Patents

Literature

37results about How to "Build pressure quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

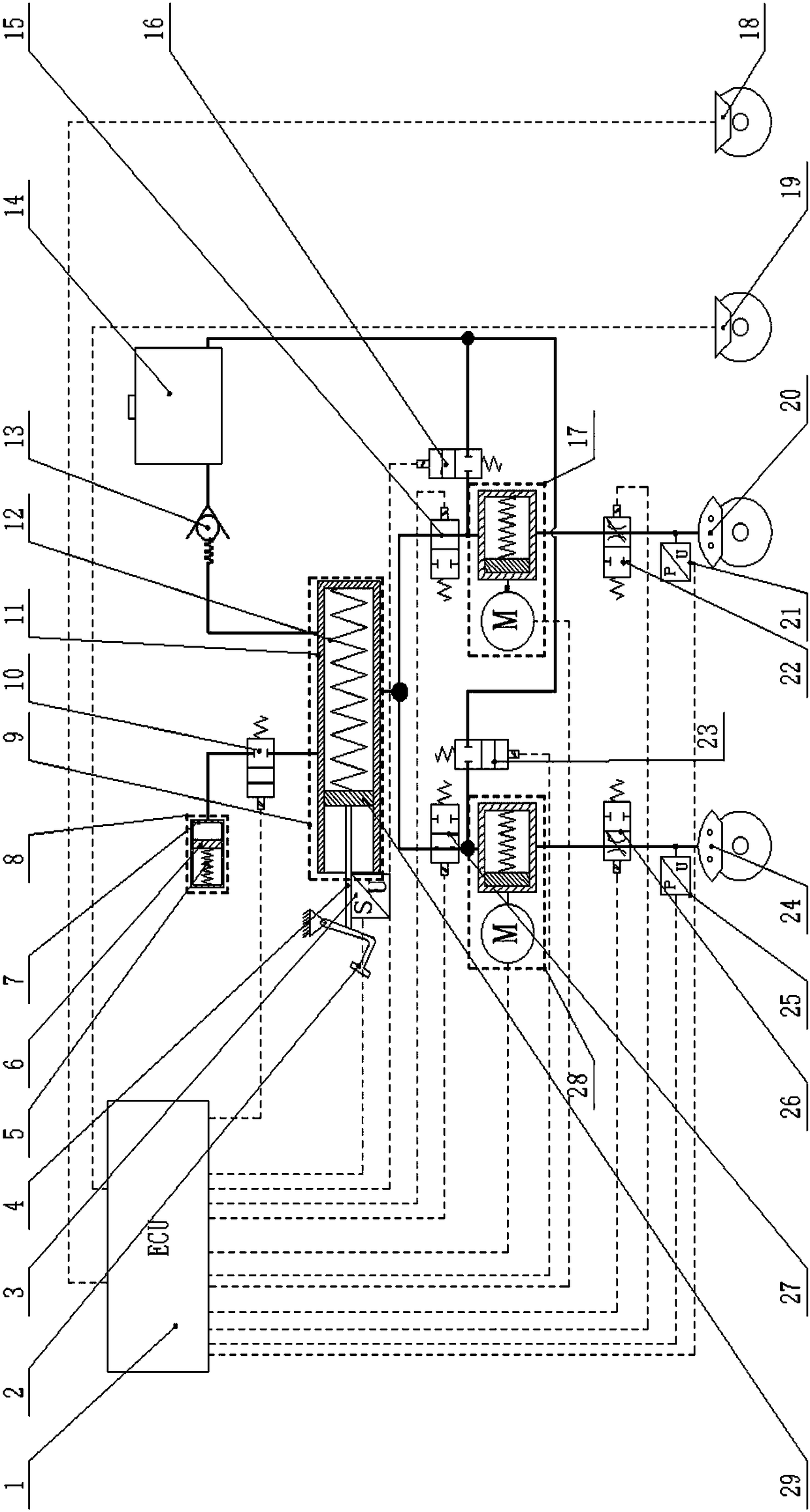

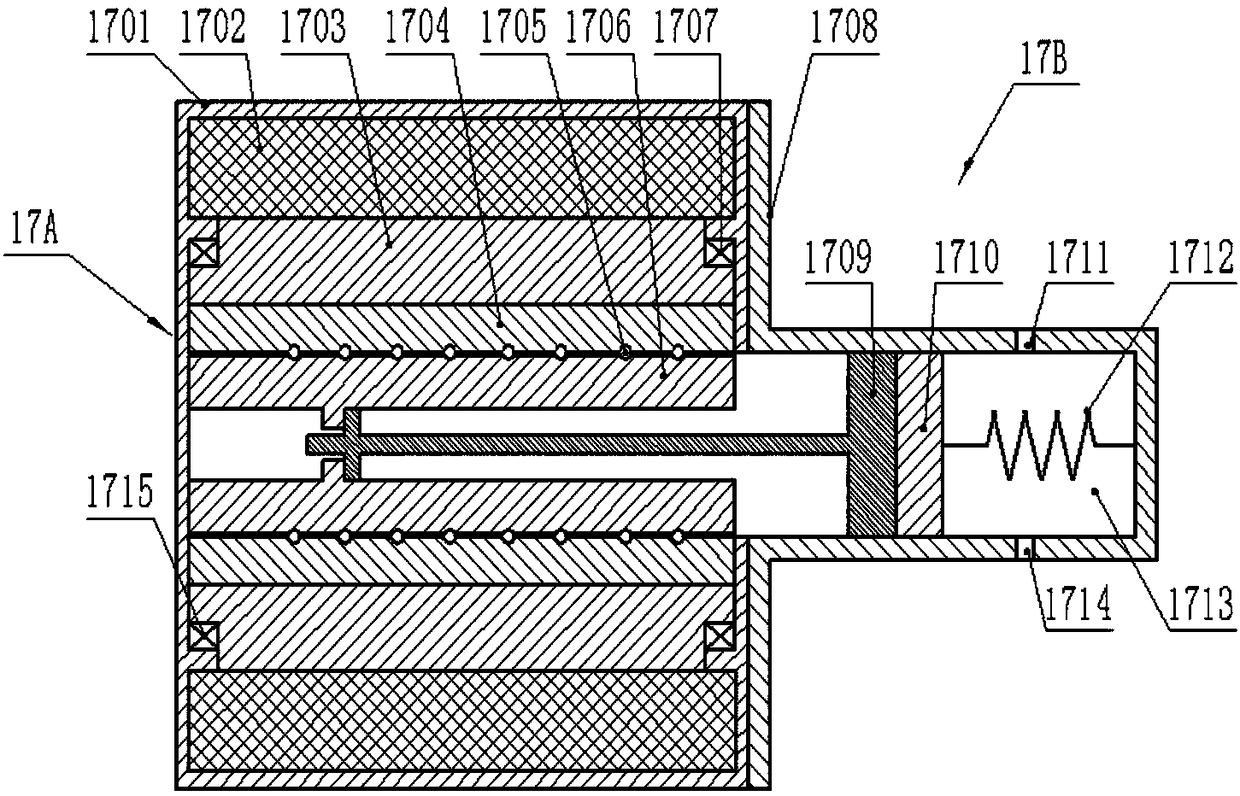

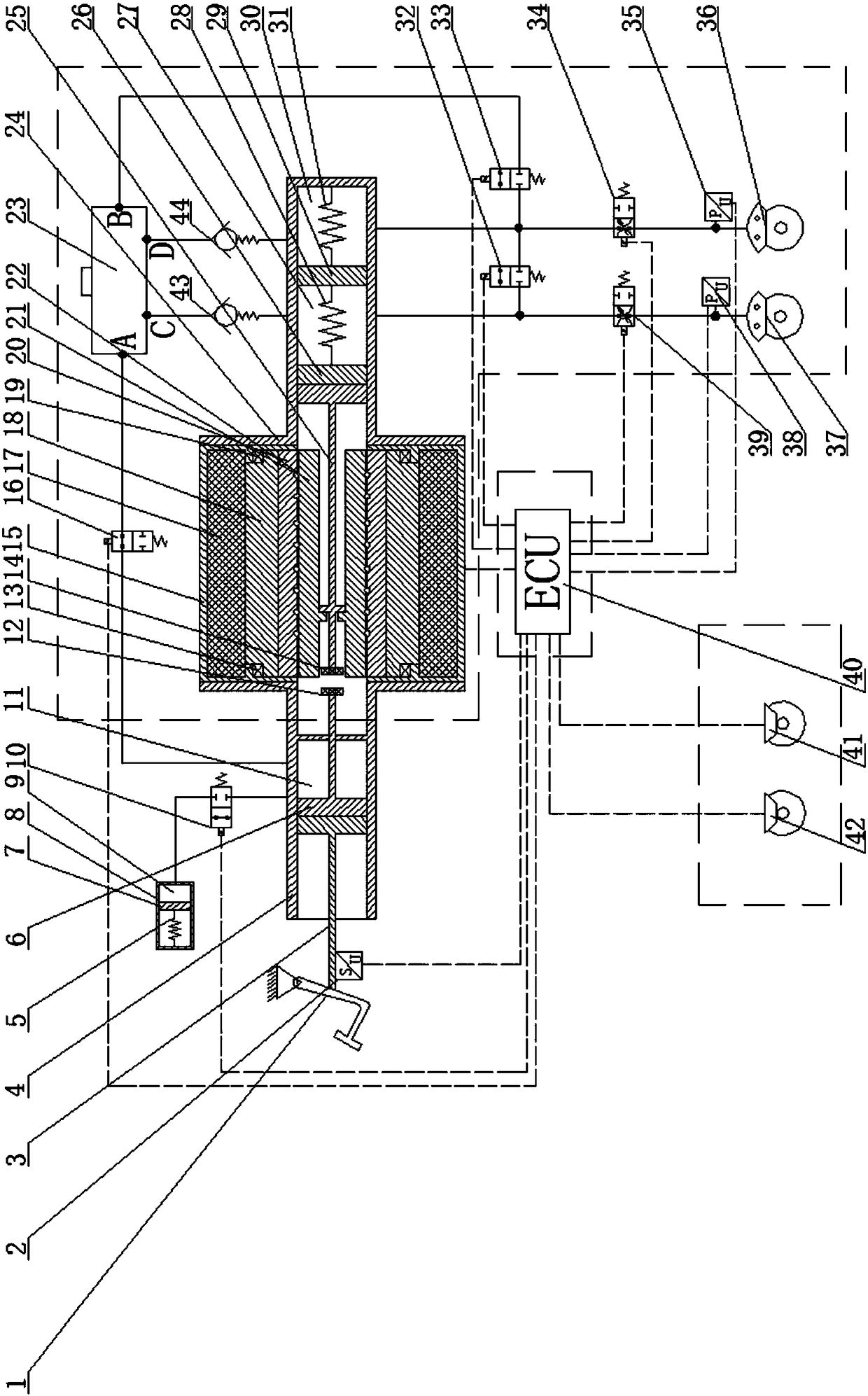

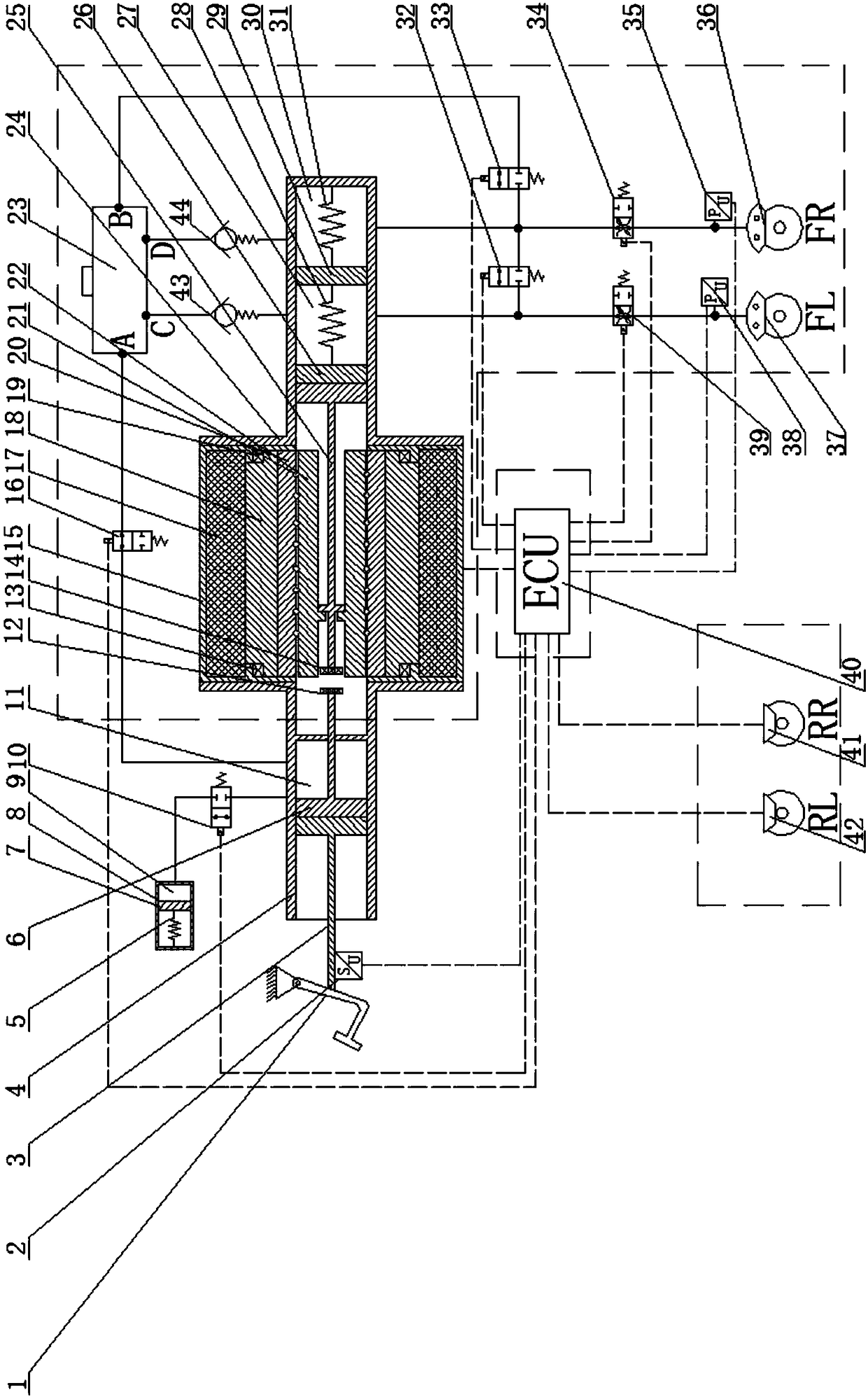

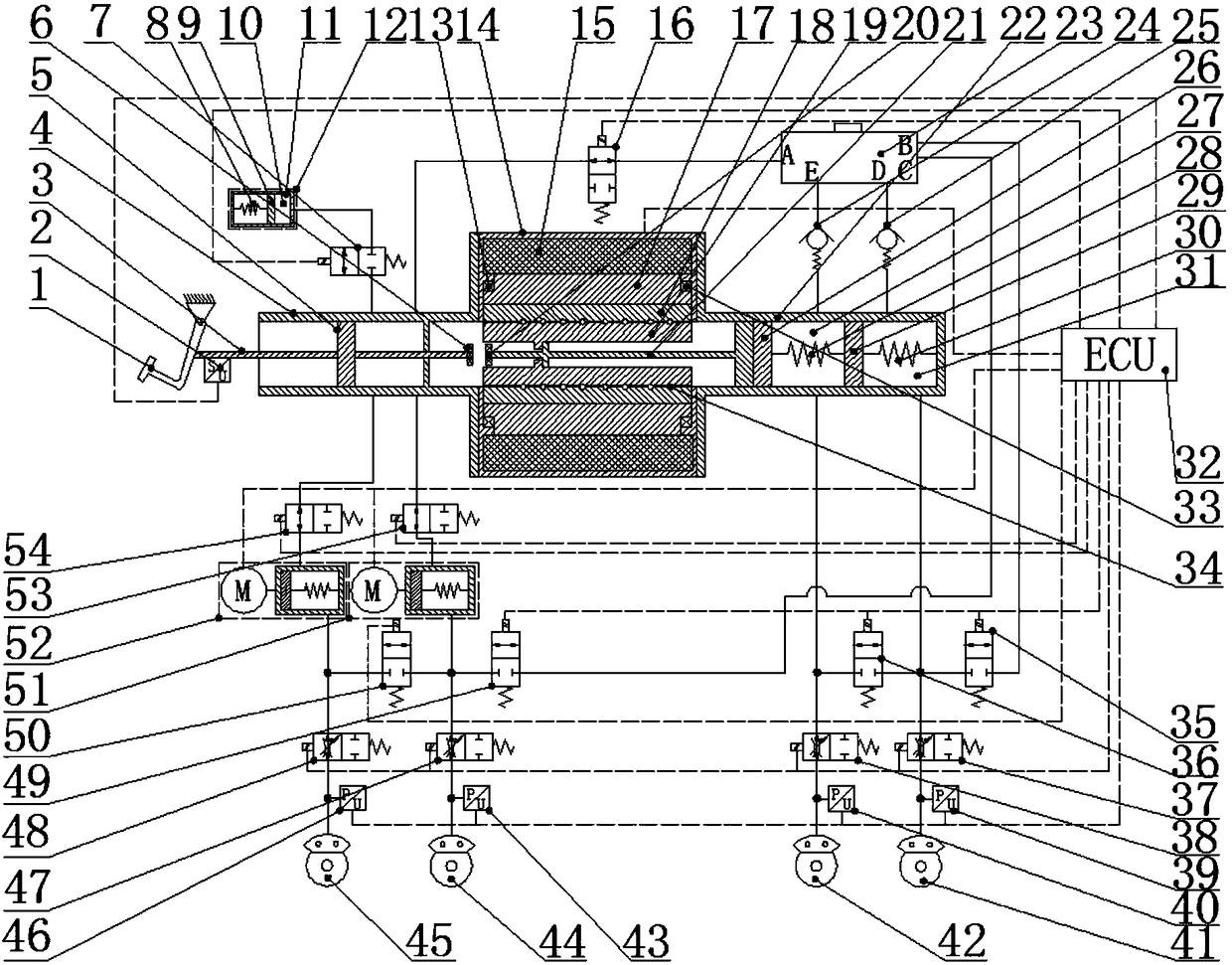

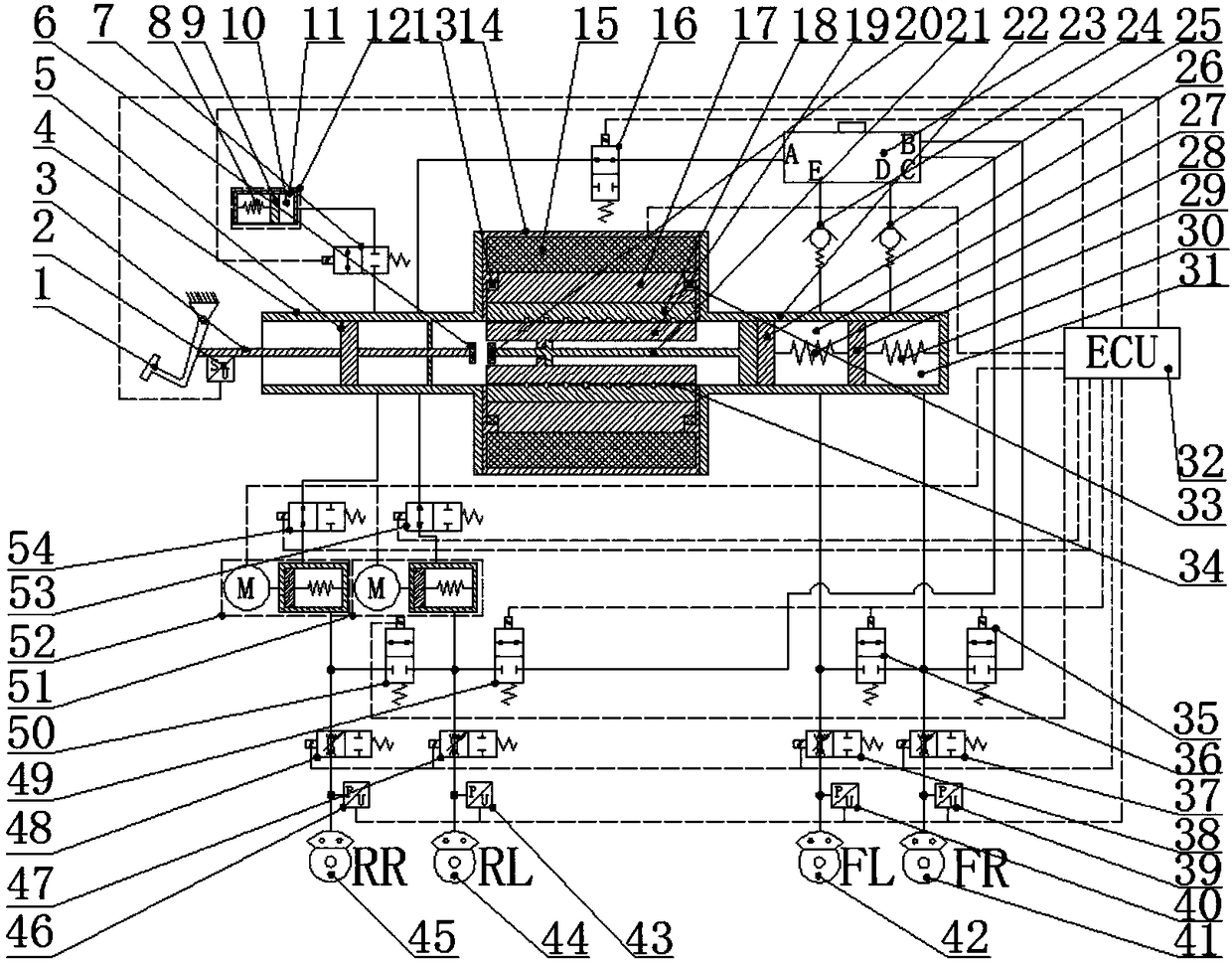

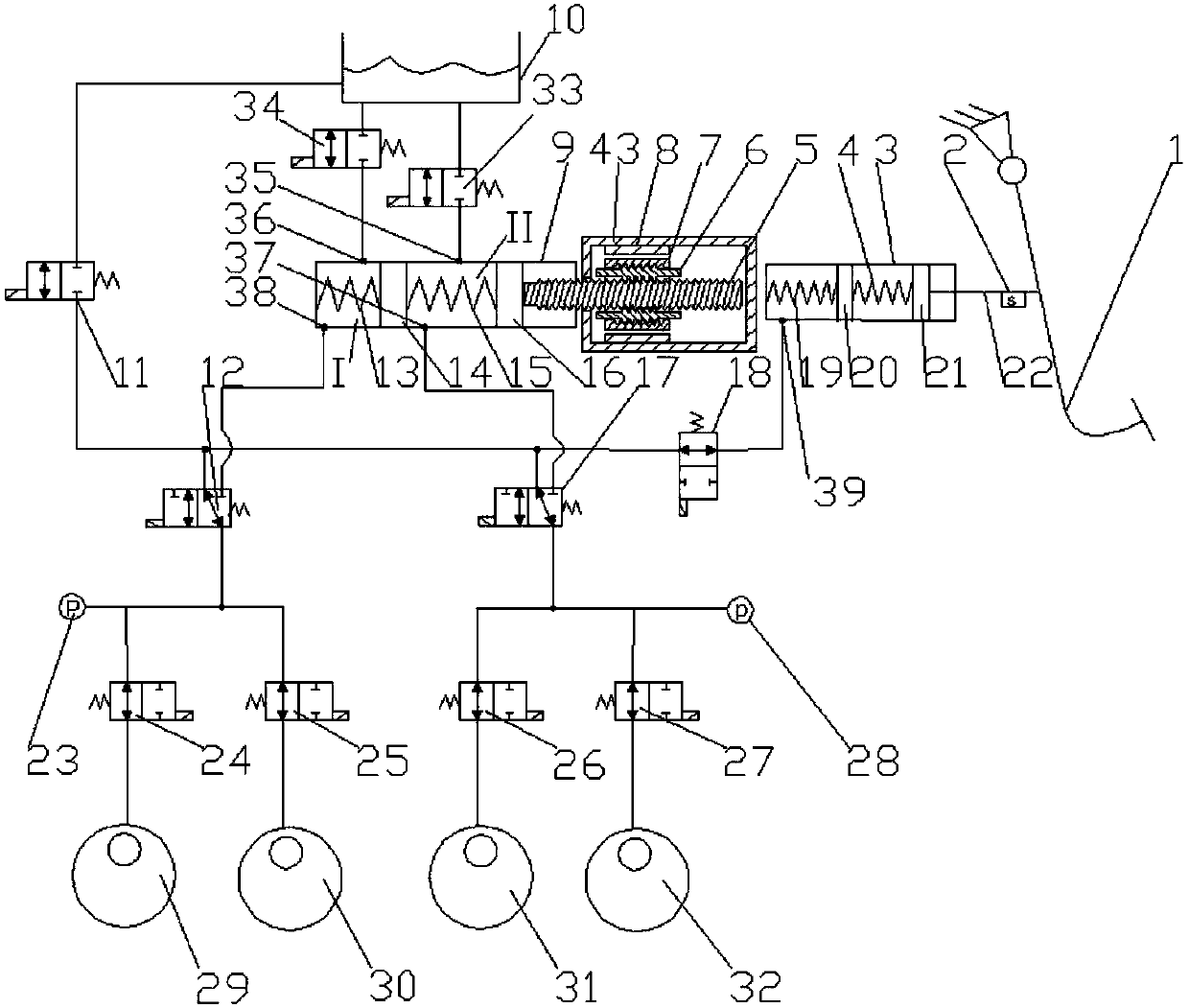

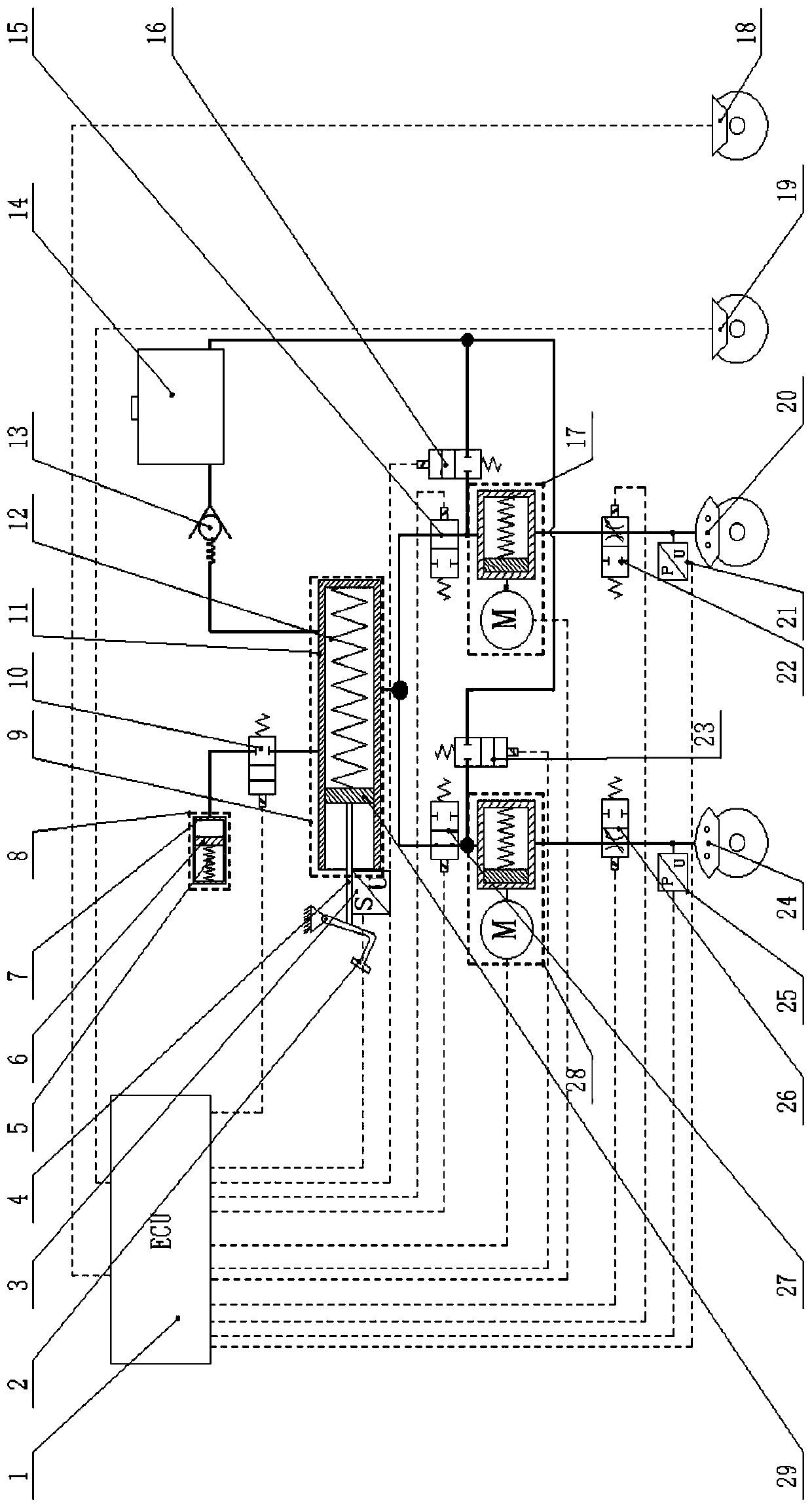

Composite drive-by-wire brake system and brake control method for independently controlling four-wheel pressure

InactiveCN108162943ACompact structureBuild pressure quicklyBraking action transmissionFoot actuated initiationsWheel cylinderHydraulic brake

The invention discloses a composite drive-by-wire brake system and brake control method for independently controlling four-wheel pressure. Two electromechanical brake modules in the system are both electromechanical pressurizing units in signal connection with an electronic control unit, two electronic hydraulic brake modules are both connected with a brake main cylinder pipeline in a brake pedalmechanism, each electronic hydraulic brake module is composed of a normally open switch electromagnetic valve, an electronic hydraulic pressurizing unit, normally open linear electromagnetic valves and a brake wheel cylinder in series sequentially through pipelines, pressure sensors are arranged on a connecting pipeline of the brake wheel cylinder, the electromagnetic valves, the electronic hydraulic pressurizing units and the pressure sensors are all respectively in signal connection with the electronic control unit; the brake control method comprises a brake control method of an effective state of electrifying and a brake control method of a failure state of outage. The composite drive-by-wire brake system and brake control method for independently controlling four-wheel pressure can overcome the deficiency of a single line control system, can independently achieve rapid pressure buildup of four wheels and accurately control pressure, and have functions of failure braking and regenerative braking.

