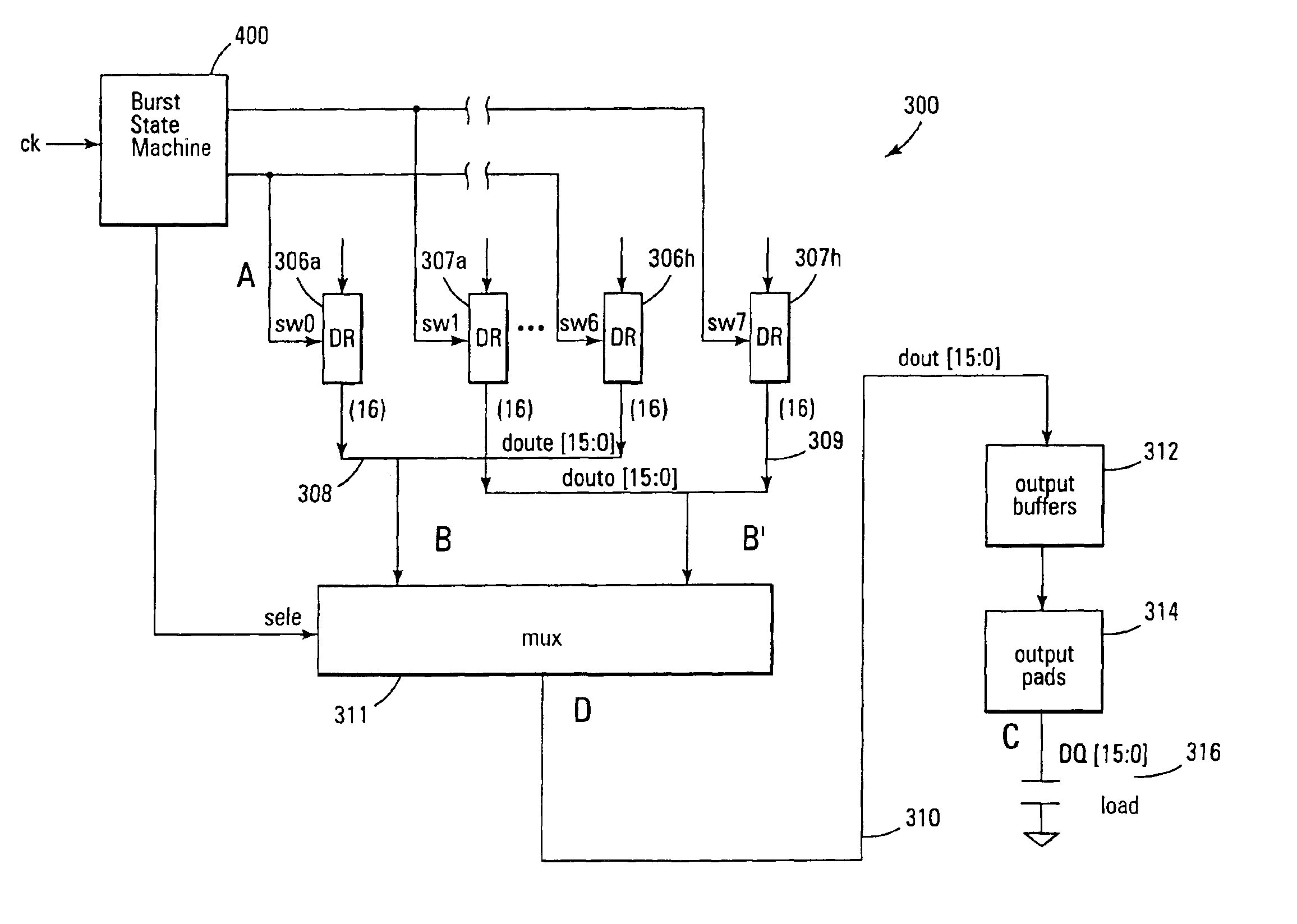

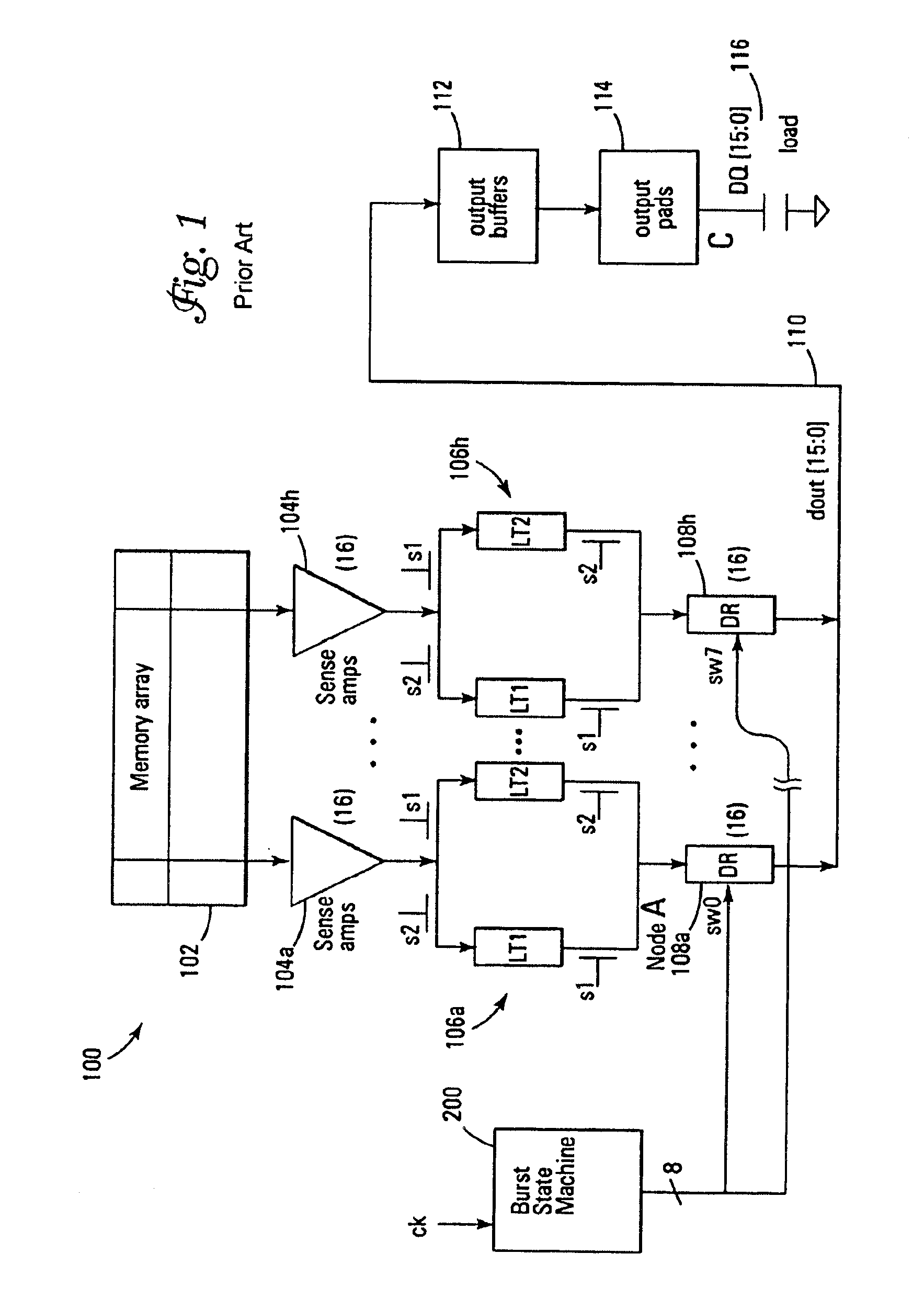

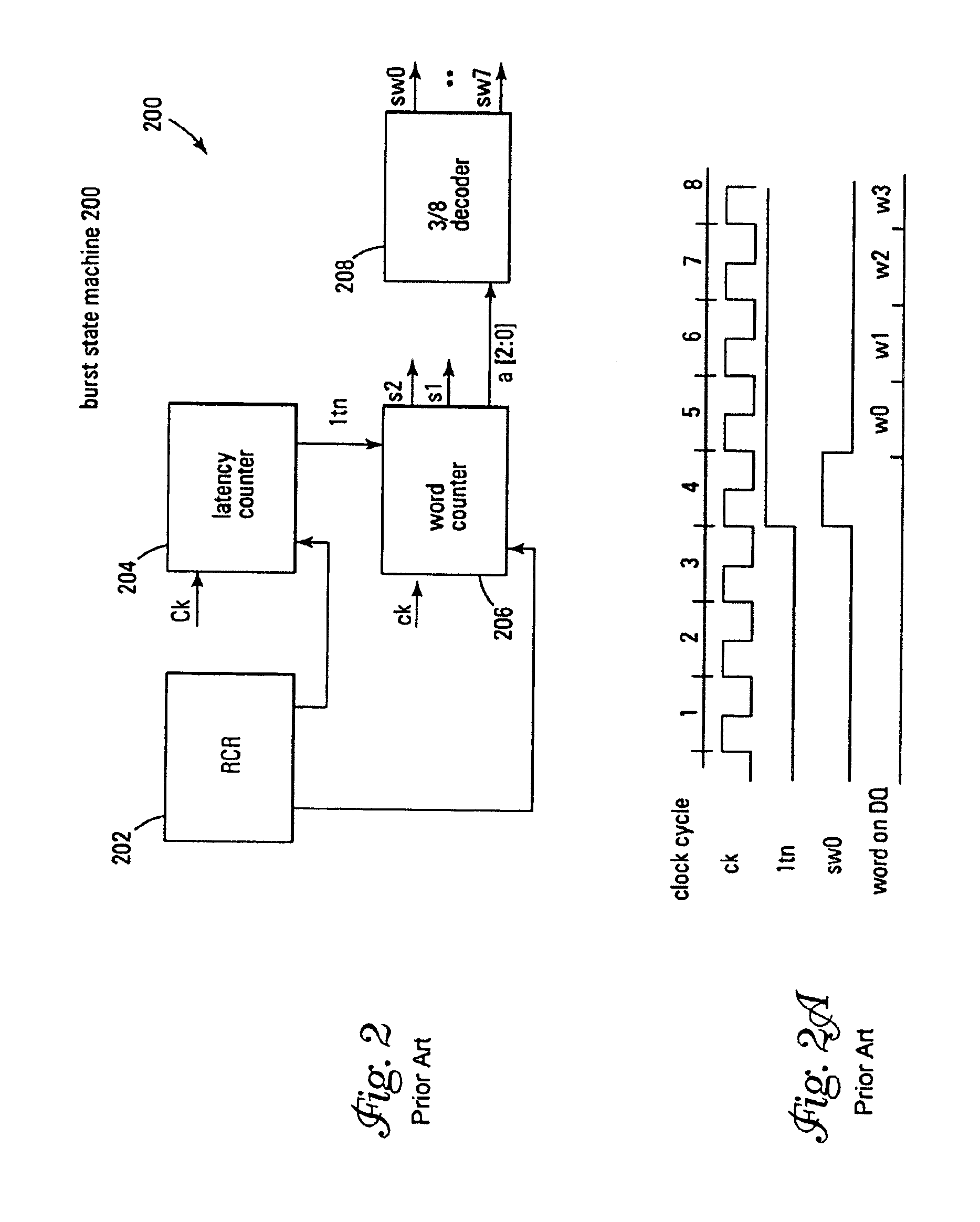

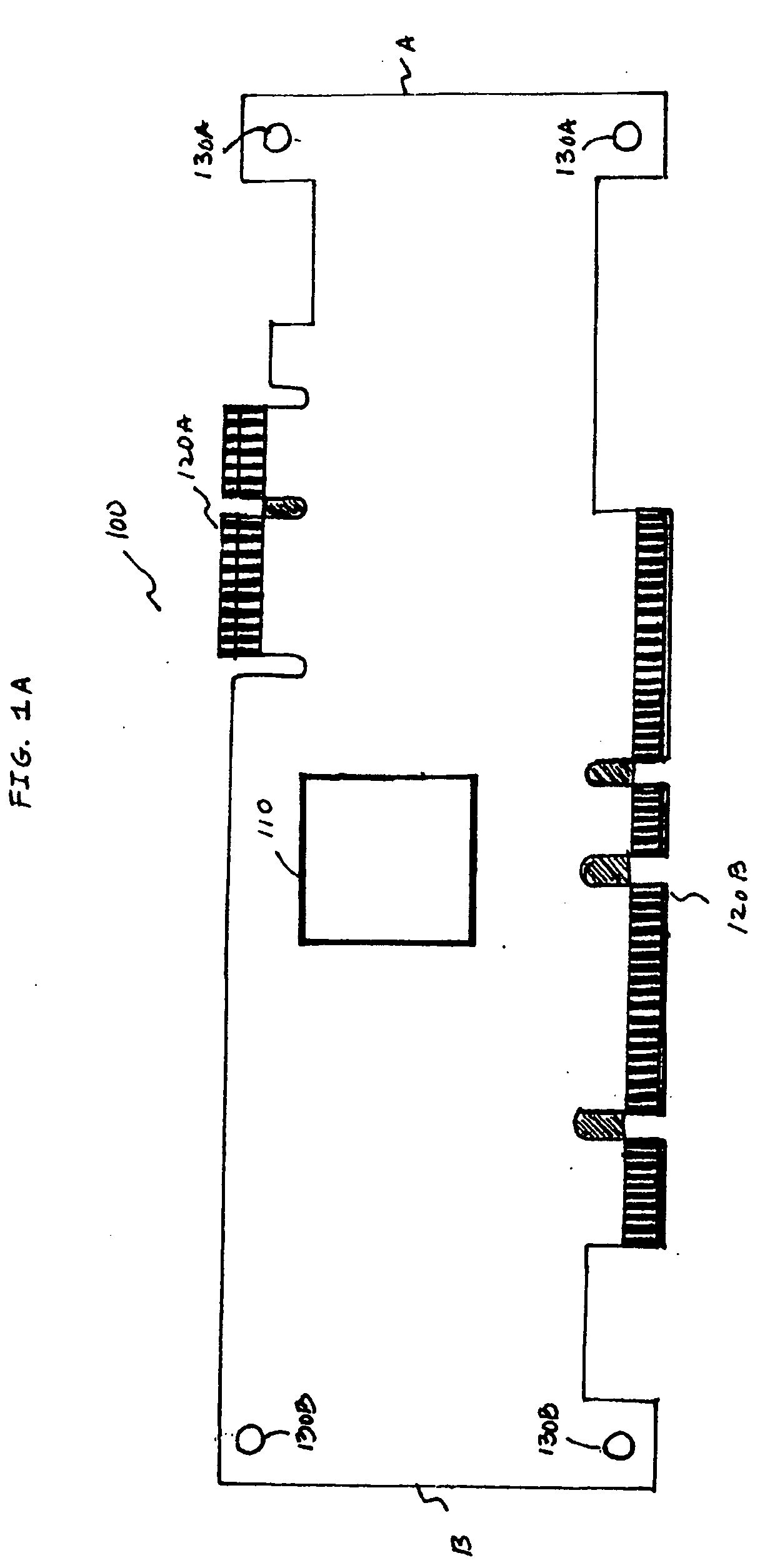

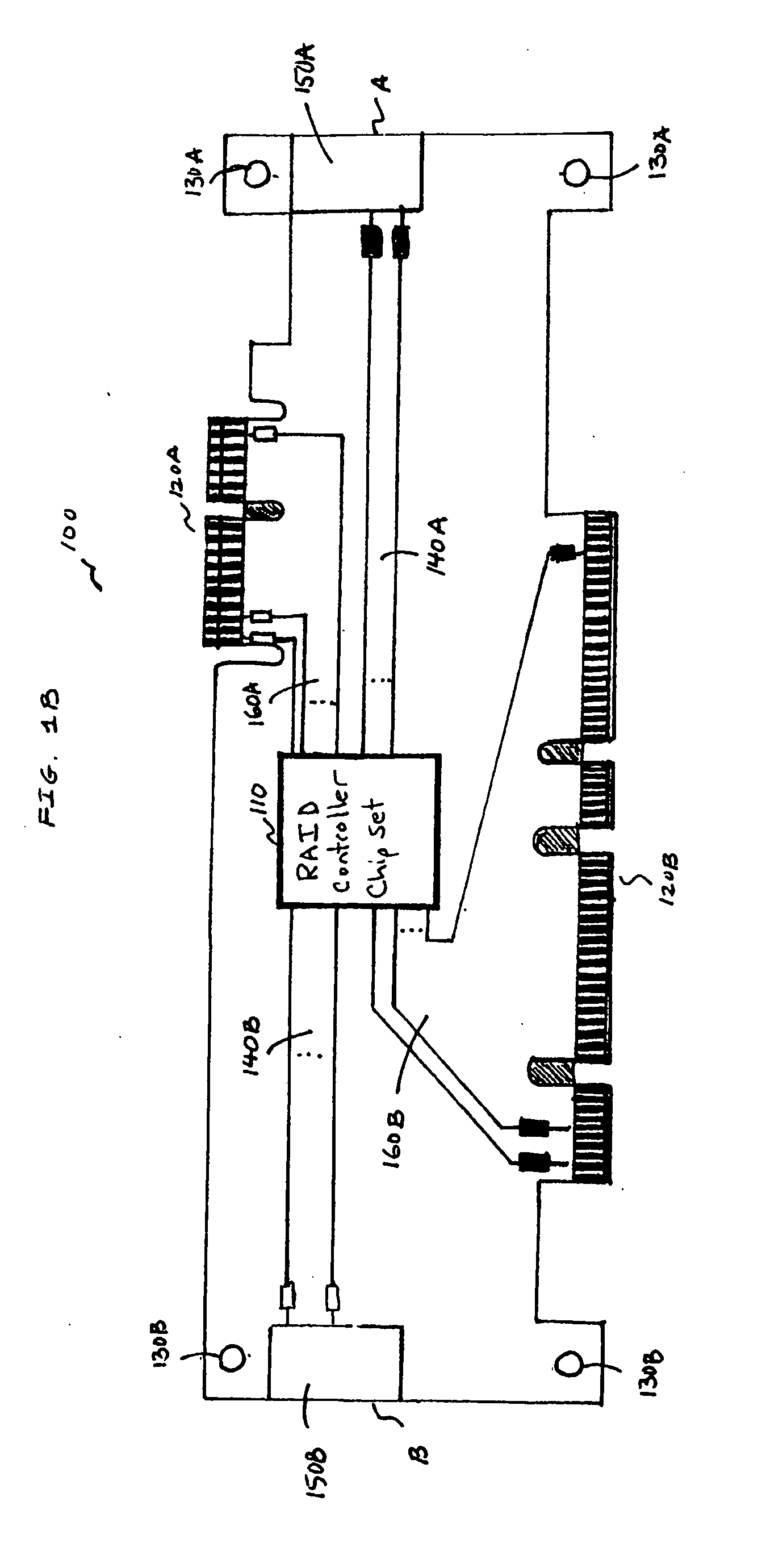

Dual bus memory burst architecture

A method and apparatus for a memory device including a burst architecture employs a double bus architecture that is multiplexed onto an output bus at clock rate that is doubled. The resulting architecture effectively doubles throughput without increasing memory device latency.

Owner:ROUND ROCK RES LLC

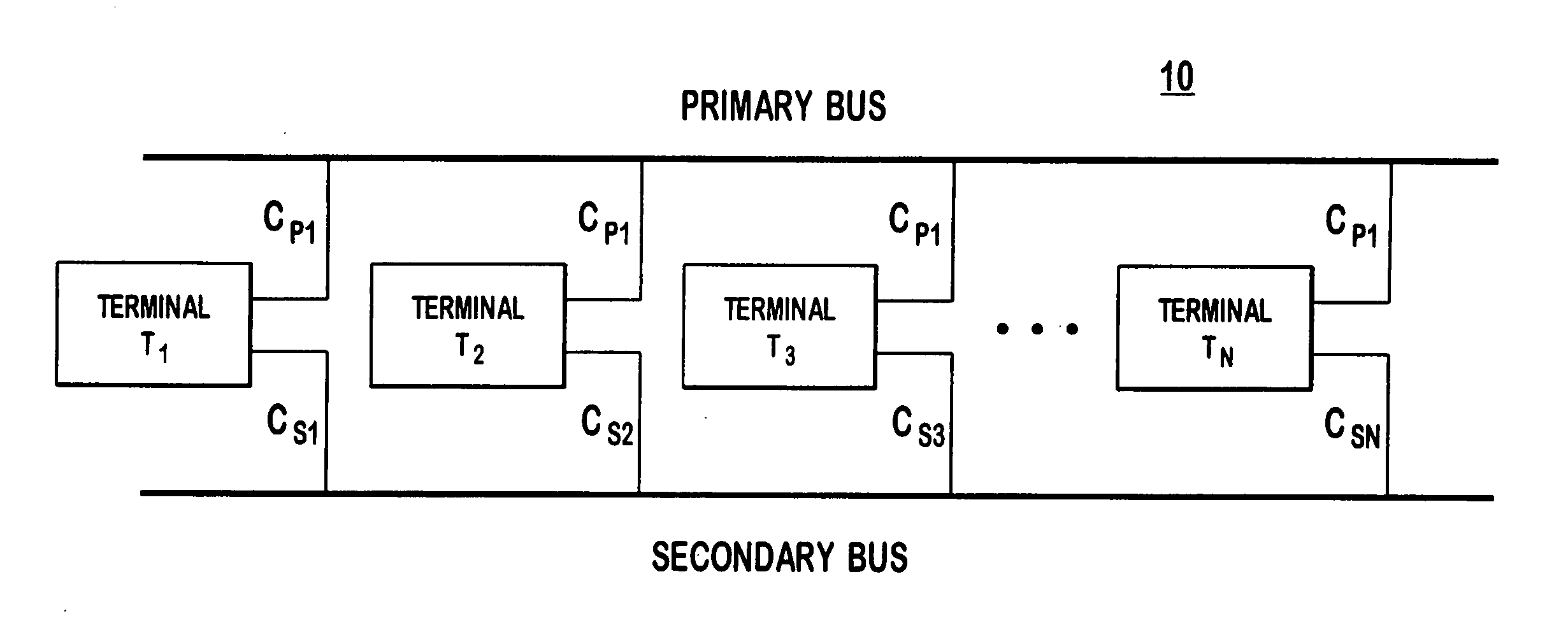

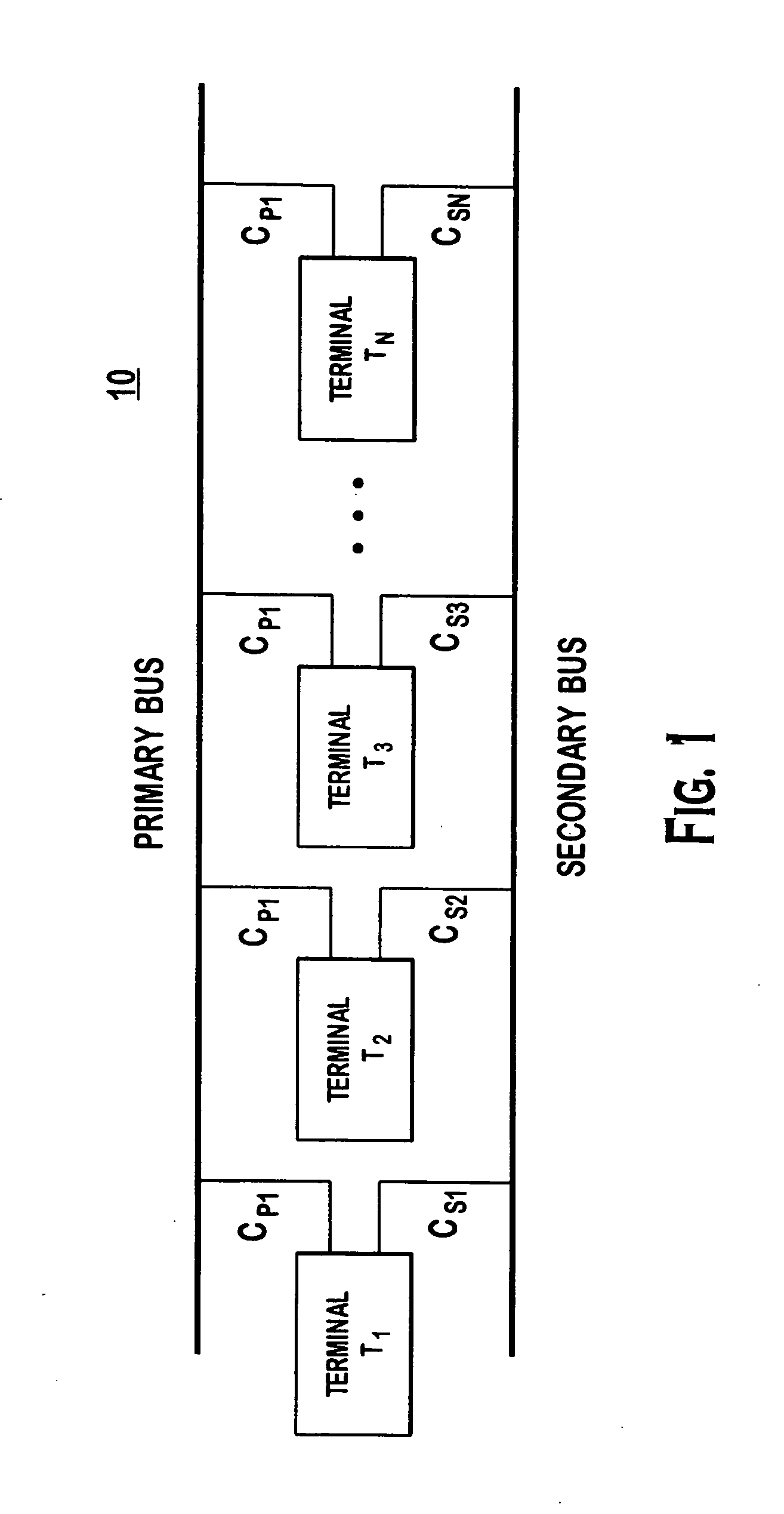

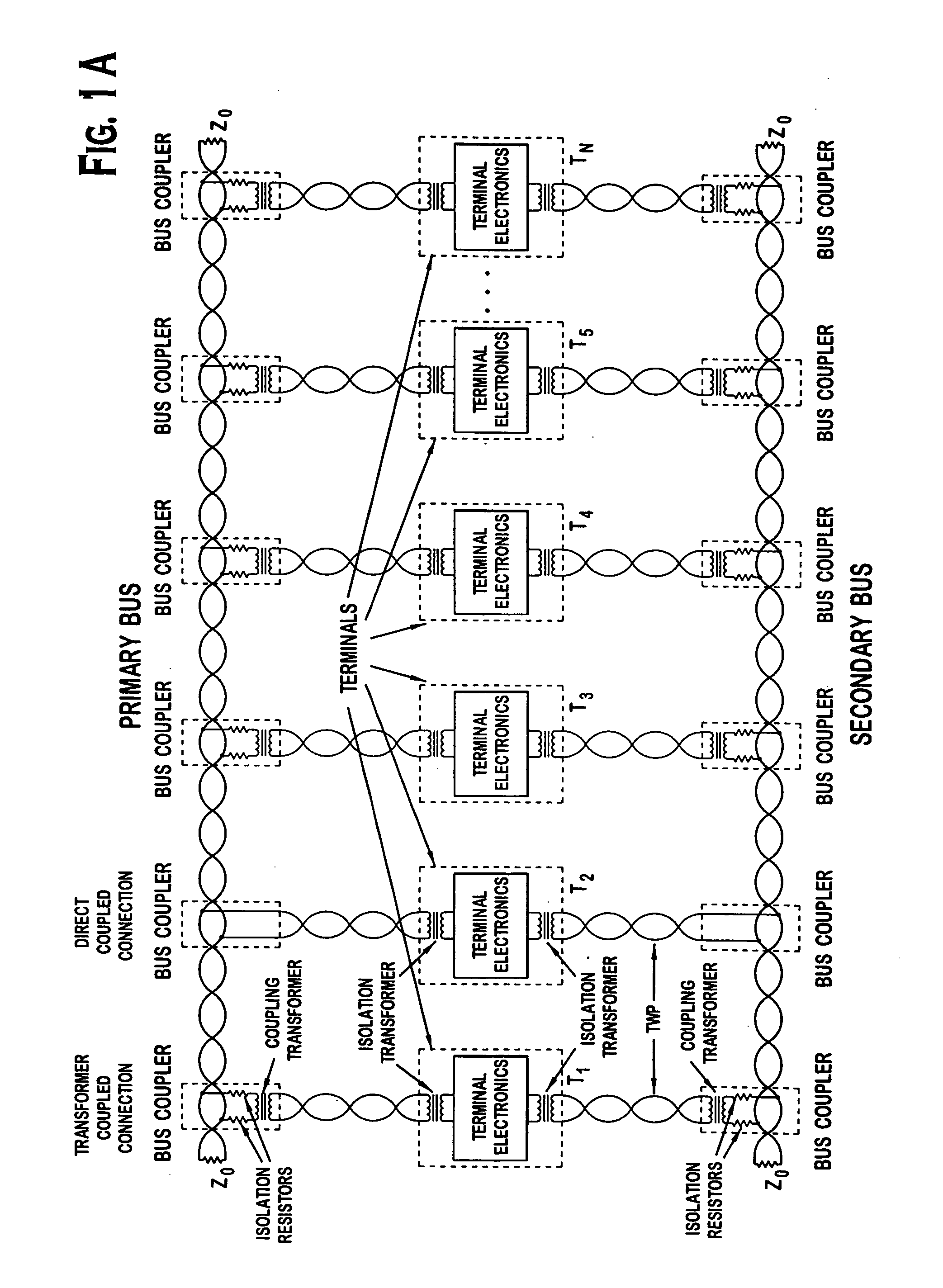

Dual speed/dual redundant bus system

InactiveUS20060101184A1Increase data rateDecreased SNRError detection/correctionData switching networksMultiplexingFault tolerance

Method and apparatus for use of the dual redundant bus network utilizing time and frequency multiplexing techniques to provide a high bit rate system that maintains a lower bit error rate with good fault tolerance by sending a low speed message on one bus and a high speed message on the remaining bus then operating at a dual bus mode and for reducing the speed of the high speed to aerate between the high speed and low speed message rates and multiplexing the low speed and reduced high speed messages when a fault condition is detected on one of the buses. Techniques are provided for continuously monitoring the buses to identify the least recently used (LRU) to facilitate bus selection and selection of one of the dual bus and concurrent modes for operation.

