Cutting blade and cutting tool

A technology for cutting blades and blades, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the finishing process and uneven residual materials, so as to improve the quality, strengthen the strength and toughness of the blade tip, and reduce chipping risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

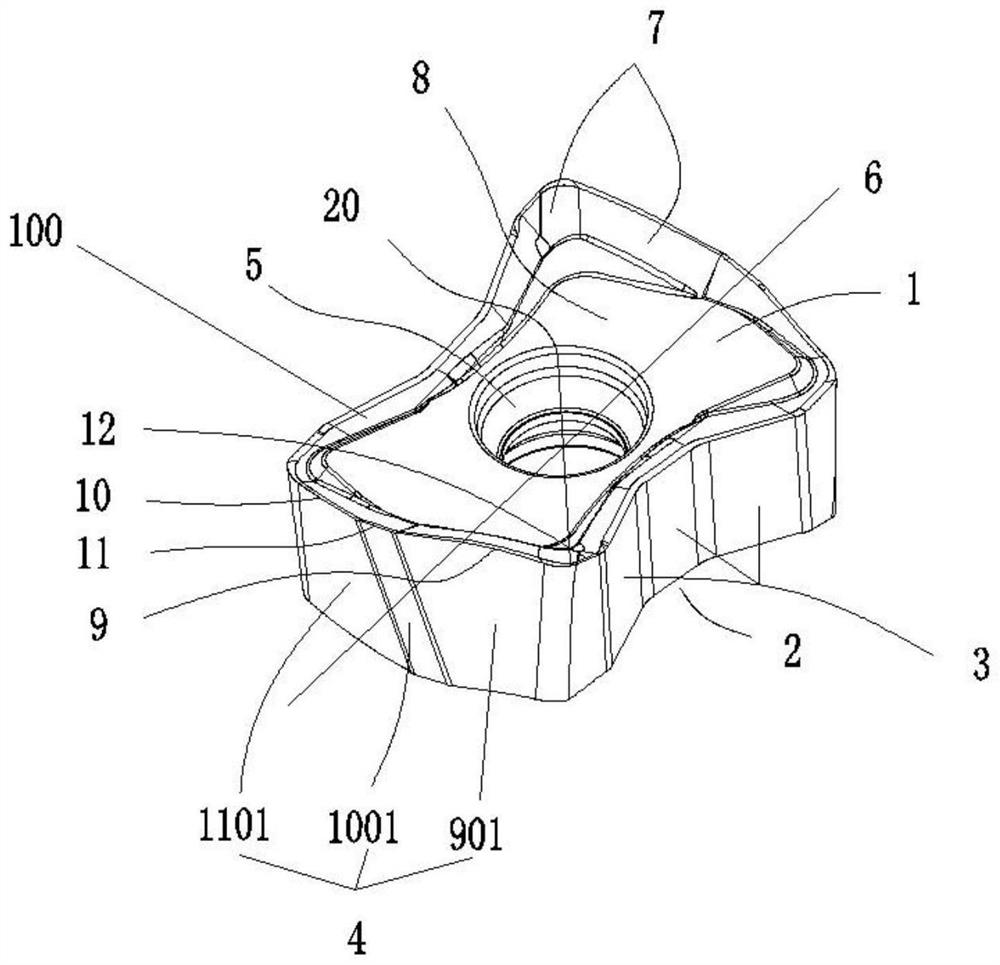

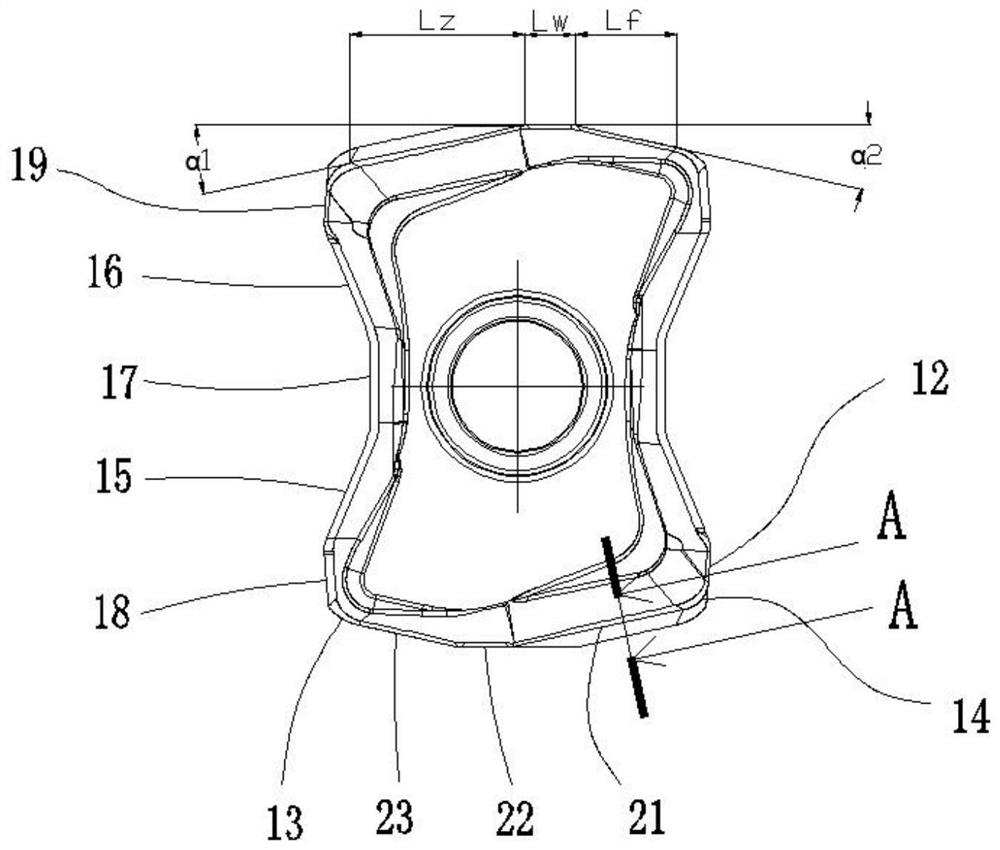

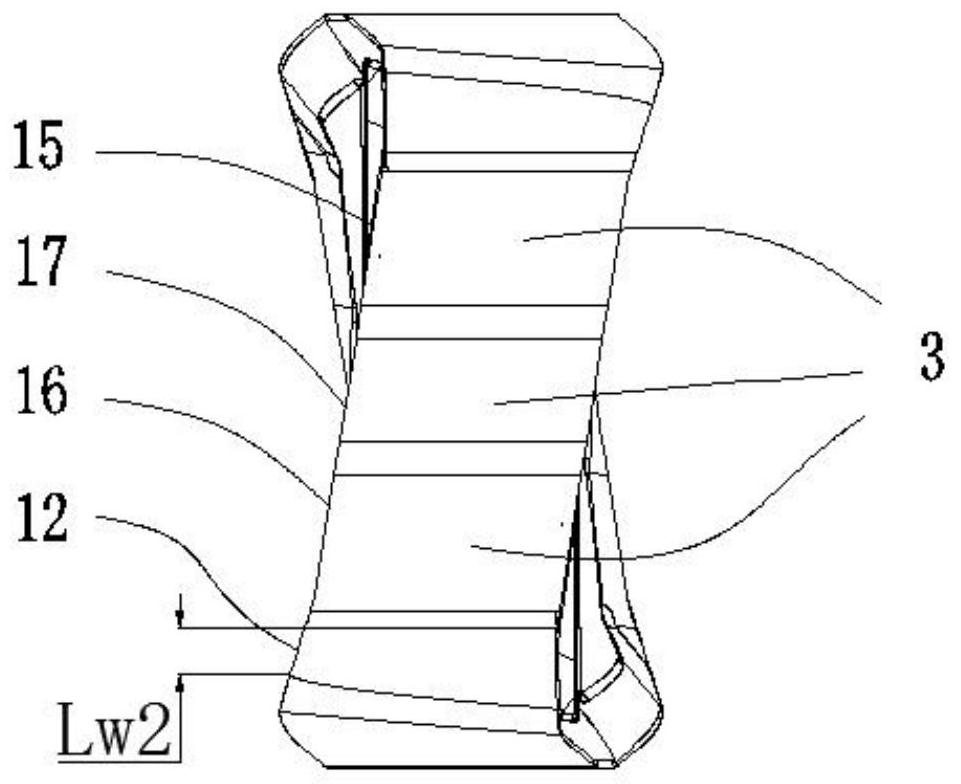

[0039] This embodiment adopts the method of plane milling, such as Figure 1-9 Shown is a cutting insert described in this embodiment, including a top face 1, a bottom face 2, a side face 3 and a relief face 4 to form a blade body 100, and the blade body 100 runs through the top face 1 and the bottom face 2. A screw hole 5 is provided, and the top surface 1 and the bottom surface are distributed rotationally symmetrically with the first central axis 6 set vertically to the screw hole 5; 8, the edge band where the rake face 7 intersects with the flank face 4 forms a cutting edge portion, and the cutting edge portion includes a main cutting edge 9, a minor cutting edge 10, a first wiper edge 11, and respectively The cutter face 4 forms the main cutting edge flank 901, the secondary cutting edge flank 1001 and the first wiper flank 1101, and the length of the main cutting edge 9 is greater than the length of the secondary cutting edge 10; the main cutting edge 9 and Minor cuttin...

Embodiment 2

[0052] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment adopts plunge milling. In the cutting process of this embodiment, the tool rotates at high speed along the direction shown in the figure, the workpiece 300 remains stationary, and the tool moves along Feed movement is performed in the direction shown by the arrow, and the cutting edge on the cutting blade participates in a cutting every time the tool rotates one circle. The vertical wall surface is smoothed until the workpiece 300 forms the desired processed surface 500; in the cutting process, if the cutting edge of the blade is worn or damaged and the processing cannot be continued, it is necessary to stop the processing and unscrew the tightening After changing the angle of the cutting blade with the fixing screw, reinstall it and use it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com