Owner:JILIN UNIV

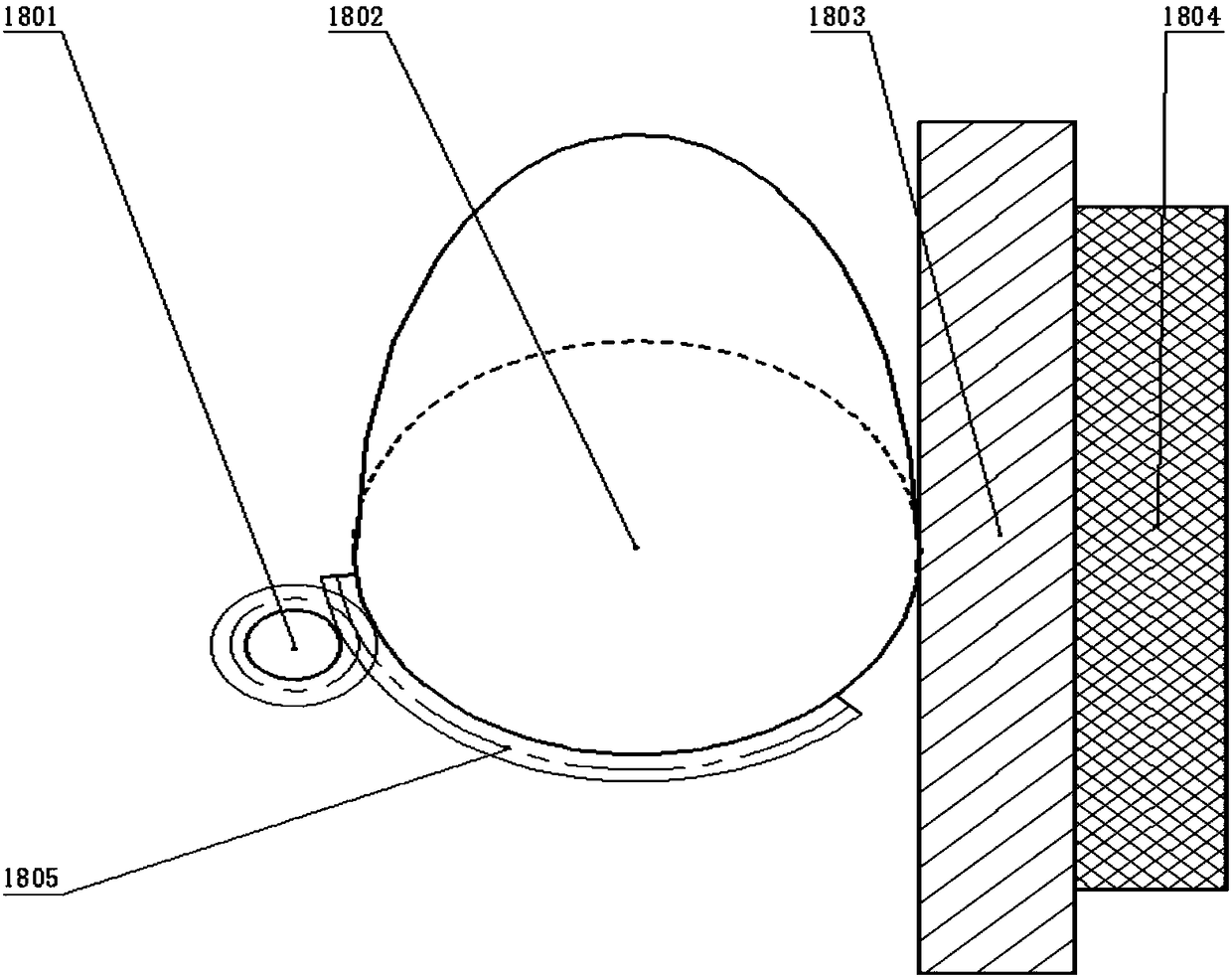

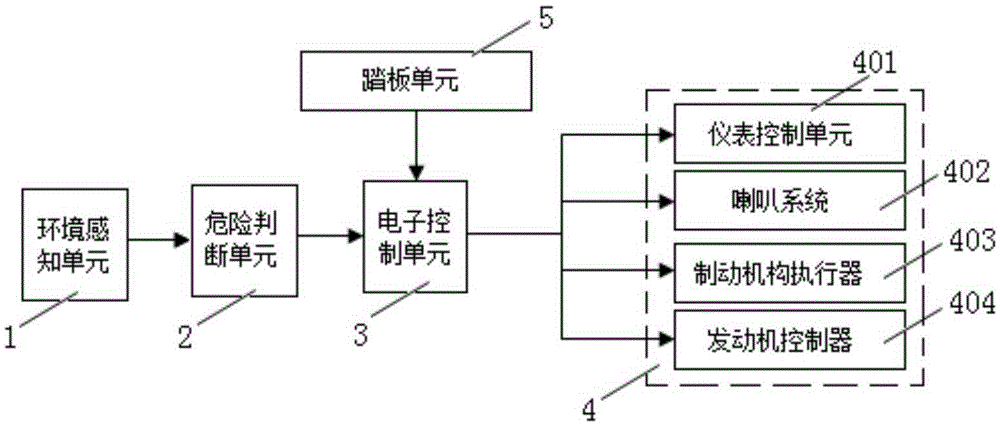

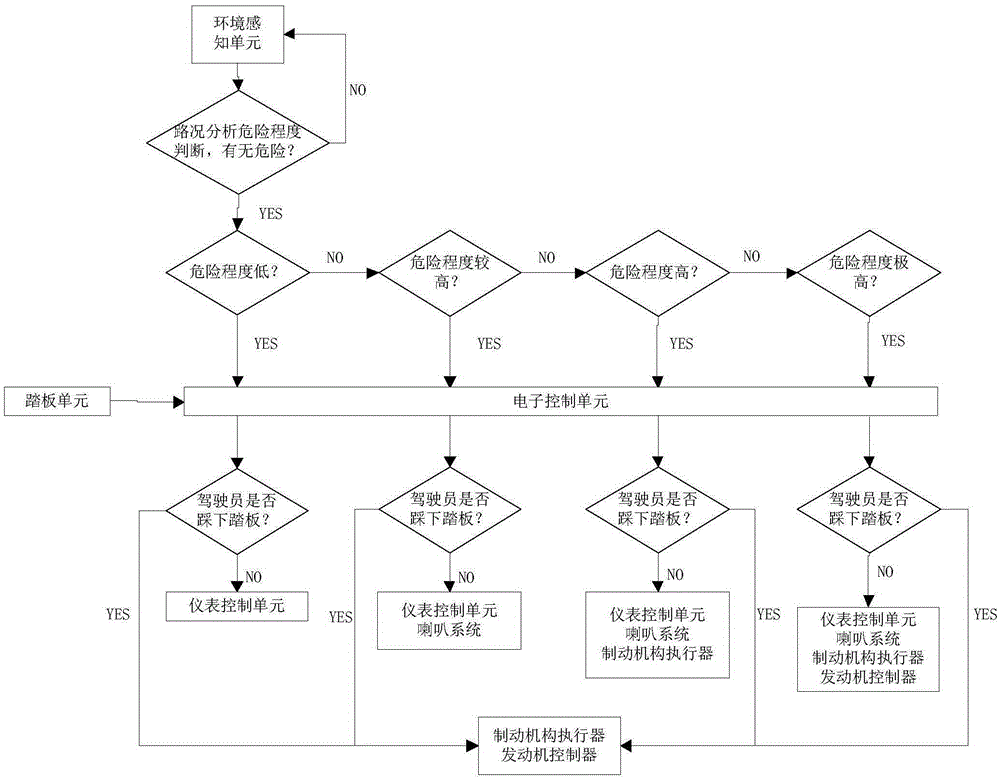

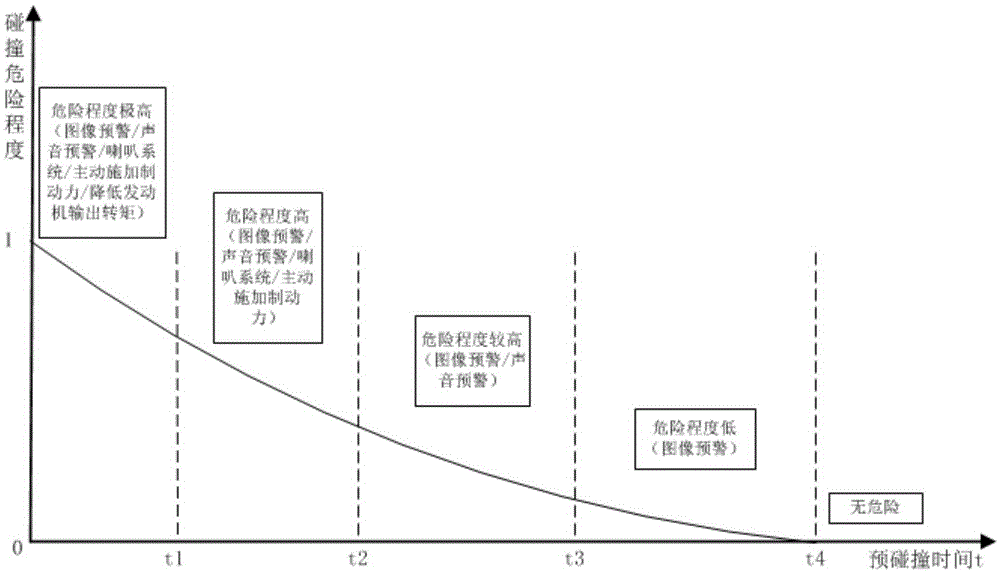

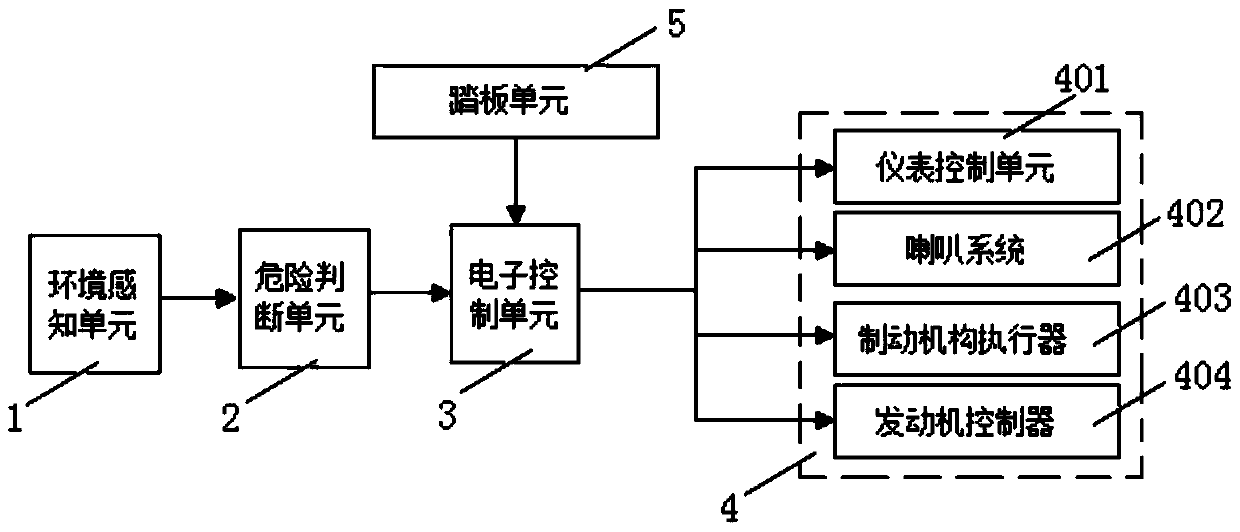

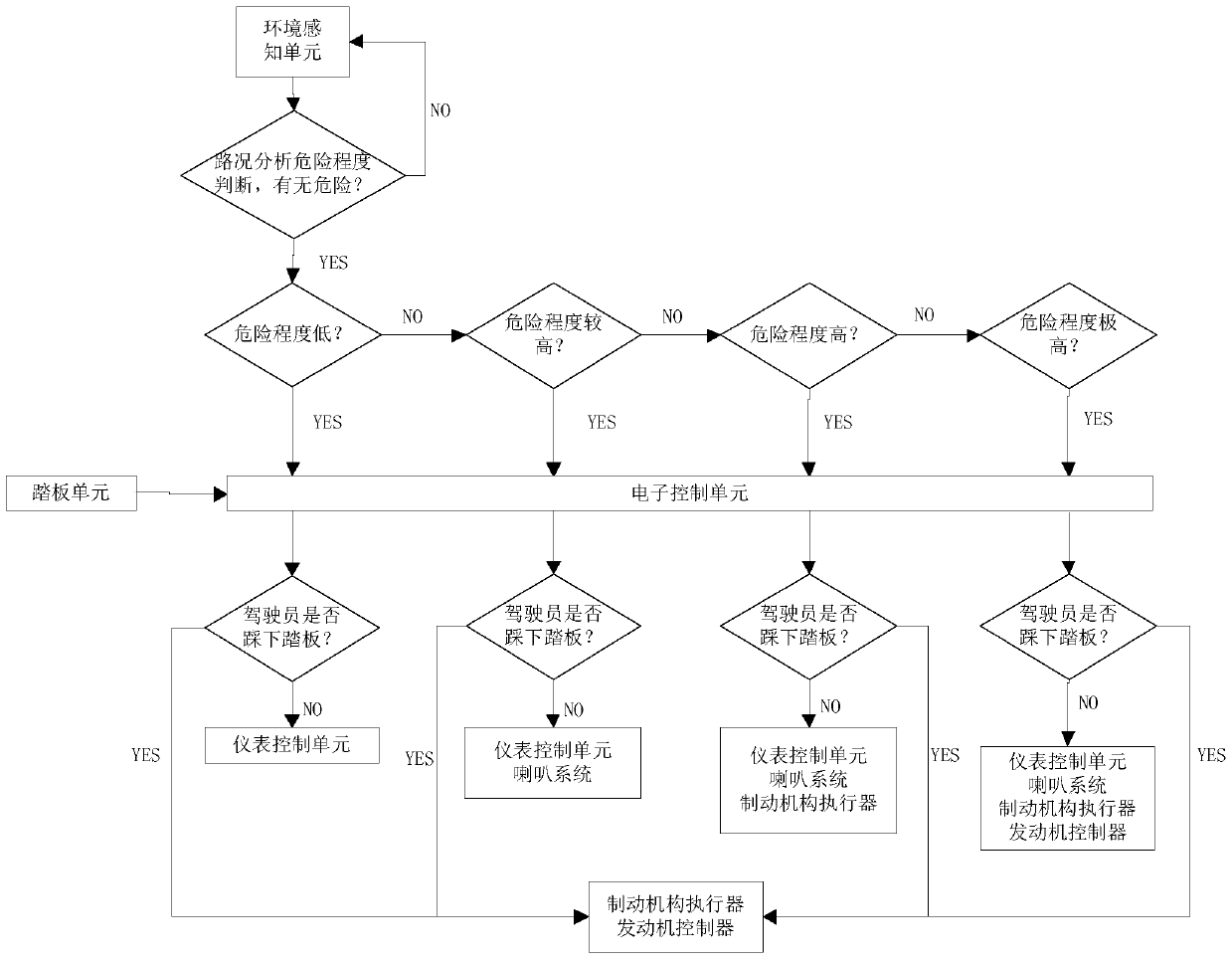

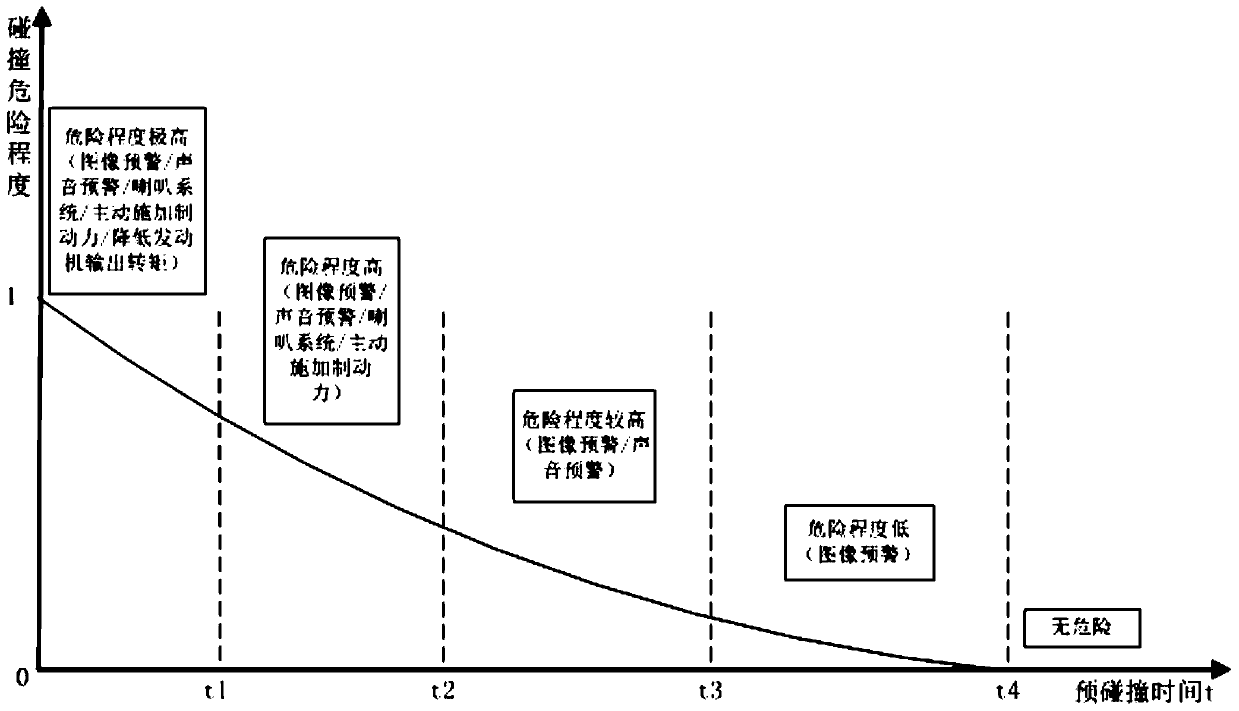

Forward collision prevention method and system based on electronic hydraulic braking

ActiveCN105346528AEasy to controlReduce distractionsAutomatic initiationsSignalling/lighting devicesDriver/operatorBraking system

The invention relates to the technical field of electronic hydraulic braking, in particular to a forward collision prevention method and system based on electronic hydraulic braking. The method includes the steps that an environment perception unit acquires and outputs environment information to a danger judgment unit; the danger judgment unit computes the pre-collision time t and judges and sends the danger level of collision to an electronic control unit; the electronic control unit sends an alarm and / or brake command to an execution unit according to the different danger levels; and the execution unit conducts alarming and / or braking according to the command. Based on an electronic hydraulic braking system, the response speed is high. According to the different danger levels, a danger alarm is given to a driver; and when the danger level is high or extremely high, a horn system can be controlled to give pedestrians a prompt that the danger exists, so that the safety of the pedestrians around vehicles is guaranteed.

