Patents

Literature

35results about How to "Large feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

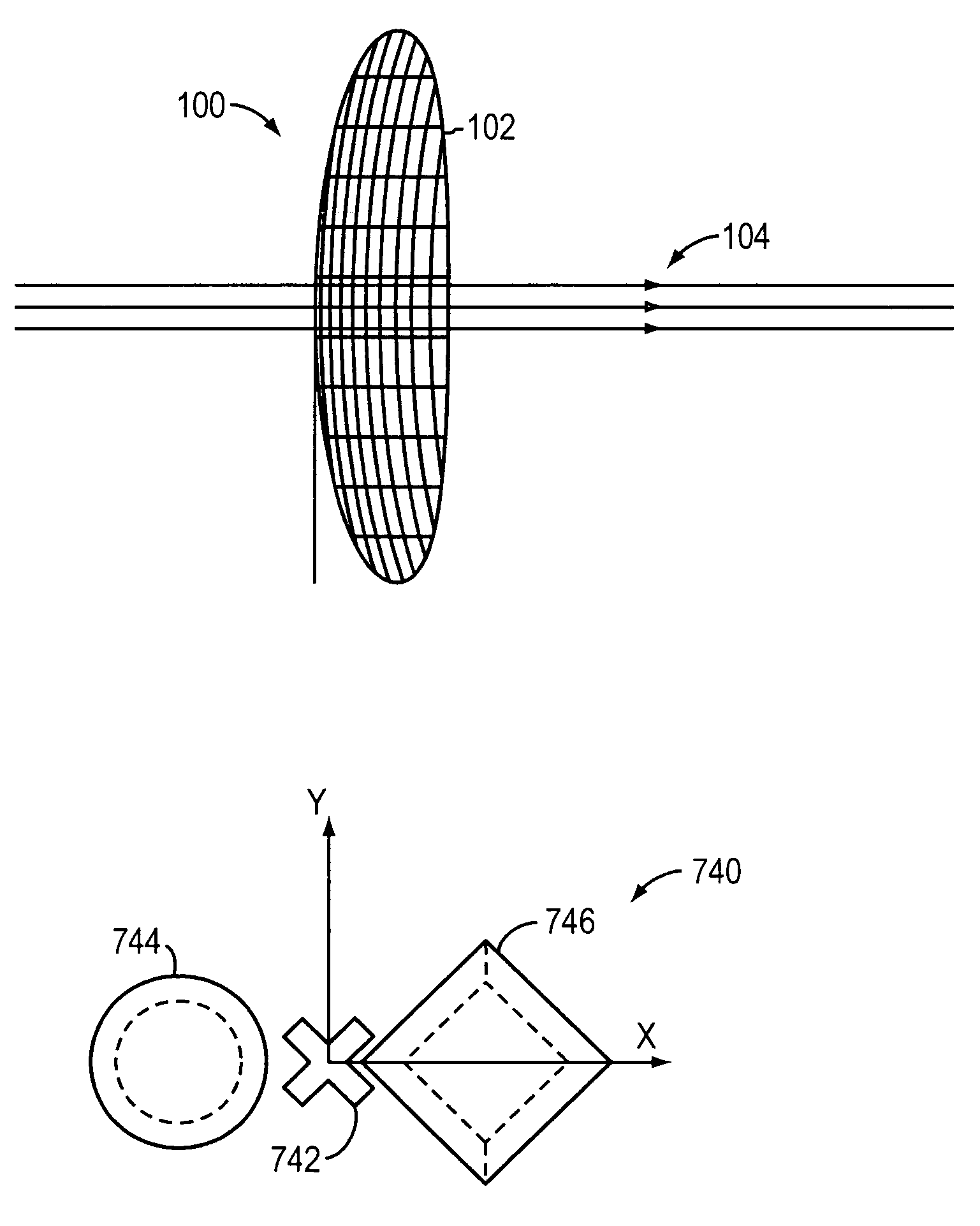

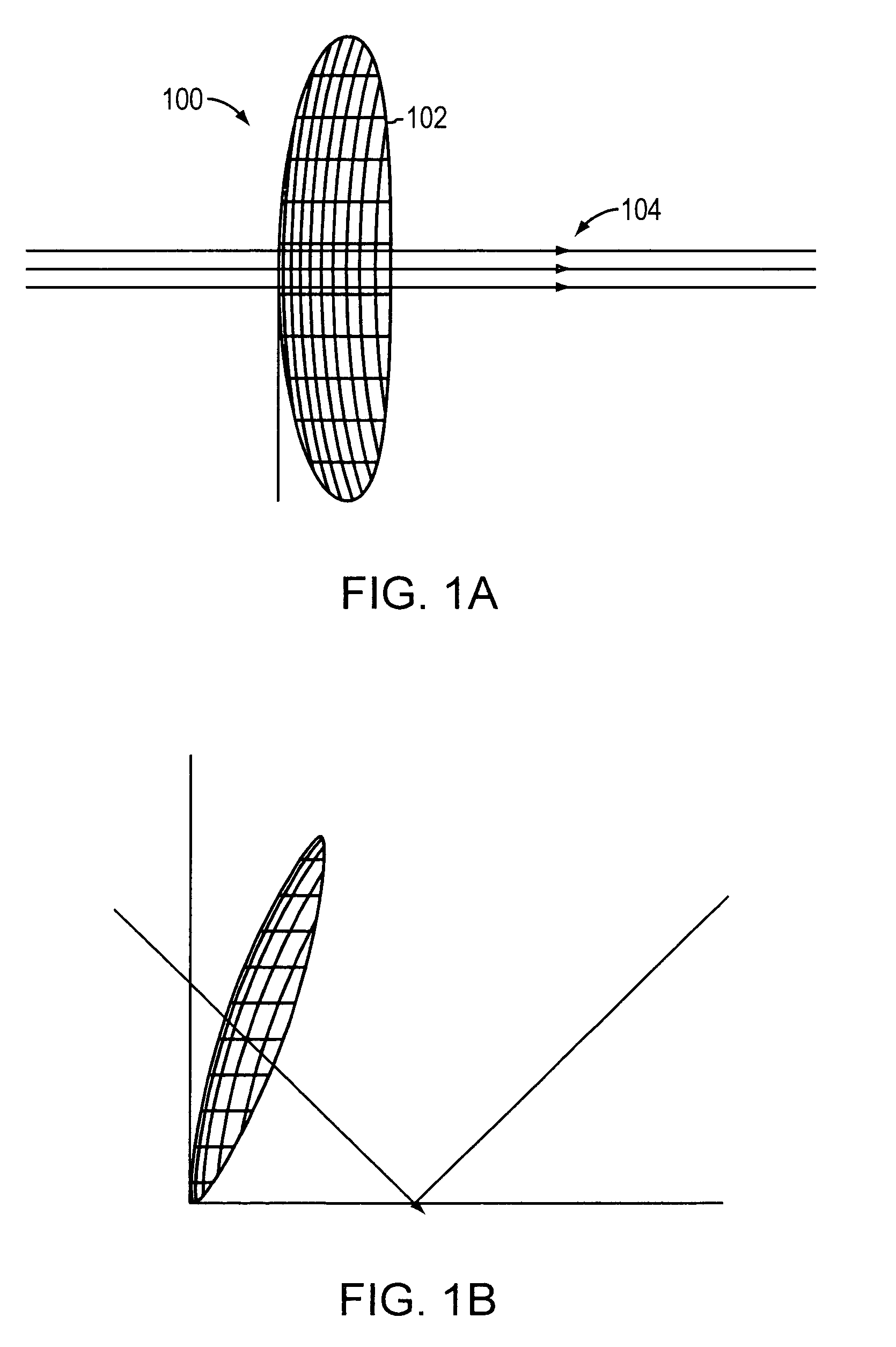

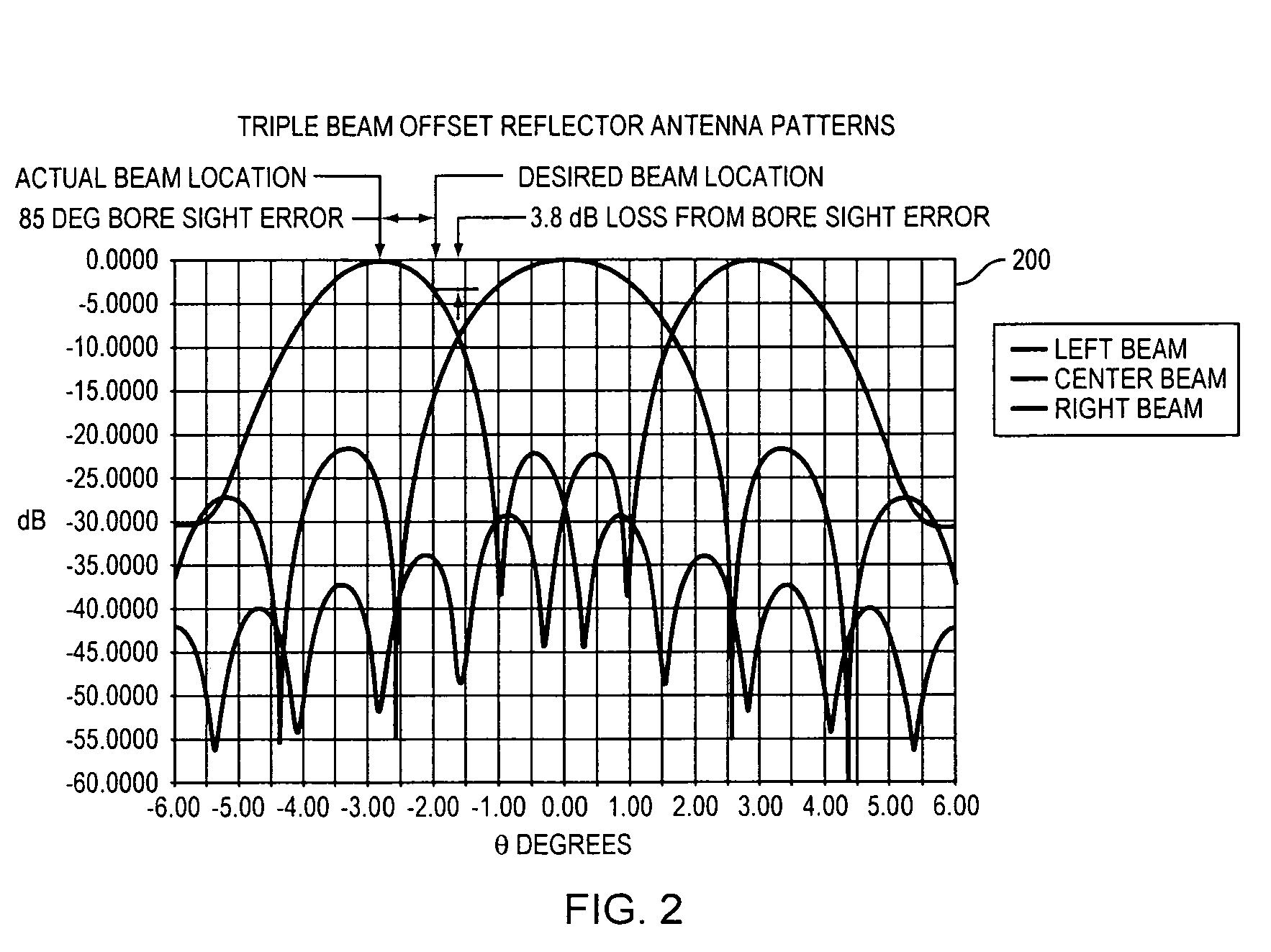

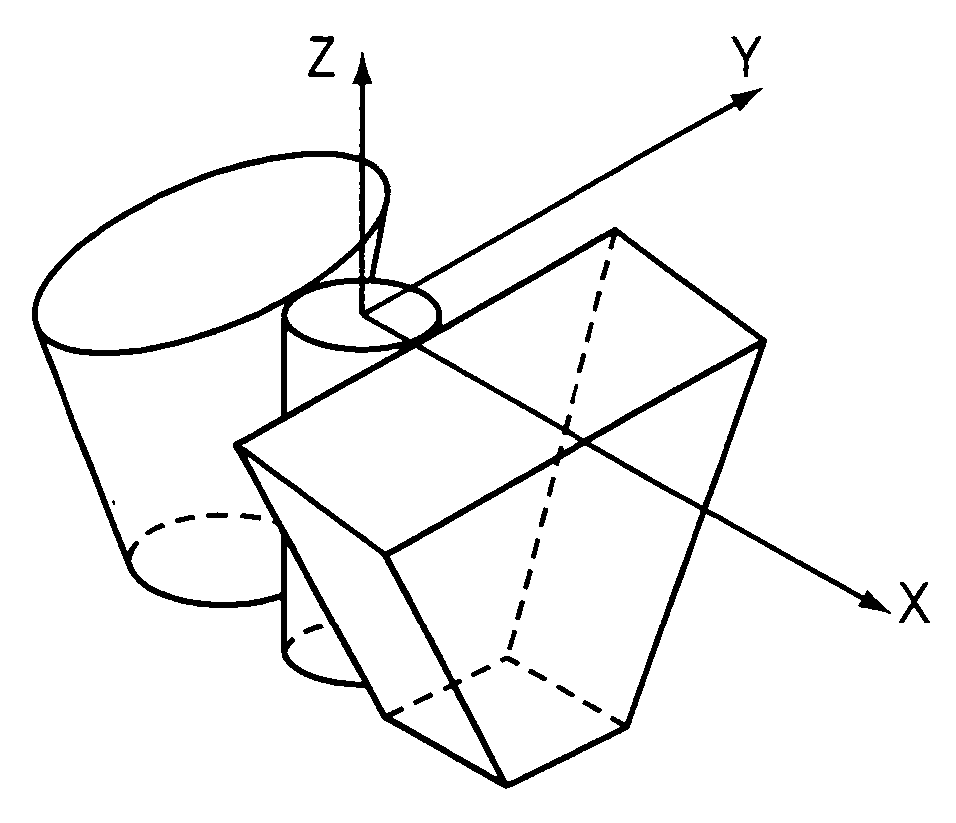

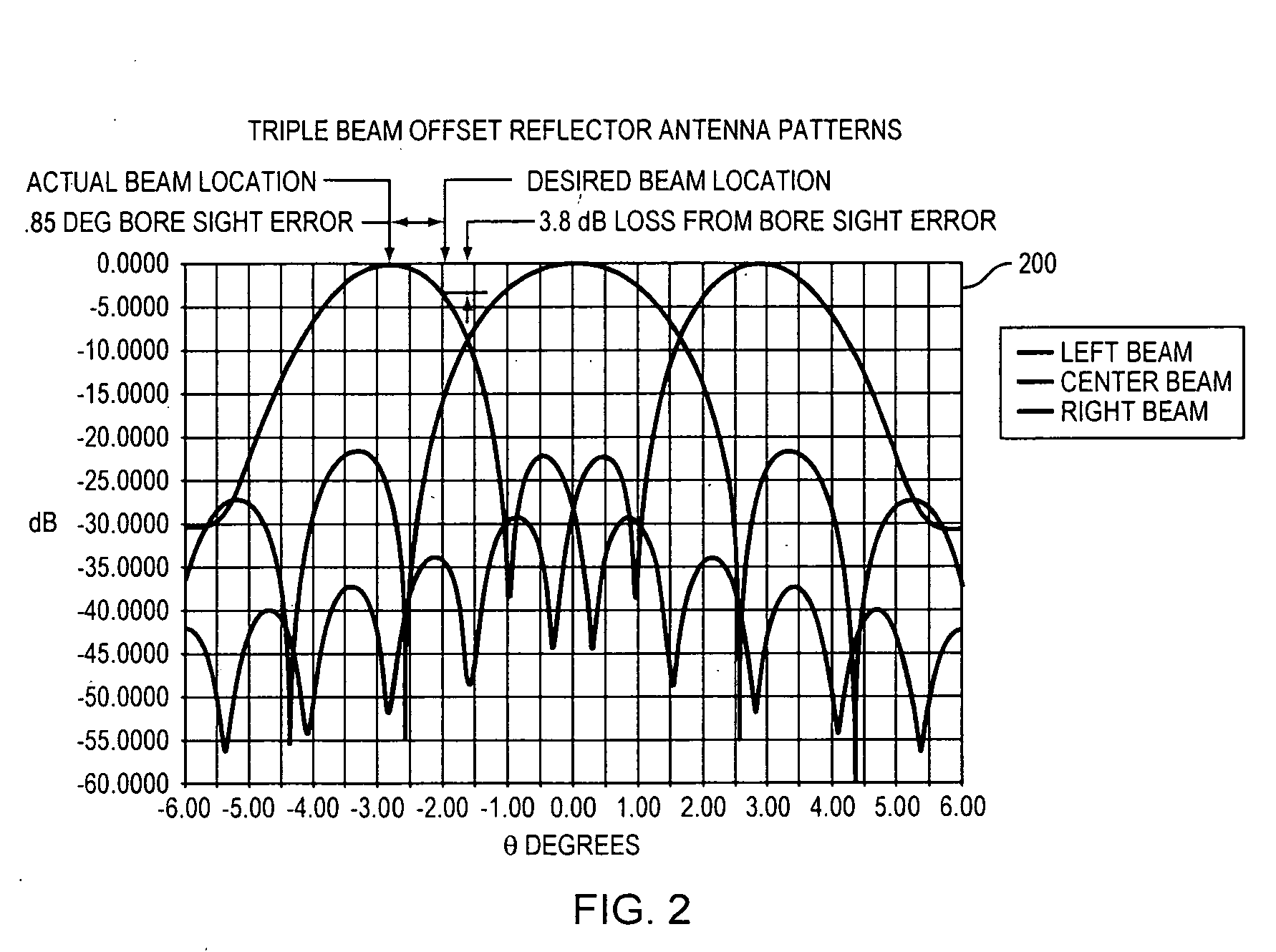

Small wave-guide radiators for closely spaced feeds on multi-beam antennas

Owner:PRO BRAND INT

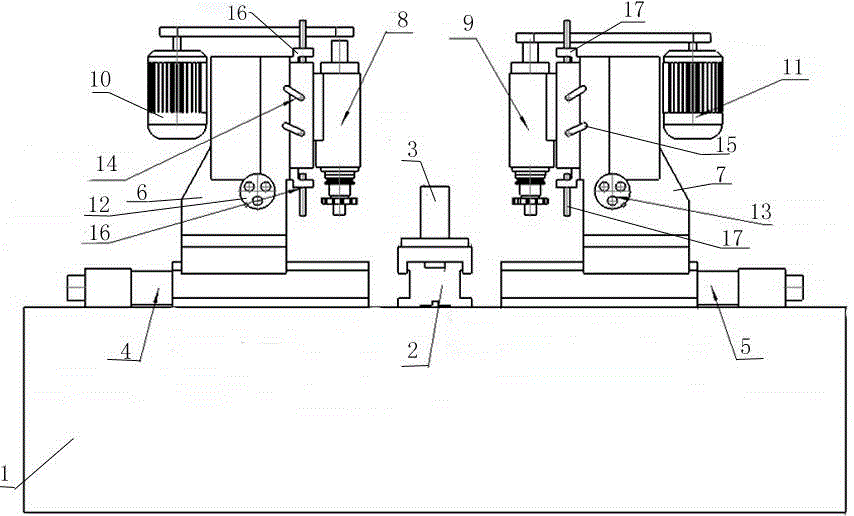

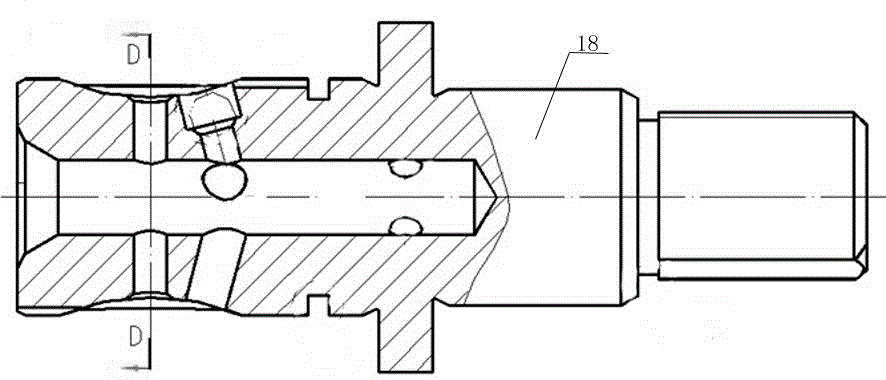

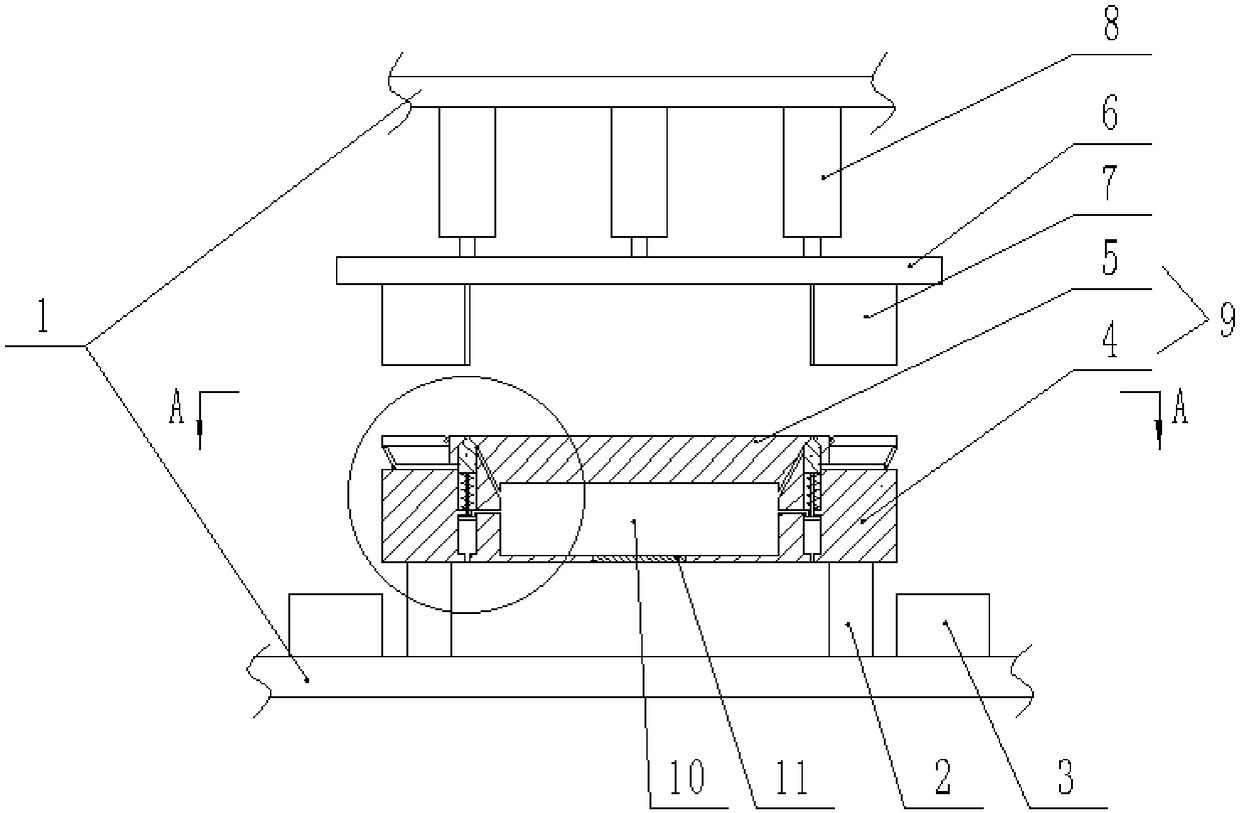

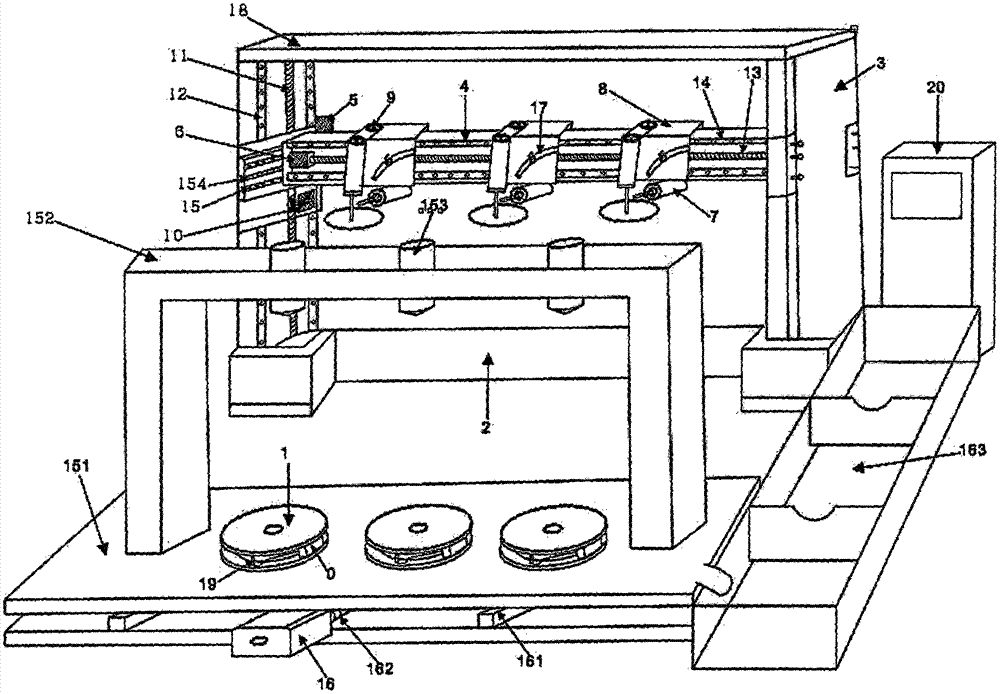

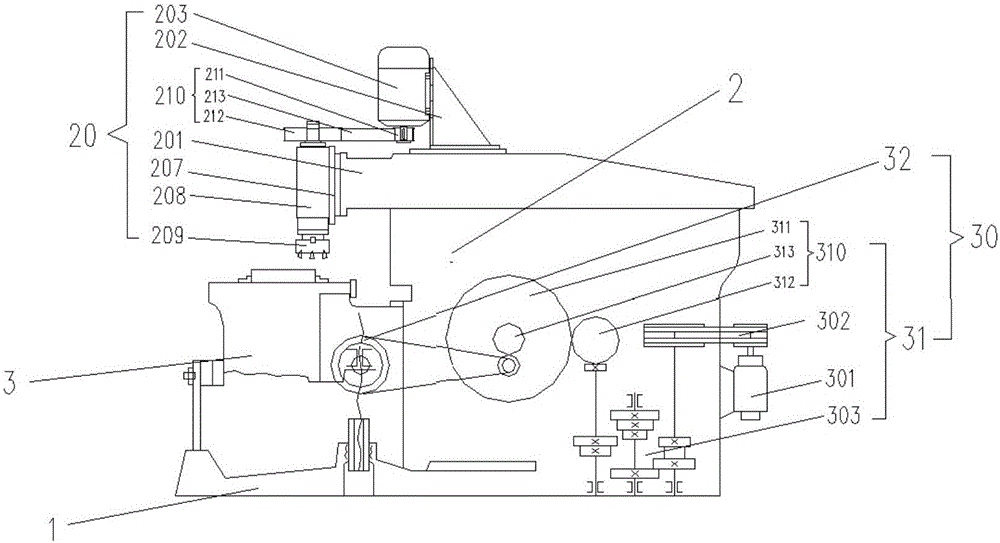

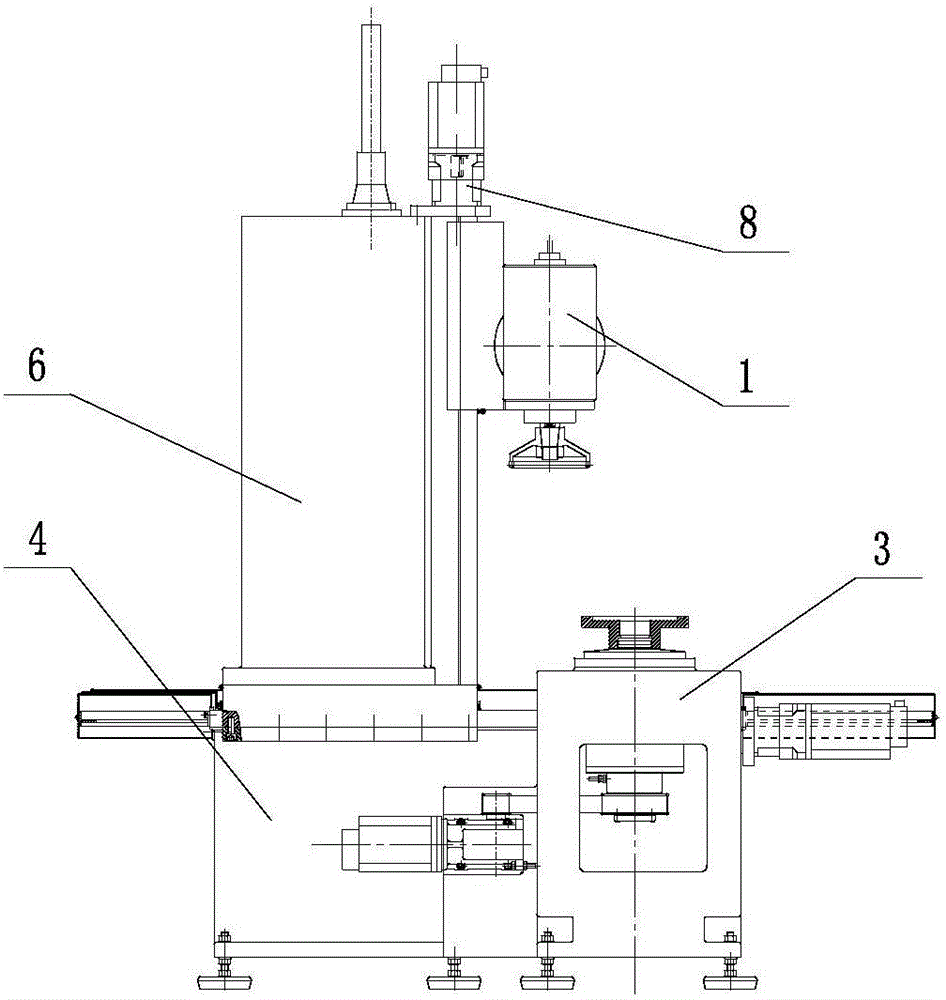

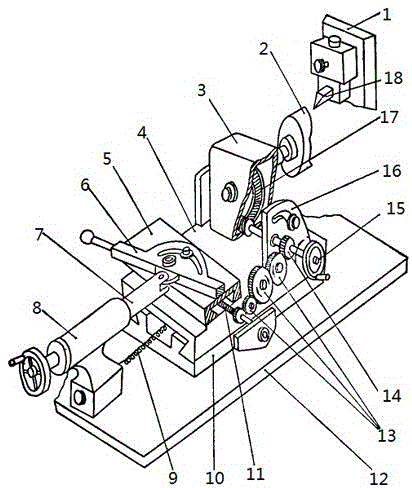

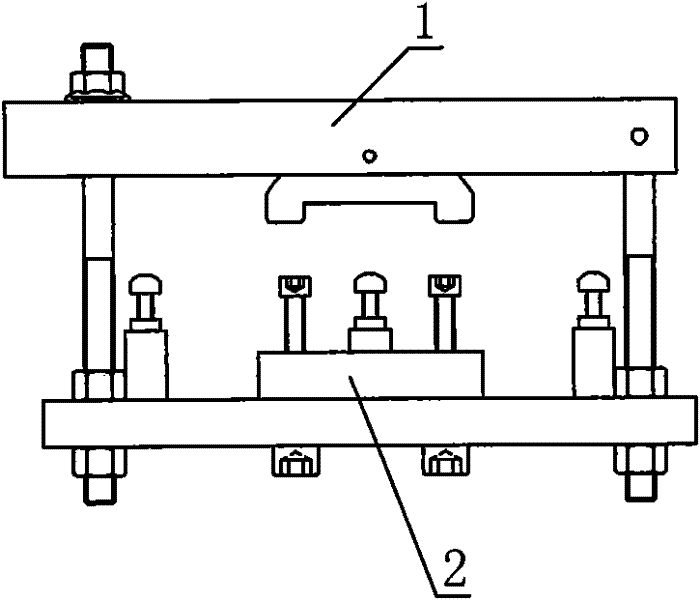

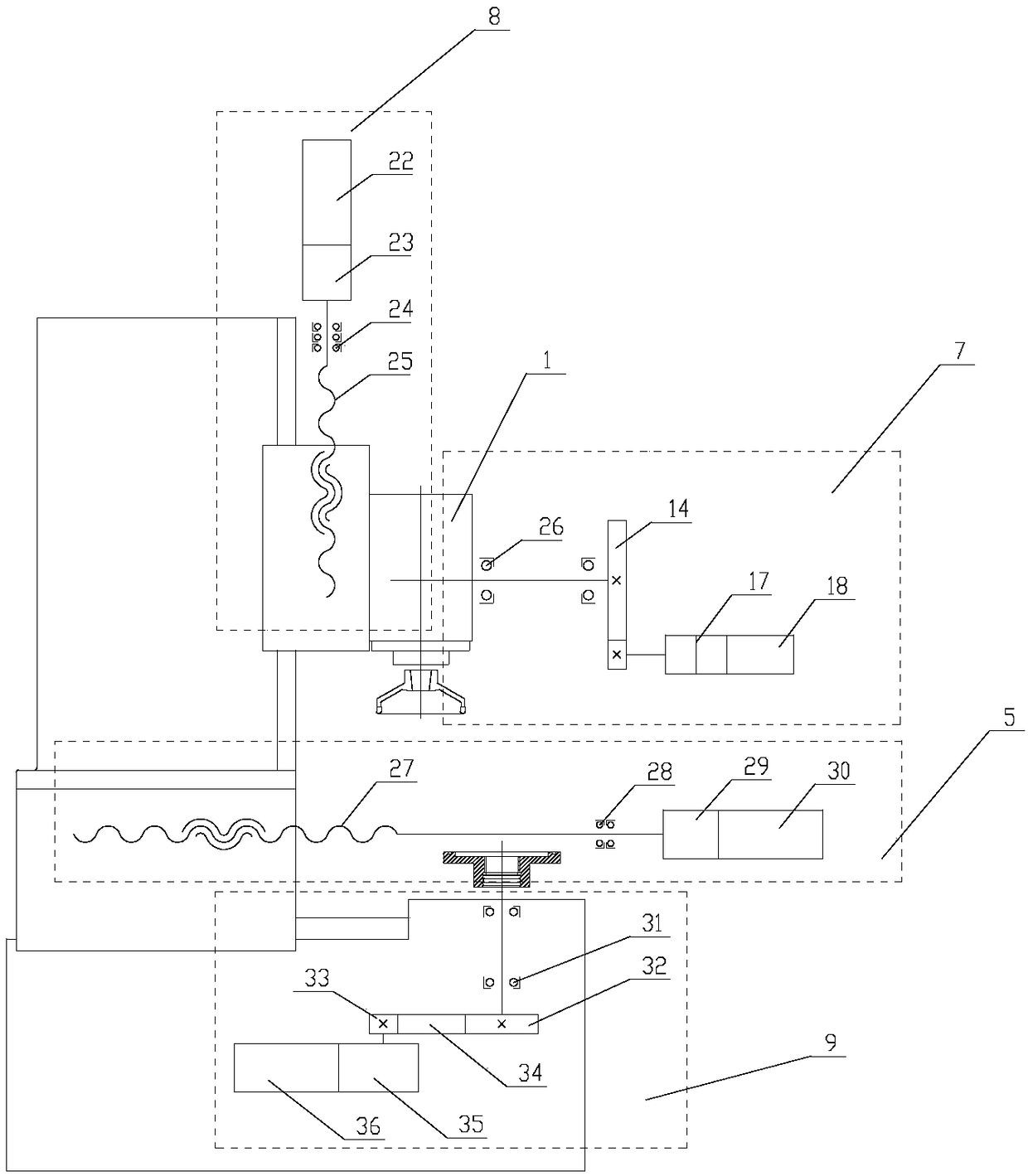

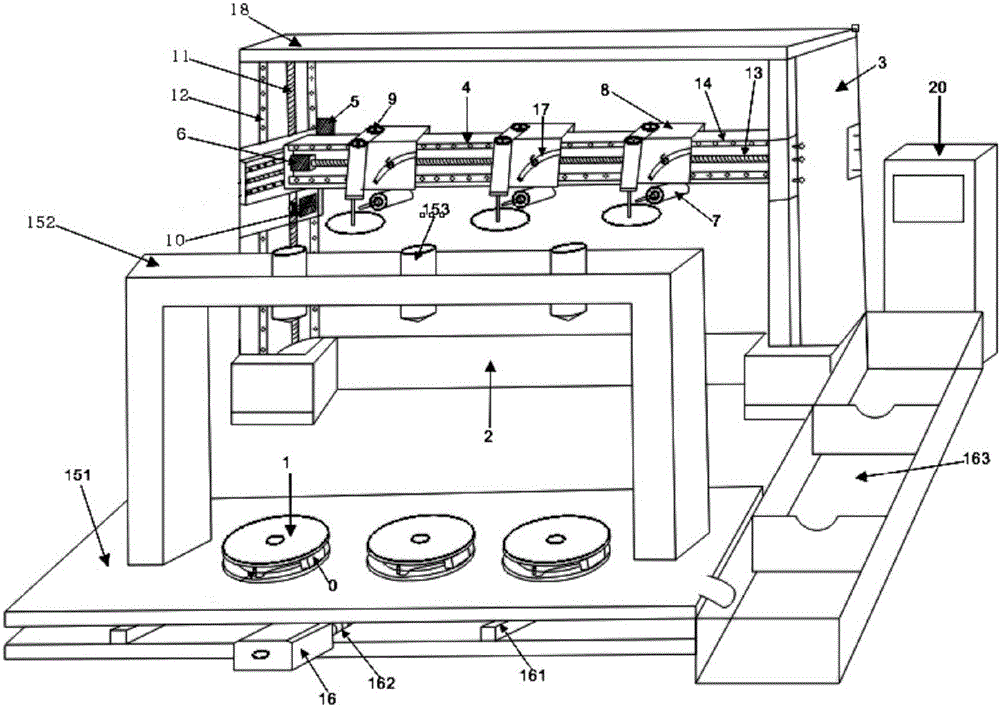

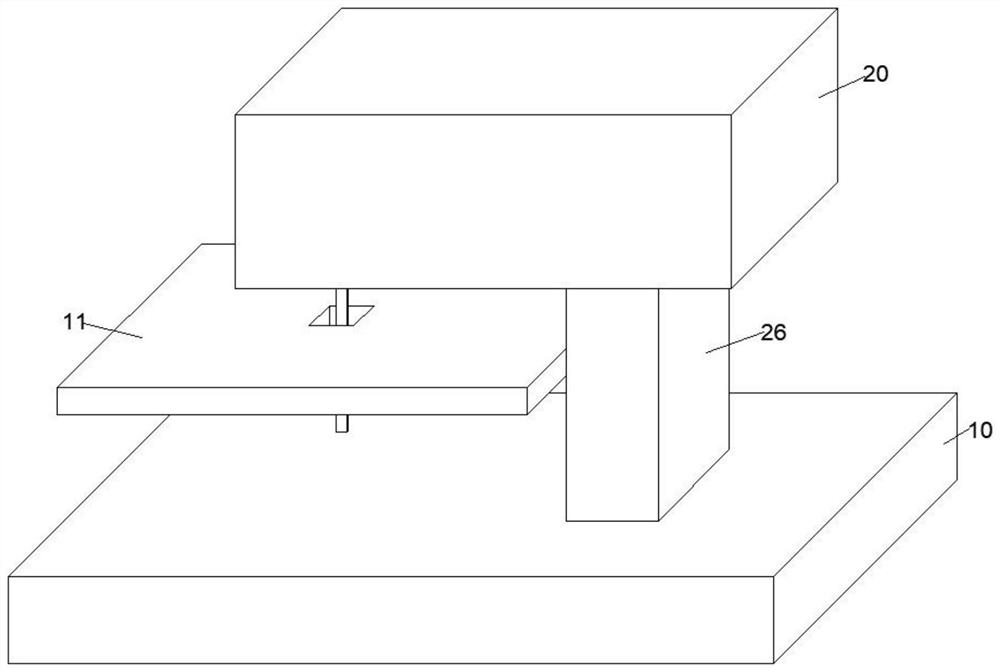

Numerical control opposite-direction slot milling machine

InactiveCN103551641ALow degree of automationEasy to processLarge fixed membersMilling equipment detailsNumerical controlEngineering

The invention provides a numerical control opposite-direction slot milling machine which comprises a machine tool base, wherein a numerical control working platform is arranged in the middle of the machine tool base; the numerical control working platform is provided with a fixture body; a left numerical control sliding table and a right numerical control sliding table are respectively and symmetrically arranged on the two sides of the numerical control working platform; the left numerical control sliding table and the right numerical control sliding table are provided with a left machine tool body and a right machine tool body, respectively; vertical guide rails of the left machine tool body and the right machine tool body are respectively provided with a left milling head and a right milling head which are connected with a left driving motor and a right driving motor, respectively. The numerical control opposite-direction slot milling machine adopts symmetrical two-way numerical control for simultaneous feed cutting, and solves the three technical problems that machining time is long caused by the factor that a symmetrical slot in the other side can be machined only by retracting and overturning a tool after one slot is machined, large feed amount is not available caused by uneven stress of parts due to single-sided milling, and the degree of automation is low when a large-thickness symmetric slot is milled by a universal milling machine.

