Haze reducing and white smoke eliminating tower for flue gas

A flue gas and whitening technology, applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve problems such as visual pollution, cost increase, and process layout complexity, and achieve the effect of cost reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

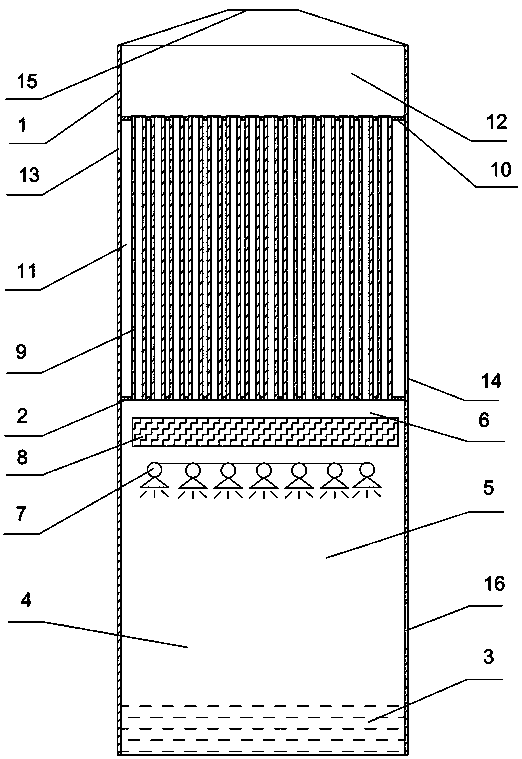

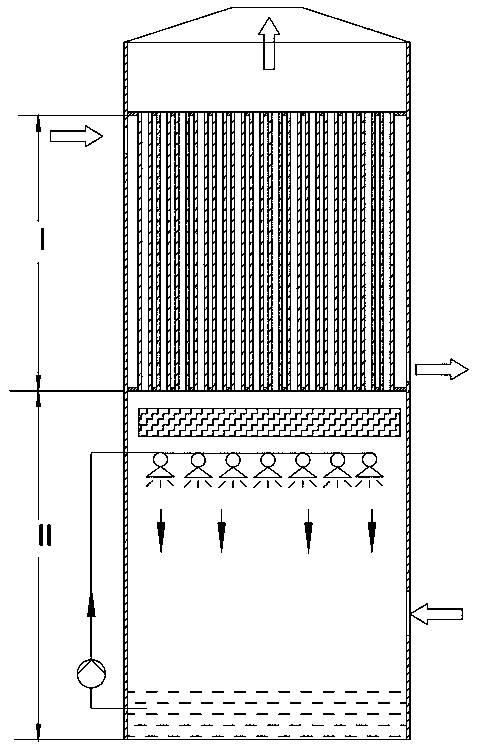

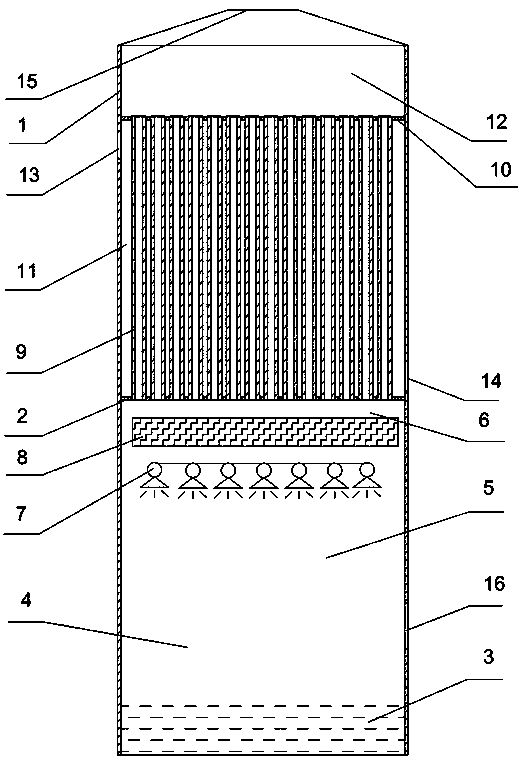

[0021] combine figure 1 and figure 2 , the present invention is described as follows:

[0022] A flue gas haze reduction and "white elimination" tower, including tower shell 1 and internal components, the tower body is divided into haze reduction part I and heating part II, upper and lower parts, heating part II is on the top, haze reduction part I is on the bottom, heating Part II and haze reduction part I are separated by the position of partition a2; the inner chamber of tower shell 1 of haze reduction part I is sequentially divided into water storage area 3, desulfurization flue gas inlet area 4, washing area 5 and demisting area from bottom to top 6. The space between the desulfurization flue gas intake area 4, the washing area 5 and the demisting area 6 is connected. A scrubber 7 is arranged in the washing area 5. The washing area 5 is an area for purifying and washing the desulfurization flue gas. The washing method is Washing with water to remove the desulfurization...

Embodiment 2

[0028] combine figure 1 , figure 2 , the present invention is described as follows:

[0029] On the basis of Embodiment 1, an air guide plate is provided in the heating zone 11. In this embodiment, the air guide plate is a spiral plate, and the heat exchange tubes 9 pass through the spiral plate. The raw flue gas inlet 13 is set above the heating zone 11, and the raw flue gas outlet 14 is set under the heating zone 11 of the tower shell 1. The raw flue gas enters from the raw flue gas inlet 13, goes down the spiral plate, and finally flows through the Outlet 14 goes out tower shell 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com