Owner:DONGFENG MOTOR CORP HUBEI

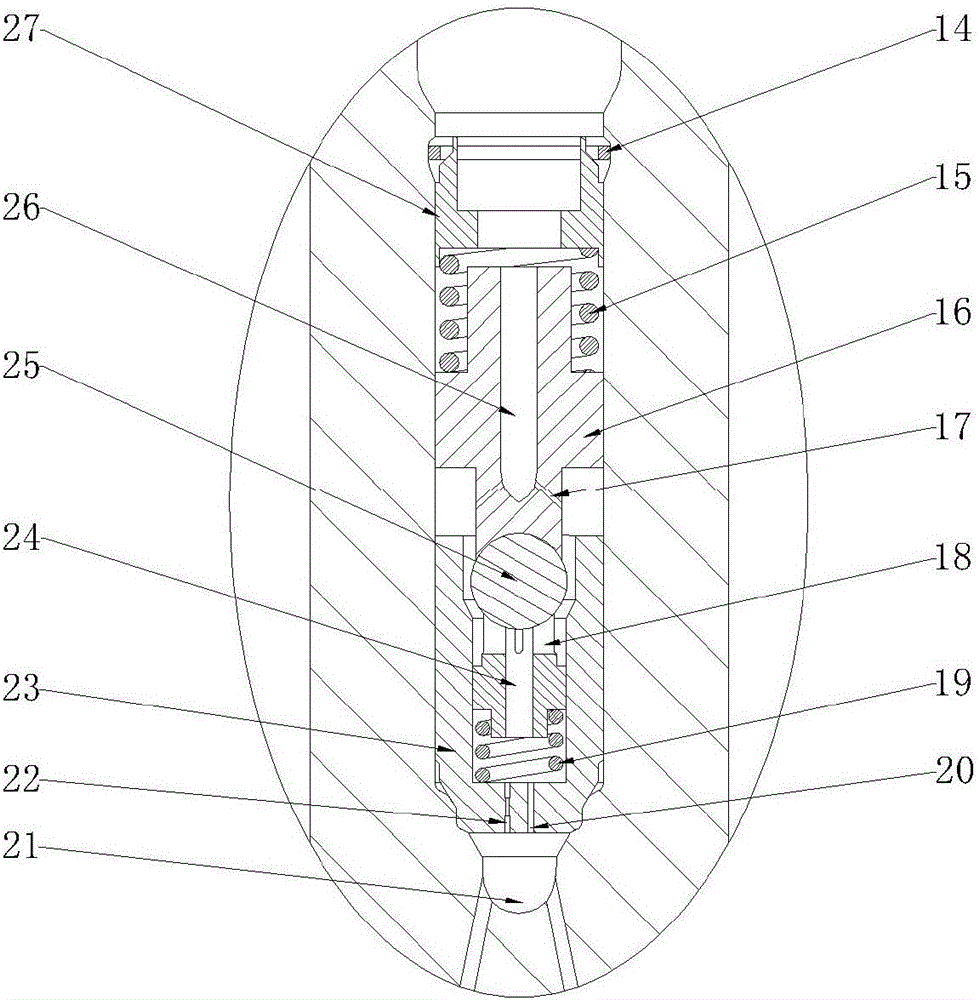

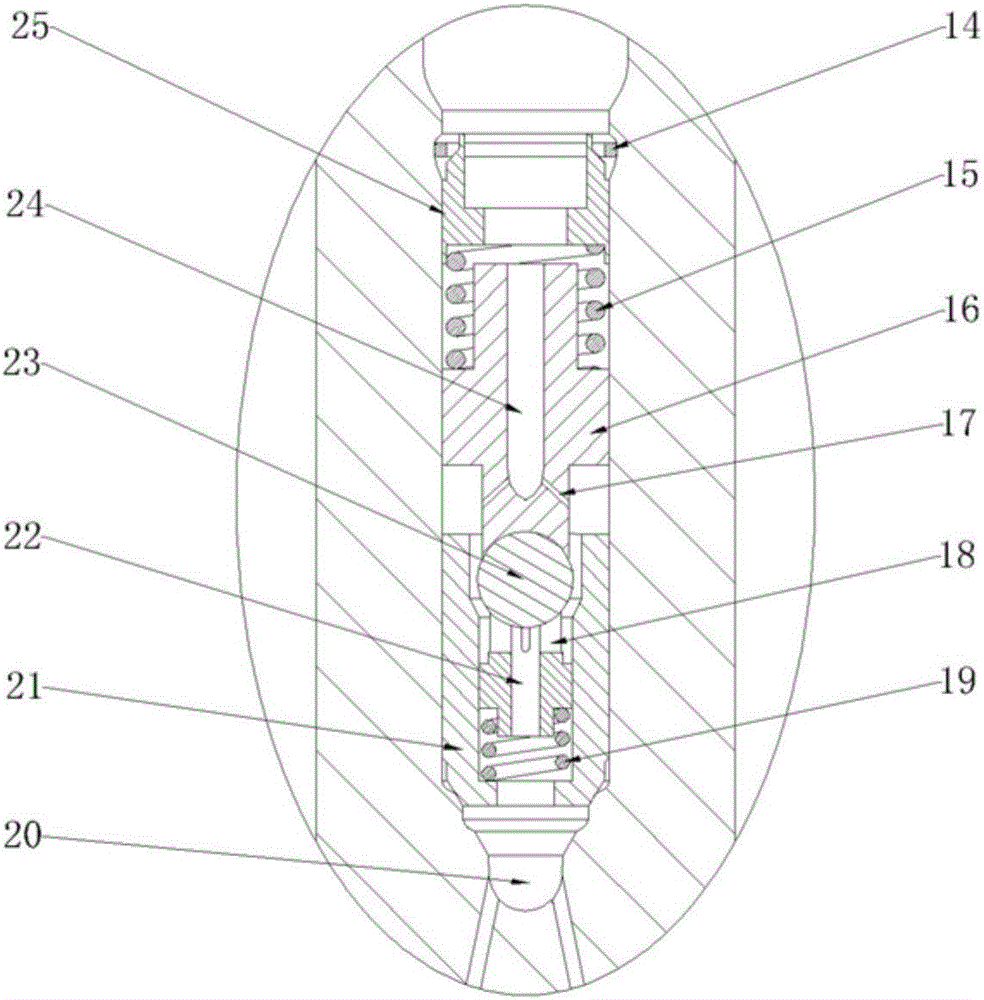

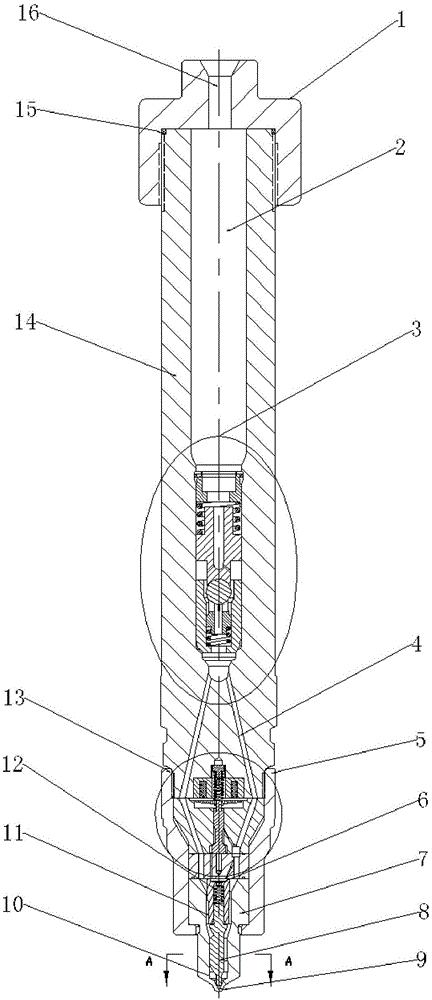

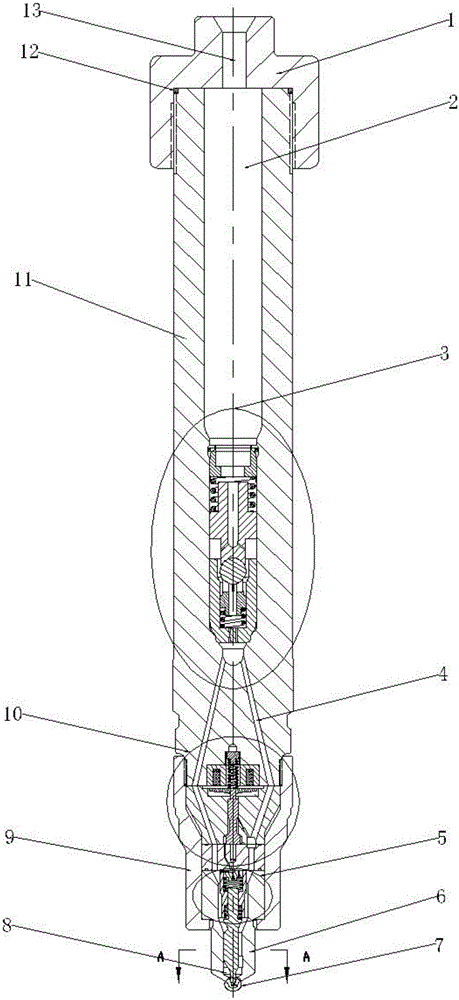

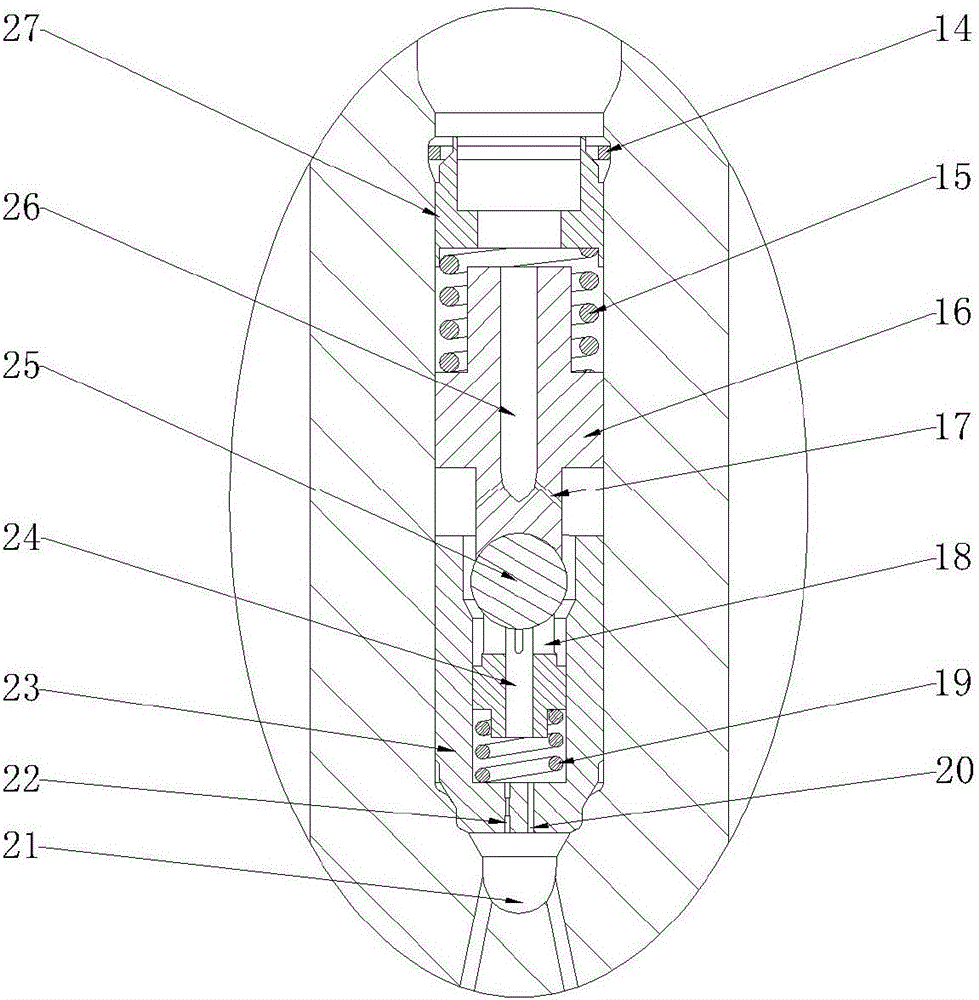

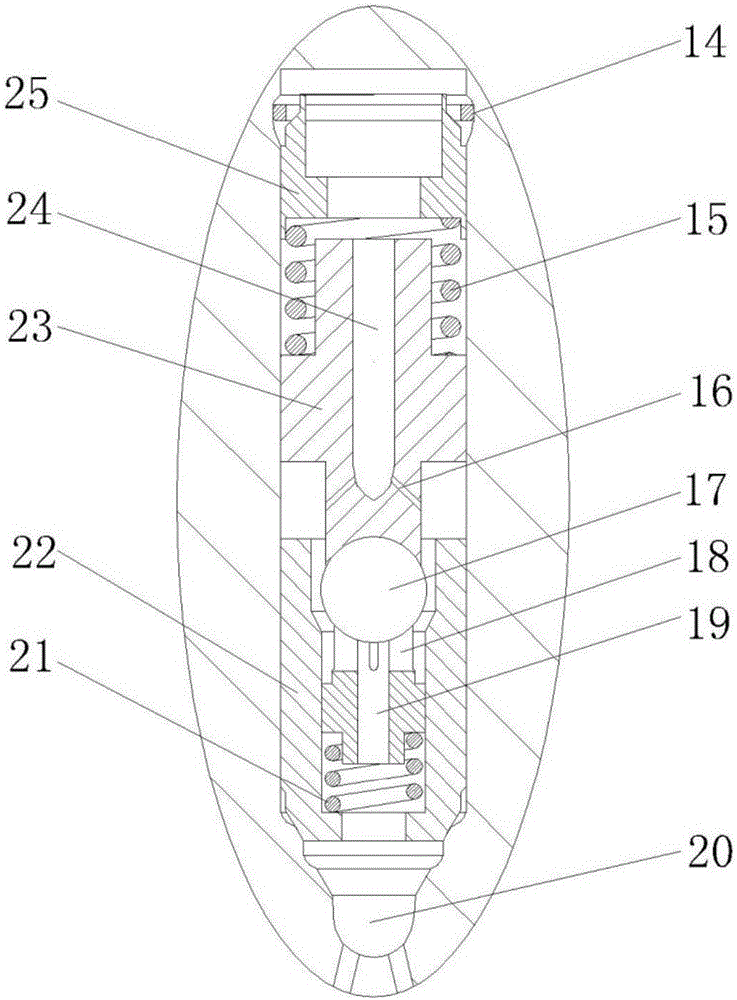

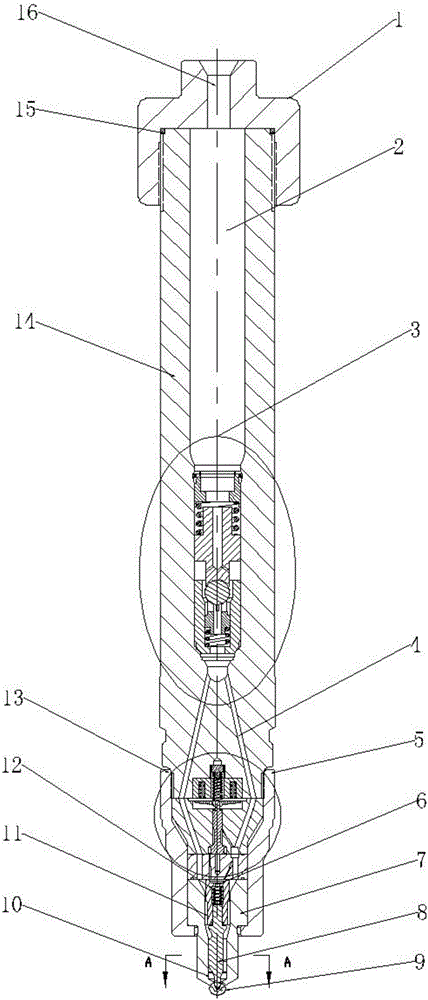

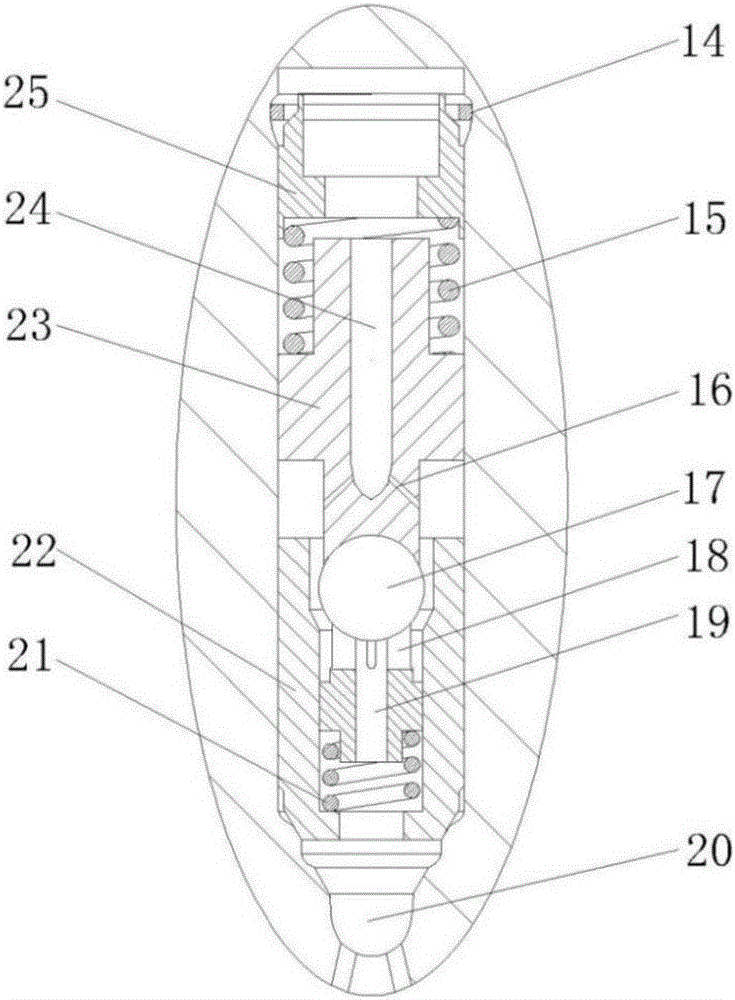

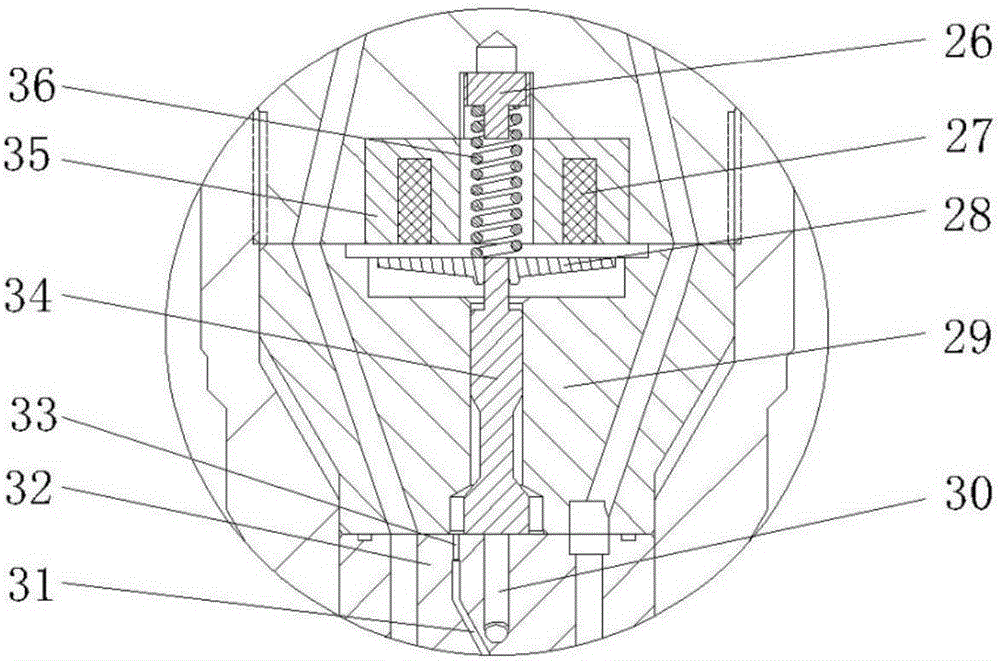

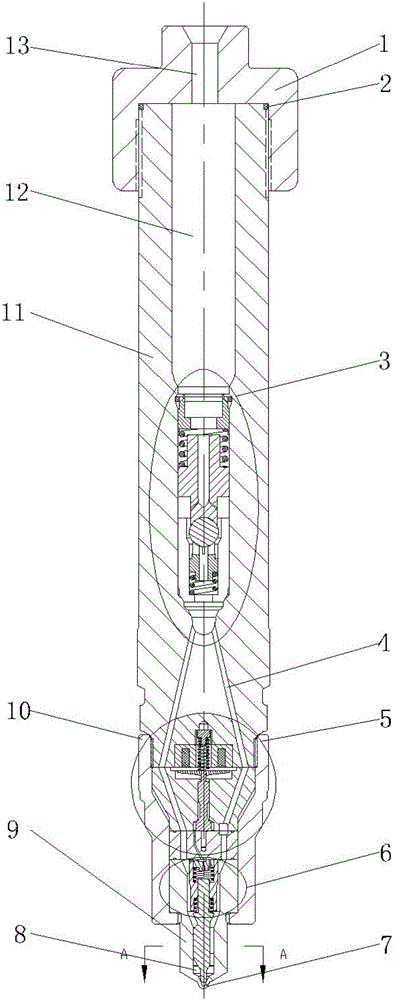

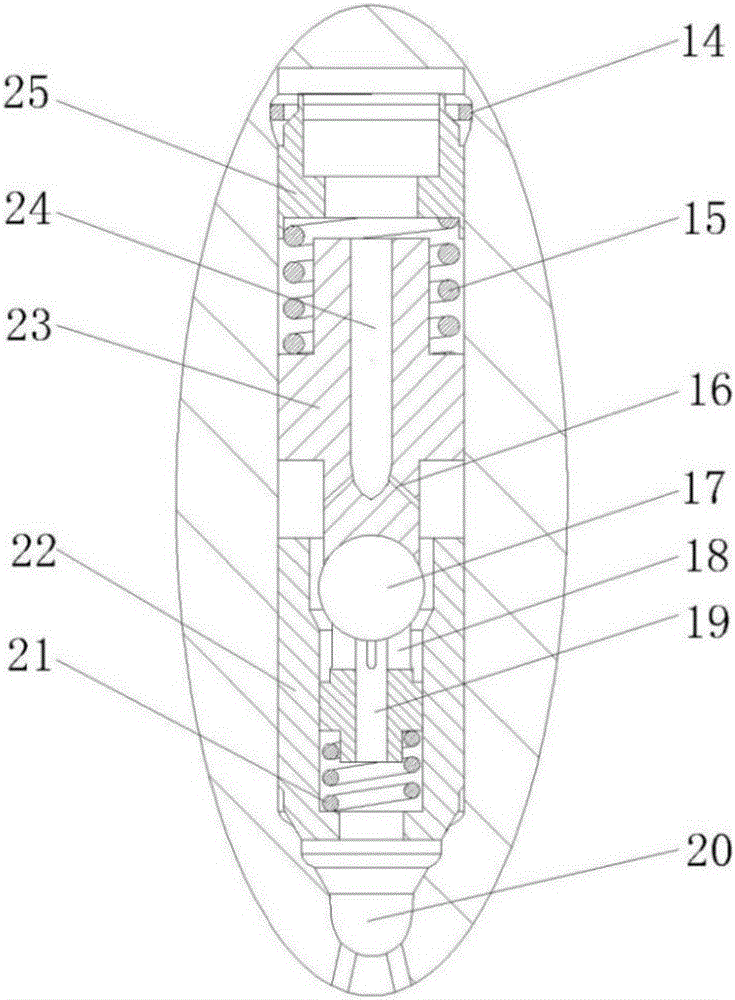

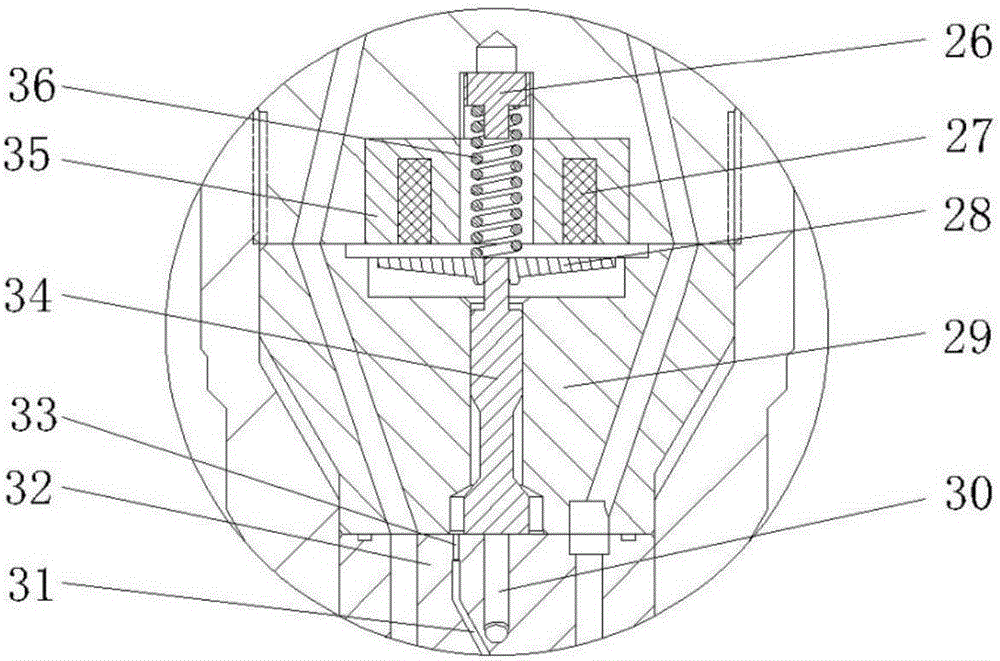

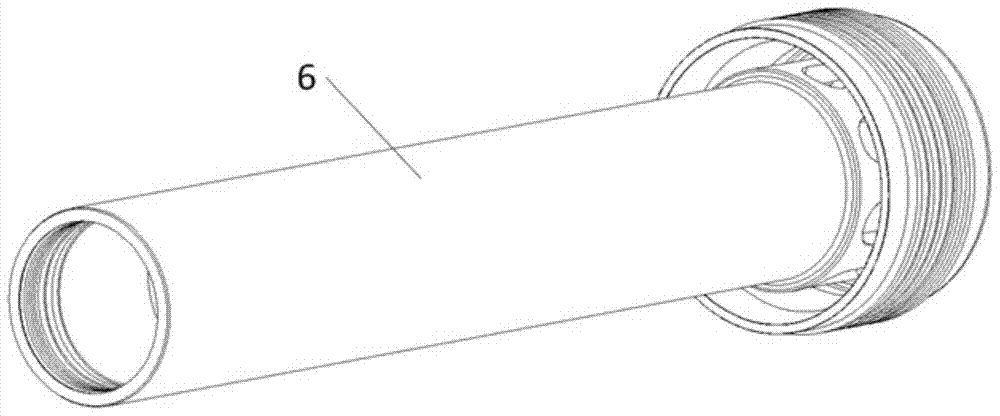

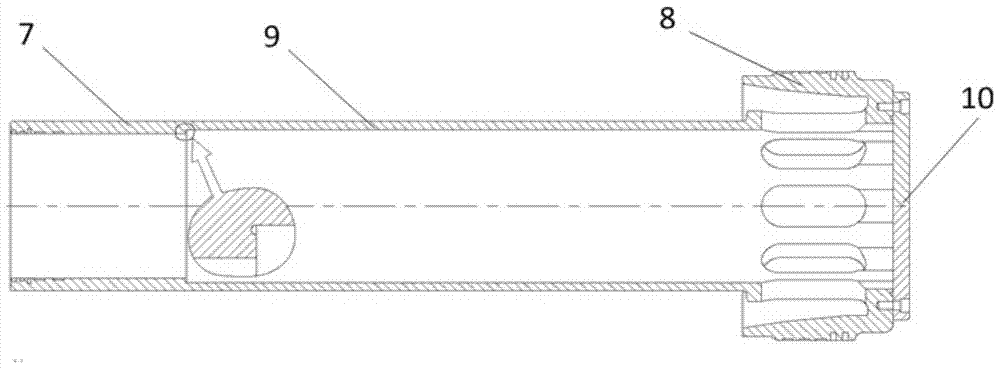

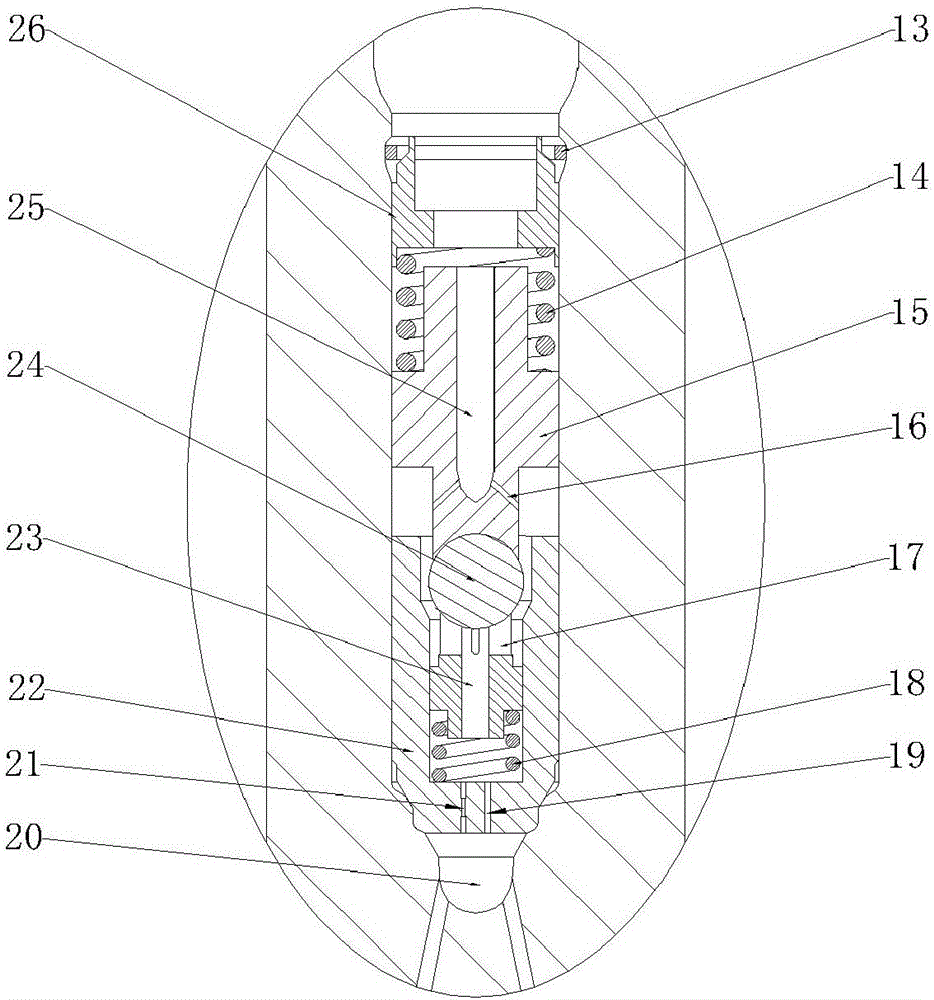

Two-way-oil-inlet resonance bypass type electronic-control fuel injector

ActiveCN106545448ASmall pressure fluctuationsImprove economyMachines/enginesSpecial fuel injection apparatusResonanceSolenoid valve

The invention aims at providing a two-way-oil-inlet resonance bypass type electronic-control fuel injector comprising a fuel injector head, a fuel injector body, a flow-limiting valve assembly, an electromagnetic valve assembly, a needle valve assembly and a spray nozzle. The flow-limiting valve assembly is located in a pressure storage cavity, and it is ensured that under the condition of the large fuel injection quantity, fuel injection processes of all cylinders are stable. A resonance through hole and a resonance throttling hole are machined in the bottom of the flow-limiting valve assembly, and fluctuation of fuel passing through the flow-limiting valve assembly is reduced according to the wave superposition principle. The electromagnetic valve assembly and the needle valve assembly are arranged on the lower portion. A two-position three-way valve form is adopted for an electromagnetic valve so that the dynamic oil return amount can be decreased. A control slide block is arranged in a control cavity and makes contact with a middle block so as to play a role in decreasing the fuel injection speed at the initial stage of injection and accelerating the needle valve seating response. The two-way-oil-inlet manner is adopted for the control cavity, and therefore the pressure buildup speed is further increased, and the rapid response characteristic of the fuel injector is achieved. No static pressure differences exist in the fuel injector, and the fuel injector is free of static leakage.

