Patents

Literature

61results about How to "Short braking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

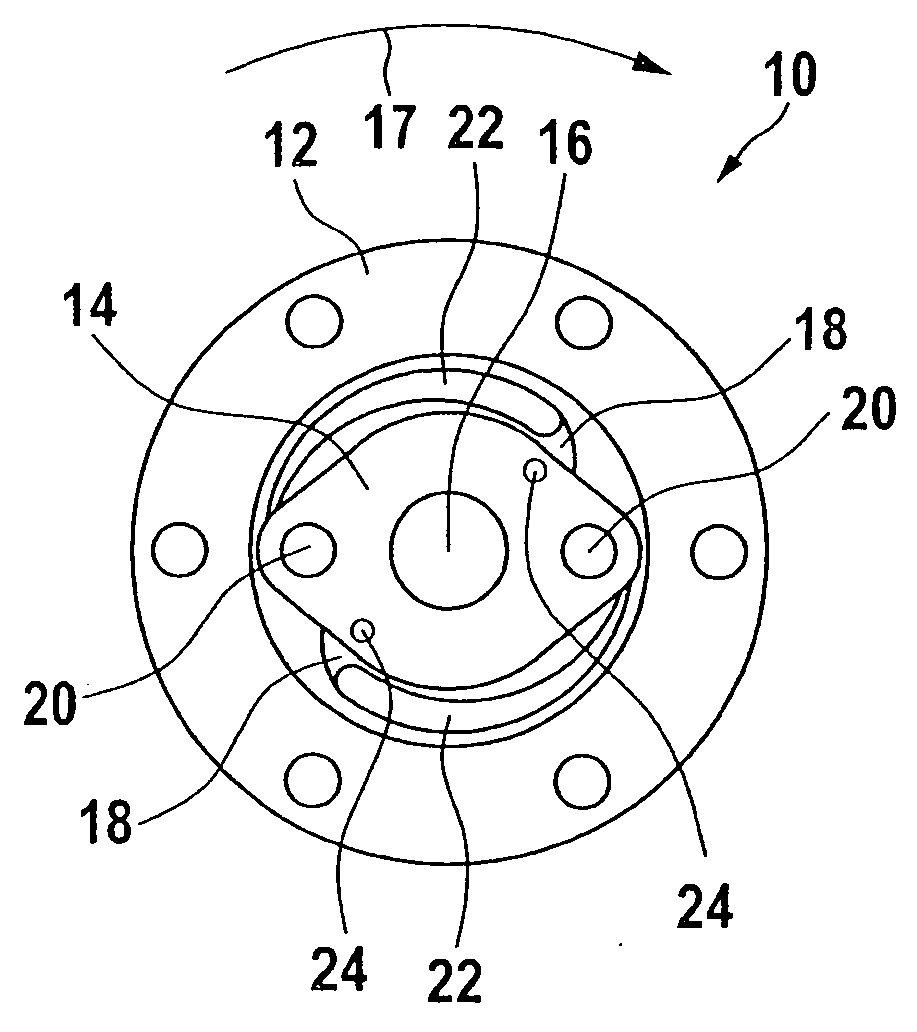

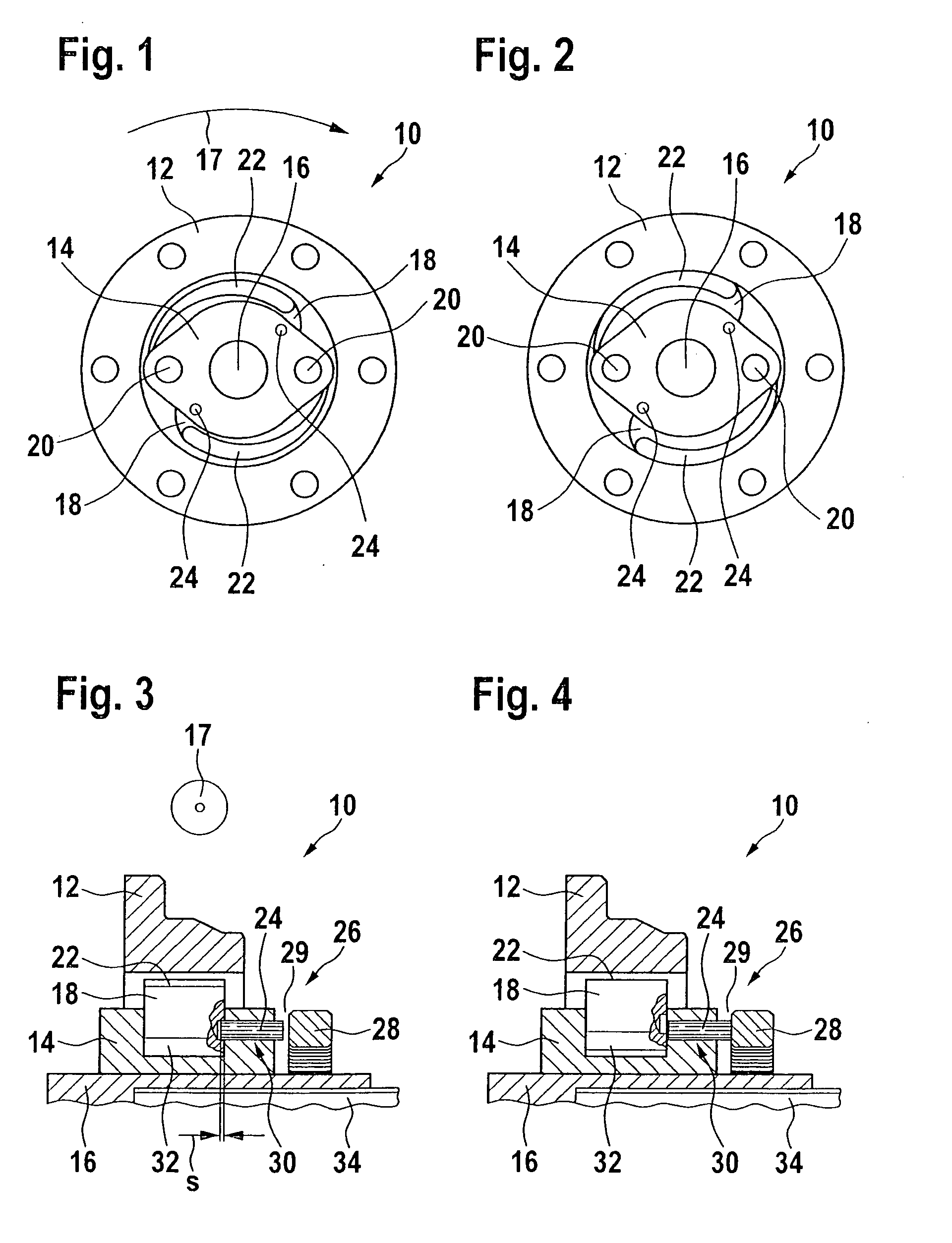

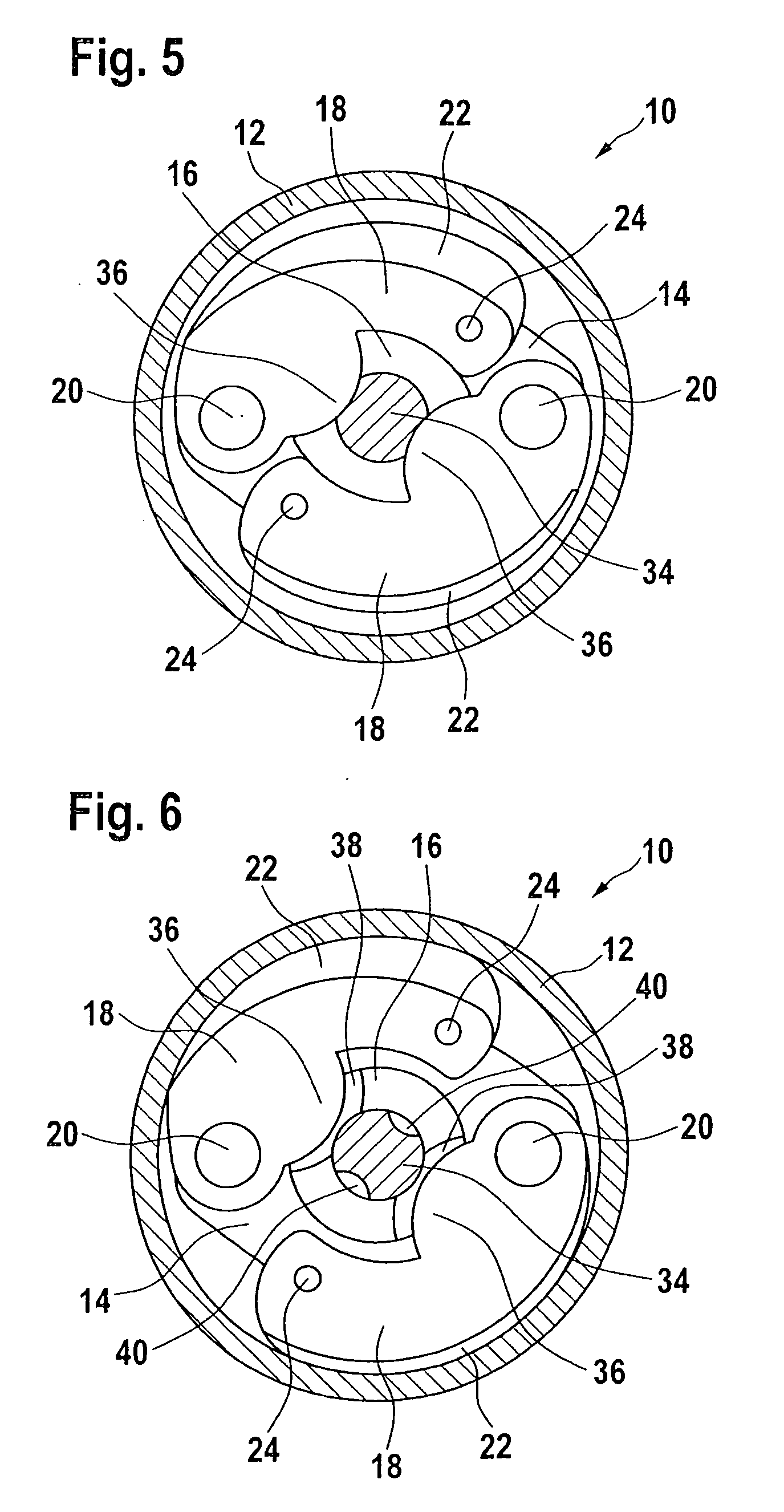

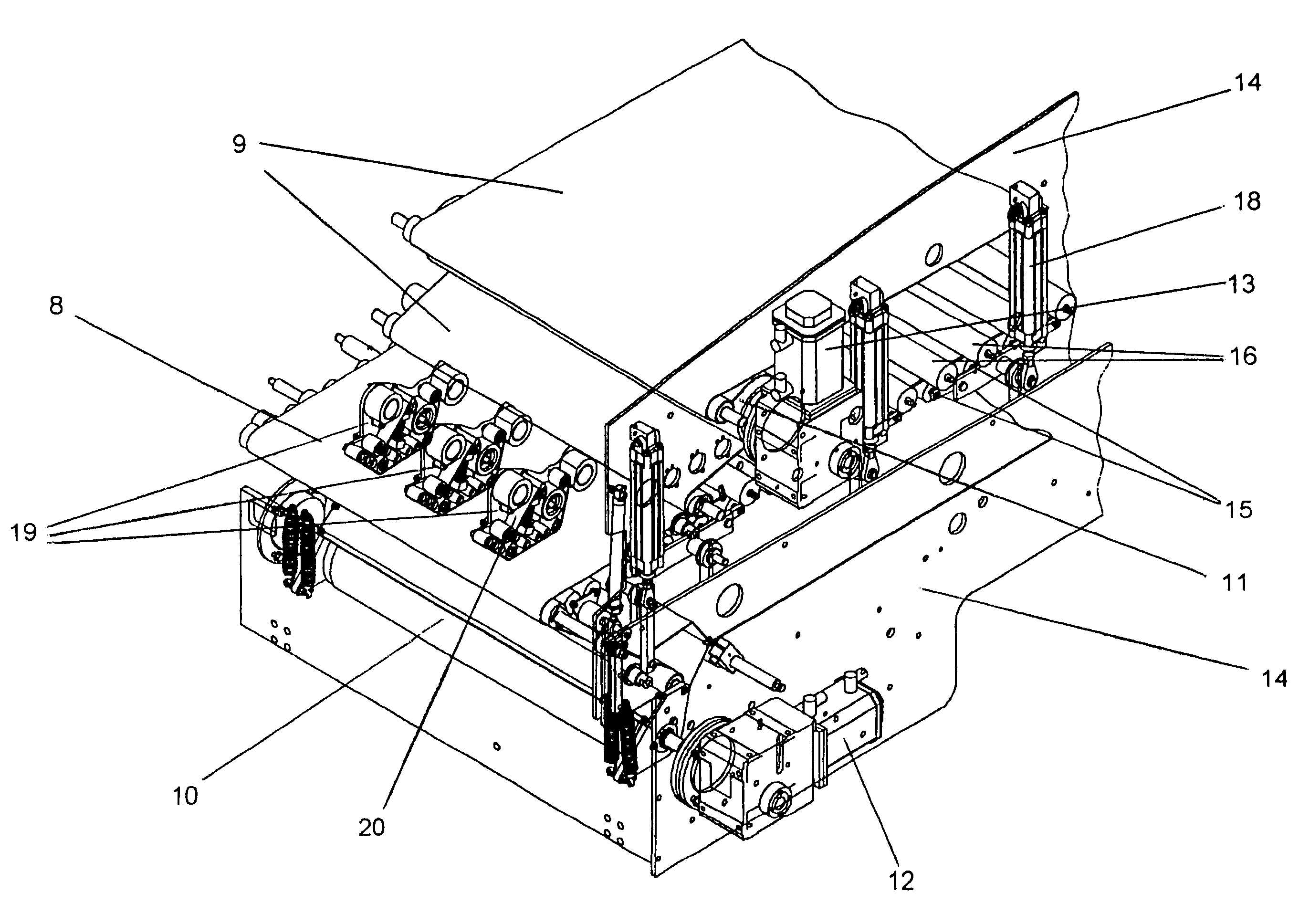

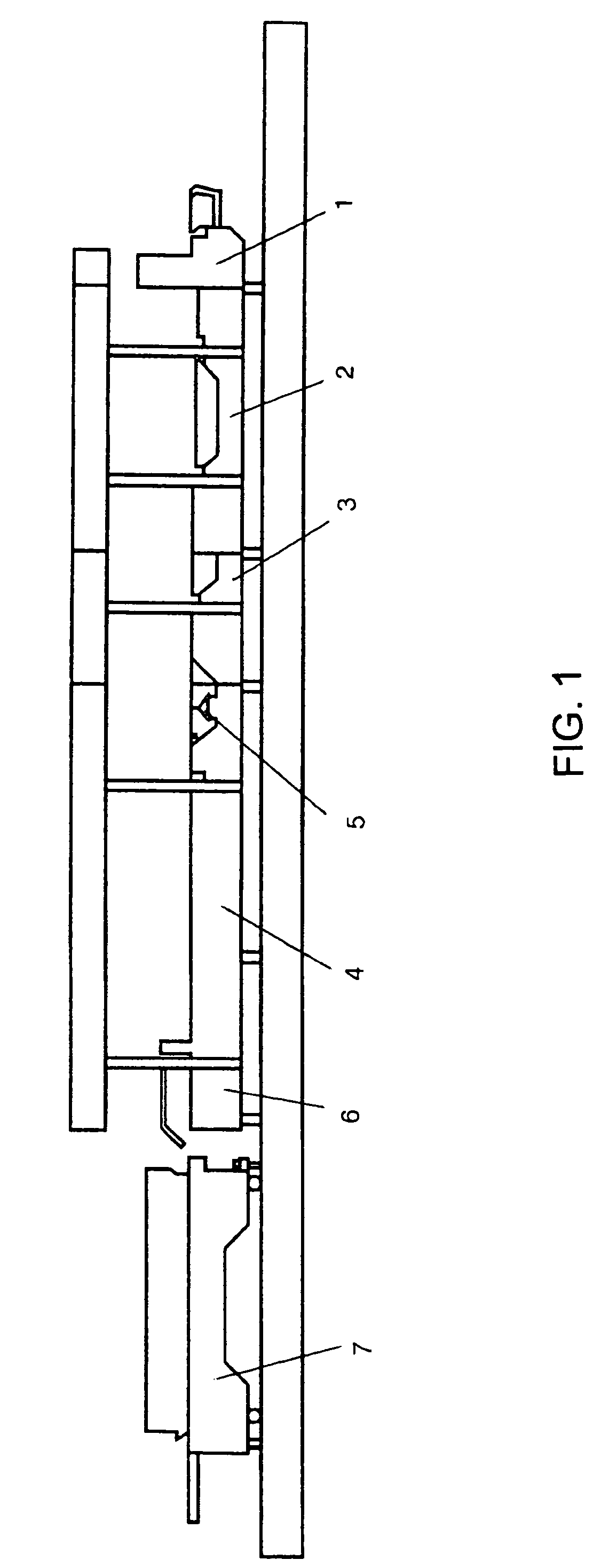

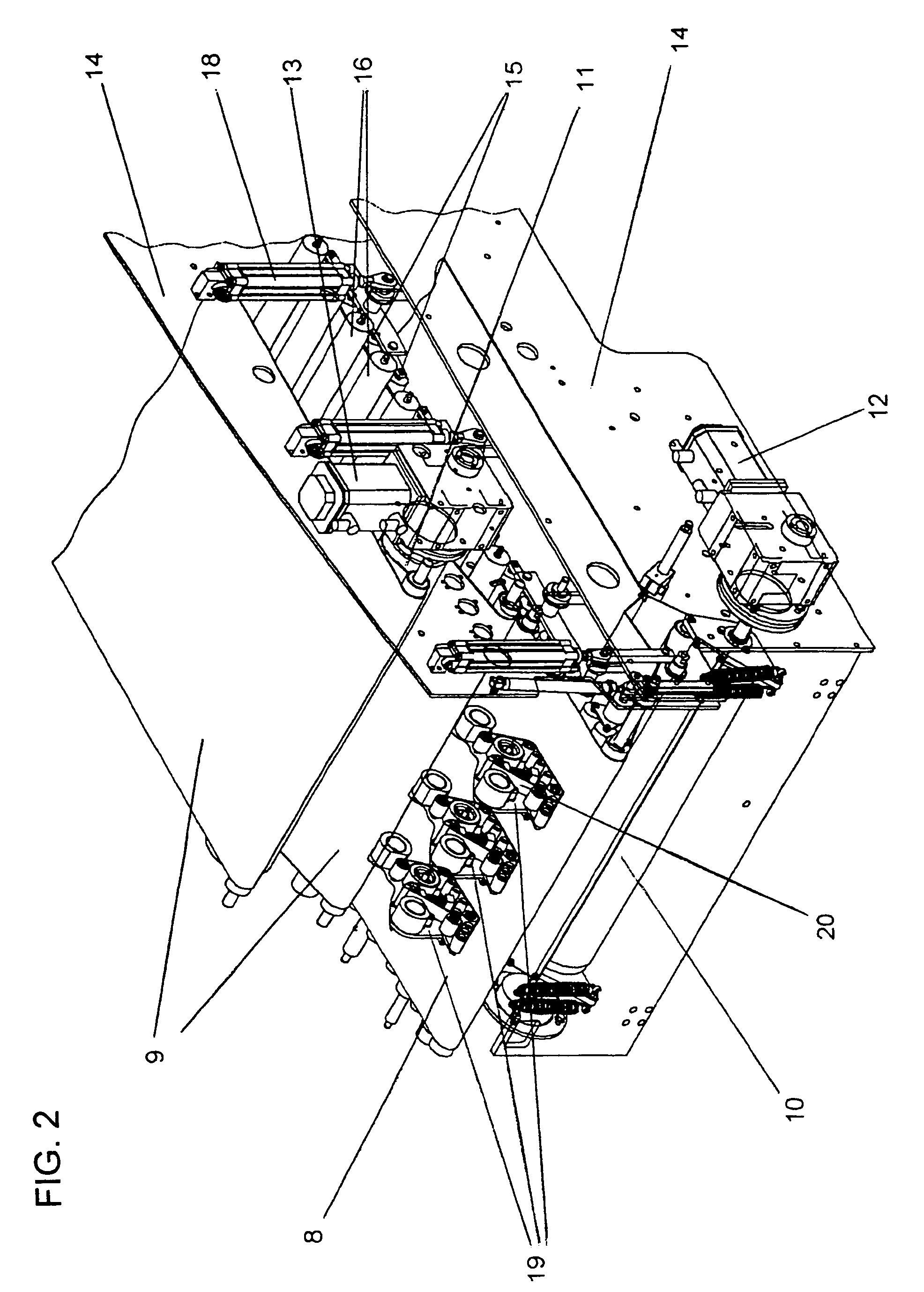

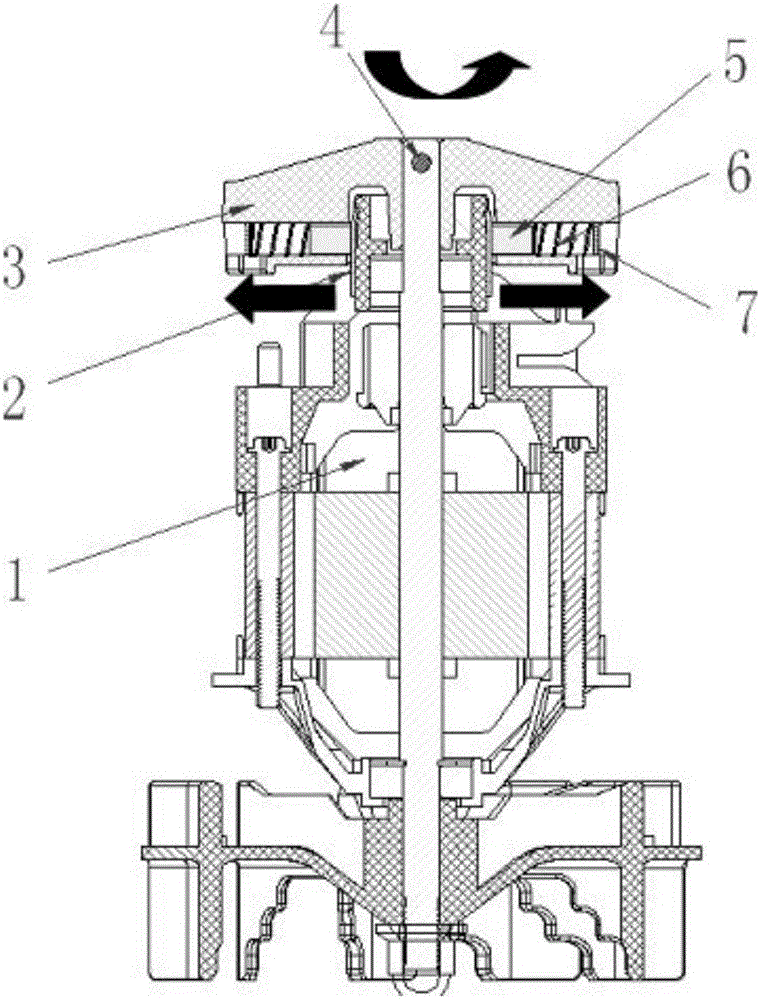

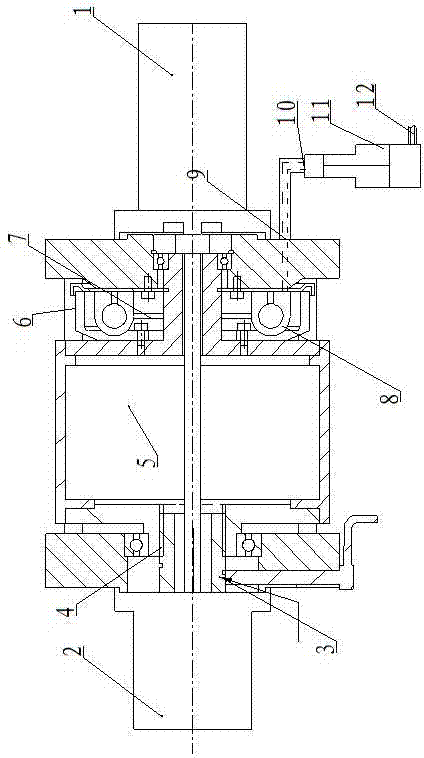