Owner:DONGFENG MOTOR PARTS & COMPONENTS GROUP

Small wave-guide radiators for closely spaced feeds on multi-beam antennas

A relatively low cost, easy to install and aesthetically pleasing digital video broadcast from satellite (DVBS) elliptical horn antenna designed to receive satellite television broadcast signals with circular polarity. This type antenna may be implemented as a multi-beam, multi-band antenna with closely spaced antenna feed horns operable for simultaneously receiving signals from multiple satellites that are closely spaced from the perspective of the antenna.

Owner:PRO BRAND INT

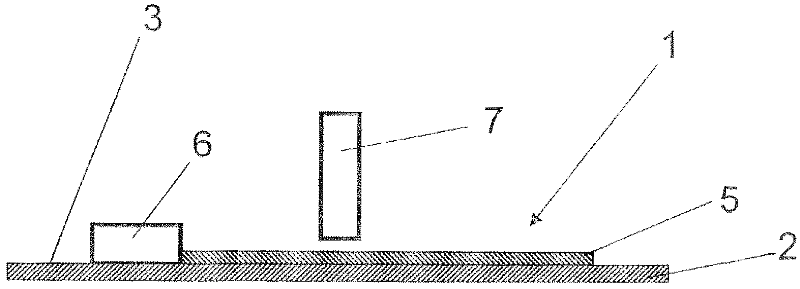

Method for producing coating material

ActiveCN102481699ALarge feedReduce consumptionOther plywood/veneer working apparatusFilm/foil adhesivesPre treatmentMaterials science

The invention relates to a method for producing coating material (1) for workpieces, comprising the steps of: providing a web-shaped or strip-shaped base material (2), feeding the base material into a coating station (6), pre-treating at least one surface of the base material (2), and applying a functional layer (5) to the pre-treated surface of the base material (2), wherein the functional layer (5) can be activated by an energy source (7), such that said layer develops adhesive properties.

Owner:HOMAG HOLZBEARBEITUNGSSYST

Packaging box production equipment

The invention belongs to machines for manufacturing paper boxes, cartons, envelopes or paper bags, and particularly discloses packaging box production equipment which comprises a machine frame. A diecutting rule, a driving mechanism used for driving the die cutting rule and a placing table for placing materials are arranged on the machine frame, the die cutting rule is located above the placing table, the upper end face of the placing table is provided with a groove matched with the die cutting rule in shape, a filling portion is connected to the interior of the groove in a sliding mode, theshape and size of the filling portion are the same as those of the die cutting rule, a pressing spring is arranged between the filling portion and the bottom face of the groove, an a paper scrap collection mechanism is arranged in the placing table and driven by the filling portion. The problem that when paper boards are subjected die cutting in the prior art, the paper boards cannot be completelycut off is solved.