Owner:HARBIN ENG UNIV

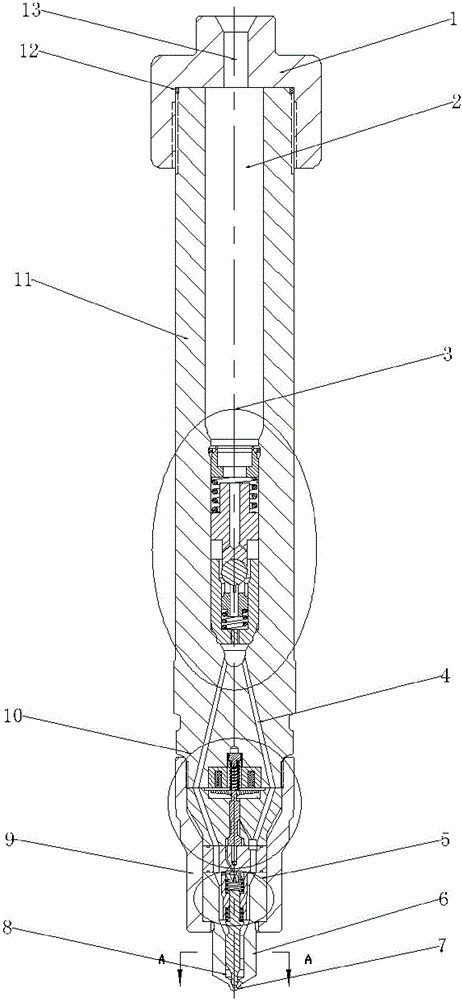

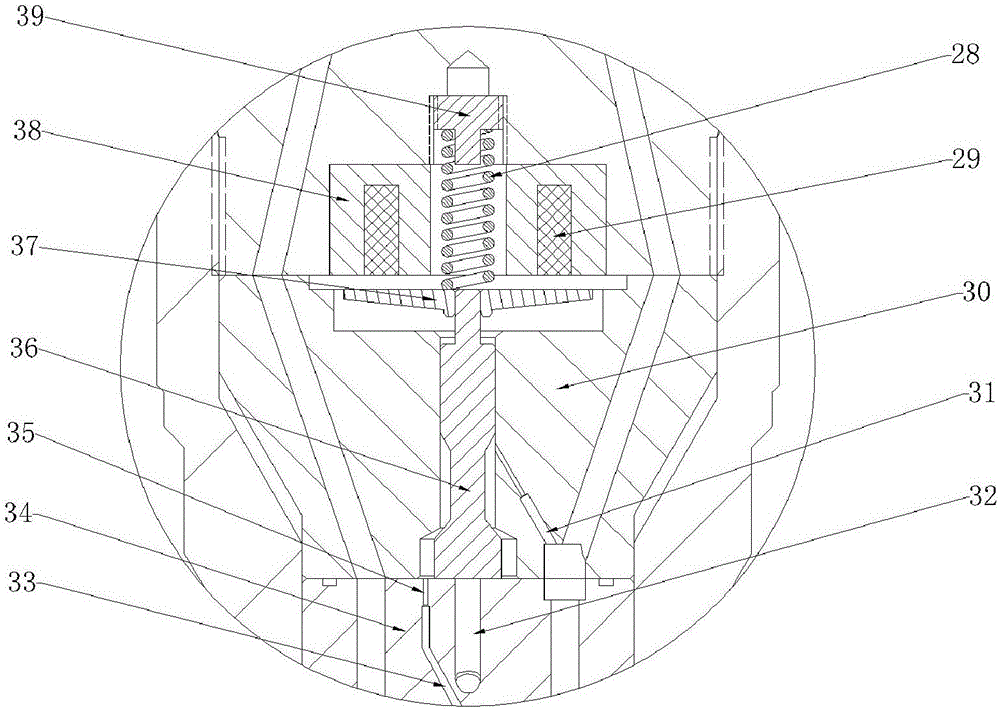

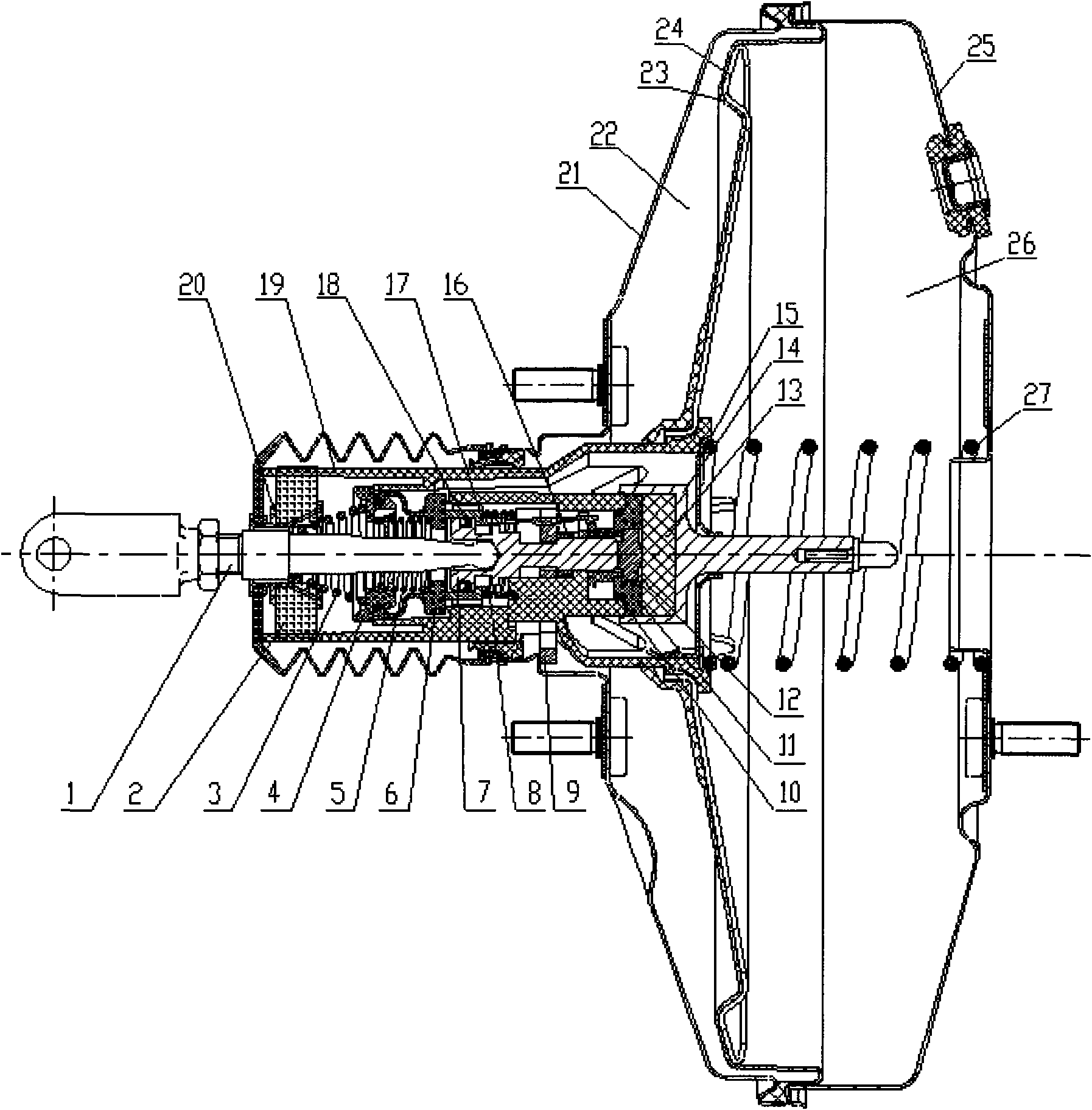

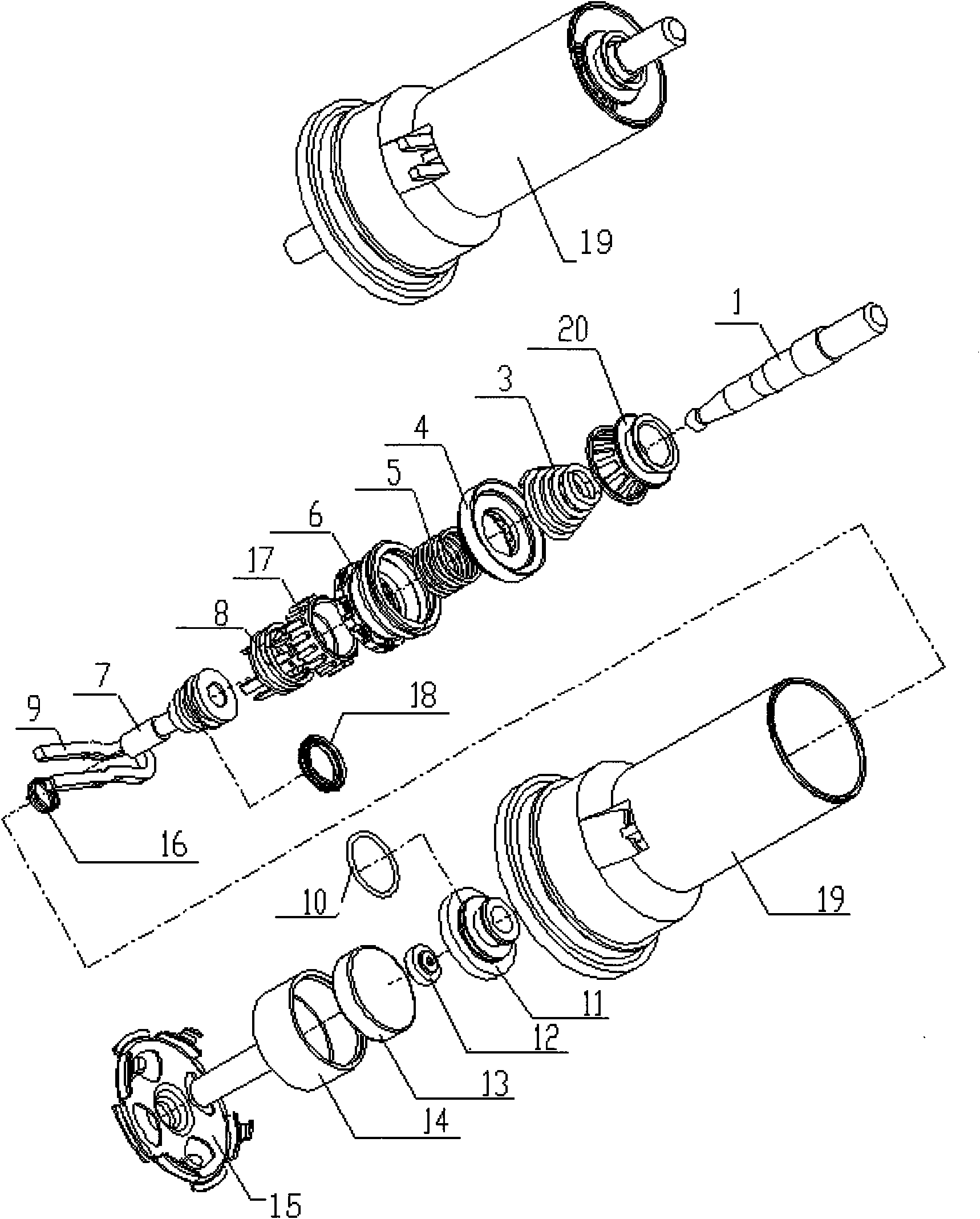

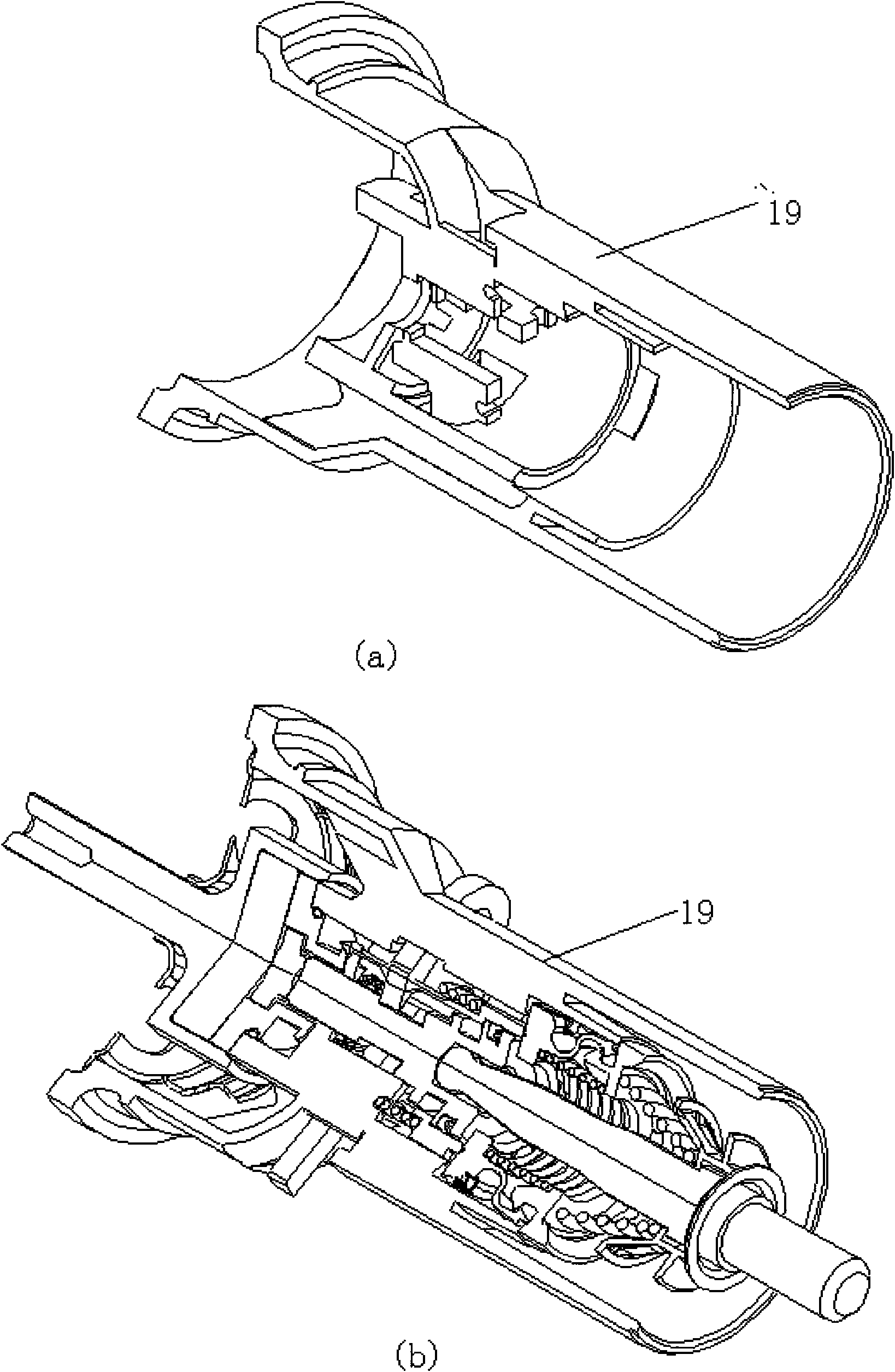

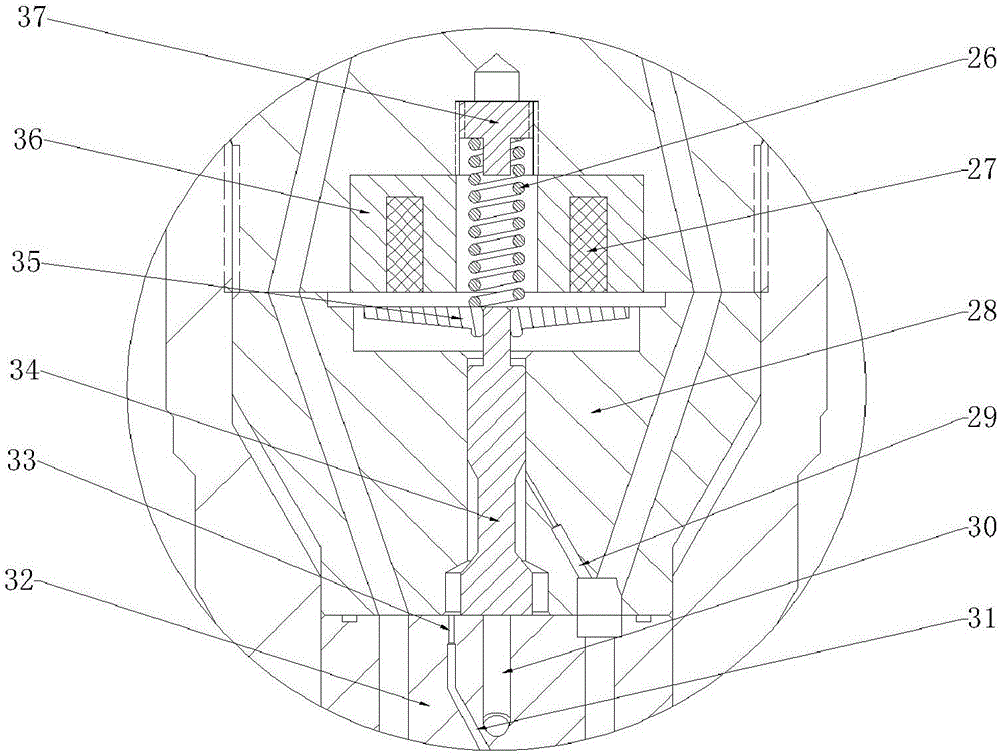

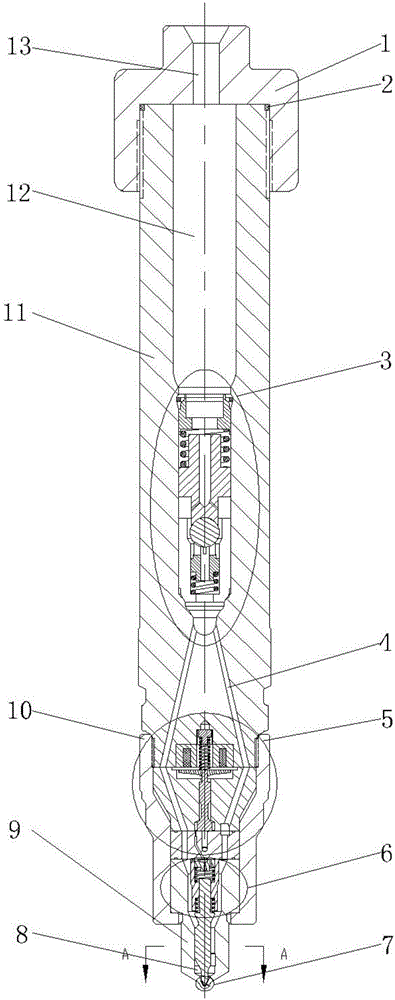

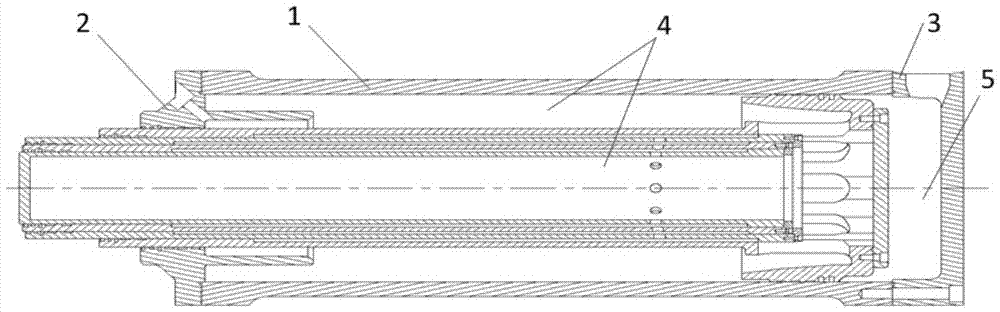

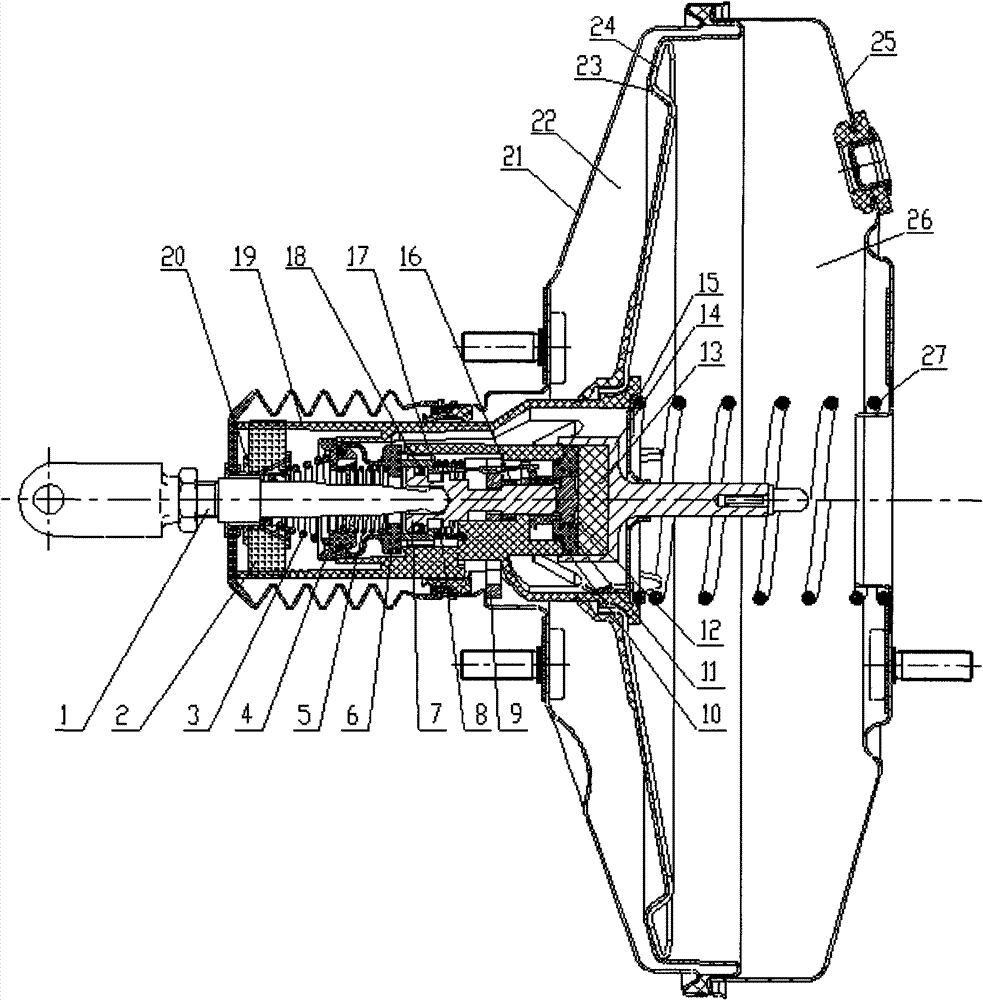

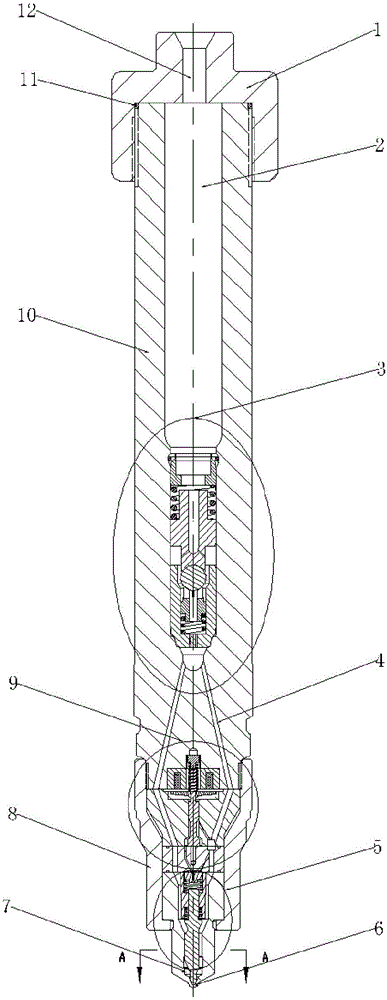

Mechanical vacuum booster with emergency braking function

InactiveCN101612933AShorter braking distanceNovel structureBraking action transmissionMaster cylinderControl valves

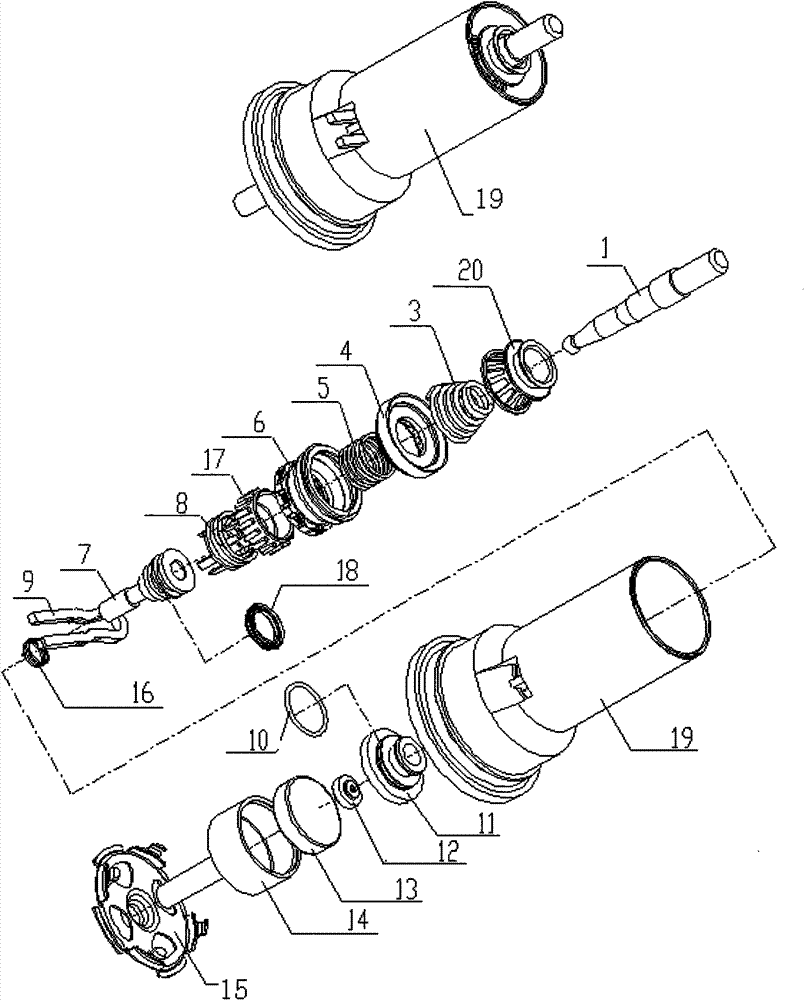

The invention relates to a mechanical vacuum booster with an emergency braking function and belongs to the automobile braking field. A control valve assembly of the mechanical vacuum booster comprises such parts as a valve body, an input link, a filter screen spring seat, a conical spring, a spring seat, a compression spring, a vacuum leather cup, a trigger mechanism, a trigger mechanism spring, a plunger, a locking plate, a locking plate spring, a valve block, a scale plate, a reaction plate, an output link, an elastic collar, as well as a rubber seal ring, a rear shell body, a diaphragm, a diaphragm plate, a front shell body, a large return spring and the like. The mechanical vacuum booster has the advantages of novel structure and low cost; and provided that the vacuum booster meets a certain input power requirement, the vacuum booster can output relatively huge applied force on a main braking cylinder when a driver performs emergency braking, and the vacuum booster maintains output pressure of the main cylinder on the condition of reducing input force, thus shortening the braking distance of the whole automobile and being especially effective for unskilled drivers and drivers who hesitate to brake.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

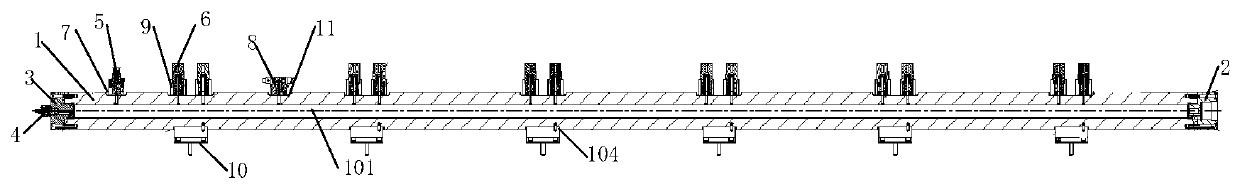

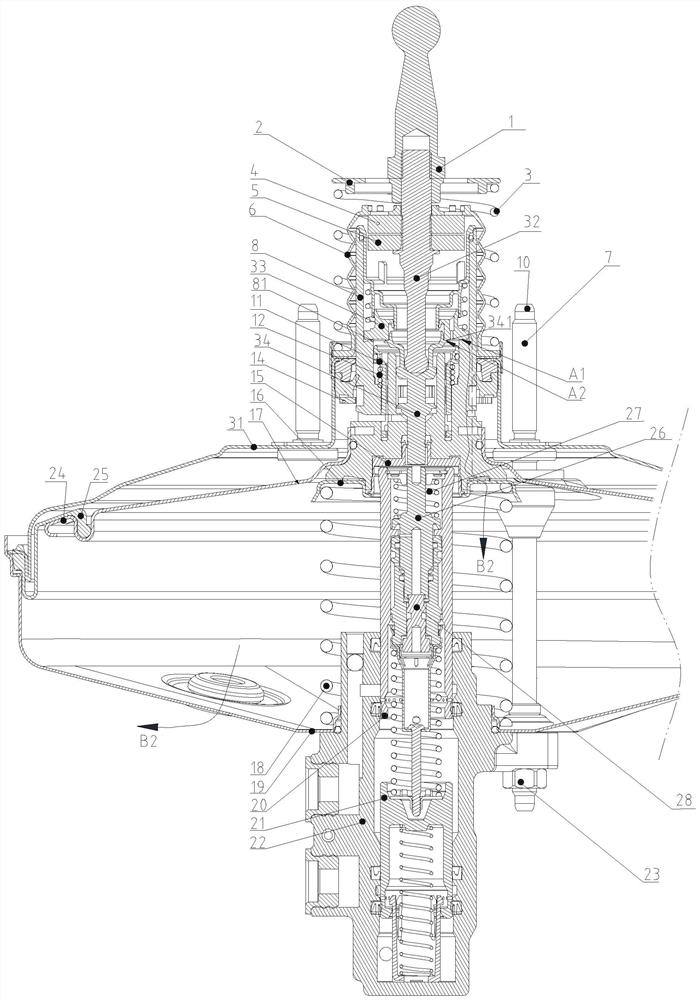

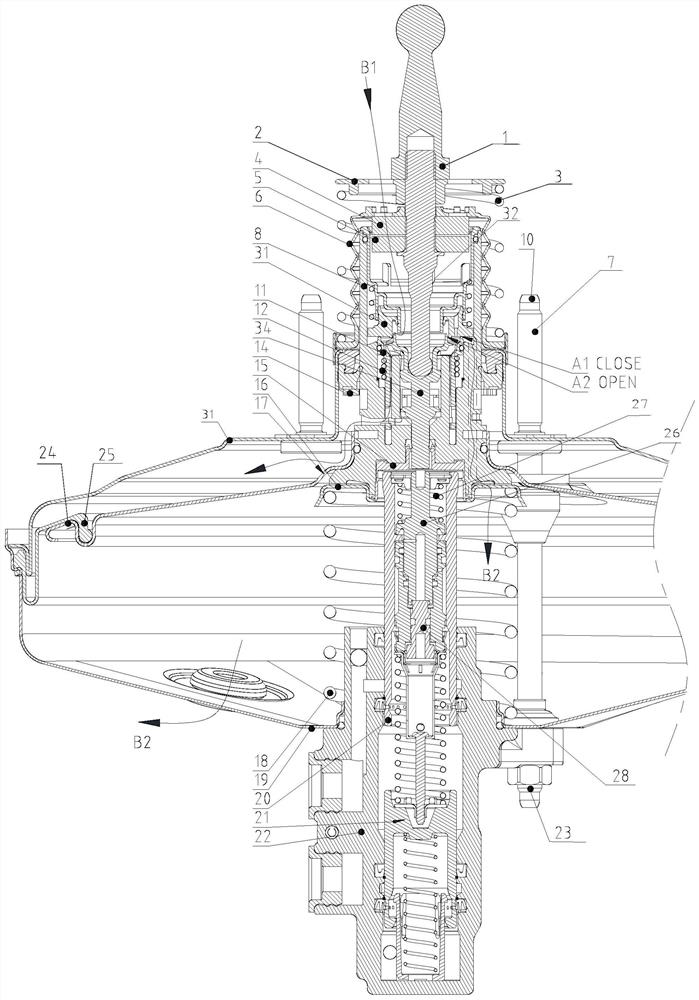

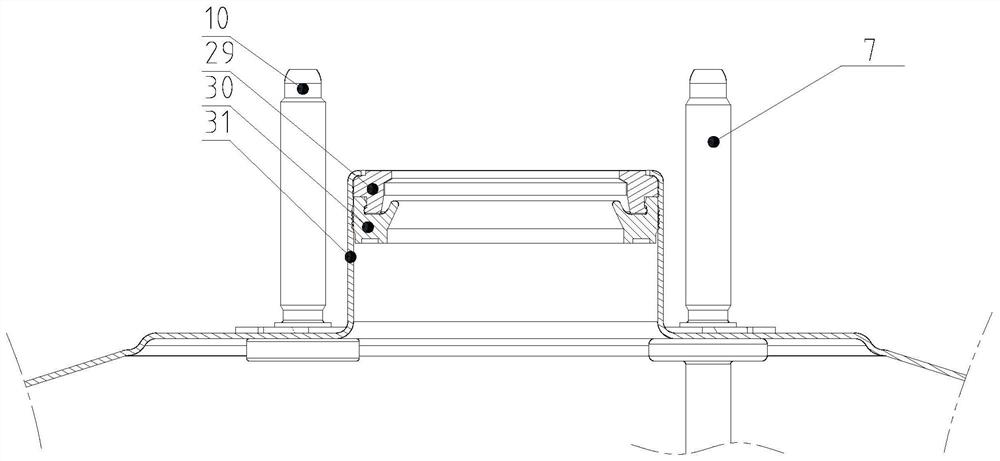

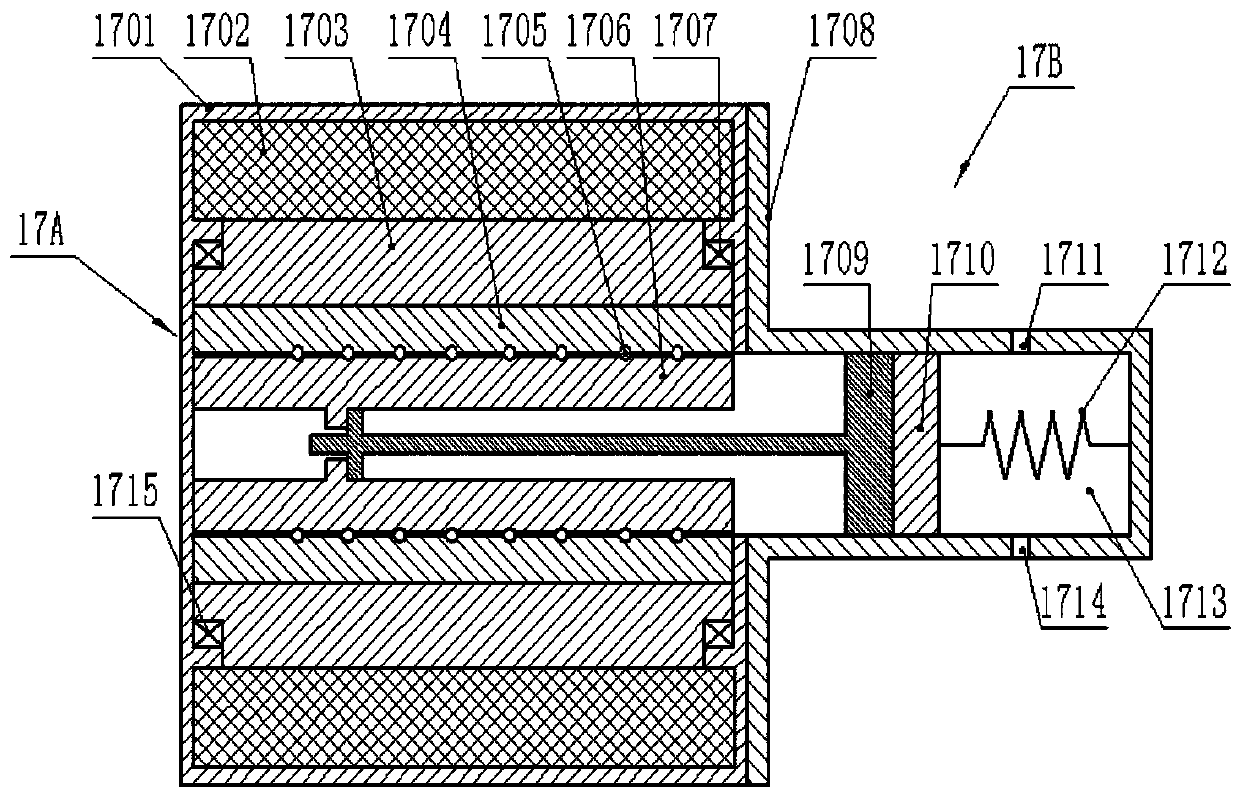

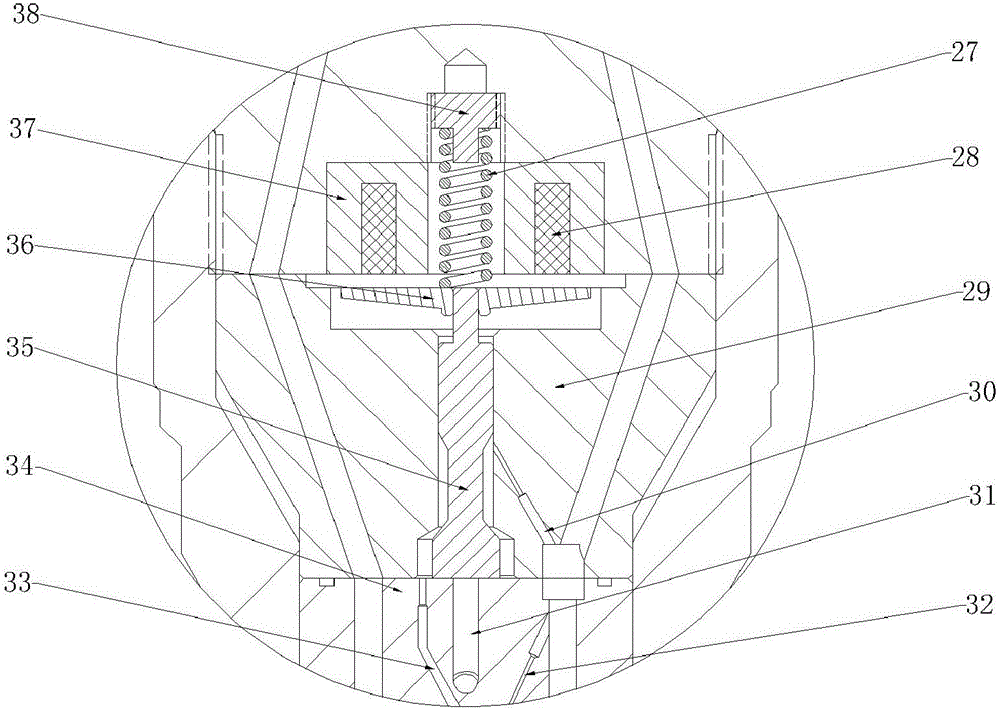

Intelligent automobile composite line control braking system and braking control method thereof

InactiveCN108162940ACompact structureBuild pressure quicklyBraking action transmissionFoot actuated initiationsTransmitted powerWheel cylinder

The invention discloses an intelligent automobile composite line control braking system and a braking control method thereof. The braking system combines a mechanical electric control braking system with an integrated motor type electric control braking system and is independently controlled by an electronic control unit. An electromechanical braking (EMB) module consists of two brakes. An integrated motor type electric control braking IBS module consists of an integrated motor, a ball screw mechanism and a braking pressure generation unit. The ball screw mechanism is fixedly connected to theinterior of a rotor of the integrated motor, and the rotor transmits power to an output push rod of the braking pressure generation unit through the ball screw mechanism. Two inner cavities of a maincylinder of the braking pressure generation unit generate braking pressure under the push of the output push rod, and braking control over two braking wheel cylinders is achieved through electromagnetic valves. The mechanical electric control braking system is combined with the integrated motor type electric control braking system, the problems of a single braking system are solved to achieve rapid pressure generation and precise pressure control, and braking under multiple conditions can be achieved.