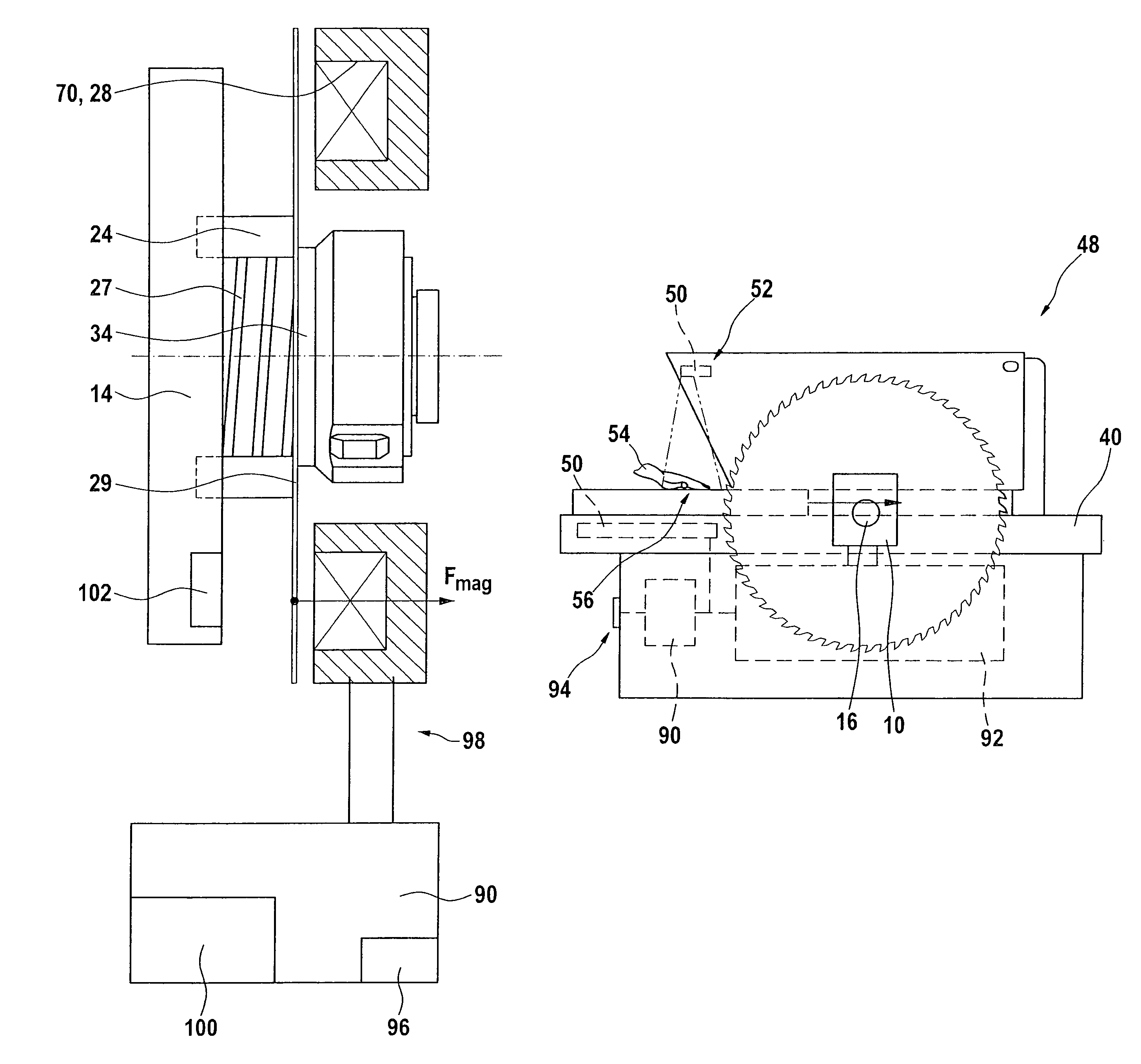

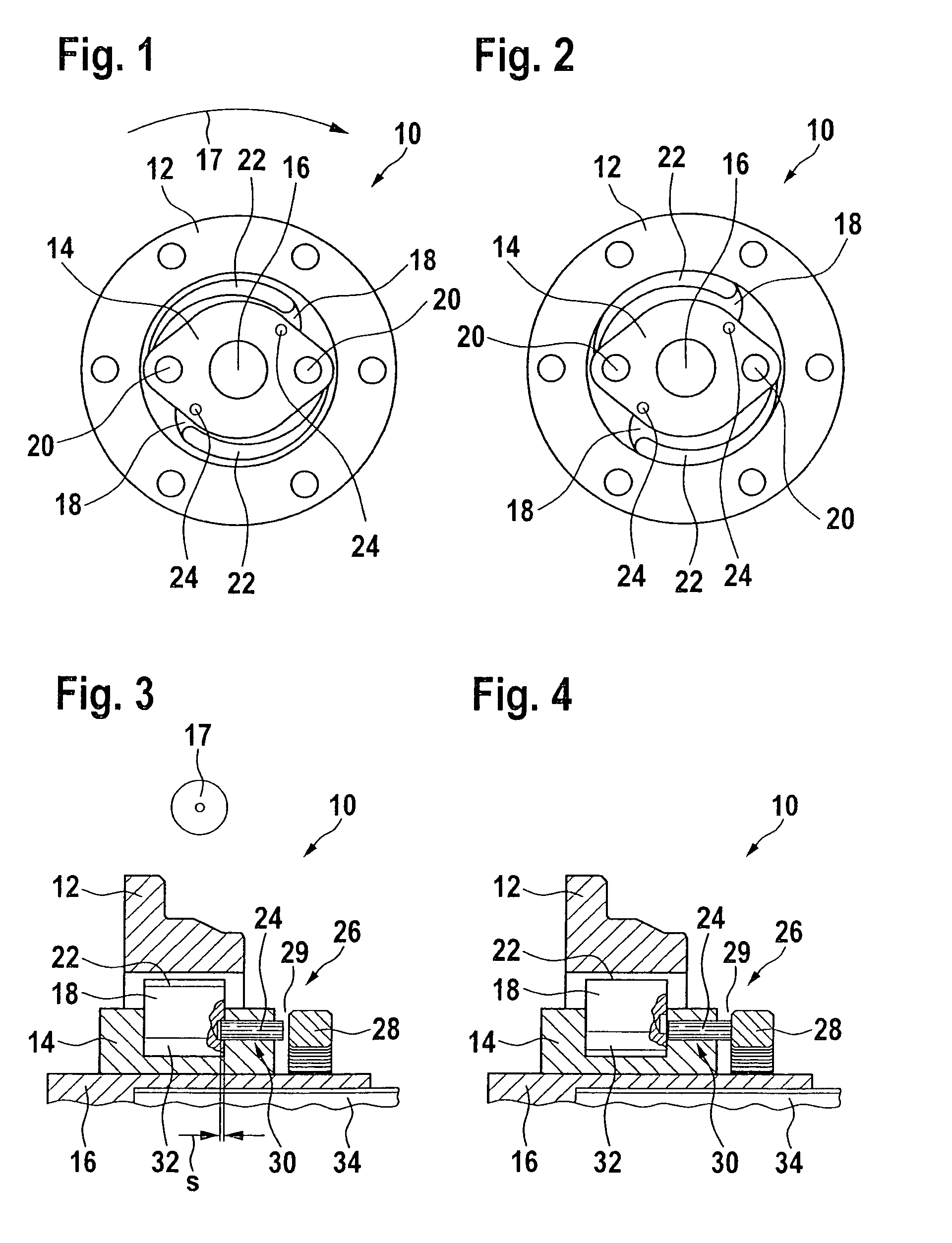

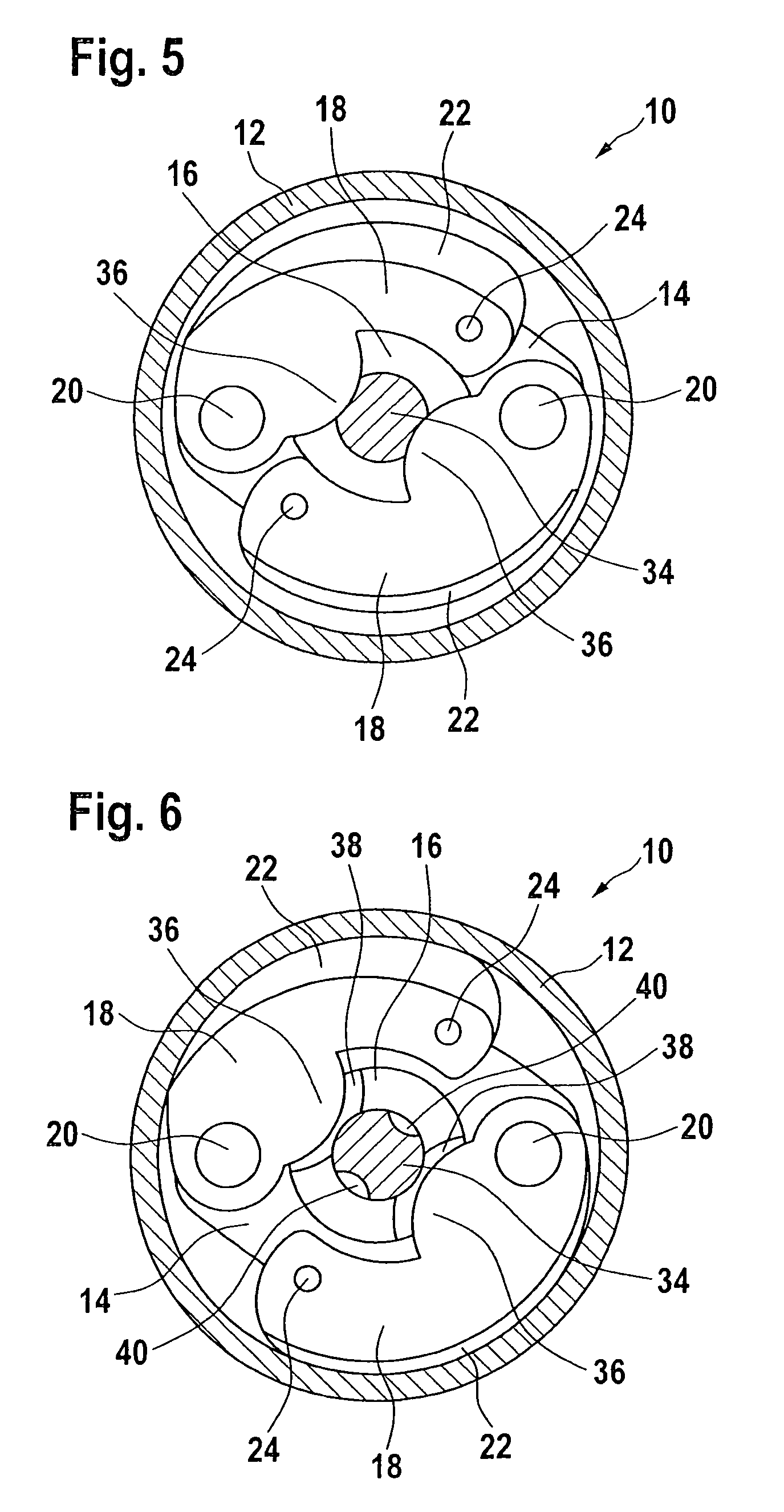

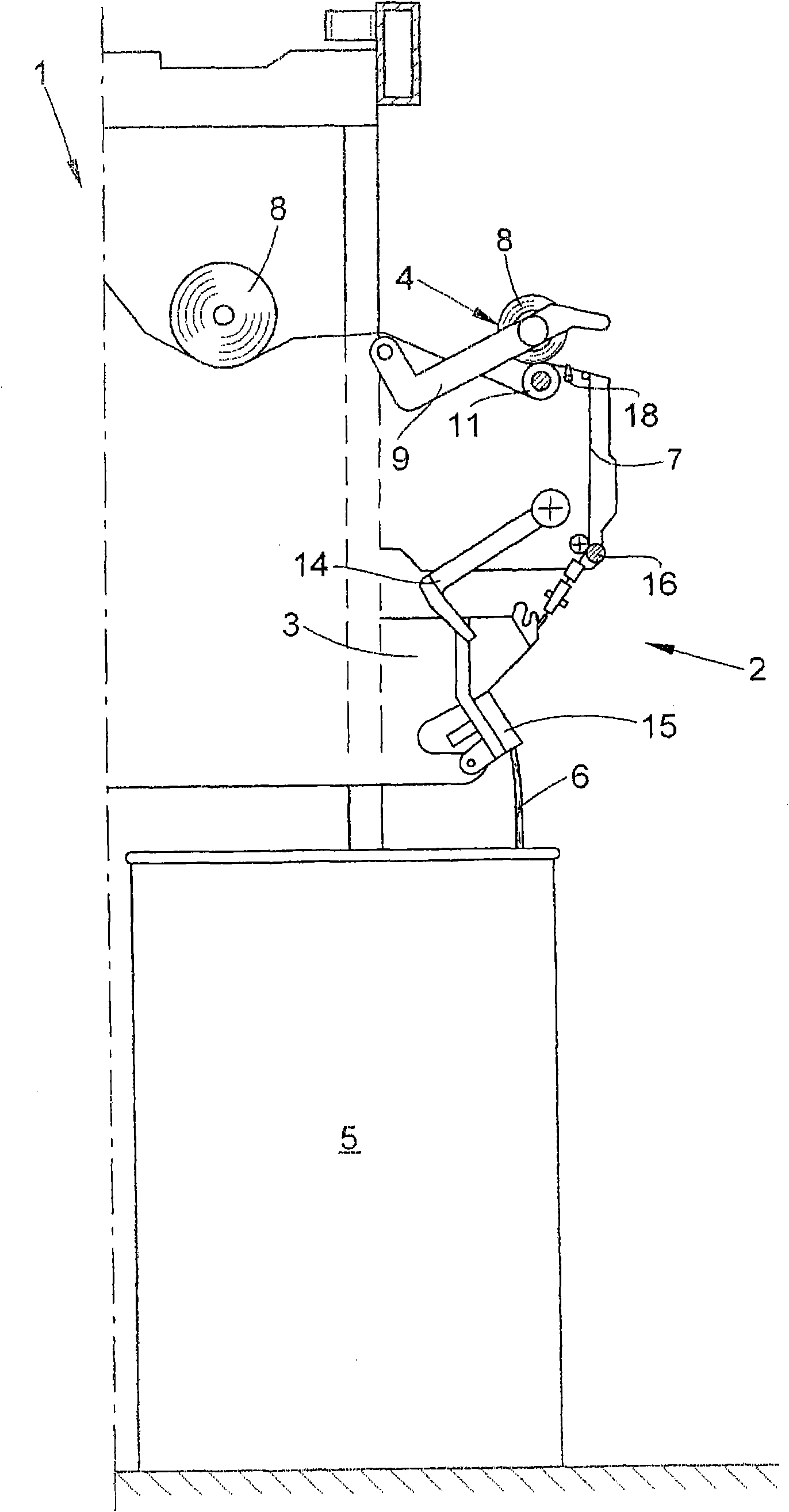

Emergency braking system for machine tools

ActiveUS20110048197A1Improve protectionShort braking timeEngineering safety devicesMeasurement/indication equipmentsCentrifugal forceBrake shoe

An emergency braking system for a machine tool for abruptly braking a revolving shaft includes at least one brake drum and at least one brake shoe which are engaged with one another in order to brake the shaft. The braking intervention between the brake drum and the brake shoe takes place under the influence of a centrifugal force resulting from the rotation of a shaft as soon as a locking device is released. Also provided in the braking system is a diagnostic system which allows the functionality of the locking device to be checked.

