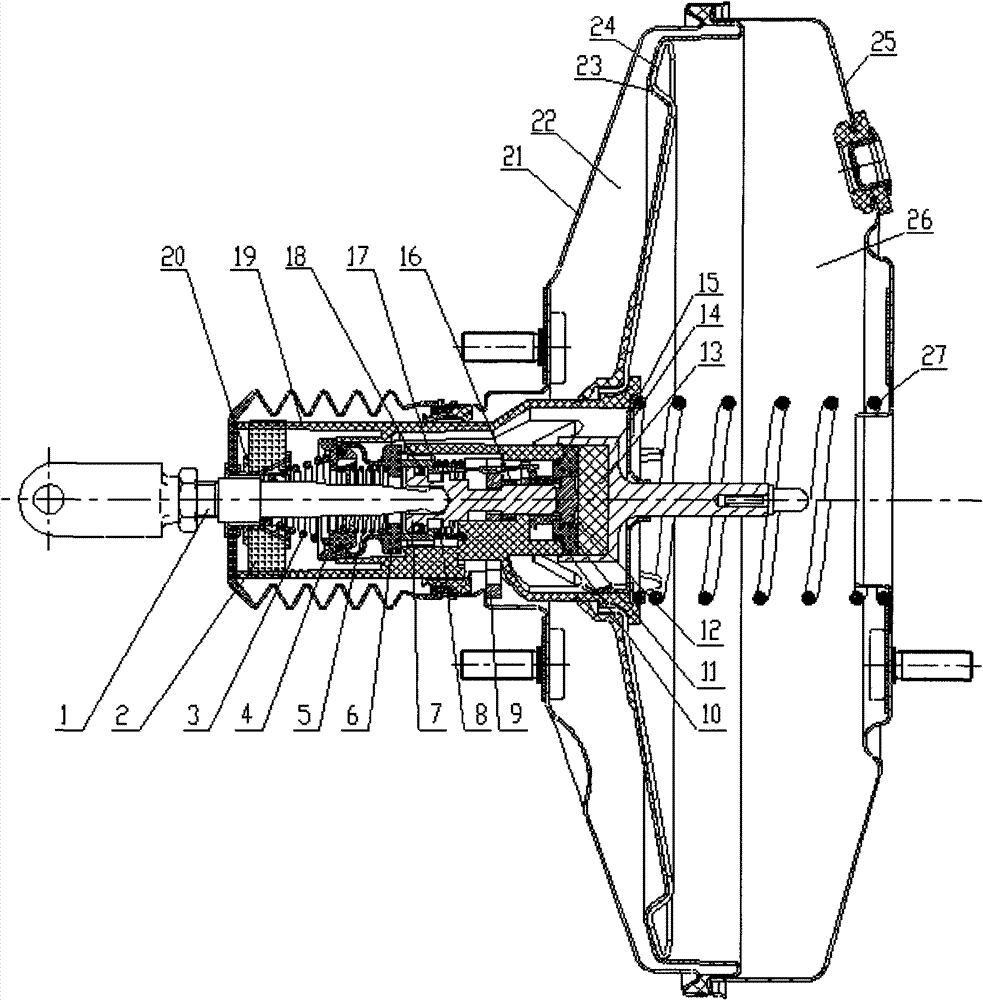

Mechanical vacuum booster with emergency braking function

A vacuum booster and emergency braking technology, applied in the directions of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of large application by the driver and difficult to maintain pedal force, and achieve shortened braking distance and novel structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