Owner:JILIN UNIV

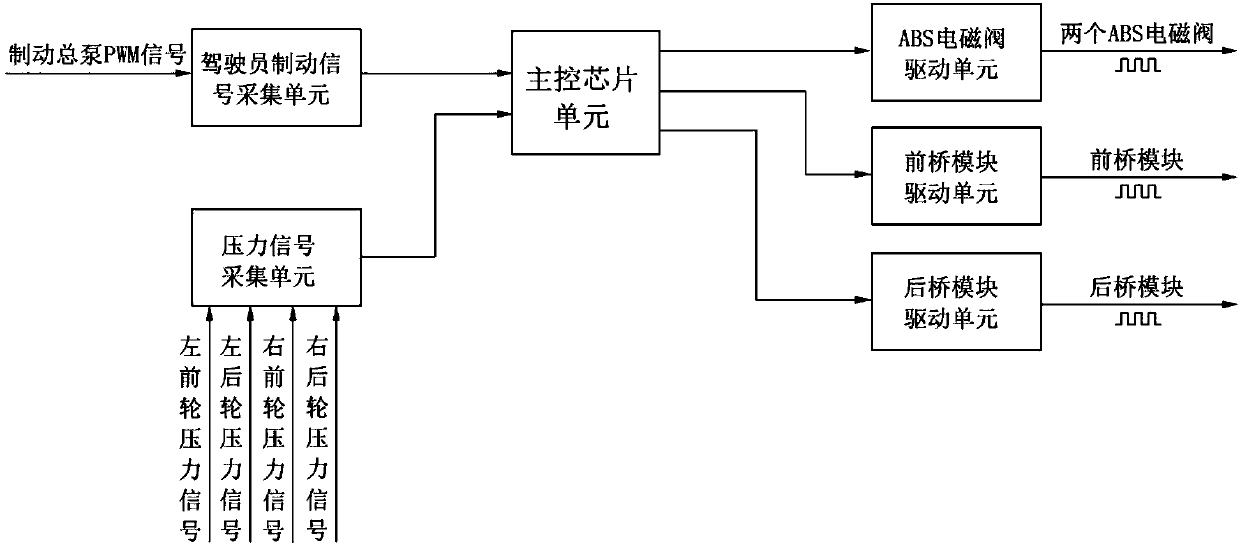

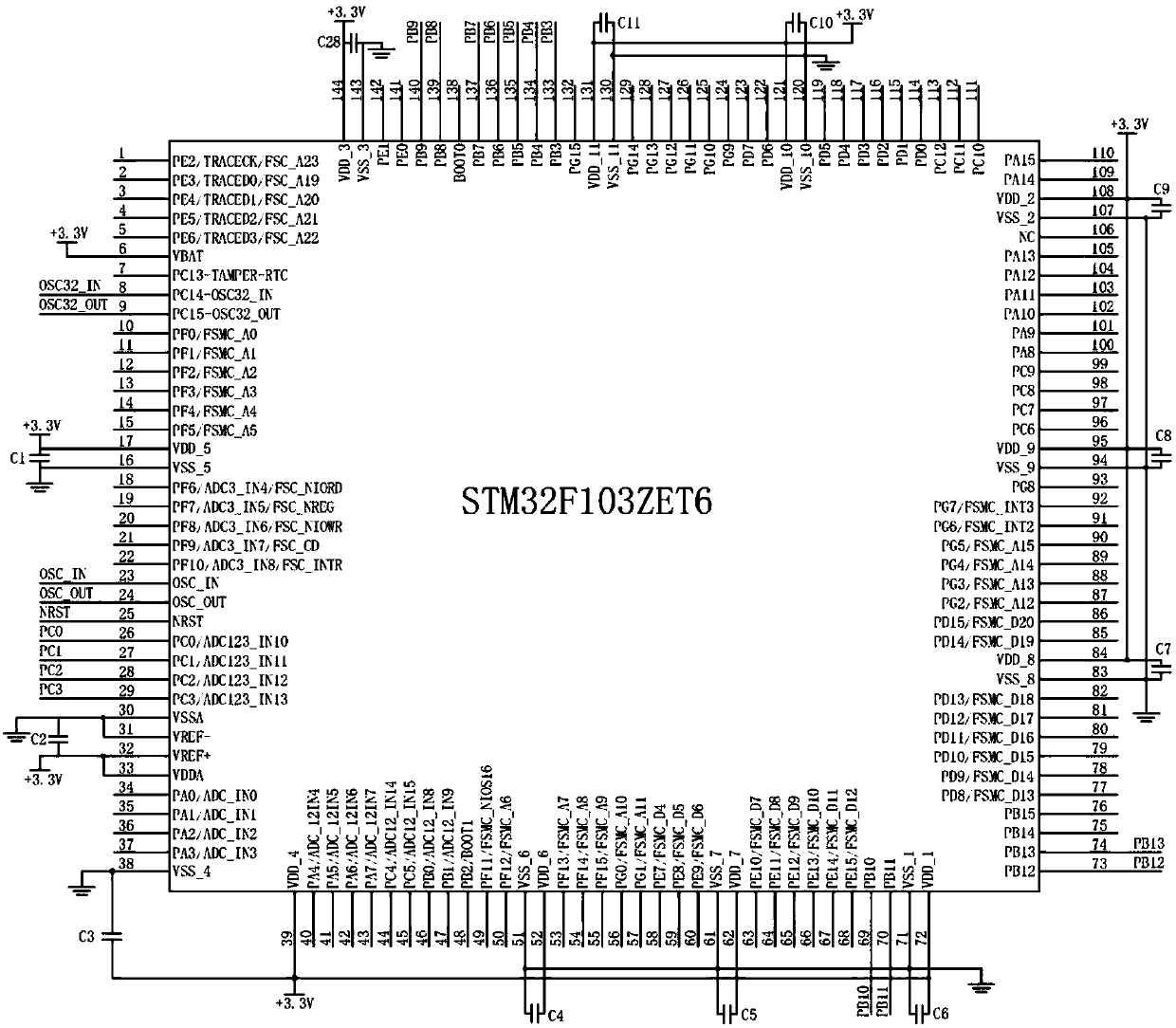

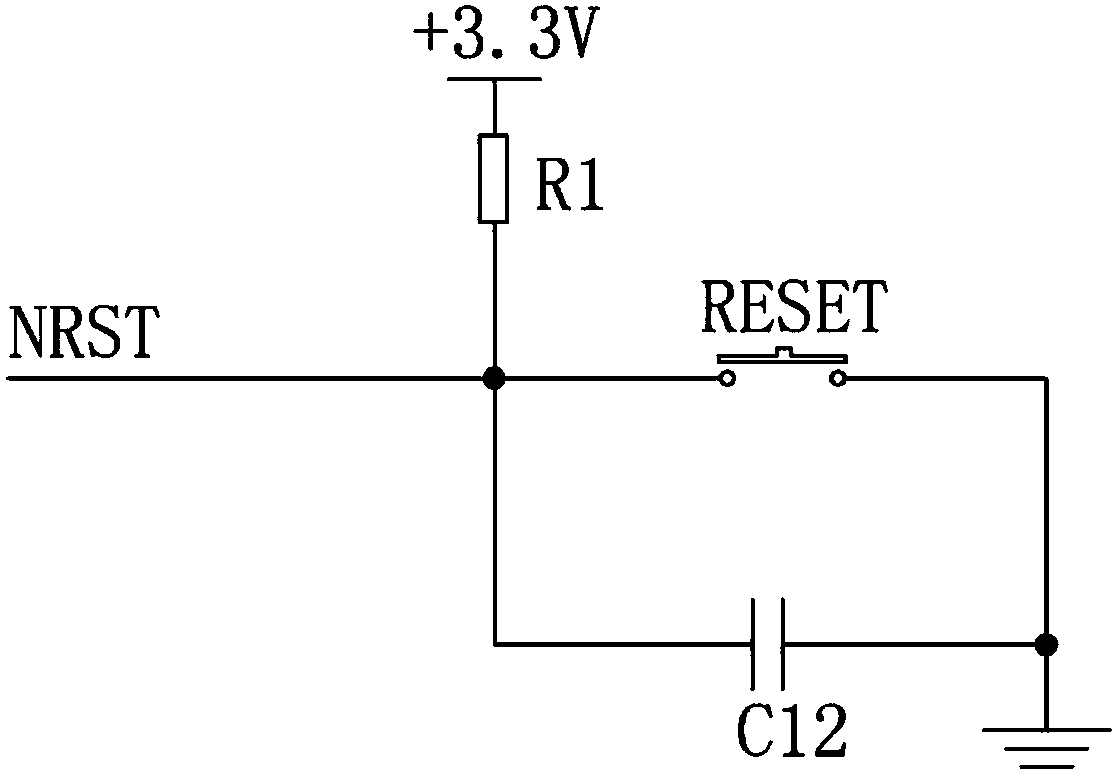

Drive-by-wire air pressure braking system controller and control method thereof

The invention discloses a drive-by-wire air pressure braking system controller and a control method thereof. The controller is composed of a main control chip unit, a driver braking signal collectionunit, a pressure signal collection unit, an ABS solenoid valve driving unit, a front bridge module driving unit and a rear bridge module driving unit; the main control chip unit is internally providedwith a single-chip microcomputer, the driver braking signal collection unit and the pressure signal collection unit are connected with a signal input end of the single-chip microcomputer separately to collect vehicle signals, and the ABS solenoid valve driving unit, the front bridge module driving unit and the rear bridge module driving unit are connected with a signal output end of the single-chip microcompute separately to output braking control signals. According to the control method based on the controller, a double-logic threshold method is adopted for conducting pressure increase and decrease control in sections. The controller highly integrates a signal collection function with a control circuit, the interior of the controller is processed by circuit optimization to improve the anti-interference performance and ensure the control accuracy and stability of a braking system, and by combining the control method, fast pressure generation and accurate pressure control of the systemcan be achieved.

Owner:JILIN UNIV

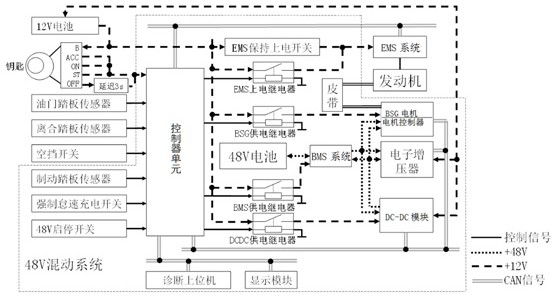

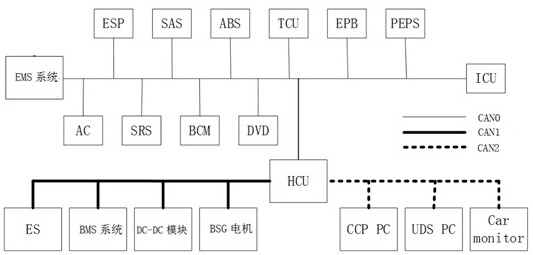

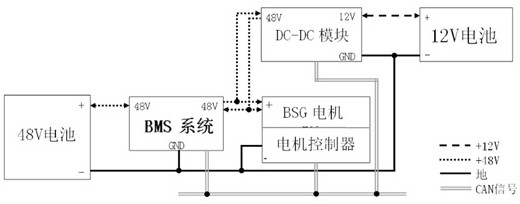

48V hybrid electric system

ActiveCN111878244APower optimizationGood dynamic responseHybrid vehiclesElectrical controlTurbochargerElectric machine

The invention discloses a 48V hybrid electric system. The system comprises a controller unit, a 12V battery, a display module, a 48V battery, a sensor unit, a DC-DC module, a BMS system, a motor controller and a BSG motor, the 48V battery provides electric energy for the BMS system and the BSG motor, the controller unit controls the motor controller to control the BSG motor through the BMS system,and the BMS system is further connected with an electronic supercharger. The controller unit obtains expected torque of an engine according to an electric signal generated by an accelerator pedal sensor, obtains target air inlet pressure of the engine by looking up a table, and obtains a target rotating speed value of the electronic supercharger by calculating a supercharging ratio. The controller unit sends the target rotating speed value to the electronic supercharger through a bus to control the air inlet pressure. The system has the advantages that working conditions of starting, stopping, starting, braking and the like of the engine are optimized, the carried electronic supercharger can rapidly build pressure, the turbine hysteresis phenomenon of a turbocharger is eliminated, and a vehicle system can have better power responsiveness in cooperation with the motor.

Owner:NINGBO YINZHOU DLT TECH CO LTD

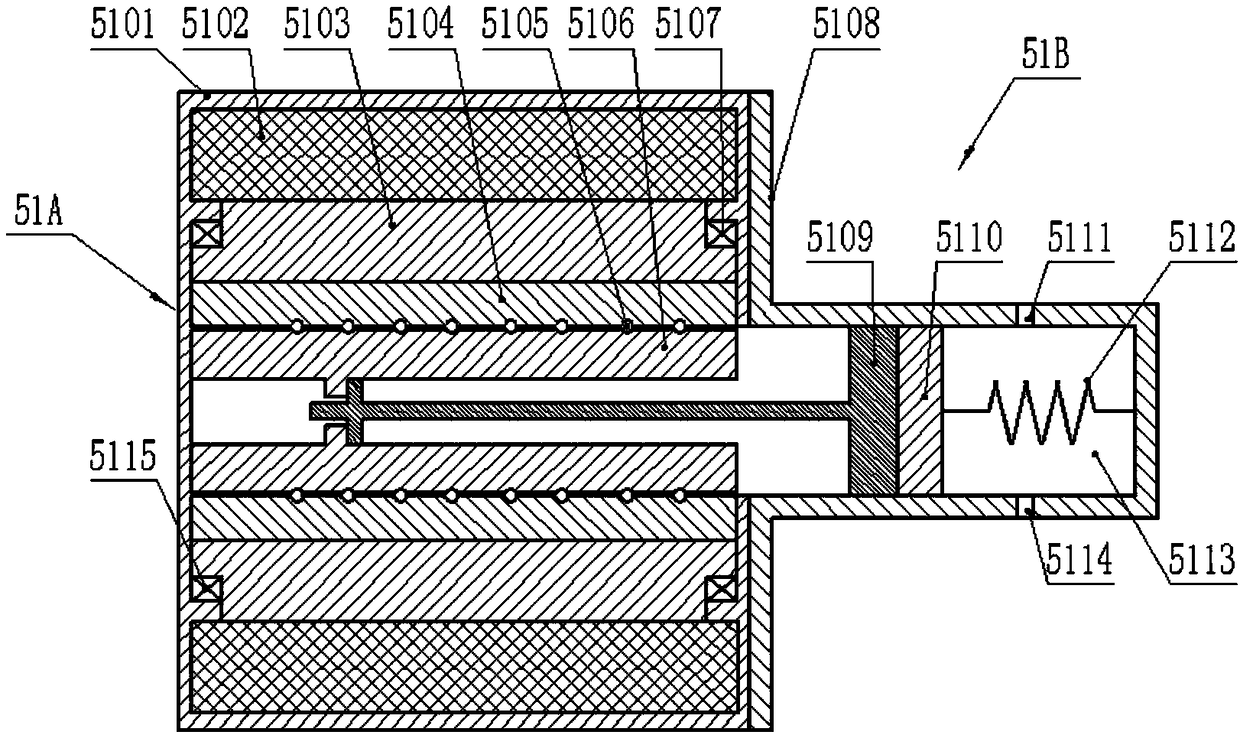

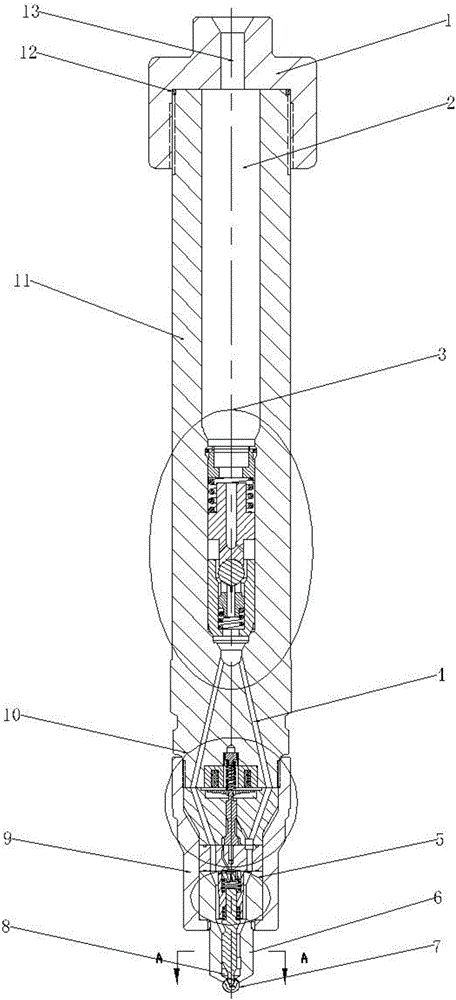

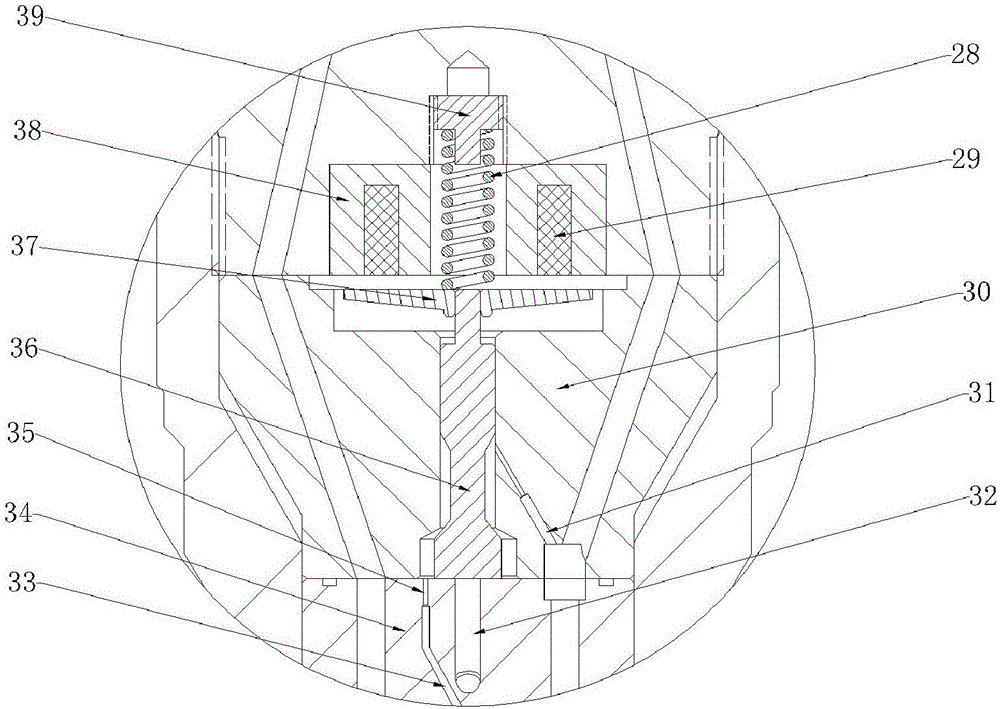

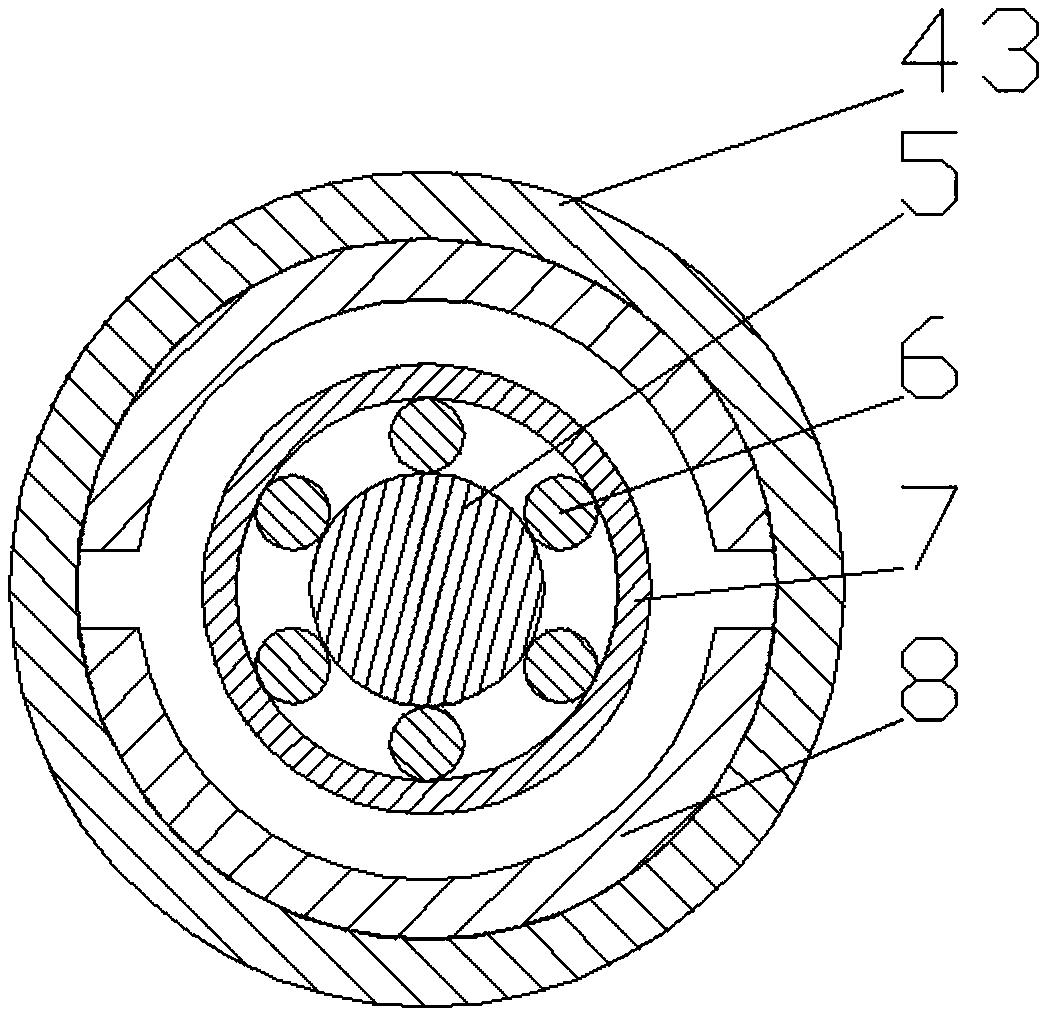

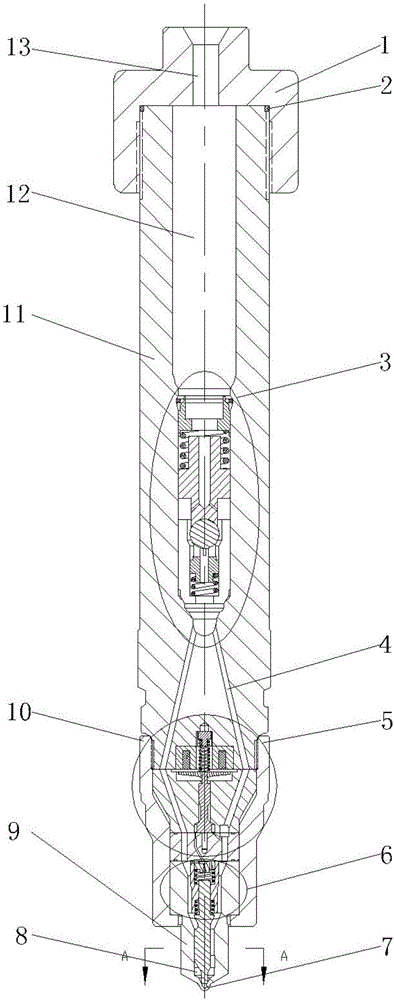

Motor direct-driven brake-by-wire system with main/auxiliary cylinder and brake control method of system

InactiveCN108248592ABuild pressure quicklyFunctionalBraking action transmissionMotor driveSolenoid valve

The invention discloses a motor direct-driven brake-by-wire system with a main / auxiliary cylinder and a brake control method of the system. The brake system is braked through combination of a double-cavity main cylinder brake module and a single-cavity auxiliary cylinder brake module and relatively independently controlled by an electronic control unit, the double-cavity main cylinder brake modulecomprises a main cylinder integrated motor, a main cylinder ball lead screw mechanism and a main cylinder brake pressure generation unit, two groups of single-cavity auxiliary cylinder brake components are parallelly connected to form the single-cavity auxiliary cylinder brake module, normally open switch solenoid valves, single-cavity auxiliary cylinder pressurizing units and wheel-brake cylinder execution pipelines are serially connected to form the single-cavity auxiliary cylinder brake components, the main cylinder brake pressure generation unit and the single-cavity auxiliary cylinder pressurizing units generate brake pressure through driving of the integrated motor and transmission of the ball lead screw mechanism, and wheel-brake cylinders are braked and controlled by the solenoidvalves. The system solves the problems that when a single motor drives a main cylinder, the building time of the pressure is long, fluctuation is large, accuracy is poor, and the requirements for performances of the motor are high.