Owner:ROBERT BOSCH GMBH

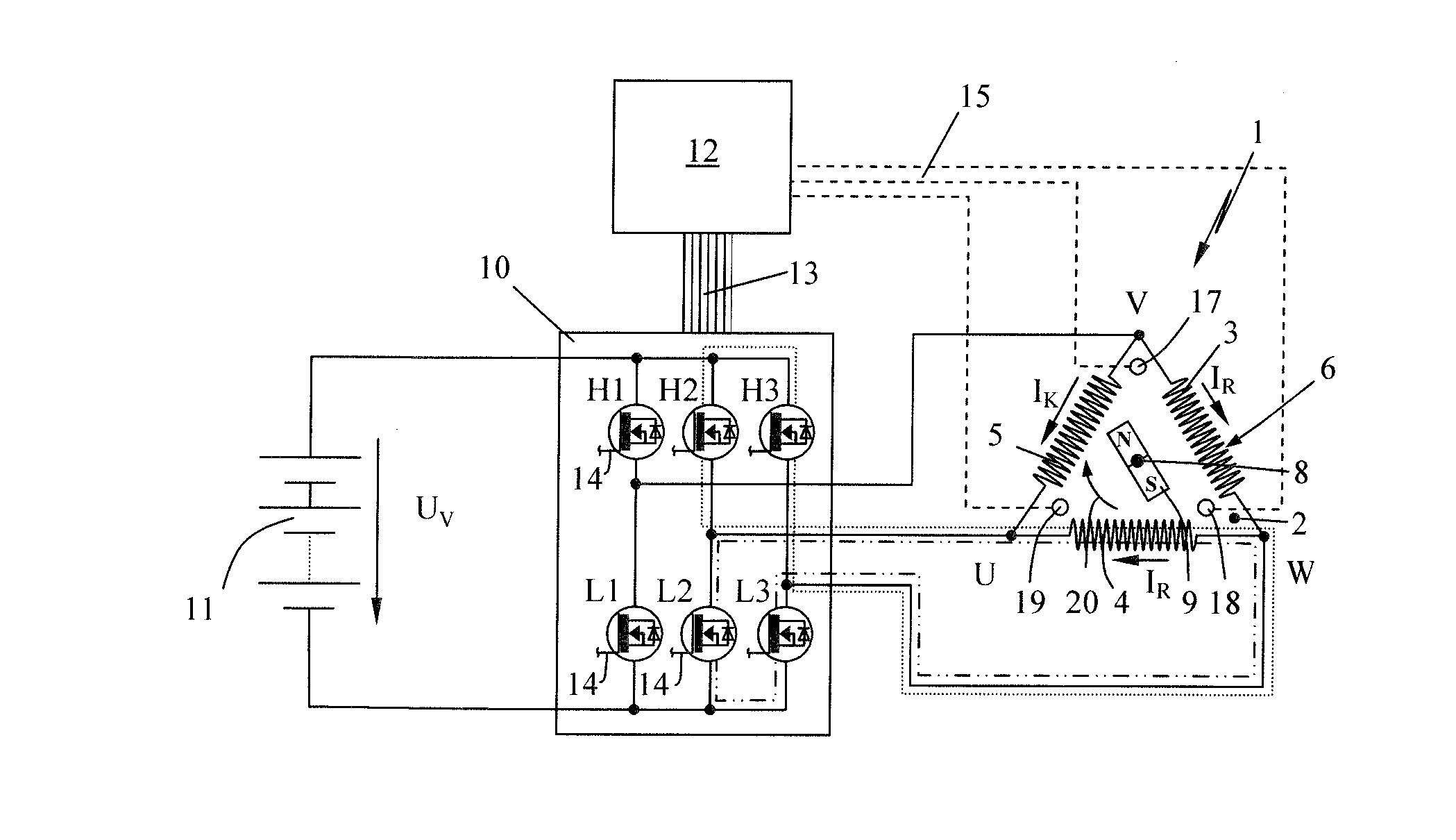

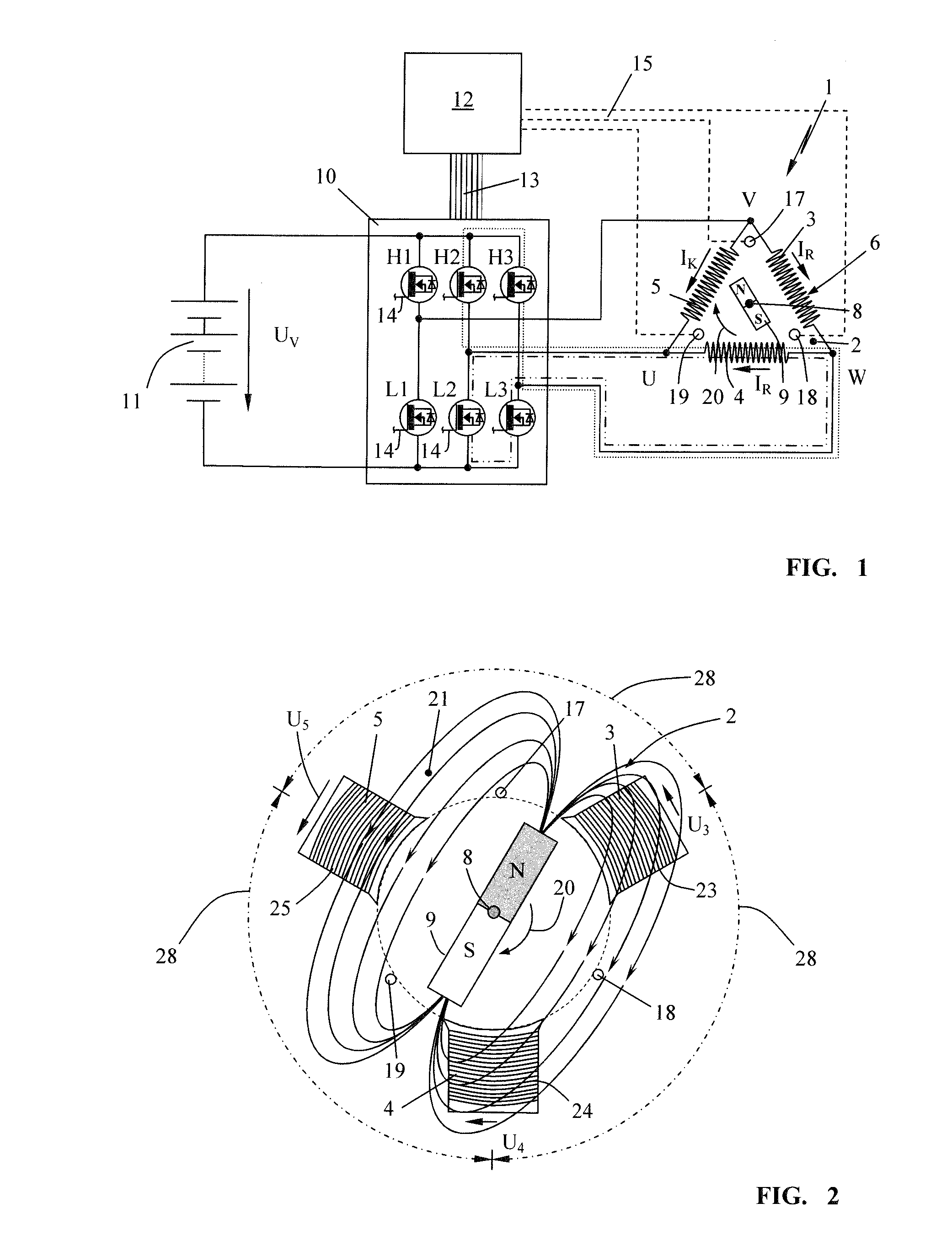

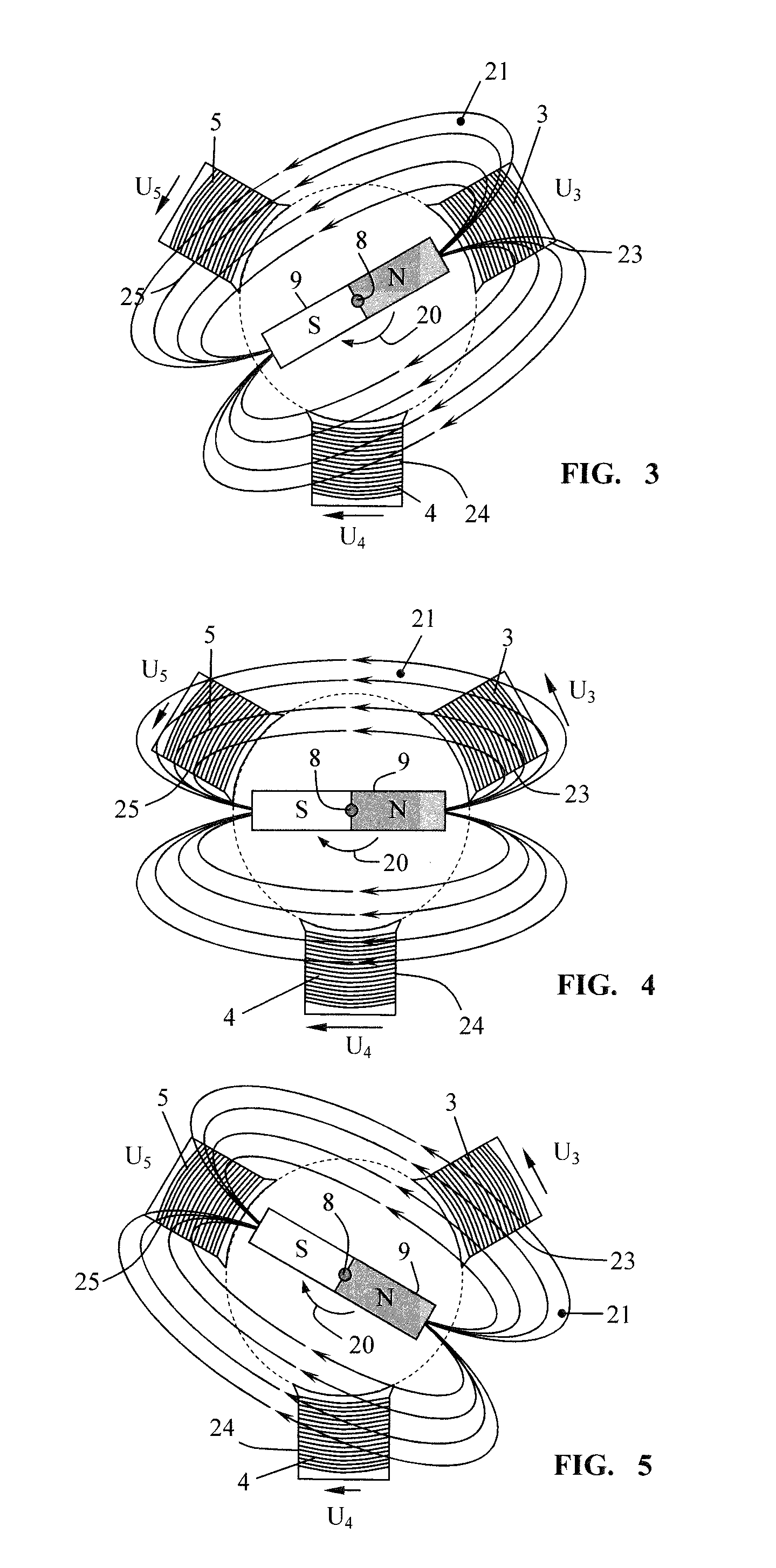

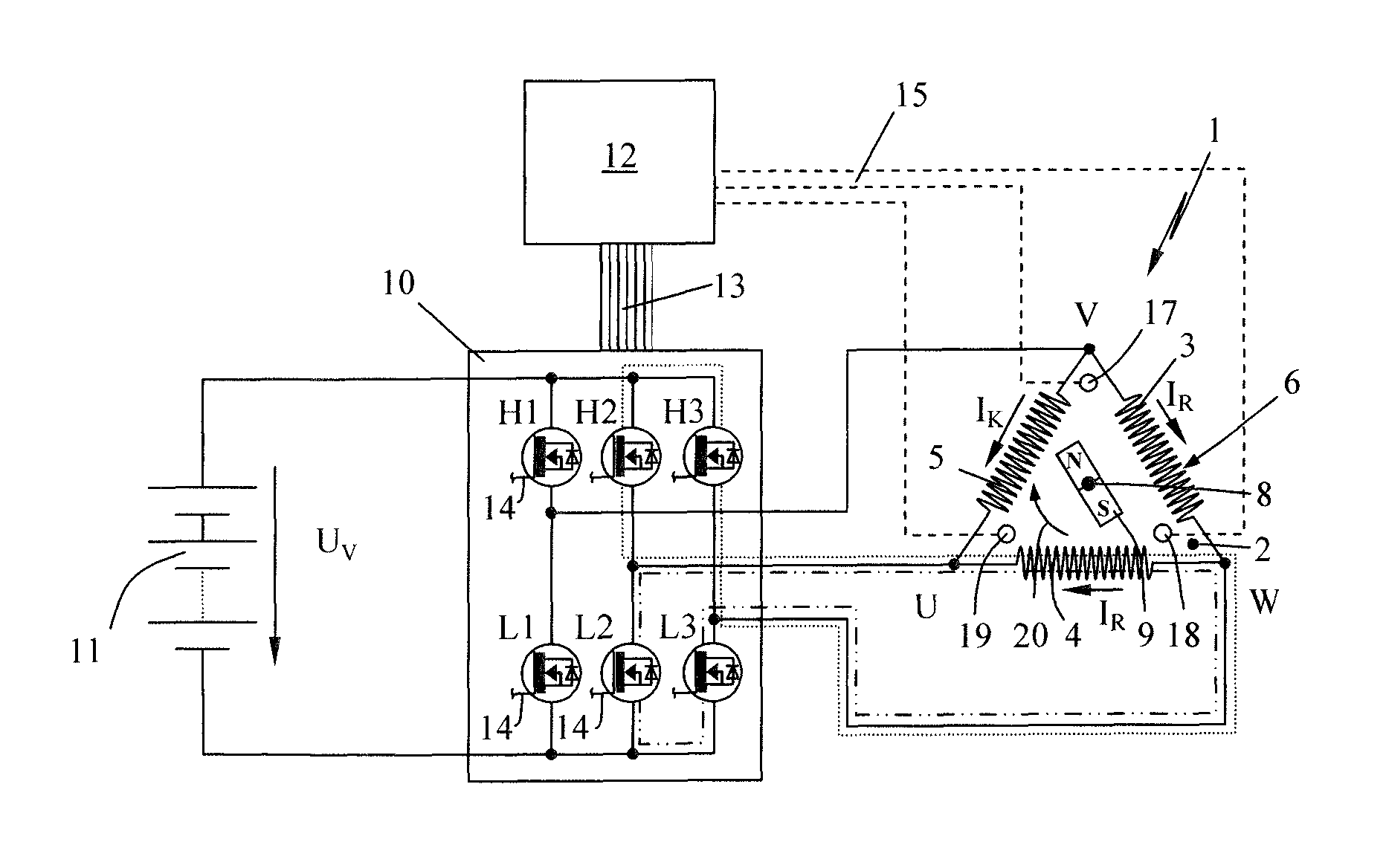

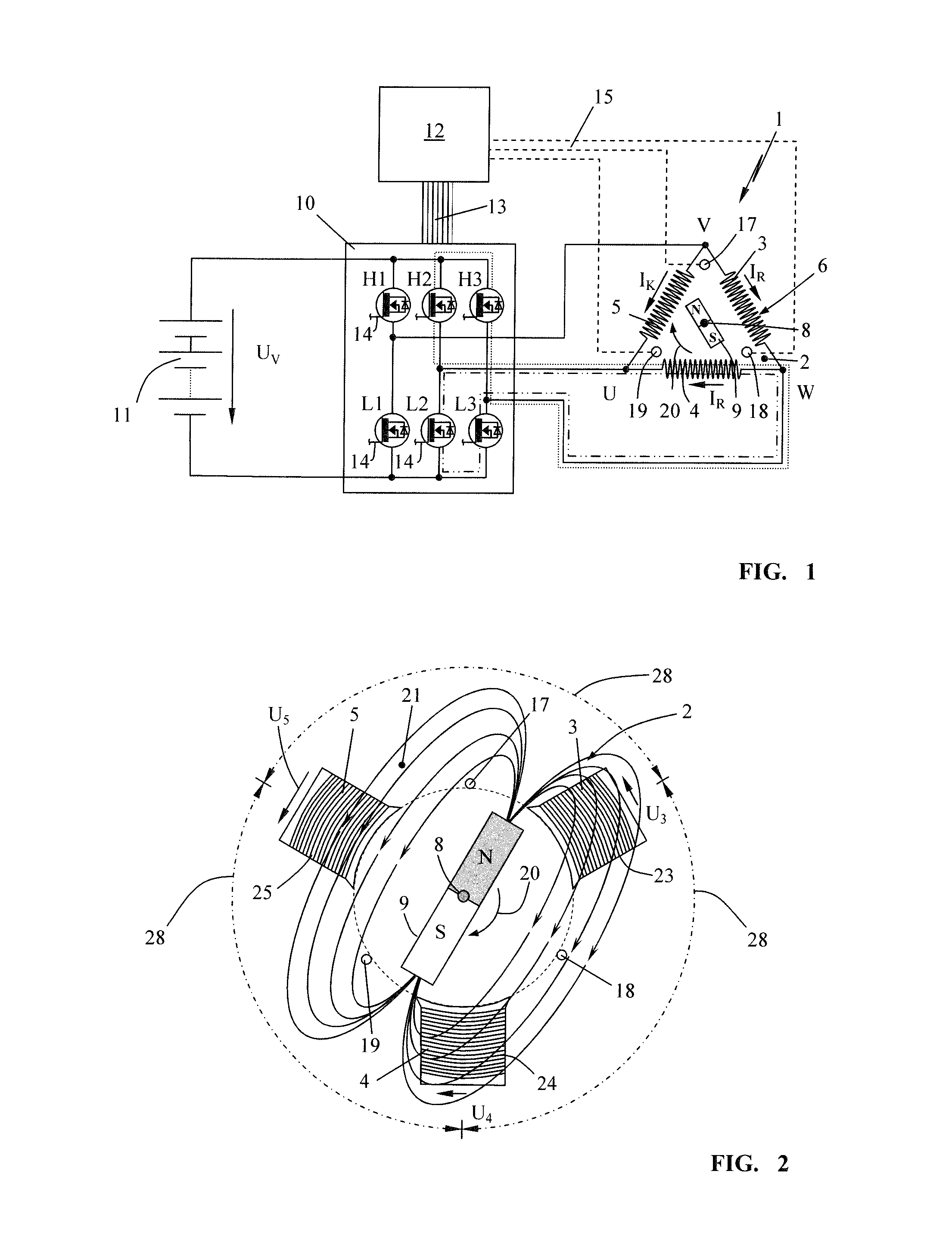

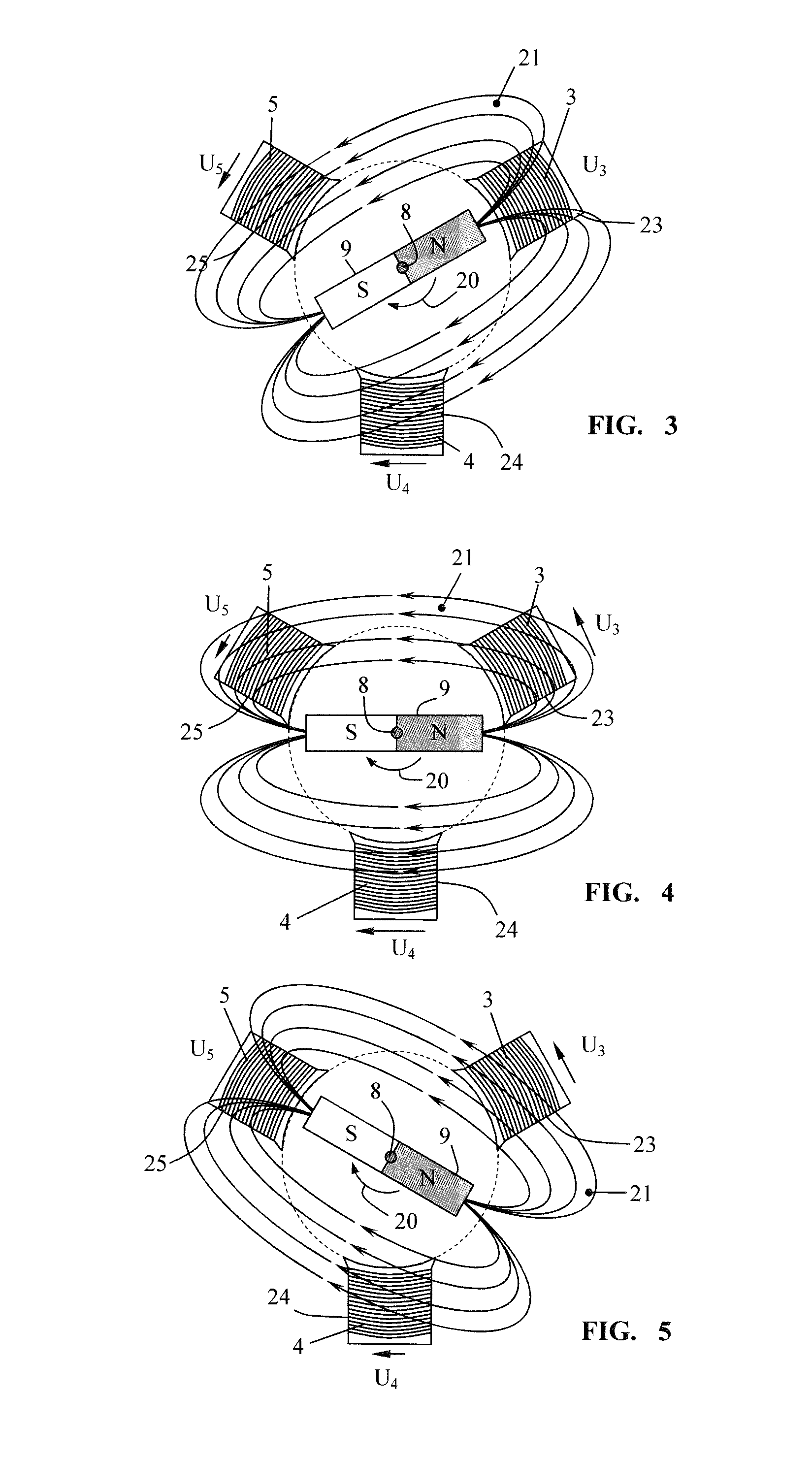

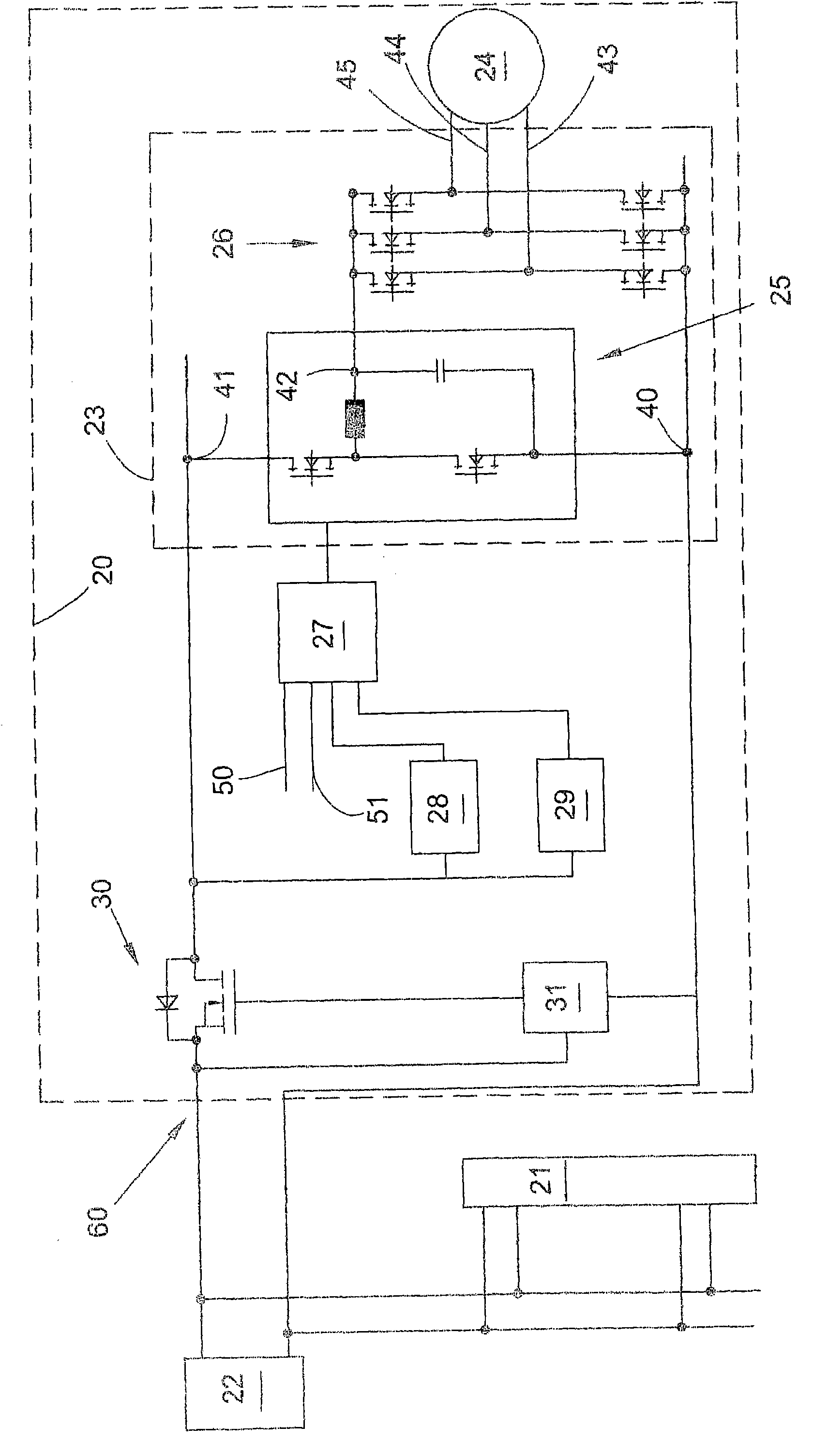

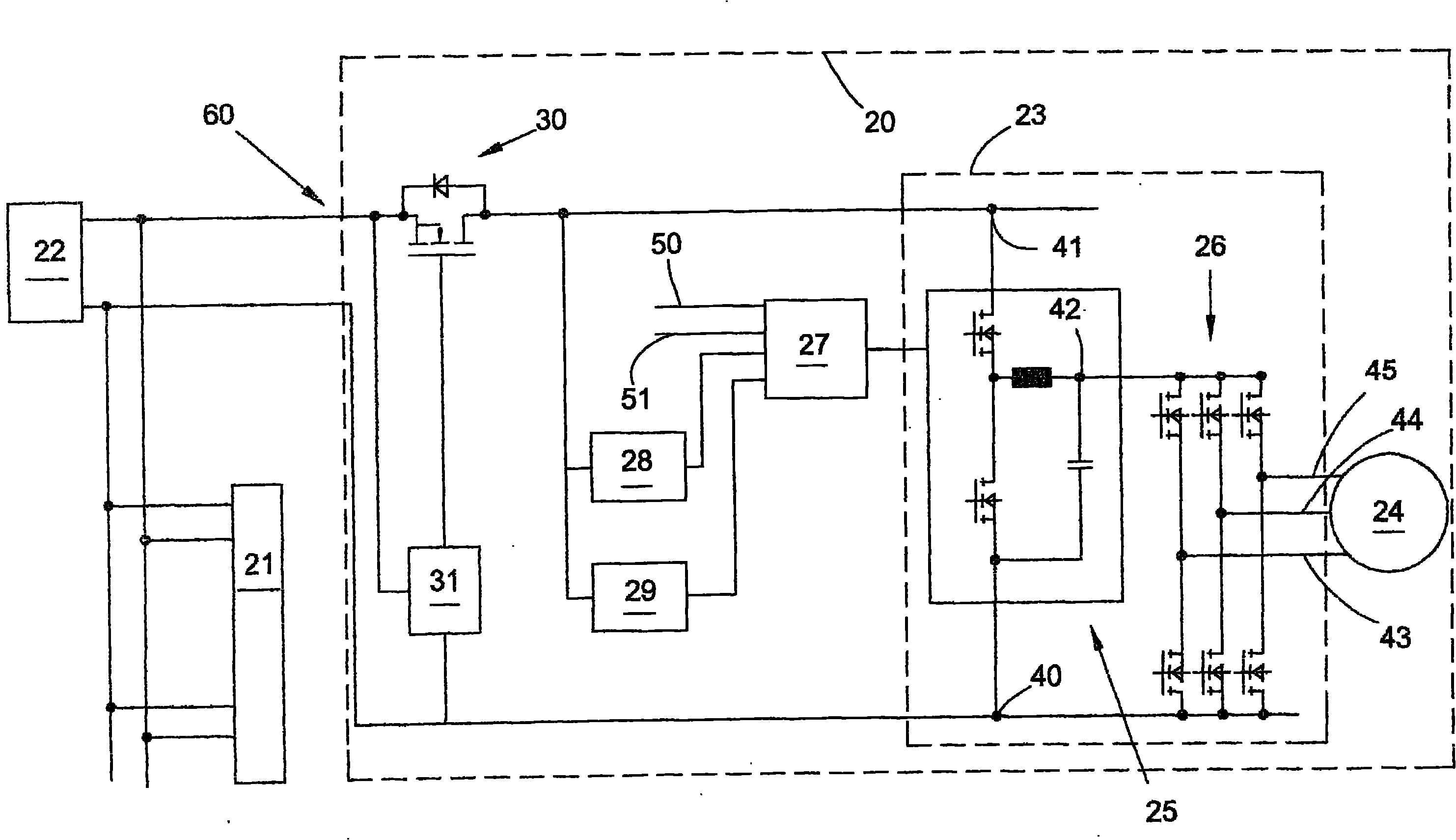

Method for braking an electric drive motor

ActiveUS20150091480A1Short braking timeSimple processDc motor stoppersDynamo-electric converter controlElectricityEngineering

The invention is directed to a method for braking an electric drive motor having a stator and a rotor. The stator has field coils which have electrical phase connections for three motor phases. To generate an electromagnetic rotating field driving the rotor, the phase connections are connected to a supply voltage via switches actuated by a control unit which closes the switches depending on the rotary position of the rotor. To brake a rotating rotor, a braking current is generated by short-circuiting the phase connections. A phase short circuit is switched in between each two phase connections of the field coils with a preset temporal sequence