A large environment-friendly vertical multifunctional 3D CNC engraving machine

A CNC engraving machine, multi-functional technology, applied in the direction of processing models, decorative arts, etc., can solve the problems of restricting the development of production enterprises, high labor intensity of workers, and large noise of electric circular saws, etc., to achieve a perfect operating environment, flexible engraving, and reduced dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

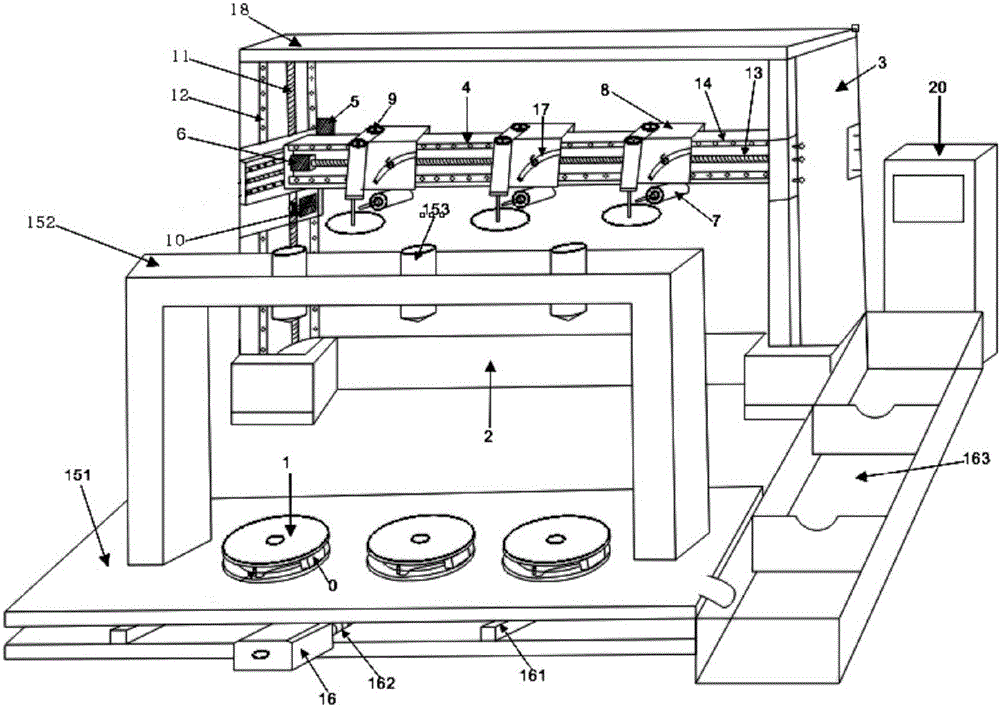

[0015] As shown in FIG. 1 , this embodiment is a large-scale environment-friendly vertical multifunctional three-dimensional CNC engraving machine, including a workpiece turntable unit, an engraving machine unit for engraving workpieces, a purifying circulating pool 163 and a CNC master control system cabinet 20 .

[0016] The engraving machine unit includes a base, at least one column arranged on the base, and a crossbeam arranged on the upright, wherein the crossbeam is provided with several mounting seats, and the mounting seats are provided with clamping The spindle motor of the tool and the motor cutting device, the engraving machine unit also includes an X-axis servo drive mechanism, a Y-axis servo drive mechanism, and a Z-axis servo drive mechanism; the extension direction of the column length is the X axis, and the beam length The extension direction of the X-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com