Owner:重庆漱心斋文化产业发展有限公司

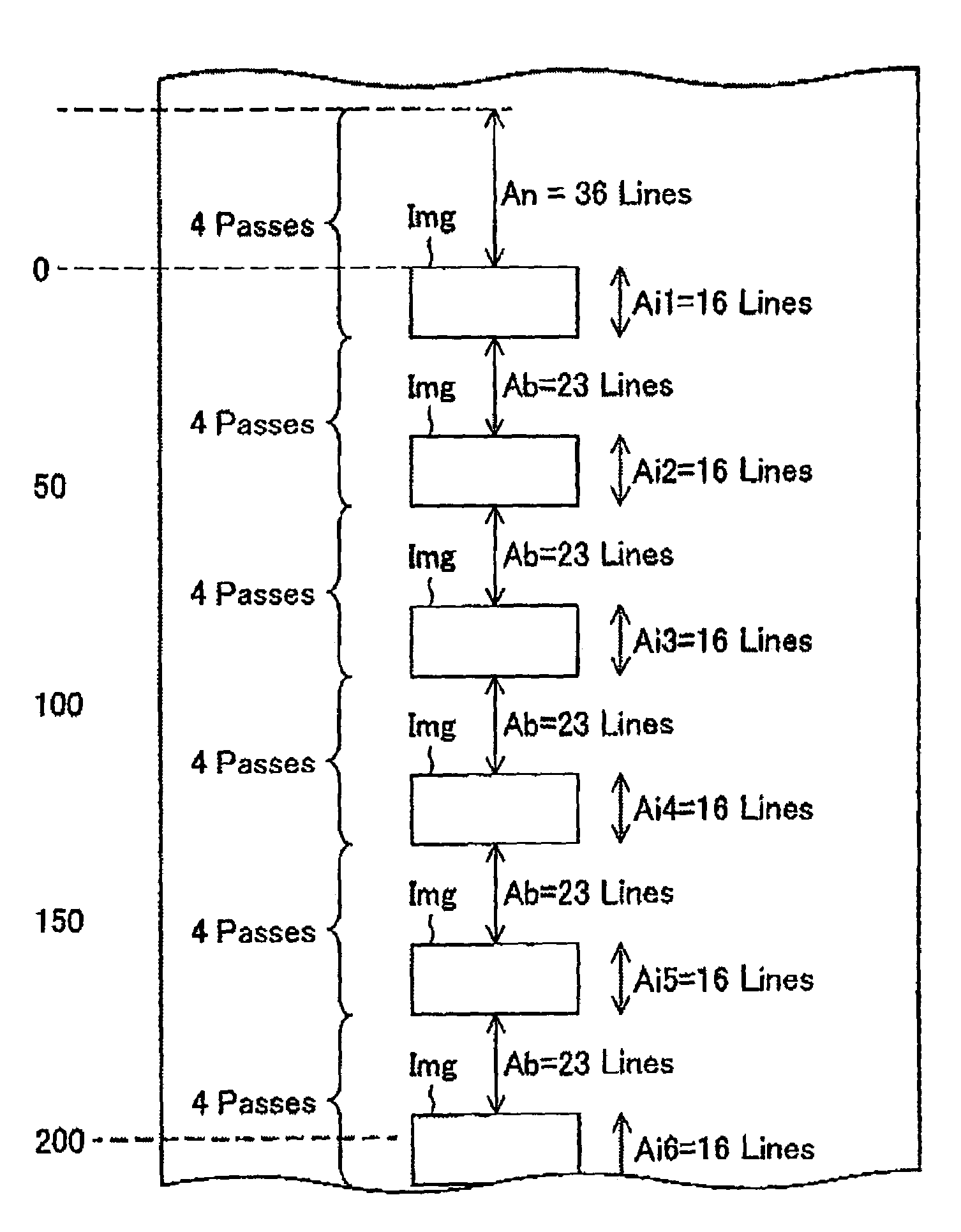

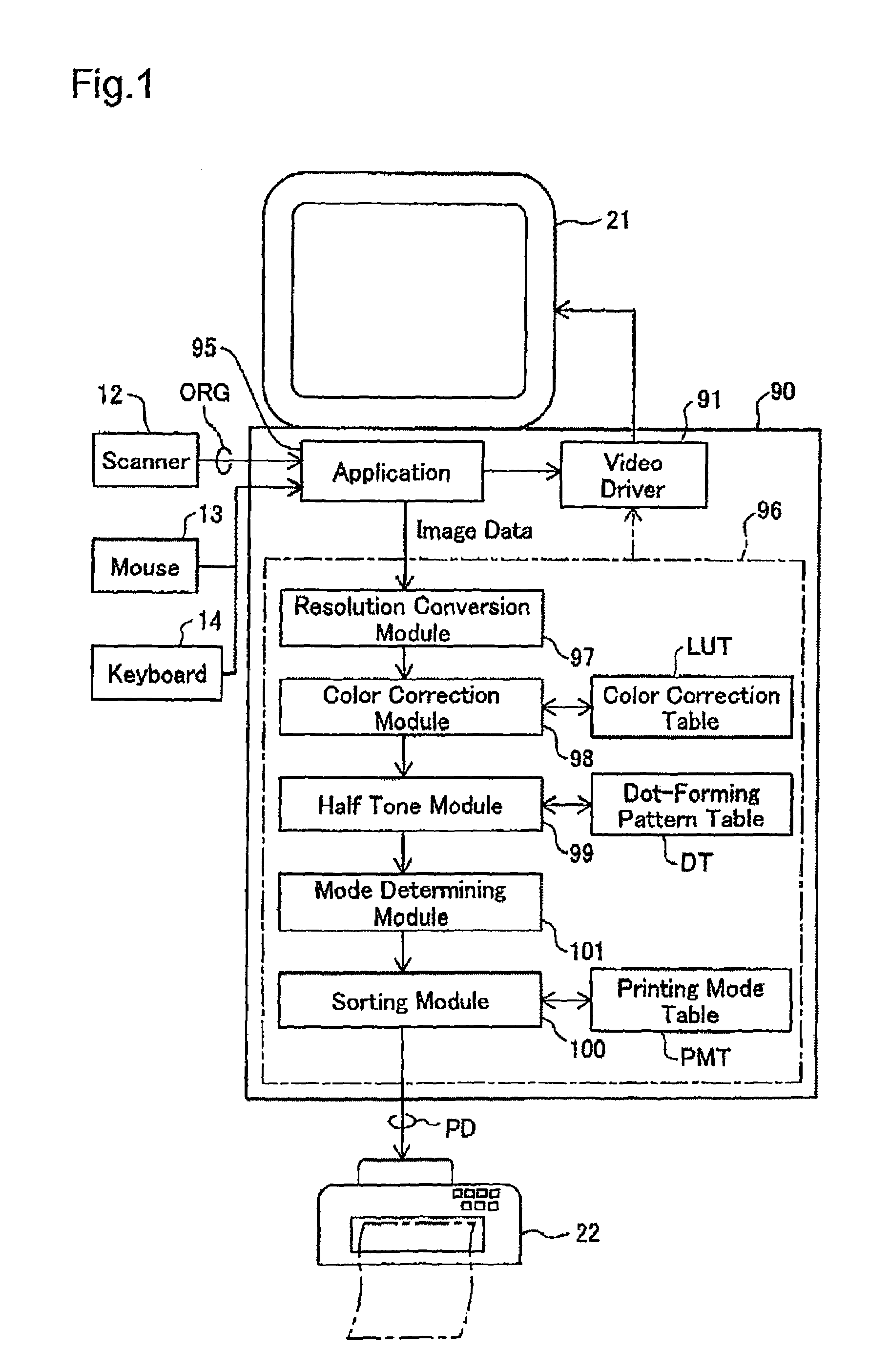

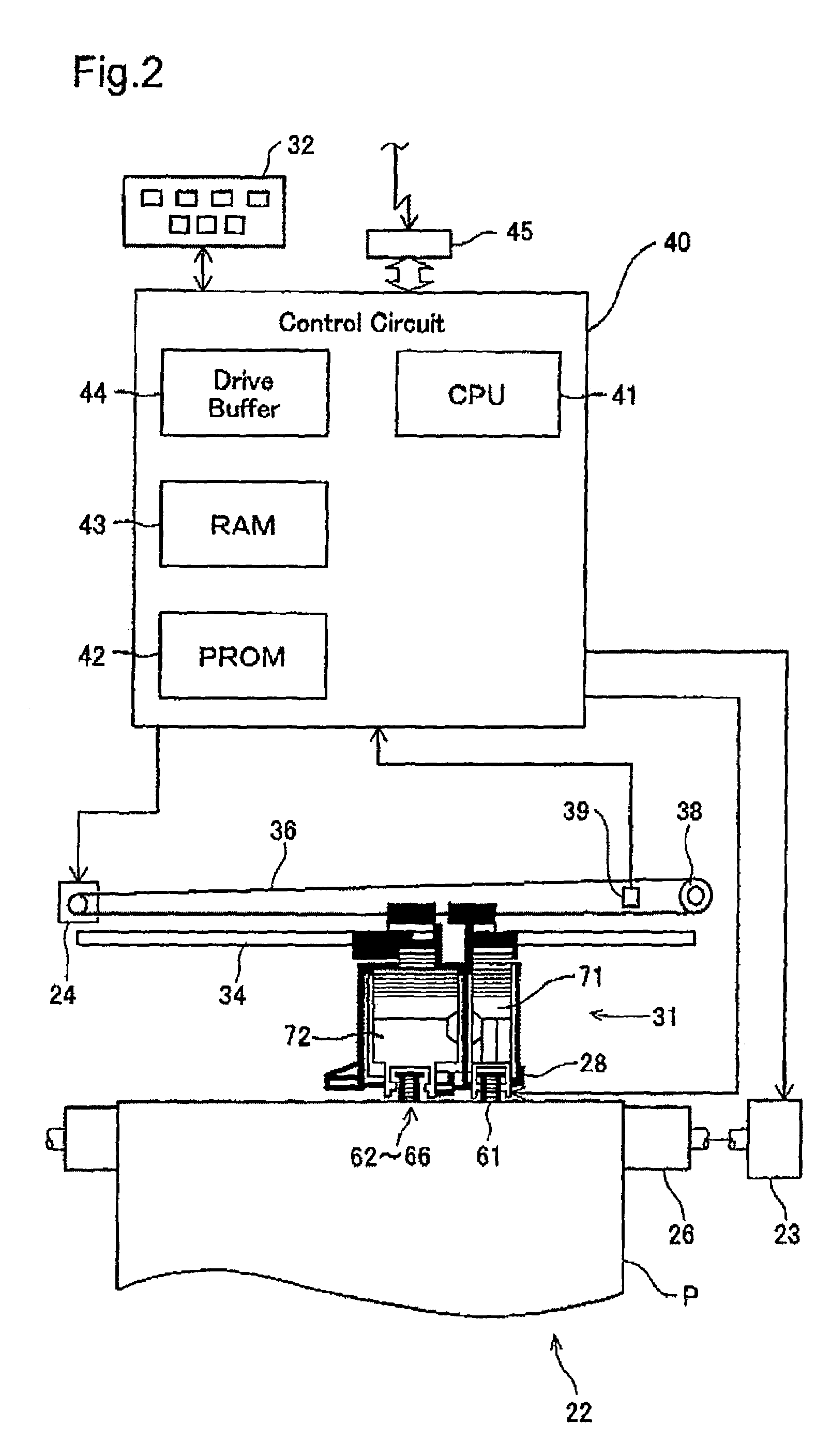

Printing in different modes according to image size

InactiveUS7377606B2Fast printEfficiently printed on printing paperDigitally marking record carriersDigital computer detailsComputer science

Owner:SEIKO EPSON CORP

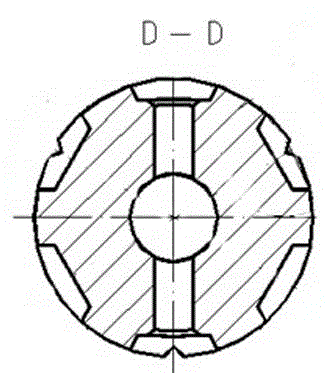

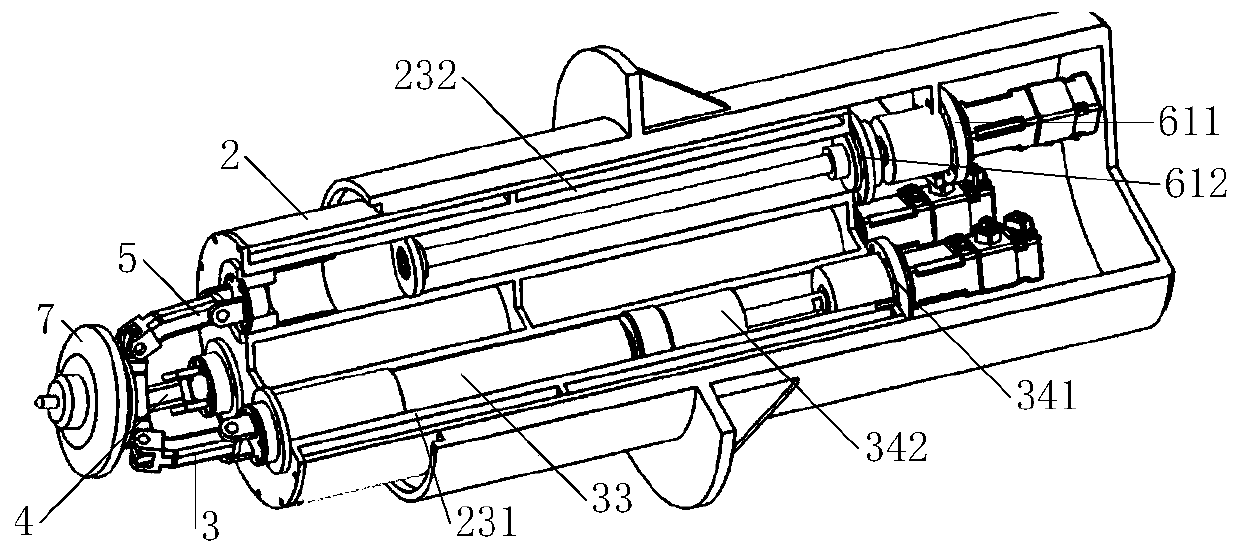

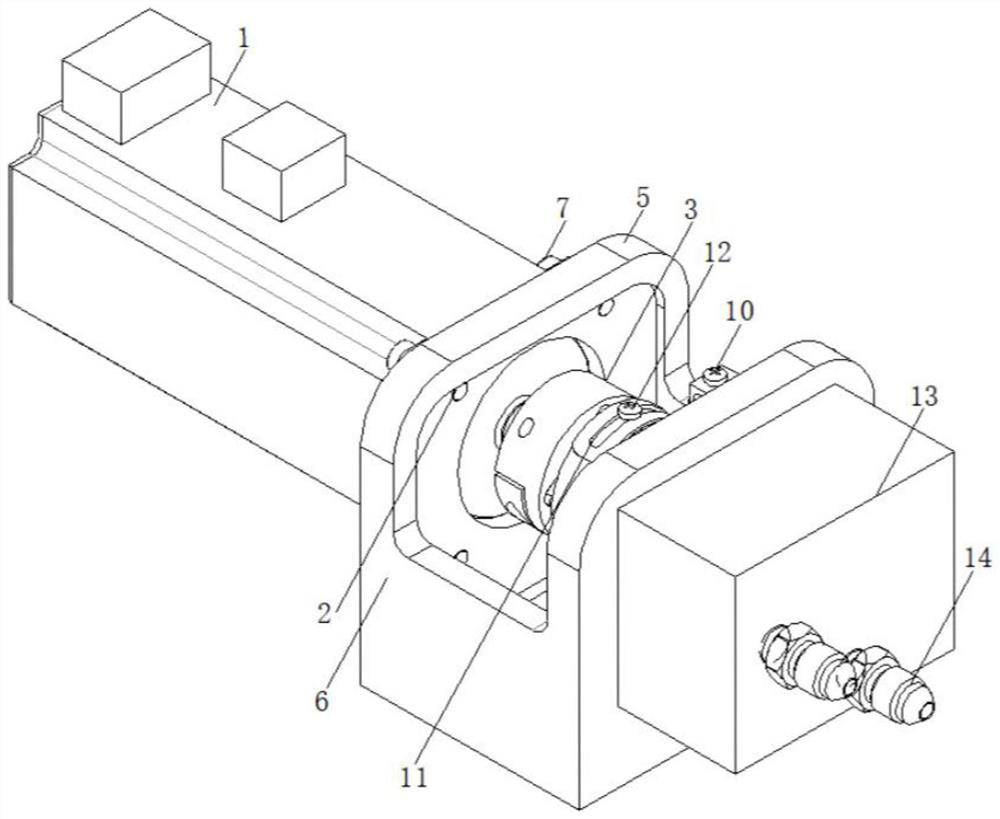

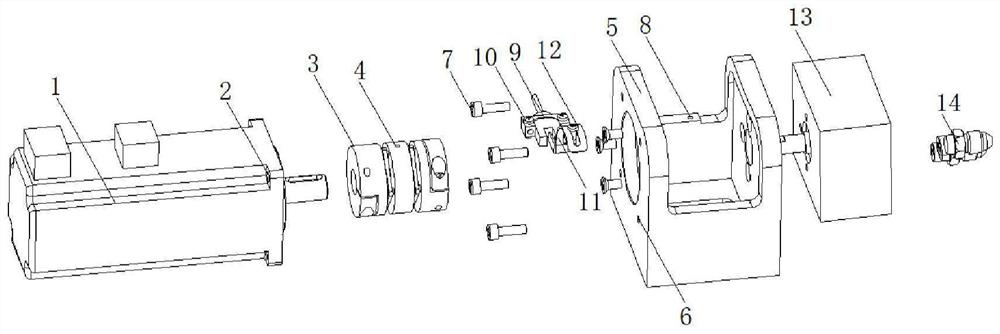

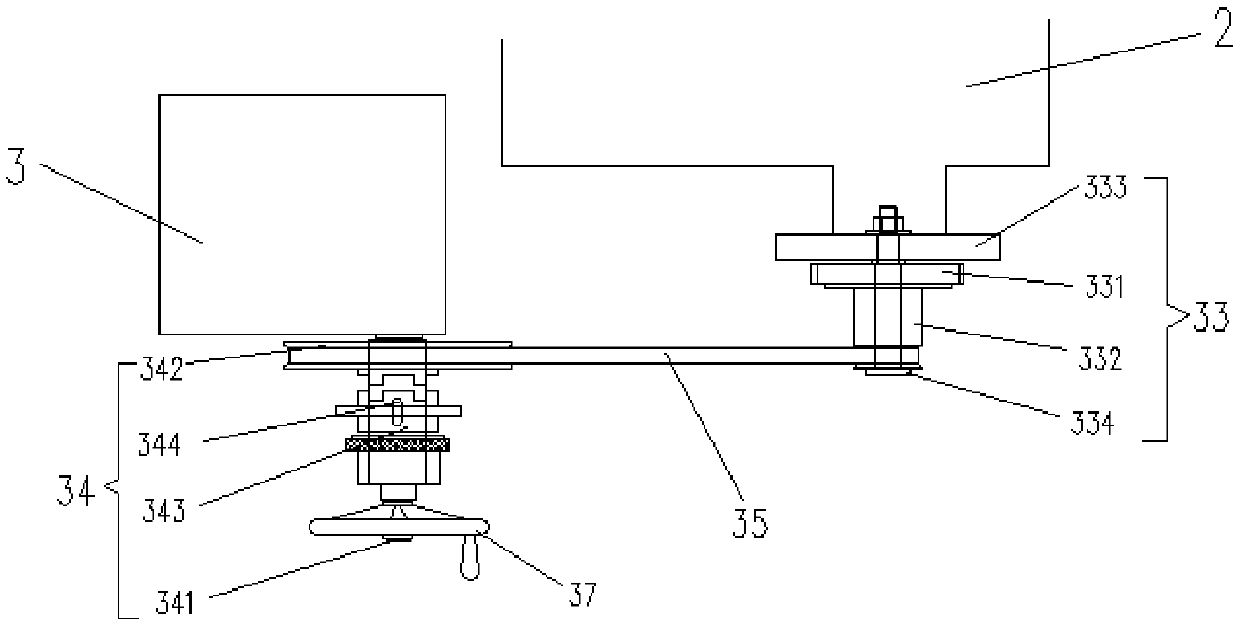

Two-rotation and one-move series-parallel parallel driving swing head mechanism with follow-up constraint

ActiveCN110480600AAvoid singularity problemsFew branchesProgramme-controlled manipulatorEngineeringMachining

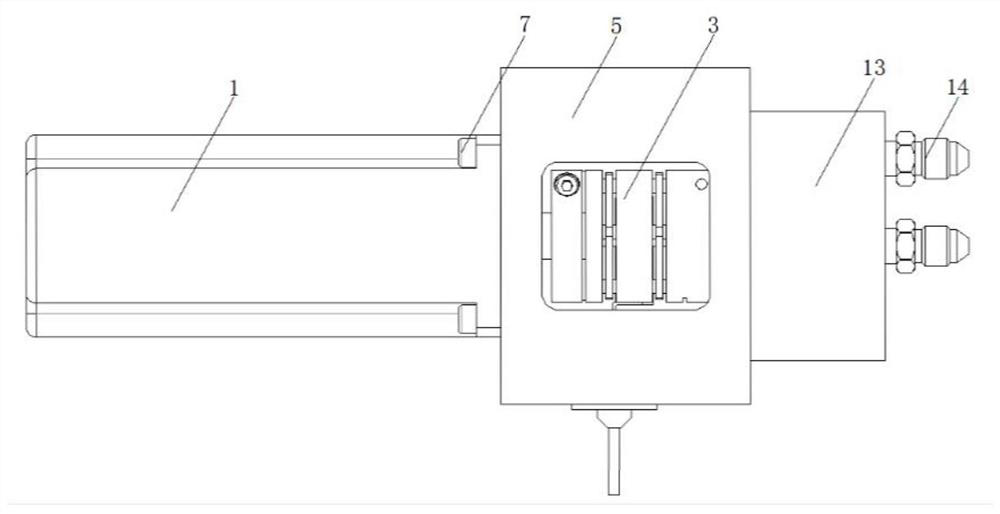

The invention provides a two-rotation and one-move series-parallel parallel driving swing head mechanism with follow-up constraint. The two-rotation and one-move series-parallel parallel driving swinghead mechanism comprises a mounting frame, a stretching-out body, a first stretching-out cylinder, a second stretching-out cylinder, a first linear driving unit, a second linear driving unit, a thirdlinear driving unit, a first connecting rod, a second connecting rod, a third connecting rod, a movable platform and an electric spindle. A parallel connection part of a series-parallel swing head only comprises two main driving branches and one follow-up constraint branch, thus compared with a parallel connection machining head with four or more moving branches, the number of branched chains issmall, and the two-rotation and one-move series-parallel parallel driving swing head mechanism has the characteristics of compact structure, high rigidity, large working space and good dynamic performance.

Owner:YANSHAN UNIV

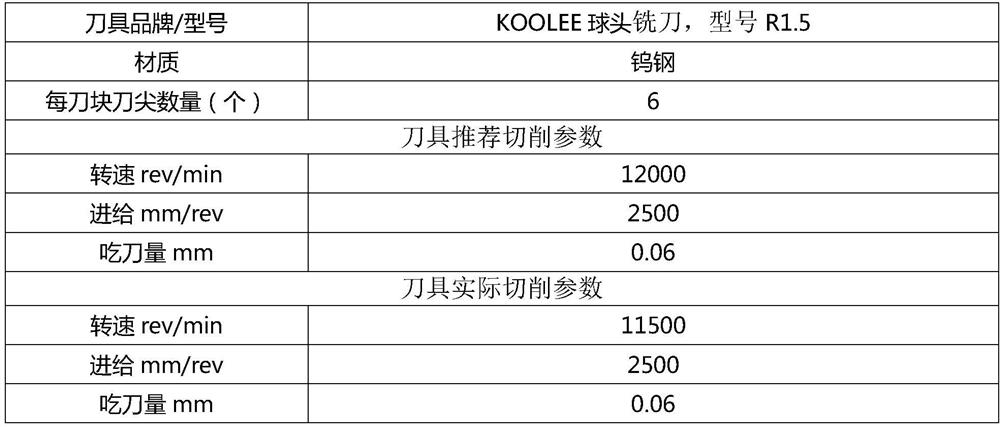

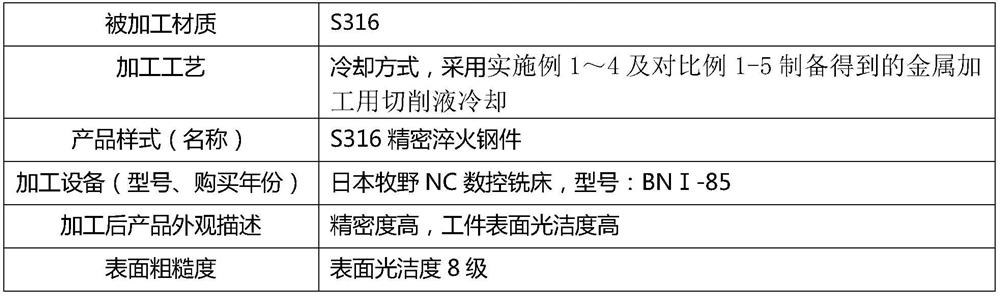

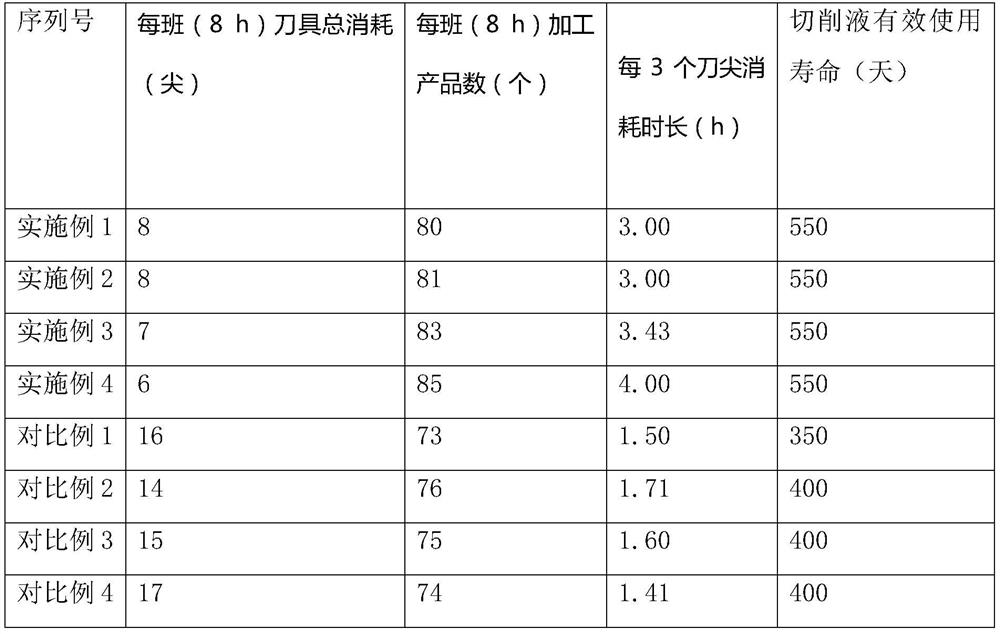

Preparation method of cutting fluid for metal processing

InactiveCN111996066ALarge specific surface areaLow densityLubricant compositionMetal machiningCarbon nanosphere

The invention provides a preparation method of a cutting fluid for metal processing. The preparation method comprises the following steps: firstly, mixing materials; then carrying out three-stage cooling; and finally, putting a formed mixture into a reaction kettle for a reaction. Compared with the preparation process of a traditional cutting fluid, the preparation method of the cutting fluid comprises the two extra steps of three-stage cooling and reaction in the reaction kettle; graphene, hollow carbon nanospheres and ceramic micro-powder are subjected to three-stage cooling, a mixed solution having undergone the three-stage cooled is put into the reaction kettle for the reaction, and under the combined action of three-stage cooling and the stirring reaction of the reaction kettle, uniform dispersion of the graphene, the hollow carbon nanospheres and the ceramic micro-powder in the cutting fluid can be promoted; and meanwhile, covalent bonds are formed among all the components of thecutting fluid, so the cooling and lubricating properties of the cutting fluid are further improved, the feeding amount of a cutter can be increased, machining precision and quality are improved, theservice life of the cutter is finally prolonged, the possibility of cutter breaking and blade breaking is greatly reduced, and production cost can be reduced.

