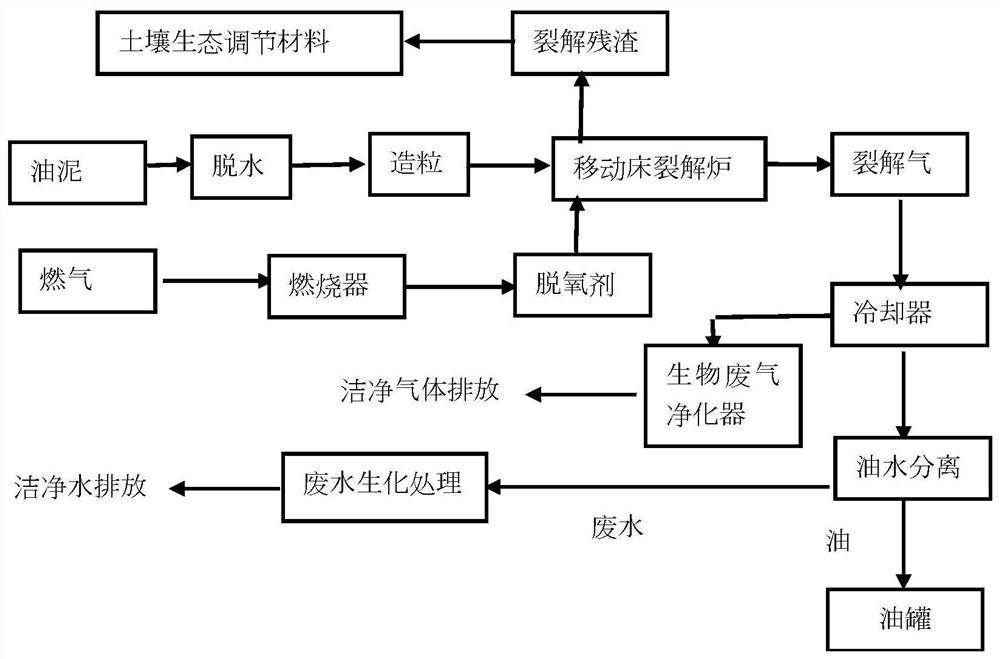

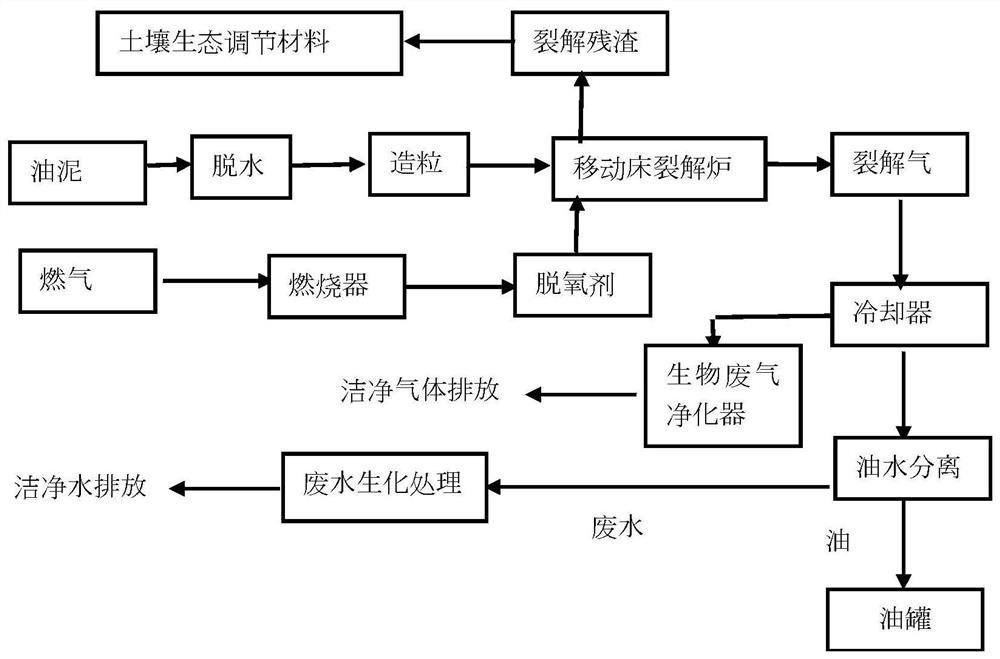

Oil-containing resourceful treatment method

A resource-based and biochemical treatment device technology, applied in the field of oil-containing resource-based treatment, can solve problems such as the inability to fundamentally overcome oil sludge pollution, low recovery rate, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dry and dehydrate the oil sludge produced by oil exploitation in Liaohe Oilfield until the oil content is 30% and the water content is 30%, and granulate to obtain particles with a particle size within the range of 1 to 2 cm;

[0050] Combust the liquefied gas to obtain a hot gas flow, pass through a mixed deoxidizer composed of 60% charcoal and 40% oil sludge residue, the oxygen content in the hot gas flow is 1%, and the temperature is 400°C;

[0051] The oil sludge particles are sent to the rotary moving bed with the conveying device, and the hot air flow is also sent into the rotating moving bed to contact the oil sludge particles. The rotating speed of the optional moving bed is 25 revolutions / min, and the contact time between the hot air flow and the oil sludge particles is 1 hour;

[0052] The obtained residue accounts for 35%, and the oil yield is 81%. After the waste gas is purified, the sulfur dioxide content is 70ppm, and the nitrogen oxide content is 40ppm. Af...

Embodiment 2

[0054] The oil sludge produced in Nanyang Tanghe Oilfield, with an oil content of 10% and a water content of 55%, is dried and dehydrated to a water content of 10%, and granulated to obtain particles with a particle size within the range of 0.5 to 2 cm;

[0055] Combust the liquefied gas to obtain a hot gas flow. After passing through a mixed deoxidizer composed of 80% charcoal and 20% sludge residue, the oxygen content in the hot gas flow is 1%, and the temperature is 350°C;

[0056] Send the oil sludge particles into the rotary moving bed with the conveying device, and the hot air flow is also sent into the rotating moving bed to contact with the oil sludge particles. The rotating speed of the optional moving bed is 15 revolutions / min, and the contact time between the hot air flow and the oil sludge particles is 0.5 hours;

[0057] The obtained residue accounts for 38%, and the oil yield is 76%. After the waste gas is purified, the sulfur dioxide content is 60ppm, the nitroge...

Embodiment 3

[0059]The oil sludge produced in the Zhongyuan Oilfield has an oil content of 20% and a water content of 45%, dried and dehydrated to a water content of 10%, and granulated to obtain particles with a particle size within the range of 0.5 to 1.5 cm;

[0060] Combust the liquefied gas to obtain a hot gas flow. After passing through a mixed deoxidizer composed of 90% charcoal and 10% sludge residue, the oxygen content in the hot gas flow is 1%, and the temperature is 450°C;

[0061] The sludge particles are sent to the rotary moving bed with the conveying device, and the hot air flow is also sent to the rotary moving bed to contact the sludge particles. The rotating speed of the optional moving bed is 50 revolutions / min, and the contact time between the hot air flow and the sludge particles is 0.5 hours;

[0062] The obtained residue accounts for 36%, and the oil yield is 76%. After the waste gas is purified, the sulfur dioxide content is 80ppm, and the nitrogen oxide content is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com