Owner:DATA DEVICE CORP

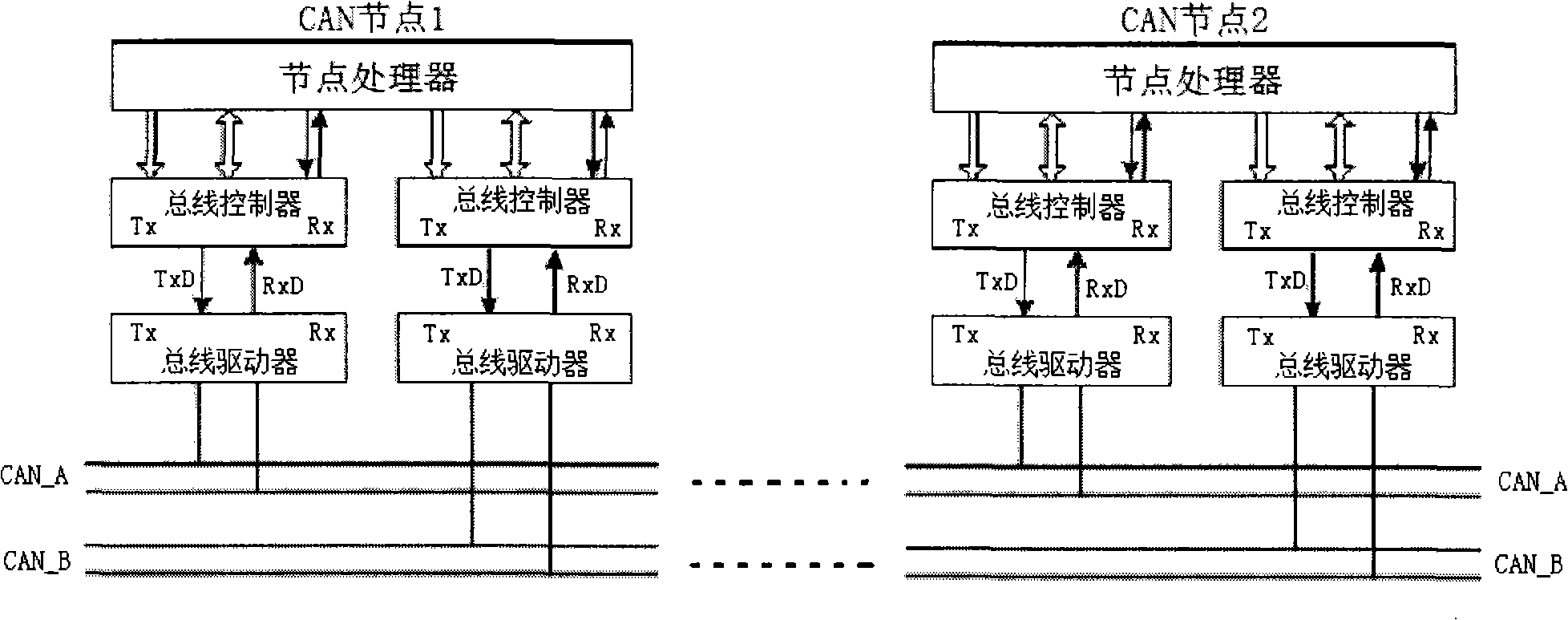

Dual-redundant CAN bus communication system and communicating method thereof

InactiveCN101286940AImprove fault toleranceImprove reliabilityError preventionBus networksTelecommunications linkDual bus

The invention provides a dual-redundancy CAN bus communication system which is characterized in that: the communication system adopts a dual-bus structure; the dual-bus is provided with a plurality of CAN nodes; the CAN nodes comprise a node processor, two bus controllers and two bus drivers; the two bus controllers are respectively connected with different buses by the two bus drivers; the node processor and the two bus controllers are connected to control the communication of the bus controllers. The special dual-bus structure of the communication system effectively improves the fault-tolerant ability of communication links and the reliability of the whole system.