Owner:NANNING COLLEGE FOR VOCATIONAL TECH

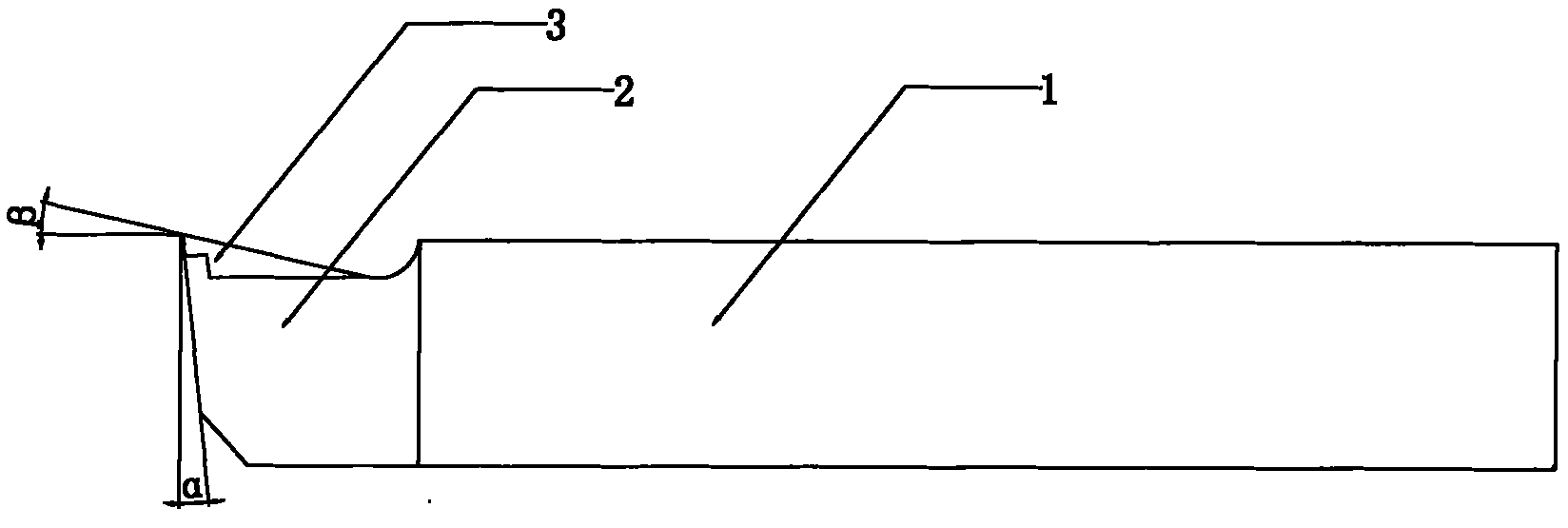

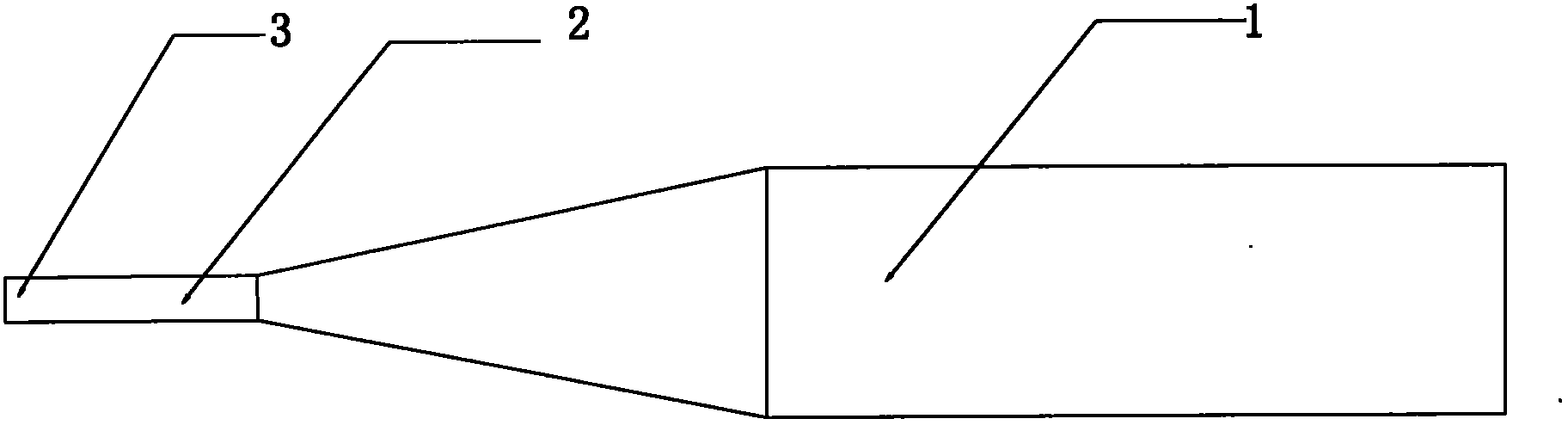

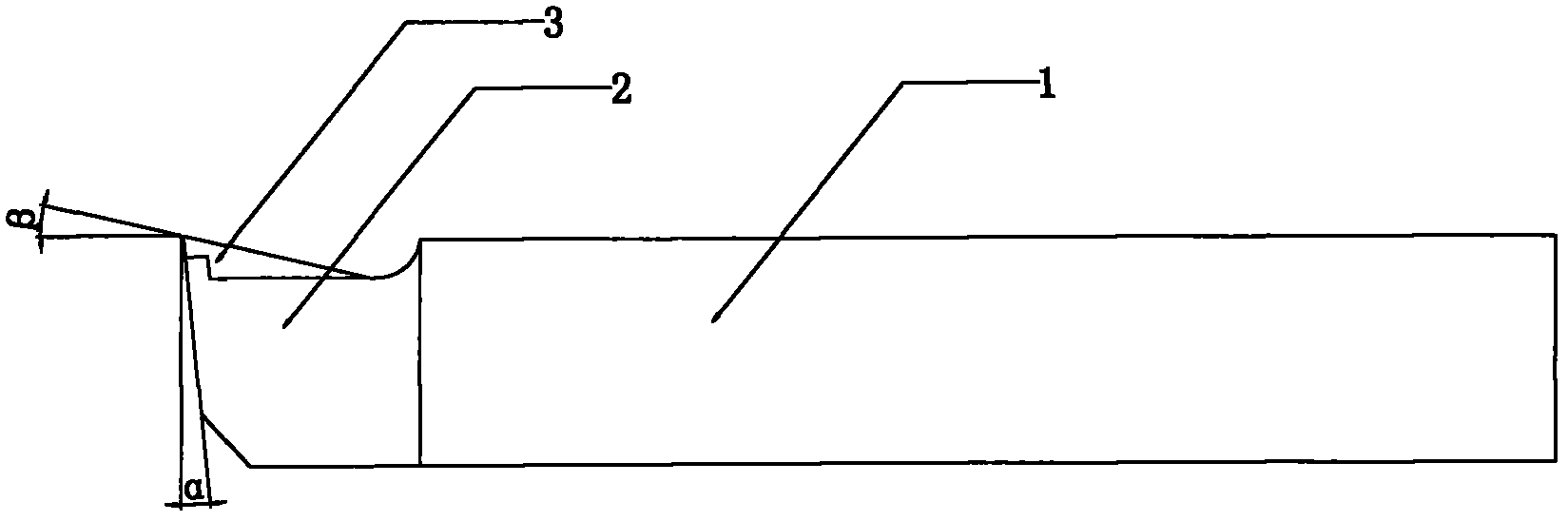

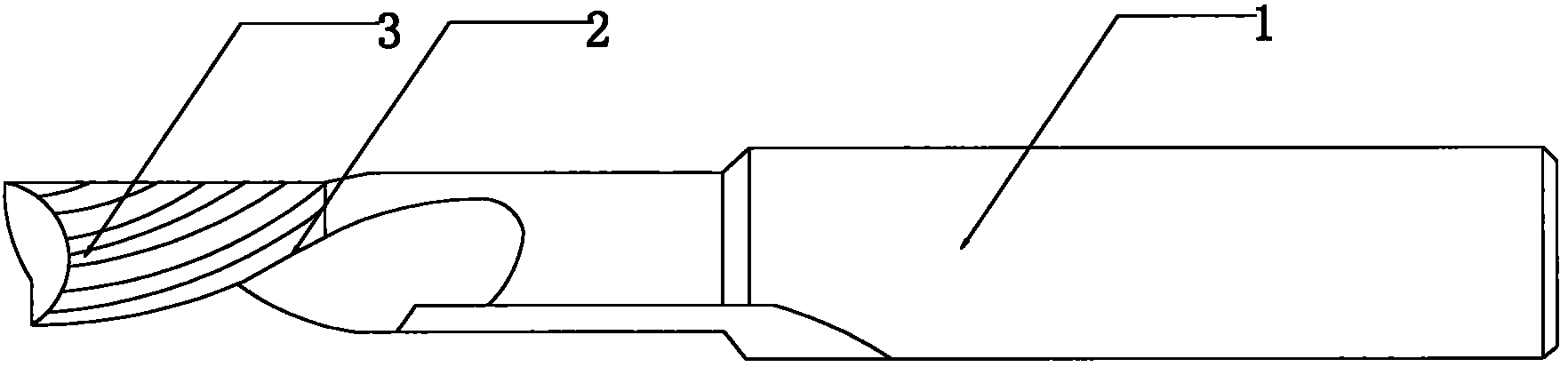

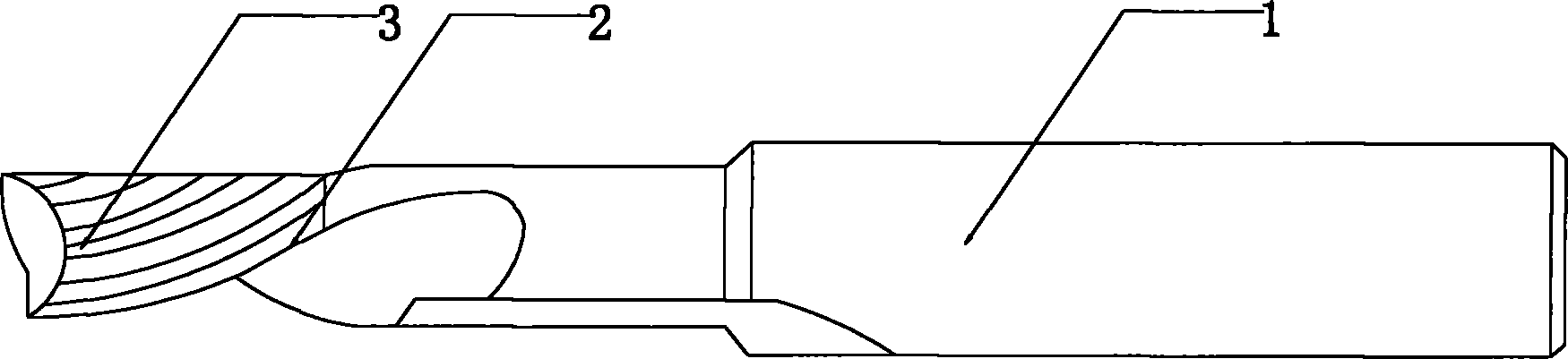

End-cut turning tool

InactiveCN102380628AStrong cutting forceReduce collision forceTurning toolsTool bitMechanical engineering

The invention relates to an end-cut turning tool, comprising a tool bar and a tool bit, wherein the front end of the tool bar is triangular, the tool bit is fixedly connected with the front end of the tool bar, and a cutting edge is arranged on the tool bit. The end-cut turning tool is characterized in that the width of the tool bit is 0.2-4mm, a certain included angle is formed between the front end face of the tool bit and a horizontal plane, and an included angle between a plane, on which the cutting edge is located, and the horizontal plane is 10-40 degrees. The end-cut turning tool disclosed by the invention has the advantages of large feed amount, high cutting efficiency and long service life.

Owner:龚晓建

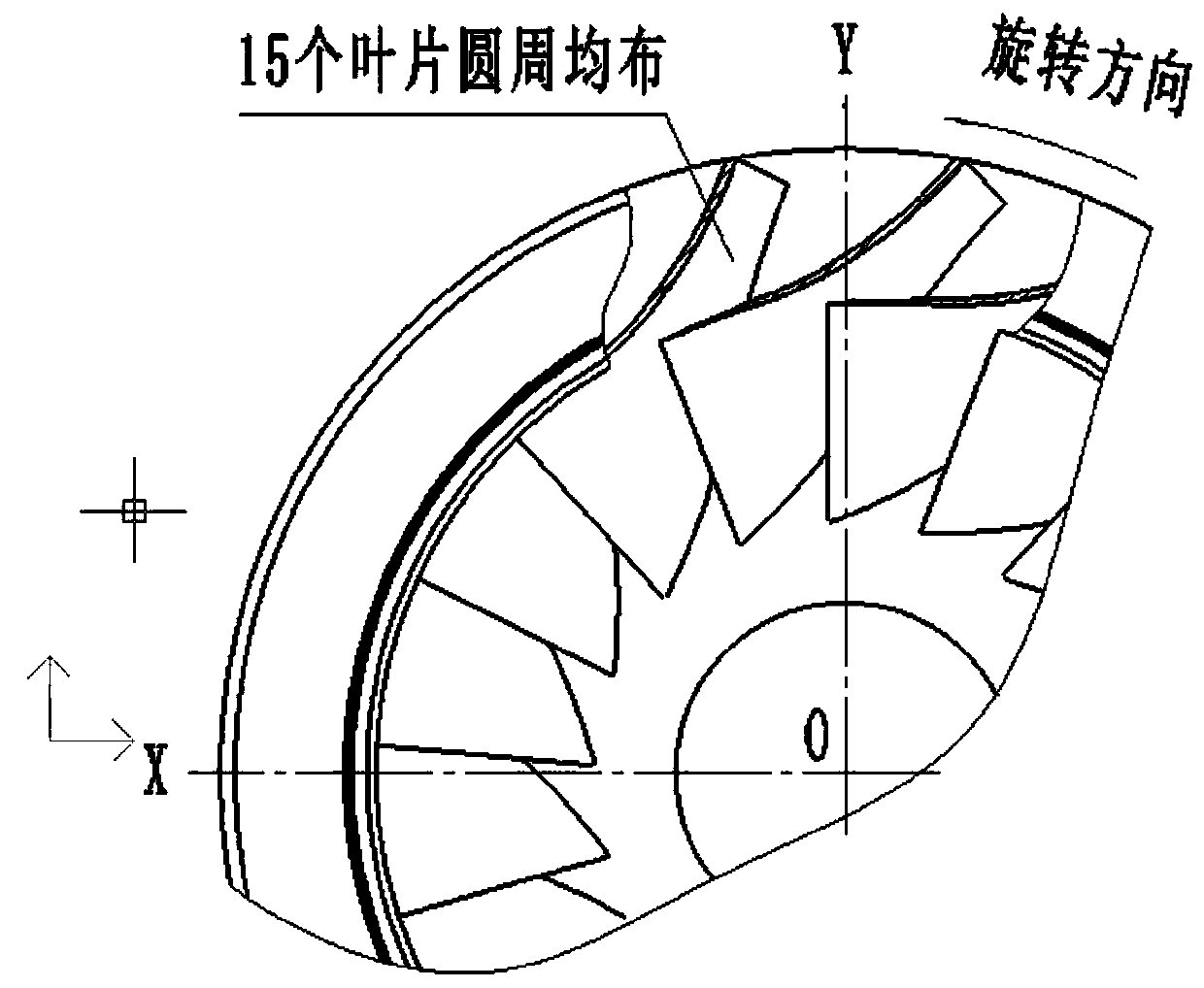

Method for finish machining of three-dimensional impeller made of FV520B material through integral hard alloy cutters

The invention provides a method for finish machining of a three-dimensional impeller made of an FV520B material through integral hard alloy cutters. The method comprises the steps that after rough machining is carried out on a three-dimensional impeller blank milled by a shaft disc, it is required that the machining allowance of 0.7-1 mm is reserved on the single side of each blade; root cleaningis carried out on rounded corners of the blades, front round heads of the blades are subjected to finish machining, and a hub of the impeller is subjected to finish machining; semi-finish machining iscarried out on the blades by using the long-bladed taper ball integral hard alloy corrugated milling cutter, and the finish machining allowance of 0.2-0.5 mm is reserved on the single side of each blade; and finish machining is carried out on the blades by using the long-bladed taper ball integral hard alloy milling cutter, and the thickness of the blades is machined to a designed sizes. The method for finish machining of the three-dimensional impeller made of the FV520B material through the integral hard alloy cutters is high in machining efficiency and good in economic benefit.

Owner:SHENYANG TURBO MASCH CORP

Large-sized environmental-friendly vertical multi-functional three-dimensional numerical control carving machine

InactiveCN106926624ALarge feedFlexible engravingModel makingEnvironmental resistanceNumerical control

The present invention provides a large-scale environment-friendly vertical multifunctional three-dimensional numerical control engraving machine. As an improvement to the existing large-scale engraving machine, the feed amount of the Z-axis engraving distance from the central axis is increased, and the distance between the engraving tool of Z and the central axis is increased by Y. The crossbeam replaces the front and back moving feed, the Z feed stroke moves within the width of the column, and the Y beam has a self-weight of about 3 tons, so that it moves back and forth to cut large-scale carving blanks (up to 3 meters high * 3 meters wide or more) compared with the current market. The machine has good stability, high precision, superior mechanical strength and speed, and the processing speed is increased by about 3-5 times. When cutting the blank, combined with NC control multi-axis programming post-processing path, the excess material of the blank is divided into blocks After cutting, the remaining materials are used for secondary processing and utilization, and there is also a purification pool to purify sewage for recycling, so as to avoid water pollution and waste of water resources. The invention not only reduces noise and dust pollution, but also makes the whole more perfect.

Owner:储晓东

Clamp

The invention discloses a clamp, the existing clamp is difficult to meet the using requirements of leading a guide rod to realize big-step feeding in neutral gear and obtaining greater clamping force during clamping, a fixed clamp body of the clamp comprises a grab handle which extends to the end which is not fixed with a clamping head and a fixed supporting part, a force application handle is arranged by corresponding to the grab handle, and a force application part for pushing a force application clamping piece, a first fulcrum part which is farther away from the force application part and a second fulcrum part which is nearer to the force application part are arranged on the force application handle, wherein an elastic element is connected between the first fulcrum part and the fixed clamp body, and the second fulcrum part is arranged by corresponding to the fixed supporting part. The clamp can lead the force application handle to act by taking the first fulcrum part as the fulcrumin the neutral gear, thereby leading the force application part of the force application handle to obtain a greater amount of feeding and realizing fast feeding; and the clamp can further lead the force application handle to act by taking the second fulcrum part as the fulcrum during clamping, thereby leading the force application part of the force application handle to obtain the greater clamping force.

Owner:HANGZHOU UNITED ELECTRIC MFG CO LTD

Novel shaping machine

ActiveCN106583811AMain motion stabilitySmooth motionMilling machinesFeeding apparatusGear wheelMilling cutter

A novel shaping machine comprises a base, a machine body, a workbench, a main movement mechanism and a workbench feeding mechanism; the main movement mechanism comprises a ram fixedly mounted on the machine body, a first motor arranged at the upper end of the ram and a boring and milling spindle grinding head arranged at the front end of the ram; a synchronous transmission device is arranged between the first motor and the boring and milling spindle grinding head; a milling cutter disk is arranged at the bottom end of the boring and milling spindle grinding head; and the workbench feeding mechanism comprises a gear transmission mechanism arranged on the machine body and a belt pulley transmission mechanism, one end of the belt pulley transmission mechanism is arranged on the machine body, and the other end of the belt pulley transmission mechanism is arranged on the workbench. The main movement mechanism and the workbench feeding mechanism of the shaping machine are two completely independent mechanisms, main movement and feeding movement of the shaping machine are conducted simultaneously, and the machining efficiency is improved; and the main movement mechanism of the shaping machine is fixed on the machine body, so that the main movement of the shaping machine is relatively stable, and the machining precision is improved.

