End-cut turning tool

A technology of turning tool and cutting head, which is applied in the field of turning and breaking turning tools, which can solve the problems of low feed rate, low work efficiency and danger, and achieve the effect of high cutting force, high cutting efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

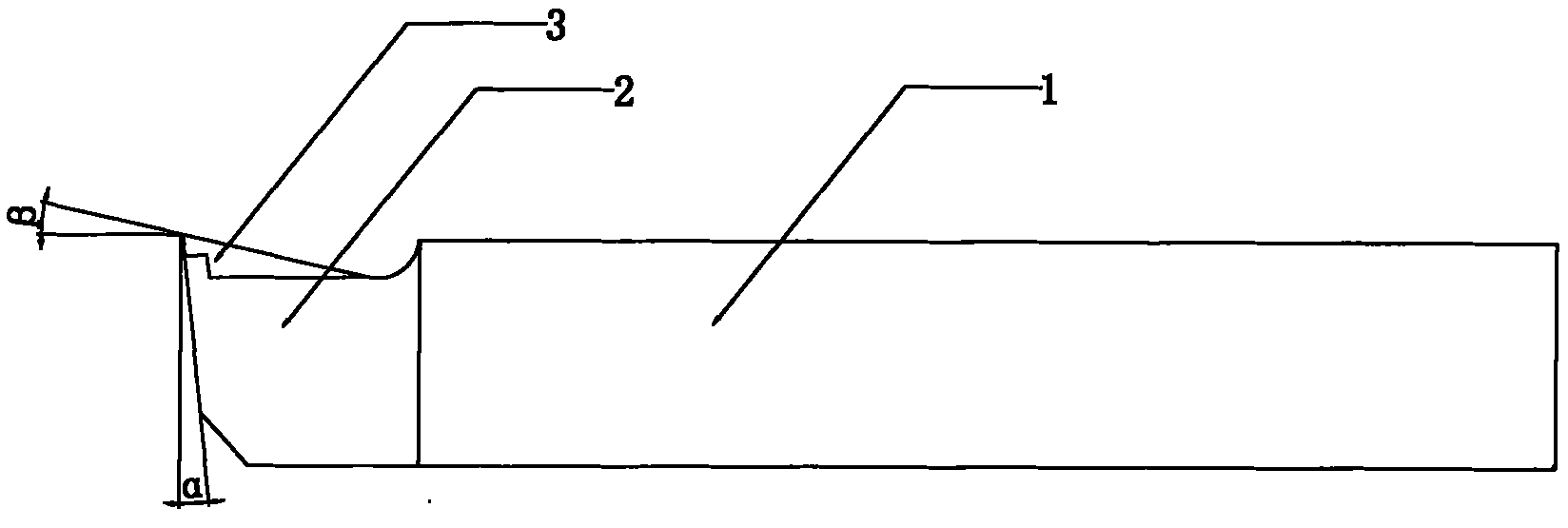

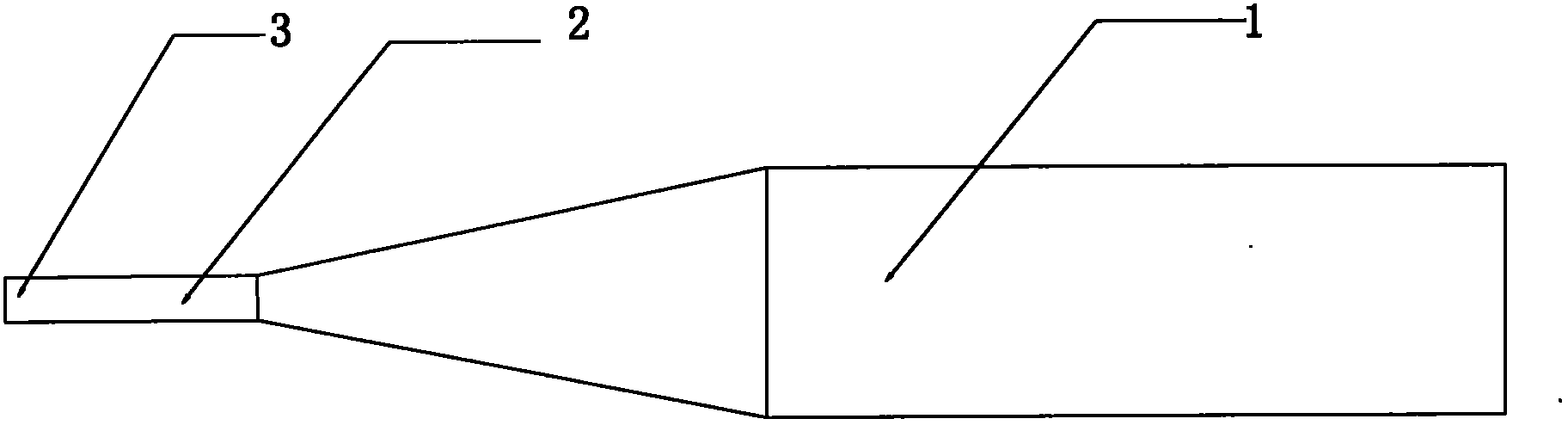

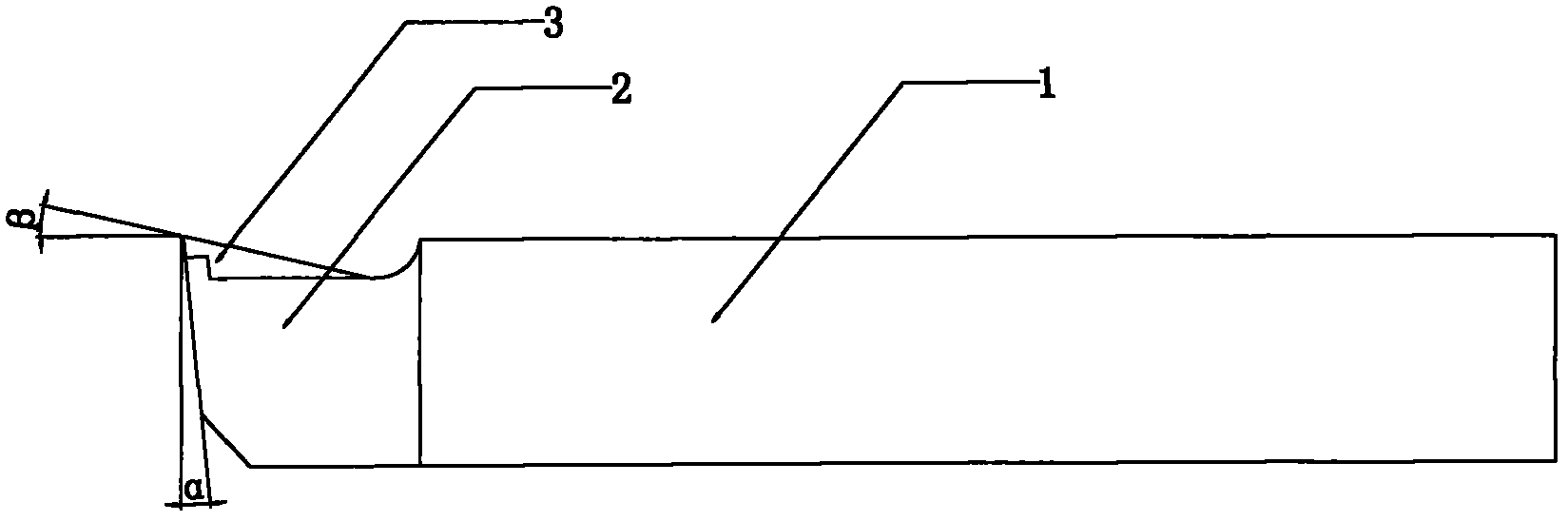

[0012] like figure 1 and figure 2 As shown in the figure, the turning tool includes a tool holder 1 and a tool head 2, the front end of the tool holder 1 is triangular, the tool head 2 is fixedly connected with the front end of the tool holder 1, and the tool head 2 is provided with a cutting edge 3. The width of 2 is 0.2-4mm, the front end face of the cutter head 2 and the horizontal plane form a certain angle α, the angle α is 5-15°, the plane where the blade 3 is located and the horizontal plane form a certain angle β, the angle β is 10 -40°, so that the cutting force of the cutting edge 3 is large, the collision force of the workpiece is small, and the phenomenon of knife jumping is not easy to occur under the condition of large feed rate, which provides cutting efficiency and service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com