Method for finish machining of three-dimensional impeller made of FV520B material through integral hard alloy cutters

A solid carbide, FV520B technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of long processing and manufacturing cycle, low economic benefits, slow processing speed, etc., to achieve good surface quality, improve enterprise Economic benefits, the effect of fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

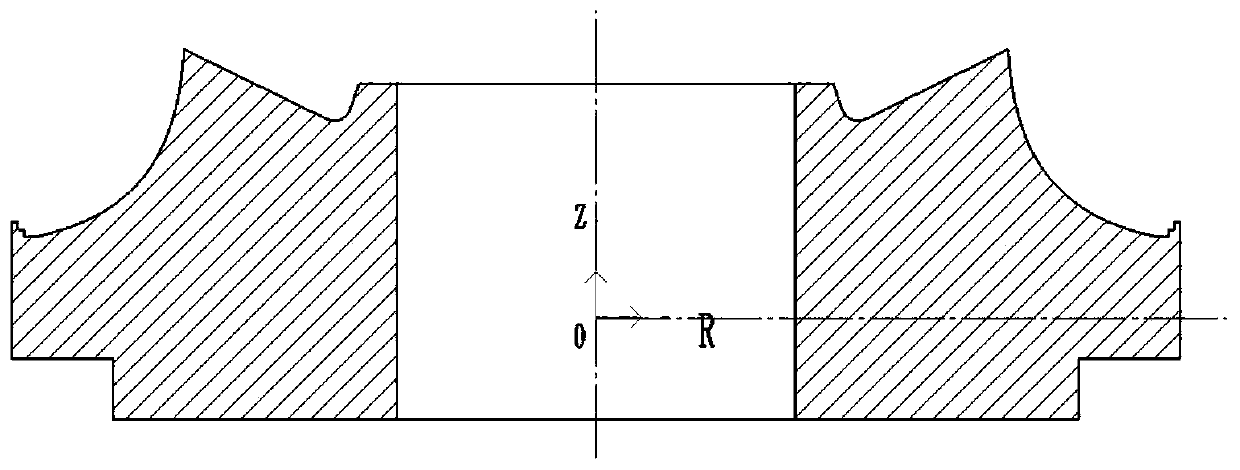

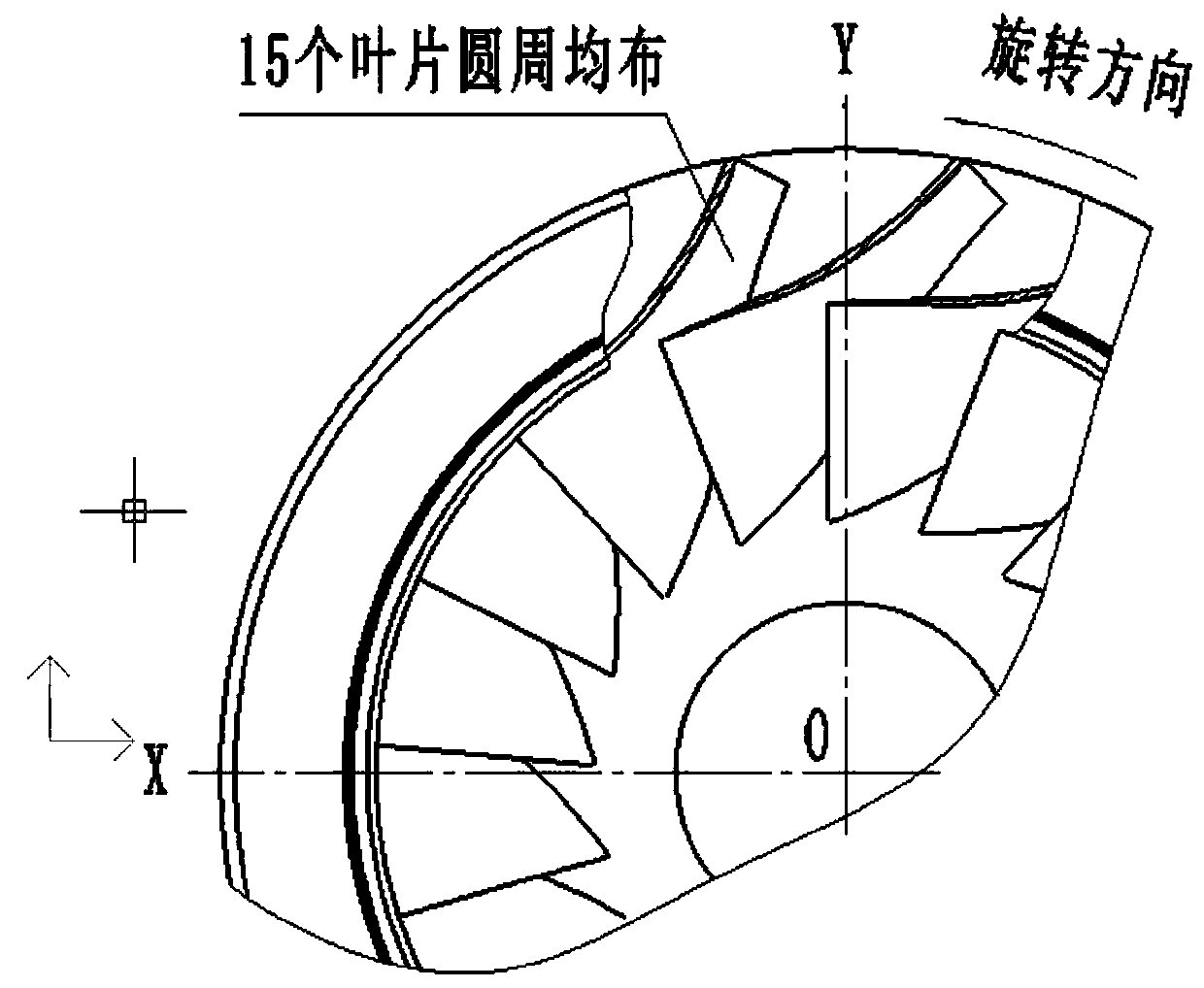

[0016] The embodiment of the present invention provides a method for finishing the three-dimensional impeller made of FV520B with a solid carbide tool, including the following steps:

[0017] After the rough machining of the three-dimensional impeller blank by milling the shaft disk, it is required to reserve a machining allowance of 0.7-1mm on one side of the blade.

[0018] Cleaning of the rounded corner of the blade, finishing of the round head of the leading edge of the blade, and finishing of the impeller hub. Among them, the clearance value between the tool ball head and the hub during blade fillet cleaning process is set to 0.5mm.

[0019] The blade is semi-finished with a long-blade tapered ball-end integral carbide wave-edge milling cutter, and a finishing allowance of 0.2-0.5mm is reserved on one side of the blade. Among them, the gap between the tool ball and the hub during the semi-finishing process of the blade is set to 0.7 mm, and the gap between the tool ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com