Owner:安庆安帝技益精机有限公司

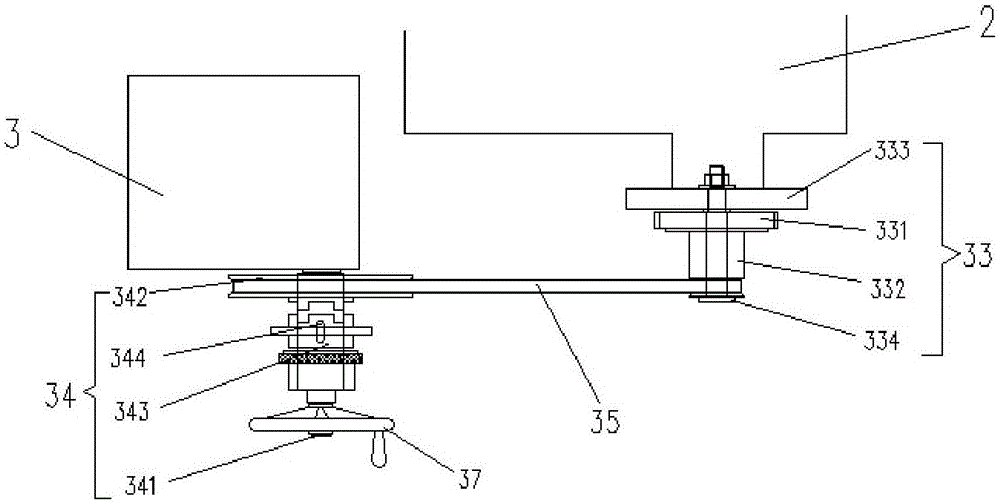

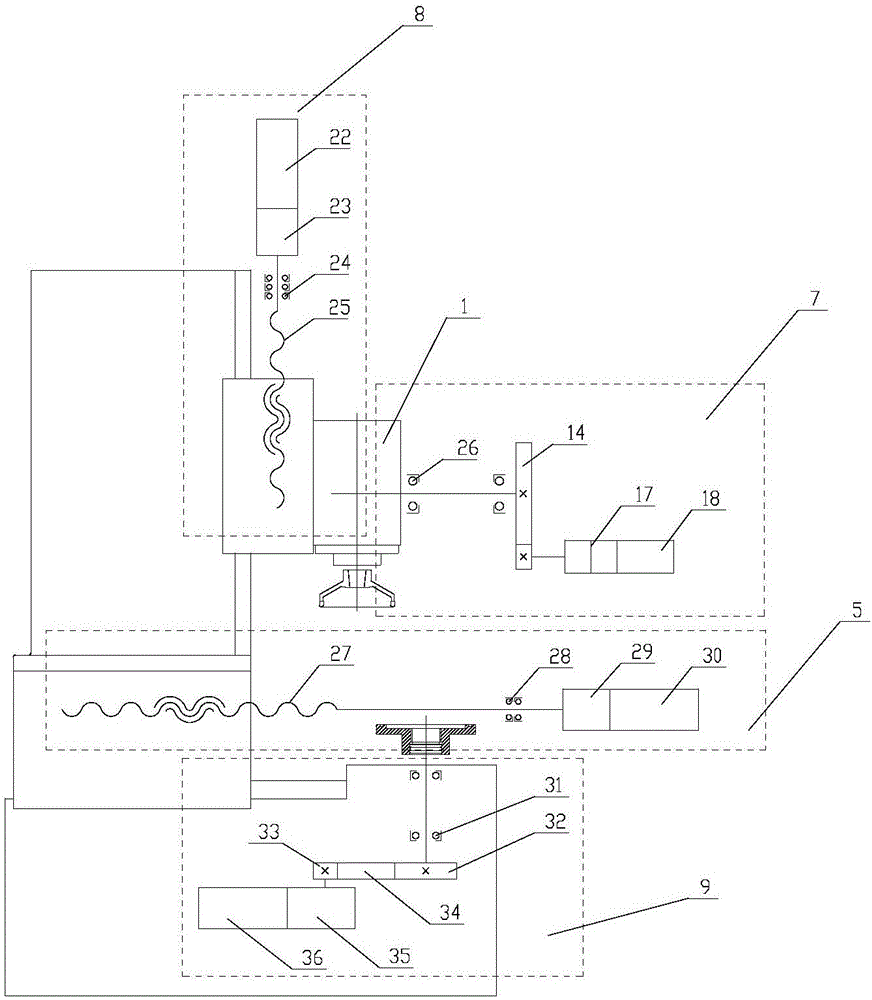

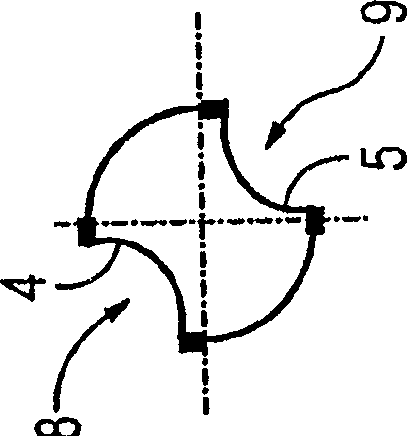

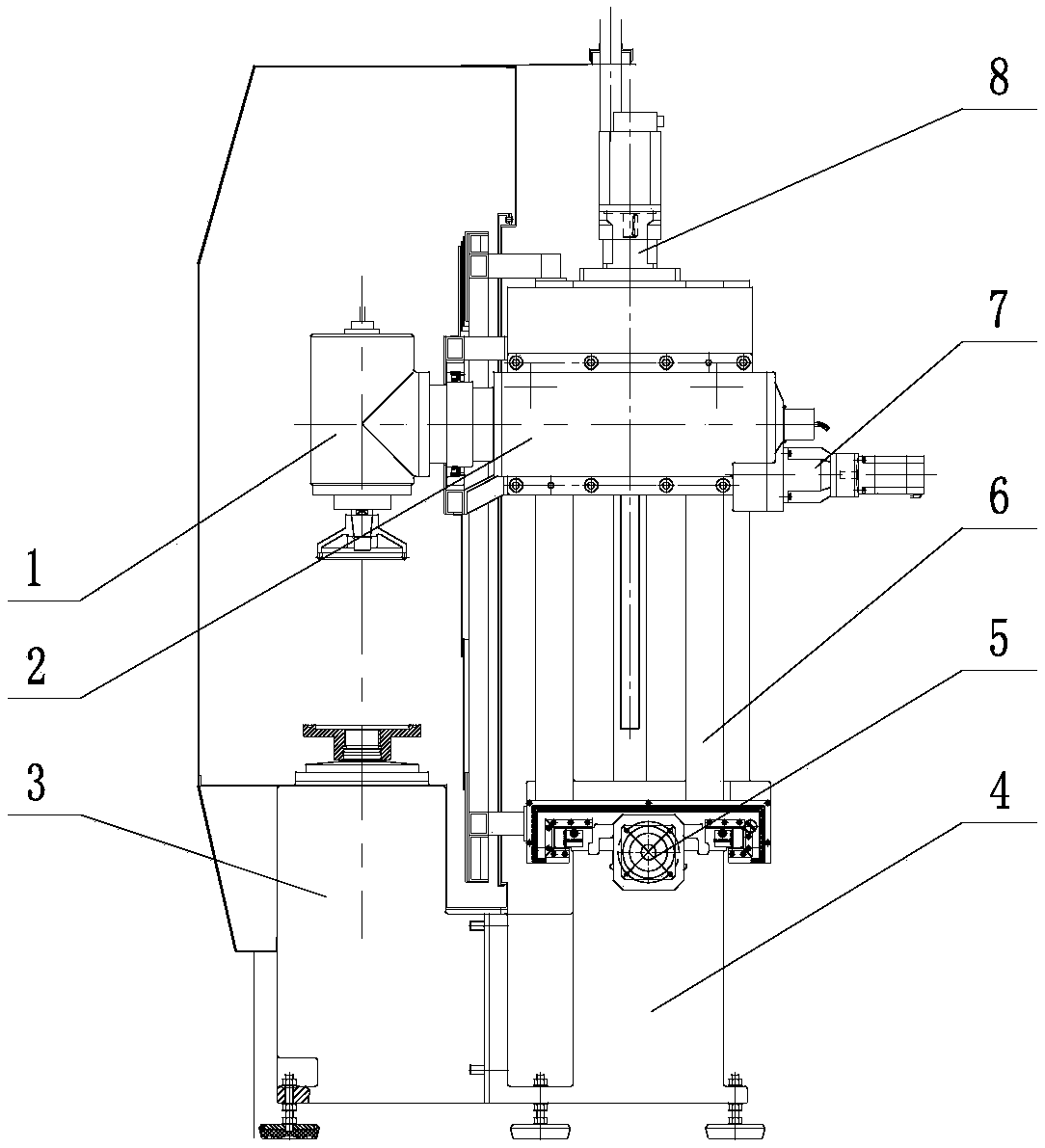

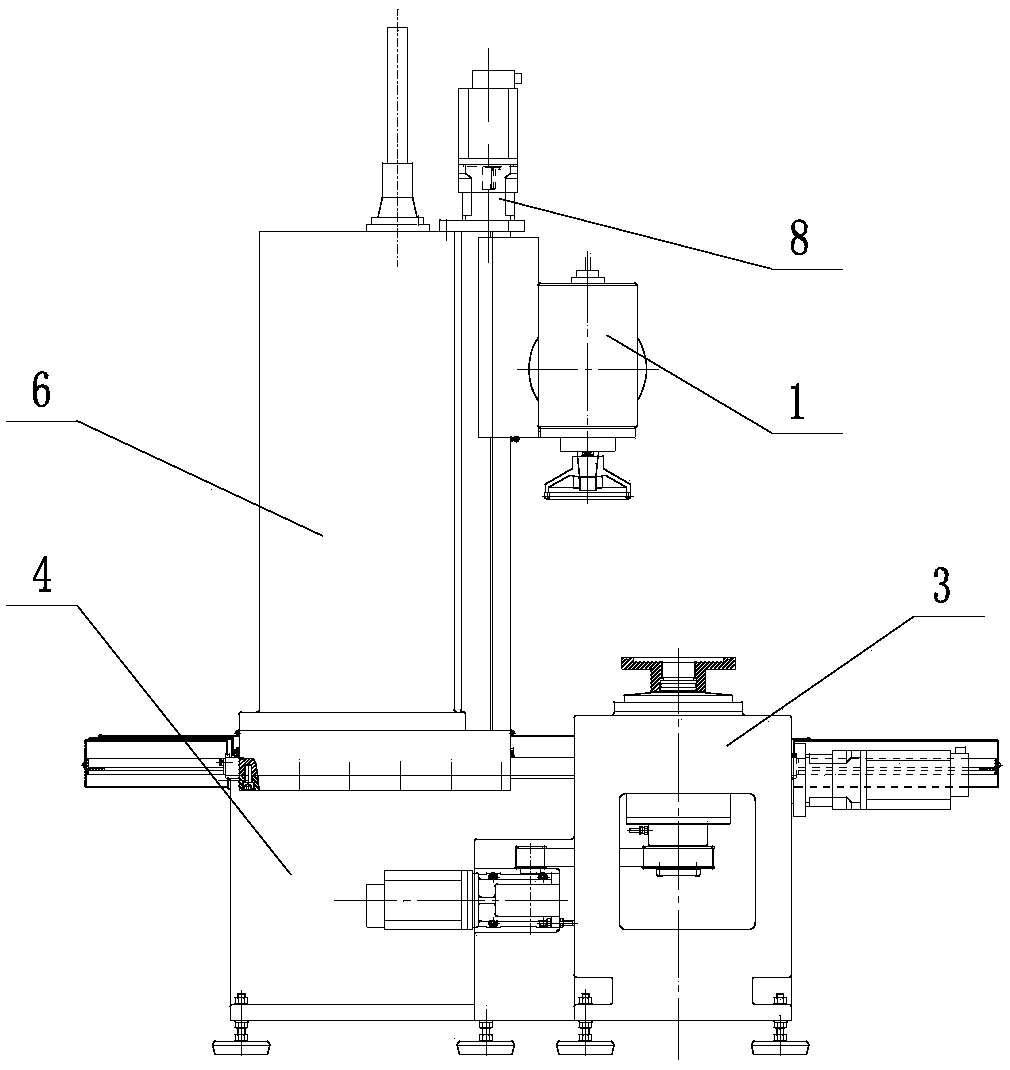

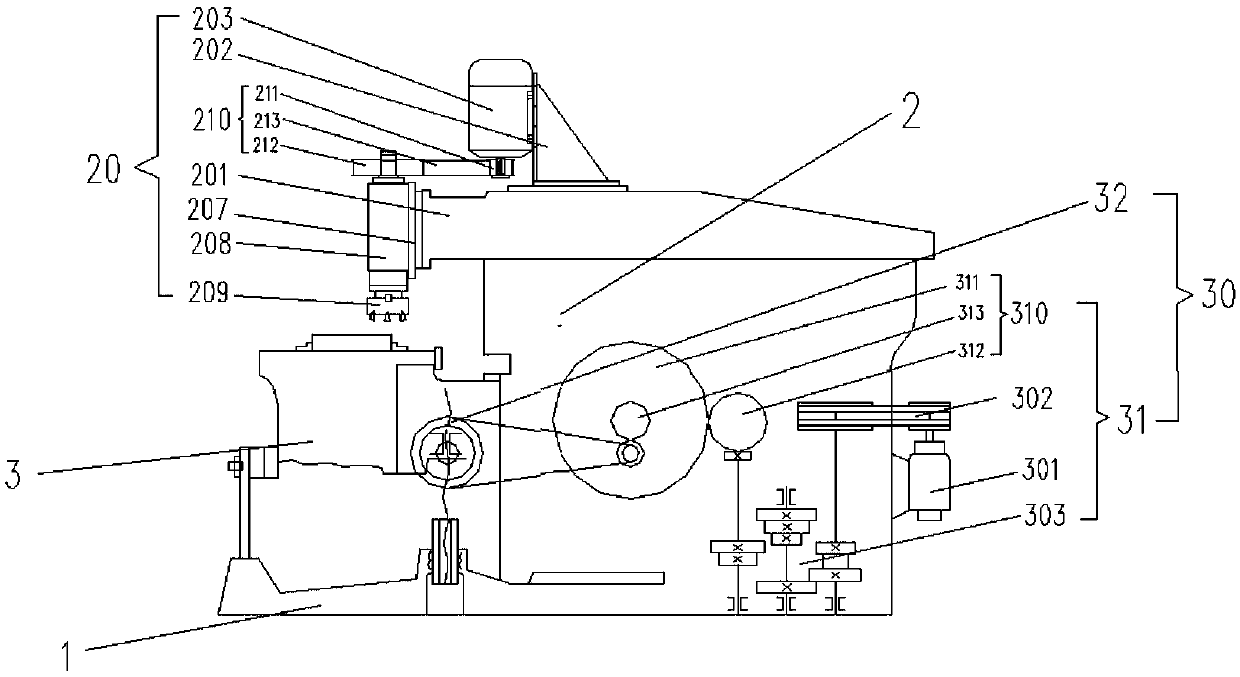

Numerically-controlled pendulum shaft milling-grinding machine tool

ActiveCN106425752AImprove rigidityImprove processing efficiencyGrinding carriagesGrinding drivesEngineeringMachine tool

The invention relates to a numerically-controlled pendulum shaft milling-grinding machine tool, and mainly solves the problems of low machining efficiency and instable accuracy during machining for large-diameter optical lenses, of an existing milling-grinding machine tool. The numerically-controlled pendulum shaft milling-grinding machine tool is characterized in that a pendulum shaft drive mechanism (7) and a vertical feeding mechanism (8) are connected to a milling-grinding head (1); and a horizontal feeding mechanism (5) and a rotary drive mechanism (9) are arranged on a workbench (3) respectively. The numerically-controlled pendulum shaft milling-grinding machine tool is high in rigidity, and capable of increasing the feeding amount on the basis of ensuring machining accuracy, thus increasing the machining efficiency and improving the machining accuracy of the machine tool.

Owner:齐齐哈尔孟维机床制造有限公司

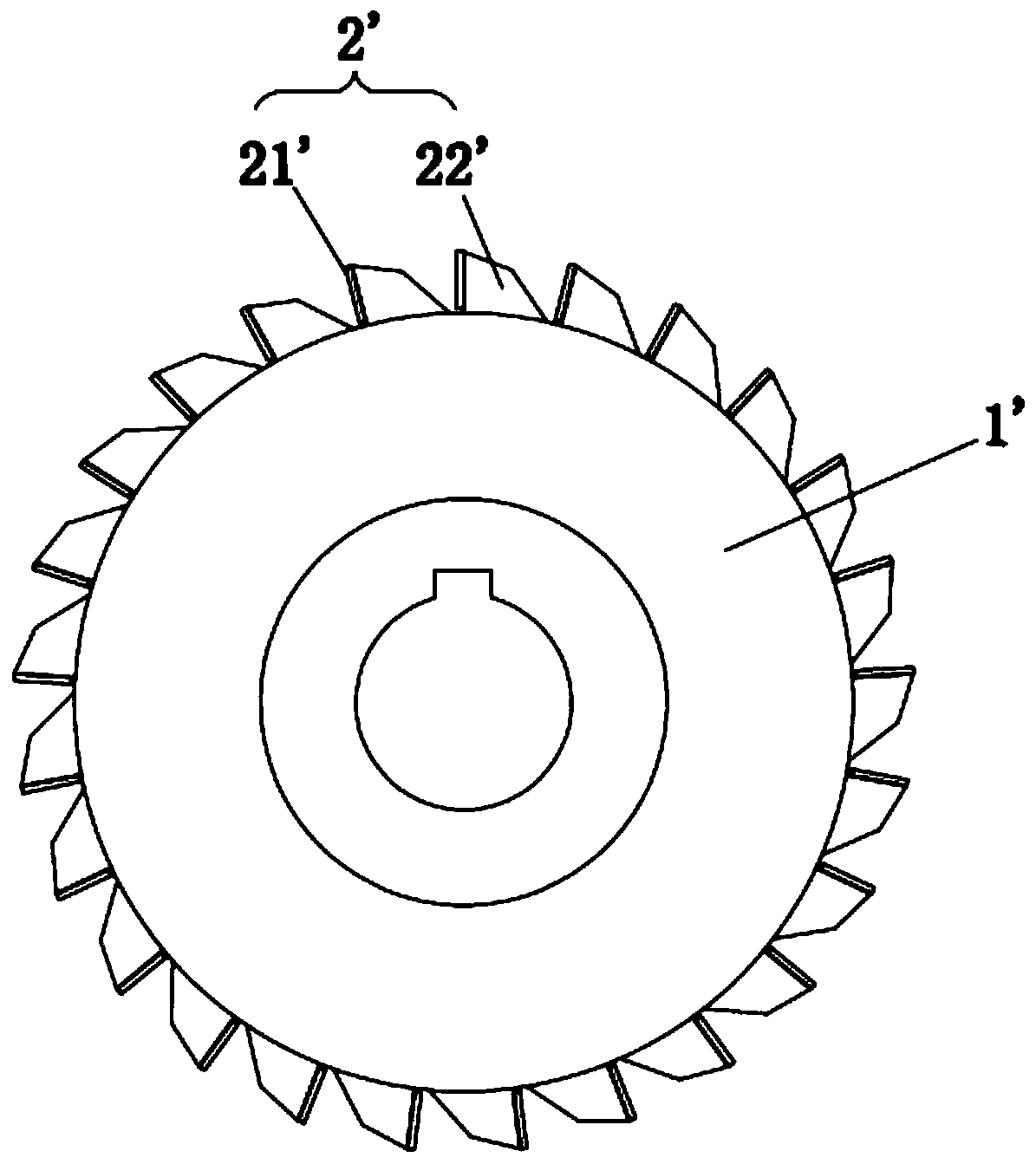

Milling cutter

The invention relates to a milling cutter, comprising a cutter handle and a cutter bit. The milling cutter is characterized in that the cutter bit is of a hollow spiral structure, and a plurality of spiral grooves are formed on the surface of the cutter bit. The milling cutter provided by the invention is light and quick for cutting, large in feed amount and good in chip discharging effect.

Owner:陈晓花

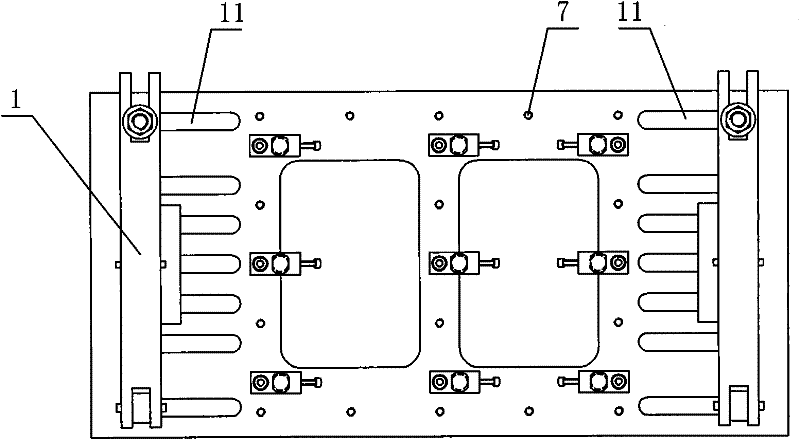

Method for machining vane of graphite vane pump and special clamp thereof

ActiveCN107639755AEasy to fixEffective clampingWorking accessoriesFine working devicesEngineeringGraphite

The invention discloses a method for machining a vane of a graphite vane pump. The method comprises a step (1) of cutting, a step (2) of ablaengen, a step (3) of location hole drilling, a step (4) ofslitting, a step (5) of polishing and a step (6) of slicing. According to the method, vane machining precision can be ensured, the machining cycle is shortened, production efficiency is improved, andthe rate of finished products is high. In addition, the invention further discloses a special sawing machine clamp and a special milling machine clamp used by the machining method. The special sawingmachine clamp has very high adsorption capacity, and it is ensured that a graphite strip unit does not move in the process of forming the graphite strip unit; and by adopting the special milling machine clamp, a plurality of vanes can be machined, and machining efficiency is improved.

Owner:深圳市石金科技股份有限公司

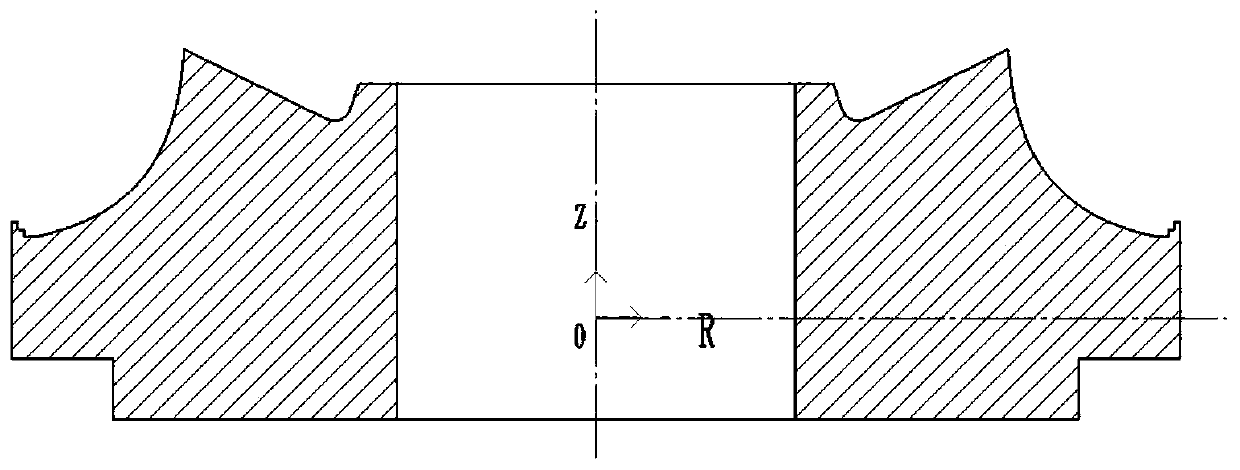

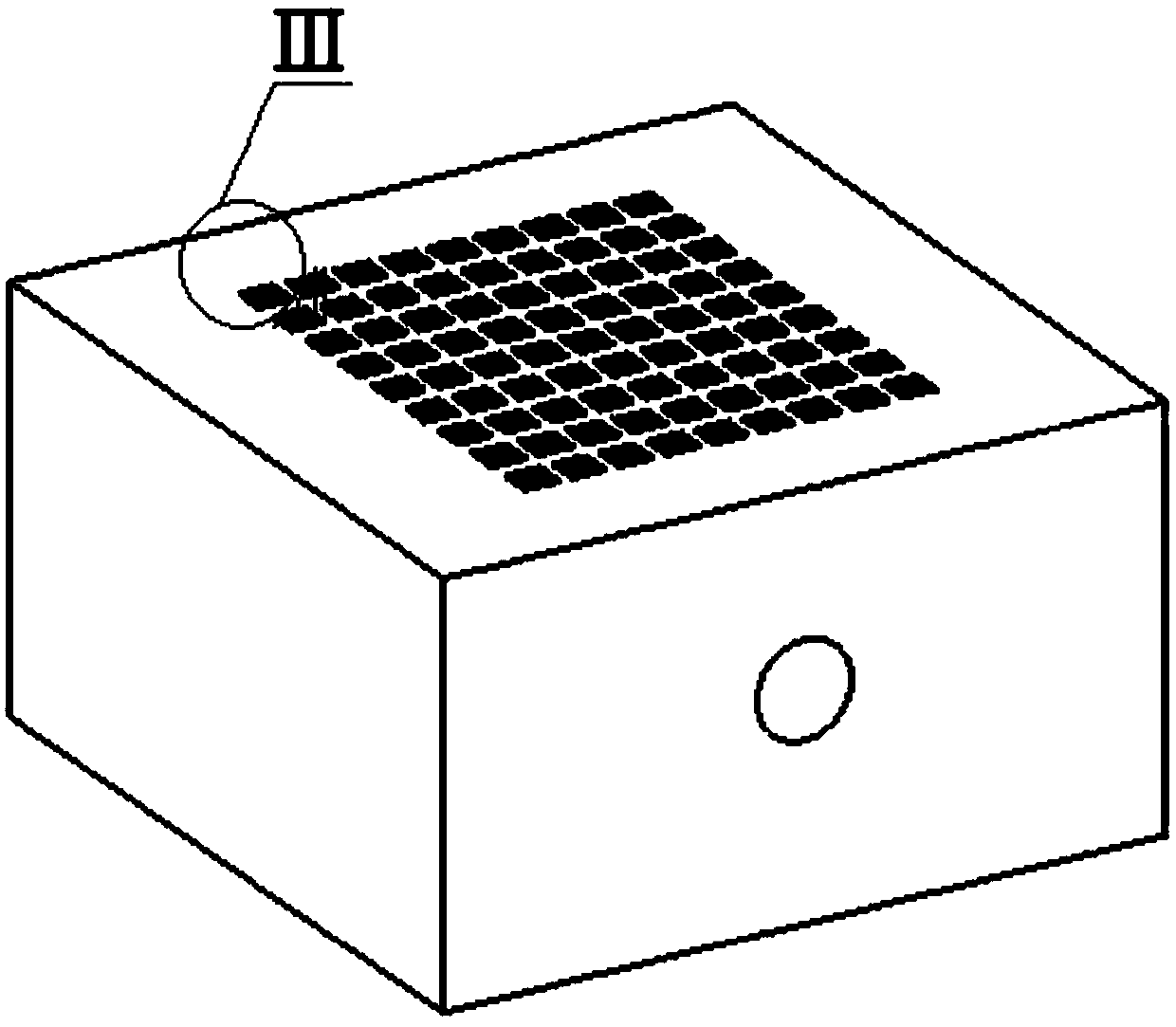

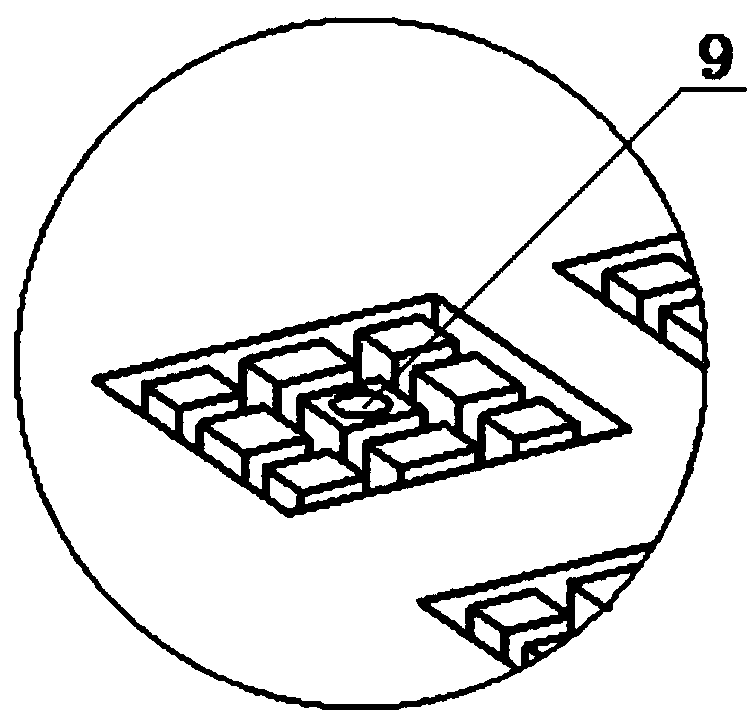

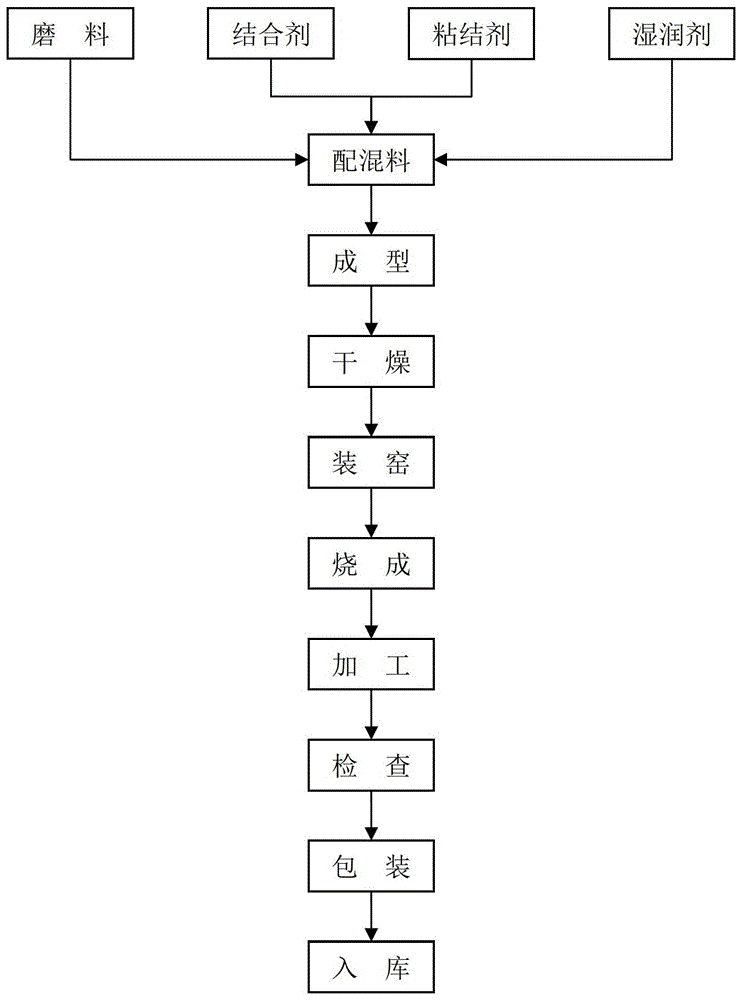

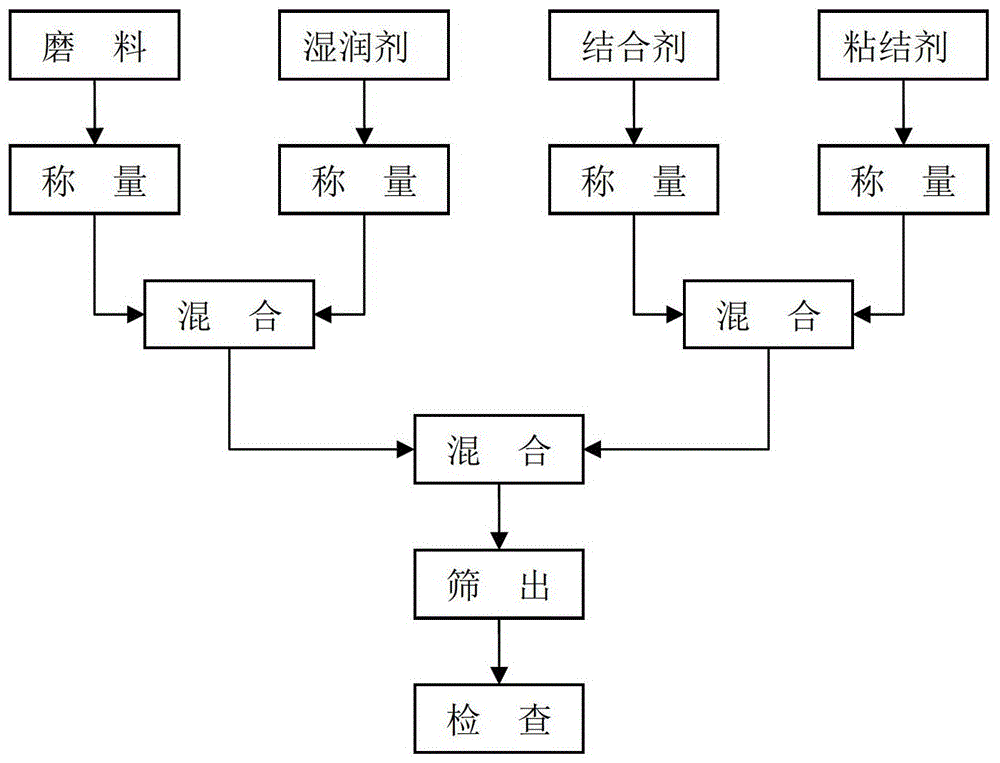

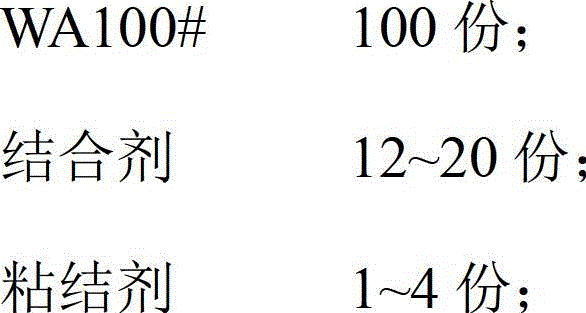

Ceramic microcrystalline abrasive gear grinding wheel and processing method thereof

ActiveCN103862393BHigh strengthImprove grinding efficiencyAbrasion apparatusGrinding devicesGear grindingVolumetric Mass Density

The invention specifically relates to a ceramic crystallite abrasive gear grinding wheel and a processing method thereof. The ceramic crystallite abrasive gear grinding wheel is characterized in that a central enhancement part comprises the following raw material components in parts by weight: 100 parts of WA100, 12-20 parts of binding agent, 1-4 parts of adhesion agent and 3-6 parts of wetting agent, wherein the forming density is 2.1-2.3kg / cu.cm.; a grinding using part comprises the following raw material components in parts by weight: 10-50 parts of CA60-120, 50-90 parts of WA60-120, 8-18 parts of binding agent, 1-4 parts of adhesion agent and 2-6 parts of wetting agent, wherein the forming density is 2.06-2.28kg / cu.cm., the adhesion agent is dextrin, and the wetting agent is maltose. The processing method is characterized by comprising the following steps: 1) mixing; 2) forming; 3) drying; 4) sintering. The ceramic crystallite abrasive gear grinding wheel and the processing method have the advantages of high grinding wheel strength, good well-closed formation, large amount of feed, high grinding efficiency, high grinding precision and low production cost.