to brake the rotor. The phase connections short-circuited are each selected corresponding to the rotary position of the rotor so that that field coil is short circuited in which the voltage induced by the magnetic field of the rotating rotor passes through its maximum.

Owner:ANDREAS STIHL AG & CO KG

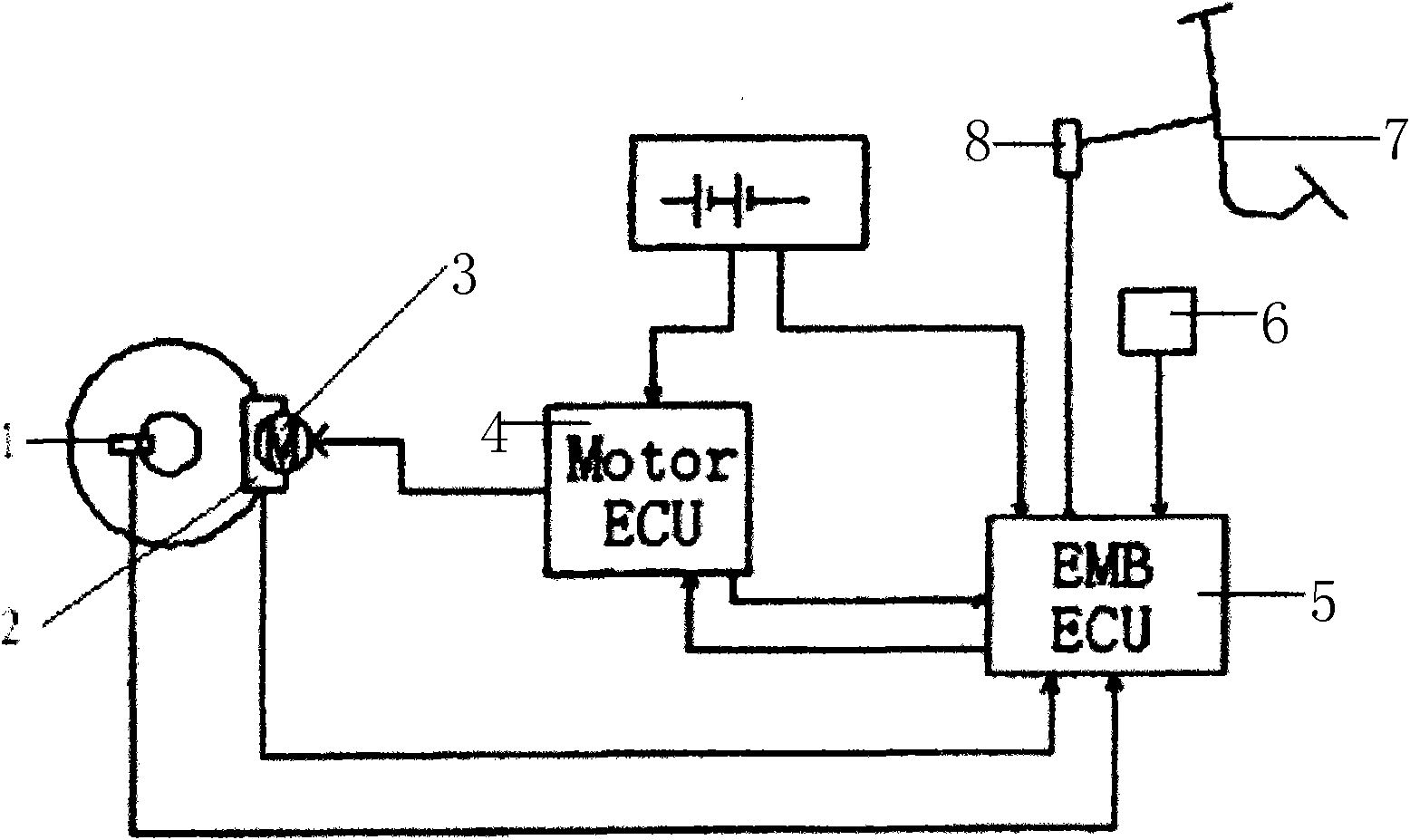

Control method and device based on an automobile line control brake system

InactiveCN101549684ABest braking forceEasy to implement integrated managementBraking action transmissionElectricityControl signal

Control method and device based on an automobile line control brake system, with features of simple structure, short brake reaction time and high reliability. The control method based on an automobile line control brake system is characterized in that: an electric brake main control unit receives the brake state signals and sends the control signals to a brake control unit based on the brake state signals and the brake control unit obtains the required brake force of each vehicle wheel based on the signals sent from the electric brake main control unit and the command is sent to make the motor in the electric brake operate.

