a head planer

A technology of planer and bed, applied in milling machines, milling machine equipment, manufacturing tools, etc., can solve the problems of poor precision and low processing efficiency, and achieve the effect of improving processing efficiency, improving processing accuracy and increasing feed rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

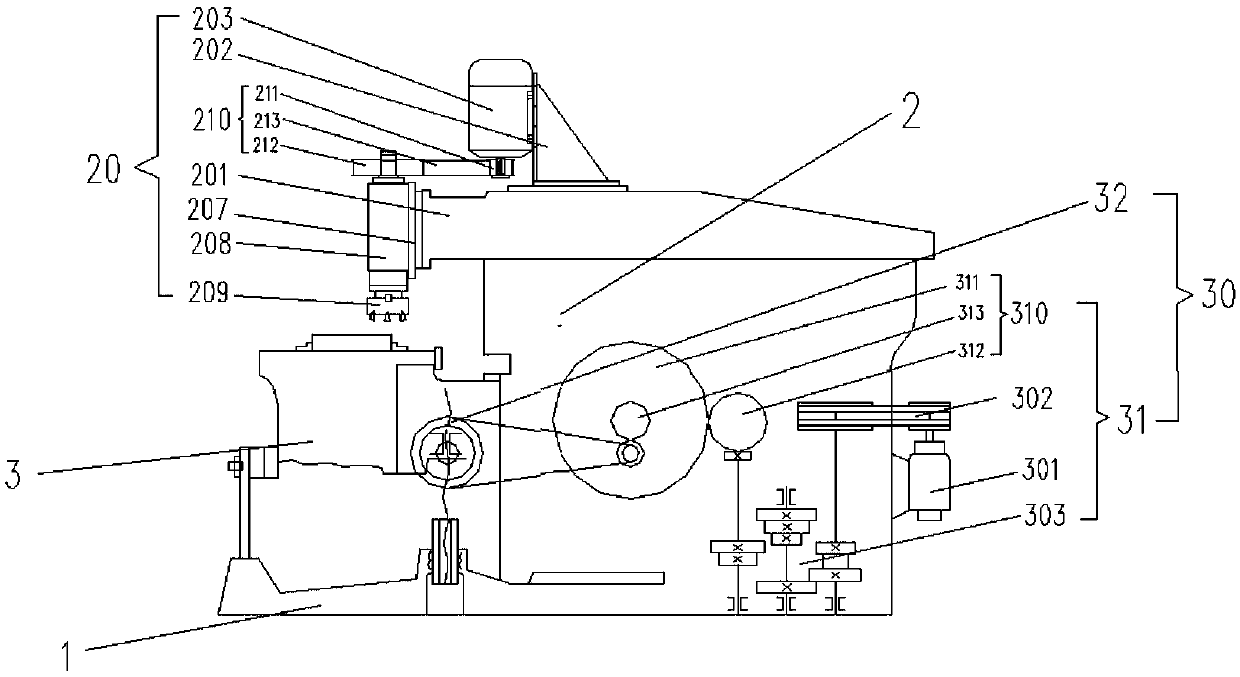

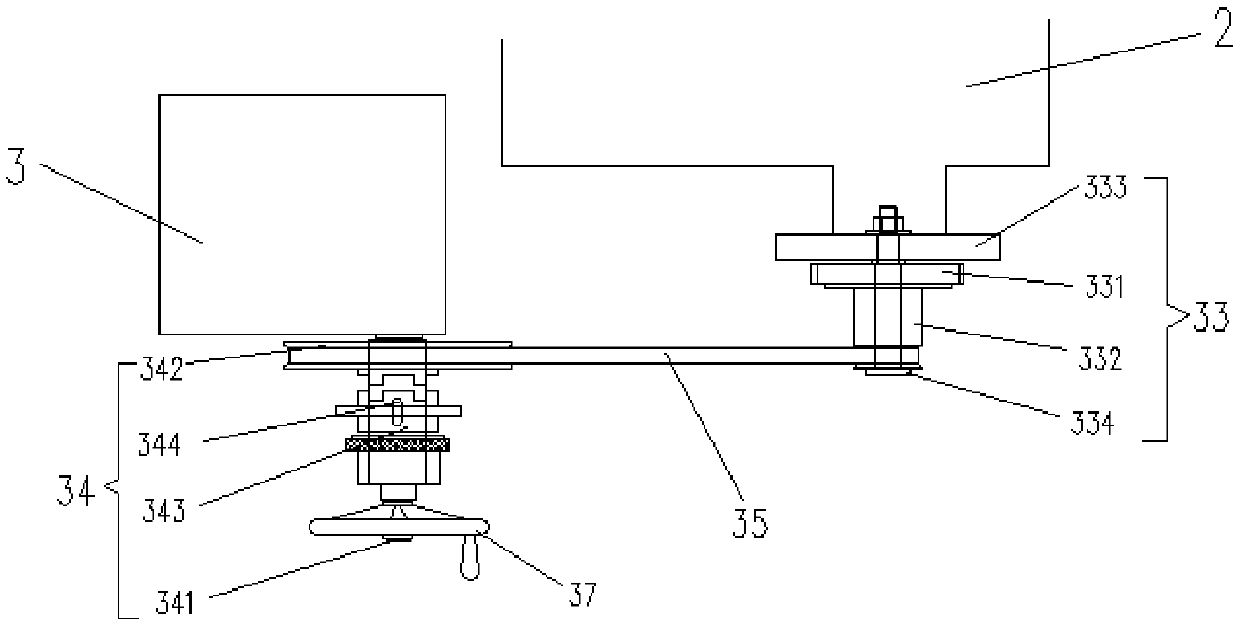

[0021] figure 1 Described, a kind of planer, comprises the bed 2 that is installed on the base 1 and the workbench 3, the main motion mechanism 20 that is arranged on the bed 2 top, and the workbench that is arranged on the bed 2 and the workbench 3 Give agency 30. A lifting device 36 for controlling the lifting movement of the workbench 3 is provided between the base 1 and the workbench 3 .

[0022] The main motion mechanism 20 includes a ram 201 fixedly installed on the bed, a first motor 203 arranged on the upper end of the ram 201 through a motor mounting plate 202, and a boring machine mounted on the front end of the ram 201 through a spindle grinding head mounting plate 207. Milling spindle grinding head 208, a synchronous transmission device 210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com