Owner:山东鲁信四砂泰山磨具有限公司

Intelligent speed adjusting system for automatically adjusting feeding speed according to material saw cutting face

InactiveCN111618364ATime-consuming and laborious to solveSolve the problem that the speed cannot be adjusted accuratelyMetal sawing devicesAutomatic control devicesCouplingControl engineering

The invention discloses an intelligent speed adjusting system for automatically adjusting the feeding speed according to a material saw cutting face, and relates to the field of intelligent speed adjusting systems. For the problems that according to an existing turning sawing machine speed adjusting system, manual speed adjustment is manually conducted, time and labor are wasted, and accurate speed adjusting cannot be achieved, the following scheme is provided at present, the intelligent speed adjusting system comprises a servo motor, a plurality of first bolt holes are formed in the right side face of the servo motor, a coupler is fixedly connected to the output end of the servo motor, second bolt holes are formed in the upper surface of the coupler, a speed adjusting device installing base is arranged on the right side of the servo motor, the left side face of the speed adjusting device installing base is provided with a plurality of third bolt holes, first bolts are arranged on theright sides of the first bolt holes, a plurality of fourth bolt holes are formed in the upper side and the rear side of the speed adjusting device installing base, and a photoelectric sensor is arranged in the speed adjusting device installing base. According to the device, the service life of a saw belt is prolonged, and the saw cutting efficiency is improved.

Owner:浙江奥林发机床有限公司

Device used for machining end face cam

The invention discloses a device used for machining an end face cam. By means of the device, the position of a working table can be adjusted. The device comprises a worm shaft driven through power. The worm shaft drives a worm wheel shaft to rotate through a worm and a worm wheel. The worm wheel shaft is sued for driving the end face cam to rotate. A driving gear is arranged on the worm shaft and drives a transverse lead screw to rotate through driven gears which are sequentially meshed with one another. The transverse lead screw is connected with a nut in a threaded manner. The nut is fixed to the bottom of a transverse slide plate which is guided in the transverse direction through a slide block on the upper portion of a vertical slide plate. The vertical slide plate is arranged on a vertical guide rail. A limiting block abutting against the side face of a longitudinal slide plate is fixed to the end of the transverse lead screw. A guide column is fixed to the upper portion of the transverse slide plate and located in an arc-shaped groove of an inclined ruler. The arc top of the arc-shaped groove faces one side of the end face cam. The inclined ruler is located on the upper portion of the transverse slide plate. The side, away from the end face cam, of the inclined ruler is hinged to one end of a threaded rod which is connected to a horizontal base in a threaded manner. A handle is arranged at the other end of the threaded rod.

Owner:重庆市合川区均恒金属加工厂

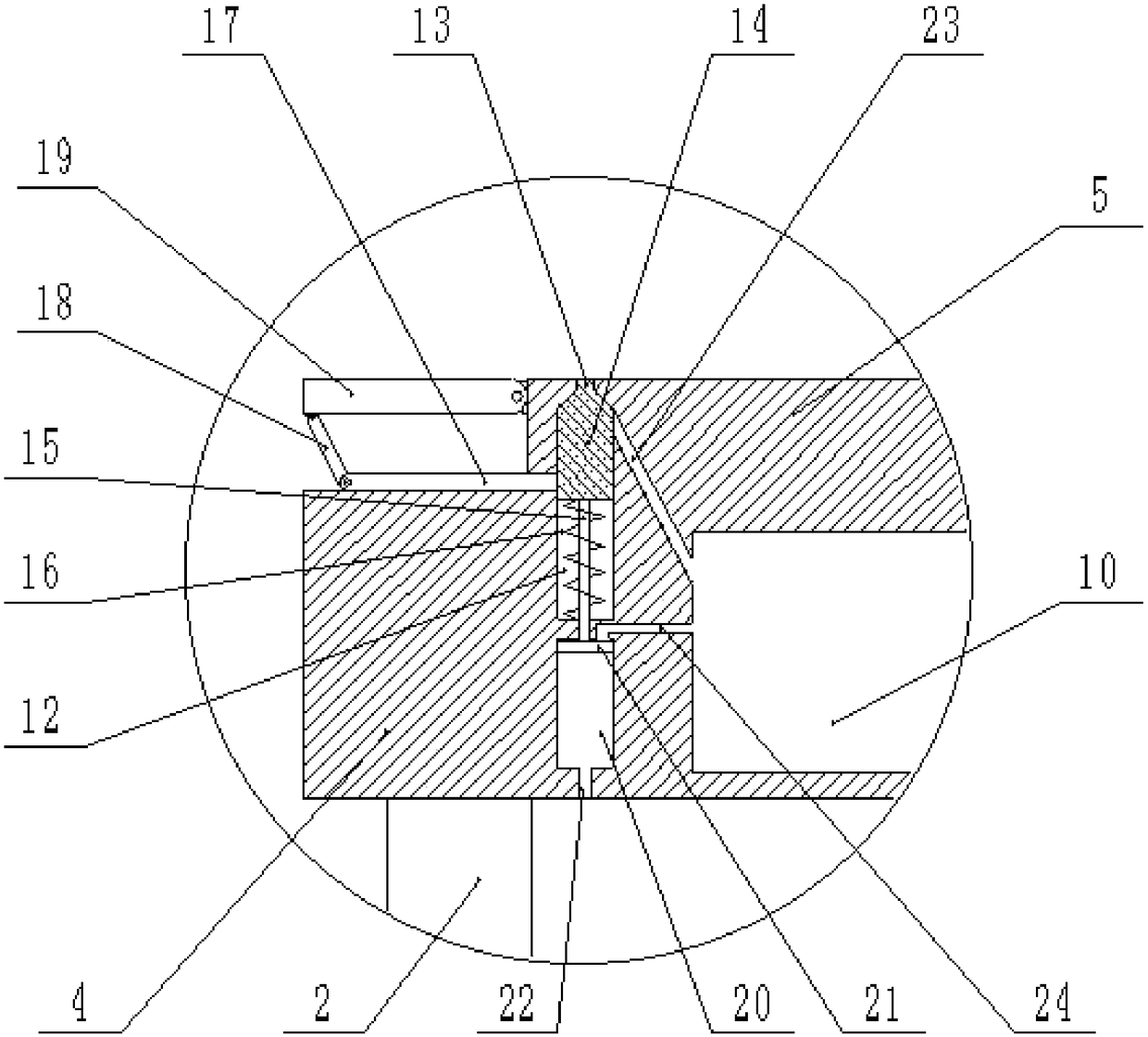

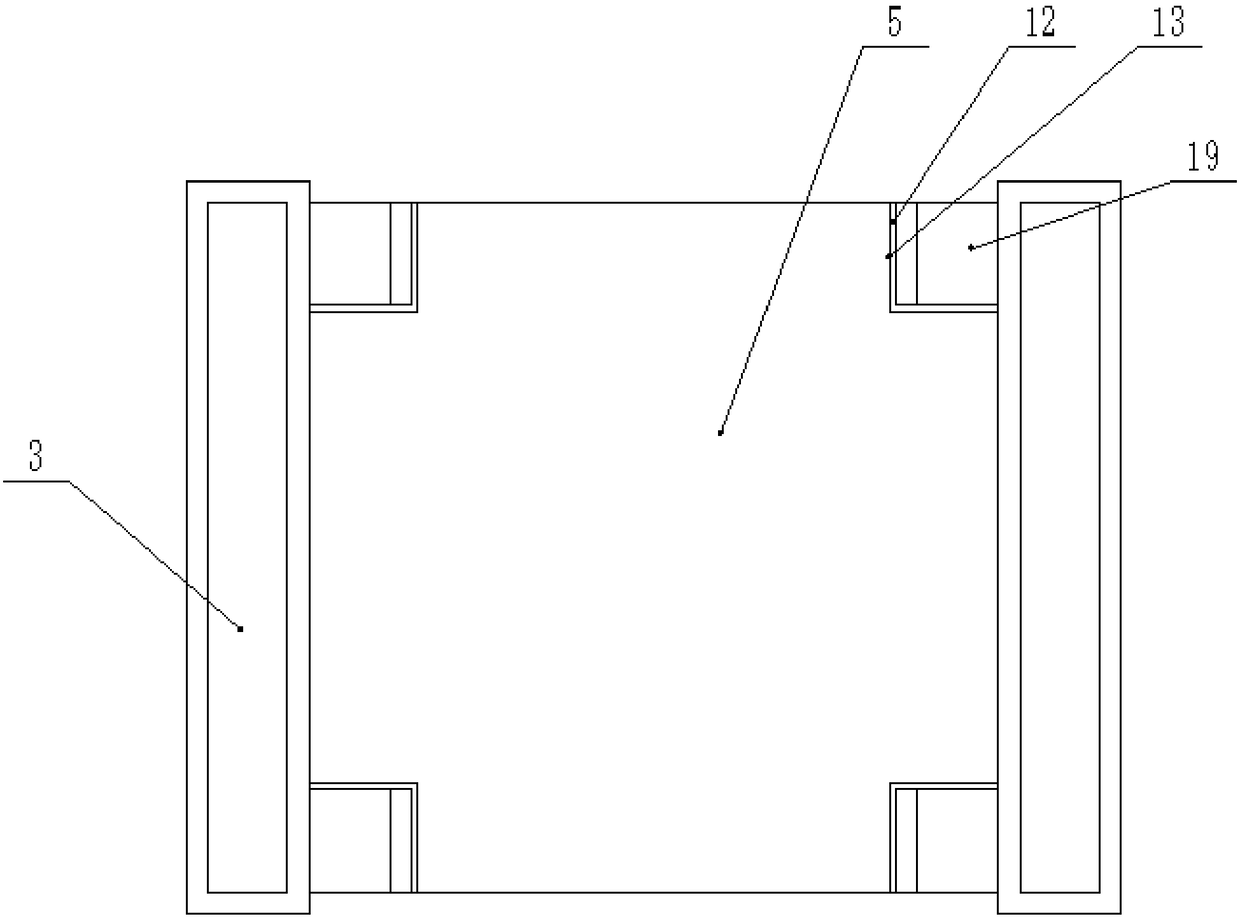

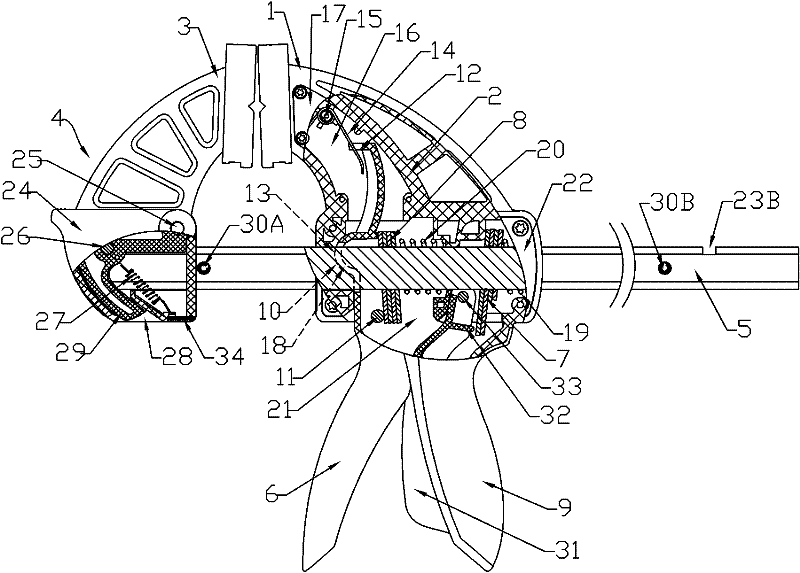

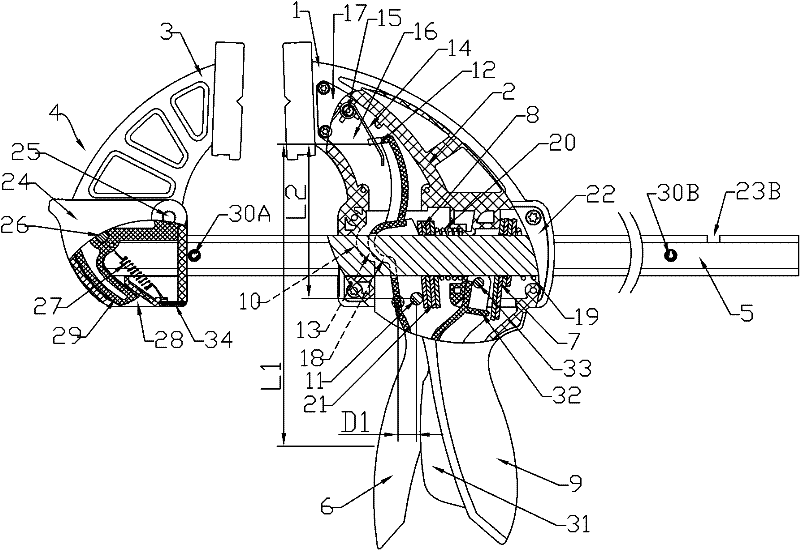

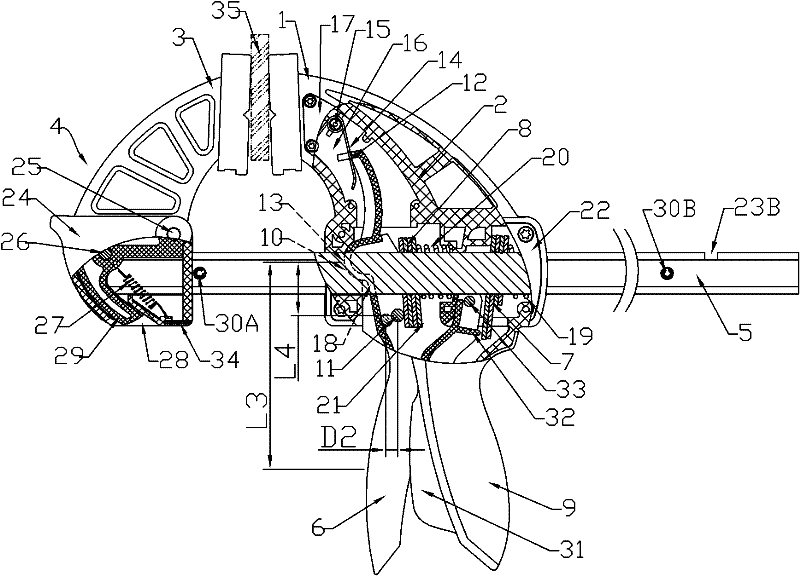

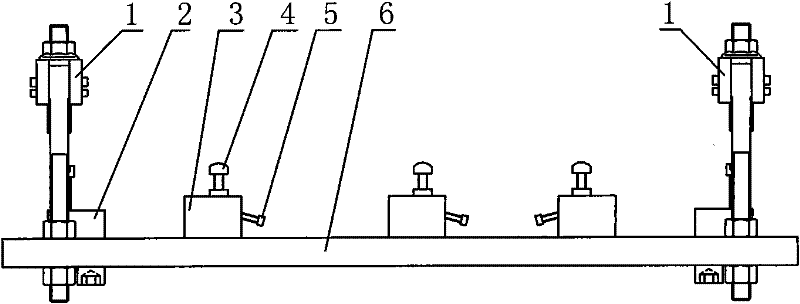

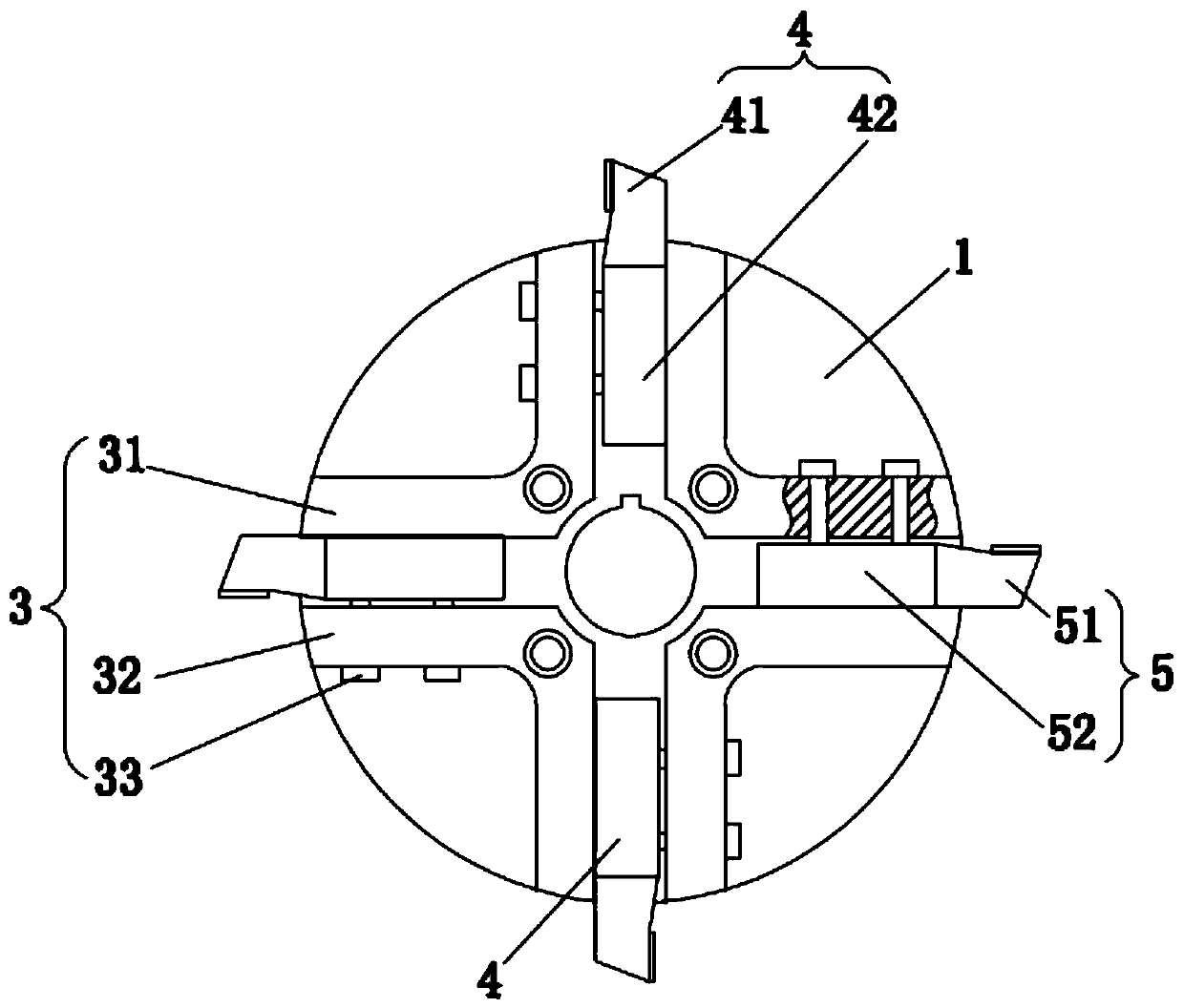

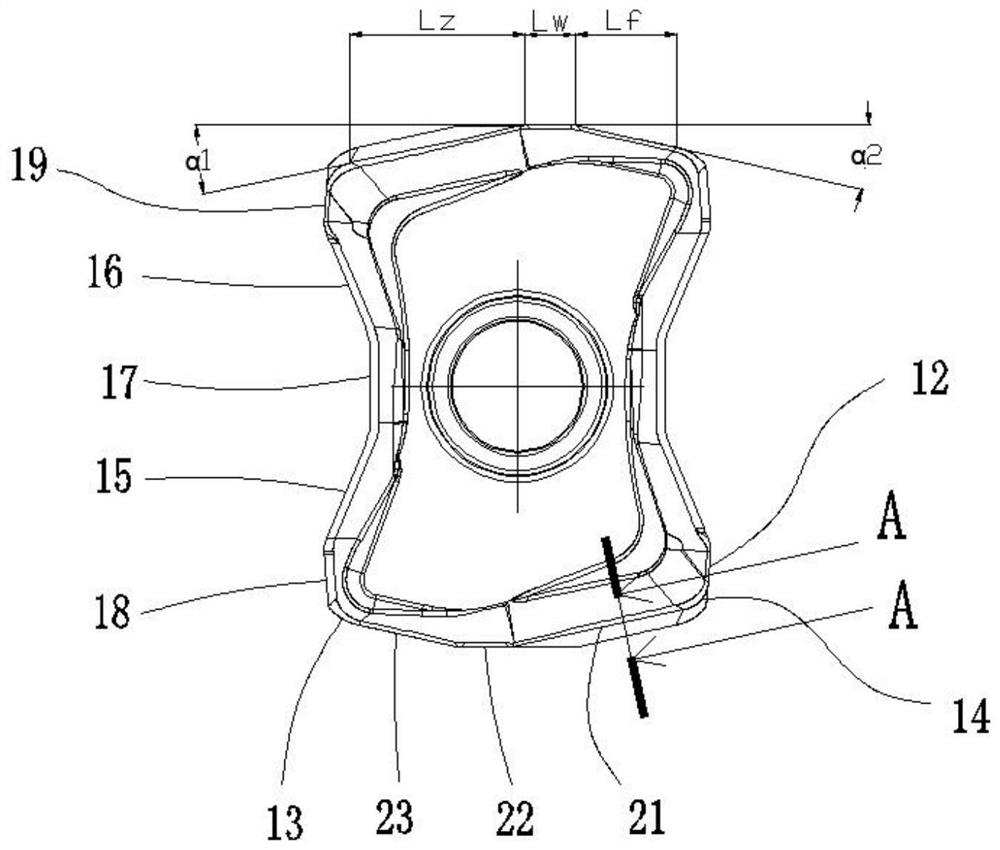

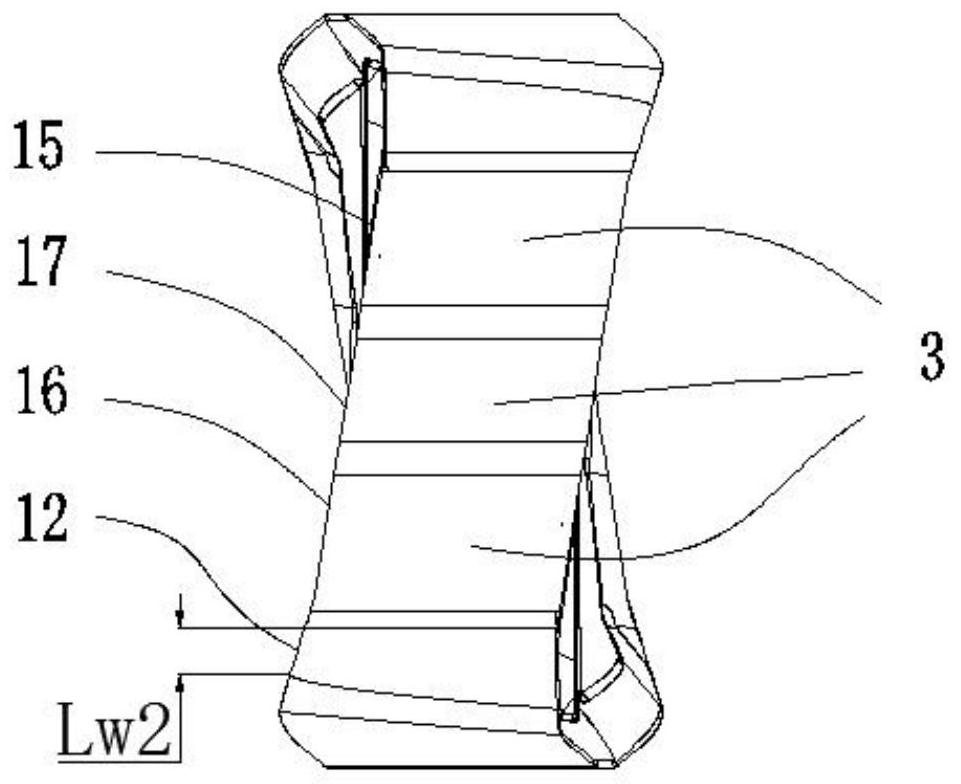

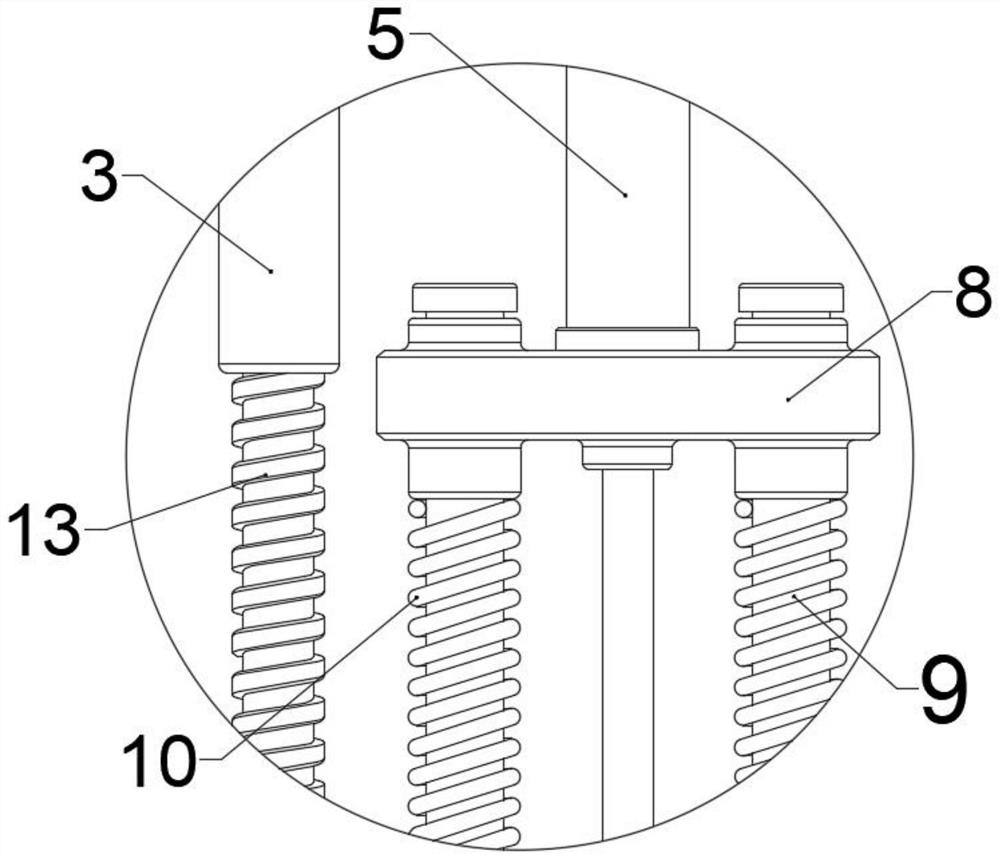

An Improved Auxiliary Clamping Mechanism for Five-Axis Rotary Machining of Blade Profiles

ActiveCN101733657BImprove rigidityImprove surface qualityMilling equipment detailsPositioning apparatusSurface modificationRotary machine

The invention provides an improved auxiliary clamping mechanism for five-axis rotary machining blade profiles. It can effectively strengthen the rigidity of the large aluminum alloy blade during the rotary milling process, greatly reduce the deformation of the surface milling, and improve the processing quality of the blade surface. It includes a bottom plate, and the feature is that hinge pressing plates and positioning blocks are installed on both sides of the bottom plate, and a spring tightening device is installed on the bottom plate.