Owner:BEIJING UNIV OF POSTS & TELECOMM

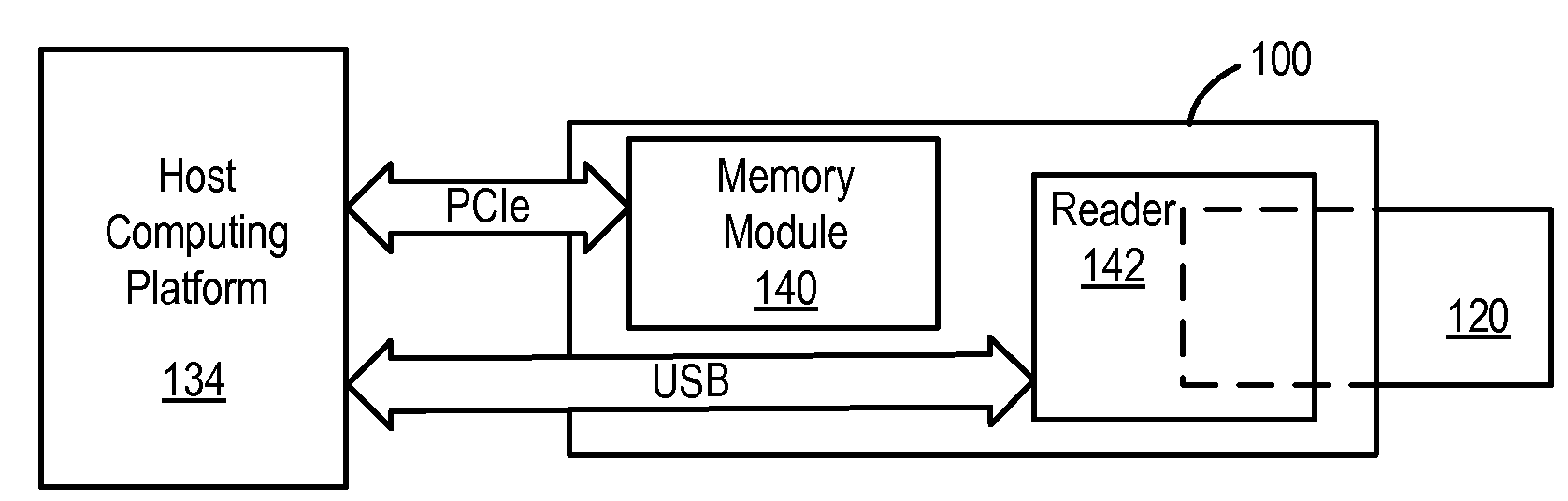

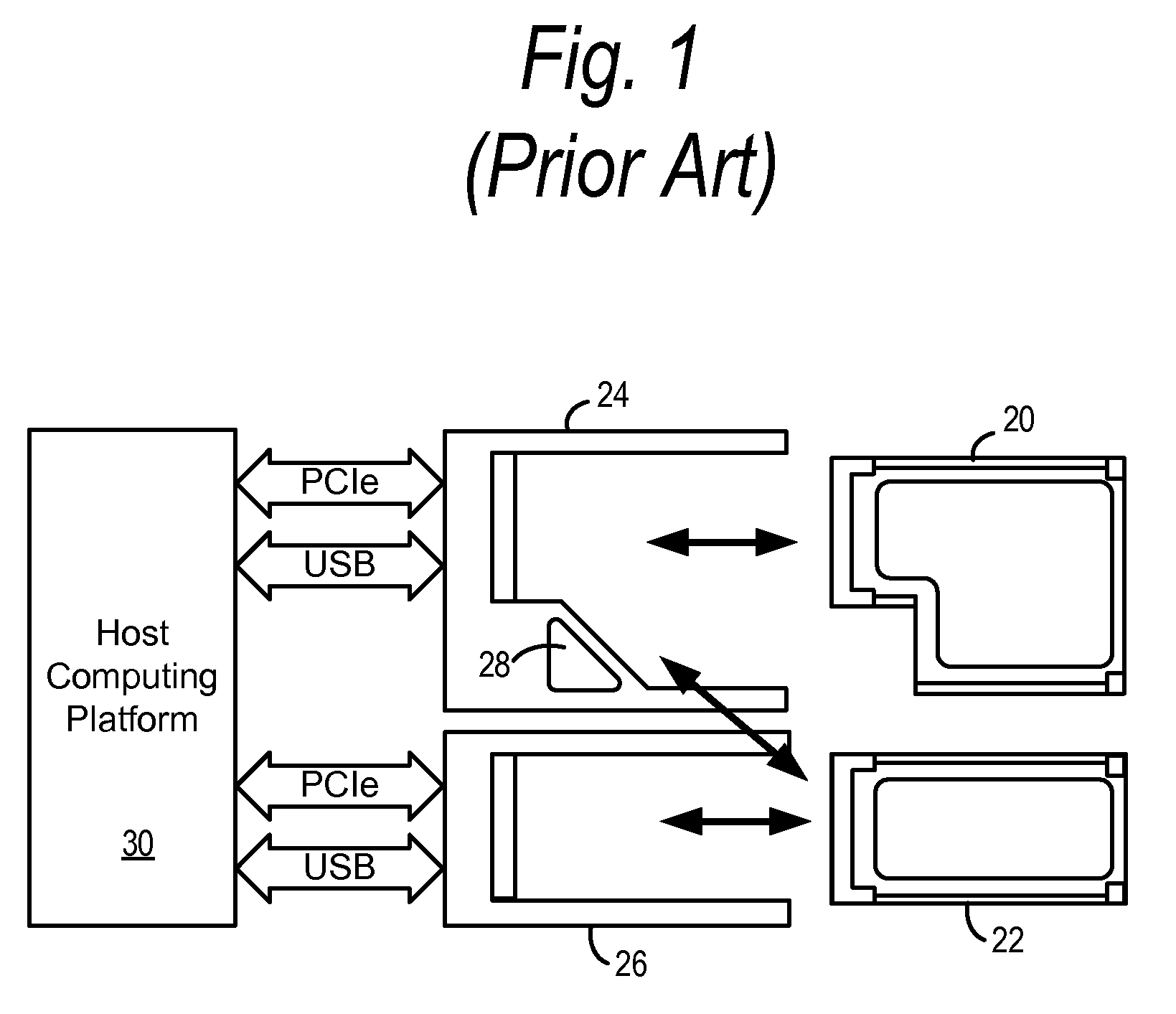

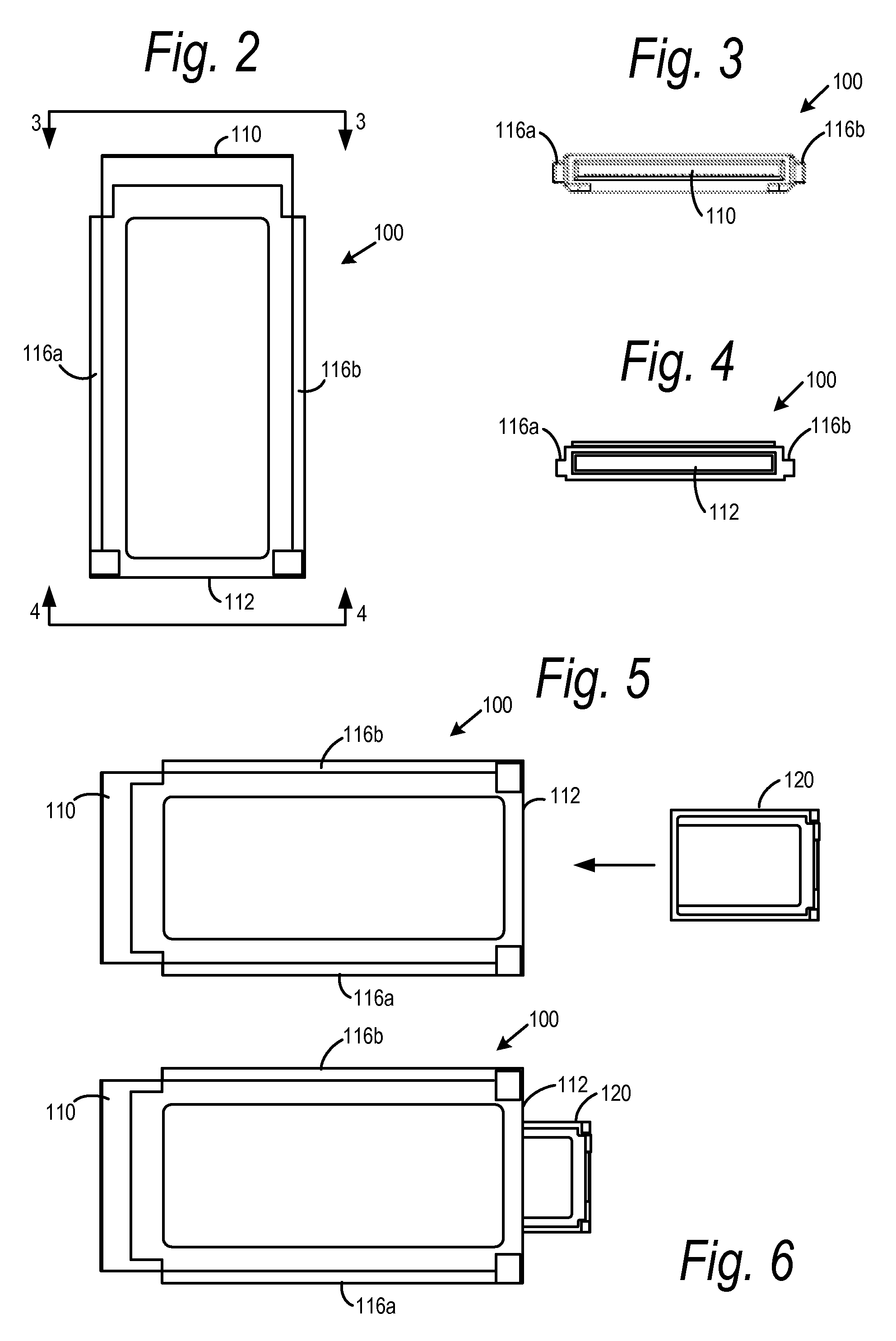

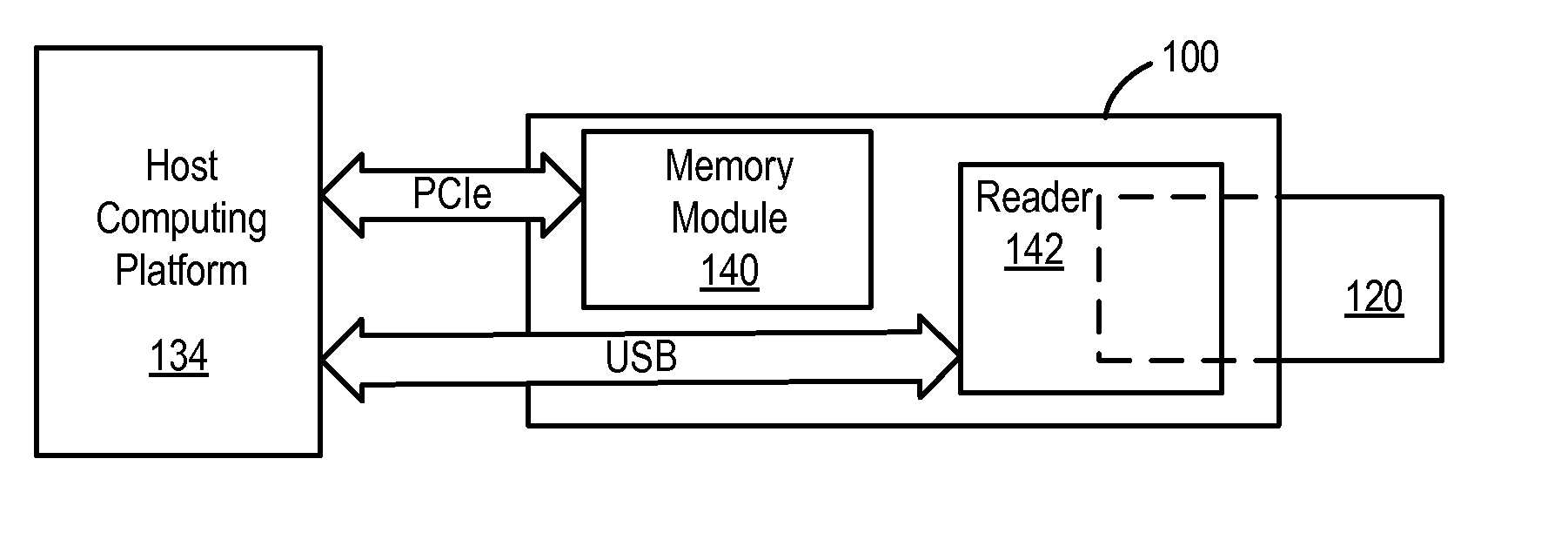

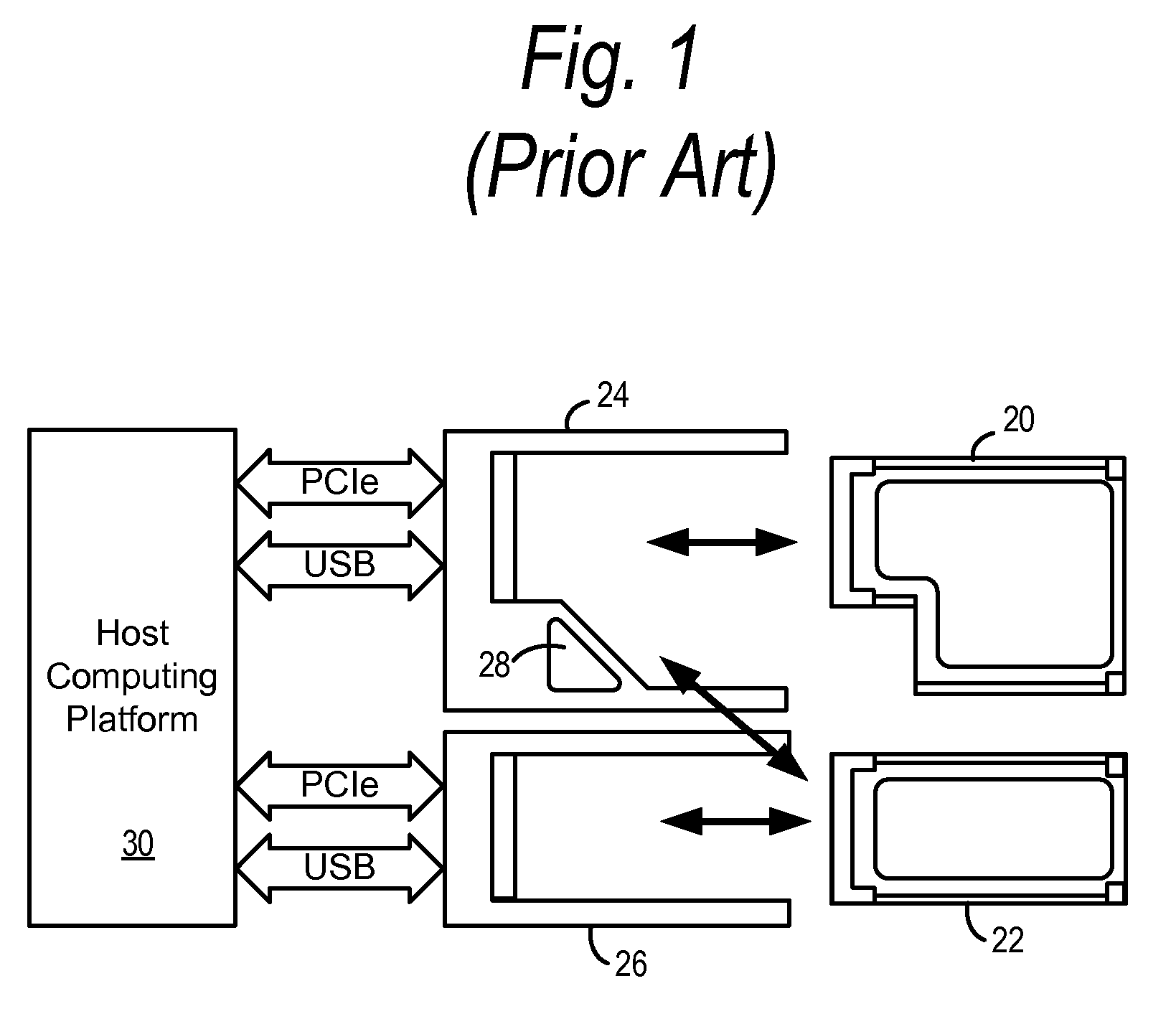

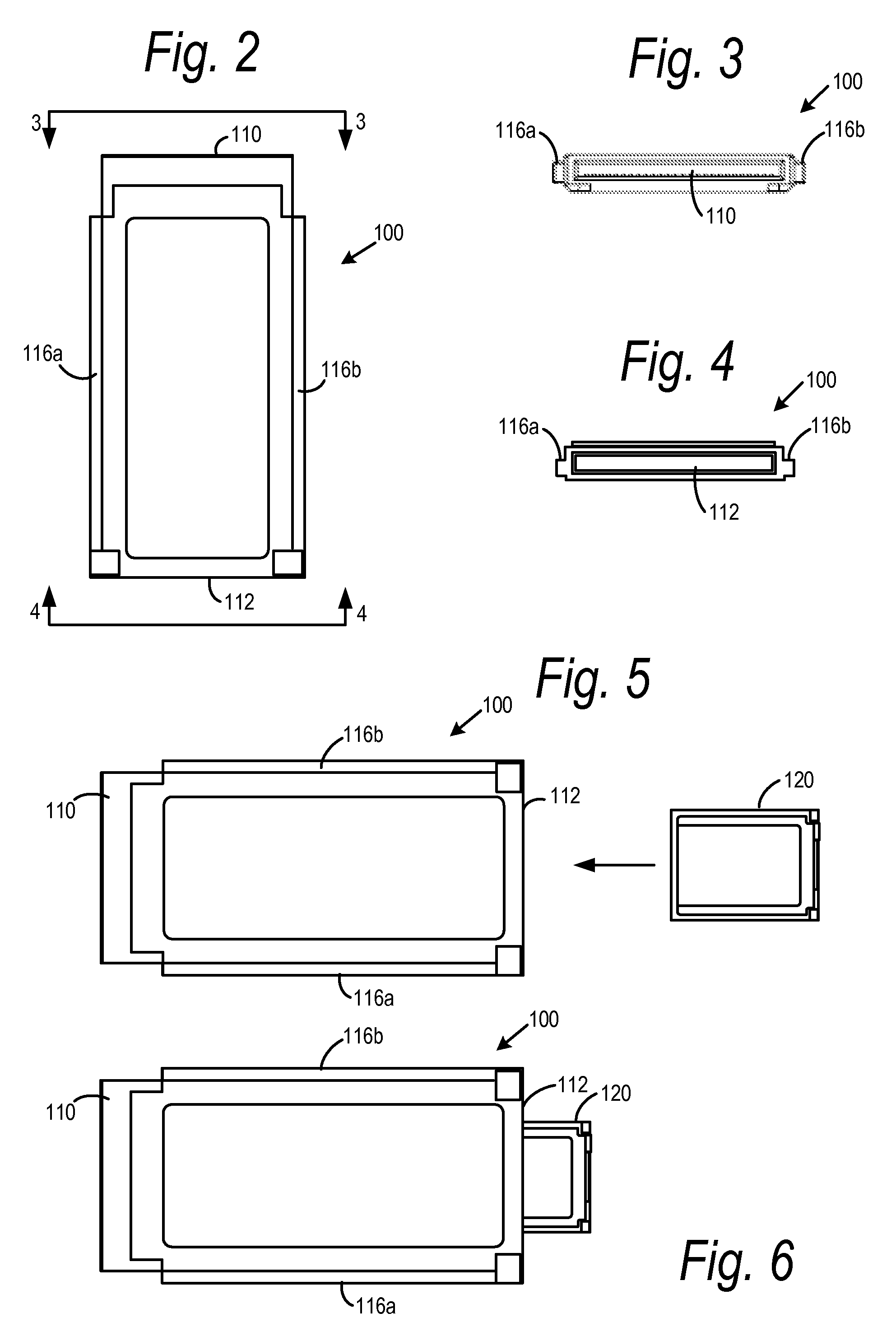

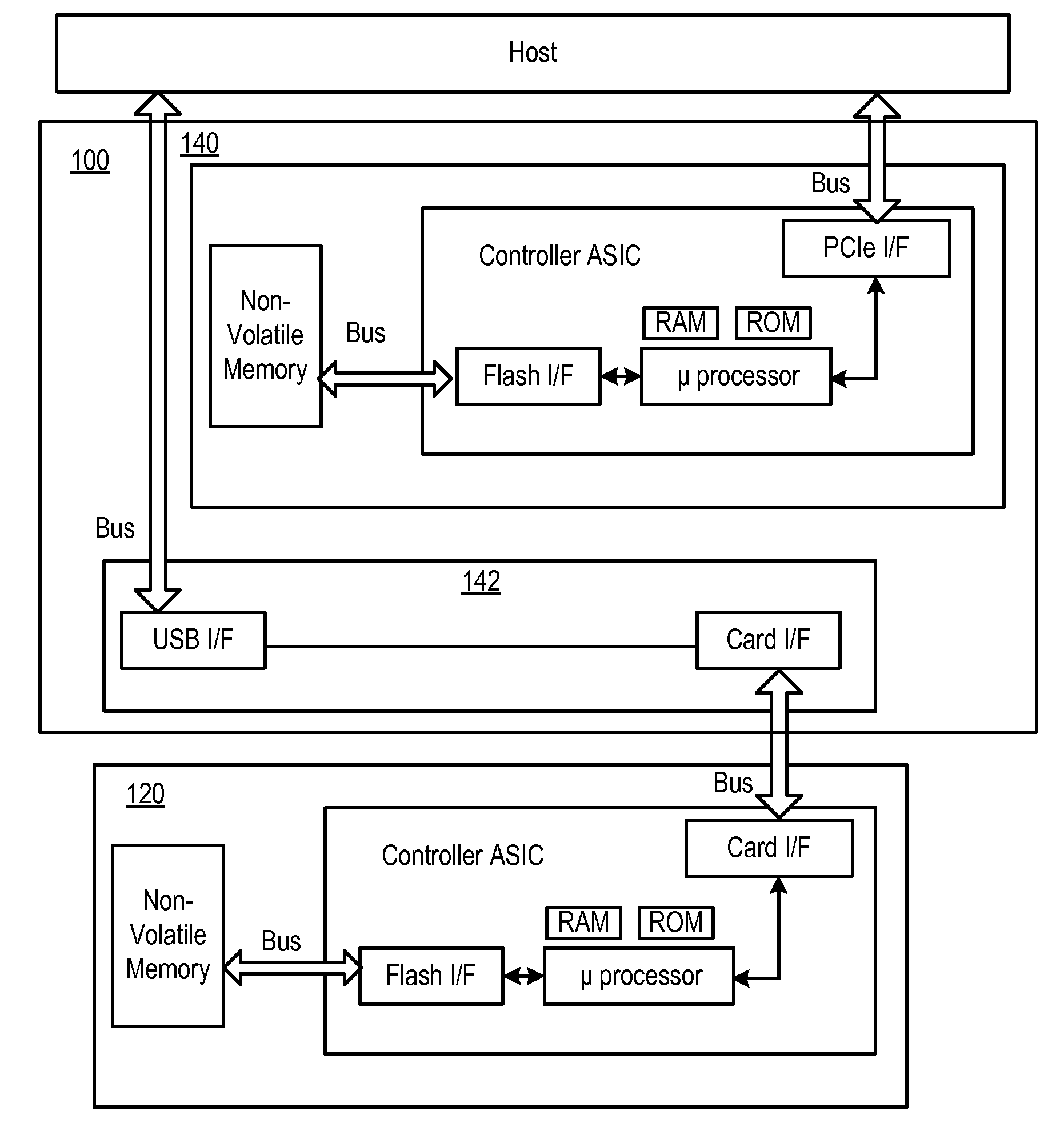

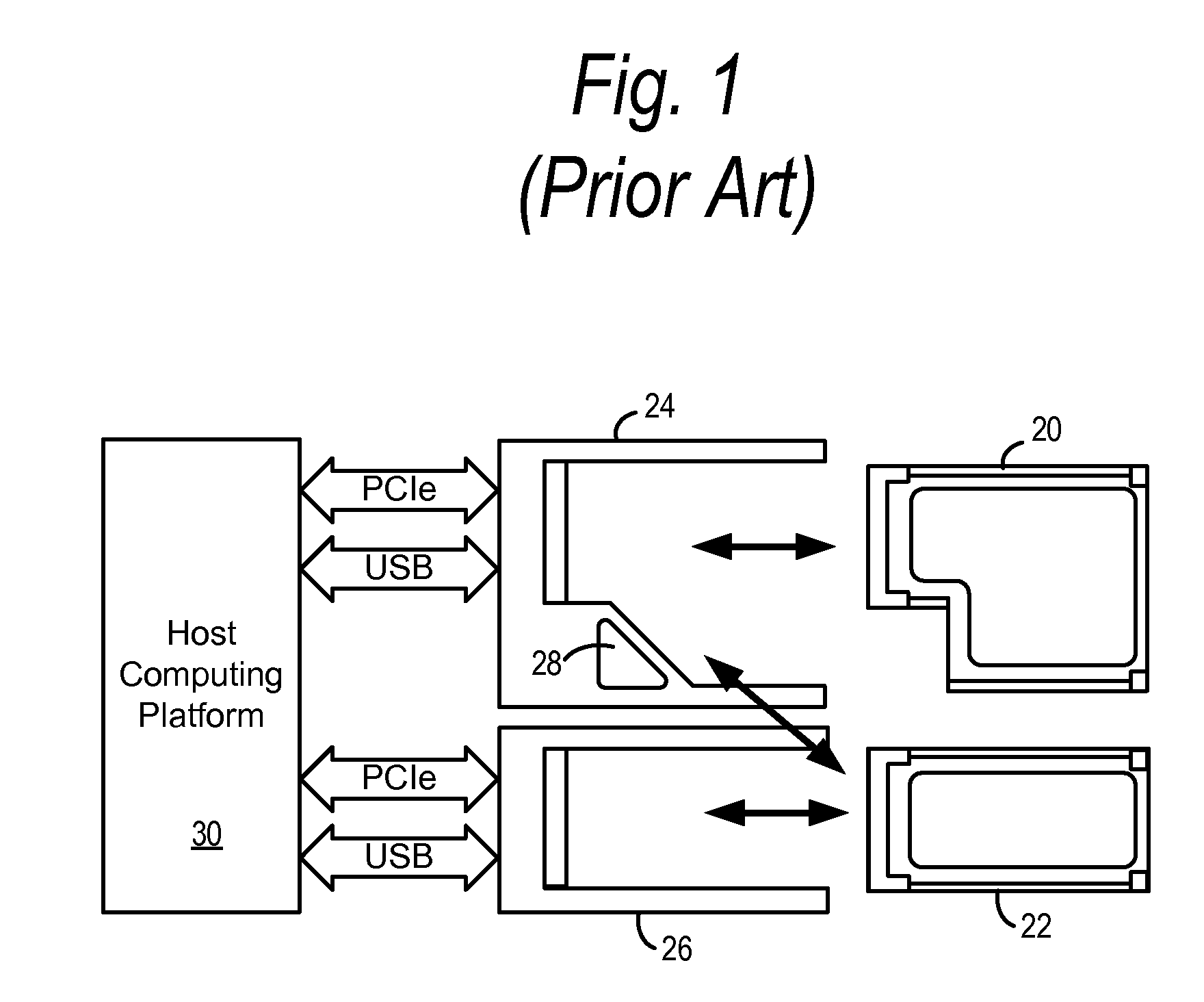

Dual bus expresscard peripheral device

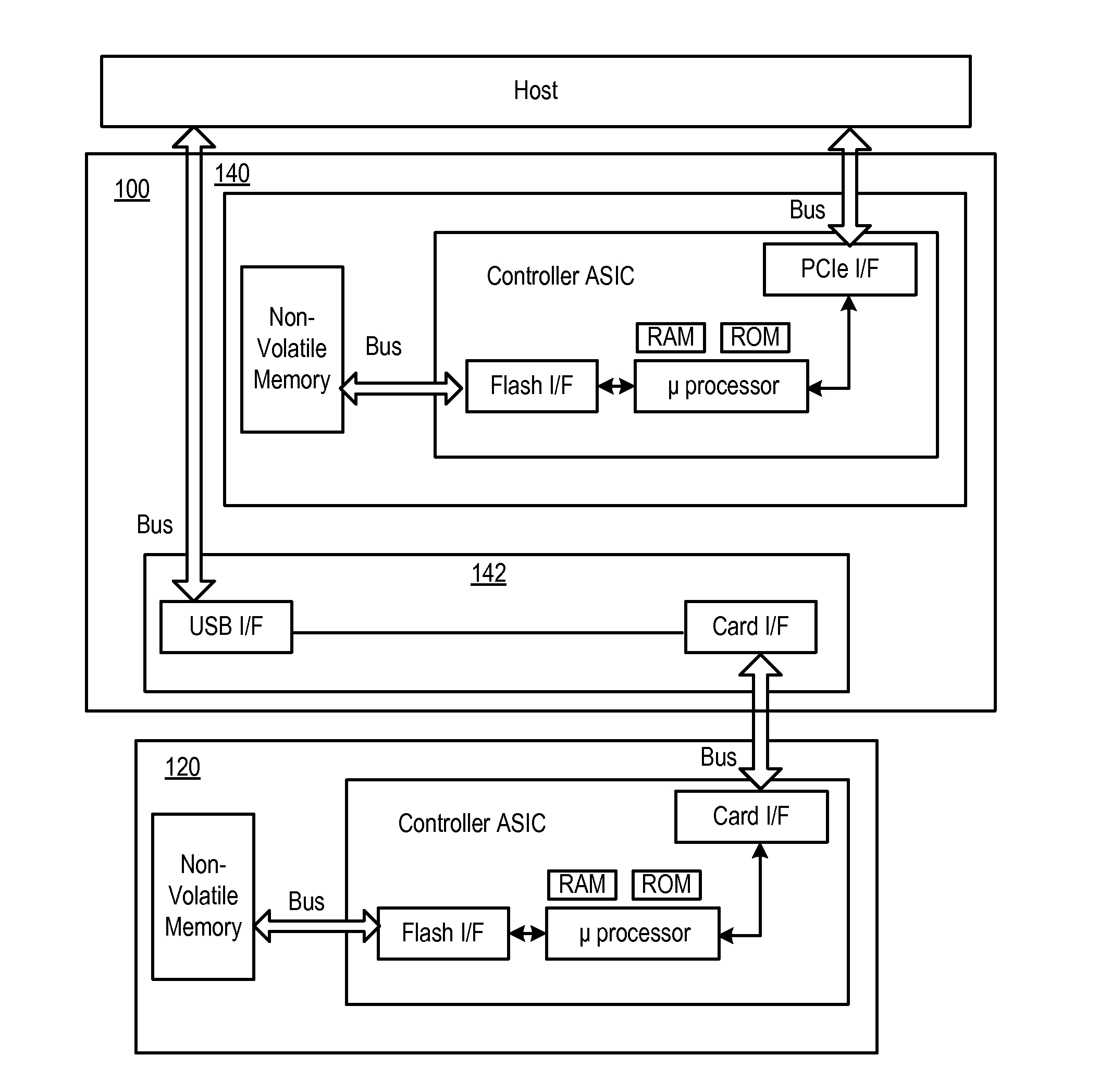

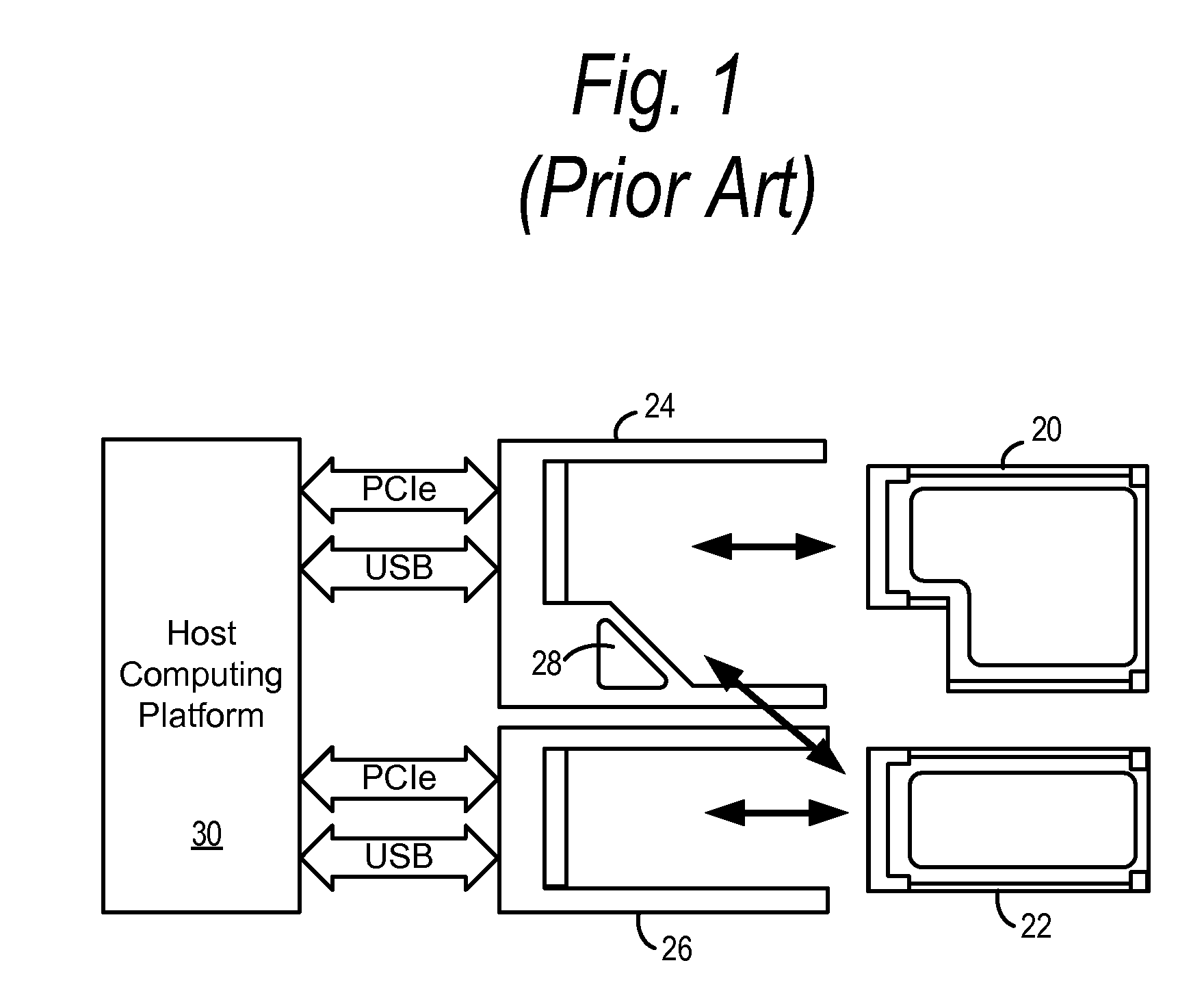

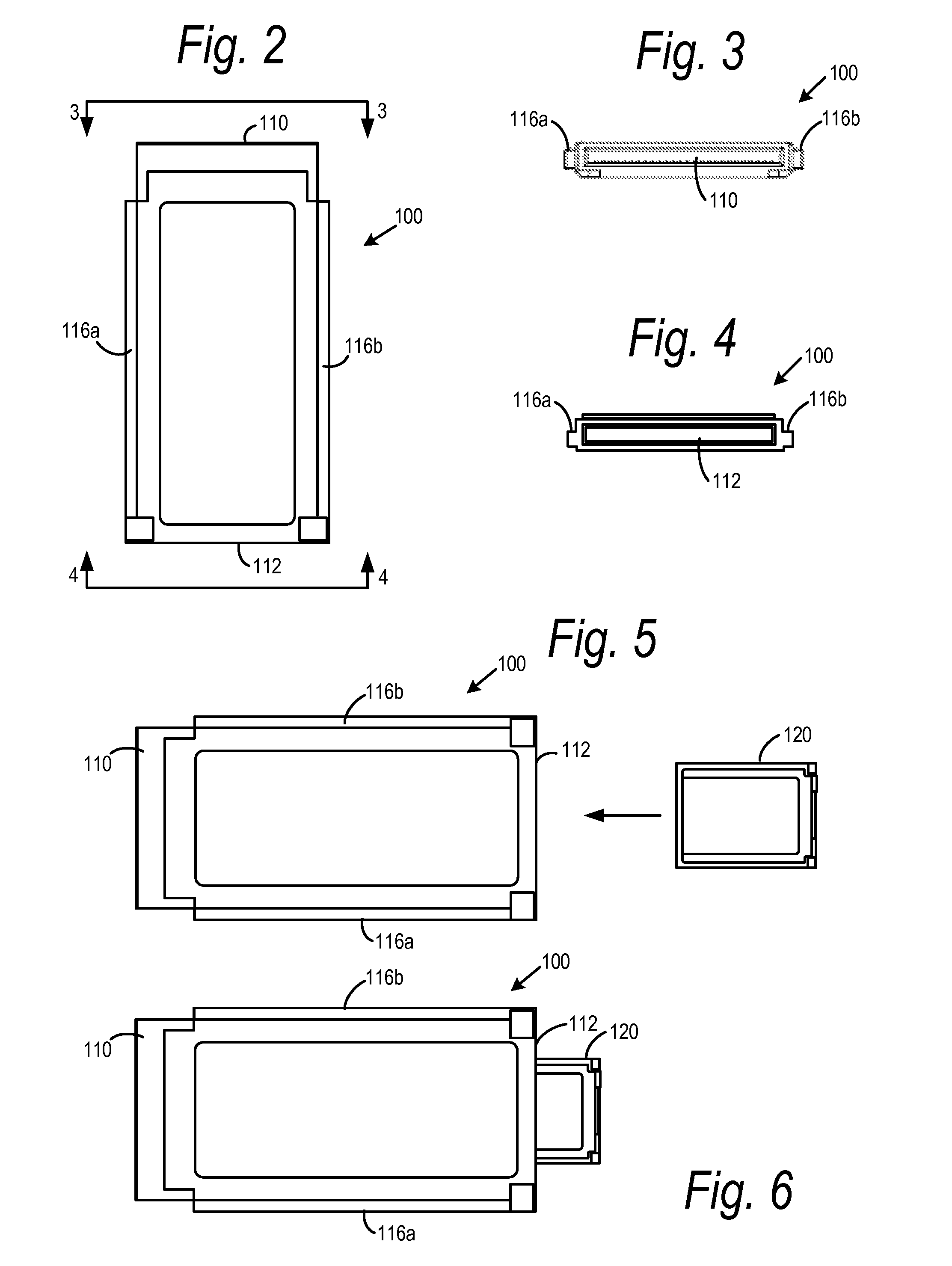

A peripheral device is disclosed having two associated memory modules, and which is configured to fit within the ExpressCard slot. One memory module communicates with a host over the PCIe bus interface of the ExpressCard slot, while the other memory module communicates with the host over the USB interface of the ExpressCard slot.

Owner:SANDISK TECH LLC

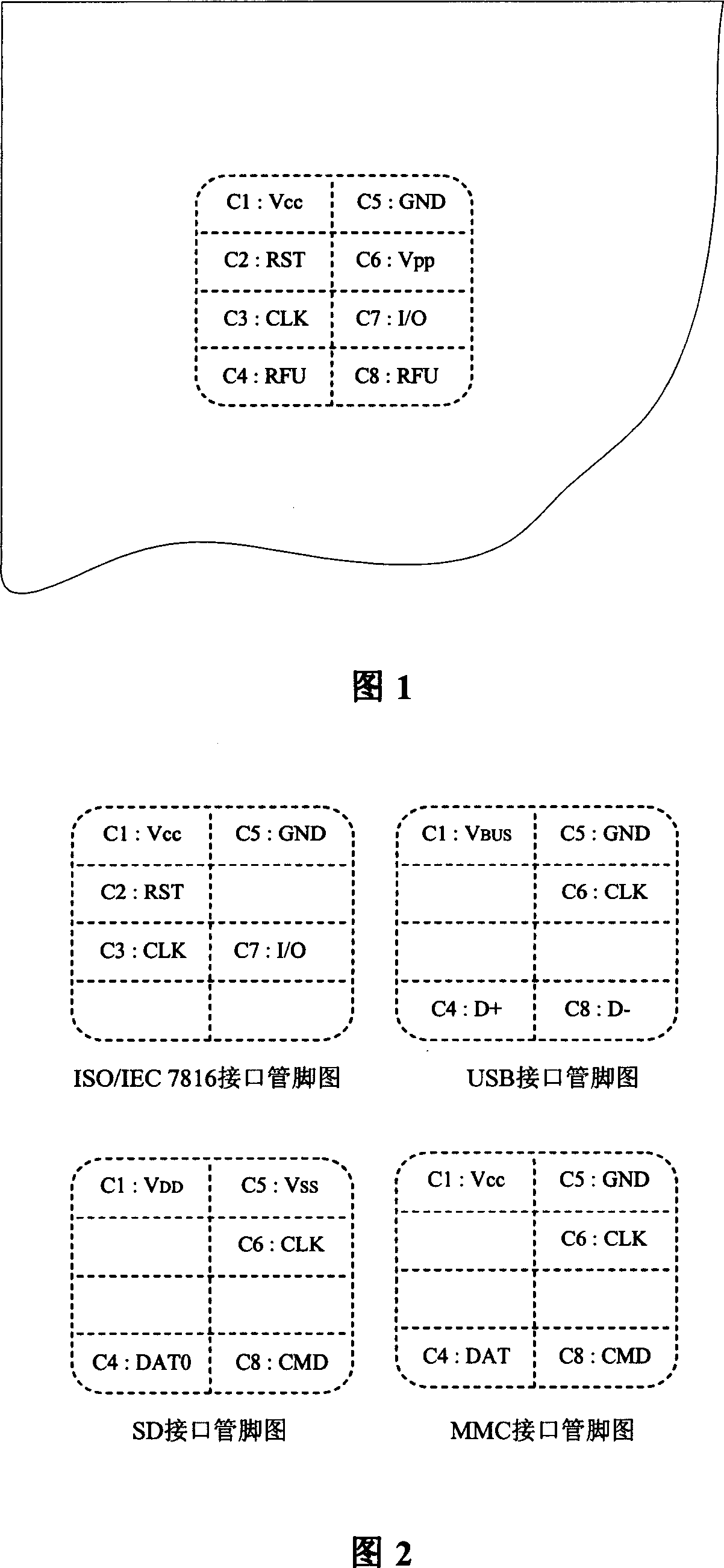

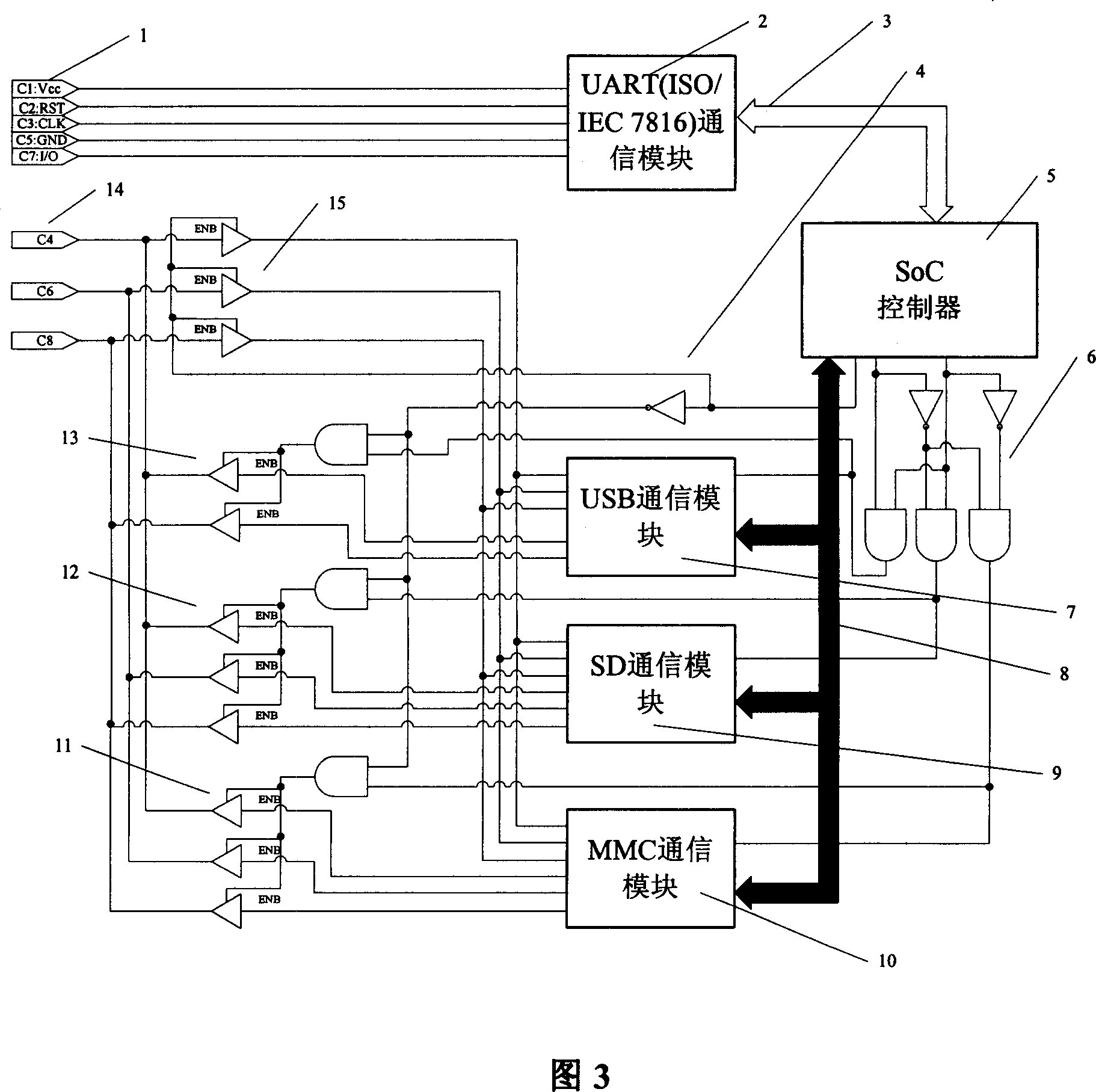

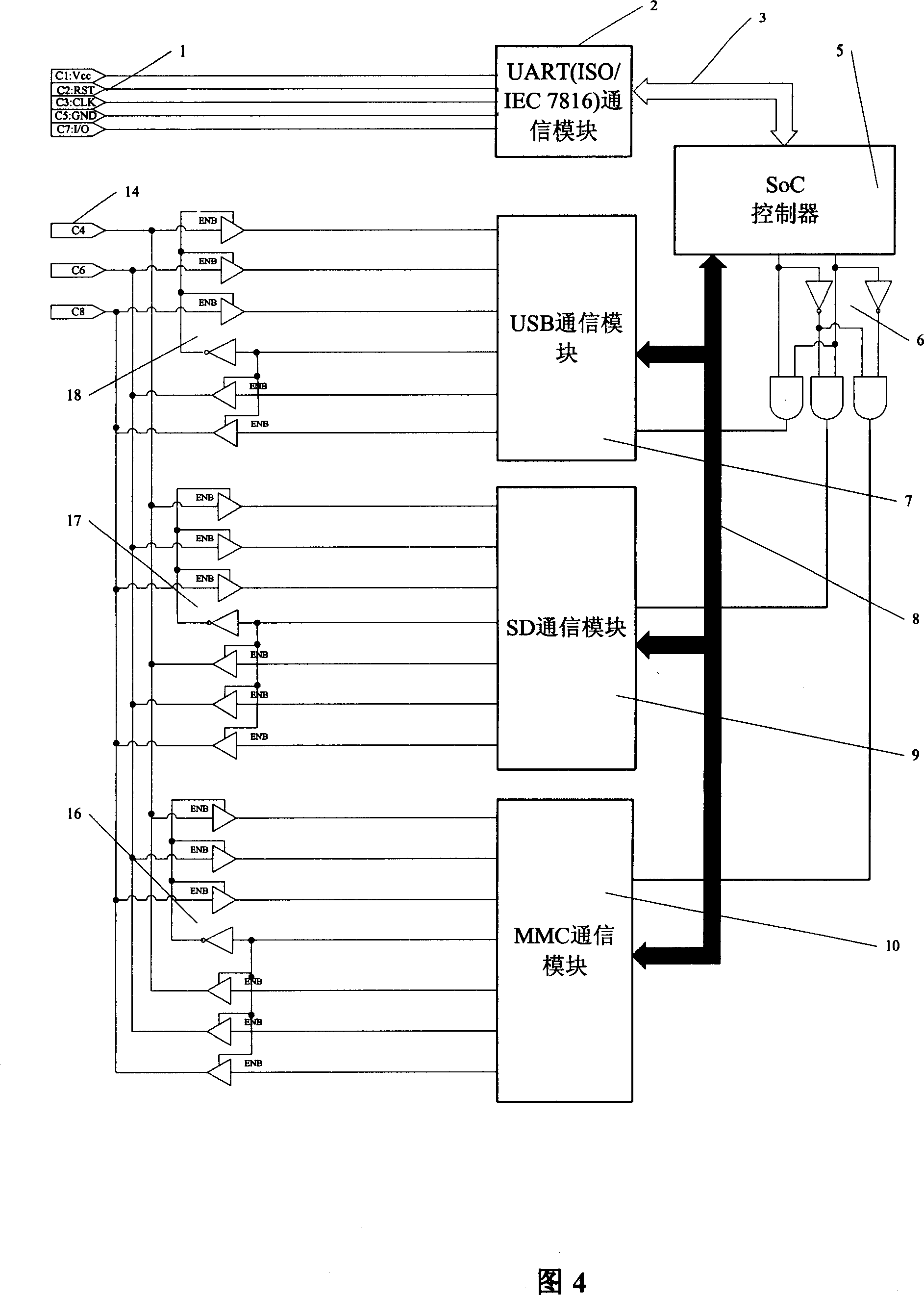

Method for integrating multiple data transmission interfaces on smart card and novel smart card

ActiveCN1936934AQuick exchangeImprove compatibilityInput/output to record carriersMemory record carrier reading problemsDual busSmart card

The invention is related to design and application of smart card with multiple transmission interfaces in high speed. Based on communication protocol of ISO / IEC7816 interface, the technical scheme carries out signal multiplexing for pins C4,C6,C8 unused by signal of ISO / IEC7816 interface. Multiple transmission interfaces in high speed are integrated in the three pins. Using dual bus structure, the scheme carries out control and transmission for data interface in high speed and ISO / IEC7816 interface. Data interface in high speed and ISO / IEC7816 interface can work by itself / independently, or can transfer data simultaneously / synergetically. Identifying interface signal of data in high speed, the scheme determines types of interface and communication protocol, as well as switch on / off relevant working circuits of interface. Features are: high compatibility so as to increase serviceable range, and convenience of use.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

