Groove milling method and high-speed milling cutter device

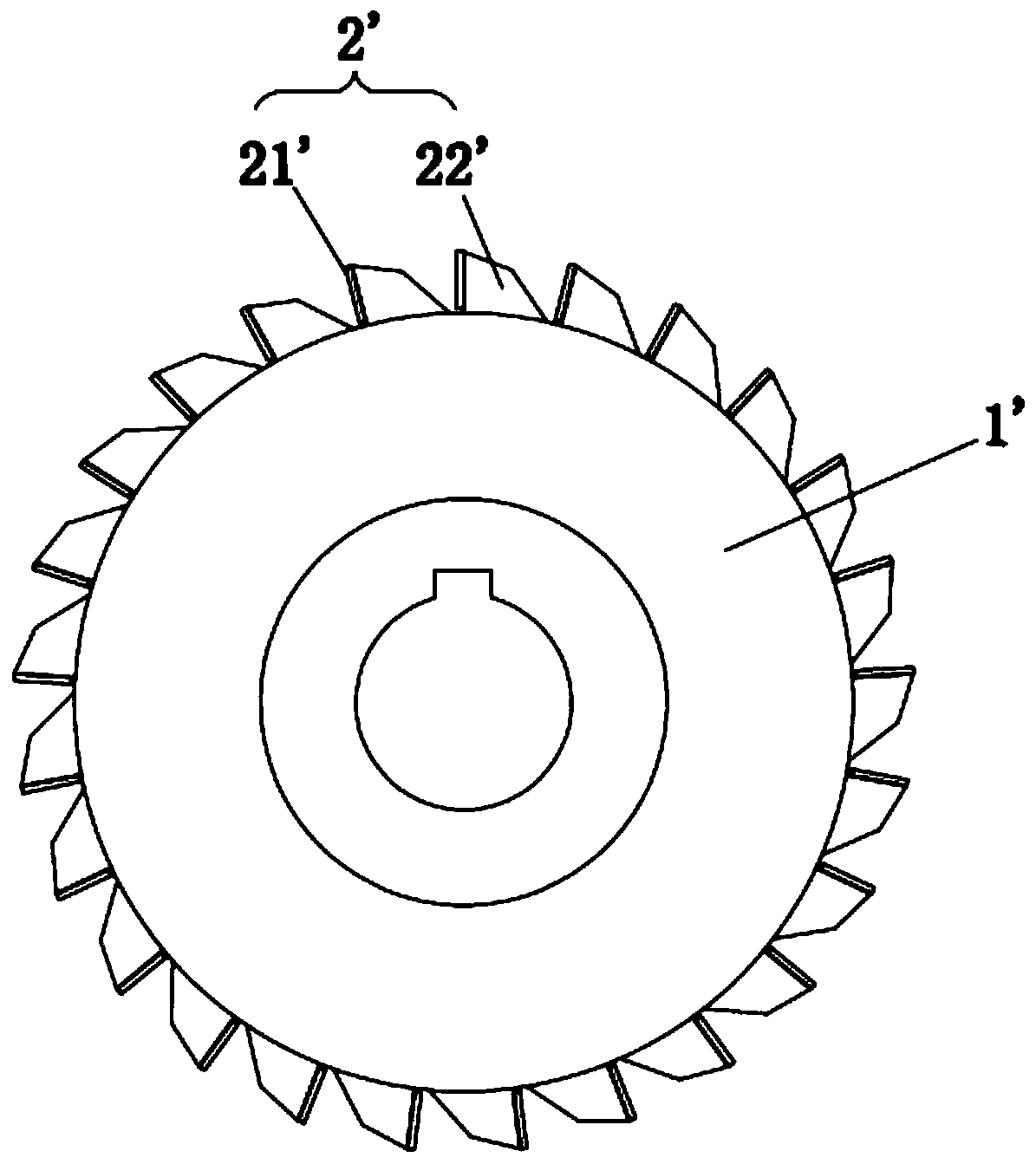

A cutter device, high-speed milling technology, applied in milling cutters, positioning devices, milling machine equipment, etc., can solve the problems of shortening the service life of the cutter teeth 2', hindering the cutting action, and deteriorating the milling efficiency, so as to reduce costs and maintenance. Difficulty, avoid rotation instability, ensure the effect of strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