Owner:WUXI TURBINE BLADE

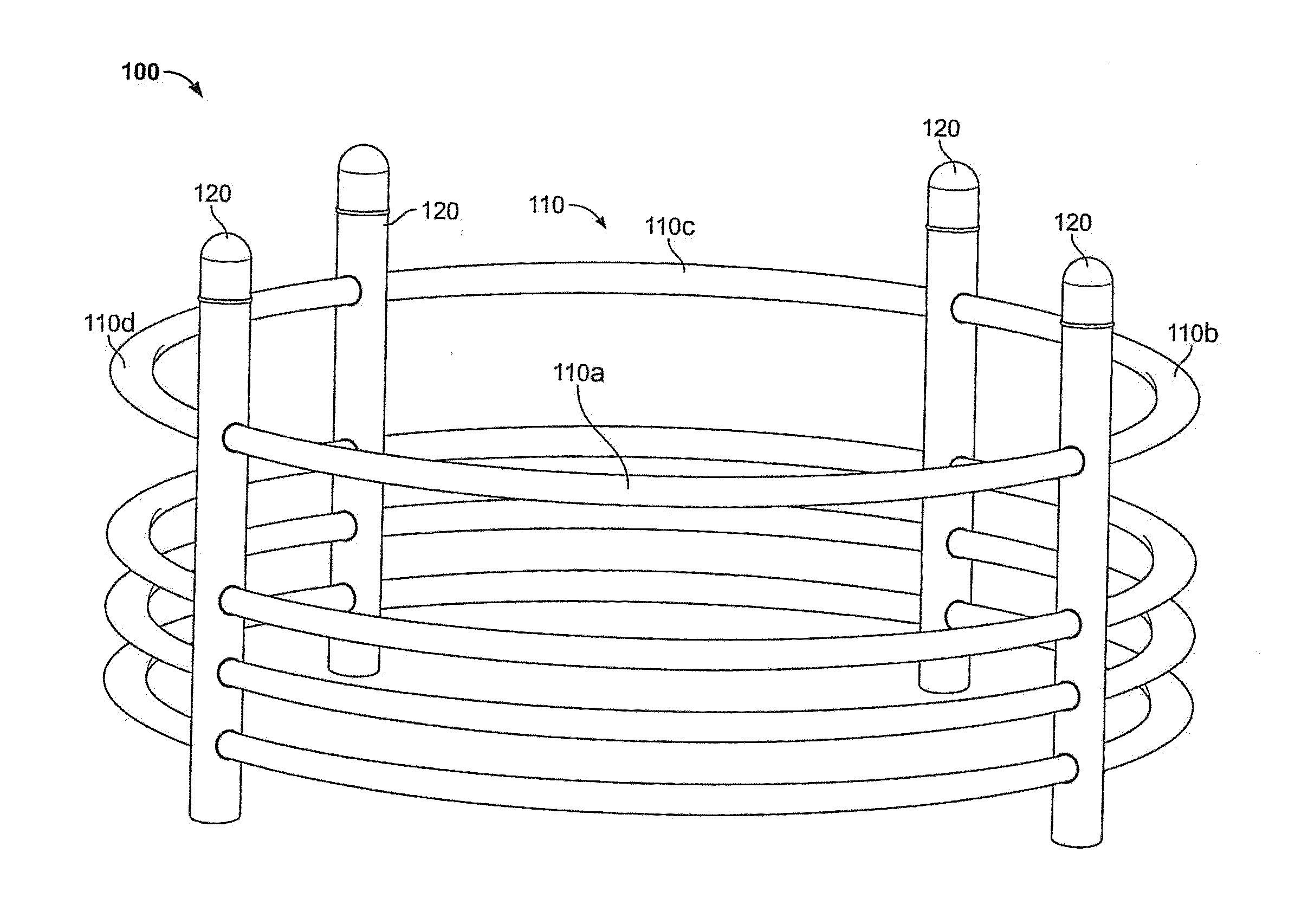

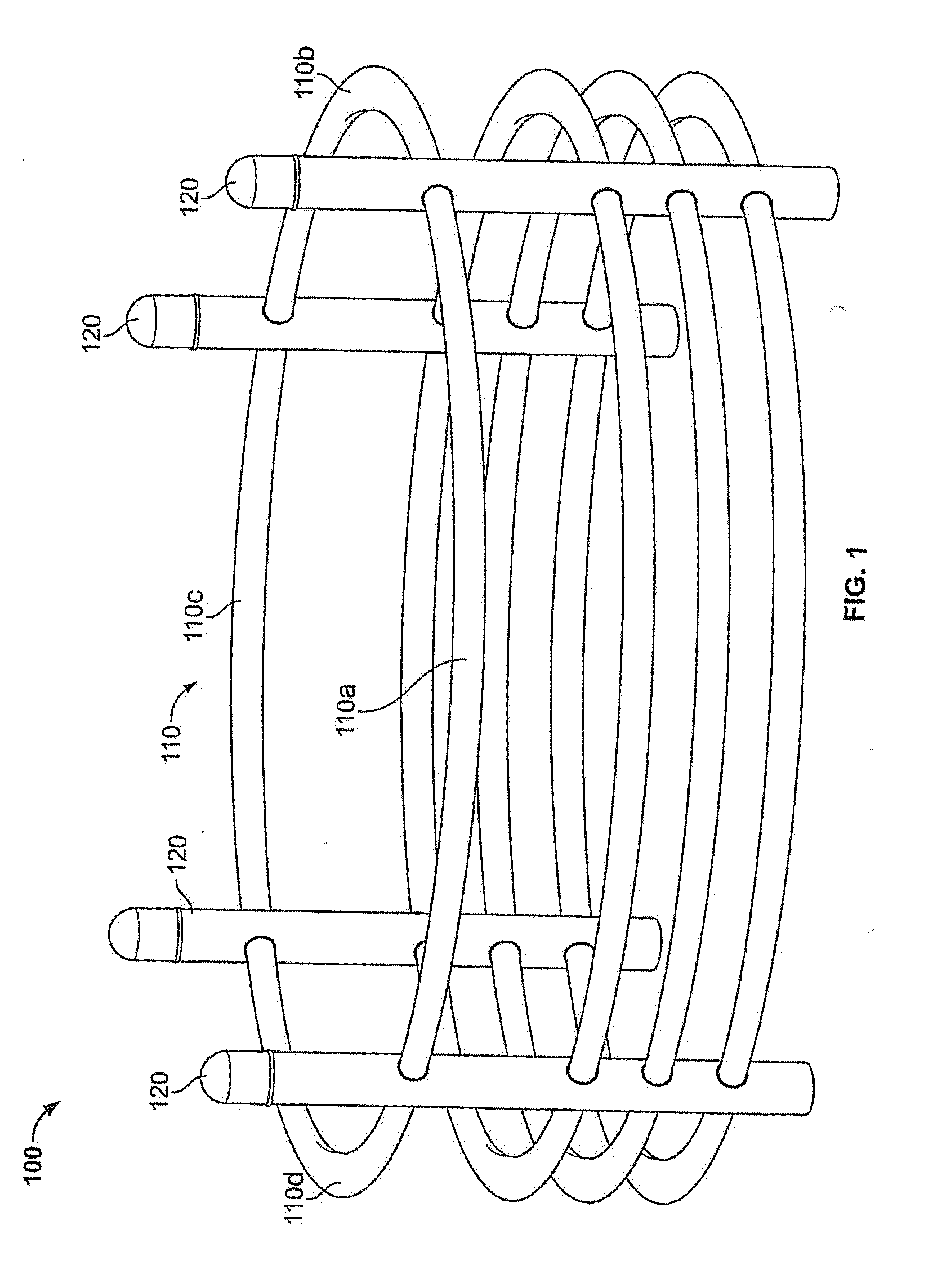

Portable animal feeding device

Four or more concentric rings are vertically separated from each other by placement along the vertical axis of four support members. The circular construction accommodates hay bales for feeding animals. The openings between the concentric circles are defined by their placement along the vertical axis of the support members. The structure may be comprised of one or more sections that may disassembled for relocation. Alternatively, the system may be of a unitary construction.

Owner:MOUNTS JOHN W

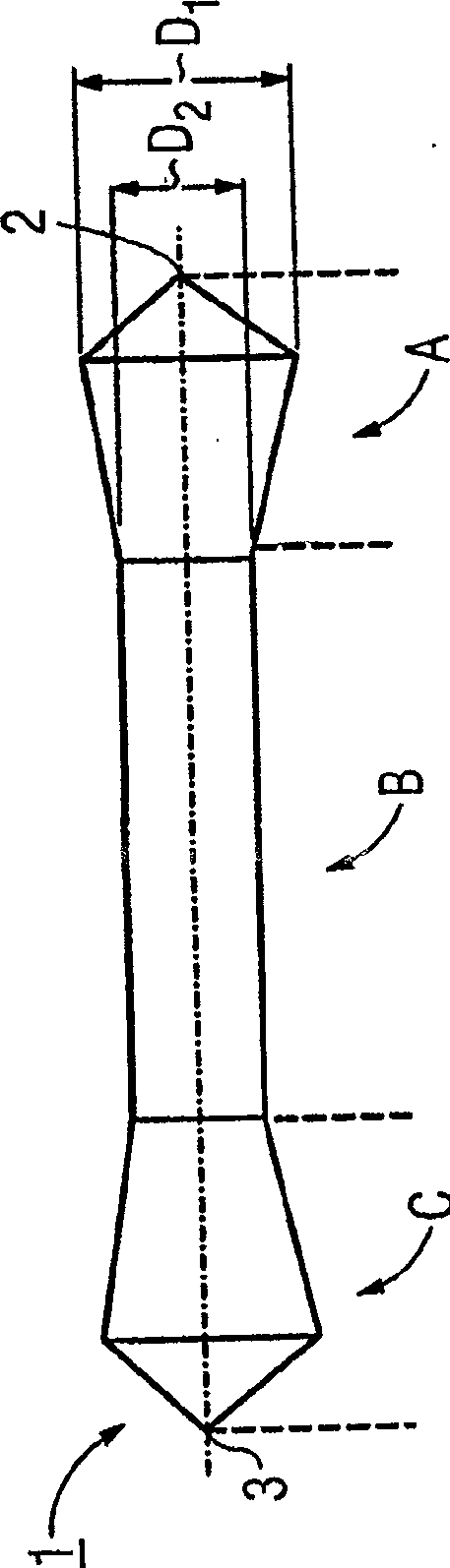

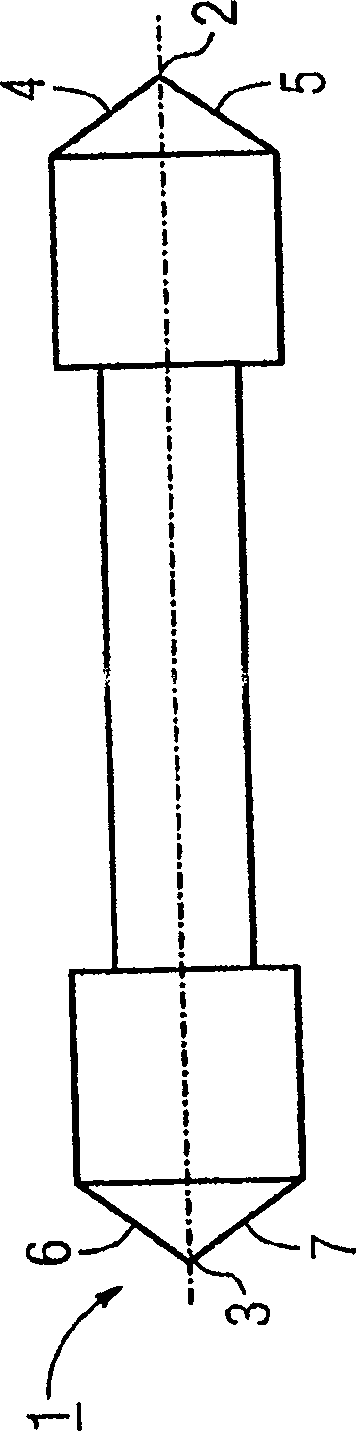

Drilling tool, drilling tool set comprising same and drilling device

InactiveCN100503104CExtend your lifeImprove drilling effectTool workpiece connectionTransportation and packagingFluteClassical mechanics

Disclosed is a drilling tool comprising a first drill bit (2) that is provided with at least two forward cutting edges (4, 5) and a second drill bit (3) which encompasses at least two rear cutting edges (6, 7). A cutting groove (8, 9) runs continuously from one respective forward cutting edge (4, 5) to a rear cutting edge (6, 7). Said cutting groove (8, 9) is embodied in an asymmetric manner in an area (A) bordering the forward drill bit (2), in a symmetric manner in a central area (B), and asymmetric in an area (C) bordering the rear drill bit (3).

Owner:KENNAMETAL INC

A CNC pendulum milling machine

ActiveCN106425752BImprove rigidityImprove processing efficiencyGrinding carriagesGrinding drivesNumerical controlMachine tool

The invention relates to a numerically-controlled pendulum shaft milling-grinding machine tool, and mainly solves the problems of low machining efficiency and instable accuracy during machining for large-diameter optical lenses, of an existing milling-grinding machine tool. The numerically-controlled pendulum shaft milling-grinding machine tool is characterized in that a pendulum shaft drive mechanism (7) and a vertical feeding mechanism (8) are connected to a milling-grinding head (1); and a horizontal feeding mechanism (5) and a rotary drive mechanism (9) are arranged on a workbench (3) respectively. The numerically-controlled pendulum shaft milling-grinding machine tool is high in rigidity, and capable of increasing the feeding amount on the basis of ensuring machining accuracy, thus increasing the machining efficiency and improving the machining accuracy of the machine tool.

Owner:齐齐哈尔孟维机床制造有限公司

Groove milling method and high-speed milling cutter device

PendingCN110216317AWill not increase the loadLarge feedMilling cuttersMilling equipment detailsMilling cutterEngineering

The invention discloses a groove milling method and a high-speed milling cutter device. The groove milling method comprises the steps that at least two cutters in a cutter set on a milling cutter turntable rotate along with the turntable, and the workpieces are sequentially cut; and in the same cutter set, the cutting ranges of every two adjacent cutters in front and back are staggered in the width direction of the groove milling and partially overlapped. The high-speed milling cutter device comprises the turntable, at least one cutter set is arranged on the turntable, and one cutter set comprises at least two cutters arranged around a rotation axis of the turntable; in every two adjacent cutters in the cutter set, a cutting edge on one side of the front cutter protrudes out of the cuttingedge on the same side of the a back cutter; the cutting edge of the other side of the front cutter is positioned between the cutting edges on the two sides of the back cutter; and the cutting edge onthe other side of the back cutter protrudes out of the cutting edge at the same side of the front cutter. According to the groove milling method and the high-speed milling cutter device, the cuttingwidth of one-circle rotation of the milling cutter is large, the service life of the cutter can be ensured to be long enough, and the groove milling efficiency is high.

Owner:颜亚秀

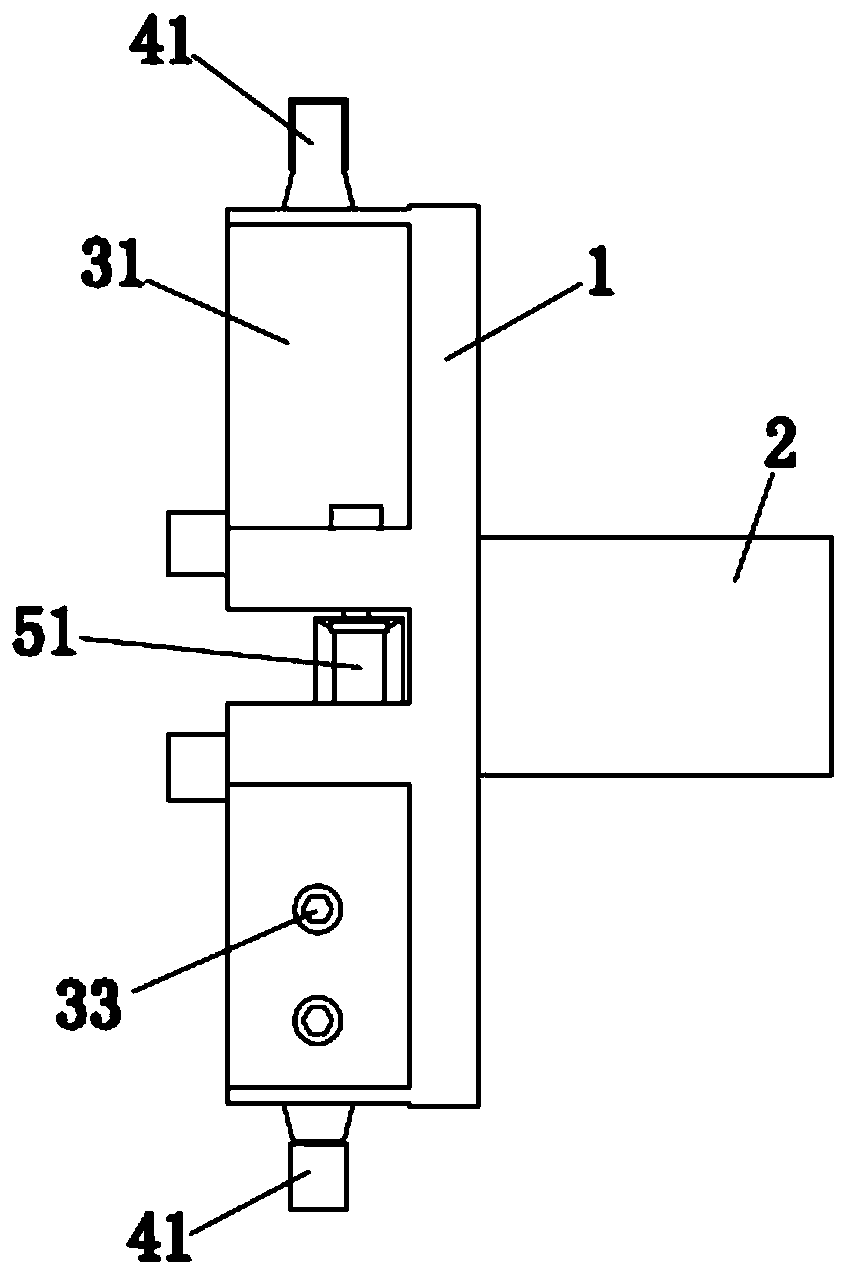

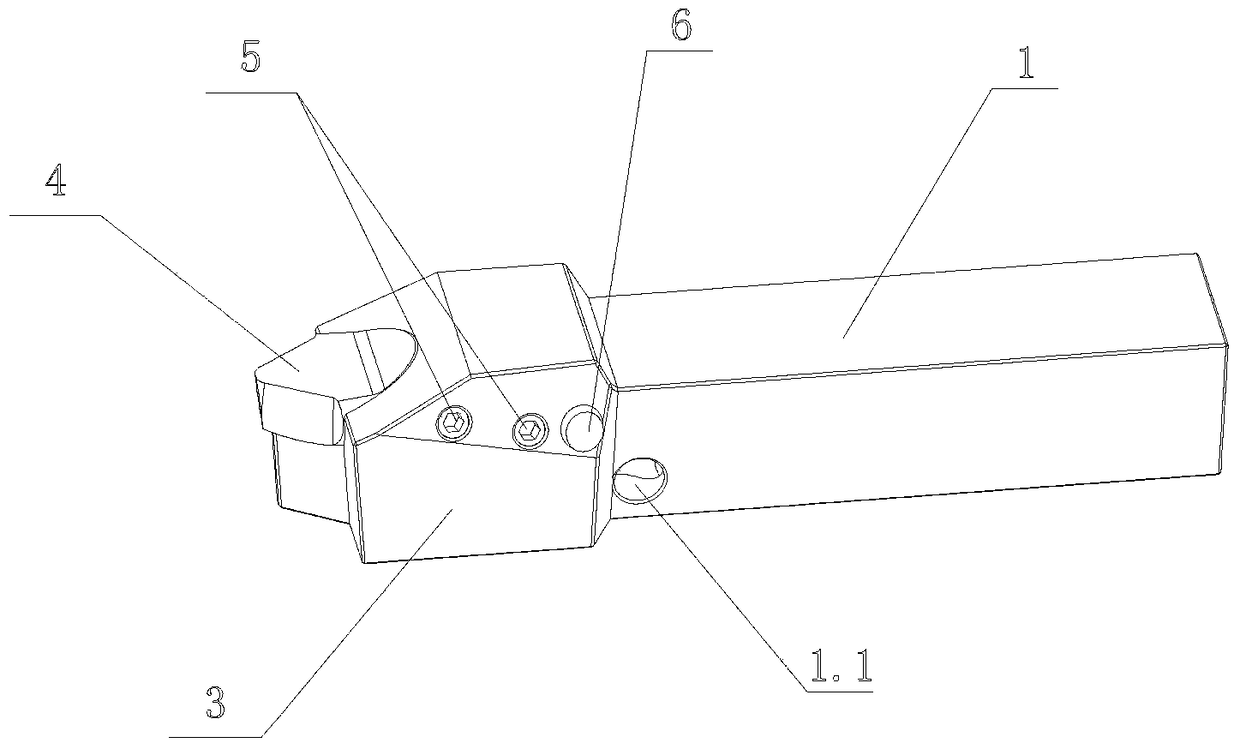

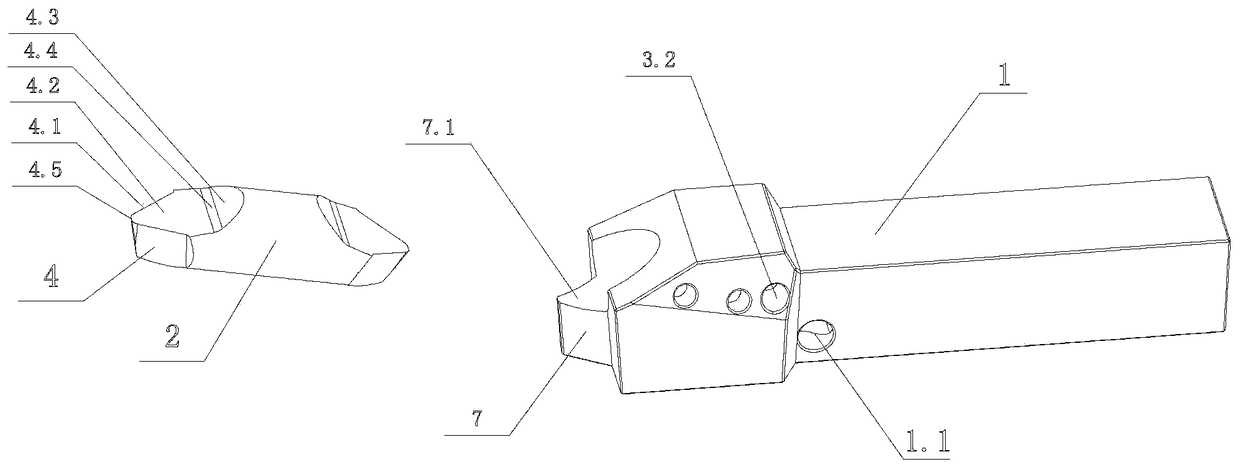

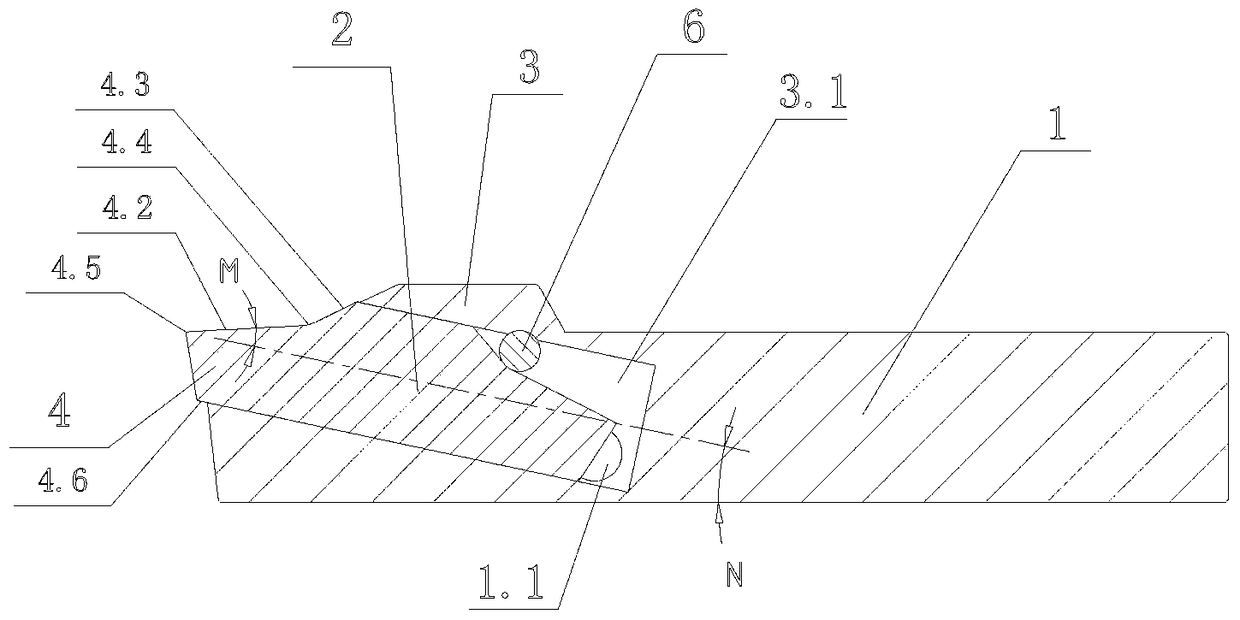

A machine clip type thread turning tool

The invention discloses a mechanical clamp type threading tool. The mechanical clamp type threading tool comprises a tool handle (1) and a tool bit body (2). The tool handle (1) is provided with a tool bit connecting base (3) used for installing the tool bit body (2). The mechanical clamp type threading tool is characterized in that the tool bit body (2) is of a cylindrical structure, the end of the tool bit body (2) is cut into a tool bit (4) along a plurality of cutting faces, and the tool bit connecting base (3) is provided with an installing hole (3.1) allowing the tool bit body (2) to be inserted therein; the tool bit body (2) is in sliding fit with the installing hole (3.1), a cutting edge (4.1) of the tool bit (4) is exposed out of the tool bit connecting base (3), and the tool bit connecting base (3) is provided with a fastening mechanism used for limiting the tool bit body (2) to move relative to the tool bit connecting base (3). The mechanical clamp type threading tool is large in cutting feed amount and high in cutting speed.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