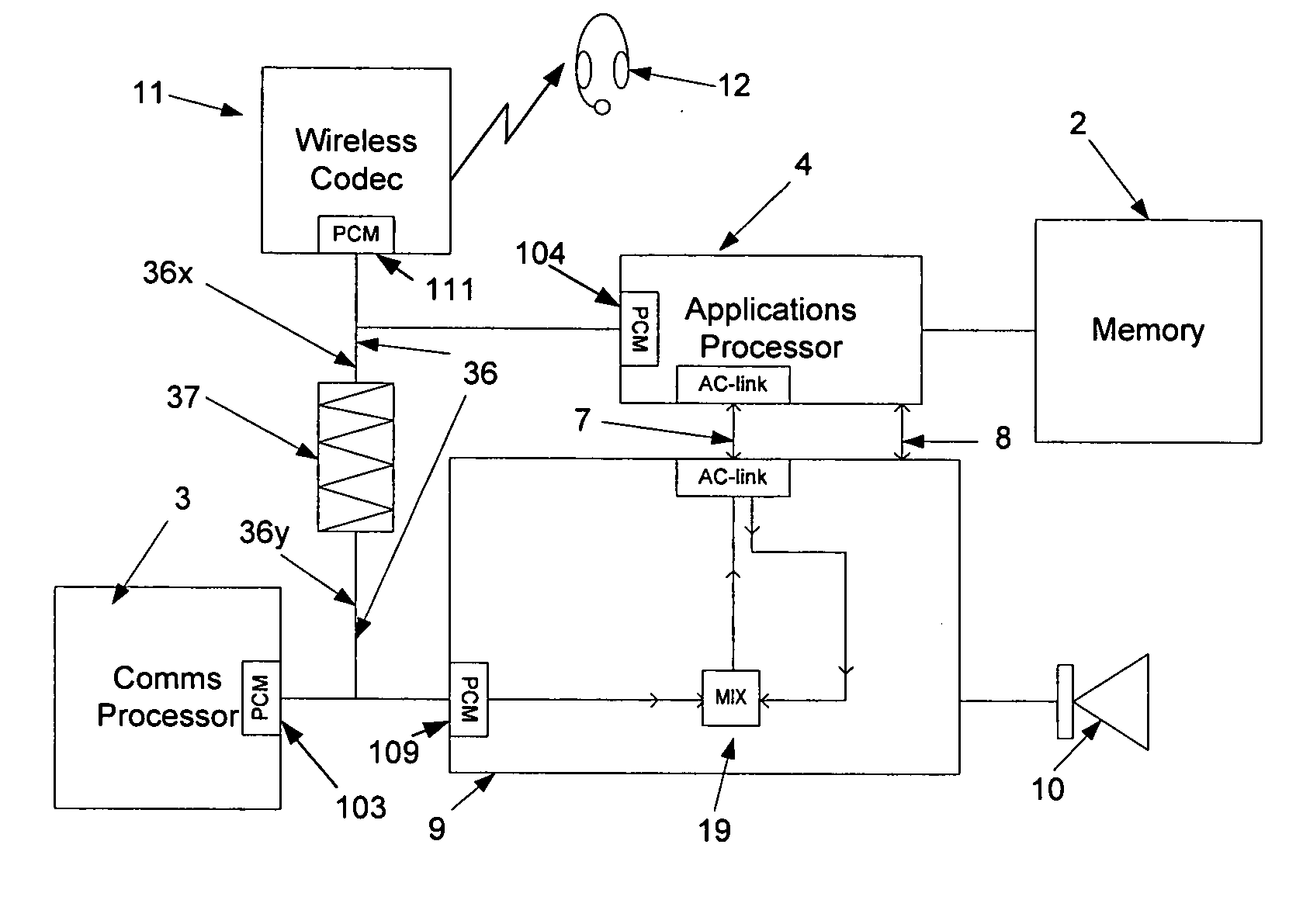

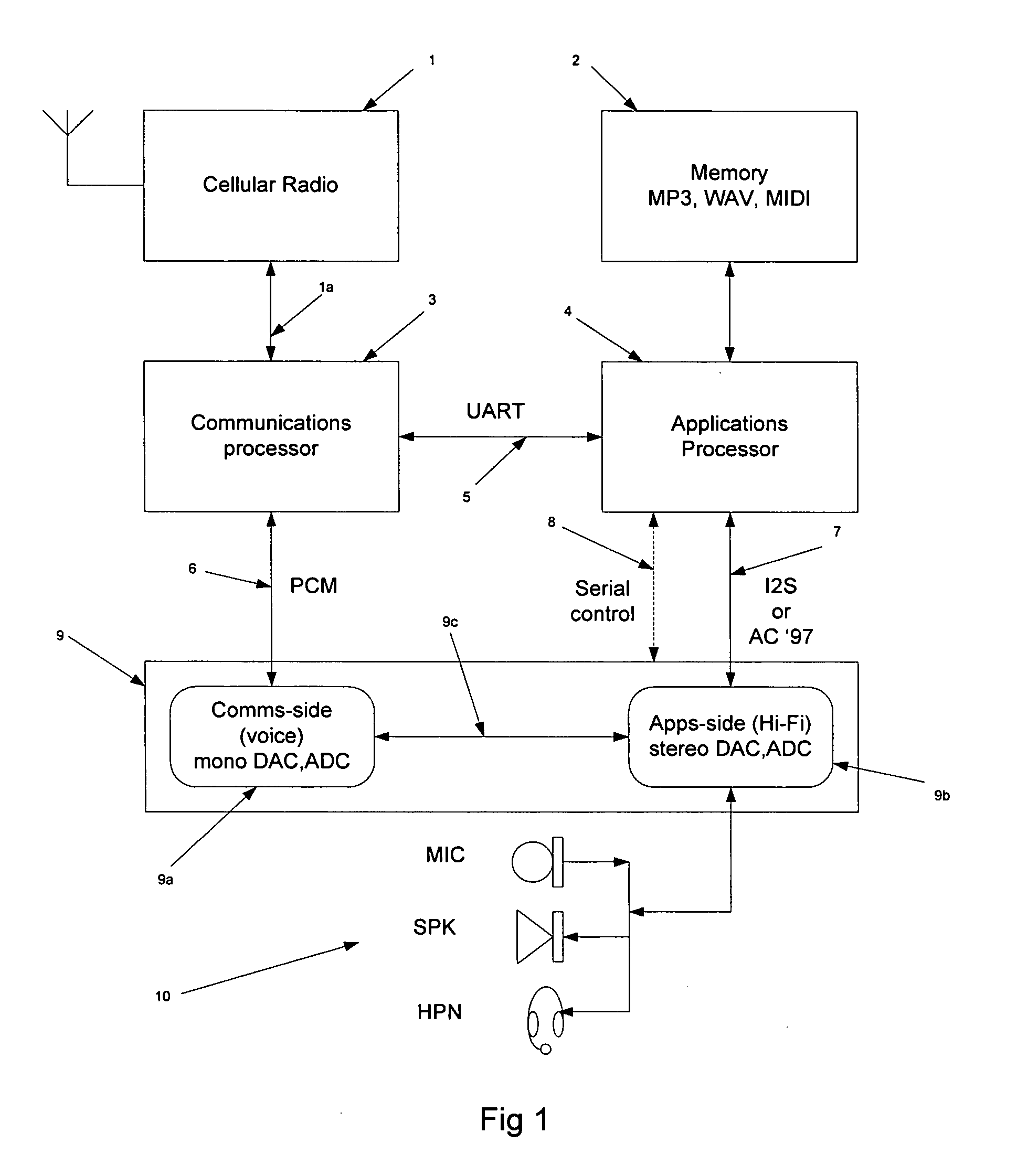

Audio device

ActiveUS20070124526A1Reduce in quantityIncrease flexibilityDigital computer detailsSubstation equipmentElectrical conductorDual bus

The present invention provides a digital bus circuit comprising: a bus conductor having two sections each connected to a pass circuit, each bus section being connected to two bus interfaces for respective circuits; at least three of the bus interfaces comprising a tri-state output buffer having a tri-state mode and one or more logic output modes; wherein in a unitary bus mode the tri-state output buffers are arranged such that only one of said output buffers is not in a tri-state mode, and the pass circuit is arranged to substantially couple said bus sections; and wherein in a dual bus mode the tri-state output buffers are arranged such that only one of the output buffers connected to each bus section is not in a tri-state mode, and wherein the pass circuit is arranged to substantially isolate said bus sections.

Owner:CIRRUS LOGIC INC

Audio device

ActiveUS7376778B2Reduce in quantityIncrease flexibilityDigital computer detailsSubstation equipmentDual busBus interface

The present invention provides a digital bus circuit comprising: a bus conductor having two sections each connected to a pass circuit, each bus section being connected to two bus interfaces for respective circuits; at least three of the bus interfaces comprising a tri-state output buffer having a tri-state mode and one or more logic output modes; wherein in a unitary bus mode the tri-state output buffers are arranged such that only one of said output buffers is not in a tri-state mode, and the pass circuit is arranged to substantially couple said bus sections; and wherein in a dual bus mode the tri-state output buffers are arranged such that only one of the output buffers connected to each bus section is not in a tri-state mode, and wherein the pass circuit is arranged to substantially isolate said bus sections.

Owner:CIRRUS LOGIC INC

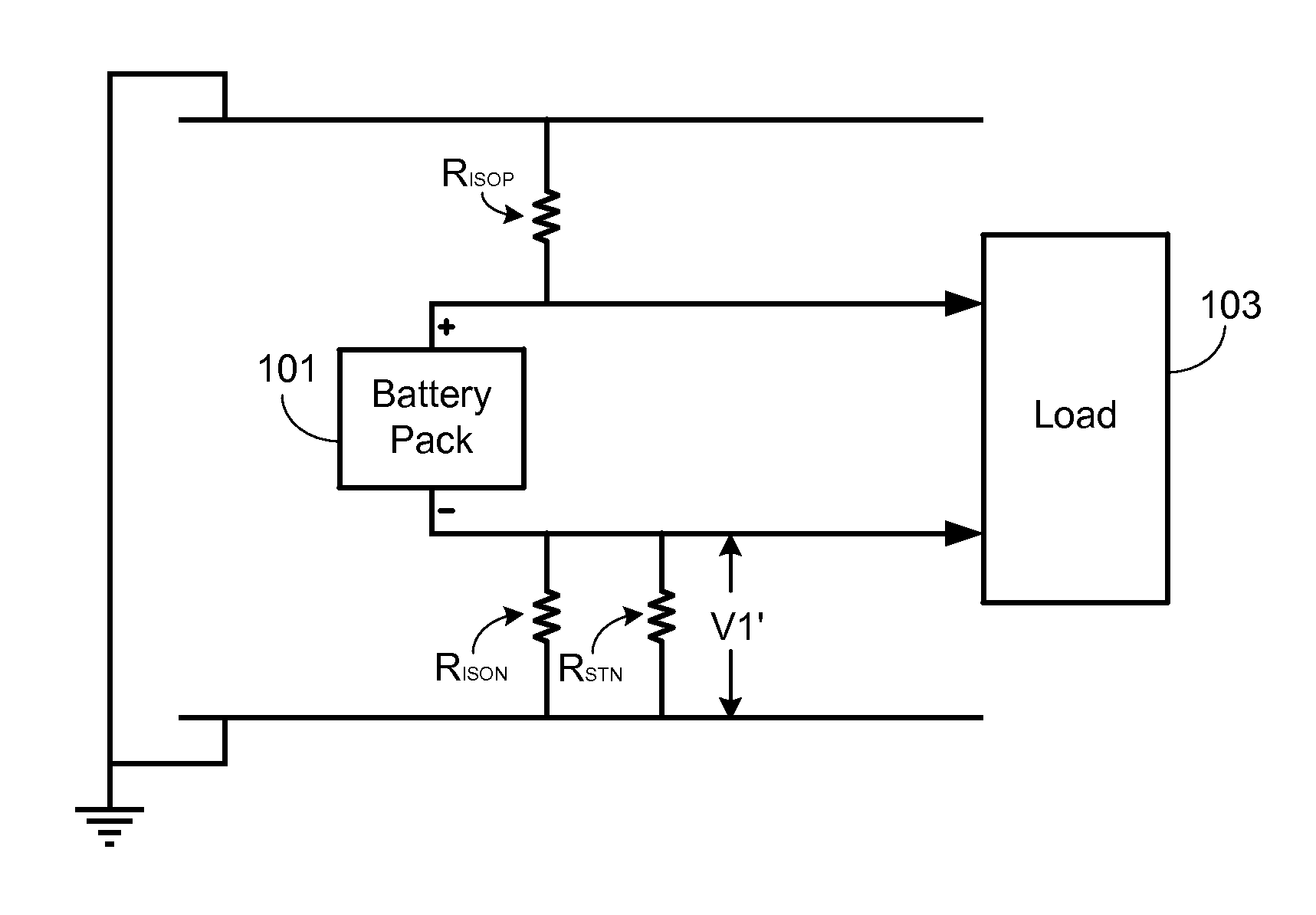

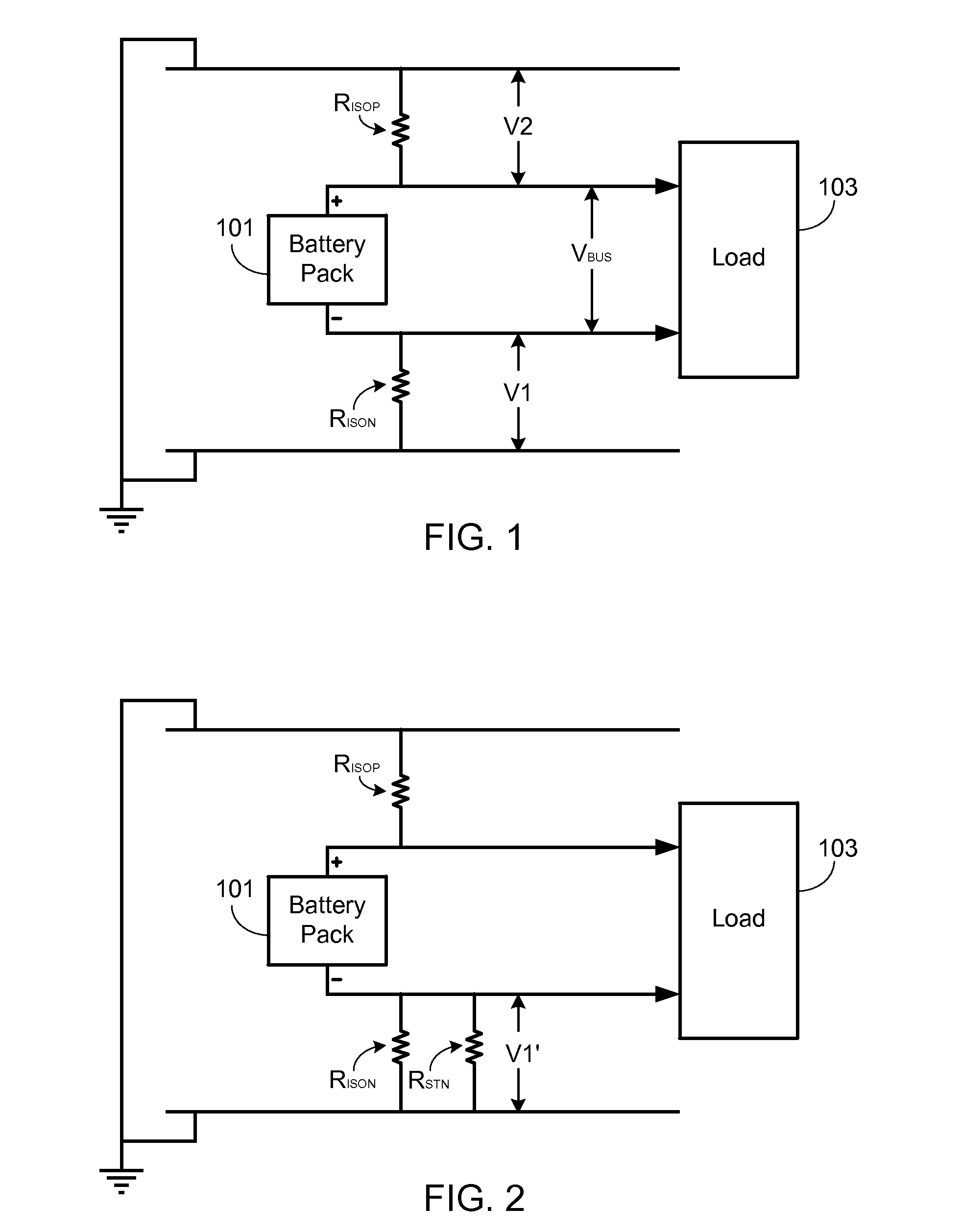

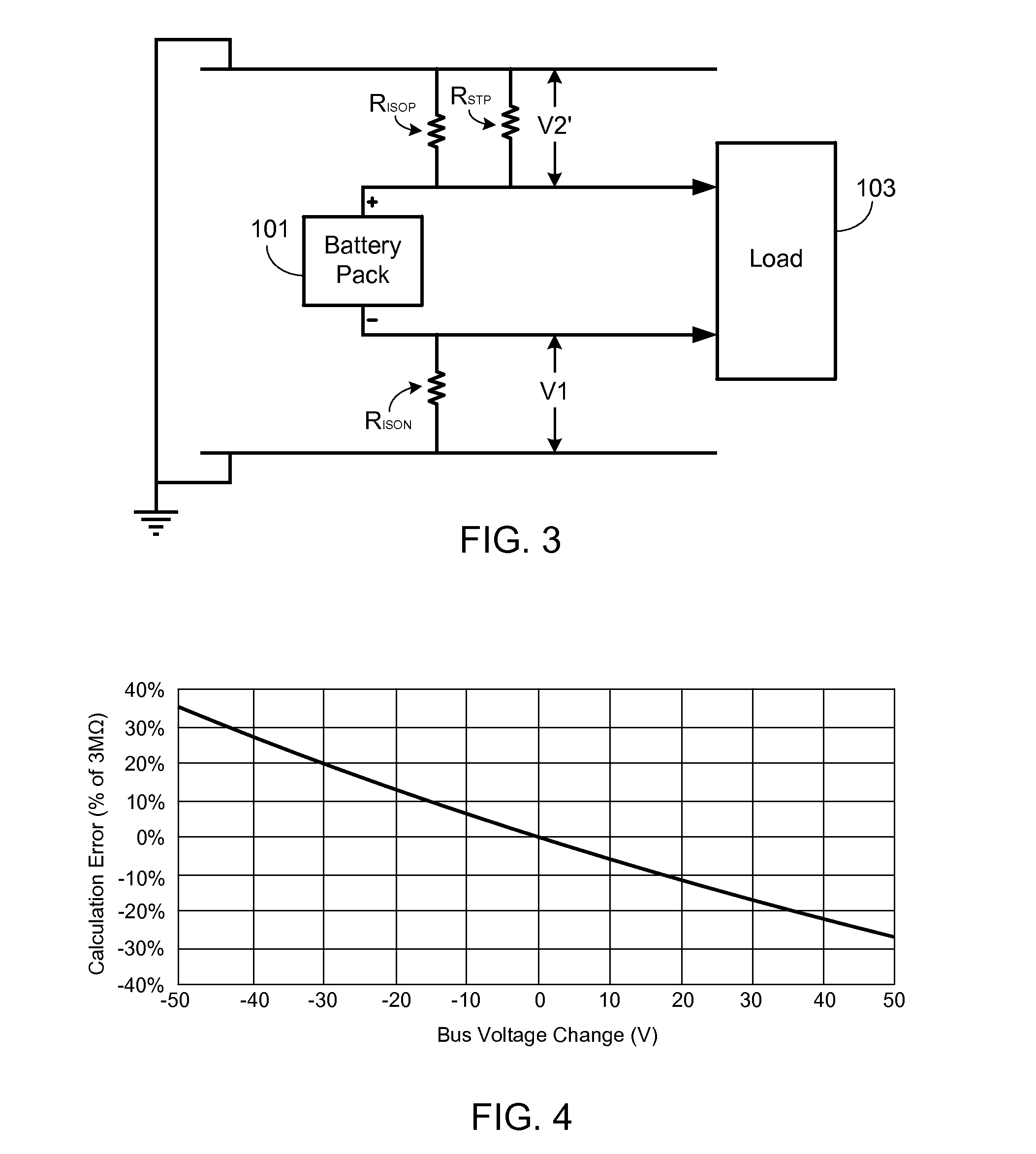

Method for Determining Battery Pack Isolation Resistance Via Dual Bus Monitoring

InactiveUS20130027049A1Very high resistance measurementsMaterial analysis by electric/magnetic meansElectrical resistance and conductanceDual bus

A method for measuring and calculating the isolation resistance of a battery pack is provided, the method being invulnerable to changes in the bus voltage that may take place between measurements.

Owner:TESLA INC

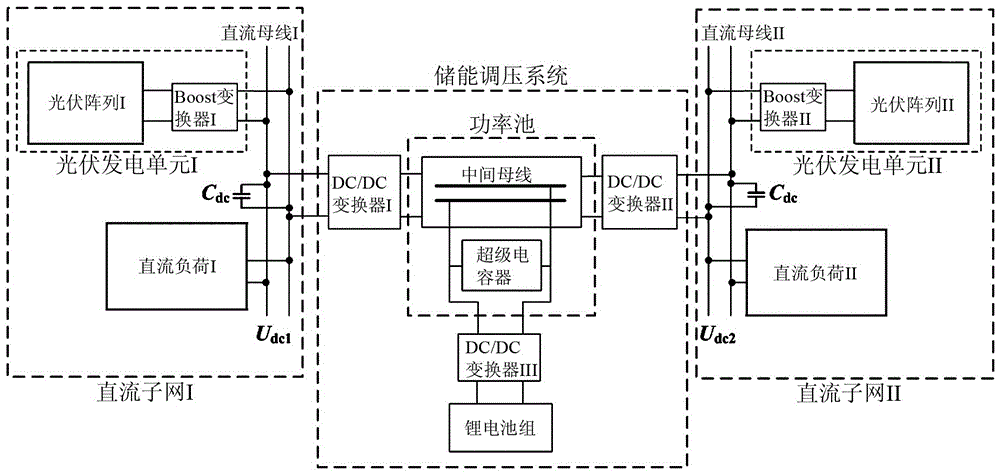

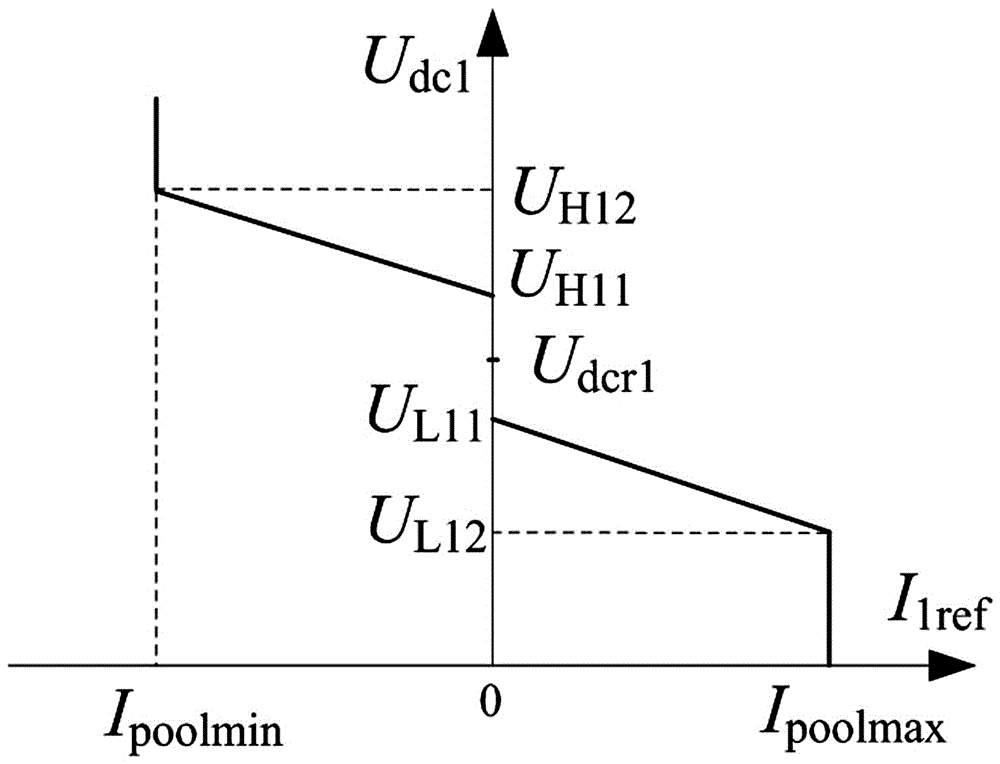

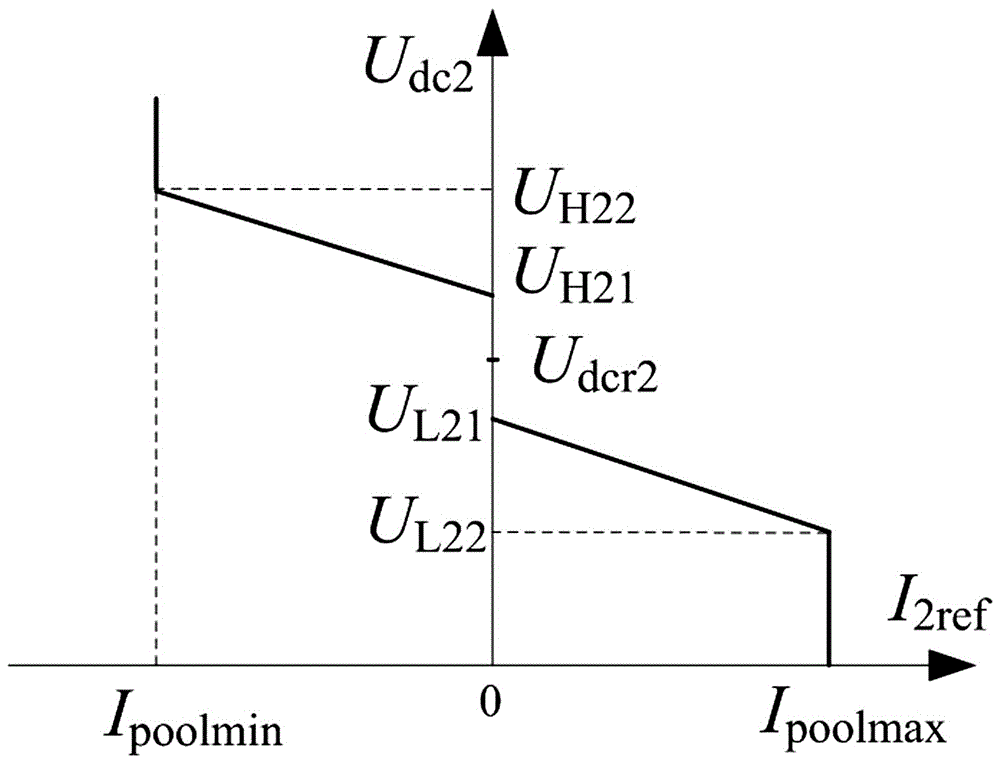

Power pool-based dual-layer bus direct microgrid and control method therefor

ActiveCN106505552AIncrease flexibilityReduce conversion lossLoad balancing in dc networkDc source parallel operationMicrogridHigh energy

The invention relates to a direct current microgrid, specifically relates to a power pool-based dual-layer bus direct microgrid and a control method therefor, and solves the problems of high energy conversion loss and low system operating efficiency of the existing single-bus direct current microgrid, and high probability of power interference and poor system operating economy of the existing dual-bus direct current microgrid. The power pool-based dual-layer bus direct microgrid comprises an energy storage voltage regulation system, a direct current sub grid I and a direct current sub grid II, wherein the energy storage voltage regulation system comprises a power pool, a lithium battery pack, a DC / DC converter I, a DC / DC converter II and a DC / DC converter III; the power pool comprises a supercapacitor and a middle bus in parallel; the direct current sub grid I comprises a photovoltaic power generation unit I, a direct current load I and a direct current bus I; the direct current sub grid II comprises a photovoltaic power generation unit II, a direct current load II and a direct current bus II; and the direct current sub grid I and the direct current sub grid II have different voltage levels. The power pool-based dual-layer bus direct microgrid is applicable to a variety of fields.