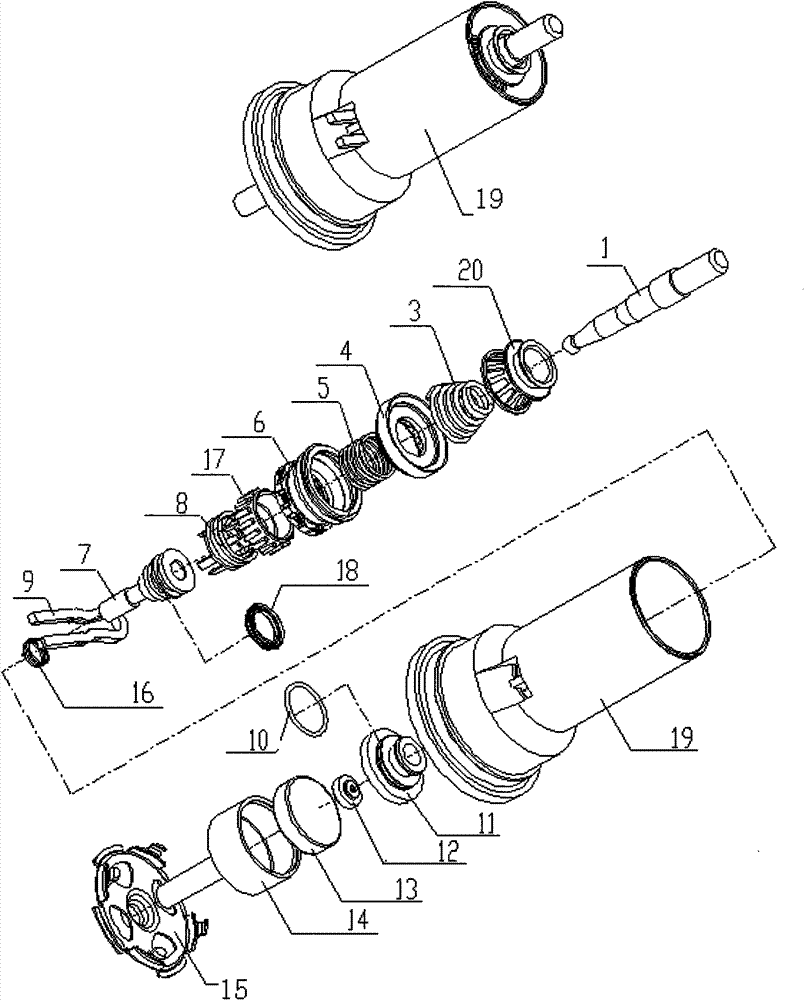

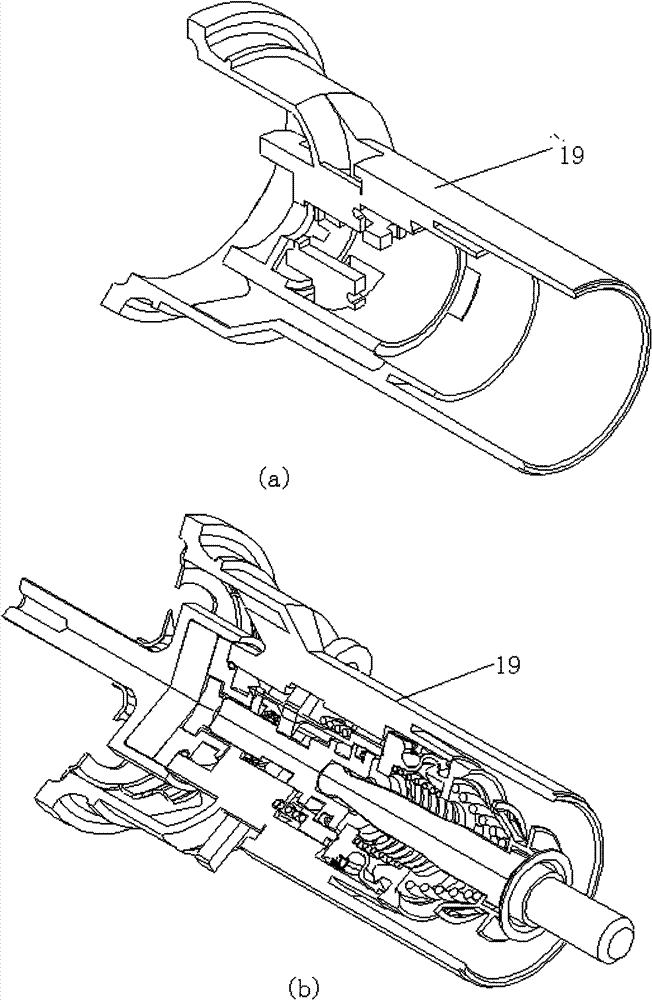

[0030] Explanation of all symbols in the accompanying drawings:

[0031]1-input rod, 1a-step on the input rod, 2-inner filter element, 3-conical spring, 4-spring seat, 5-compression spring, 6-vacuum cup, 6a-end face of vacuum cup bottom, 6b -Inner retaining ring on the vacuum cup, 7-Plunger, 7a-Plunger outer boss, 7b-The first stepped surface of the outer wall of the plunger, 7c-The second stepped surface of the outer wall of the plunger, 7d-Ring groove on the outer wall of the plunger Left end face, 7e-the right end face of the annular groove on the outer wall of the plunger, 7f-the end face of the plunger head, 8-the spring of the trigger mechanism, 9-the locking piece, 9a-the right end face of the middle part of the locking piece, 9b-the end surface of the locking piece, 9c- The left end face of the middle part of the locking piece, 10-rubber sealing ring, 11-valve block, 11a-the step surface on the outer wall of the valve block, 11b-the ring edge on the groove of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com