Energy-gathered tile surface polishing machine

A scraper and energy-concentrating technology, which is applied in the field of scraper, can solve problems such as difficulty in obtaining flatness, low cutting ability, and high noise, and achieve the effects of low noise, strong cutting ability, and reduced inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

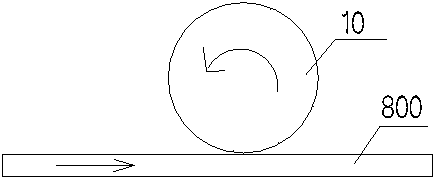

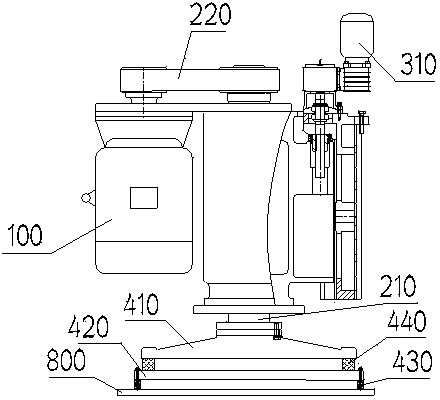

[0019] The invention discloses an energy-gathering tile scraper, such as figure 2 As shown, it includes a motor 100, a transmission structure, a cutting structure and a lifting mechanism. The motor drives the cutting structure to move through the transmission structure, and the lifting mechanism drives the cutting structure to move up and down to process the workpiece 800.

[0020] In this embodiment, the transmission structure includes a power shaft 210 and a belt 220, the power shaft 210 is vertically arranged, the top of the power shaft 210 is connected to the motor 100 through the belt 220, and the bottom of the power shaft 210 is connected to the cutting structure. In this embodiment, the lifting mechanism includes a lifting track, a lifting seat installed in the lifting track, and a lifting motor 310 that drives the lifting seat to move up and down. The motor 100 and the transmission structure are fixedly installed on the lifting seat.

[0021] In this embodiment, the c...

Embodiment 2

[0029] The structure of the ceramic tile scraper disclosed in this embodiment is basically the same as that in Embodiment 1. The difference is that the cutting structure in this embodiment includes an energy-gathering disc and a diamond knife, and the diamond knife is fixedly installed at the edge of the bottom of the energy-gathering disc. The top of the energy gathering disk is connected with the power shaft through an elastic structure.

[0030] Specifically, see image 3 , the power shaft is connected to the center of the energy-gathering plate, and a layer of elastic rubber layer is set at the connection between the power shaft and the energy-gathering plate. The elastic rubber layer can be fixed with glue or screws. This method of setting costs more and is more practical. powerful. Since the elastic rubber layer is arranged at the center of the energy collecting disk, when the energy collecting disk starts to rotate or stops, the received horizontal friction force is re...

Embodiment 3

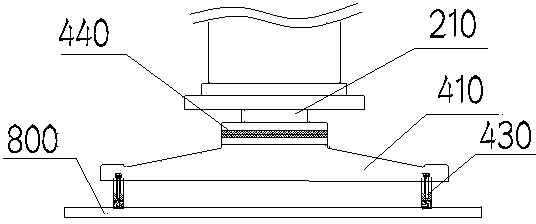

[0032] The structure of the ceramic tile scraper disclosed in this embodiment is basically the same as that in Embodiment 1, the difference is that two elastic structures are set in this embodiment, see Figure 4 , including a first elastic structure 441 and a second elastic structure 442, the first elastic structure is the same as that in Embodiment 1, and the second elastic structure is arranged at the connection between the top of the energy collecting disc and the power shaft.

[0033] In this embodiment, considering that during the start and stop process of the energy collecting plate, a horizontal pulling force (friction force) will be generated on the first elastic structure and the second elastic structure, and referring to the positions of the two elastic structures, it can be found that the first The tensile force on the first elastic structure is relatively large. Considering factors such as the service life of the two elastic structures, production and maintenance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com