Owner:TAIYUAN UNIV OF TECH

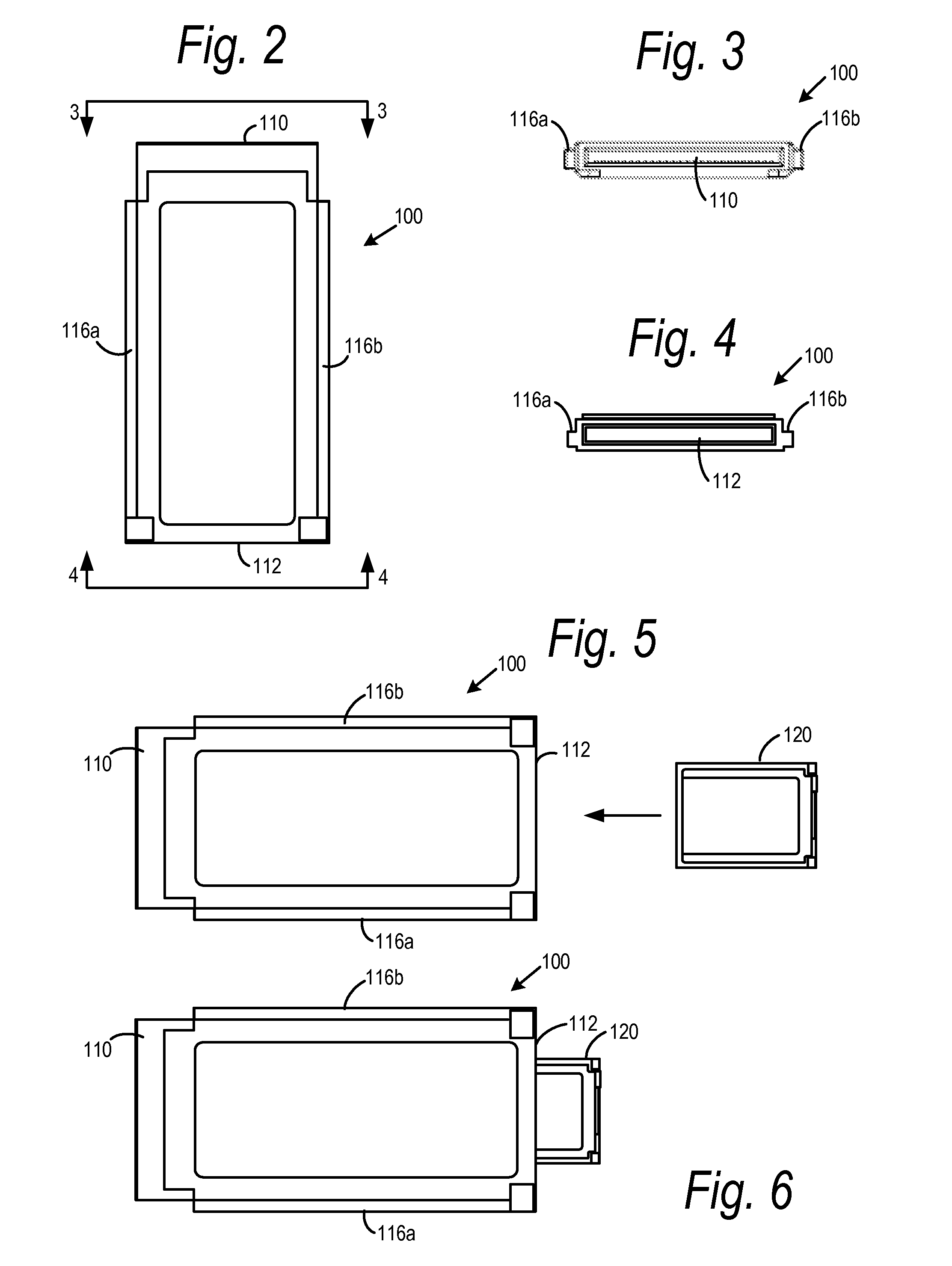

Integral stack columns

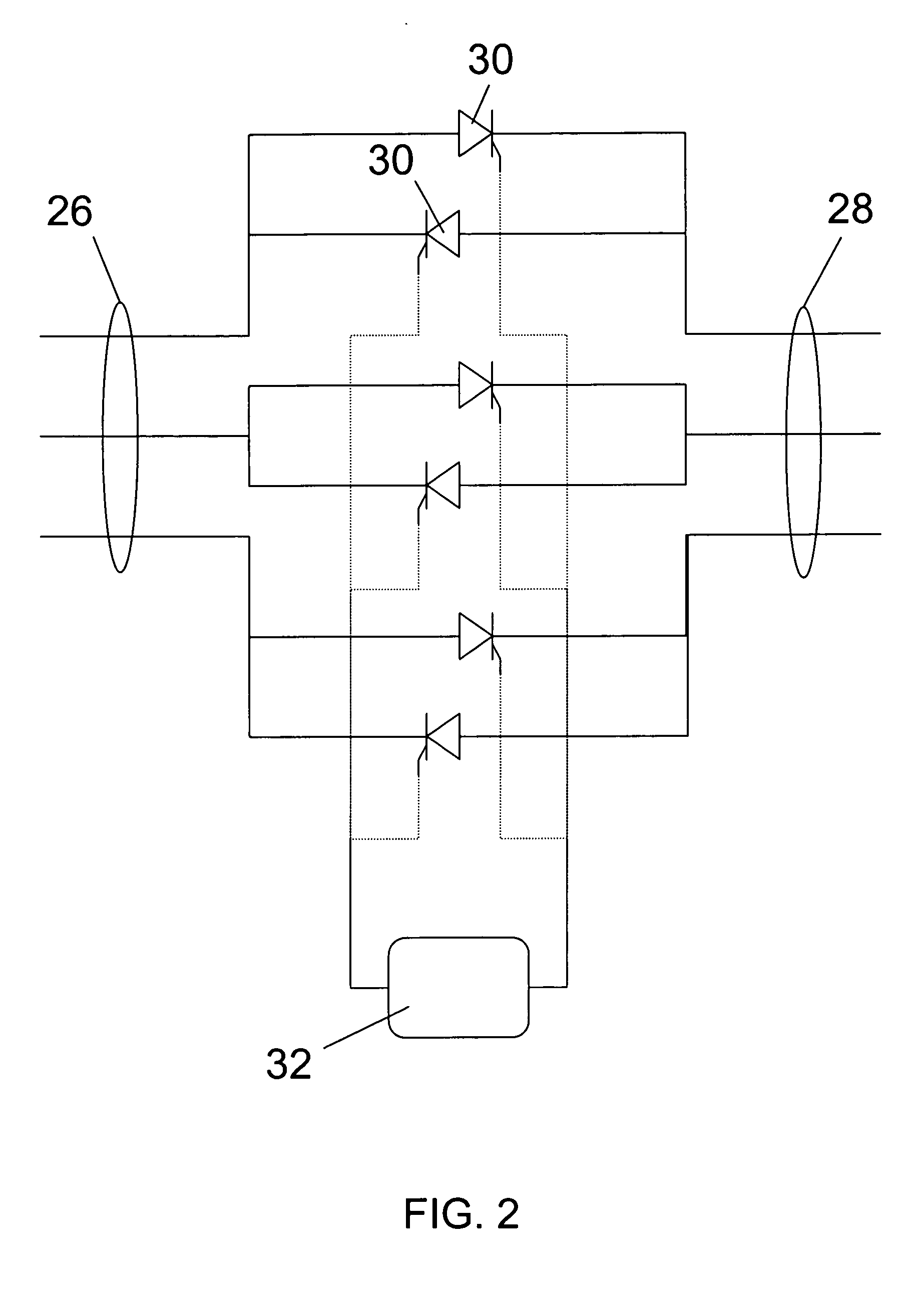

ActiveUS20080278968A1Facilitate modular approachEasy to controlAc-dc conversionDc source parallel operationFuel cellsDual bus

Systems and methods for power conversion are illustrated. Power conversion architecture for fuel cell systems in particular are described that use dual bus architectures having stack segment pairs and a center-tapped neutral line, and / or an architecture employing integer multiple of three DC / DC converter branches.

Owner:BLOOM ENERGY CORP

Method of using the dual bus interface in an expresscard slot

A peripheral device is disclosed having two associated memory modules, and which is configured to fit within the ExpressCard slot. One memory module communicates with a host over the PCIe bus interface of the ExpressCard slot, while the other memory module communicates with the host over the USB interface of the ExpressCard slot.

Owner:SANDISK TECH LLC

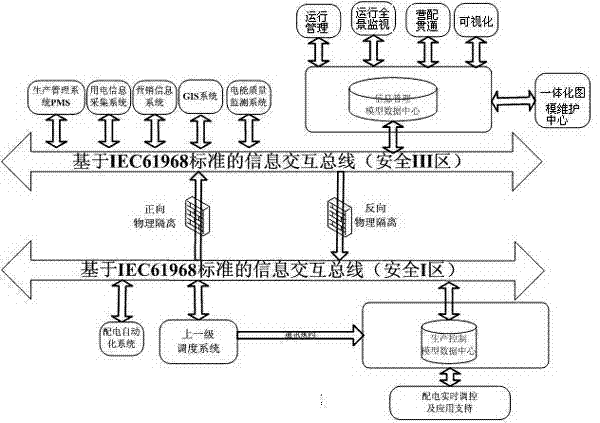

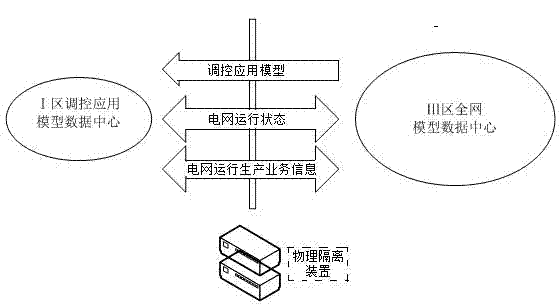

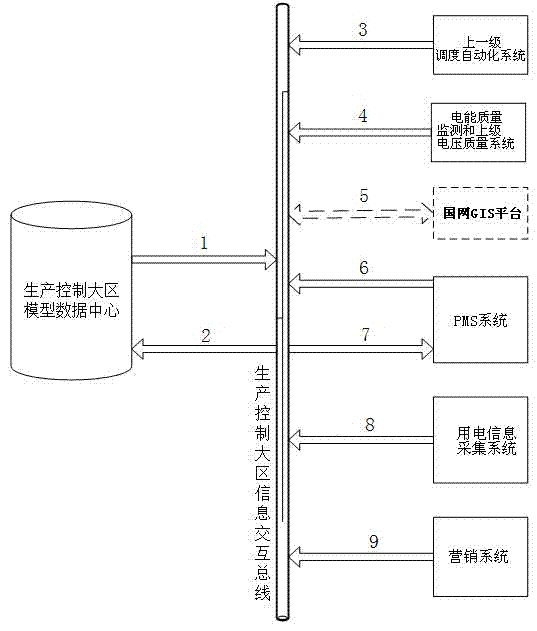

Distribution network integrated platform information integration method based on model data center

The invention discloses a distribution network integrated platform information integration method based on a model data center. The method includes: a 'double-bus and double-data-center' structure is used, an information interaction bus comprises a production control region information interaction bus, an information management region information interaction bus and a direction safety isolating device, and the model data center comprises a 'production control region model data center' and an 'information management region model data center'. The model data center allows for integration, central storage and unified service for parameter models, status data and service data of a power distribution network production management system. Synchronization of forward operational status information from a production control region to an information management region is achieved by a cross-region synchronous mechanism. Synchronization of reverse statuses and service information from the information management region to the production control region is achieved by an information interaction bus. By the distribution network integrated platform information integration method, information integration for various application systems in the existing distribution network can be realized.

Owner:STATE GRID CORP OF CHINA +1

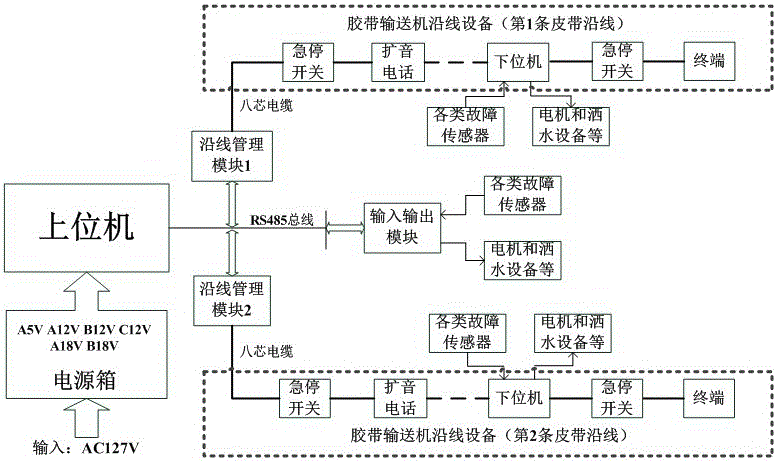

Rubber belt conveyor monitoring system with fault positioning function

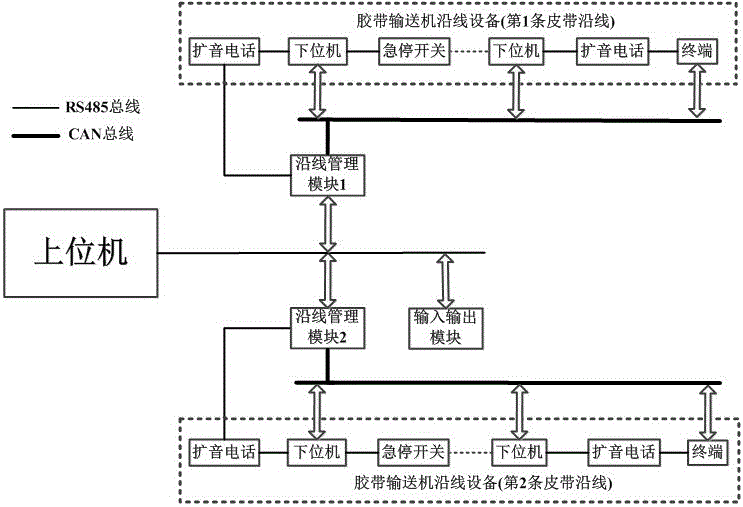

ActiveCN106115219ASolve the problem of not being able to quickly locateReal-time monitoring of running statusConveyorsControl devices for conveyorsDual busNetwork structure

The invention discloses a rubber belt conveyor monitoring system with a fault positioning function, and aims to solve the problem that the conventional rubber belt conveyor monitoring system can hardly position faults such as deviation, coal stacking, slippage, tearing, overheat and smog. By the adoption of modular system structures, all modules are combined into a system, and the system adopts a dual-bus network structure; firstly, an RS485 bus automatically distributes addresses to equipment along the line; and after the a rubber belt conveyor has the faults such as deviation, coal stacking, slippage, tearing, overheat and smog, a CAN bus transmits the position where the fault occurs and the type of the fault in real time. The system can monitor an operating state of the rubber belt conveyor in real time and find the fault of the rubber belt conveyor during operation in time, and can precisely position the fault and sound a voice alarm; different protection signals can be output according to the type of the fault, so that the safety protection of the rubber belt conveyor is realized; and the safety, the stability and the continuity of the operation of the rubber belt conveyor are improved.

Owner:TAIYUAN UNIV OF TECH

Apery robot distributed dual-bus motion control system

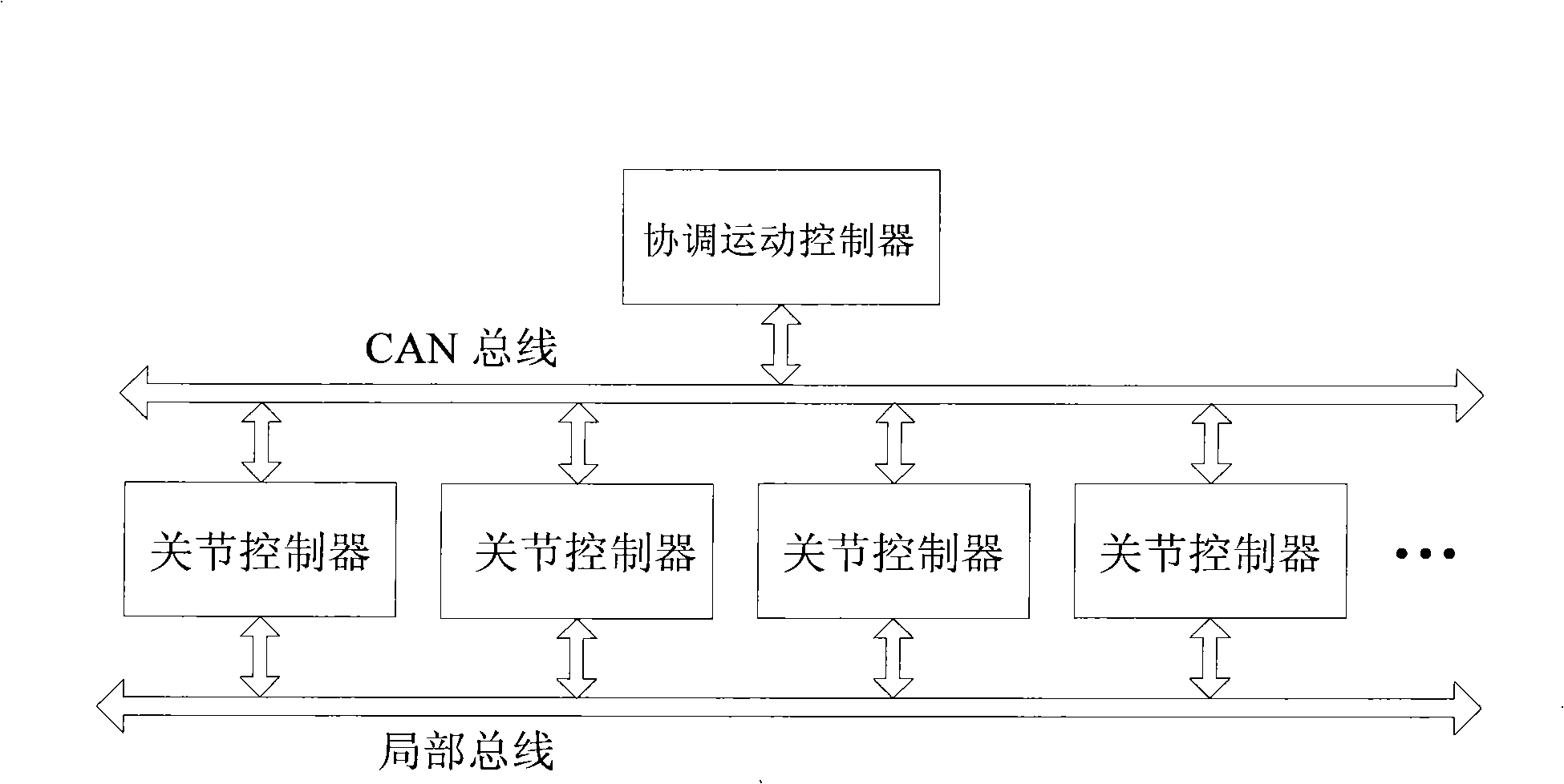

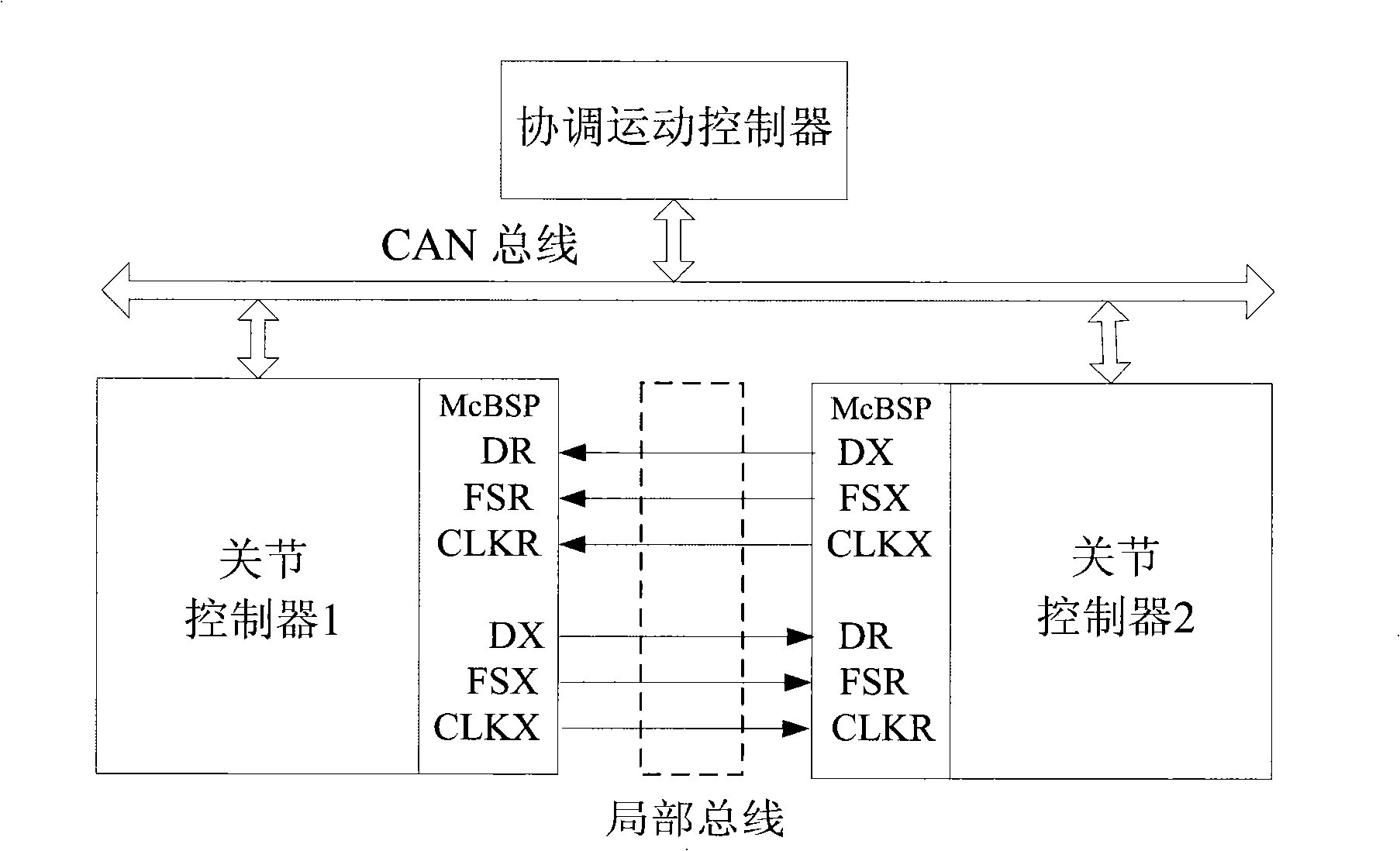

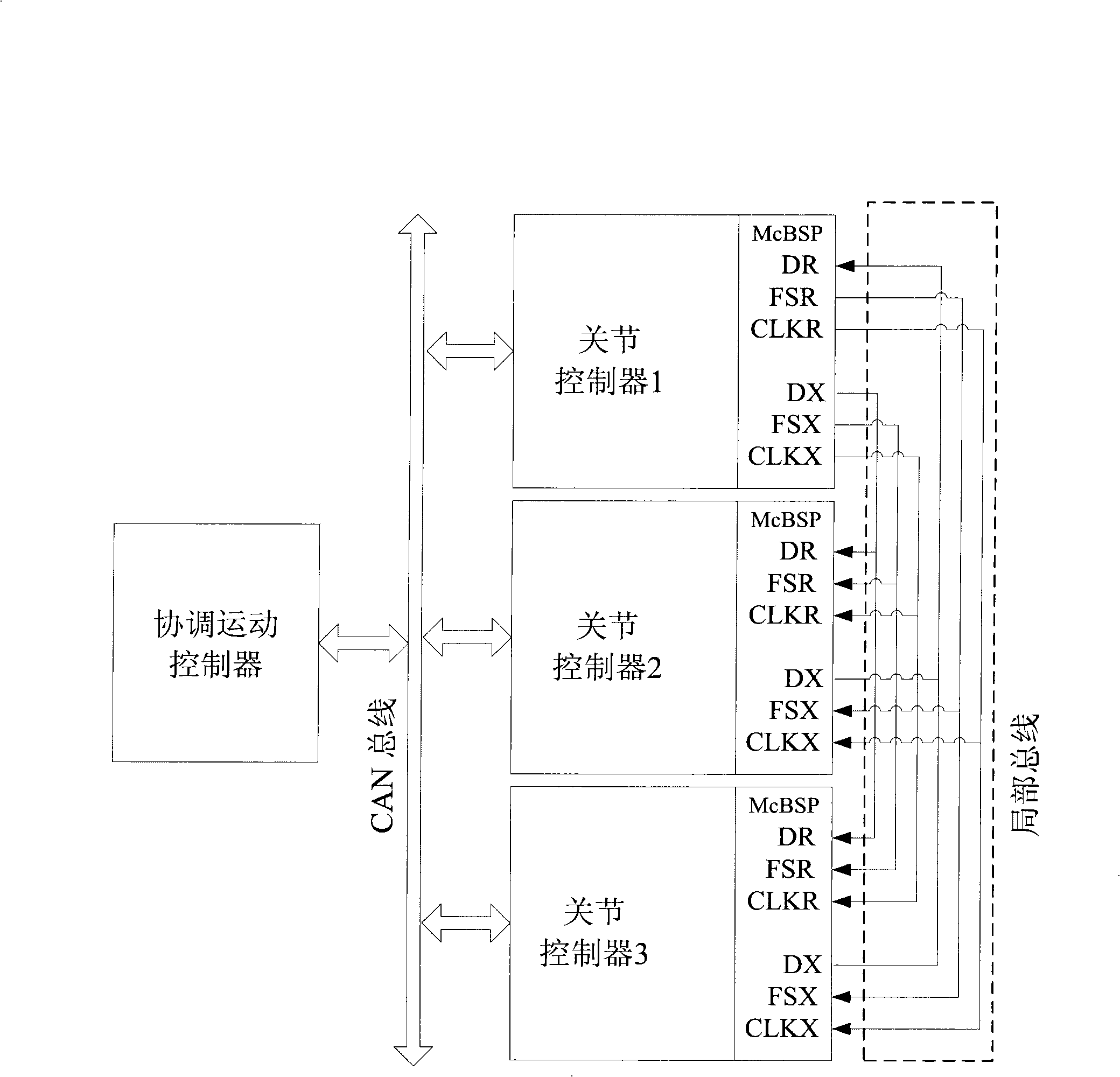

InactiveCN101293350AAchieve sharingReduce data volumeProgramme-controlled manipulatorTotal factory controlDual busControl system

The invention relates to a distribution type double-bus moving control system of a humanoid robot which belongs to a multi-freedom moving control system used for the moving control of the humanoid robot; the distribution type double-bus moving control system of the humanoid robot includes a coordinate moving controller, a CAN bus, joint controllers and a partial bus. The coordinate moving controller is connected with the joint controllers by the CAN bus; all or partial joint controllers are mutually connected with each other by the partial bus. The invention realizes the share of states and sensing information between the joint controllers by adding the partial buses and reduces the data amount transmitted on the CAN bus; thereby realizing the distribution type control based on the CAN bus and meeting the requirement of the system on a higher real time property simultaneously.

Owner:SHANGHAI JIAO TONG UNIV

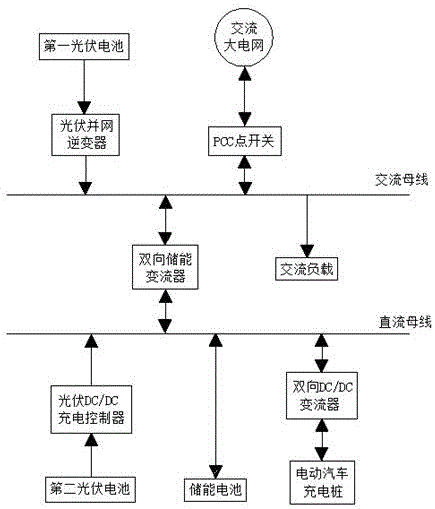

Light storage and charging integrated system based on dual-bus microgrid architecture

InactiveCN106505644AImprove conversion efficiencyReduce multilevel transformationsElectrical storage systemClimate change adaptationDual busMicrogrid

The invention discloses a light storage and charging integrated system based on a dual-bus microgrid architecture. The light storage and charging integrated system comprises a first power generation unit, a second power generation unit, an energy storage unit, a bidirectional energy storage converter and a PCC point switch, wherein the first power generation unit is connected with an AC bus, the second power generation unit and the energy storage unit are arranged in parallel on a DC bus, the bidirectional energy storage converter is connected between the AC bus and the DC bus, the PCC point switch is connected between the AC bus and an AC large power grid, and the bidirectional energy storage converter is used for achieving switch-on and switch-off of the PCC point switch. With the adoption of the structure, multi-stage conversion is reduced, the energy conversion efficiency of the system is improved, the power utilization cost is reduced, and meanwhile, the safety and the stability of the system are also improved.