Owner:CHERY AUTOMOBILE CO LTD

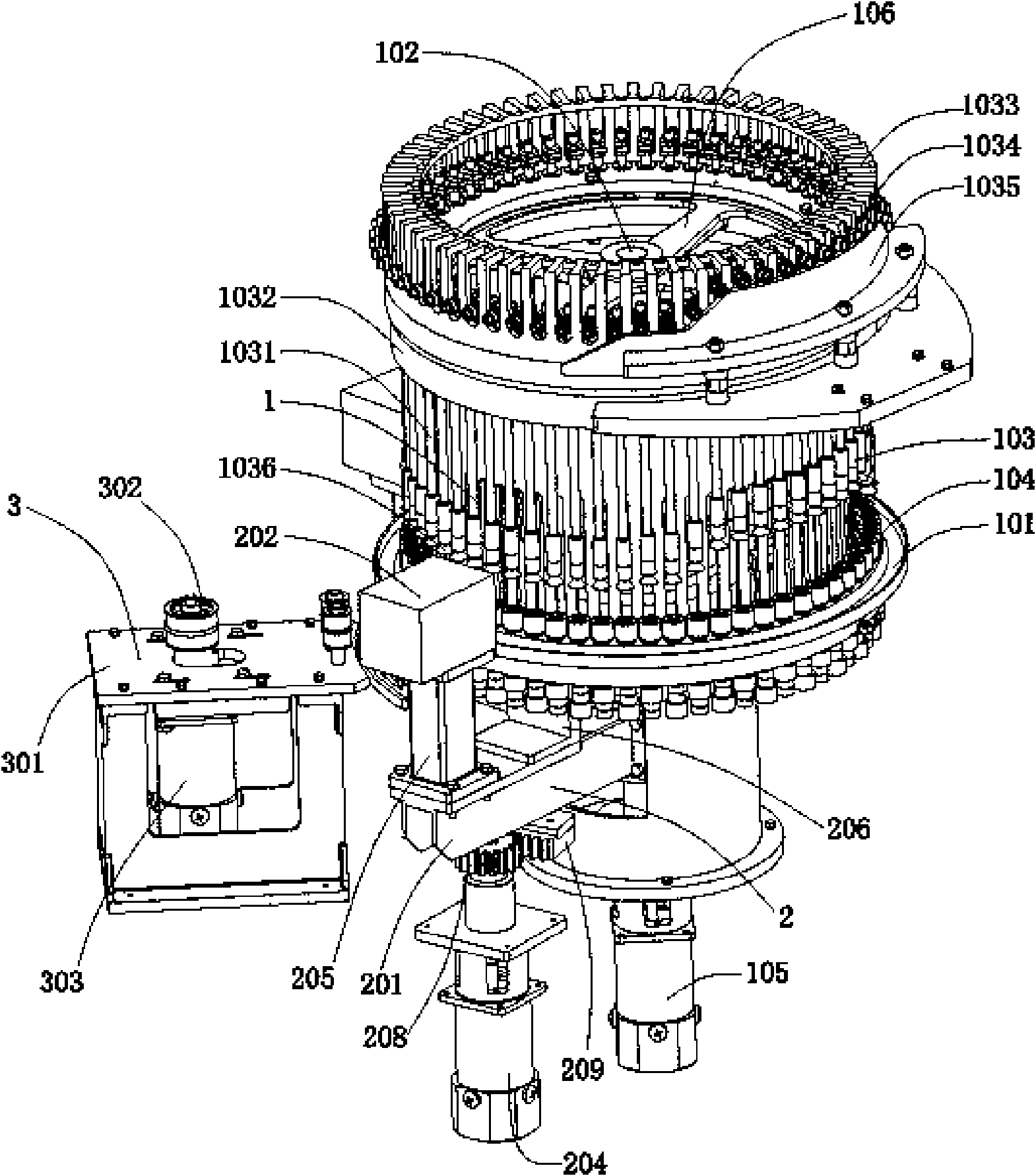

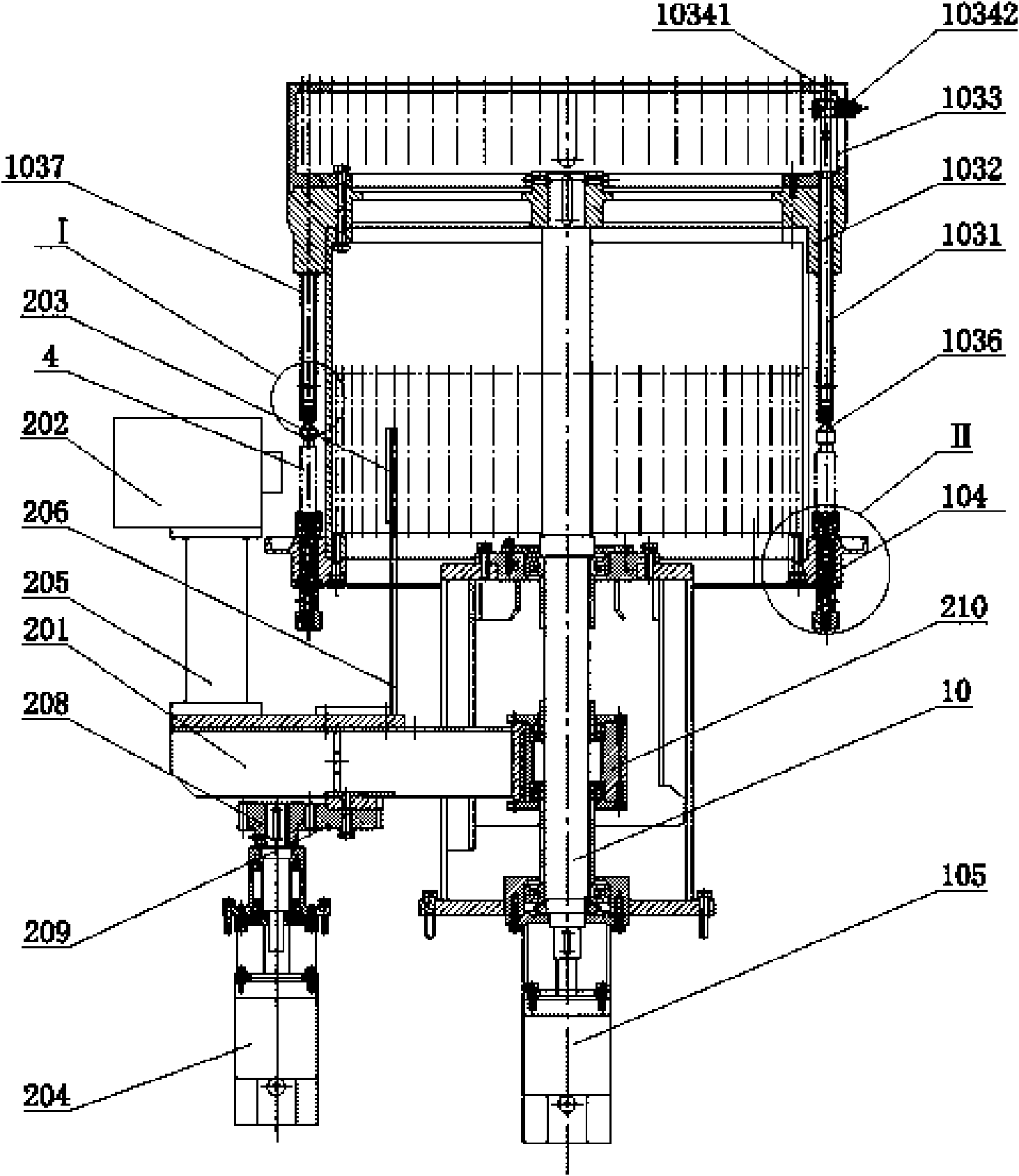

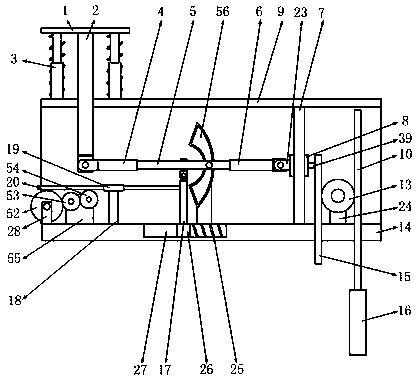

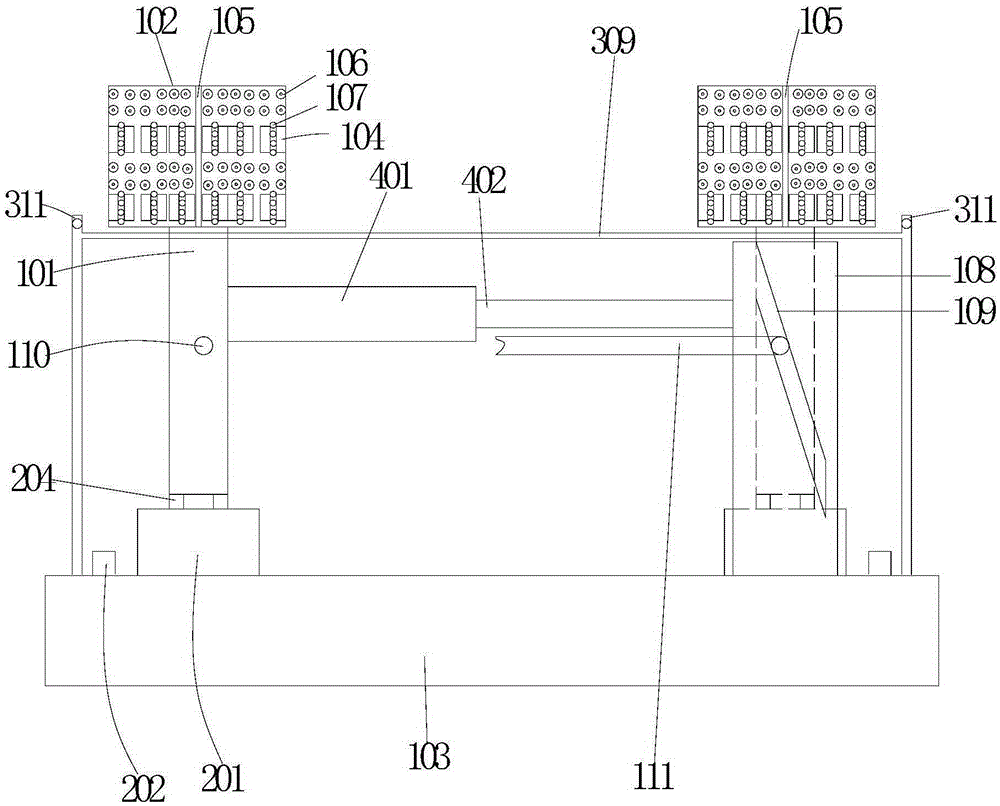

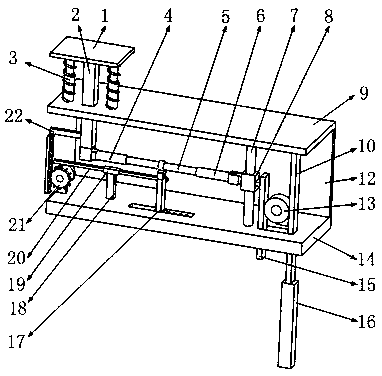

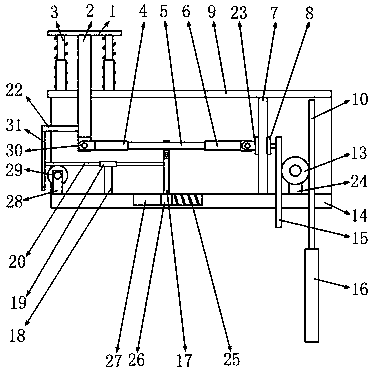

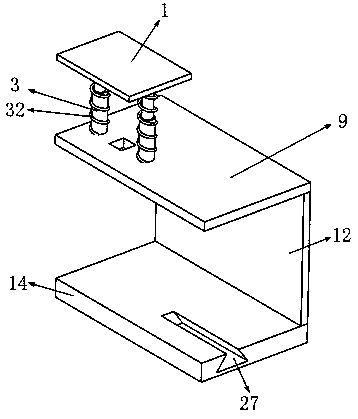

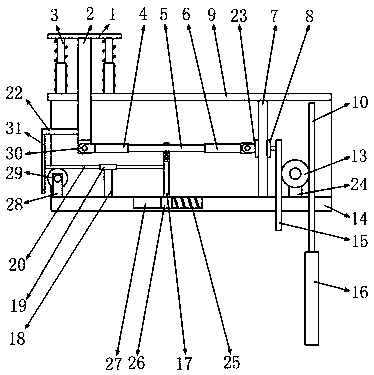

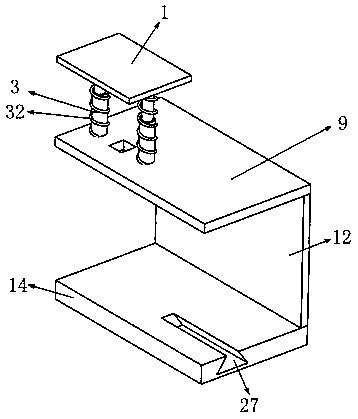

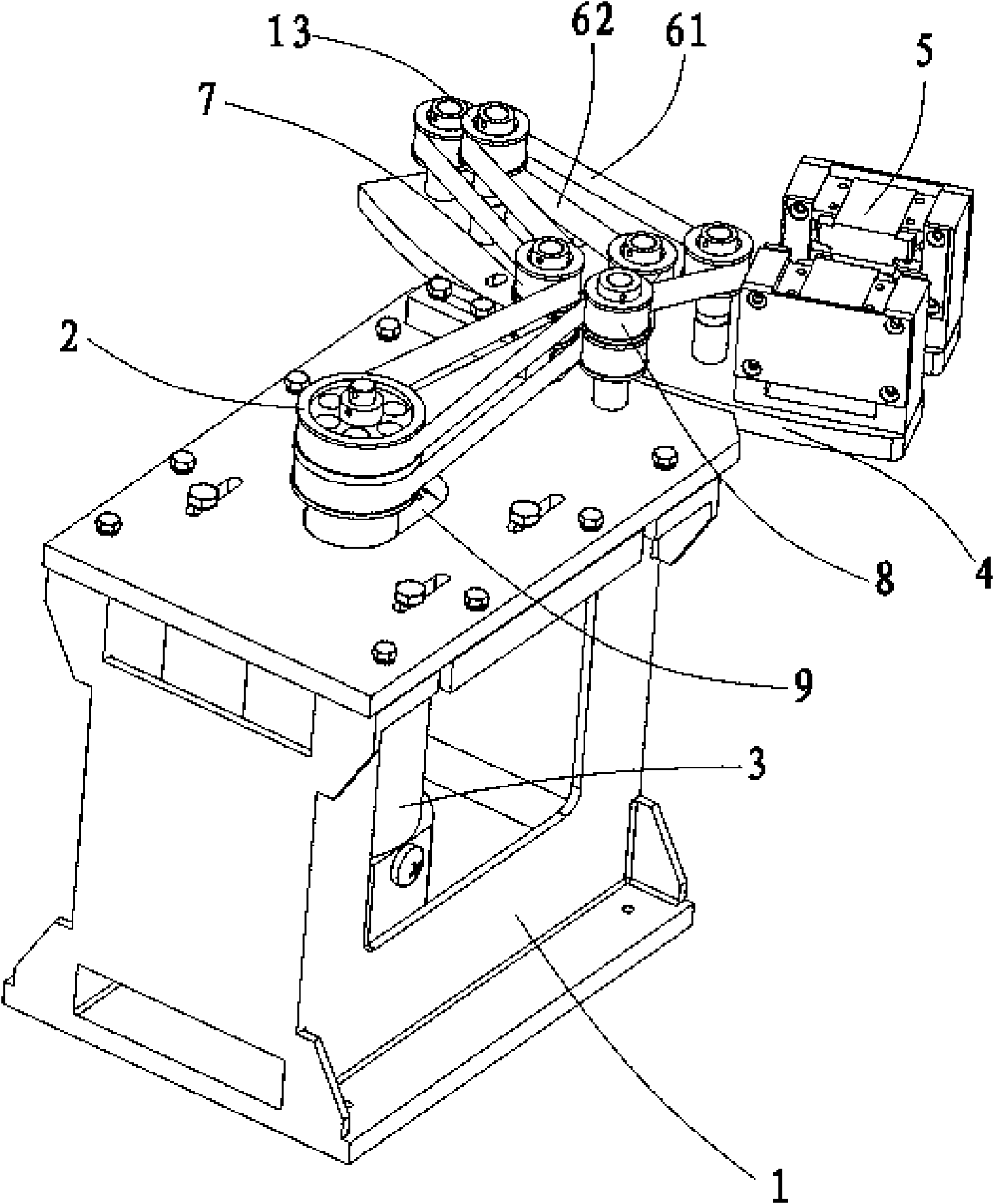

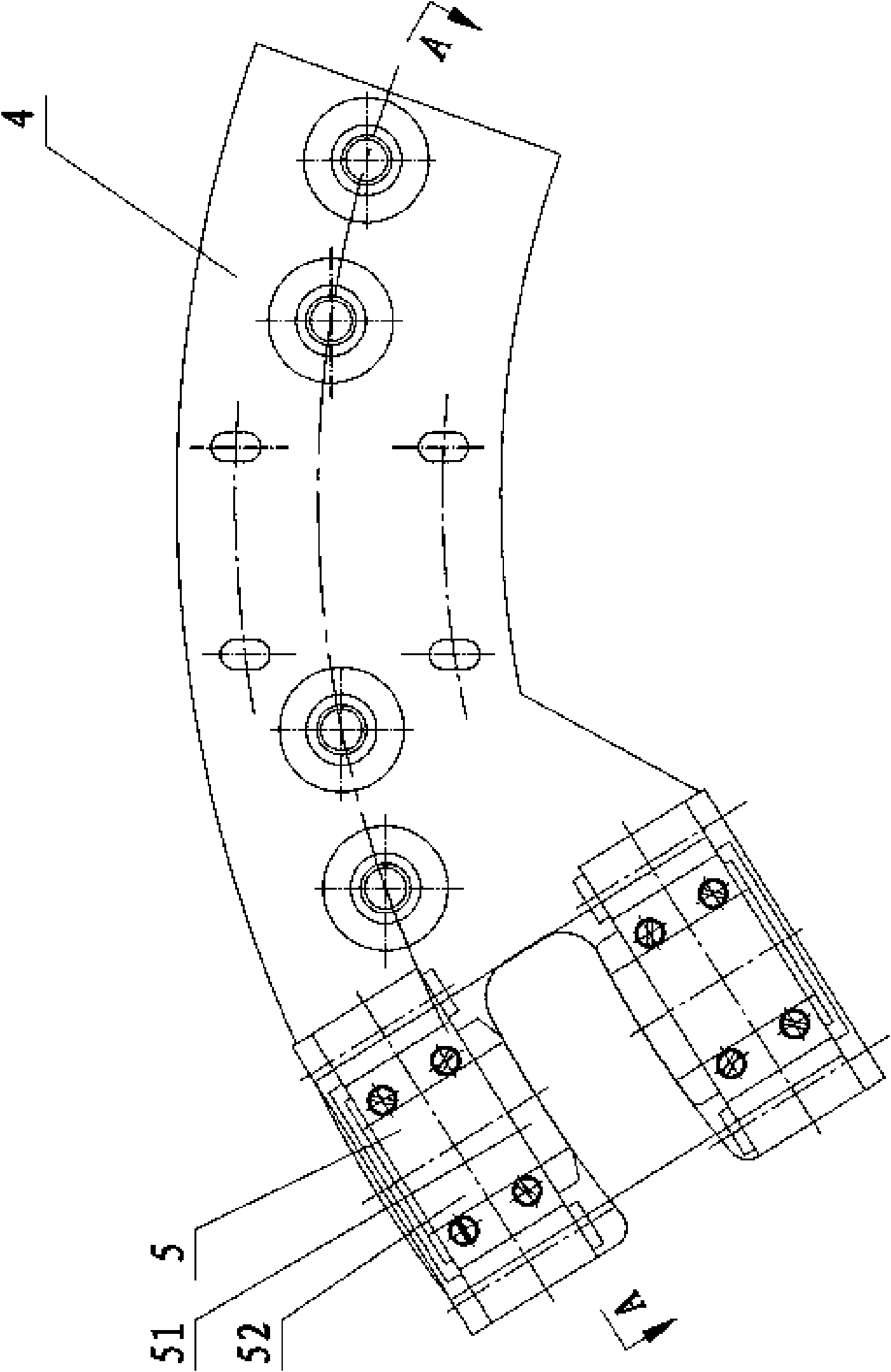

Foreign matter inspection device for automatic light inspection machine

ActiveCN101644663AImprove light inspection efficiencyImprove the accuracy of light inspectionOptically investigating flaws/contaminationForeign matterEngineering

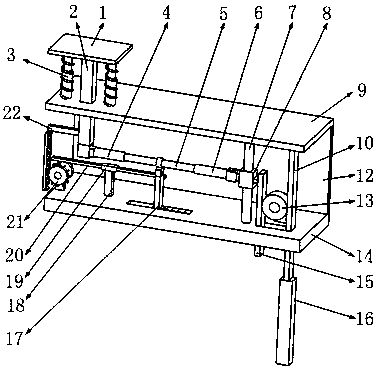

The invention discloses a foreign matter inspection device for an automatic light inspection machine. The foreign matter inspection device comprises a light inspection disk assembly, more than one setof image acquisition assemblies and an autorotation driving assembly, wherein each image acquisition assembly comprises a rotating arm, a camera, a light source and a rotating arm driving mechanism,the camera and the light source are fixed on the rotating arm, and the rotating arm is connected with the rotating arm driving mechanism by a transmission mechanism. The invention is the foreign matter inspection device for the automatic light inspection machine, having the advantages of simple and compact structure, low cost, and high inspection accuracy, stability and inspection efficiency.

Owner:TRUKING TECH LTD

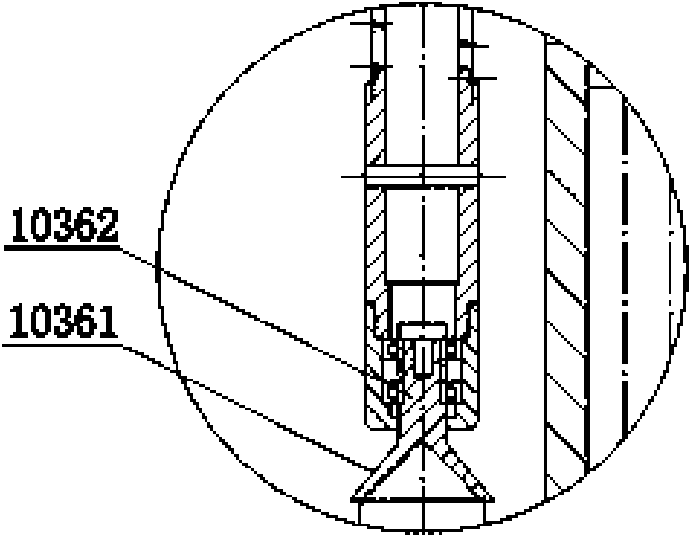

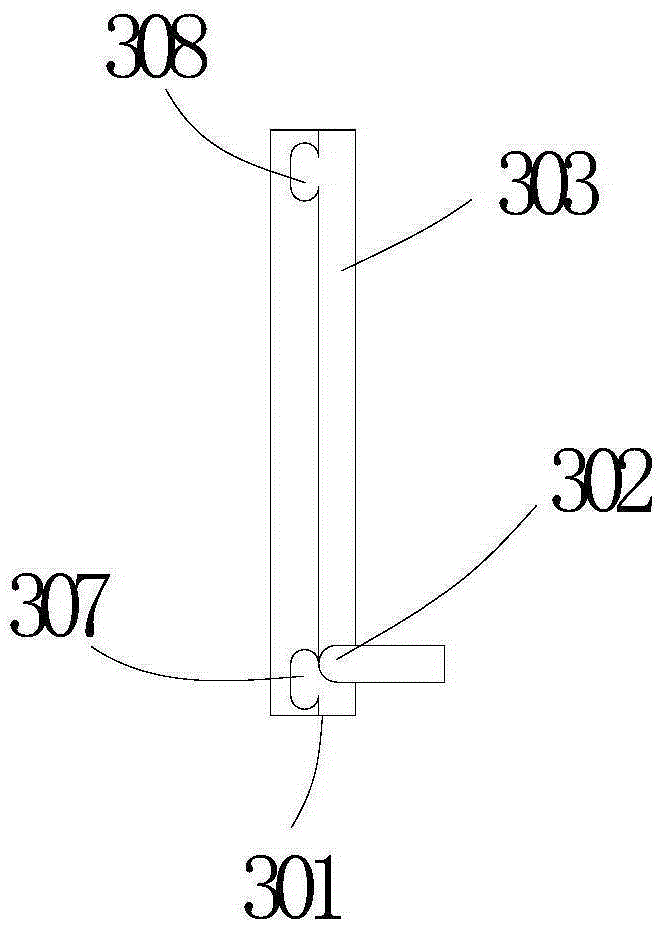

Fall prevention brake device of inclined shaft transportation car

InactiveCN103434533AEffectively holdShort braking timeBufferTrack-braking member co-operationAutomatic brakingFall prevention

The invention relates to a fall prevention brake device of an inclined shaft transportation car. The fall prevention brake device comprises a main pull rod, colliding iron, a clamping jaw, a support block, a holding jaw, a brake spring, a guide rod, baffle plate channel steel and a starting spring, wherein the colliding iron is installed on the main pull rod to divide the main pull rod into a front pull rod and a rear rod, and one end of the rear pull rod penetrates through the baffle plate channel steel and the starting spring to be connected with a retaining nut; the clamping jaw is connected