Owner:JILIN UNIV

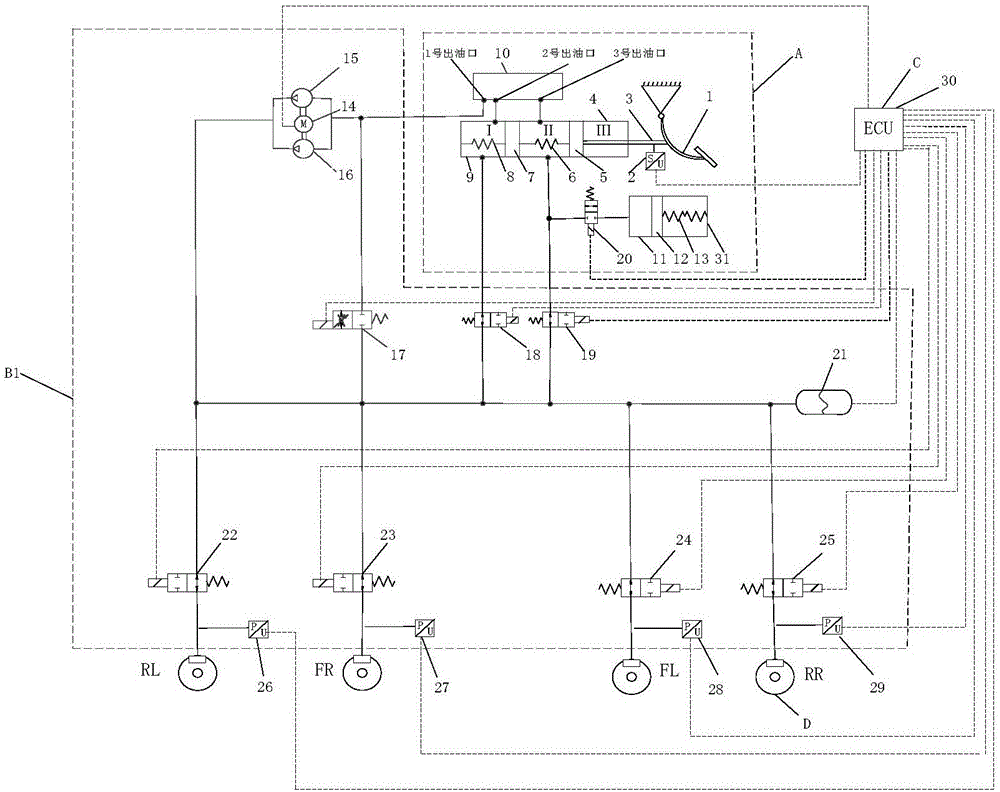

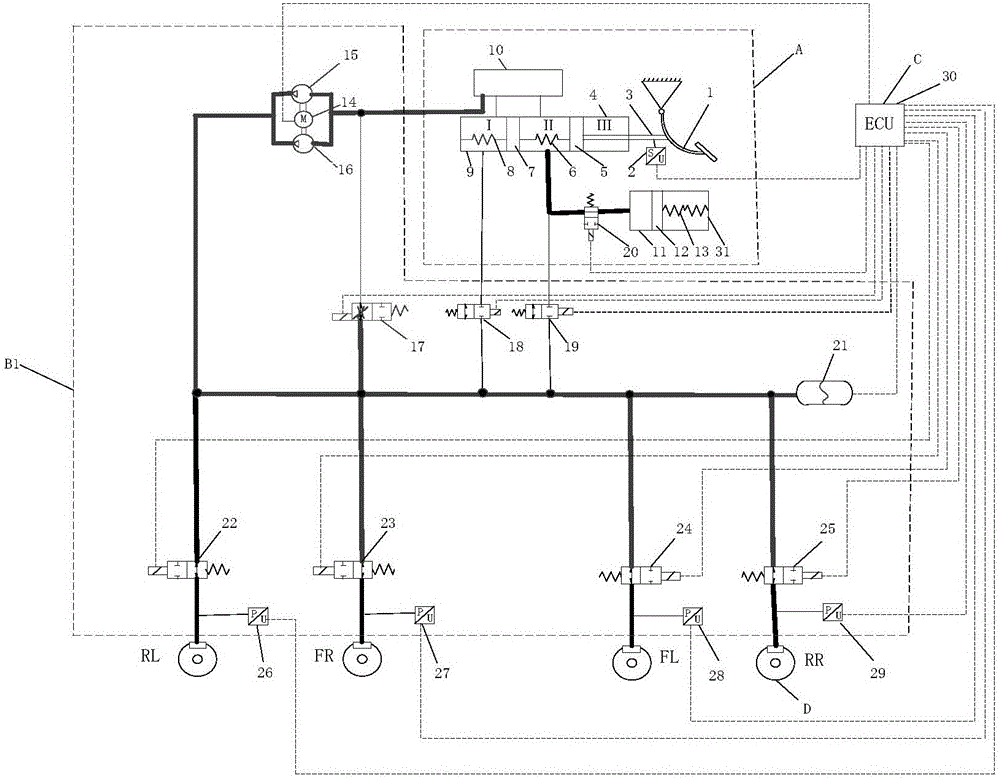

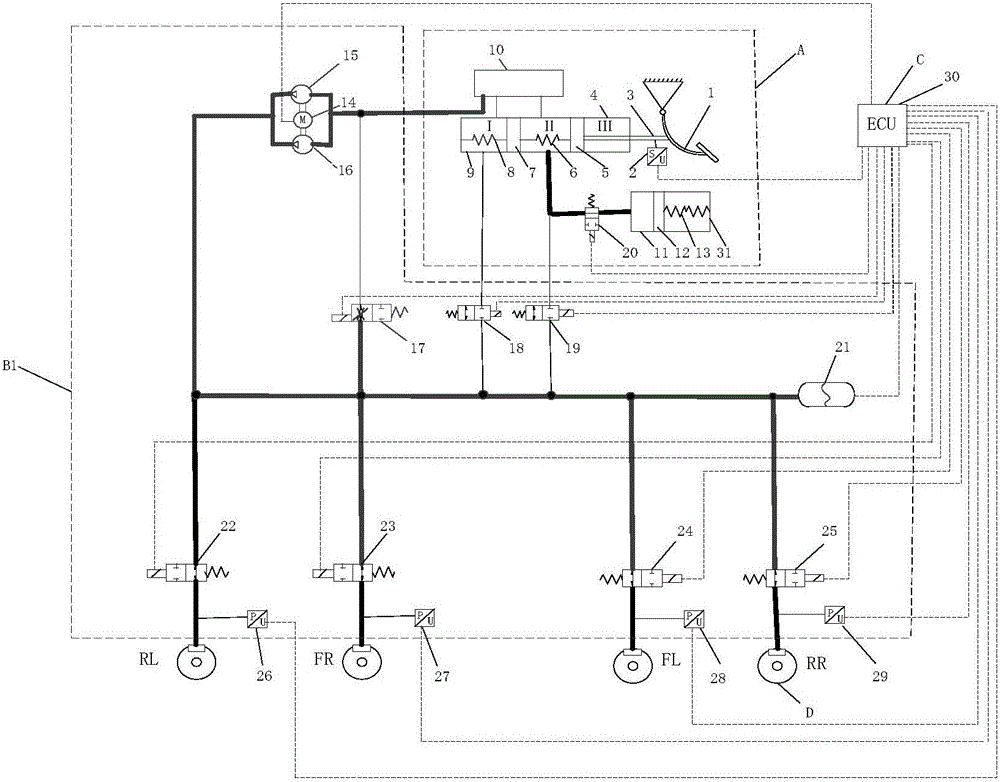

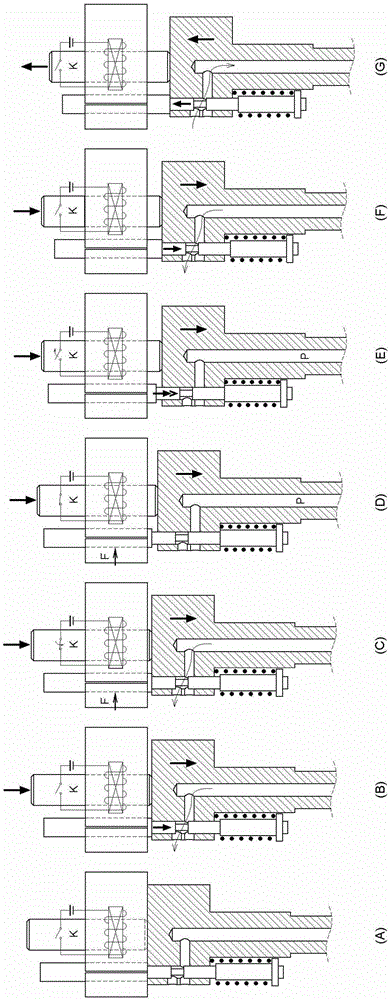

Wire control brake system based on time-division serial control and simultaneous parallel control

InactiveCN106740787ARealize hydraulic brake by wireEnsure driving safetyBraking action transmissionFoot actuated initiationsHydraulic control unitMaster cylinder

The invention discloses a wire control brake system based on time-division serial control and simultaneous parallel control and aims to solve the problems that a traditional brake system vacuum booster is large in size and expensive, and a motor-assisted wire control hydraulic brake system is high in motor requirements, expensive and incapable of guaranteeing precise pressure control. The wire control brake system comprises a wire control brake system body based on the time-division serial control and a wire control brake system body based on the simultaneous parallel control, wherein the wire control brake system body based on the time-division serial control comprises a brake master cylinder output unit (A) with an oil cup, a first hydraulic control unit (B1), an electronic control unit (C) and a wheel brake (D); the wire control brake system body based on the simultaneous parallel control comprises a brake master cylinder output unit (A) with an oil cup, a second hydraulic control unit (B2), an electronic control unit (C) and a wheel brake (D); that is to say, only the first hydraulic control unit (B1) and the second hydraulic control unit (B2) of the two system bodies are different.

Owner:JILIN UNIV

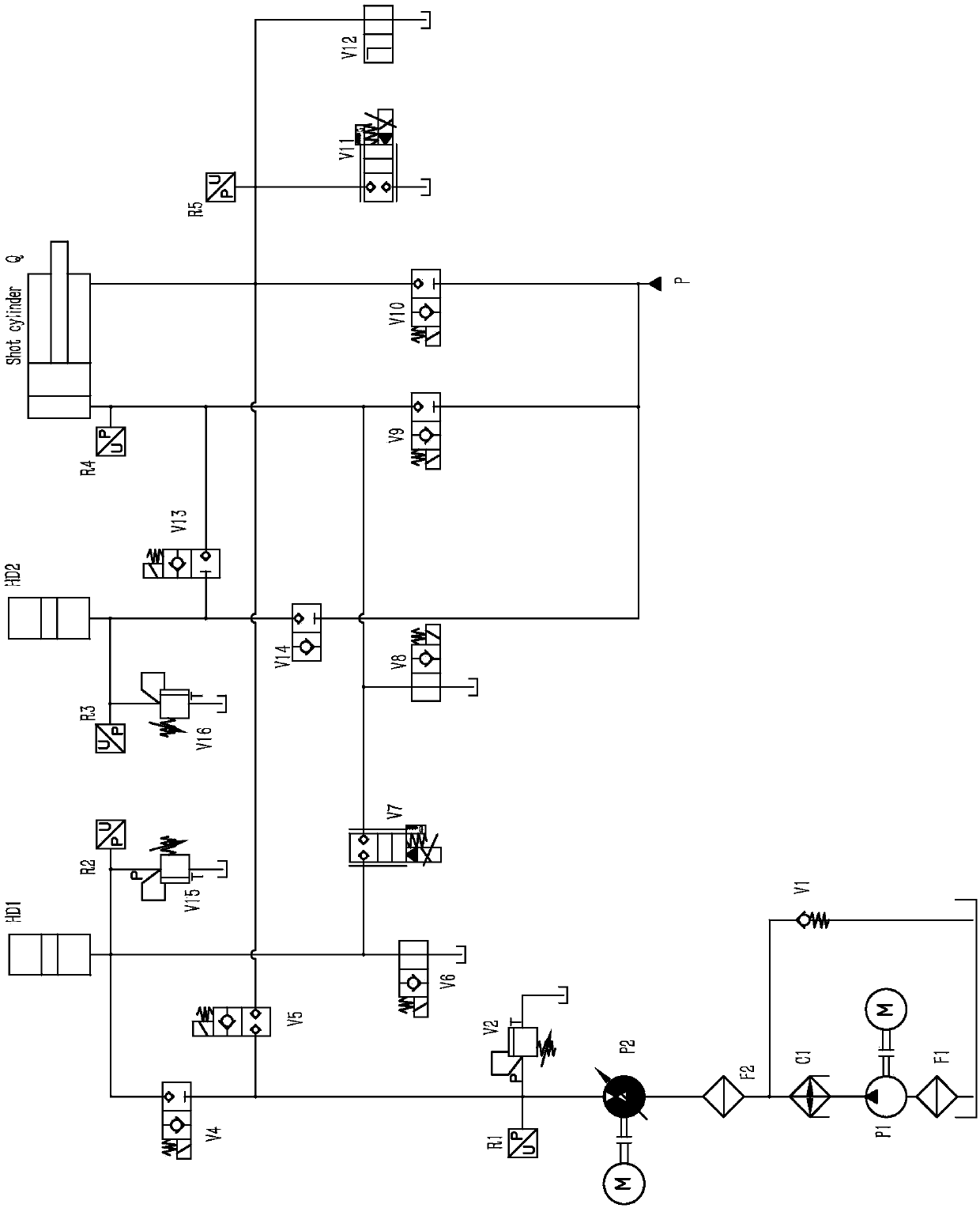

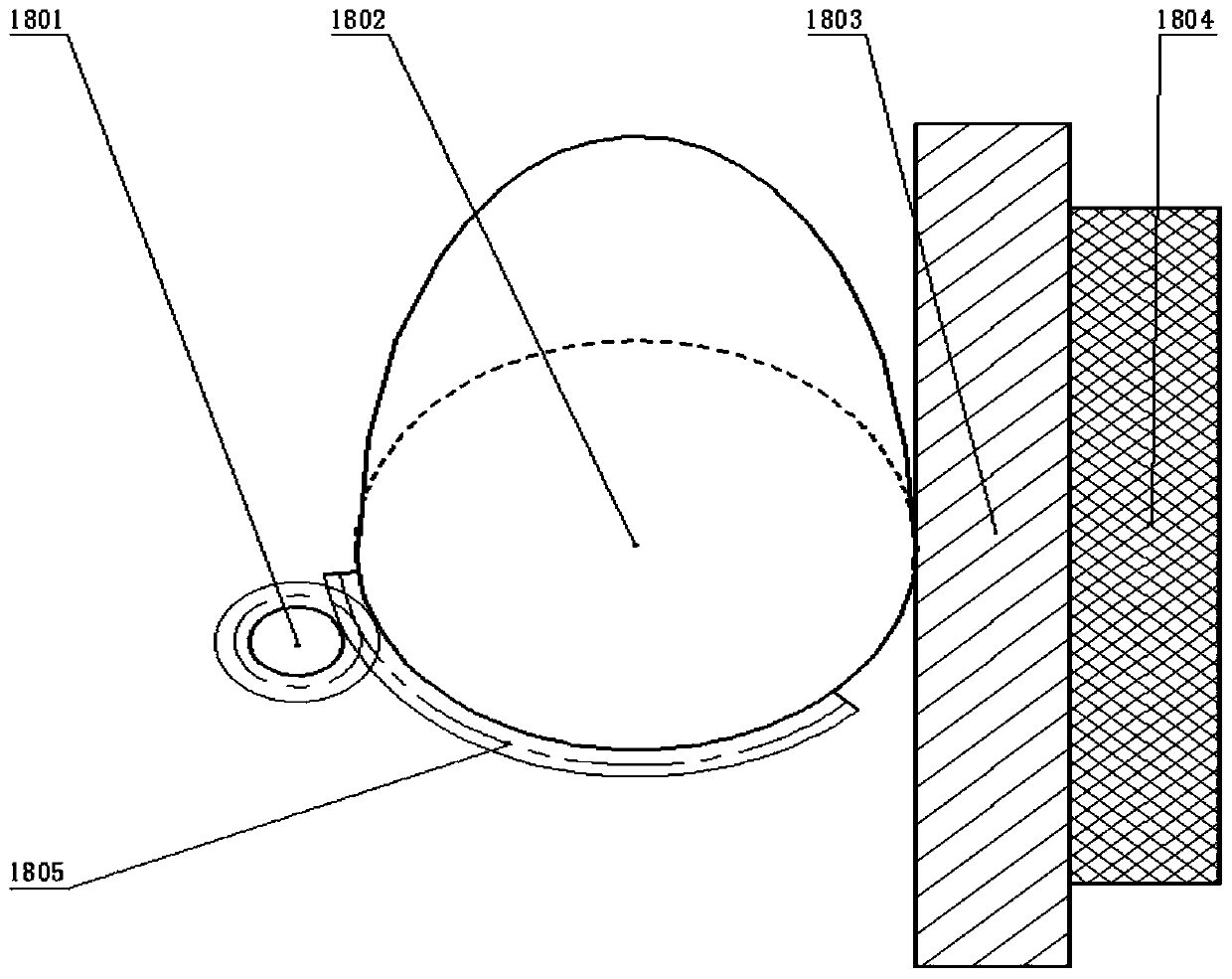

Pressurizing device and method of unpressurized oil cylinder

PendingCN108443240AIncrease boost effectSimple structureFluid-pressure actuator testingAccumulator installationsLow speedDie casting

The invention discloses a pressurizing device and method of an unpressurized oil cylinder. The device comprises an injection oil cylinder, a low-pressure pump set, a high-pressure variable pump set, ahigh-pressure energy storing device and a rapid energy storing device, wherein a hammer front valve is arranged at the front end of the injection oil cylinder and is connected to the rapid energy storing device; a hammer rear valve is arranged at the rear end of the injection oil cylinder and is connected to a P end oil supplying port; the P end oil supplying port is connected to the rapid energystoring device; the low-pressure pump set is connected to the high-pressure variable pump set which is connected to an HD1 energy storing valve; and the HD1 energy storing valve is connected to the high-pressure energy storing device. The method comprises the steps of early-stage preparation of action of an injection part, first-stage low-speed action, second-stage low-speed action, high-speed action, pressurizing, following and hammer returning. The device is simple in structure; the pressure buildup time can be increased to be 12ms, so that the pressurizing performance of the injection partof a large die-casting machine can be extremely improved; the difficulty that the parameters of a die casting machine in the prior art cannot meet the requirements of some precision products on casting technologies can be solved; and the yield of products can be effectively increased.

Owner:NINGBO HAITIAN METAL MOLDING EQUIP CO LTD

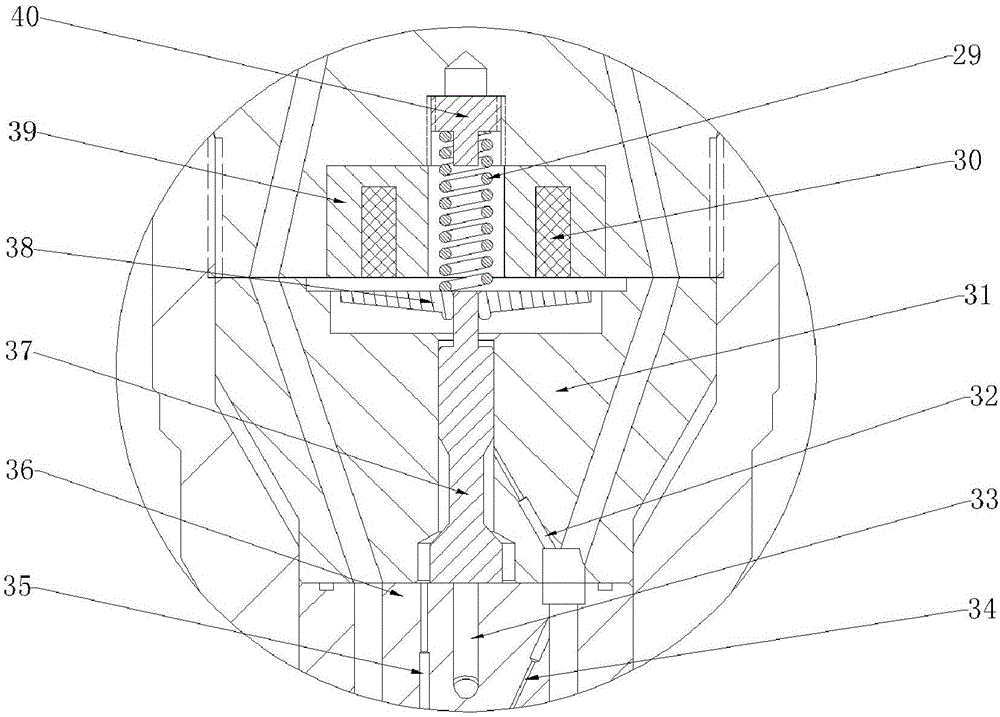

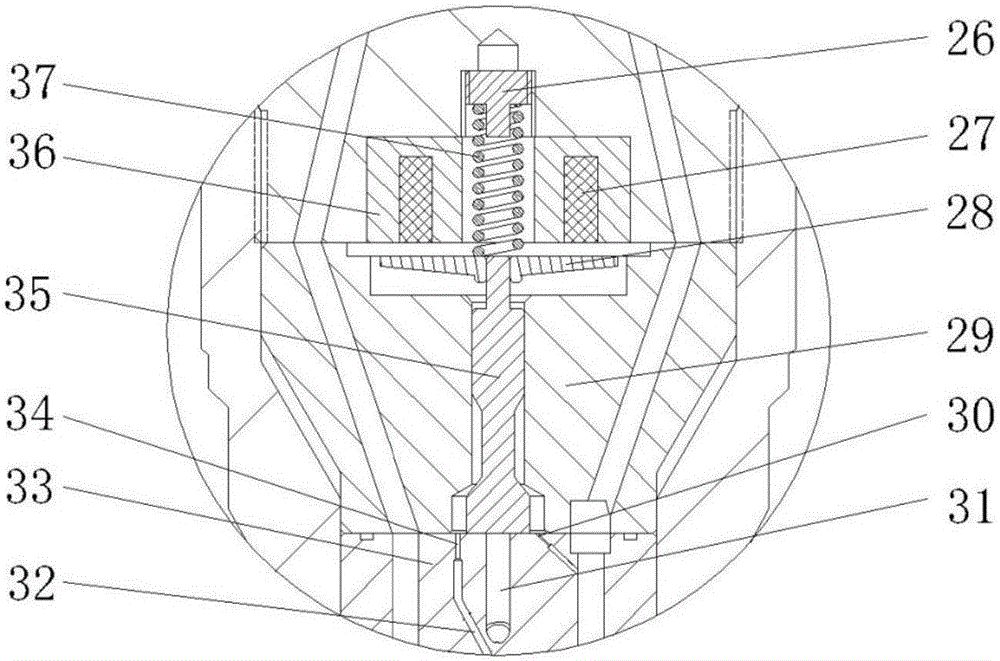

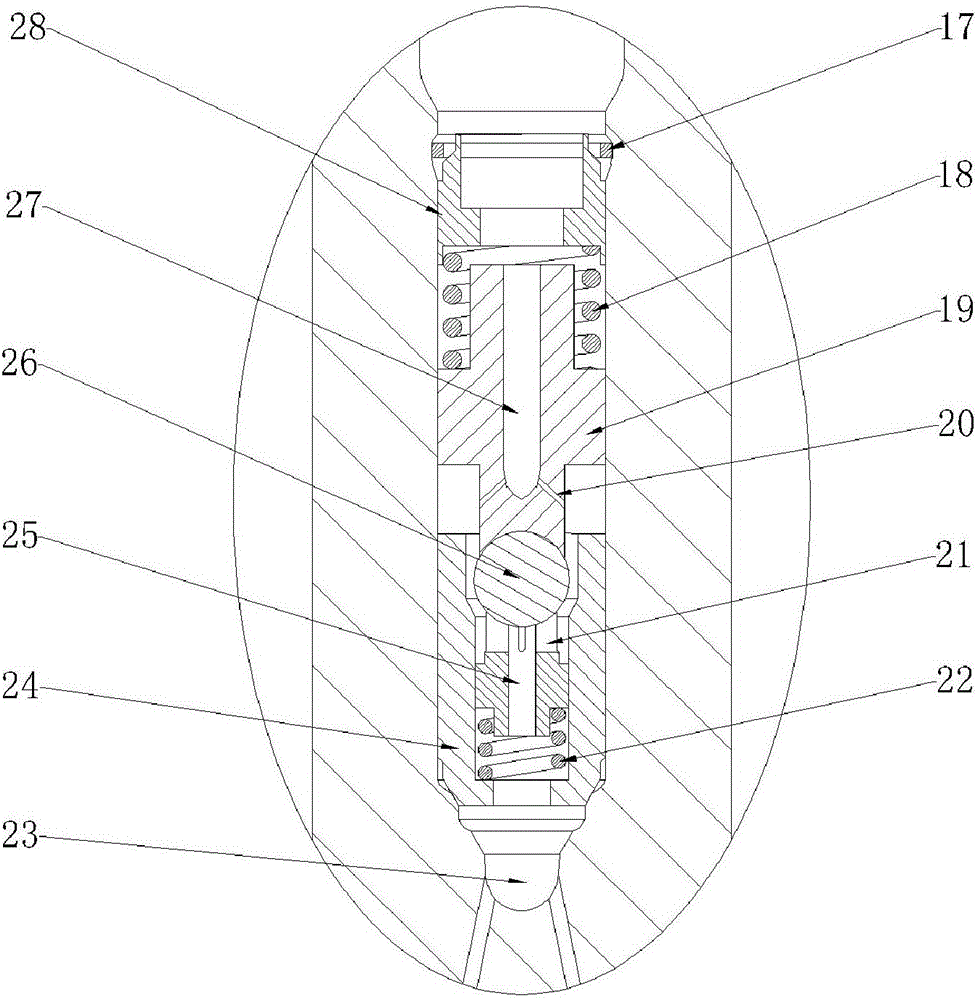

Double-path oil inlet bypass electric control oil sprayer with carving grooves

PendingCN106545444AReduce abnormal fuel injection conditionsImprove control precision and flexibilityFuel injection apparatusMachines/enginesCavitation flowMicrometer

The invention aims at providing a double-path oil inlet bypass electric control oil sprayer with carving grooves. The double-path oil inlet bypass electric control oil sprayer comprises an oil sprayer head, an oil sprayer body, a current limiting valve assembly, an electromagnetic valve assembly, a needle valve assembly, a needle valve seat and a spray nozzle, wherein the current limiting valve assembly is positioned inside a pressure accumulation cavity to guarantee the stable oil spraying process of each cylinder under the condition of great oil spraying quantity. The electromagnetic valve assembly and the needle valve assembly are arranged at the lower side. The electromagnetic valve uses a two-position three-way form so as to reduce the dynamic oil return quantity. A control slide block is arranged inside the control cavity, and is in contact with an intermediate block; the effects of decelerating the oil spraying speed at the primary spraying stage and accelerating the needle valve seating response are achieved. An oil inlet throttle hole is formed in the control slide block; the control cavity pressure building is further accelerated. The carving grooves in the micrometer levels are formed in the surface of the spray needle valve body; the stability of the cavitation flowing can be effectively improved; the cavitation erosion degree of the oil sprayer is reduced. A control plunger piston structure of the oil sprayer is omitted, so that no static pressure difference exists at the inside of the oil sprayer; the characteristic of no static leakage of the oil sprayer is ensured.