Owner:BEIJING SOARING ELECTRIC TECH CO LTD

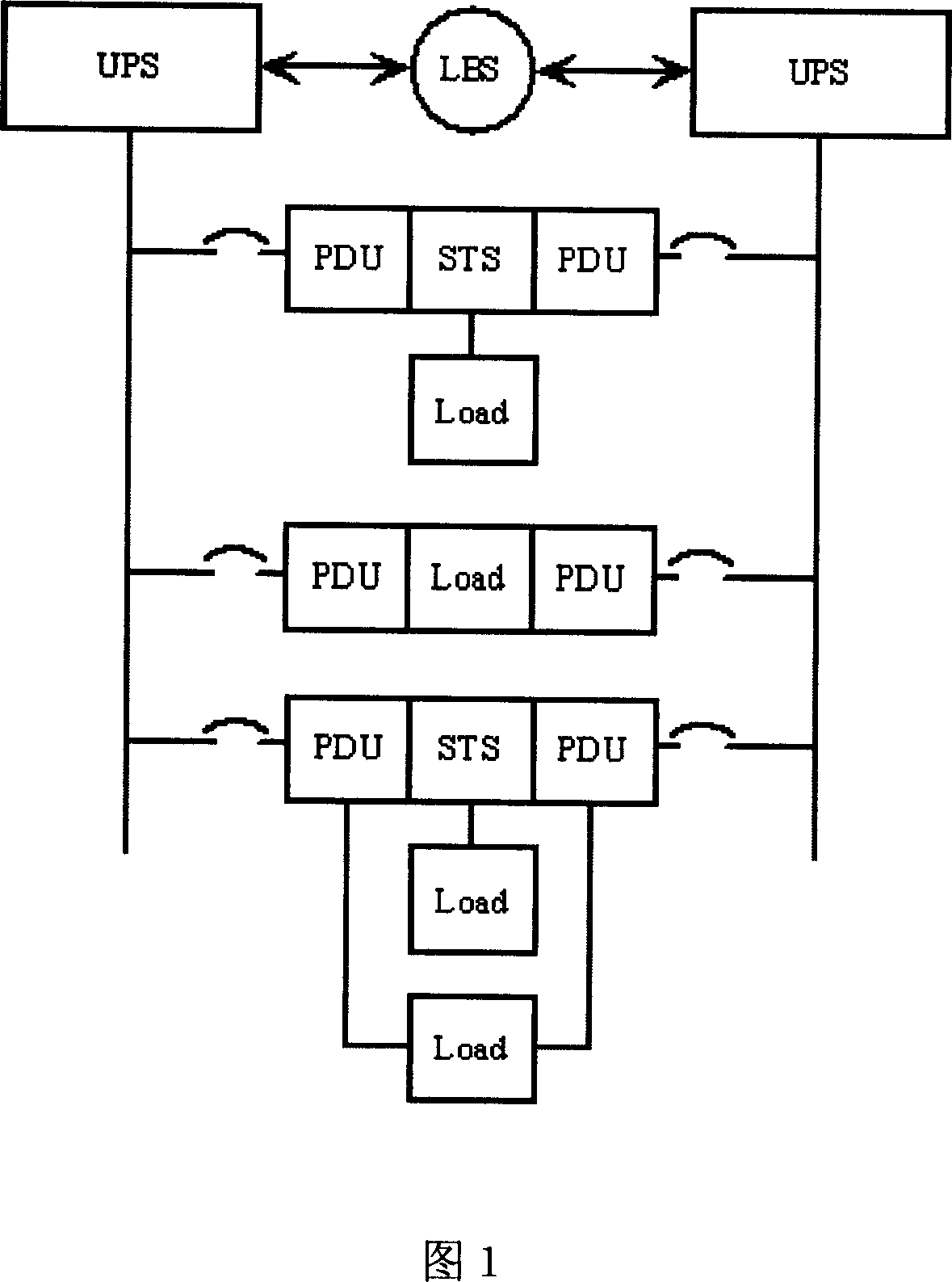

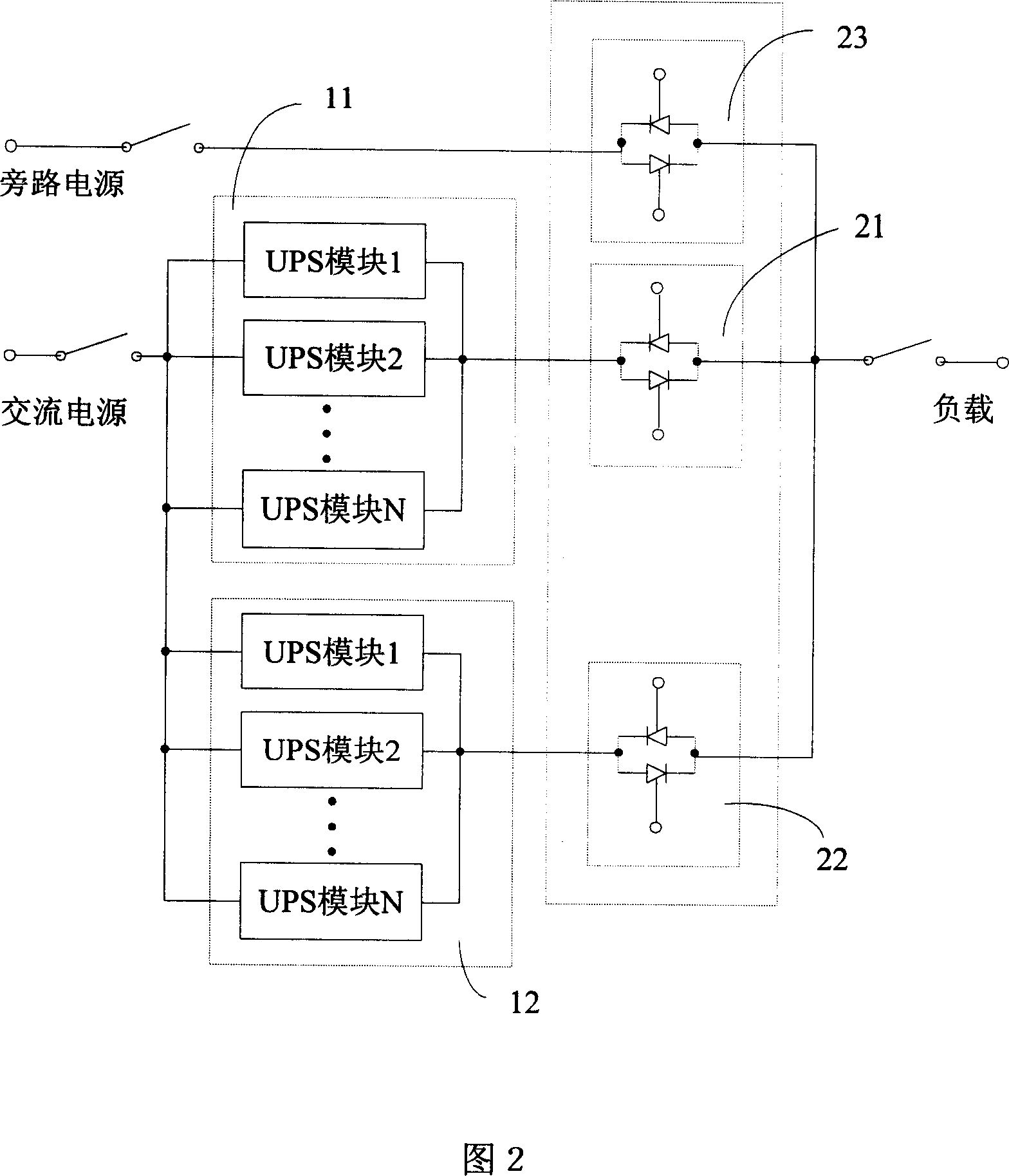

Uninterrupted power supply and its configuration method

InactiveCN101136557AImprove reliabilityFlexible configurationBatteries circuit arrangementsElectric powerDual busTransfer switch

This invention discloses an USP system including at least two sets of UPS parallel modules, each of which includes one or at least two parallel UPS modules and static transfer switches in the same number with the UPS parallel module sets, and the inputs of which are coupled with the output ends of the UPS parallel modules. This invention also discloses a configuration method for two kinds of UPS, which sets a supply system a dual-bus mode or a redundant parallel mode, besides, each UPS parallel module and the STS can be set in a supply cabin, so synchronous signals among parallel modules are transmitted easily and the control of the STS module can be integrated into the UPS parallel module.

Owner:LIEBERT

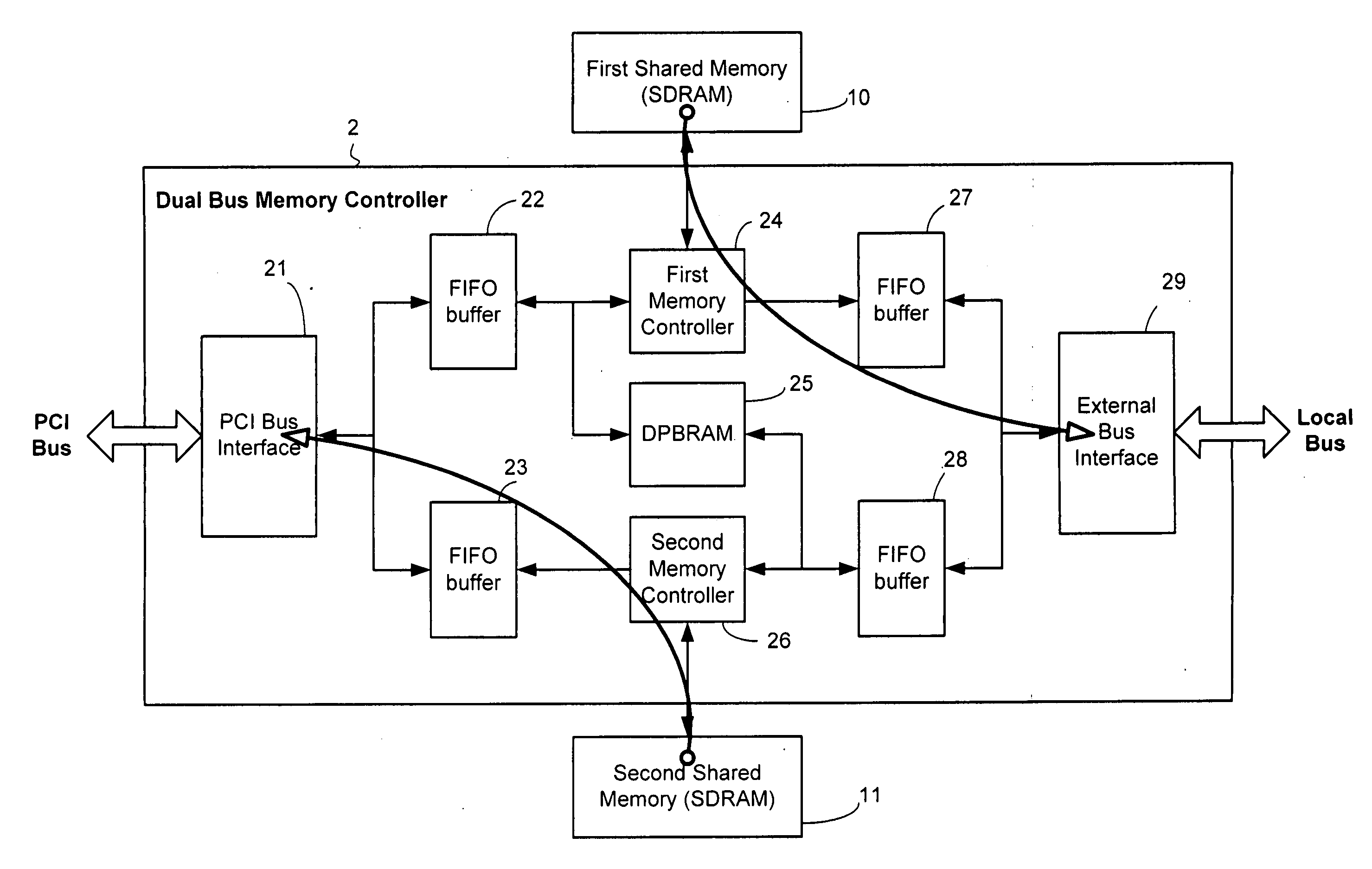

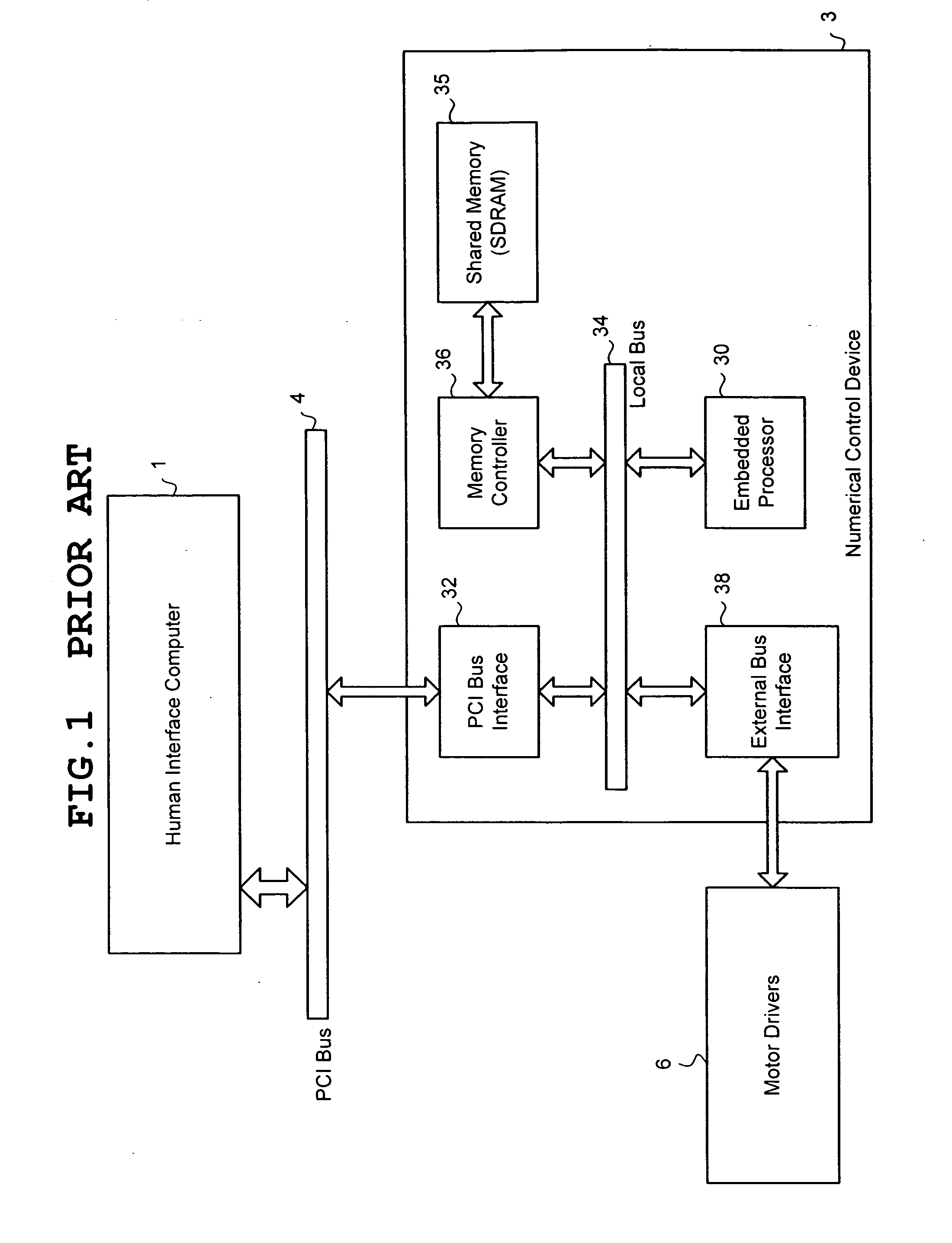

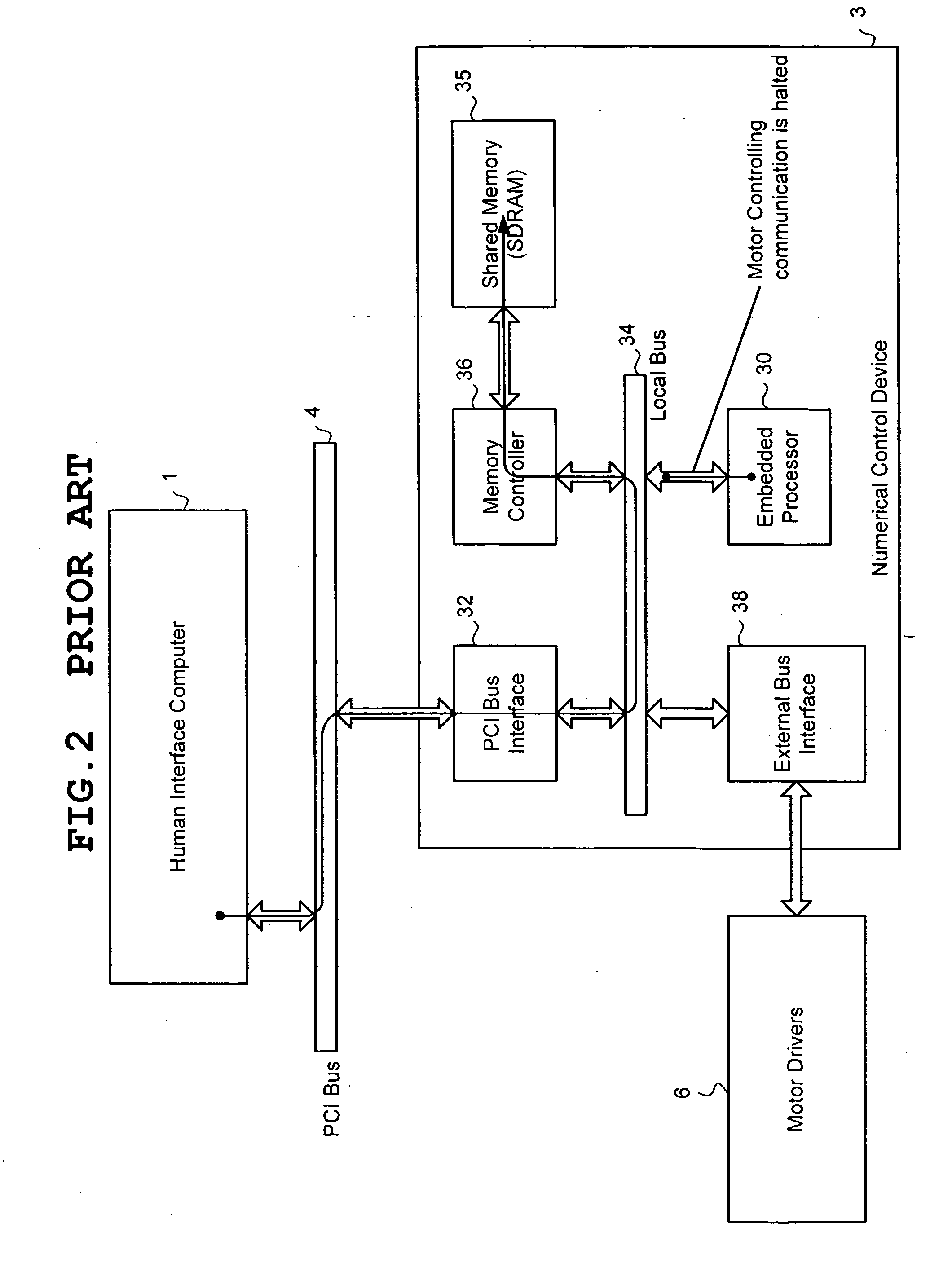

Computerized numerical control system with human interface using low cost shared memory

A computerized numerical control system includes a human interface computer (1), a PCI bus (4) which is adapted to couple to the human interface computer, and a numerical control device (3). The numerical control device includes an embedded processor (30) and a local bus (34) coupled to the embedded processor. A first and second low cost shared memories such as SDRAMs (10, 11) and a dual bus memory controller (2) are provided. The first and second shared memories are shared by the human interface computer and the embedded processor. The dual bus memory controller is configured for concurrent communication with the PCI bus and the local bus and is adapted to couple to the first and second shared memories.

Owner:SODICK AMERICA CORP +1

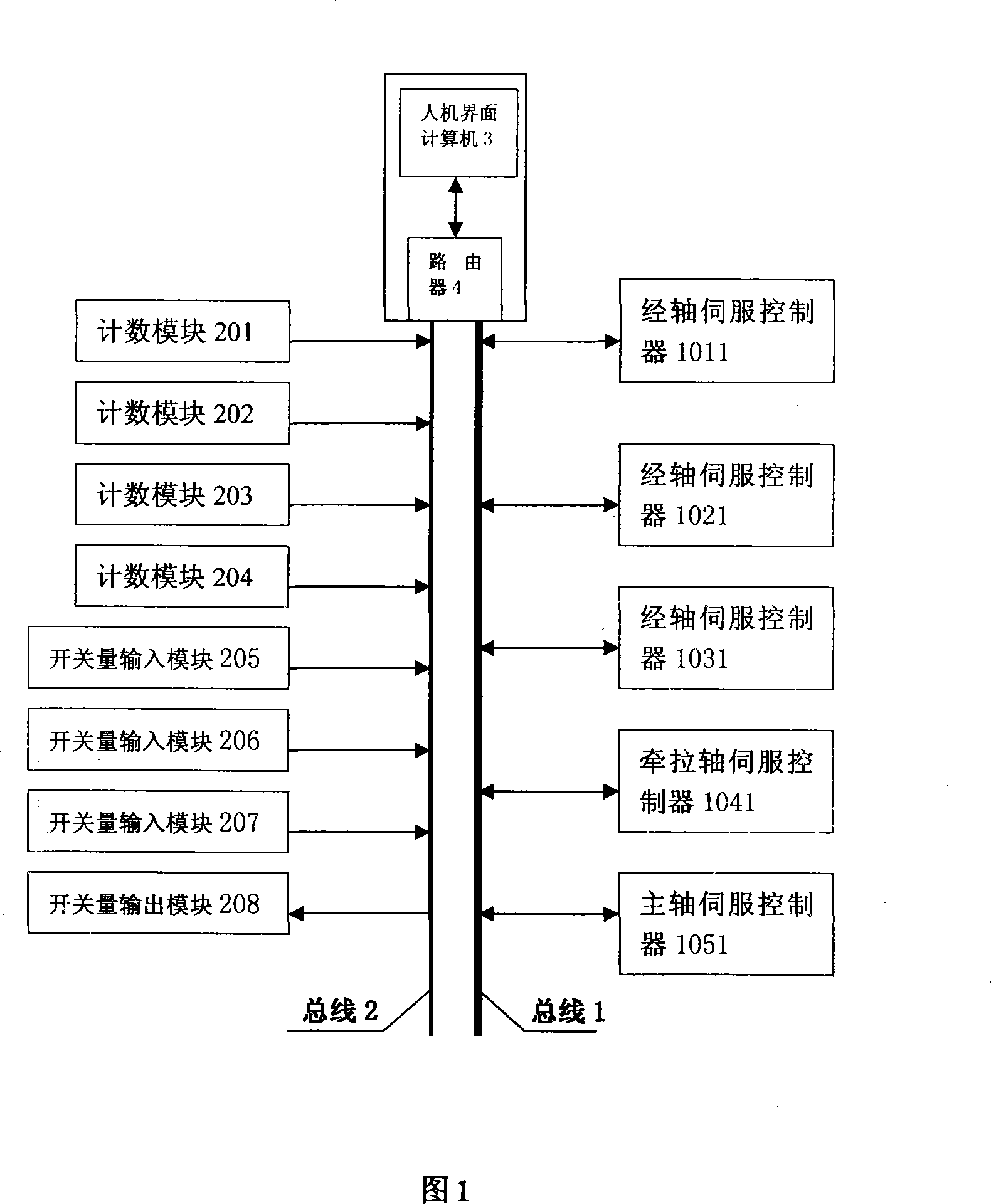

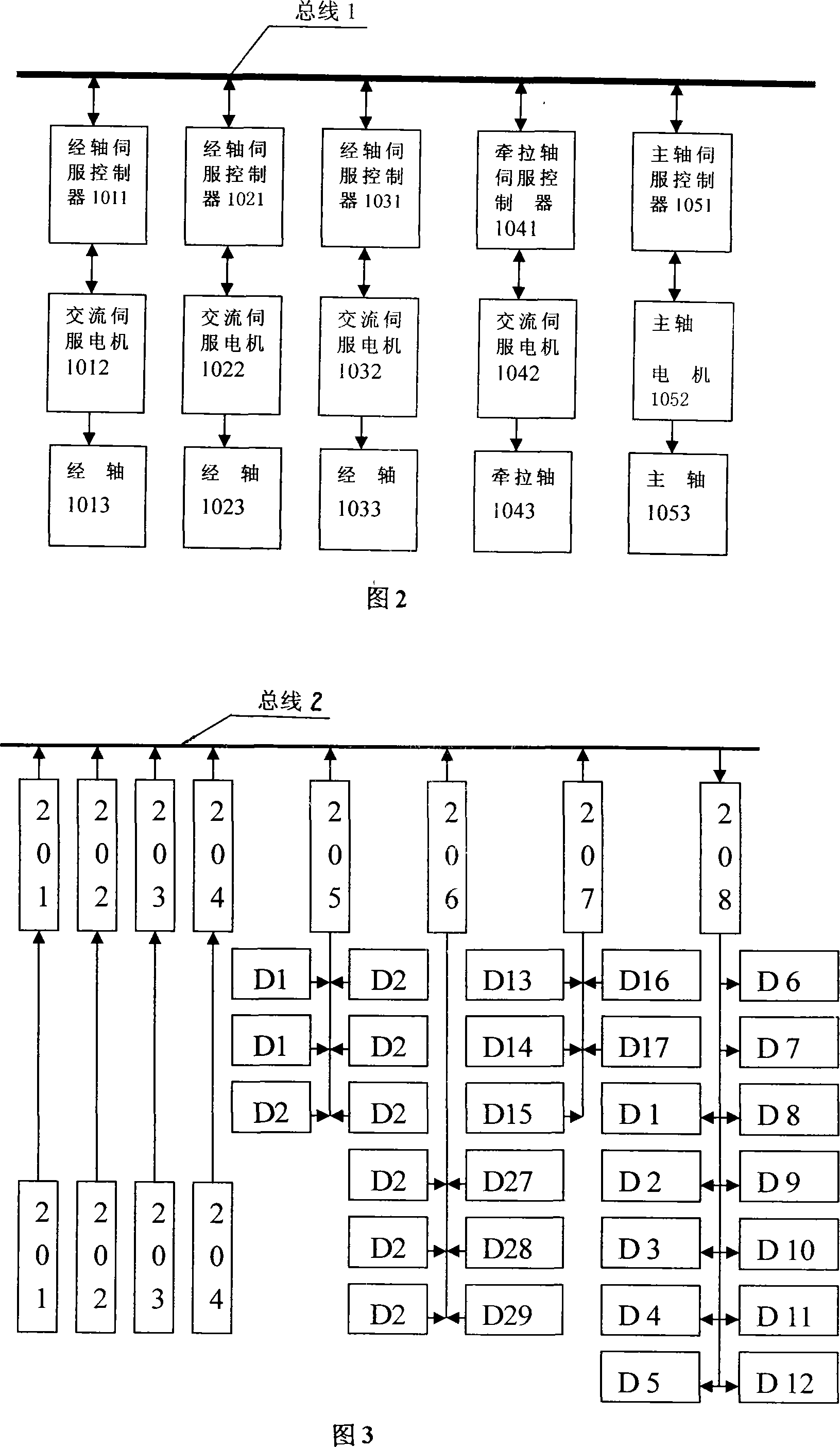

Real time dual bus control method for warp knitting machine

InactiveCN101231524AMeet the requirements of 3000 rpm for high-speed warp knitting machinesEasy maintenanceWarp knittingTotal factory controlHuman–machine interfaceDual bus

A real-time dual-bus control method for a warp knitting machine is provided. The method utilizes two buses. The bus No.1 controls the operation of three warp shafts, a traction shaft and a main shaft individually. A warp knitting command is sent to a corresponding warp shaft servo controller via the bus No.1, and the warp shaft servo controller controls the rotation of a servomotor and regulates the rotation speed in real time according to the warp knitting command, thereby ensuring the feed capacity of the three warp shafts to meet the requirement for patterns. A traction command is sent to a traction shaft servo controller via the bus No.1, and the traction shaft servo controller controls an AC servomotor to pull fabrics out of the warp knitting machine according to the speed required for patterns. The bus No.2 is connected with a counting module and an on-off input / output module. The buses No. 1 and No. 2 are interconnected and intercommunicated via a router. A man-machine interface computer is also used to process signals to control the two buses. The invention has the advantages of rapid data processing, high reliability, independent control circuits with no interference upon failure of on computer or module, easy maintenance and good maintainability.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

Dual bus ExpressCard peripheral device

A peripheral device is disclosed having two associated memory modules, and which is configured to fit within the ExpressCard slot. One memory module communicates with a host over the PCIe bus interface of the ExpressCard slot, while the other memory module communicates with the host over the USB interface of the ExpressCard slot.