with the support block, and the support block is hinged with the guide rod; the brake spring is installed on the guide rod, and the holding jaw is connected with the support block; the front pull rod of the main pull rod is connected with a car main-rope connecting device, is arranged at the center of a chassis of the transportation car, and bears the traction load of the whole car. The brake device adopts double braking modes of automatic braking and manual braking and solves the problem that the transportation car falls when traction is lost after hoisting equipment breaks down or a steel wire rope is broken. Meanwhile, a damping device is installed on the car to ensure that the transportation car overcomes the action of inertia force during braking and can steadily brake.

Owner:SINOHYDRO BUREAU 14 CO LTD +1

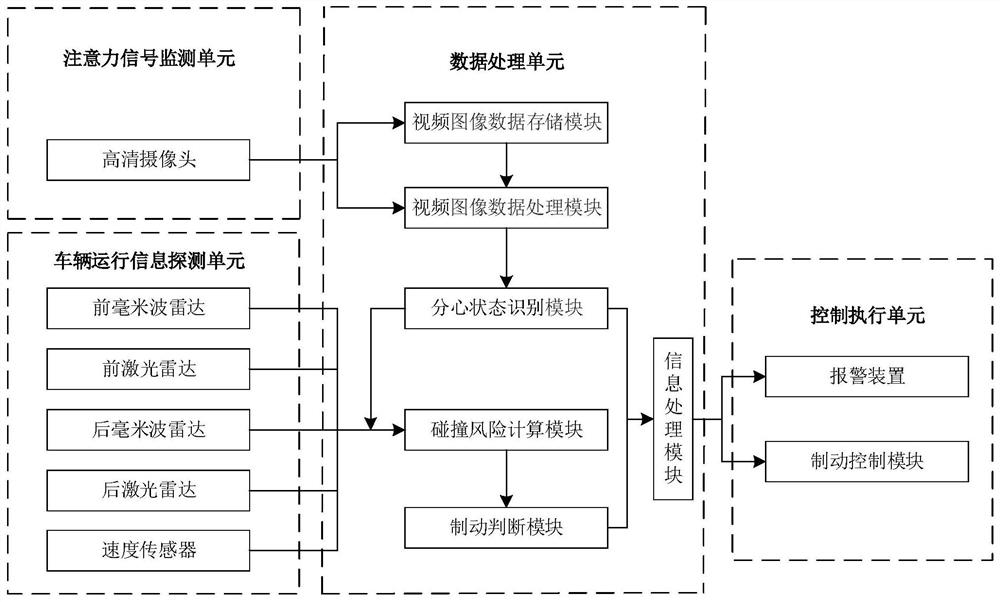

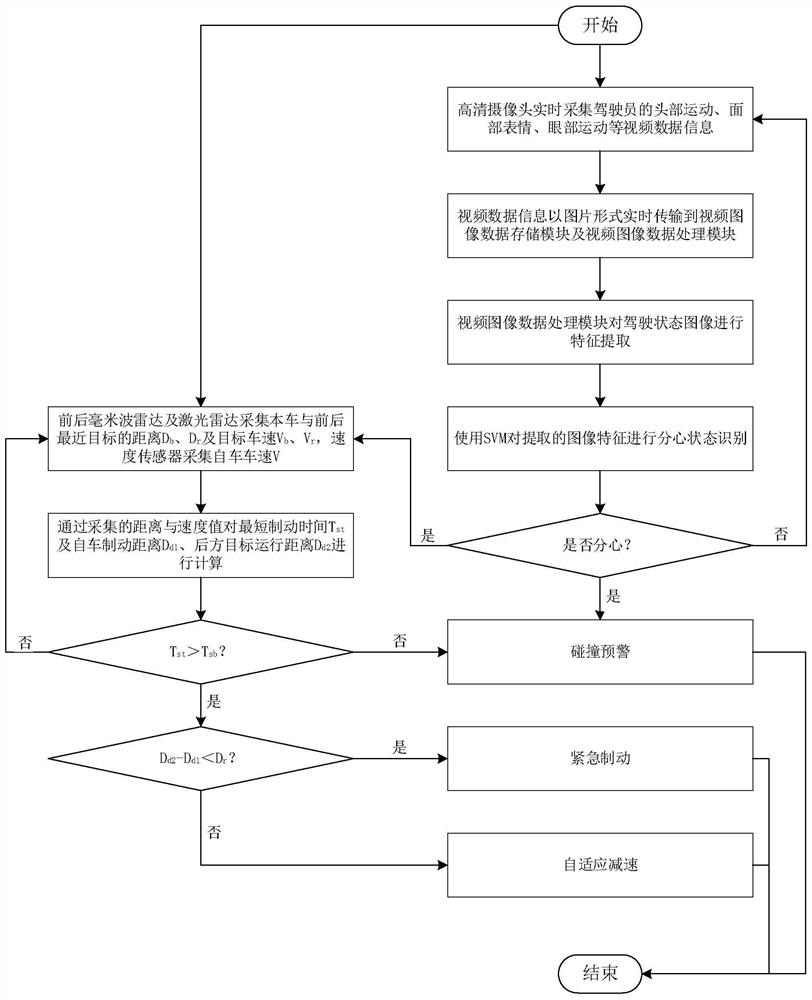

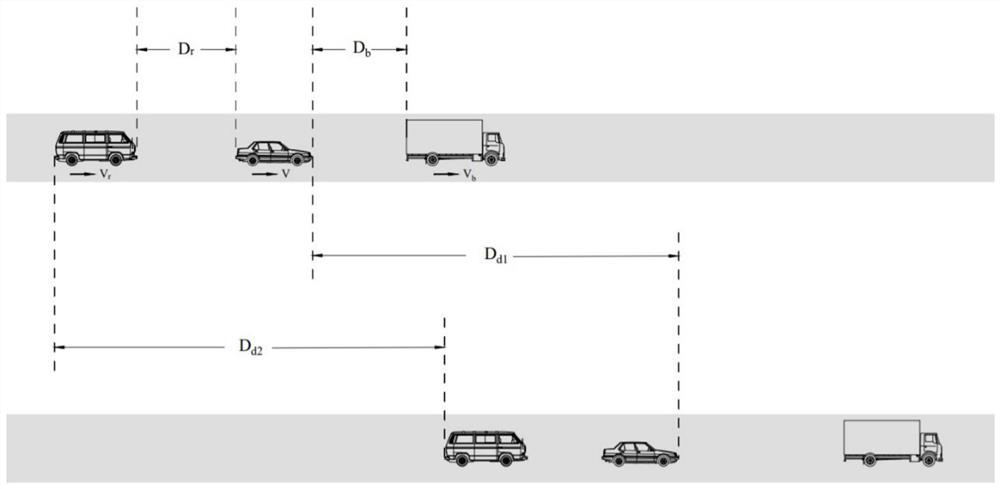

Distraction monitoring triggering type vehicle collision early warning system and control method

PendingCN111845736AShort braking timeReduced risk of collisionCharacter and pattern recognitionControl devicesVideo monitoringDriver/operator

The invention discloses a distraction monitoring triggering type vehicle collision early warning system and a control method. The distraction monitoring triggering type vehicle collision early warningsystem comprises a vehicle operation information detection unit, a data processing unit, a control execution unit and an attention signal monitoring unit. The attention signal monitoring unit and thevehicle operation information detection unit transmit measured data to the data processing unit, the data processing unit sends an instruction to the control execution unit, and the control executionunit executes alarming and braking. The attention signal monitoring unit carries out real-time video monitoring on the body of a driver and transmits information to the data processing unit. According to the invention, the driving state is monitored in real time; active early warning is carried out on driving safety in advance, negative effects caused by misjudgment of a driving assistance function can be avoided, collision risk calculation and secondary early warning or emergency braking are carried out by collecting vehicle operation data, the accuracy of collision early warning can be further improved, driving safety is guaranteed, and the traffic accident rate is reduced.