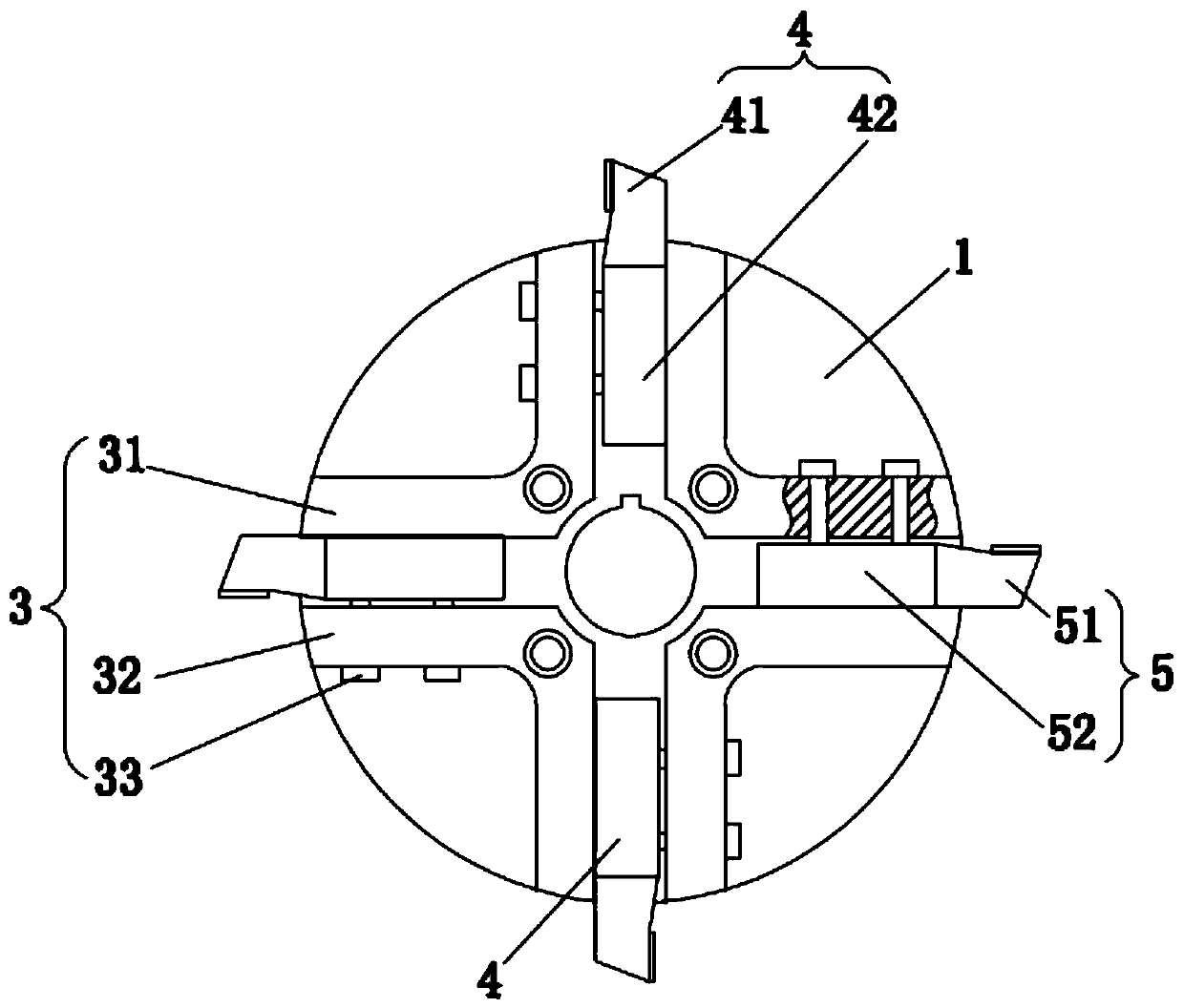

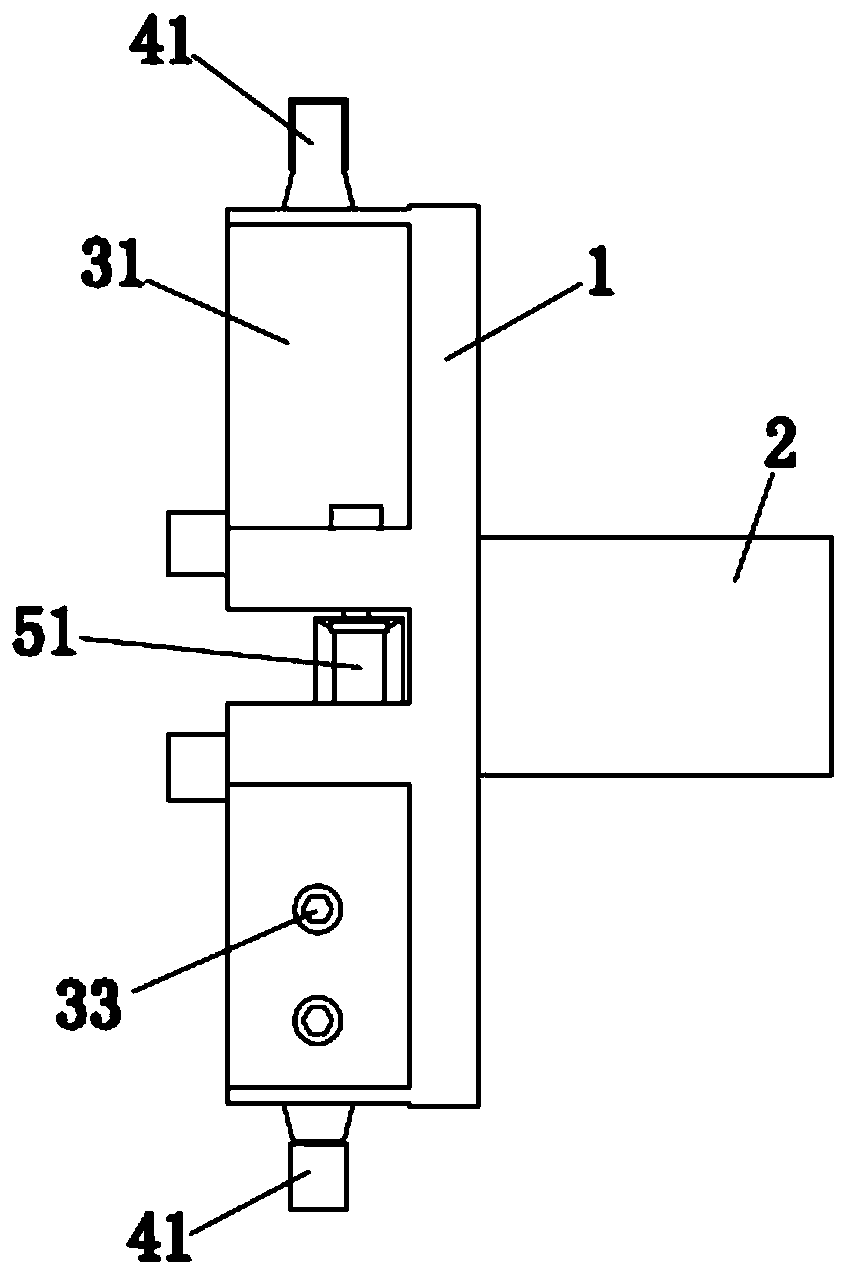

[0029] The specific embodiment of the present invention is as Figure 2 to Figure 4 As shown, a high-speed milling cutter device includes a turntable 1, and two cutter sets are arranged on the turntable 1, and two cutters are arranged around the rotation axis of the turntable 1 in each cutter set, that is, four cutter sets are arranged on the turntable 1 , the four cutters are evenly distributed around the axis of rotation of the turntable 1. One side of the turntable 1 is provided with an installation shaft 2 for connecting with the power mechanism, and the installation shaft 2 is coaxially arranged with the turntable 1 . In a tool group, the cutting range of two adjacent tools is staggered along the milling groove width direction and partially overlapped, that is, among the two adjacent tools in a tool group, the cutting edge of one side of the front tool protrudes from the rear tool The same side cutting edge of the front cutter is located between the two side cutting edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com