Owner:SANDISK TECH LLC

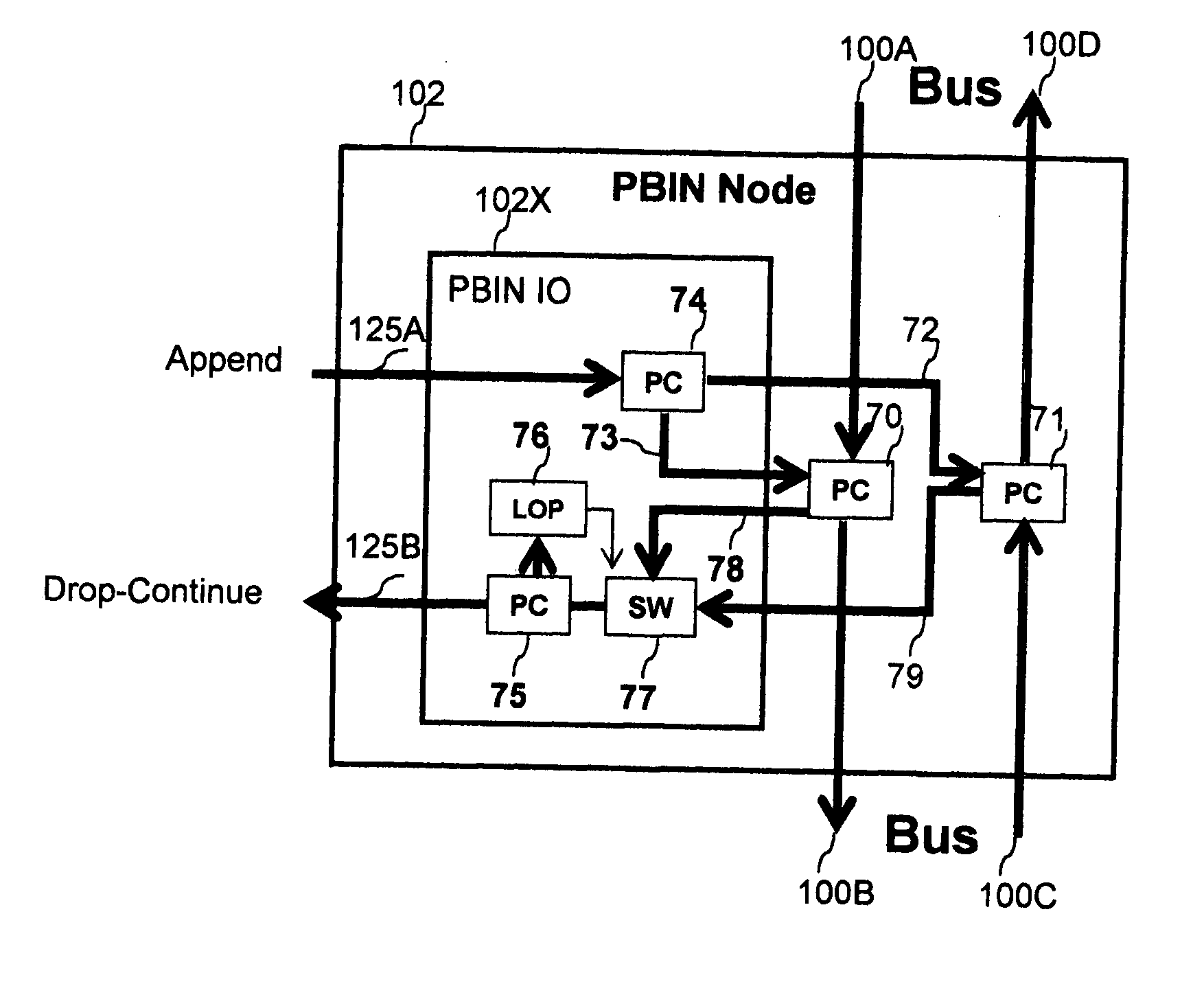

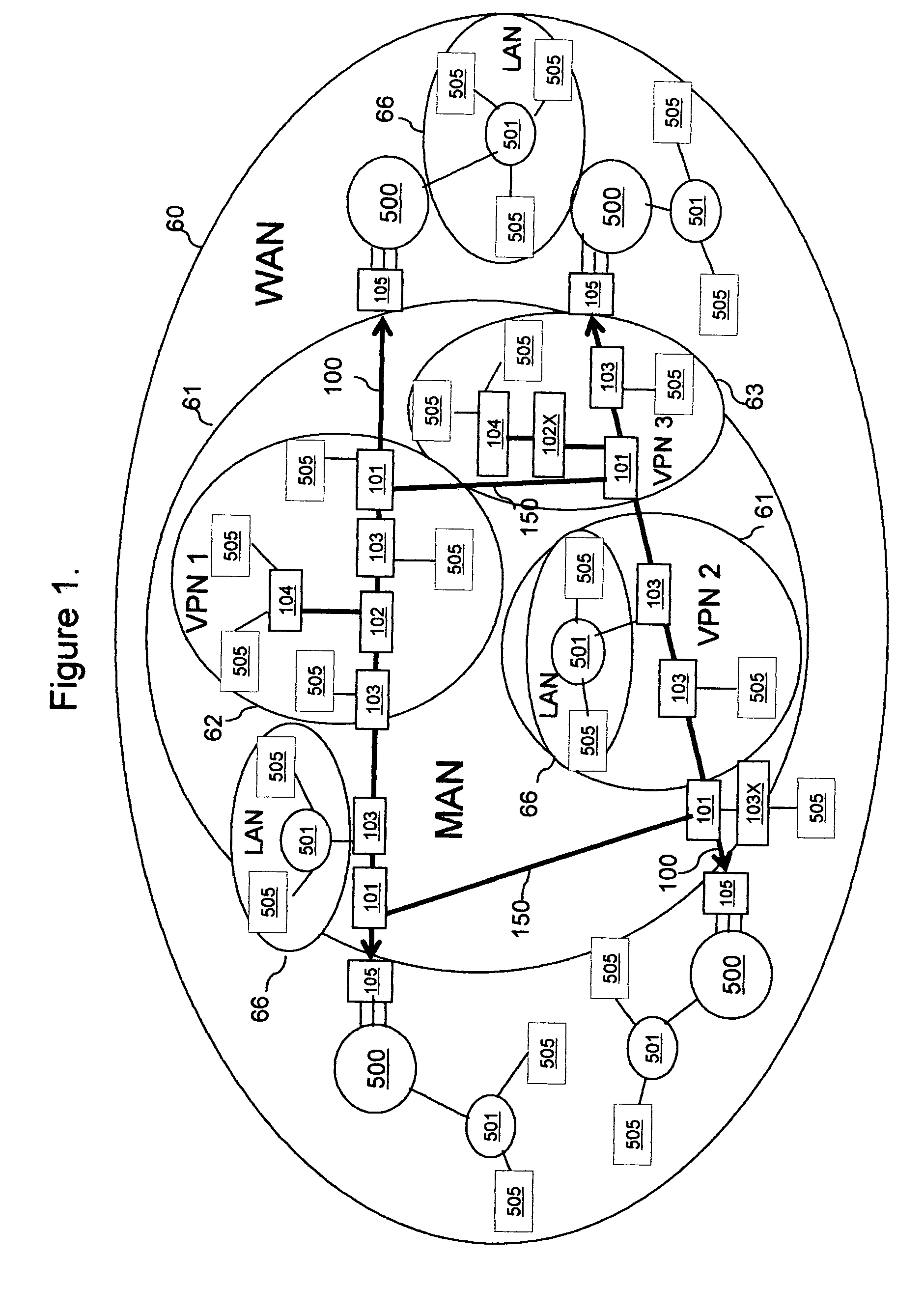

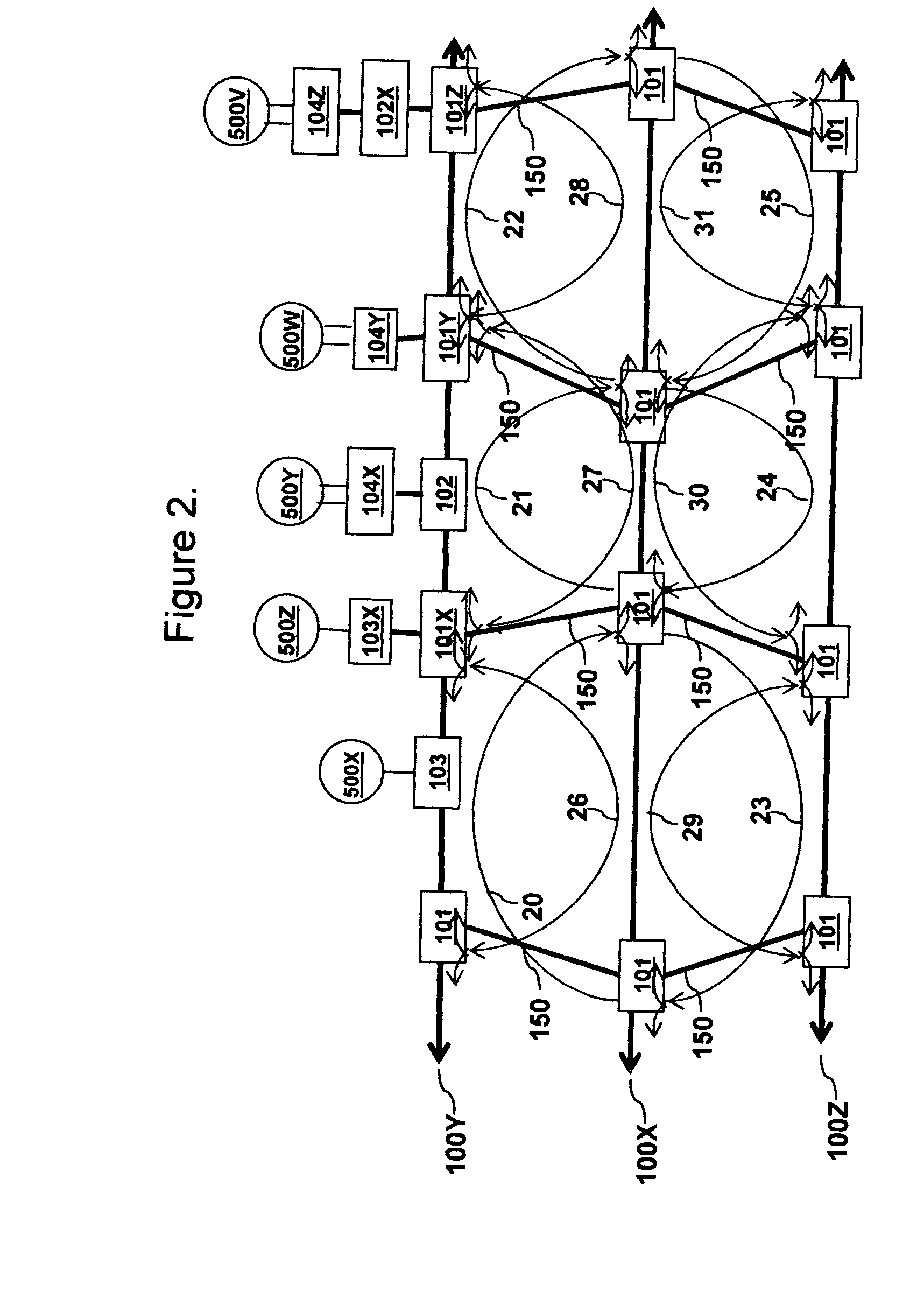

Process of optical WDM bus networking with DWDM expansion for the method of protected point to point, point to multipoint and broadcast connections

InactiveUS20050047713A1Low start-up costLow costMultiplex system selection arrangementsWavelength-division multiplex systemsFiberRing protection

A process for all-optical multi-bus networking of two-fiber bidirectional buses with two-fiber bidirectional Bus-To-Bus Links for a method of shared mesh protected Point-To-Point, Point-To-Multipoint and Broadcast Networking with the steps of: providing protected Bus-To-Bus service networking and Bus-To-Bus protection networking and in-service expansion with more buses, in place of networking with isolated rings connected through un-protected ring-to-ring connections, providing capacity expansion by replacement of single Wavelength Division Multiplexed (WDM) optical signals in few, wide bandwidth WDM channels with a plurality of optical signals Dense Wavelength Division Multiplexed (DWDM) to each WDM channel, and switching few WDM optical channels with small size modular Switching Fabrics, in place of high startup-cost, high capacity DWDM systems switching many DWDM optical signals with expensive and unreliable large size Switching Fabrics, providing the Add / Drop capability integrated with the Append / Drop-Continue capability, to Append more DWDM optical signals to a WDM channel already partially occupied by DWDM optical signals at non overlapping carrier frequencies, in place of requiring to Drop those signals before new ones could be Added, providing optical switching capability integrated with selective broadcast capability of Added or arriving at the Bus or the Bus-To-Bus input terminals WDM channels in place of using external optical Power Couplers with reduced transmission reach, providing one local, shared mesh protection with bus protection loops integrated with dedicated 1+1 Dual Bus Interworking protection to protect Bus Link failures, Bus-to-Bus Link failures, and Switching Fabrics and other equipment failures with reserved as low as 25% of protection bandwidths, in place of ring protection with 50% of reserved protection bandwidth and un-protected ring-to-ring connections.

Owner:ANTOSIK ROMAN

Method of using the dual bus interface in an expresscard slot

A peripheral device is disclosed having two associated memory modules, and which is configured to fit within the ExpressCard slot. One memory module communicates with a host over the PCIe bus interface of the ExpressCard slot, while the other memory module communicates with the host over the USB interface of the ExpressCard slot.

Owner:SANDISK TECH LLC

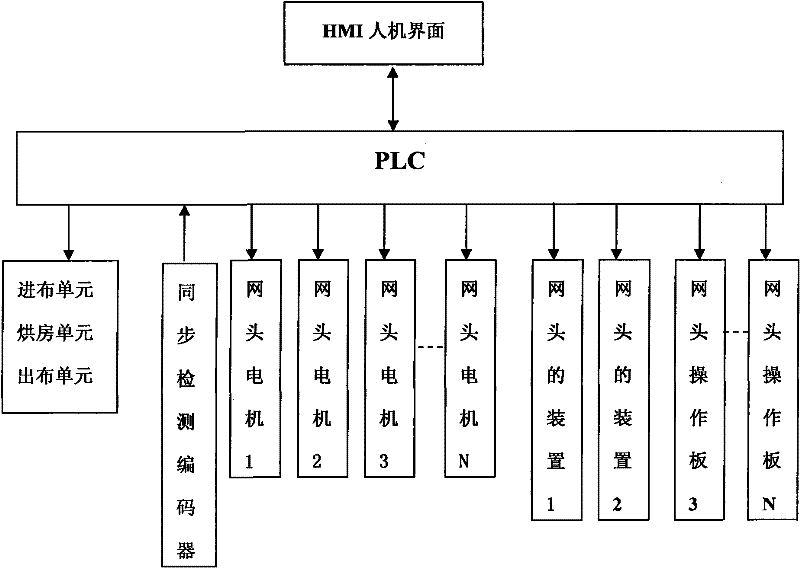

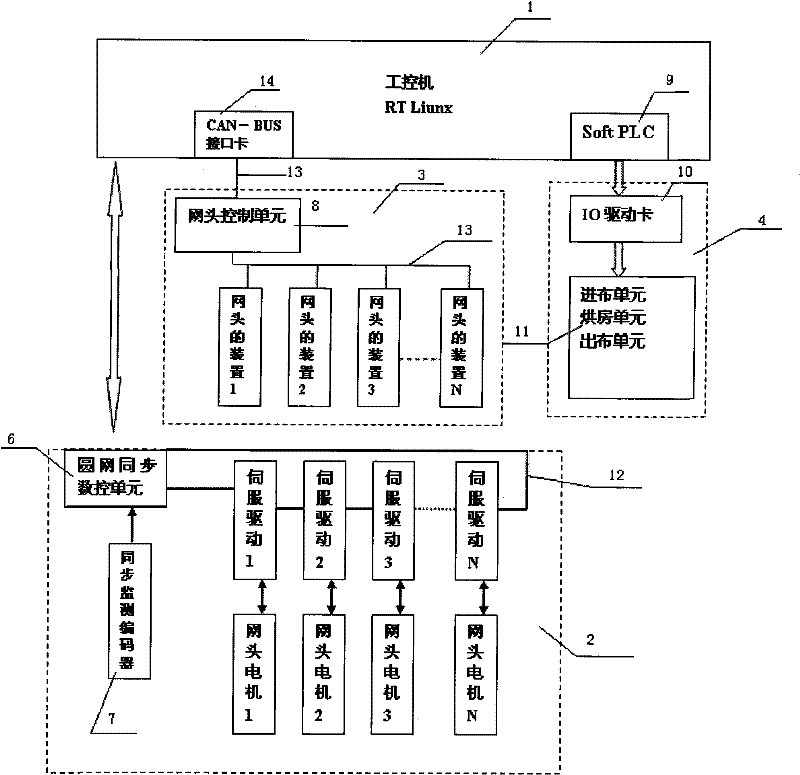

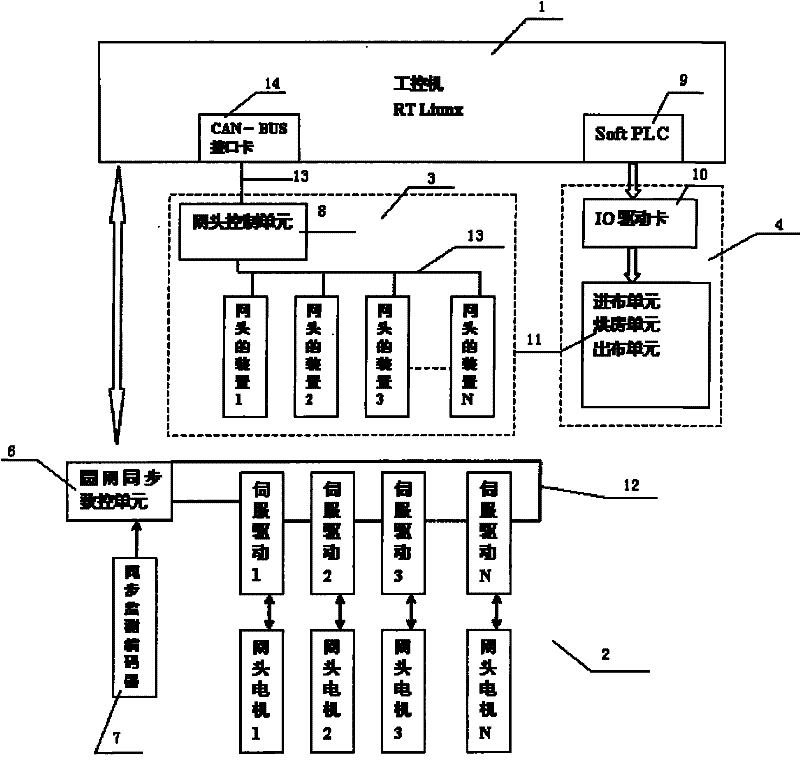

Control System of Rotary Screen Printing Machine

ActiveCN102267284AGood synchronizationQuick responseScreen printersPrinting press partsScreen printingMachine control

The invention discloses a control system for rotary screen printing machines, which comprises a main controller, an electrical control module, a rotary-screen synchronous control module and a multi-path screen head control unit, wherein the main controller is the core of the whole control system, and used for coordinating the operations of the electrical control module, the rotary-screen synchronous control module and the screen head control unit, receiving and processing data sent from each module, and realizing the mutual cooperation and coordination of the modules, therefore, the main controller is the 'brain' and 'nerve center' of the control system of a whole printing machine. The control system disclosed by the invention adopts a dual-bus structure, therefore, the stability and response speed of system control of the rotary screen printing machine are improved. By using the control system disclosed by the invention, the problem of retaining the precise synchronization performance and efficient automatic registering performance of the ascending and descending speeds of the rotary screen printing machine in the processes of printing and dyeing can be solved, the accidents of fabric breaking, network disconnection, and 'pattern error' can be completely eradicated, and the production efficiency and product quality of equipment can be improved.

Owner:上海乾得智能科技有限公司

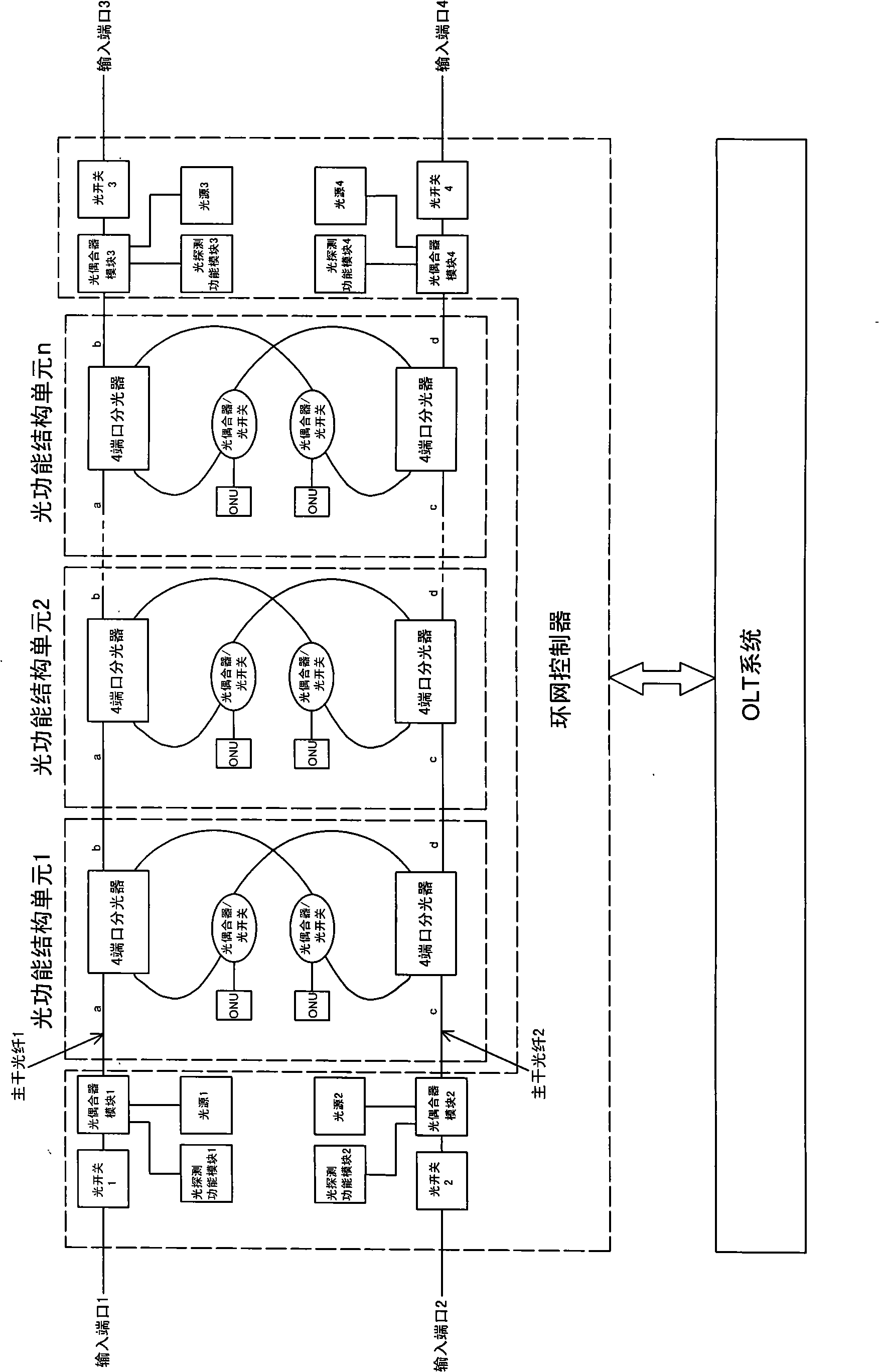

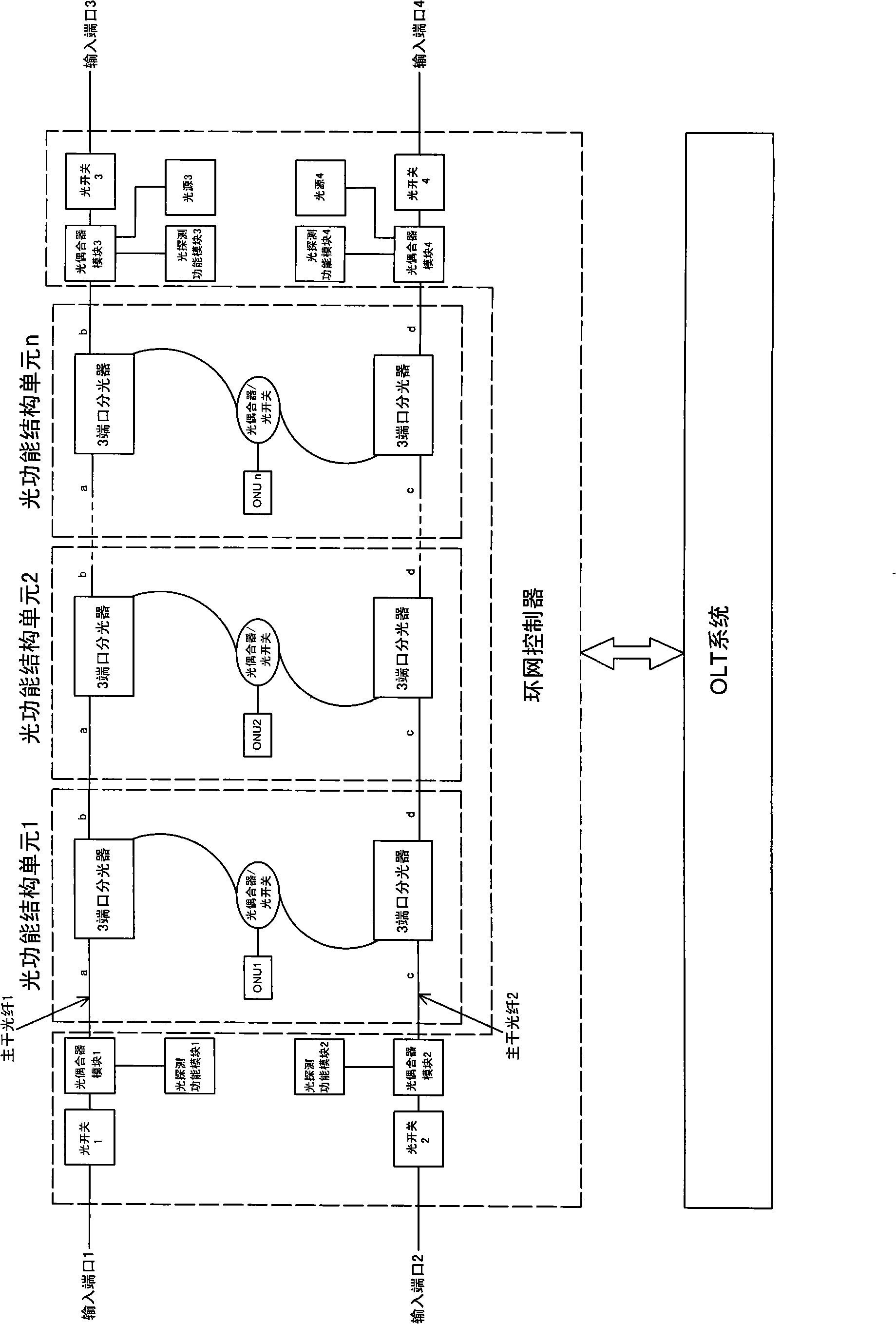

Annular double-bus redundancy protection architecture of passive optical network

ActiveCN101277152AGuaranteed redundancyReal-time monitoring of working statusError preventionTime-division multiplexSystem integrationFiber

The invention relates to an annular dual-bus redundancy protective structure of passive optical network which includes: an OLT system, an annular net controller and a plurality of light function structure units with special structure. Four input ports of the annular net controller connect with corresponding light switches respectively, four light switches connect with corresponding light coupler modules, each light coupler module connects with a light detection function module and corresponding light source, then, connects with the light function structure through tow channels main fiber, the whole light function structure is composed of N light function structure units; a, b, c, d ports of a light splitter with four ports in the light function structure unit upper part and down part can be concatenated according to figure or connect with the light coupler module, other four ports are cross connected through the coupler or the light switch, then connect with the corresponding ONU; a light resuscitation module can generate four or a plurality of input ports according to need. The annular dual-bus redundancy protective structure has advantages that: using dual-bus annular net structure can reach better protective redundancy effect, increase system reliability, and heal remarkably quickly; the annular dual-bus redundancy protective structure with low cost can realize uniform network management, and is convenient for system integration.

