Clamp

A clamp and clip technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of inconvenient operation, labor-saving, and difficult to realize convenient disassembly and assembly, and achieve the effect of compact structure, convenient operation, convenient disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing of description:

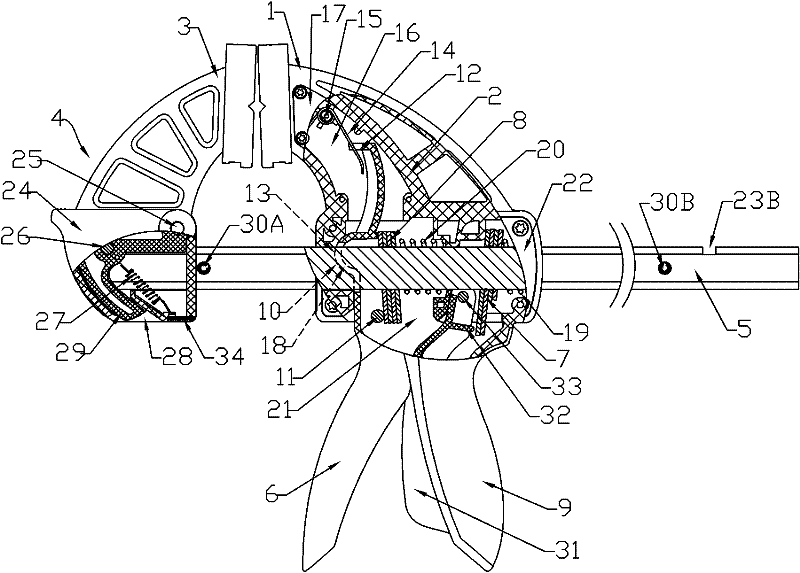

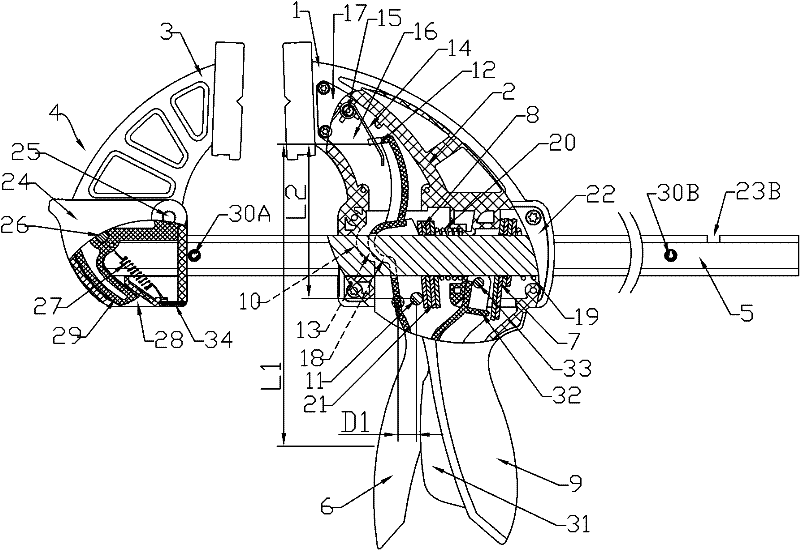

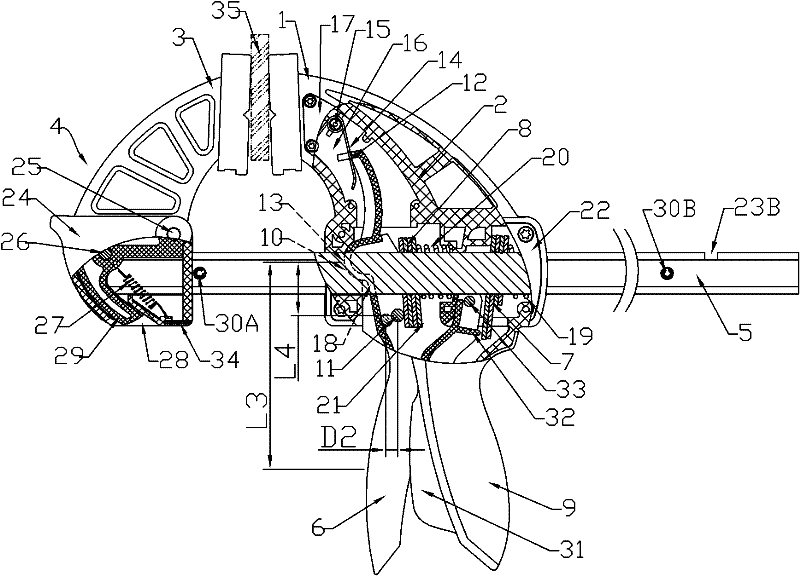

[0021] Such as figure 1 As shown, the fixture of the present invention includes a fixed clamp body 2 with a fixed chuck 1, a movable clamp body 4 with a movable chuck 3, a guide rod 5, and a force handle 6, and the guide rod 5 is penetrated on the fixed clamp body 2 , and configure the locking clip 7 and the force clip 8 for the guide rod 5, the movable clip body 4 is installed on one end of the guide rod 5 (the left end in the figure) and the fixed chuck 1 corresponds to the movable chuck 3, The fixed clip body 2 has a handle 9 extending toward the other end of the fixed chuck 1, and a fixed support portion 10. The booster handle 6 is provided corresponding to the handle 9. The booster handle 6 has a handle for pushing against and adding The force applying portion 11 of the force clip 8 (specifically, it may be a shaft installed on the force applying handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com