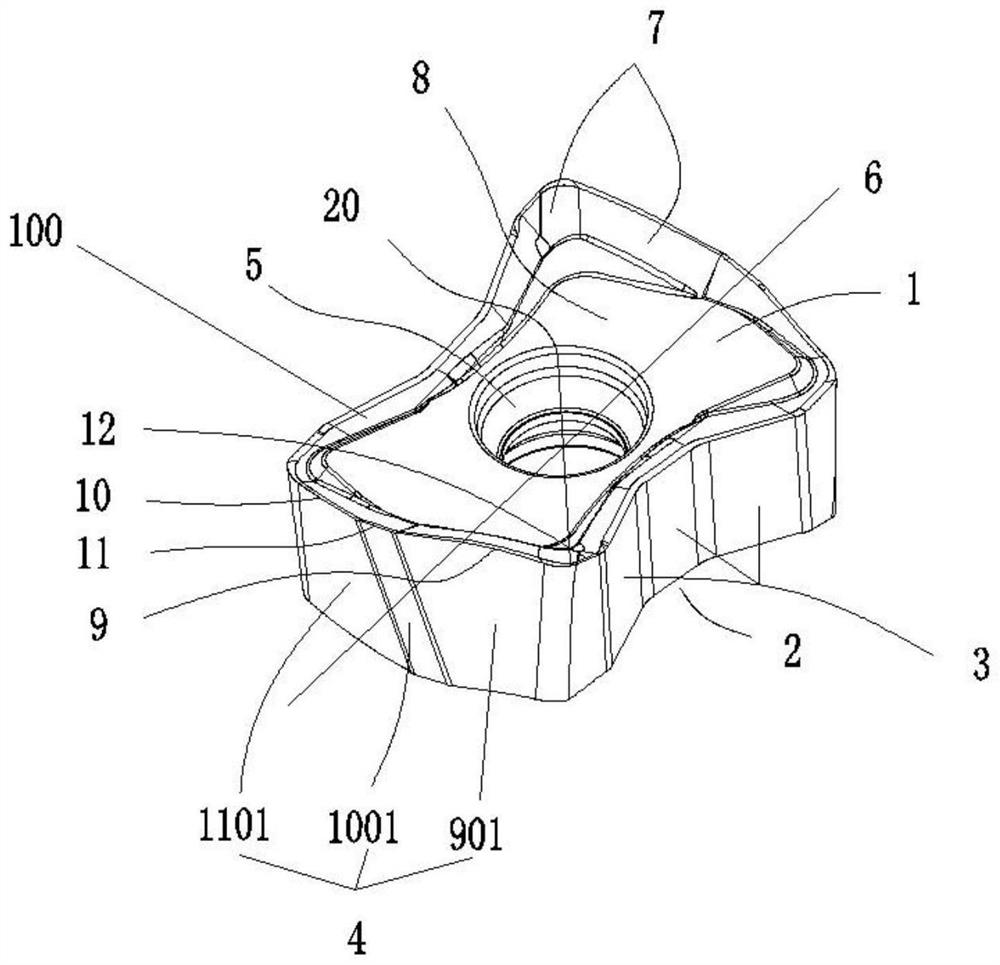

Cutting blade and cutting tool

The invention discloses a cutting blade which comprises a blade body defined by a top face part, a bottom face part, a side face part and a rear tool face, and the blade body penetrates through the top surface part and the bottom surface part and is provided with a screw hole part. Each of the top surface part and the bottom surface part is composed of a front cutter surface and a mounting surface, a cutting edge part is formed by an edge band where the front cutter surface and the rear cutter surface intersect, the cutting edge part comprises a main cutting edge, an auxiliary cutting edge and a first sleeking edge, and the main cutting edge, the auxiliary cutting edge and the first sleeking edge form a main cutting edge rear cutter surface, an auxiliary cutting edge rear cutter surface and a first sleeking edge rear cutter surface respectively with the rear cutter surface; the main cutting edge is longer than the auxiliary cutting edge; and the cutting edge part further comprises a second sleeking edge, and the second sleeking edge is smoothly connected with the main cutting edge through a second arc section. The cutting blade has the advantages of larger cutting depth and larger feeding under the same blade width, and a vertical wall surface with higher quality can be formed in the processing of a rib structure.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

A large environment-friendly vertical multifunctional 3D CNC engraving machine

Owner:福建唐煌数控雕刻机械设备有限公司

Table type jig saw capable of preventing plate vibration

InactiveCN114309800AAvoid touchingReduce vibrationMetal sawing devicesMetal sawing accessoriesPull forceReciprocating motion

The table type jig saw capable of preventing the plate from vibrating comprises a base, a supporting block is fixed to the upper end face of the base, a main box body is fixed to the upper end face of the supporting block, a resetting assembly used for resetting a saw blade is arranged in the main box body, and a vibrating assembly used for enabling the saw blade to move away from or close to the plate is arranged on the upper side of the base; in the cutting process, half gears on the left side and the right side are meshed with a reciprocating bevel gear in a staged mode, forward and reverse reciprocating rotation is achieved, and therefore a top wheel is driven to do left-right reciprocating motion, and in cooperation with the pulling force effect of a rack spring, the cutting efficiency is improved. The saw blade moves upwards to be far away from the plate rightwards, so that the saw blade is prevented from touching the uncut part of the plate in the upward moving process, vibration of the plate is reduced, meanwhile, when the saw blade moves downwards, the top wheel pushes the saw blade to approach the plate leftwards, the feeding amount is increased, and the cutting efficiency is improved.

Owner:赵凤飞

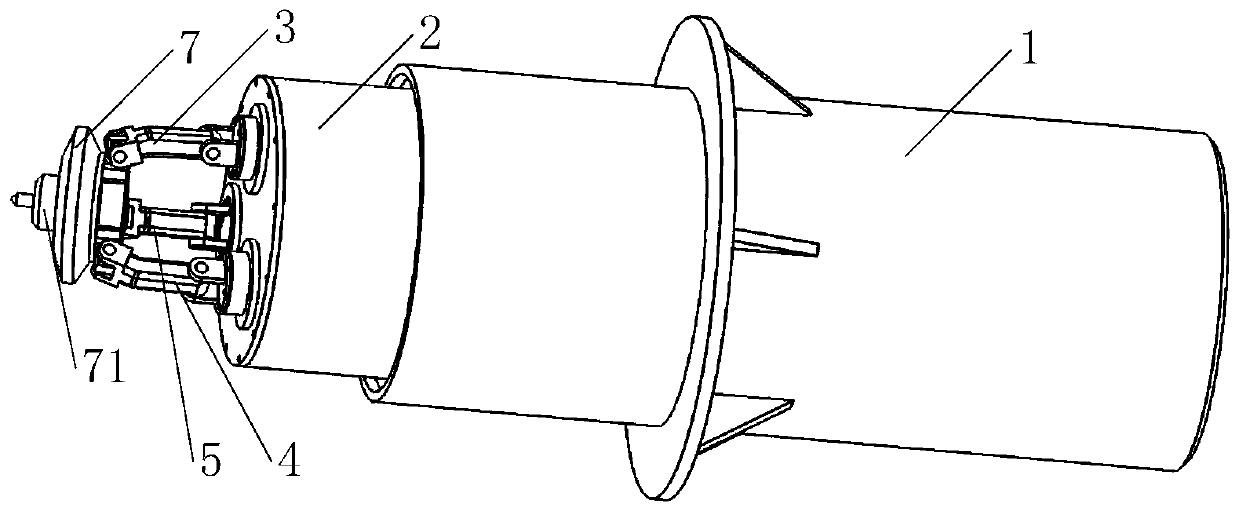

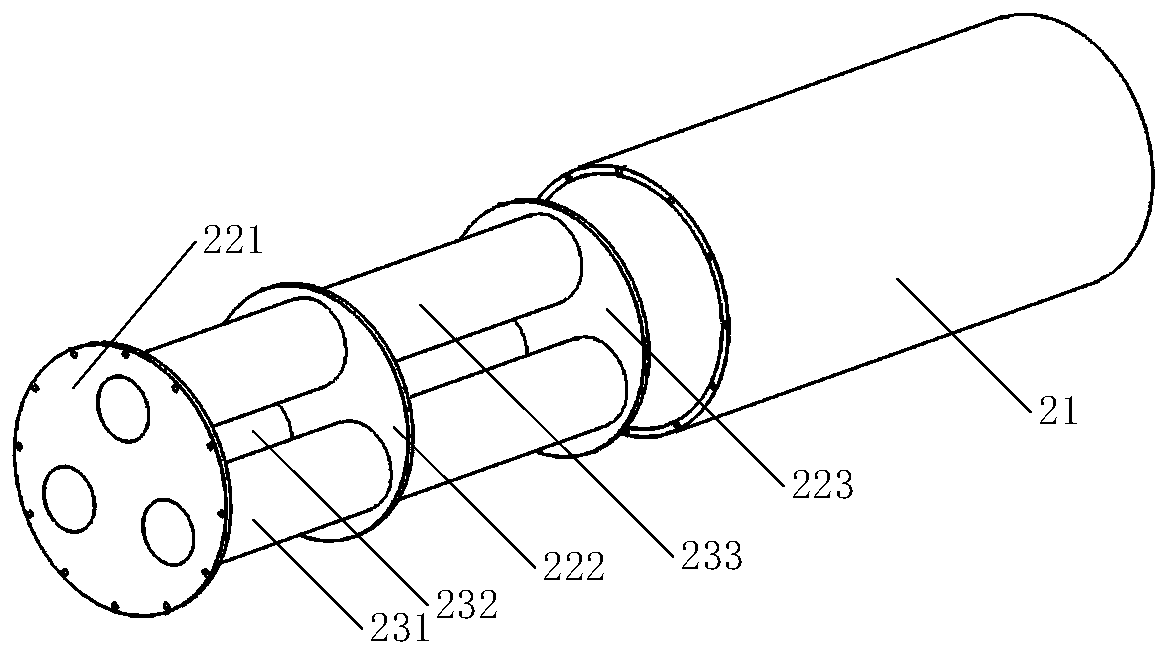

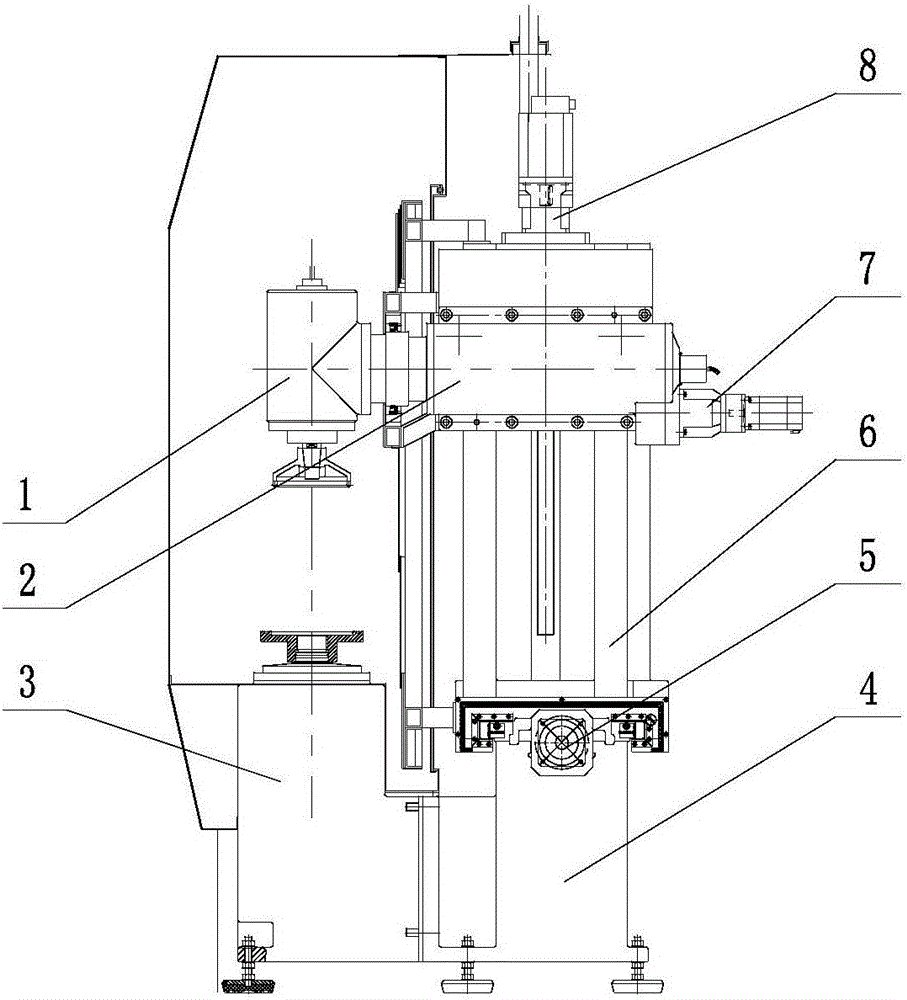

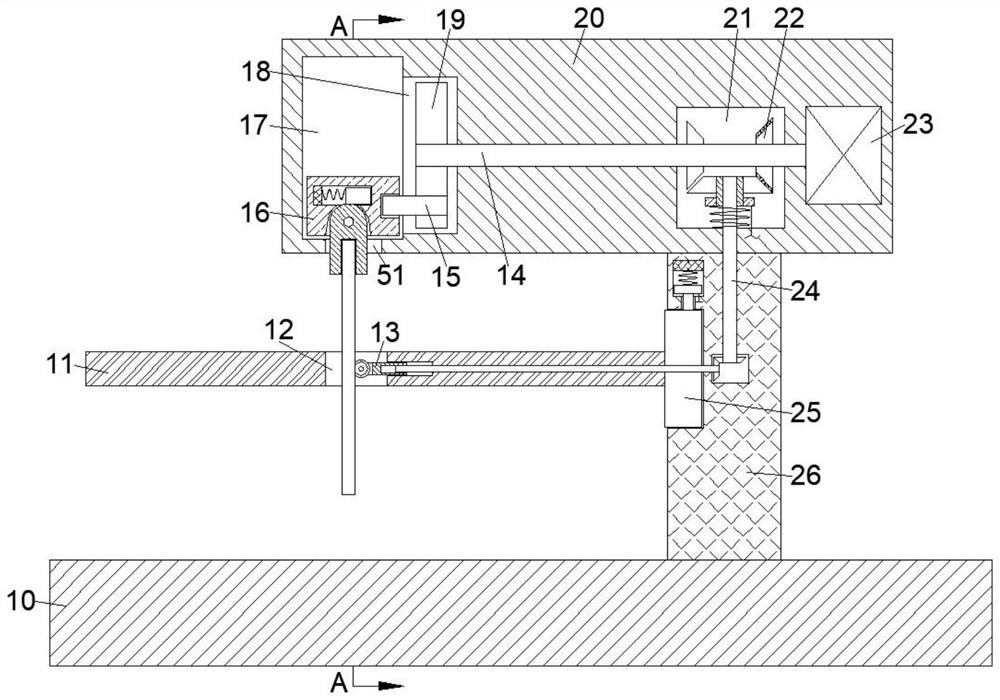

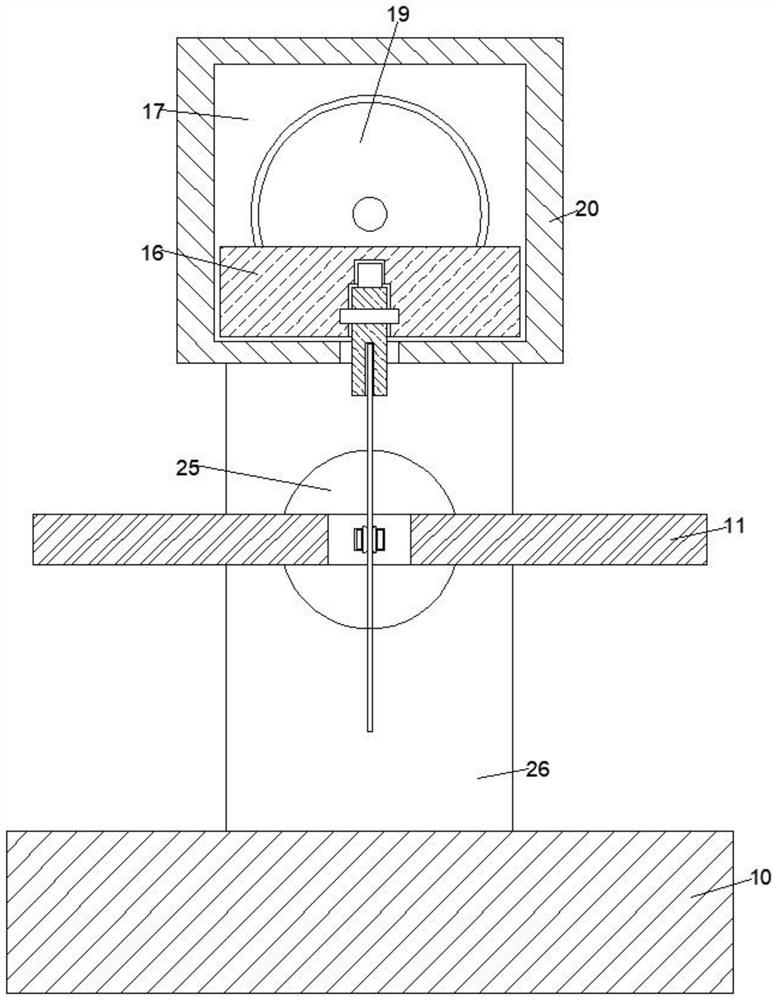

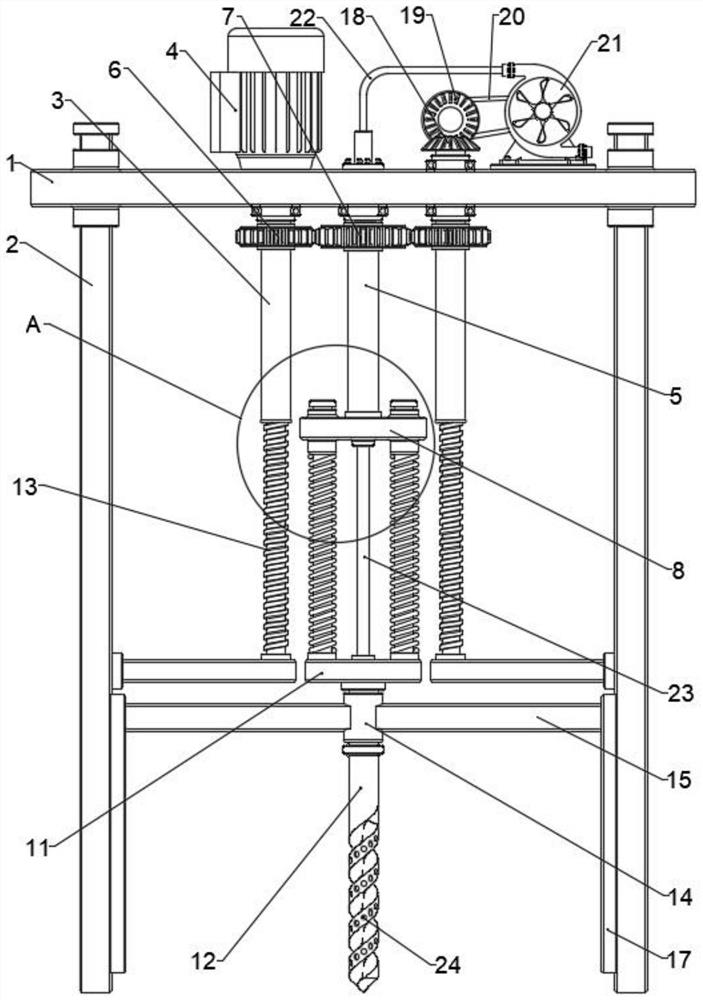

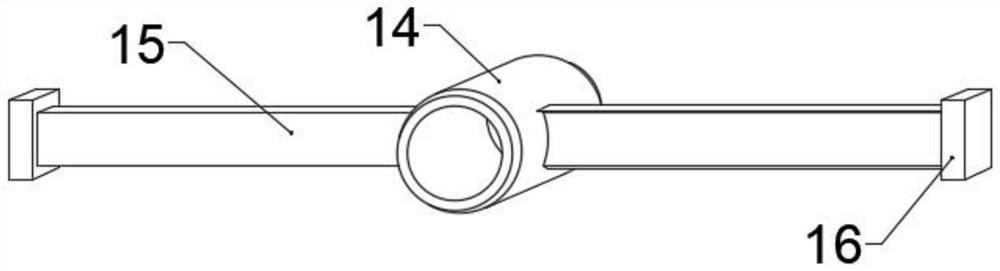

Multifunctional deep geothermal resource drilling and well completion experimental device

ActiveCN112377121ASmall feedLarge feedDrill bitsDrilling rodsStructural engineeringPetroleum engineering

The invention discloses a multifunctional deep geothermal resource drilling and well completion experiment device. The multifunctional deep geothermal resource drilling and well completion experimentdevice comprises a lifting platform and two supports arranged on the two sides of the lifting platform. The two supports penetrate through the lifting platform and are vertically connected with the lifting platform in a sliding mode. Two sets of lifting structures are arranged on the two sides of the lower portion of the lifting platform and are connected with the supports on the two sides respectively. A rotary drilling assembly connected with the lifting structures is installed in the center of the lower portion of the lifting platform, and the rotary drilling assembly rotates when the lifting structures drive the lifting platform to descend along the supports. When a drill rod drills to a hard part, although the lifting structures still drive the drill rod to extend downwards for feeding, sliding rods slide upwards to compress pressure springs to drive the drill rod to reduce the feeding amount, and the drill rod is prevented from being damaged by forced drilling; and when the drillrod drills to a part with low hardness, the compressed pressure springs can increase the feeding amount of the drill rod through resetting.

Owner:任丘市荣昌石油机械设备制造有限公司

a head planer

ActiveCN106583811BMain motion stabilitySmooth motionMilling machinesFeeding apparatusGear wheelMilling cutter

A novel shaping machine comprises a base, a machine body, a workbench, a main movement mechanism and a workbench feeding mechanism; the main movement mechanism comprises a ram fixedly mounted on the machine body, a first motor arranged at the upper end of the ram and a boring and milling spindle grinding head arranged at the front end of the ram; a synchronous transmission device is arranged between the first motor and the boring and milling spindle grinding head; a milling cutter disk is arranged at the bottom end of the boring and milling spindle grinding head; and the workbench feeding mechanism comprises a gear transmission mechanism arranged on the machine body and a belt pulley transmission mechanism, one end of the belt pulley transmission mechanism is arranged on the machine body, and the other end of the belt pulley transmission mechanism is arranged on the workbench. The main movement mechanism and the workbench feeding mechanism of the shaping machine are two completely independent mechanisms, main movement and feeding movement of the shaping machine are conducted simultaneously, and the machining efficiency is improved; and the main movement mechanism of the shaping machine is fixed on the machine body, so that the main movement of the shaping machine is relatively stable, and the machining precision is improved.

Owner:安庆安帝技益精机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com