Gear honing machine tool without axial feed and gear honing method

A technology of axial feeding and honing, applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of difficult to improve gear machining accuracy, high price, high maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

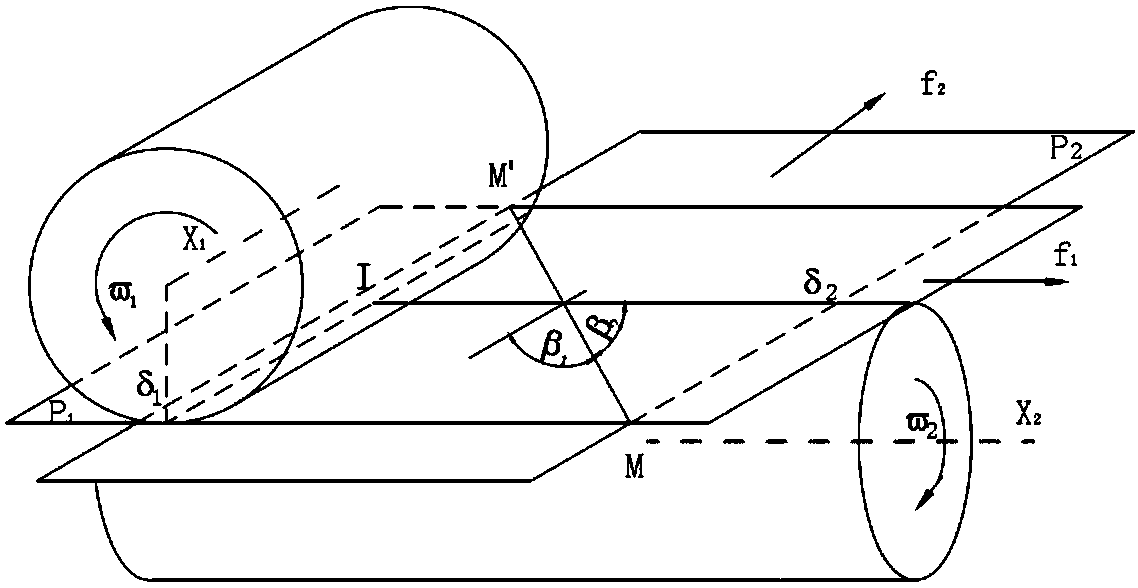

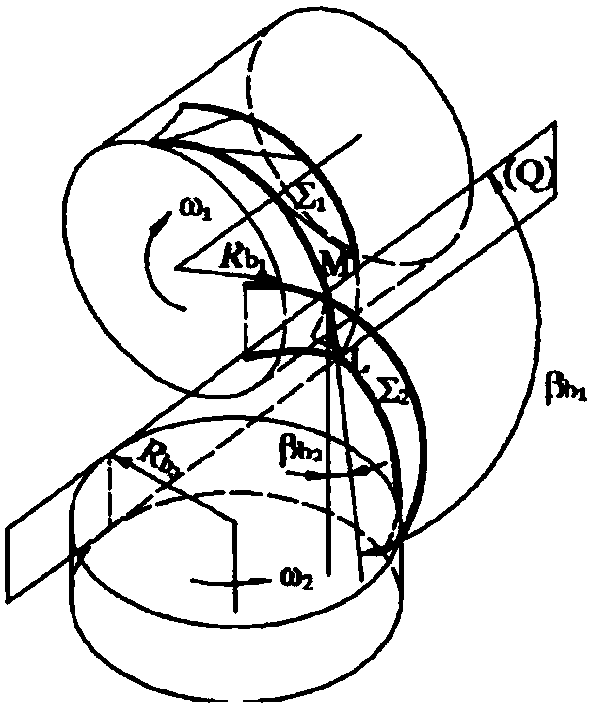

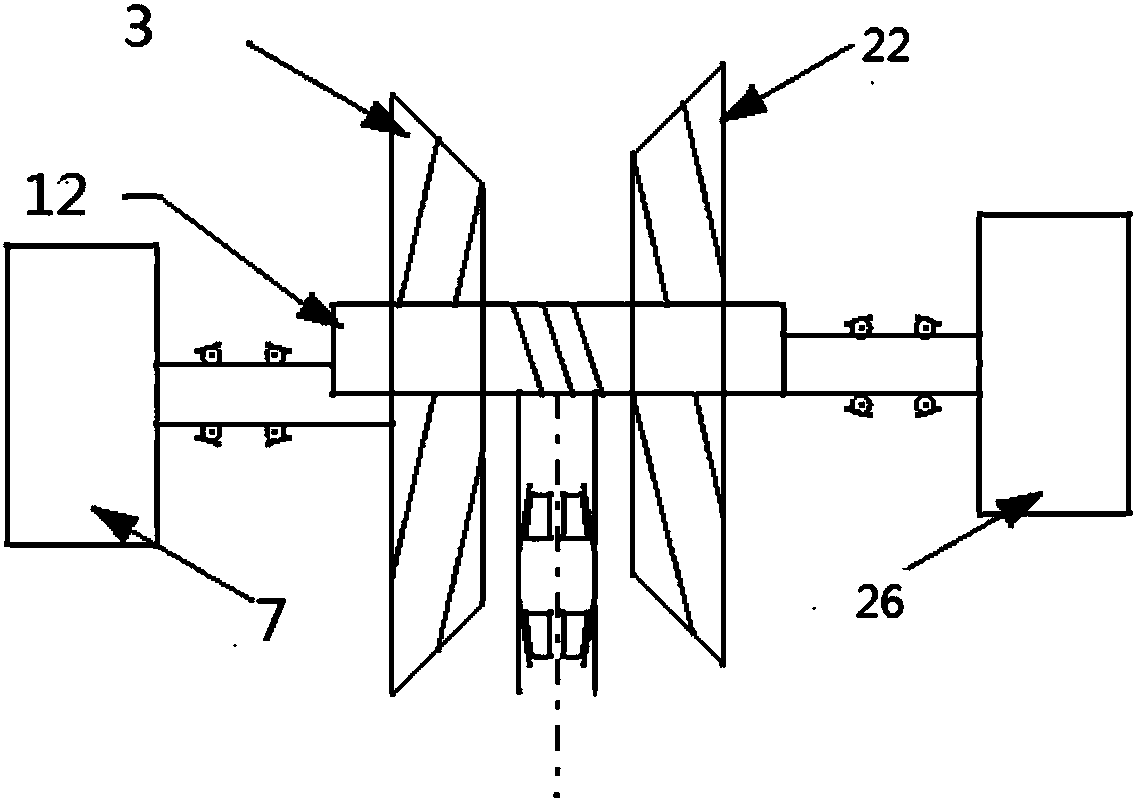

[0061] Such as Figure 1 to Figure 14 As shown, the gear honing machine without axial feed is a finishing honing machine for mass production of large-sized involute cylindrical helical gears. The main structure of the machine tool includes a bed 18, a left gear honing wheel drive shaft 1 and a right gear honing wheel drive shaft 20, a workpiece shaft 8, a first servo motor 7 and its matching driver and connecting cables, a second servo motor 26 and Its matching driver and connecting cable, processed helical gear 12, left tooth surface honing wheel 3, right tooth surface honing wheel 20, supporting bearings, and standard spare parts fastening nuts, air-cooled hoses, industrial air-cooled equipment, Control System. The non-axial feed gear honing machine of the present invention can complete the finishing honing of involute cylindrical helical gears with designed dimensions, has simple machine tool movement, easy manufacture, and low manufacturing and processing costs. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com