fuel injector

A technology of fuel injectors and nozzles, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., and can solve problems such as many high-pressure leakage links, unsatisfactory pressure response speed, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

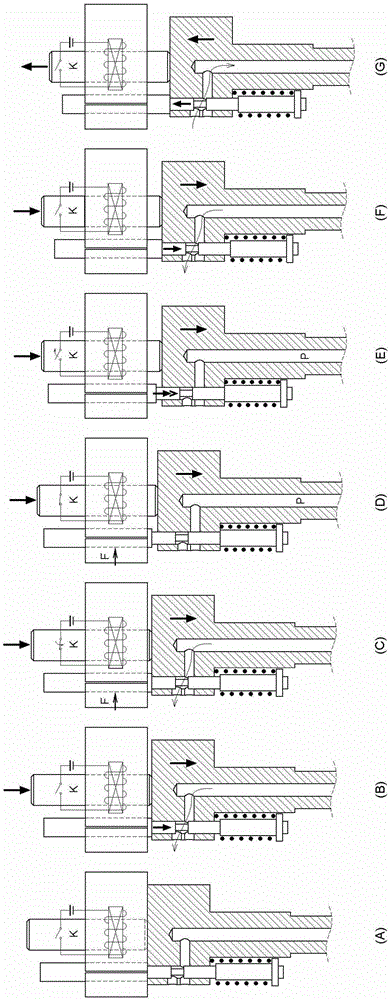

[0027] This patent provides three embodiments.

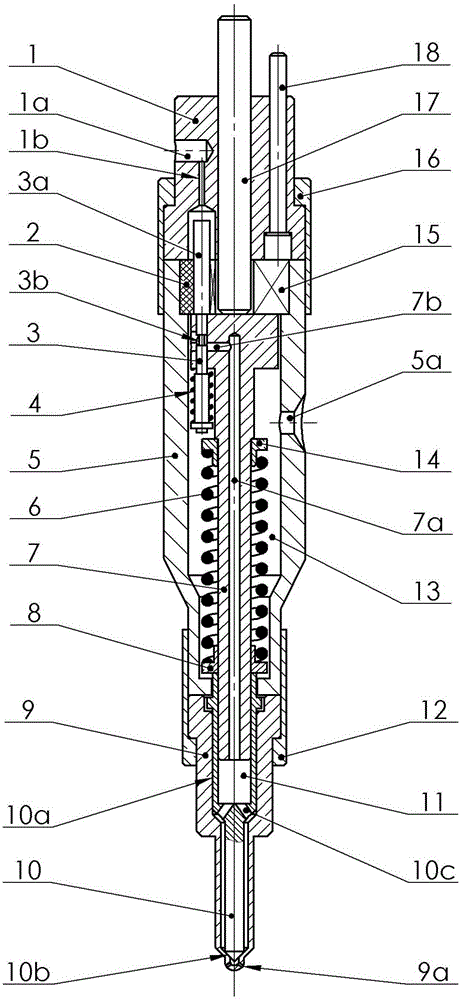

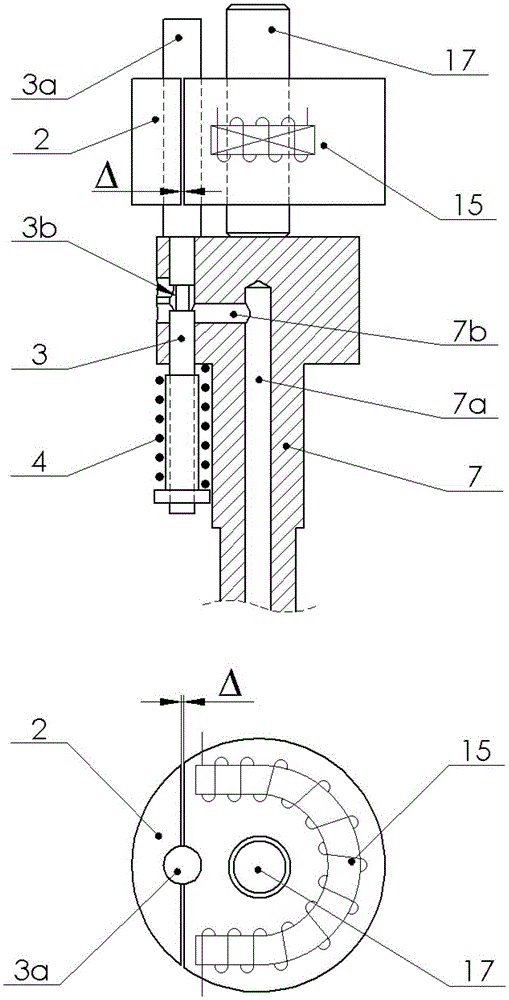

[0028] Figure 1~Figure 3 It is the first embodiment. In this embodiment, the plunger is installed in the inner hole of the needle valve of the oil nozzle, the fuel injection and the oil inlet into the high-pressure chamber are controlled by electric control, and the plunger is pushed by a mechanical method.

[0029] figure 1 As shown, same as the traditional injector, there are injector body (5), nozzle body (9), nozzle needle valve (10), pressure spring (6), nozzle tight cap (12) and nozzle body (9 ) nozzle hole (9a) on the head, the outer circle of the nozzle needle valve guide rod (10a) and the nozzle body (9) are in a precise sliding fit.

[0030] The oil nozzle needle valve guide rod (10a) has an inner hole in the axial direction, and a plunger (7) is installed in the inner hole. The plunger (7) and the inner hole of the oil nozzle needle valve (10) are in a precise sliding fit. ) and the nozzle needle valve (10) are mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com