Owner:BEIJING ENYITONG TECH DEV

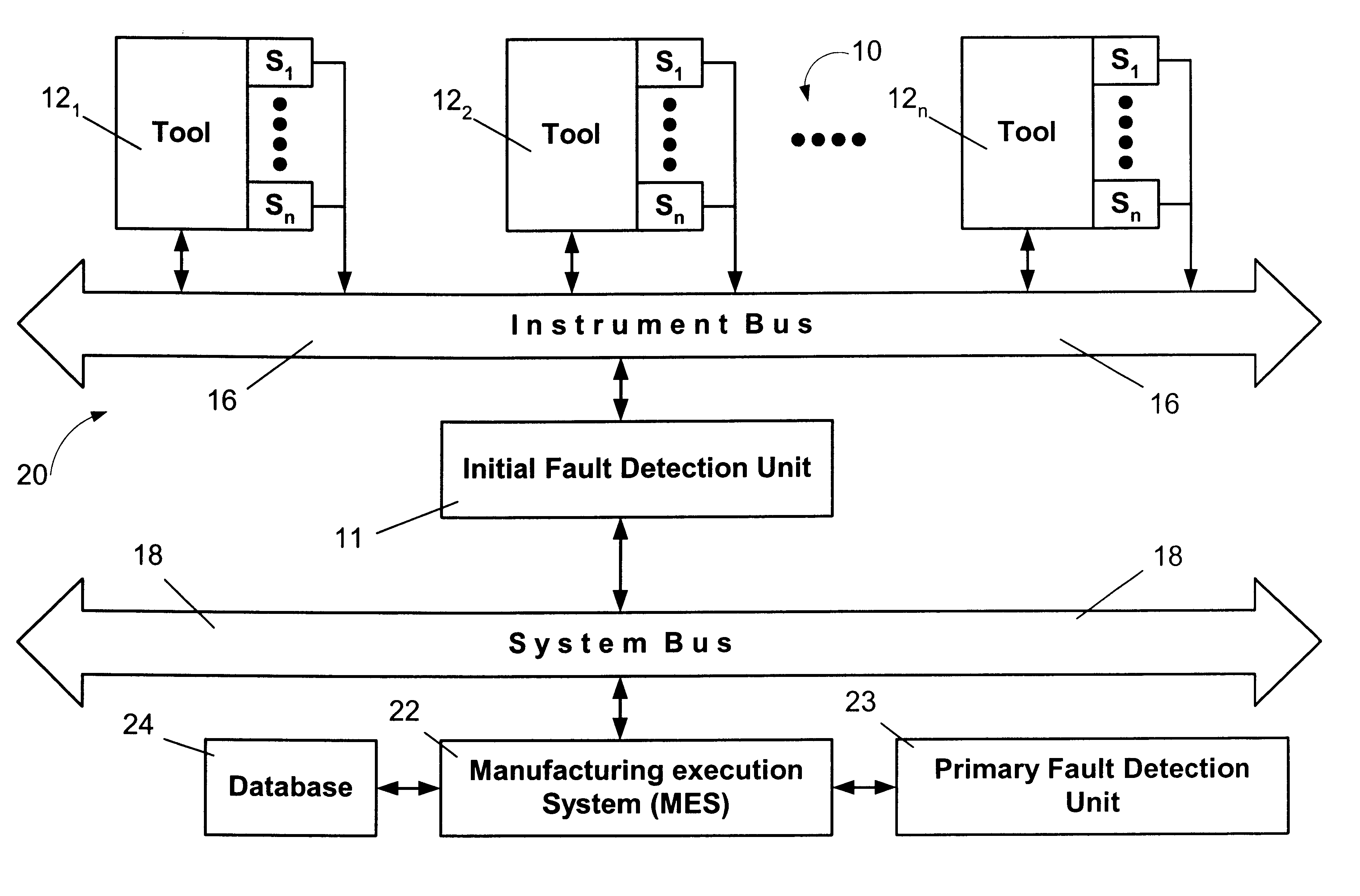

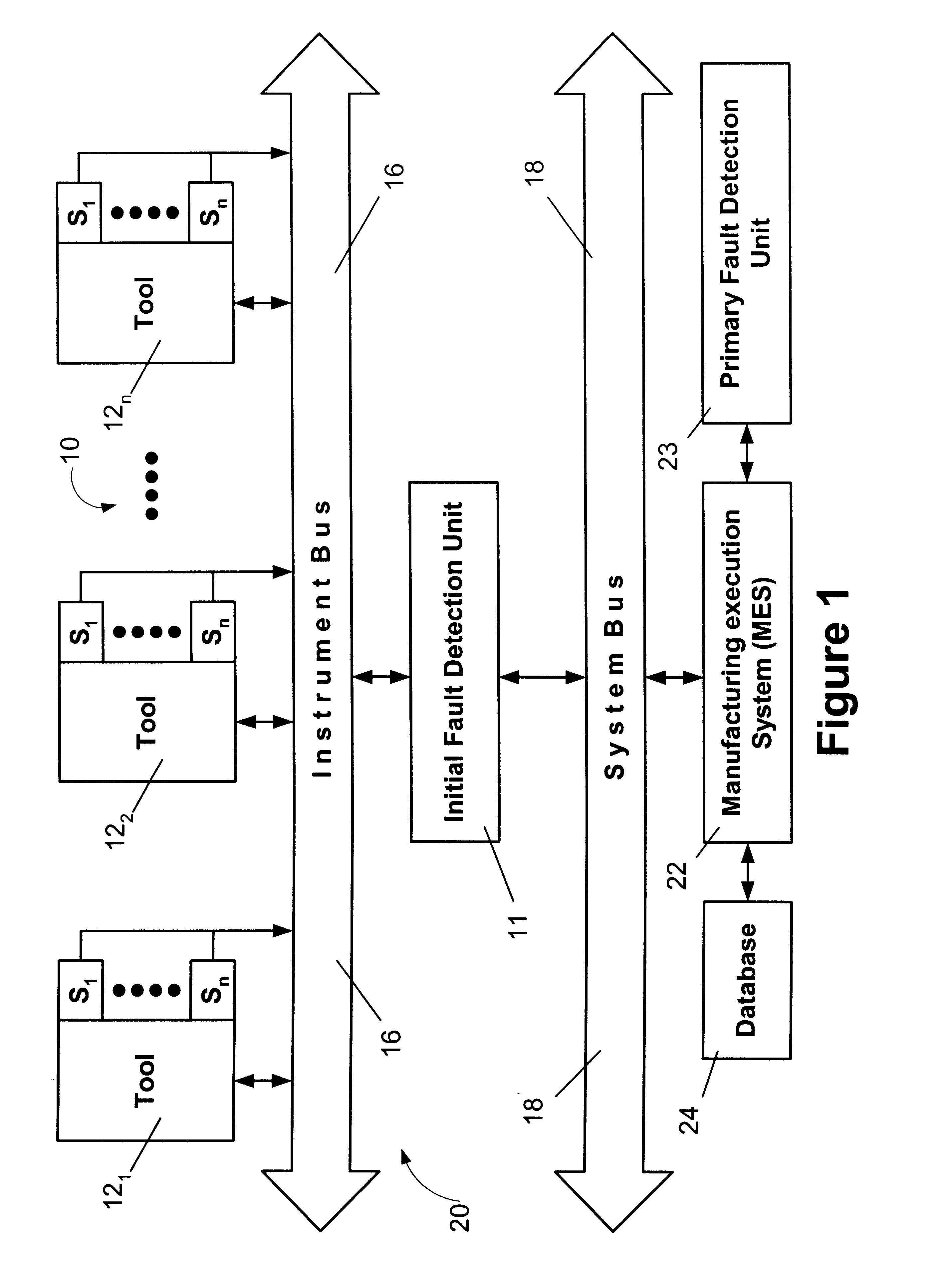

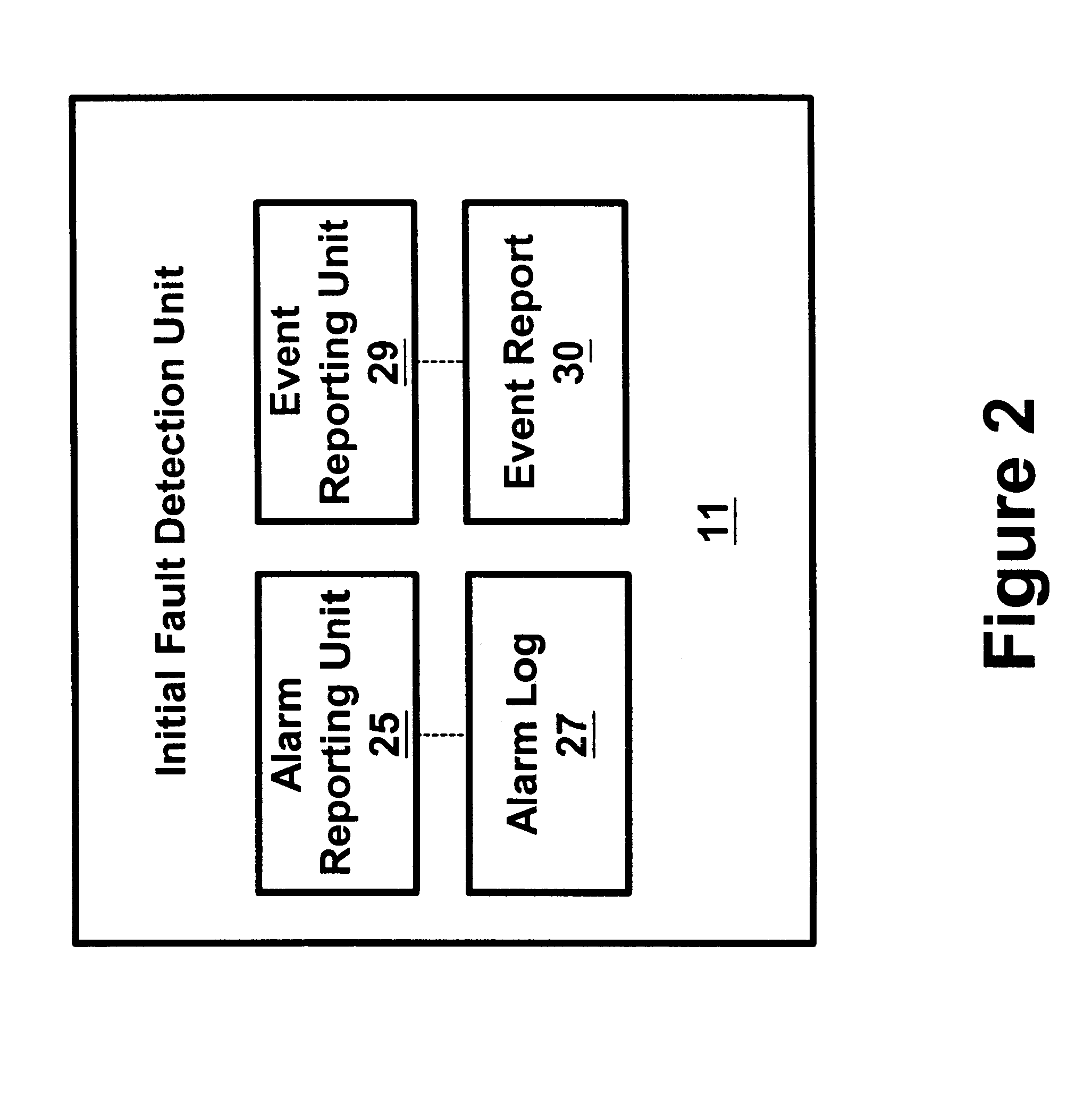

Fault detection control system using dual bus architecture, and methods of using same

The present invention is generally directed to a fault detection control system using dual bus architecture, and methods of using same. In one illustrative embodiment, the system comprises a plurality of process tools, each of the tools adapted to perform at least one process operation on at least one workpiece, at least one sensor that is operatively coupled to each of the process tools and adapted to sense at least one parameter associated with at least one process operation, an initial fault detection unit coupled to an instrument bus, the initial fault detection unit adapted to receive data from at least one sensor on each of the plurality of process tools via the instrument bus, and a primary fault detection unit operatively coupled to a manufacturing execution system and a system bus, the data from the sensors on each of the plurality of process tools being provided to the primary fault detection unit after the data is processed in the initial fault detection unit. In one illustrative embodiment, one of the methods of identifying faults in a manufacturing system comprises processing a workpiece in a process tool, obtaining data regarding the processing of the workpiece in the process tool via at least one sensor that is operatively coupled to the process tool, providing the data obtained by the at least one sensor to an initial fault detection unit that is adapted to receive the data via an instrument bus, the initial fault detection unit determining if an alarm condition exists, and providing the data to a primary fault detection control unit via a system bus after the data is processed through the initial fault detection unit.

Owner:ADVANCED MICRO DEVICES INC

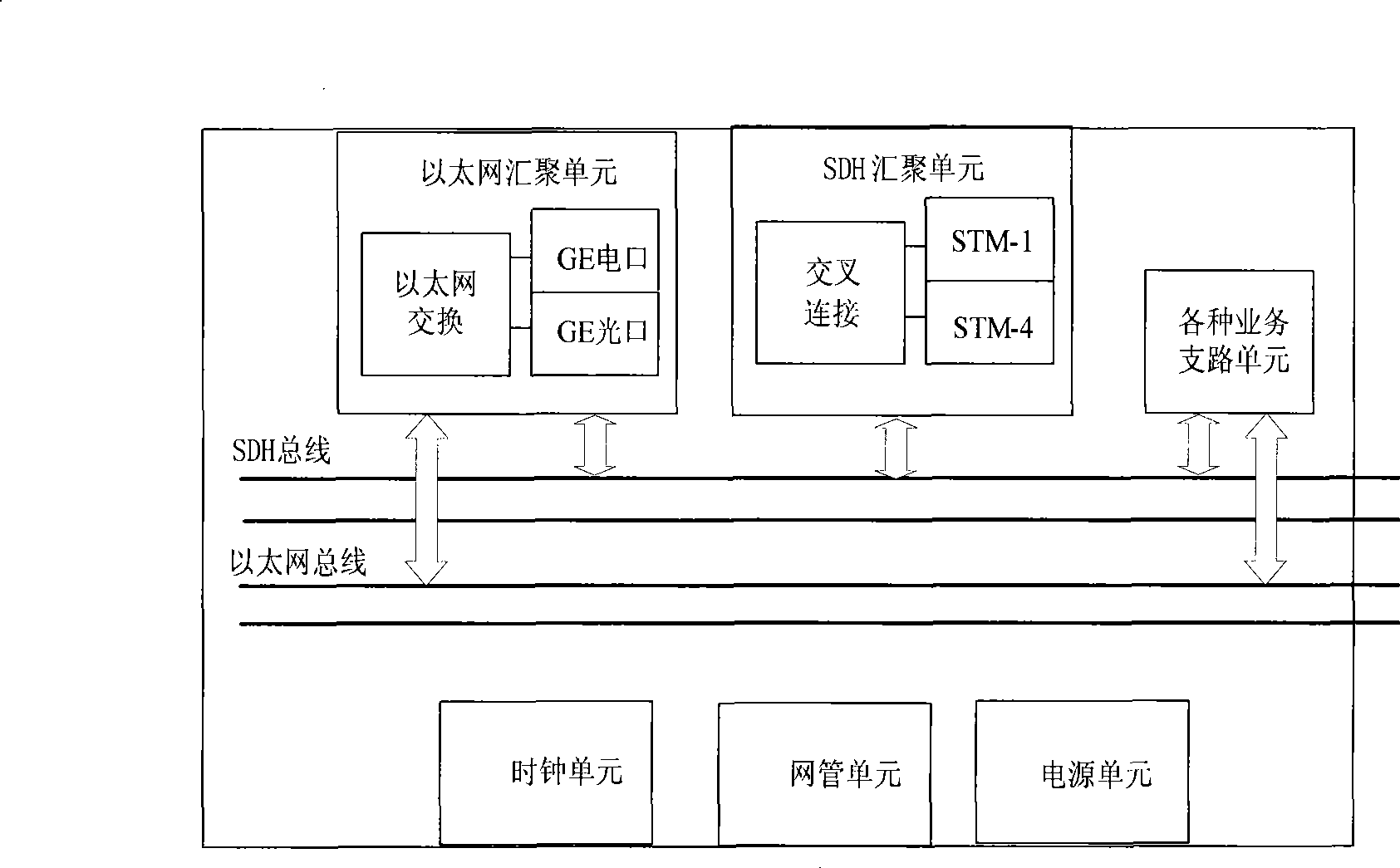

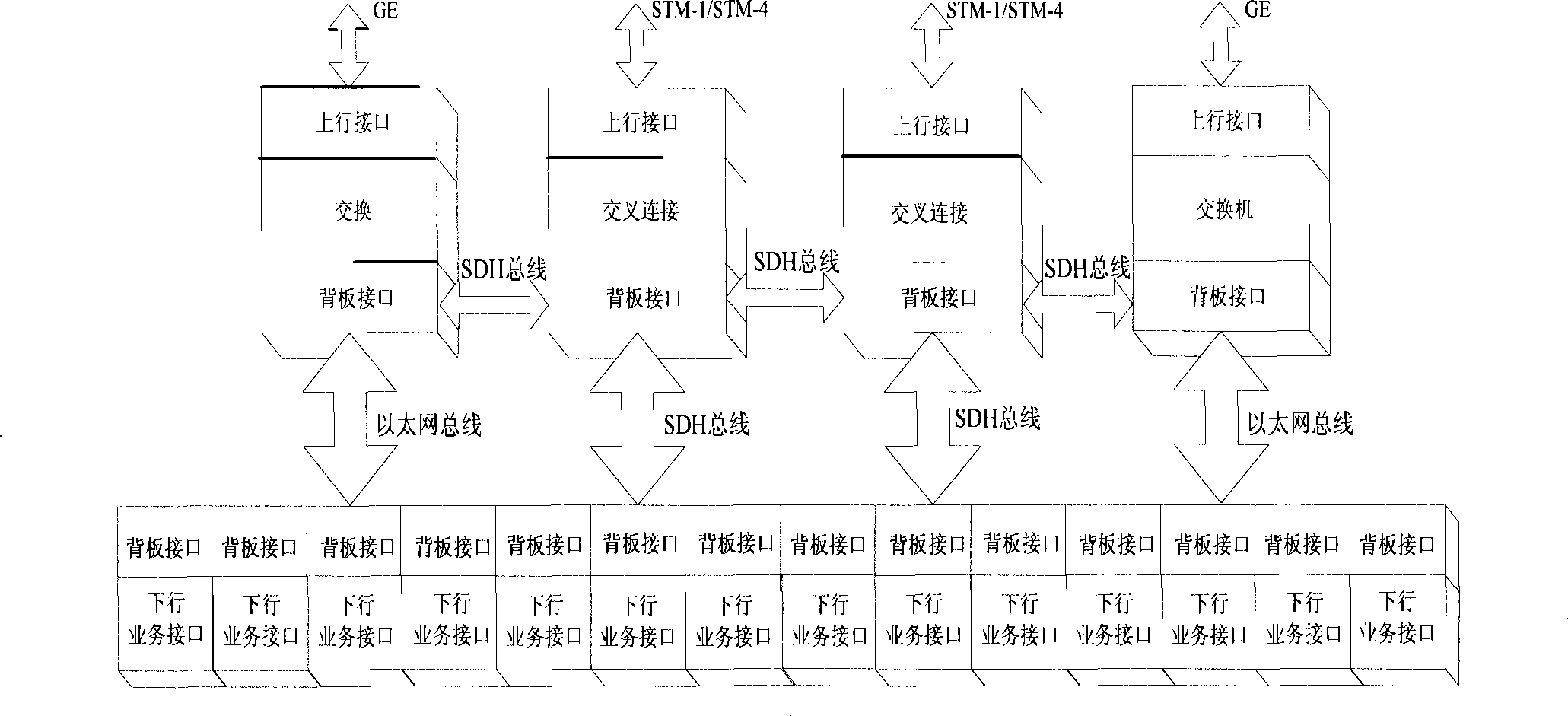

Dual bus system implementing SDH aggregation and Ethernet aggregation

InactiveCN101459486ALow costImprove performanceEnergy efficient ICTTime-division multiplexControl signalNetwork management

Owner:BEIJING HUAHUAN ELECTRONICS

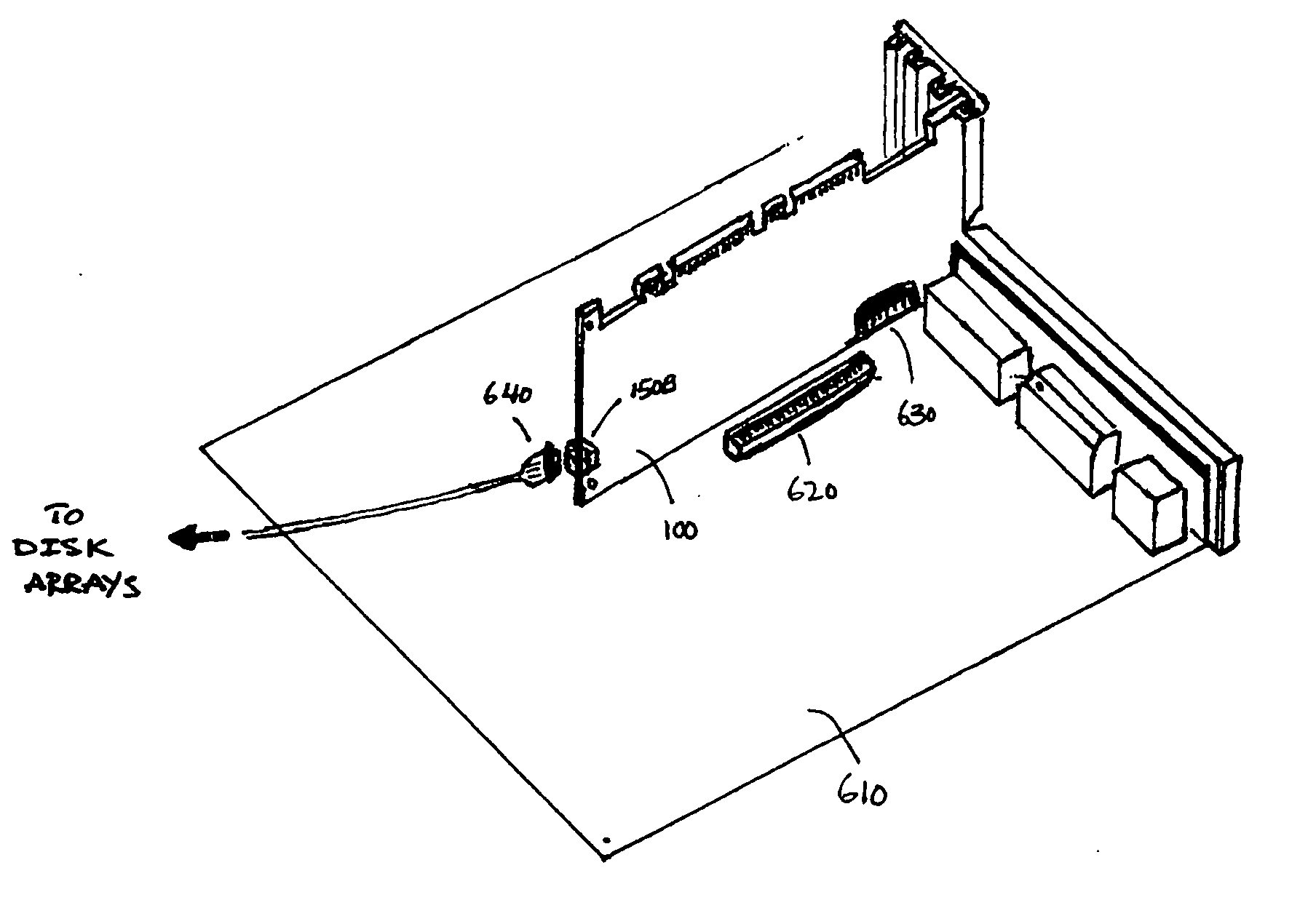

Dual PCI-X/PCI-E card

ActiveUS20060161717A1Reduce manufacturing costSimplify the manufacturing processPrinted circuit aspectsComponent plug-in assemblagesMemory chipDual bus

A dual bus interface PCB includes a main chipset component, a first type bus interface connector, and a second type bus interface connector. The PCB can be configured at fabrication time to enable a variety of configurations for operation. Optionally, the PCB can also be provided at least one memory chip and a NIC (Network Interface Card) chip. By virtue of having a dual interface, the PCB can be used with either the first type or the second type bus. Furthermore, the dual interface PCB eliminates the need by chipset manufacturers to carry multiple PCB variations of the same product in order to support various bus interfaces. In one embodiment, the PCB is a dual PCI-X / PCI-E interface PCB.

Owner:AVAGO TECH INT SALES PTE LTD

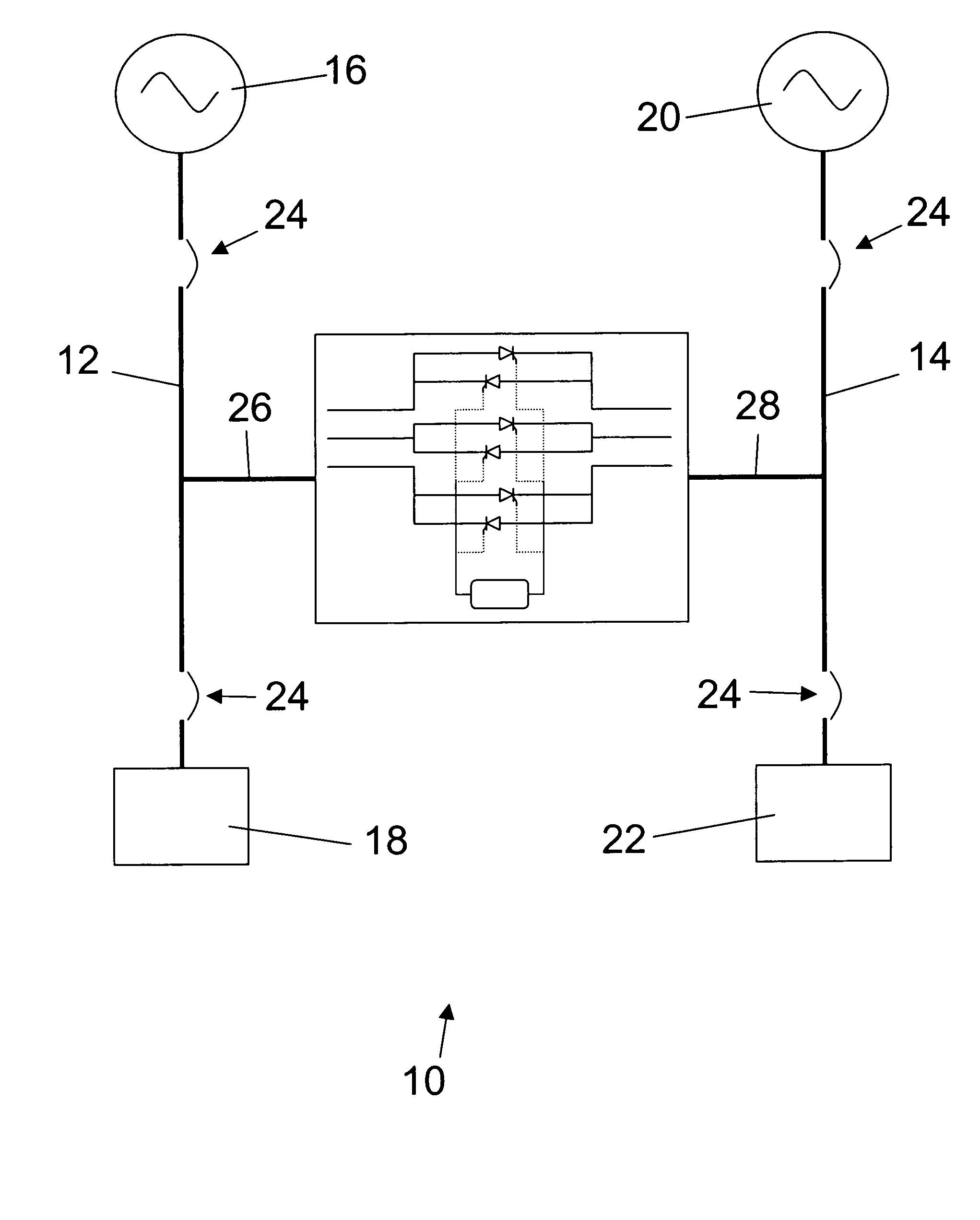

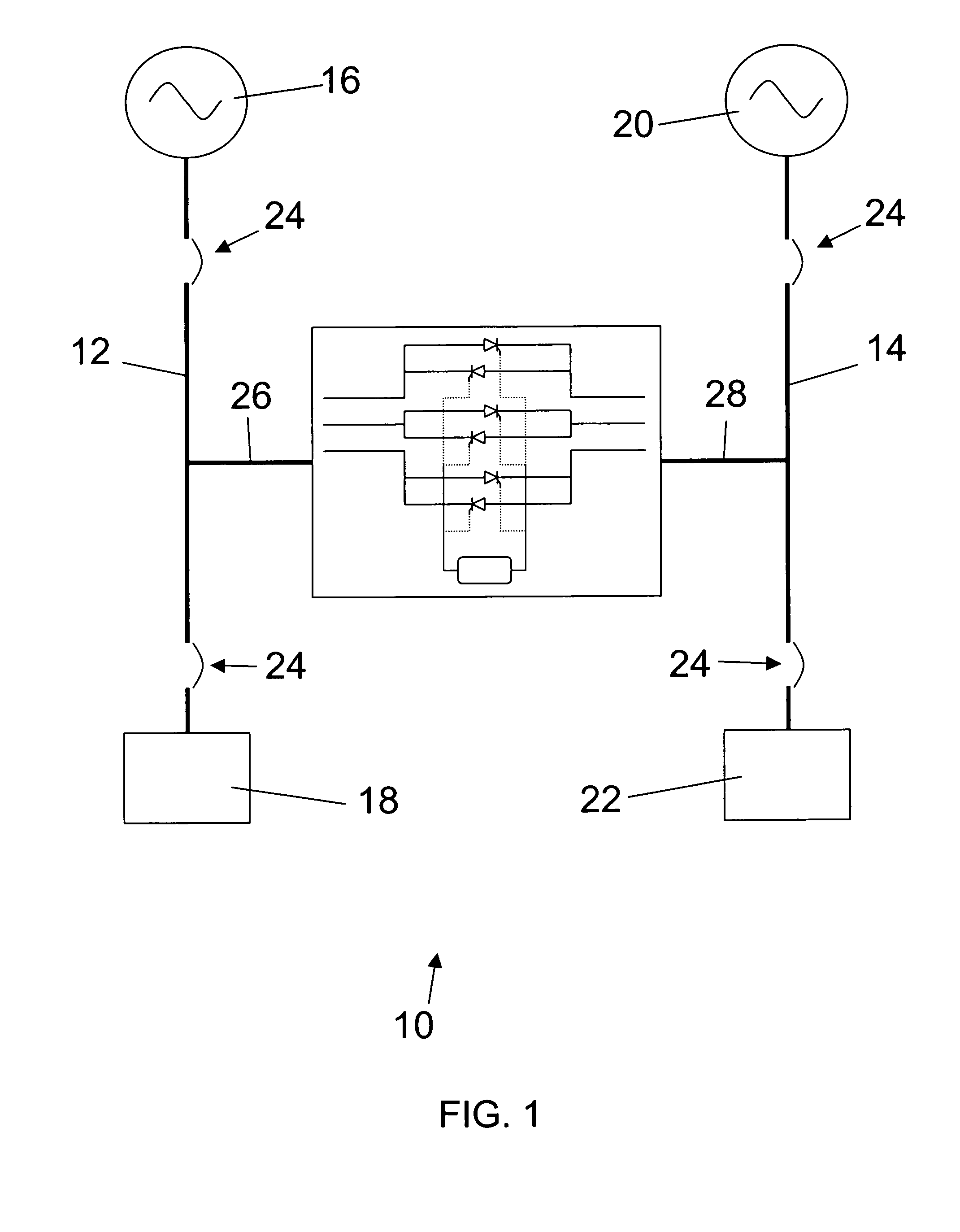

Dual bus static tie switch

InactiveUS20050207082A1Effectively shortingInstantly control power flowEmergency protective circuit arrangementsEmergency power supply arrangementsDual busControl theory

A static tie switch (10) designed to provide the upmost in reliable power to critical equipment, such as communications and computing equipment. The switch uses solid state devices, wherever possible, and preferable uses silicon controlled rectifiers (SCR)s (30) to tie corresponding phases of multiple buses (12,14) together. In the preferred embodiment, the switch (10) broadly comprises three pairs of SCRs (30), one pair for each phase, and a controller (32) to control the SCRs (30). The SCRs (30) can be triggered or biased to selectively allow current to flow between the buses (12,14), thereby allowing a first source (16) to power both a first load (18) and a second load (22). Similarly, the SCRs (30) can be triggered to selectively allow a second source (20) to power both the first load (18) and the second load (22).

Owner:ENERGY SYST TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com