Owner:HARBIN ENG UNIV

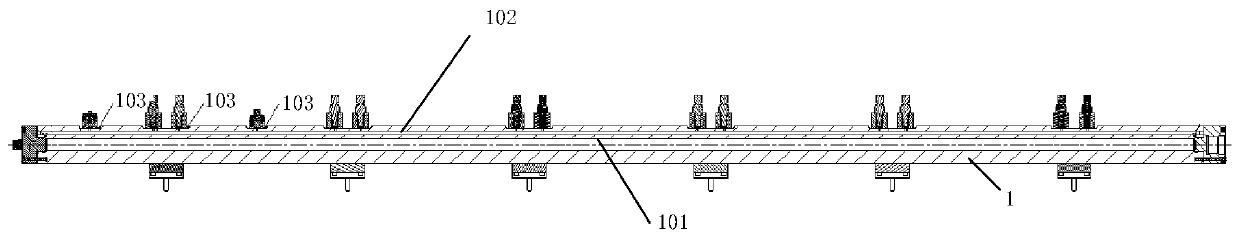

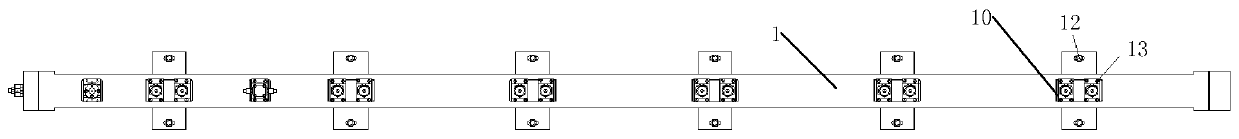

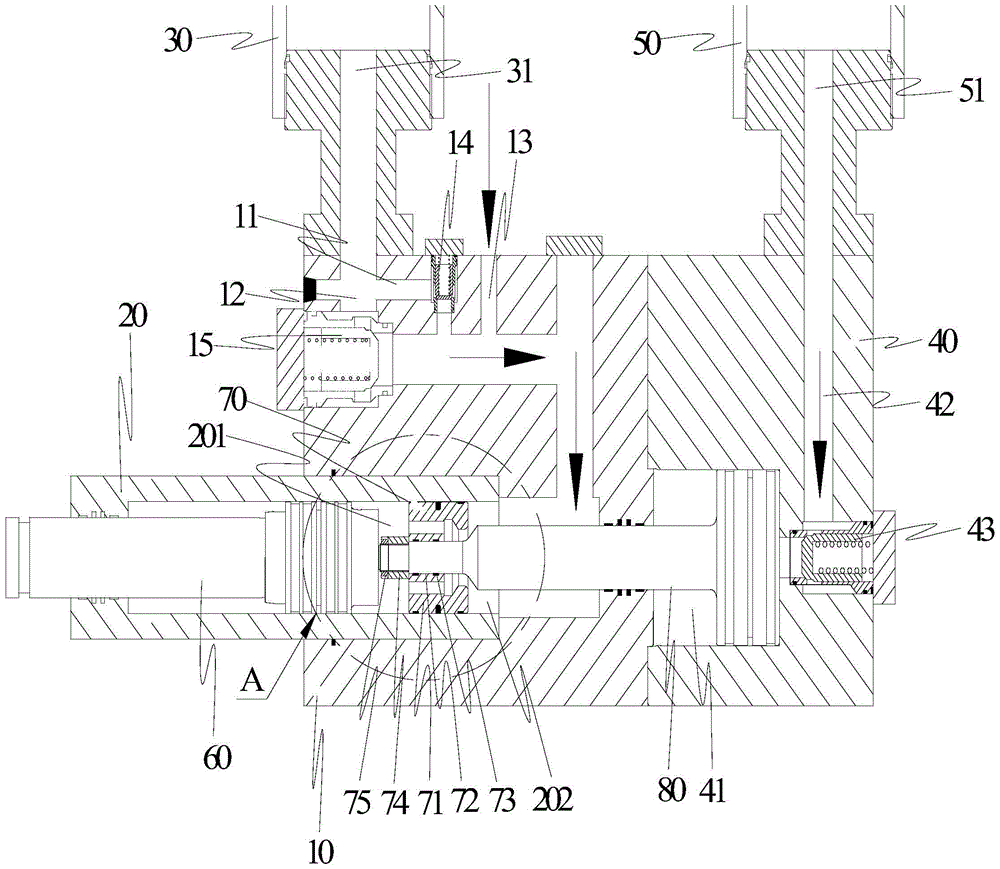

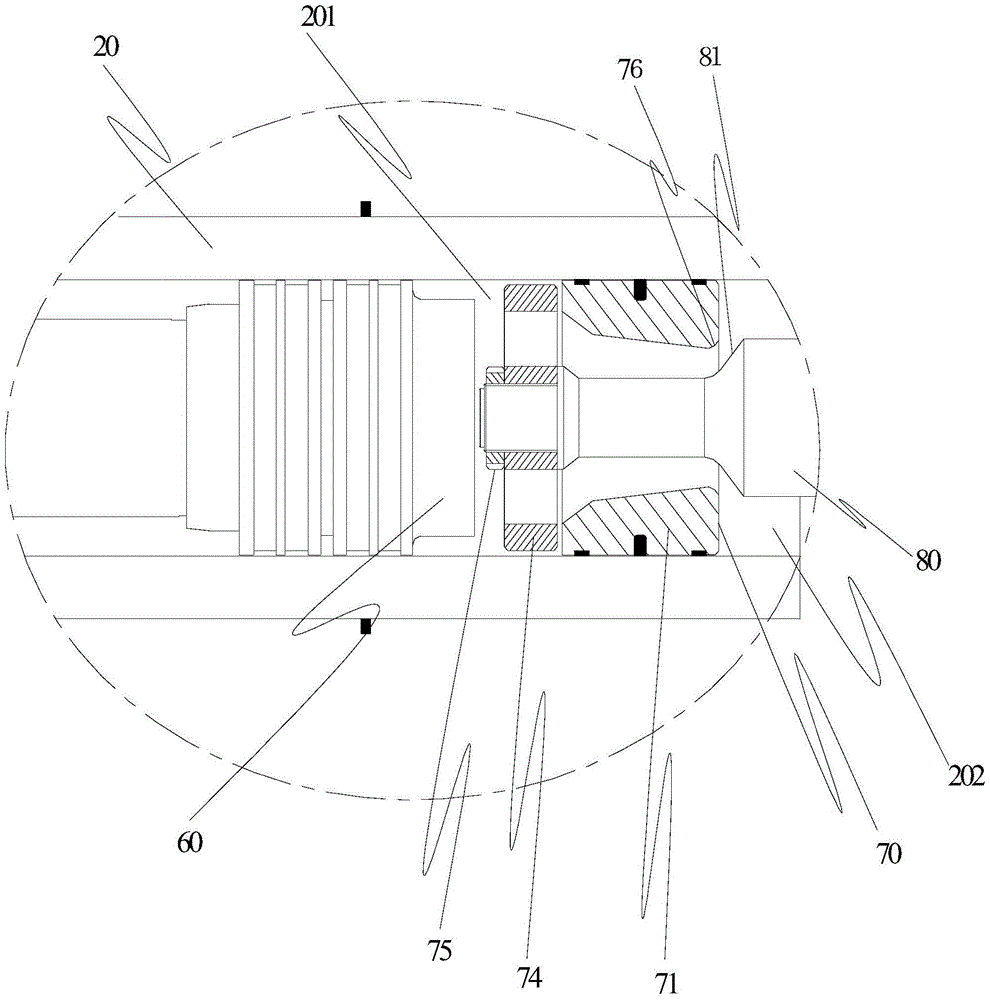

Low-speed machine integral common rail

PendingCN110761926AEasy to set upEasy to processMachines/enginesSpecial fuel injection apparatusPressure Limit ValveCommon rail

The invention relates to a low-speed machine integral common rail so as to reduce pressure fluctuation in a common rail pipe. According to the scheme, the common rail pipe, an oil inlet end cover andan end cover are included. The common rail pipe is provided with an oil inlet oil way and an oil return oil way which penetrate through the two ends. The oil inlet end cover is fixedly arranged at oneend of the common rail pipe and provided with an oil inlet communicating with the oil inlet oil way. The end cover is fixedly arranged at the other end of the common rail pipe and provided with an oil outlet communicating with the oil inlet oil way, and a circulation valve is fixed to the end cover. A pressure limiting valve and at least two flow limiting valves are fixed to the common rail pipeand communicate with the oil inlet oil way and the oil return oil way, and the flow limiting valves are each used for being connected with one electric control oil atomizer.

Owner:CHONGQING HONGJIANG MACHINERY

Improved booster device for die casting machine

The invention discloses an improved die-casting machine supercharging device. The improved die-casting machine supercharging device comprises a first base, a knock-out cylinder barrel, a two-speed energy accumulator, a second base and a supercharging energy accumulator; a knock-out piston rod and a floating piston which can axially move are arranged in the knock-out cylinder barrel; the floating piston is arranged on the rear end portion of the knock-out piston rod; an inner hole with an abrasion-resistant ring is added to the middle of the floating piston due to the accurate matching of the floating piston and a knock-out oil cylinder. A supercharging piston rod is accurately matched with the abrasion-resistant ring in a sliding mode to enable the front end of the supercharging piston rod to obtain the reliable support and accordingly the defect of the high pressure disturbance caused by the hydraulic oil supercharging of a front oil chamber can be effectively overcome, a conical hole of the floating piston can be rapidly and stably closed through the conical surface of the supercharging piston rod to enable the supercharging contact to be stable, the supercharging to be timely and the pressure building to be rapid, and accordingly the good quality of die-casting products is guaranteed.

Owner:东莞市锐风机械有限公司

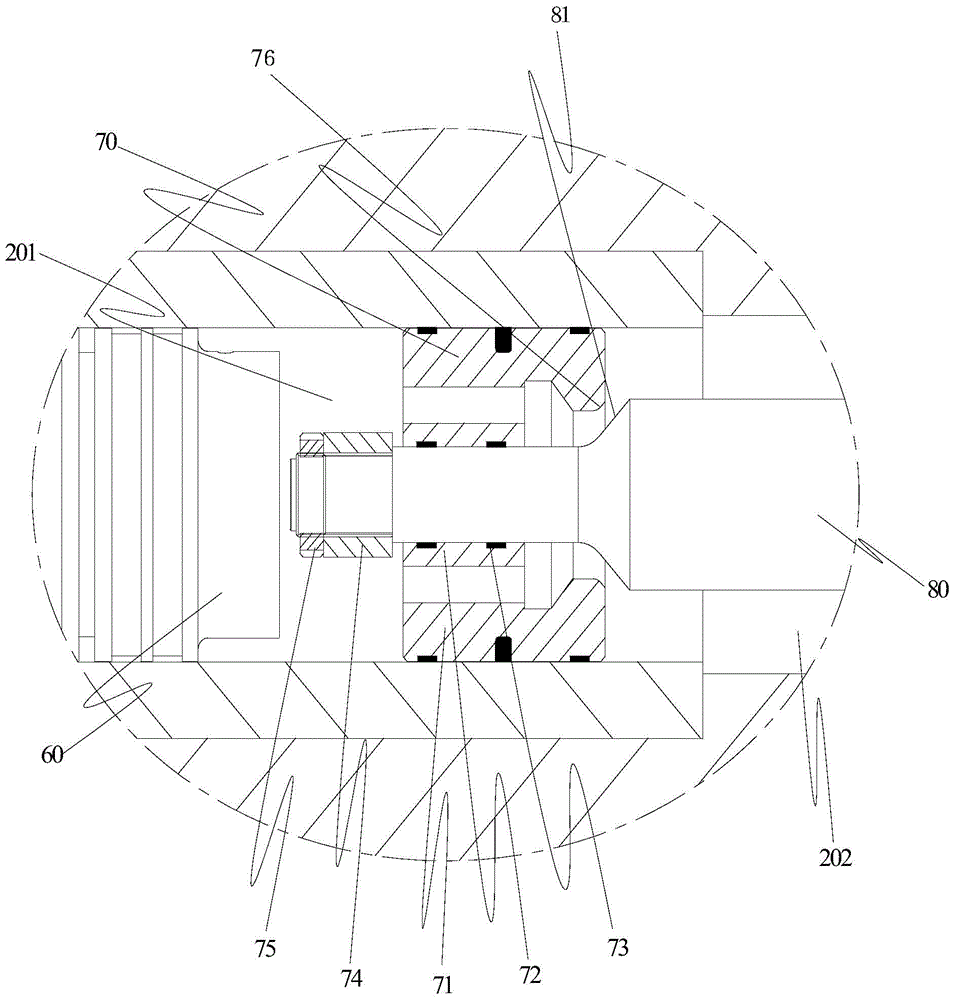

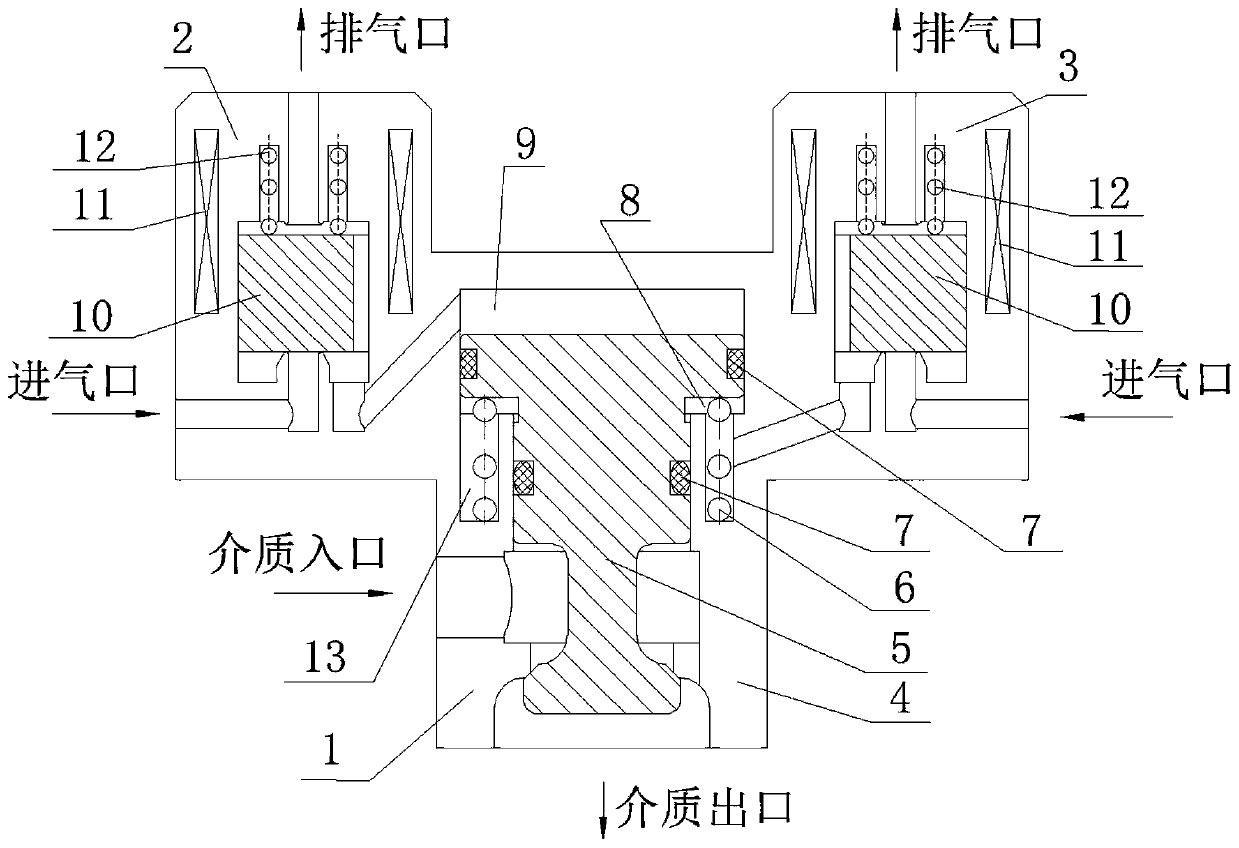

Electromagnetic pilot pneumatic control valve for opening and closing double-active control

ActiveCN110541960AQuick responseReliable actionOperating means/releasing devices for valvesMultiple way valvesElectromagnetic valveControl valves

The invention provides an electromagnetic pilot pneumatic control valve for opening and closing double-active control, and solves the problem of difficult meeting of quick closing deceleration requirements of an engine caused by slower closing response due to influence on a traditional engine control valve by gradual reduction of the exhaust speed and the spring loading force. The electromagneticpilot pneumatic control valve comprises a main valve, an opening secondary valve and a closing secondary valve; the main valve comprises a main valve body, a main valve element and a main valve spring; the main valve element is arranged in the main valve body to form two independent air cavities in the main valve body: an opening air cavity and a closing air cavity; the main valve spring is arranged in the closing air cavity; the main valve body is provided with a medium inlet and a medium outlet; the opening secondary valve and the closing secondary valve are both electromagnetic valves; theopening secondary valve is used for controlling inflation and deflation of the opening air cavity and providing opening force to the main valve element; and the closing secondary valve is used for controlling inflation and deflation of the closing air cavity and providing closing force to the main valve element.

Owner:XIAN AEROSPACE PROPULSION INST

fuel injector

InactiveCN102748179BEmission cleanReduce consumptionFuel injection apparatusMachines/enginesSolenoid valveEngineering

Provided is a fuel injector for a diesel engine. A plunger is arranged in the fuel injector, and the plunger and a fuel nozzle needle valve are combined into a pair of matching parts. The matching parts can be in a mode that the fuel nozzle needle valve is installed in an inner hole of the plunger or in a mode that the plunger is installed in an inner hole of the fuel nozzle needle valve. Fuel injection and fuel feeding of a high-pressure cavity can be controlled through an electric control method or a mechanical method. The plunger can be pushed through a mechanical method or a hydraulic method, wherein pressurizing injection can be further achieved by means of the hydraulic method. The fuel injector reduces volume of the high-pressure cavity and a leakage link furthest. Therefore, the fuel injector is quick in pressure building up, less in leakage amount, high in injection pressure, clean in discharged tail gas and low in fuel consumption. An electric control valve is not driven by an armature directly, and clearance between a solenoid valve and the armature can be smallest, so that miniaturization of the solenoid valve is facilitated.

Owner:袁辉

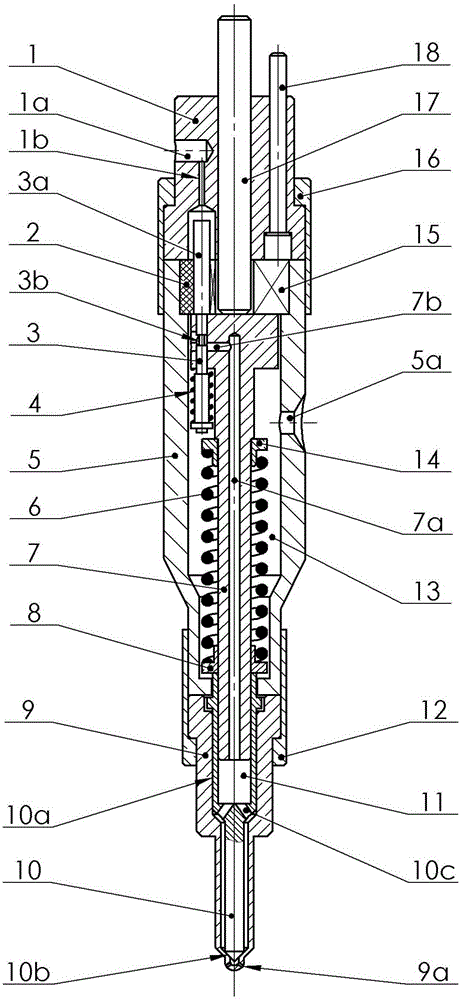

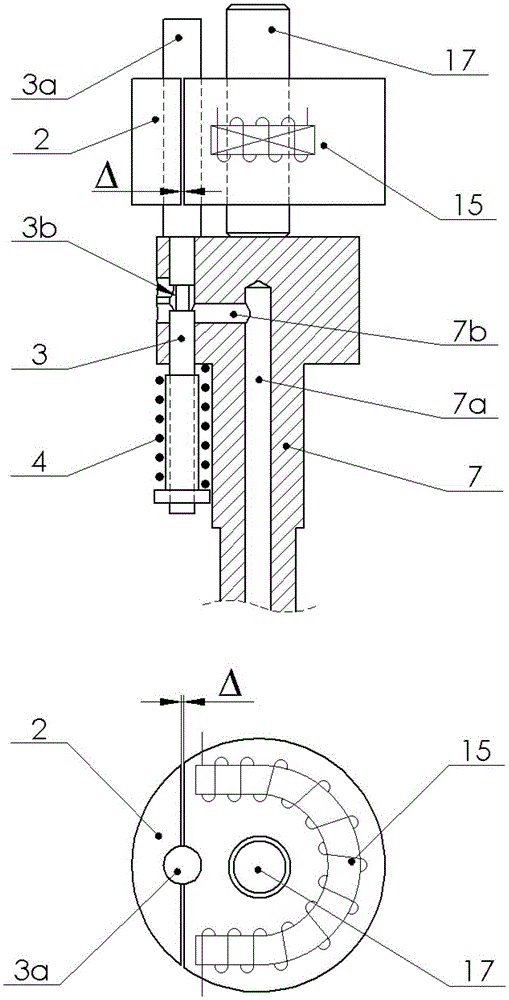

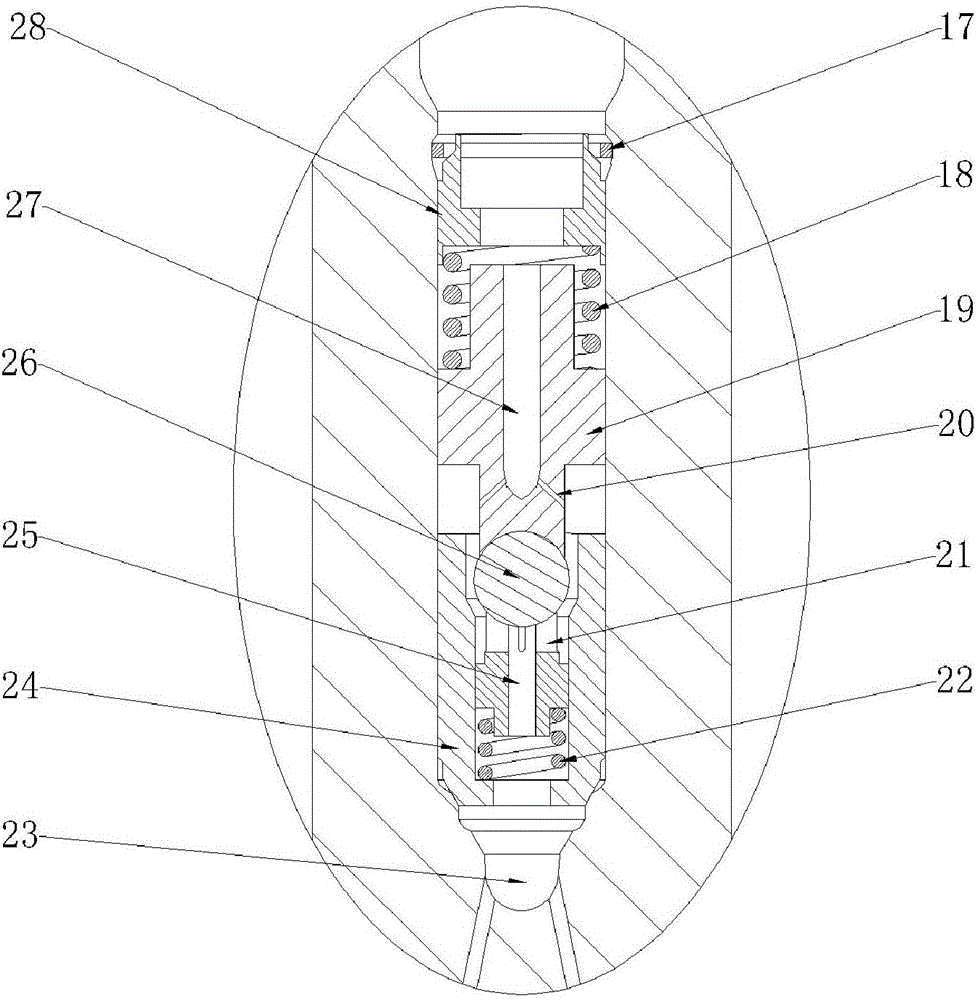

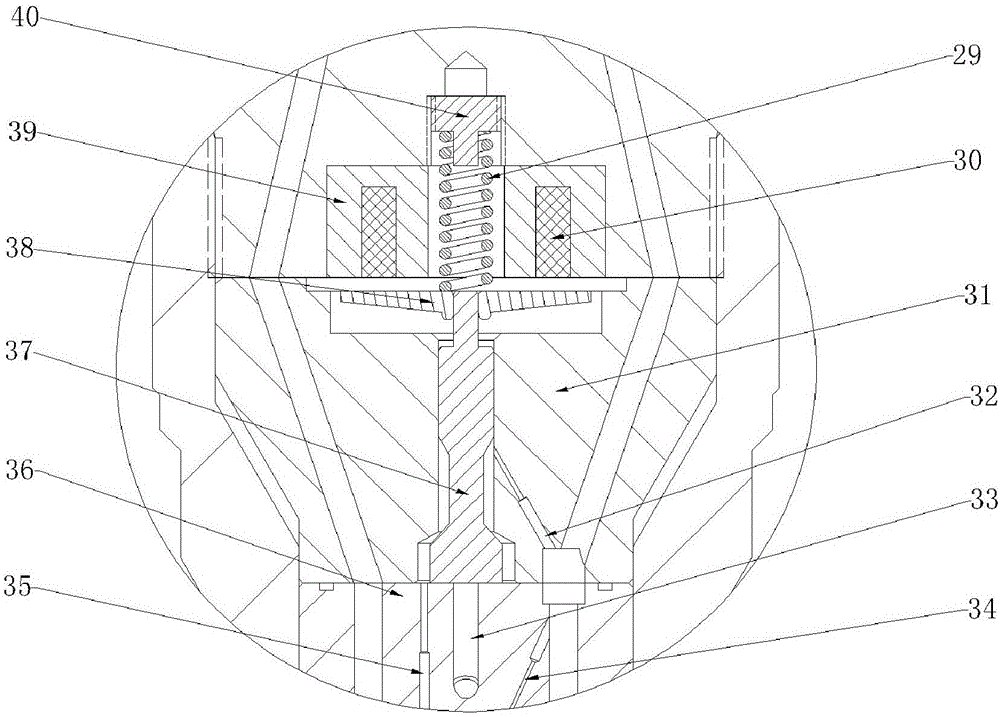

Electric control oil injector with dual-channel oil supply

ActiveCN106545447ABuild pressure quicklyAchieving a static leak-free functionInternal combustion piston enginesSpecial fuel injection apparatusSolenoid valveElectric control

The invention aims to provide an electric control oil injector with dual-channel oil supply. The electric control oil injector comprises an oil injector head, an oil injector body, a flow limiting valve component, an electromagnetic valve component, a nozzle and a needle valve body, wherein a pressure storage cavity is formed in the oil injector body, is communicated with a main oil supply hole and the flow limiting valve component, and is capable of ensuring stability of oil injection process of each cylinder under the condition of high oil injection quantity; the flow limiting valve component is arranged under the pressure storage cavity and is capable of preventing continuous abnormal oil injection; the electromagnetic valve component is processed at the bottom of the oil injector body; a valve rod is driven to move due to electromagnetic force, so that the flexible oil injection strategy and the oil injection process with quick response and high control accuracy can be achieved; the electromagnetic valve adopts a two-position three-way valve; through dual-channel oil supply in the oil injector, the dynamic oil return quantity is not increased while ensuring that the pressure buildup speed of a control cavity is accelerated and the needle valve seating response is improved; the static pressure difference is not generated in the oil injector; and the characteristic of no static leakage of the oil injector can be ensured.

Owner:HARBIN ENG UNIV

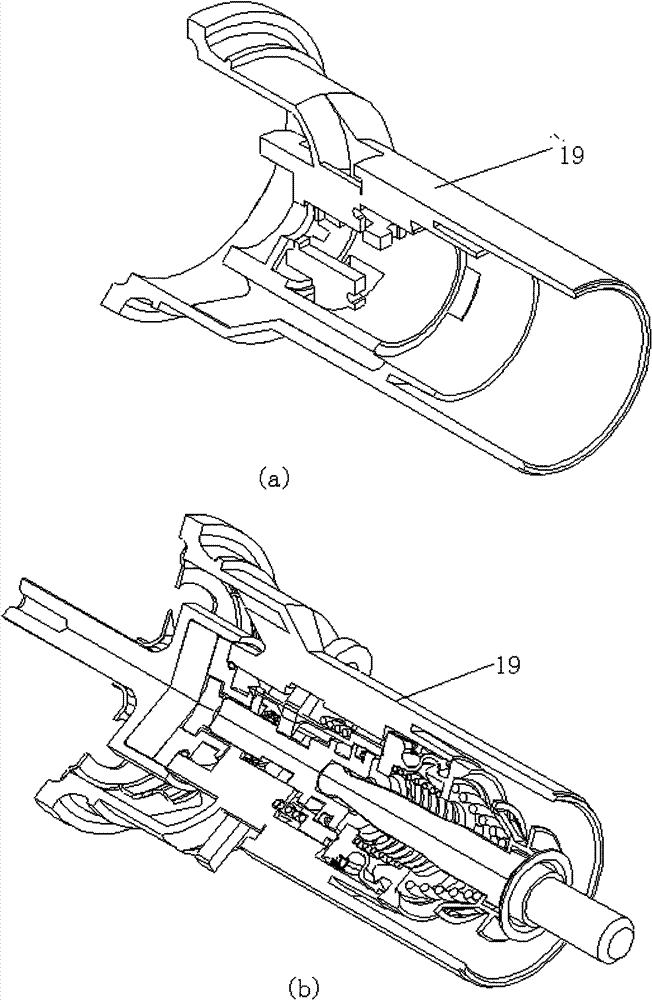

A booster assembly that improves pedal feel

ActiveCN110450765BImprove energy transfer efficiencyImproved pedal feelBraking action transmissionFoot actuated initiationsMaster cylinderEngineering

Owner:GUANGZHOU ZHONGBO BRAKE SYST CO LTD

Forward collision avoidance method and system based on electro-hydraulic braking

ActiveCN105346528BEasy to controlReduce distractionsAutomatic initiationsSignalling/lighting devicesDriver/operatorPattern perception

The invention relates to the technical field of electronic hydraulic braking, in particular to a forward collision prevention method and system based on electronic hydraulic braking. The method includes the steps that an environment perception unit acquires and outputs environment information to a danger judgment unit; the danger judgment unit computes the pre-collision time t and judges and sends the danger level of collision to an electronic control unit; the electronic control unit sends an alarm and / or brake command to an execution unit according to the different danger levels; and the execution unit conducts alarming and / or braking according to the command. Based on an electronic hydraulic braking system, the response speed is high. According to the different danger levels, a danger alarm is given to a driver; and when the danger level is high or extremely high, a horn system can be controlled to give pedestrians a prompt that the danger exists, so that the safety of the pedestrians around vehicles is guaranteed.

Owner:DONGFENG MOTOR CORP HUBEI

Double-path oil feeding resonance bypass type electrically controlled oil sprayer with engraved groove

PendingCN106593721AFunctions guaranteed to be static without leaksReduce cavitationFuel injection apparatusMachines/enginesResonanceSpray nozzle

The invention aims to provide a double-path oil feeding resonance bypass type electrically controlled oil sprayer with an engraved groove. The oil sprayer comprises an oil sprayer head, an oil sprayer body, a flow limiting valve assembly, an electromagnetic valve assembly, a needle valve assembly, a nozzle and a needle valve seat, wherein a resonance through hole and a resonance throttling hole are formed in the bottom of the flow limiting valve assembly, so that fluctuation of fuel oil passing through the flow limiting valve assembly is reduced; the electromagnetic valve assembly and the needle valve assembly are arranged below the flow limiting valve assembly; an electromagnetic valve adopts a two-position three-way valve so as to reduce a dynamic oil return volume; a control sliding block is mounted inside a control cavity, and is in contact with a middle block, so that the effects of decreasing the oil spraying rate at the initial stage of spraying and accelerating a seating response of a needle valve; the control cavity adopts a double-path oil feeding mode to further increase the pressure buildup speed and realize the fast response characteristic of the oil sprayer; the engraved groove with a depth in the micron level is formed in the surface of a needle valve body, so that the stability of cavitating flow can be effectively improved, and the cavitation erosion degree of the oil sprayer is reduced; and furthermore, no static pressure difference is generated in the oil sprayer, so that the oil sprayer does not have static leakage.

