Rubber belt conveyor monitoring system with fault positioning function

A belt conveyor, fault location technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problem of not being able to locate quickly, and achieve the effect of improving production efficiency, realizing safety protection, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the purpose and advantages of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

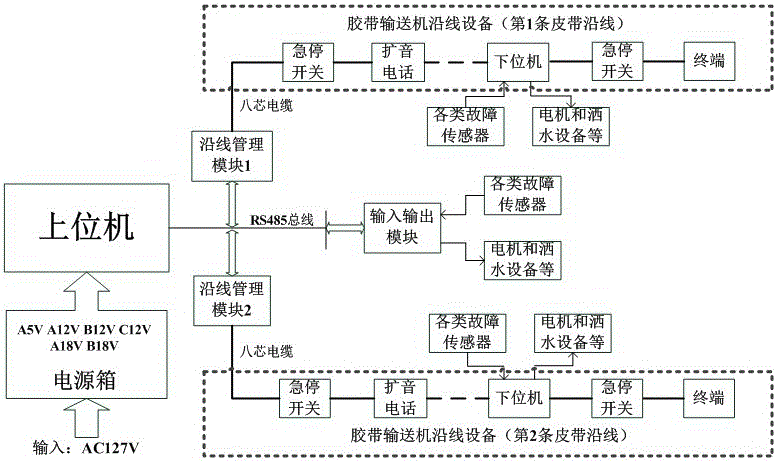

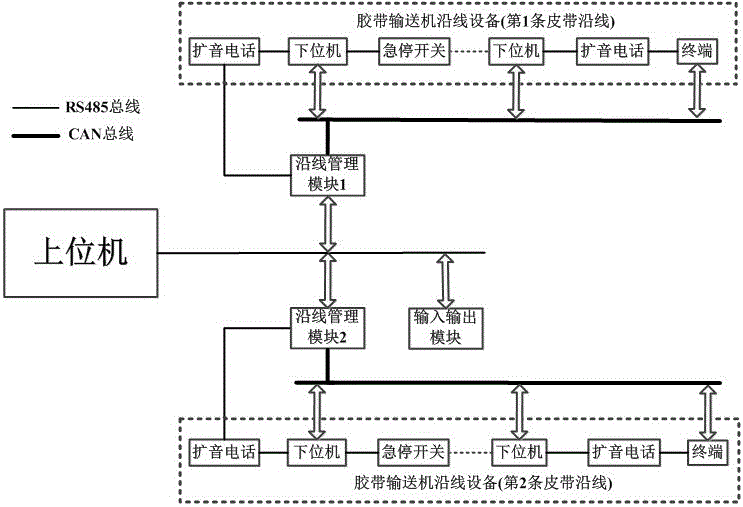

[0024] as attached figure 1 As shown, the implementation of the above-mentioned belt conveyor monitoring system with fault location function provided by the present invention is based on the prior art, aiming at the belt conveyor under the coal mine to realize the monitoring system designed for automatic mining. The belt conveyor monitoring system mainly includes the main controller and its equipment along the line. The main controller realizes the overall monitoring of the working process of the belt conveyor through the equipment along the line and its management equipment.

[0025] In the above specific embodiment, the main controller is formed by connecting the upper computer, the input and output modules and the management module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com