Owner:HARBIN ENG UNIV

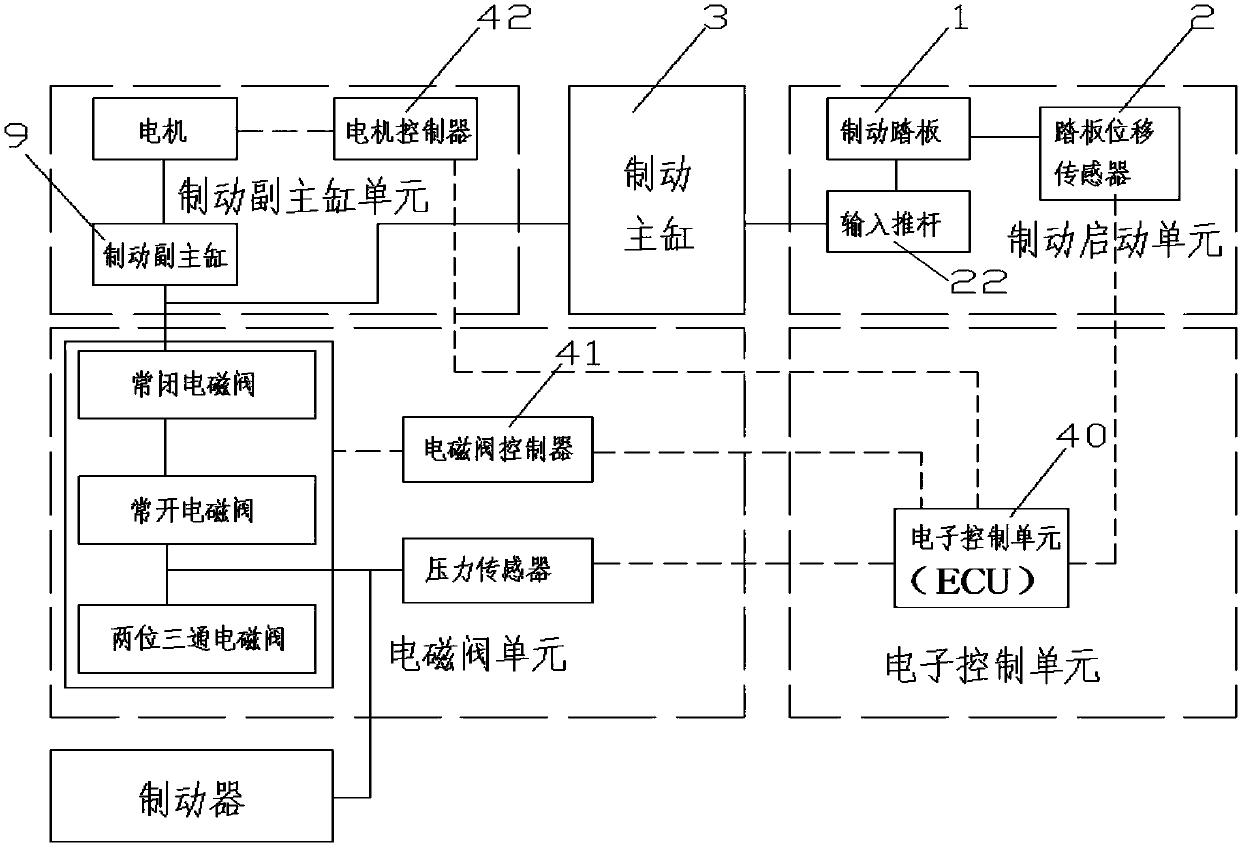

Integrated sub master cylinder wire control hydraulic brake system

ActiveCN106915343BHighly integratedGood pedal feelBraking action transmissionFoot actuated initiationsMaster cylinderSolenoid valve

The invention discloses a wire-control hydraulic braking system with an integrated vice master cylinder. The problems that the integration level is low, the braking pressure is relatively slowly set up by a motor, brake pressure variation is large, and pressure setting up accuracy is low are solved. The wire-control hydraulic braking system comprises a braking starting unit, a braking master cylinder, a braking vice master cylinder unit and an electromagnetic valve unit; the braking vice master cylinder unit comprises a motor and the braking vice master cylinder; the electromagnetic valve unit comprises a first two-position three-way electromagnetic valve, a second two-position three-way electromagnetic valve, a fifth constantly-open electromagnetic valve, a second constantly-close electromagnetic valve and a third constantly-close electromagnetic valve; the braking starting unit is connected with a first piston of a master cylinder body of the braking master cylinder through an input push rod of the braking starting unit; the braking master cylinder is in pipeline connection with the electromagnetic valve unit through the fifth constantly-open electromagnetic valve; the braking vice master cylinder is in pipeline connection with the electromagnetic valve unit through the first two-position three-way electromagnetic valve, the second two-position three-way electromagnetic valve, the second constantly-close electromagnetic valve and the third constantly-close electromagnetic valve; and the motor and the braking vice master cylinder are connected with a first vice master cylinder piston through an output shaft in the motor.

Owner:JILIN UNIV

Bypass type electronic controlled injector with hydraulic feedback function

ActiveCN106593724AImprove pressure fluctuationsImprove stabilityFuel injection apparatusMachines/enginesSolenoid valveSystem pressure

The invention aims to provide a bypass type electronic controlled injector with a hydraulic feedback function. The bypass type electronic controlled injector comprises an injector head, an injector body, a flow-limiting valve assembly, a solenoid valve assembly, a needle valve assembly and other components. A pressure storage cavity is arranged in the injector body and communicates with a main oil inlet hole and the flow-limiting valve assembly, and the stability of the oil injection processes of all cylinders during large pulse width oil injection can be ensured. The flow-limiting valve assembly is installed under the pressure storage cavity, and abnormal continuous oil injection is avoided. The opening speed of the a needle valve is decreased through a feedback oil line existing in the solenoid valve assembly, so that system pressure buildup is quick, the seating speed of the needle valve is increased, and the injector can be controlled to quickly stop oil injection. A control slide block is arranged in a control cavity and makes contact with an intermediate block, and the effects of decreasing the oil injection rate in the initial stage of oil injection and accelerating seating response of the needle valve are achieved. The internal hydraulic pressure of a nozzle part is balanced, and no static pressure difference exists, so that the non-static-leakage function of the injector is achieved.

Owner:HARBIN ENG UNIV

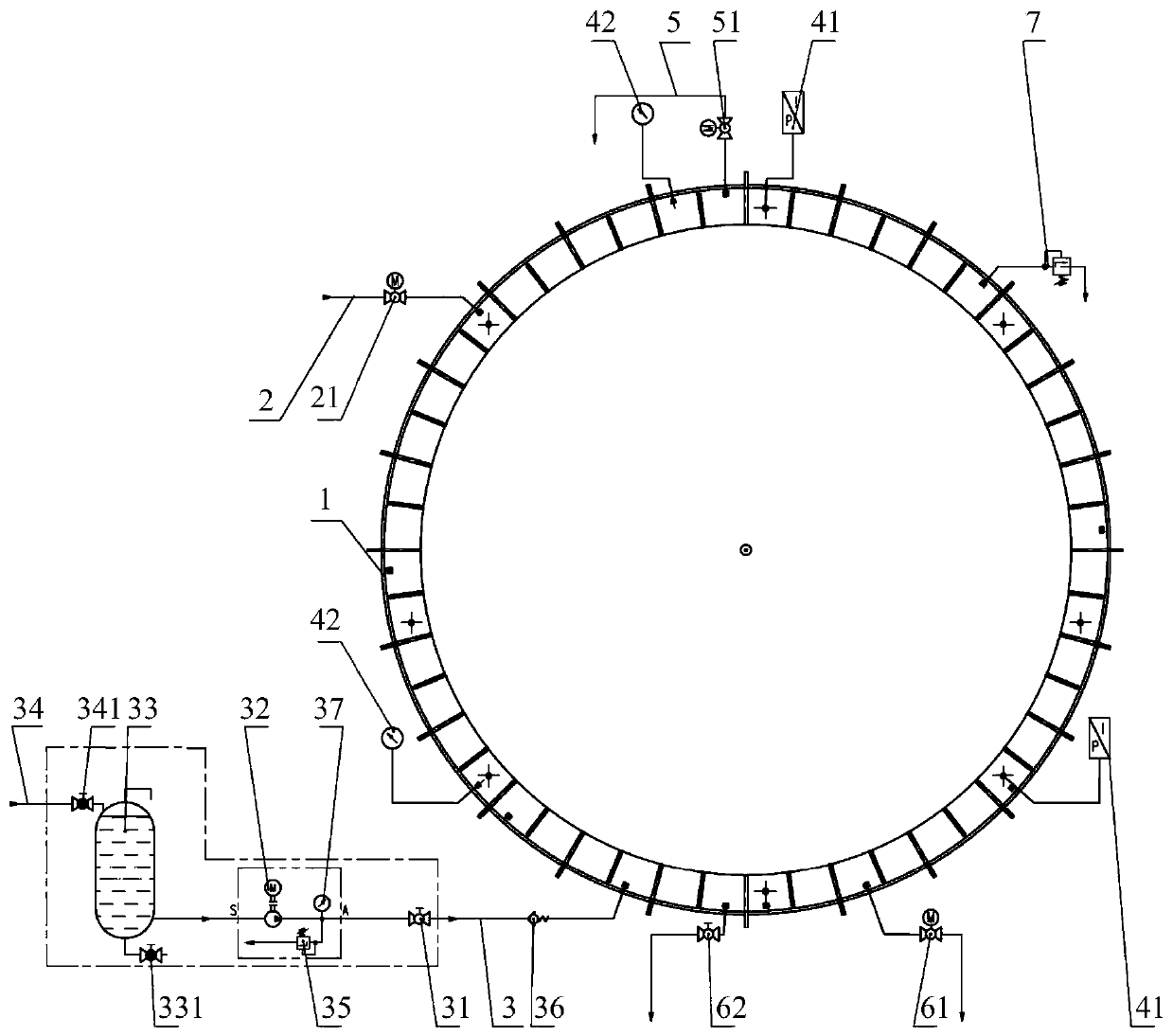

Hinged sealing test device for shield tunneling machine

PendingCN111413053AImprove pressure resistanceQuick and dynamic switchingMeasurement of fluid loss/gain rateTunnelsEngineeringShield tunneling

The invention discloses a hinged sealing test device for a shield tunneling machine, which comprises a hinged sealing ring cavity, a fluid medium pipeline and a pressurizing pipeline, wherein the hinged sealing ring cavity is provided with a first filling port and a second filling port; the fluid medium pipeline is connected with the first filling port, is used for filling a fluid medium into thehinged sealing ring cavity and is provided with a first switch valve; the pressurizing pipeline is connected with the second filling port, is used for pressurizing the hinged sealing ring cavity and is provided with a second switch valve. According to the hinged sealing test device for the shield tunneling machine, the fluid medium pipeline and the pressurizing pipeline are separately designed, afluid medium is injected into the hinged sealing ring cavity through a fluid medium pipeline, the pressurizing pipeline is used for boosting the pressure of an internal medium of the hinged sealing ring cavity, the pressure building process is fast, the hinged sealing ring cavity can rapidly and accurately reach the needed pressure, rapid dynamic switching between high pressure and low pressure can be achieved, and the pressure resistance of hinged sealing in the dynamic change process of external pressure can be conveniently tested.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Double-channel oil feeding type electronic control oil injector with carved grooves

PendingCN106545446AReduce abnormal fuel injection conditionsImprove control precision and flexibilityFuel injection apparatusMachines/enginesInjectorCavitation flow

The invention aims at providing a double-channel oil feeding type electronic control oil injector with carved grooves. The electronic control oil injector comprises an oil injector head, an oil injector body, a flow-limiting valve assembly, a solenoid valve assembly, a needle valve seat, a needle valve body and a nozzle. A pressure storage cavity is formed in the oil injector body and communicates with a main oil feed hole and the flow-limiting valve assembly, and stability of the oil injection process of all cylinders under a large oil-injection quantity condition is guaranteed. The solenoid valve assembly is machined at the bottom of the oil injector body, a valve rod is driven by electromagnetic force to move, and a flexible oil injection strategy and the oil injection process which is quick in response and high in control precision can be achieved. A two-position three-way valve mode is adopted by a solenoid valve, and by means of double-channel oil feeding inside the oil injector, it is guaranteed that the pressure buildup speed of a control cavity is increased, seat reaching response of a needle valve is increased, and meanwhile dynamic oil return quantity is not increased. The carved grooves with micron-grade depths are formed in the surface of the needle valve body, stability of cavitation flow can be effectively improved, and the cavitation degree of the oil injector is reduced. A static pressure difference does not exist in the oil injector, and it is guaranteed that the oil injector has the advantage of being free of static leakage.

Owner:HARBIN ENG UNIV

Bypass-type electronically-controlled oil injector with carved grooves

PendingCN106762280AImprove pressure fluctuationsImprove stabilityFuel injection apparatusMachines/enginesSolenoid valveCavitation flow

The invention aims at providing a bypass-type electronically-controlled oil injector with carved grooves. The bypass-type electronically-controlled oil injector comprises an oil injector head, an oil injector body, a flow-limiting valve assembly, an electromagnetic valve assembly, a locking nut, a needle valve assembly, a nozzle, a needle valve seat and other components. A pressure accumulation cavity is formed in the oil injector body, and communicates with a main oil inlet hole and the flow-limiting valve assembly, so that a stable oil injection process of each cylinder in the case of large-pulse-width oil injection can be ensured. The electromagnetic valve assembly and the needle valve assembly are sequentially arranged below the flow-limiting valve assembly. The electromagnetic valve assembly and the needle valve assembly are connected together through the locking nut. A control slide block is arranged in a control cavity and contacts with a middle block, thereby playing the roles of slowing down an oil injection speed in the initial stage of injection and accelerating the seating response of a needle valve. The carved grooves with micron-level depths are formed in the surface of a needle valve body, and capable of effectively improving the stability of cavitation flow, thereby lowering the cavitation erosion degree of the oil injector. The needle valve assembly part achieves internal hydraulic pressure balance and has no static pressure difference, thereby realizing the function of no static leakage of the oil injector.

Owner:HARBIN ENG UNIV

Bypass type electronic fuel injector

PendingCN106762282AImprove pressure fluctuationsImprove stabilityFuel injection apparatusMachines/enginesSolenoid valveEngineering

The invention aims at providing a bypass type electronic fuel injector which comprises a fuel injector head, a fuel injector body, a flow limiting valve assembly, a solenoid valve assembly, a cap nut, a needle valve assembly, a nozzle and other components. A pressure storage cavity is formed in the fuel injector body and communicates with a main fuel inlet and the flow limiting valve assembly, and it can be guaranteed that during large-pulse-width fuel injection, the fuel injection processes of all cylinders are stable. The flow limiting valve assembly is mounted below the pressure storage cavity, and abnormal continuous fuel injection is avoided. The solenoid valve assembly and the needle valve assembly are sequentially arranged below the flow limiting valve assembly and connected together through the cap nut. A control sliding block is arranged in a control cavity and is in contact with a middle block, and the functions of relieving the fuel injection speed in the initial injection period and accelerating needle valve sitting responses are achieved. Hydraulic pressure in the nozzle part is balanced, the static pressure difference is avoided, and the function that the fuel injector is free of static leakage is achieved.

Owner:HARBIN ENG UNIV

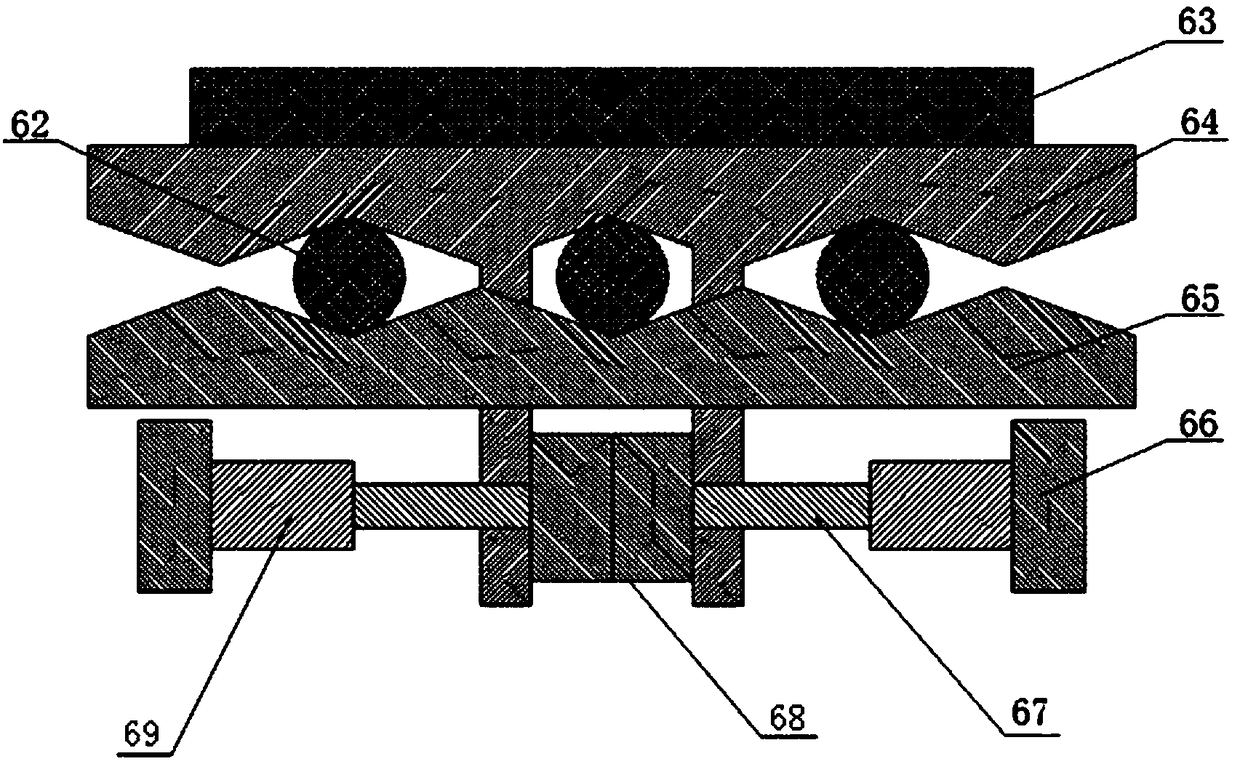

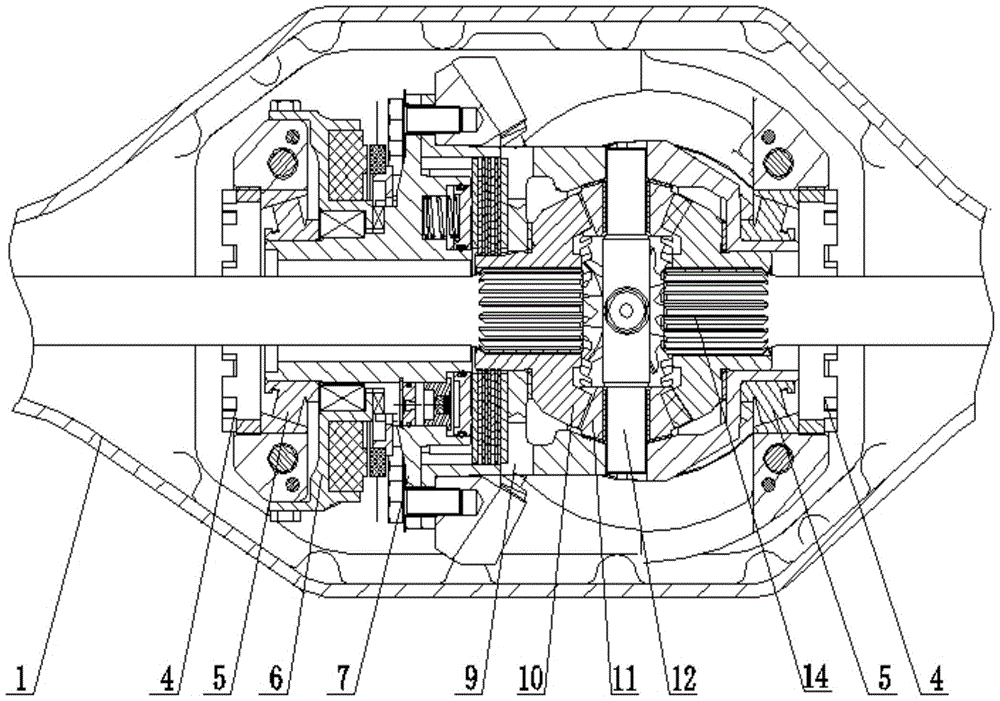

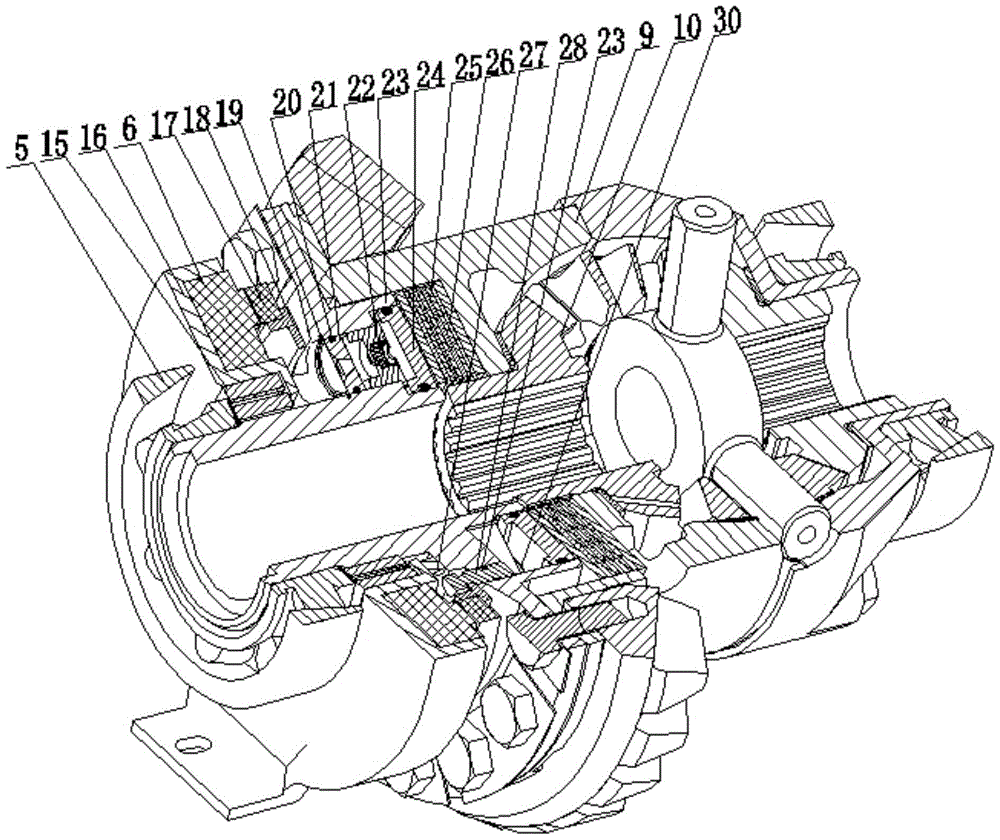

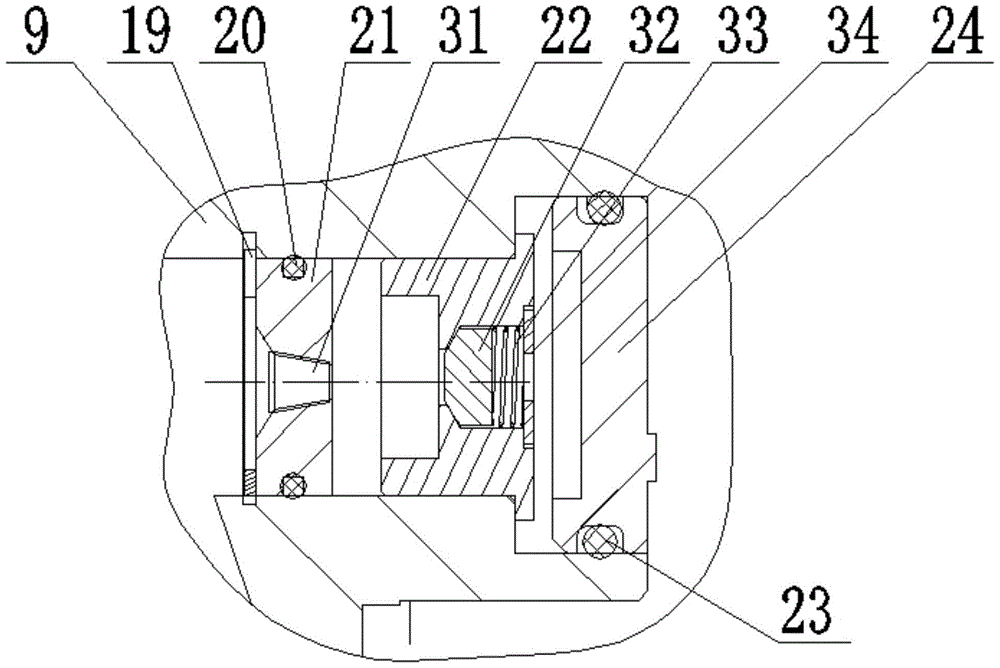

An electronic limited slip differential

ActiveCN104006139BLimited slip response time is shortLarge multiplierDifferential gearingsNeedle roller bearingElectromagnetic clutch

The invention relates to the technical field of differential mechanisms, particularly to an electronic limited slip differential mechanism. The electronic limited slip differential mechanism comprises a differential mechanism end cover, a needle bearing, an electromagnetic clutch support, an electromagnetic clutch, a magnet, a magnet support, a large piston, a small piston, an internal friction plate, an external friction plate, an air exhaust cock and a thrust unit. The electromagnetic clutch is arranged on the electromagnetic clutch support; the electromagnetic clutch support is mounted on the differential mechanism end cover through the needle bearing; the electromagnetic clutch support is mounted on the differential mechanism end cover through a thrust bearing; the magnet and the electromagnetic clutch are oppositely arranged, and the magnet is connected with the small piston through the magnet support; the large piston is arranged on the right of the small piston; the thrust unit is arranged on the left of the large piston; the right end surface of the large piston abuts against the external friction plate; the external friction plate and the internal friction plate are arranged inside a differential mechanism left casing in a crossed mode; the air exhaust cock is arranged inside the differential mechanism end cover. The electronic limited slip differential mechanism is simple in structure, good in slip limiting effects and short in slip limiting response time.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST +1

Self-buffering gas-liquid mixing multi-stage ejection mechanism

ActiveCN105240343BAccelerated ejectionDecrease the relative speed of motionFluid-pressure actuatorsCatapultEngineering

The invention discloses a self-buffering gas-liquid mixing multi-stage ejection mechanism, which uses gas as a power source, oil as a pressure transmission medium, and combines the form of multi-stage piston cylinders sliding and cooperating with each other to form a gas-liquid mixing multi-stage ejection mechanism , which reduces the relative motion speed of the moving parts at all levels of the ejection mechanism, effectively reduces the sealing difficulty during high-speed ejection, and can realize high-speed ejection within a limited motion stroke; the throttling buffer structure, oil buffer and unloading groove are adopted. Combined, the self-buffering function of the multi-stage ejection mechanism is realized, and an oil filling port is opened to facilitate oil filling and oil change maintenance; the invention can be applied to military and civilian ejection of carrier-based aircraft, missiles, unmanned aerial vehicles, ejection experimental devices, etc. In many fields, the sealing performance is reliable, and it can provide ejection with self-buffering function under the condition of limited installation space, with high efficiency and good controllability.

Owner:NANJING UNIV OF SCI & TECH

Mechanical vacuum booster with emergency braking function

InactiveCN101612933BFast brakingBuild pressure quicklyBraking action transmissionMaster cylinderControl valves

The invention relates to a mechanical vacuum booster with an emergency braking function and belongs to the automobile braking field. A control valve assembly of the mechanical vacuum booster comprises such parts as a valve body, an input link, a filter screen spring seat, a conical spring, a spring seat, a compression spring, a vacuum leather cup, a trigger mechanism, a trigger mechanism spring, a plunger, a locking plate, a locking plate spring, a valve block, a scale plate, a reaction plate, an output link, an elastic collar, as well as a rubber seal ring, a rear shell body, a diaphragm, a diaphragm plate, a front shell body, a large return spring and the like. The mechanical vacuum booster has the advantages of novel structure and low cost; and provided that the vacuum booster meets a certain input power requirement, the vacuum booster can output relatively huge applied force on a main braking cylinder when a driver performs emergency braking, and the vacuum booster maintains output pressure of the main cylinder on the condition of reducing input force, thus shortening the braking distance of the whole automobile and being especially effective for unskilled drivers and drivers who hesitate to brake.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

Composite brake-by-wire system with four-wheel pressure independent control and brake control method thereof

InactiveCN108162943BCompact structureBuild pressure quicklyBraking action transmissionFoot actuated initiationsSolenoid valveWheel cylinder

The invention discloses a composite drive-by-wire brake system and brake control method for independently controlling four-wheel pressure. Two electromechanical brake modules in the system are both electromechanical pressurizing units in signal connection with an electronic control unit, two electronic hydraulic brake modules are both connected with a brake main cylinder pipeline in a brake pedalmechanism, each electronic hydraulic brake module is composed of a normally open switch electromagnetic valve, an electronic hydraulic pressurizing unit, normally open linear electromagnetic valves and a brake wheel cylinder in series sequentially through pipelines, pressure sensors are arranged on a connecting pipeline of the brake wheel cylinder, the electromagnetic valves, the electronic hydraulic pressurizing units and the pressure sensors are all respectively in signal connection with the electronic control unit; the brake control method comprises a brake control method of an effective state of electrifying and a brake control method of a failure state of outage. The composite drive-by-wire brake system and brake control method for independently controlling four-wheel pressure can overcome the deficiency of a single line control system, can independently achieve rapid pressure buildup of four wheels and accurately control pressure, and have functions of failure braking and regenerative braking.

Owner:JILIN UNIV

Double-way oil inflow resonance pore plate type electrically-controlled oil injector

PendingCN106704064ABuild pressure quicklyReduce dynamic oil returnFuel injection apparatusMachines/enginesSolenoid valveResonance

The invention aims to provide a double-way oil inflow resonance pore plate type electrically-controlled oil injector. The oil injector comprises an oil injector head, an oil injector body, a flow limiting valve assembly, an electromagnetic valve assembly and a needle valve assembly. A pressure storage cavity is formed in the oil injector body and communicates with a main oil inlet hole and the flow limiting valve assembly, and the stability of the oil injecting process of each cylinder under the condition of large oil injection quantity is guaranteed. The flow limiting valve assembly is placed below the pressure storage cavity, so that the abnormal oil injection is prevented from being continuously carried out. A resonance structure machined at bottom of flow limiting assembly reduces water hammer pressure waves generated by rapid starting and stopping of the oil injector. Through double-way oil inflow from a balance valve rod of a solenoid valve and the inside of a middle block and double-way oil inflow from a pore plate throttling hole and an annular side surface oil way, the pressure building process of a control cavity is accelerated, and the response speed of needle valve seating is increased. Through a pore plate structure arranged in the control cavity, the dynamic oil return amount in the oil injecting process is greatly reduced, and the characteristic of micro-dynamic oil return is guaranteed.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com