Owner:JIANGSU UNIV

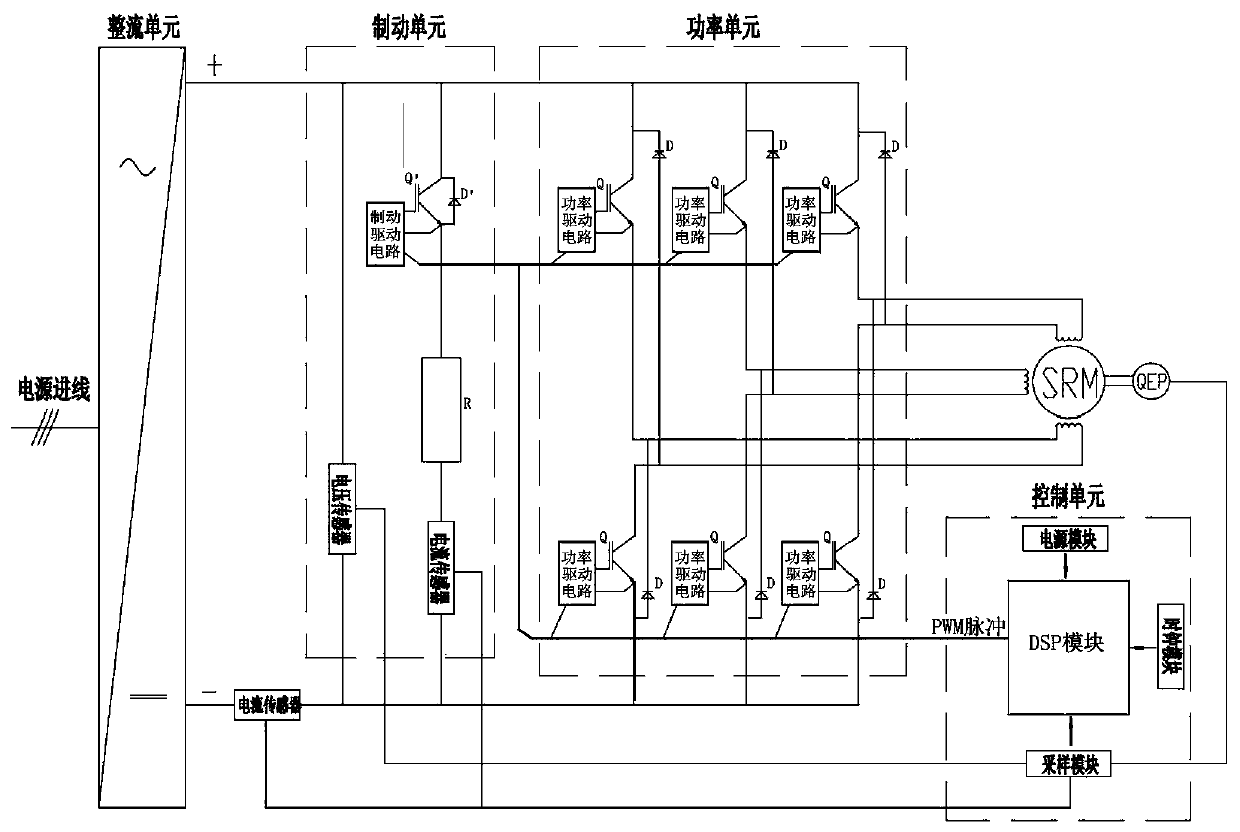

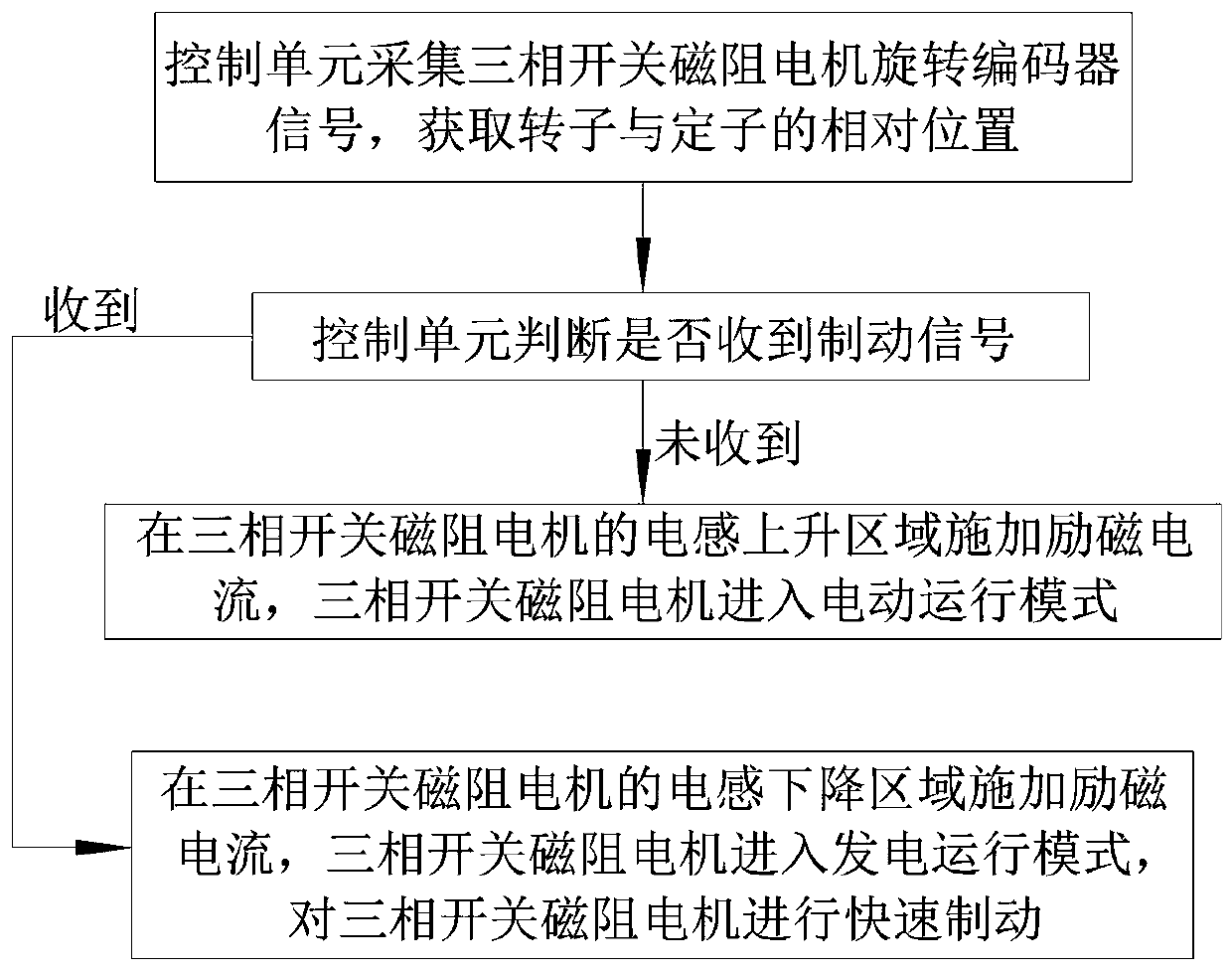

Rapid braking control system and control method for three-phase switched reluctance motor

PendingCN110829906AShort braking timeFrequent and repeated brakingAC motor controlStopping arrangementsLoop controlControl system

The invention discloses a rapid braking control system and method for a three-phase switched reluctance motor. The system comprises a rectification unit, a power conversion unit, a control unit and abrake unit. The brake unit composed of a brake IGBT module and a brake resistor is adopted, and a braking current closed loop is realized in a braking process. Rapid braking and frequent braking of the switched reluctance motor are realized. In the braking process, closed-loop control over the rotating speed and the current is achieved, and rotating speed and current signals are synchronously received. The relation among the braking time, the braking current and the shafting rotating speed is synchronously adjusted through a DSP module. Rapid braking is achieved, and at the same time shaftingrotating can be stopped within a designated braking time. The precision is high. The reliability is high. The flexibility is high.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD +1

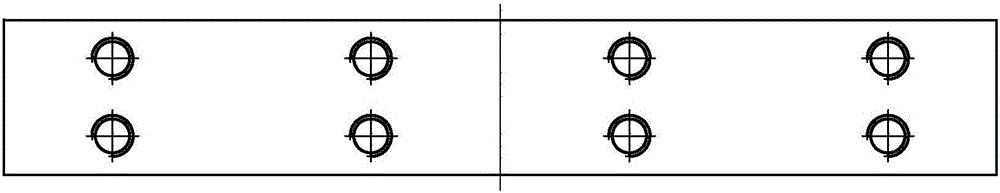

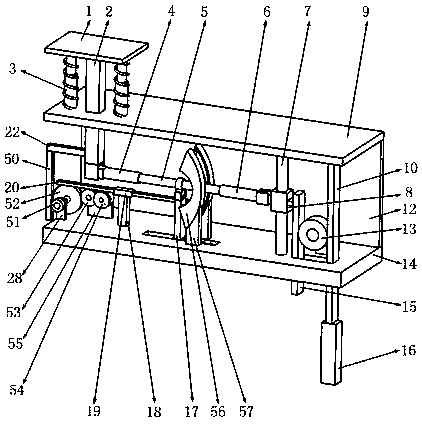

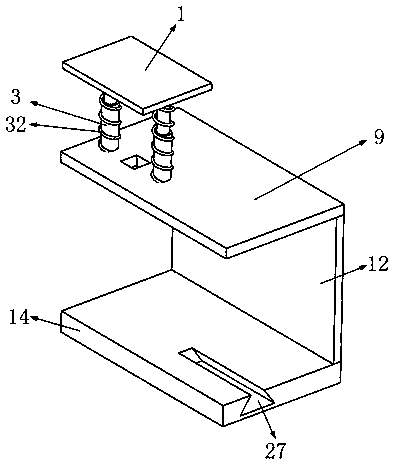

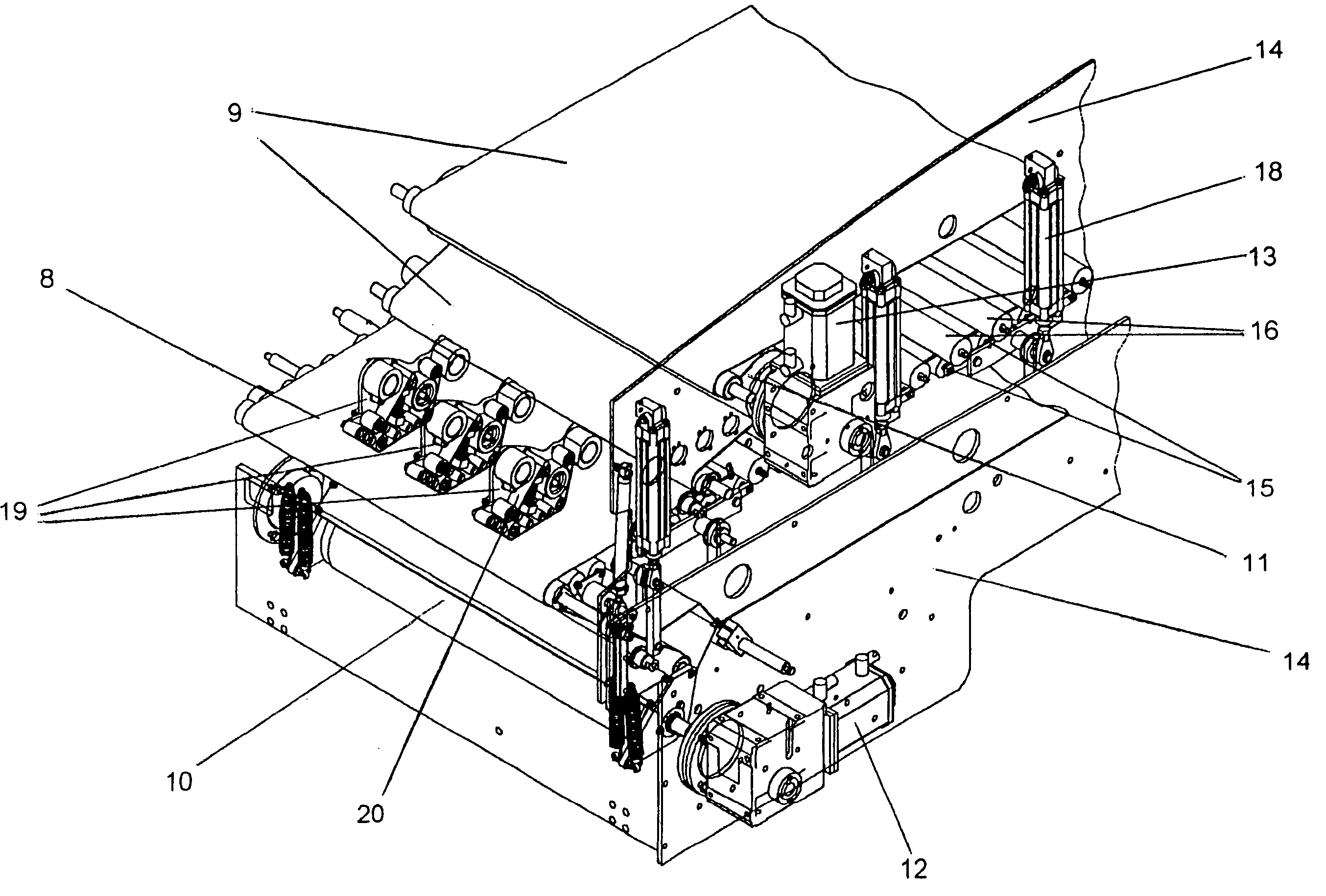

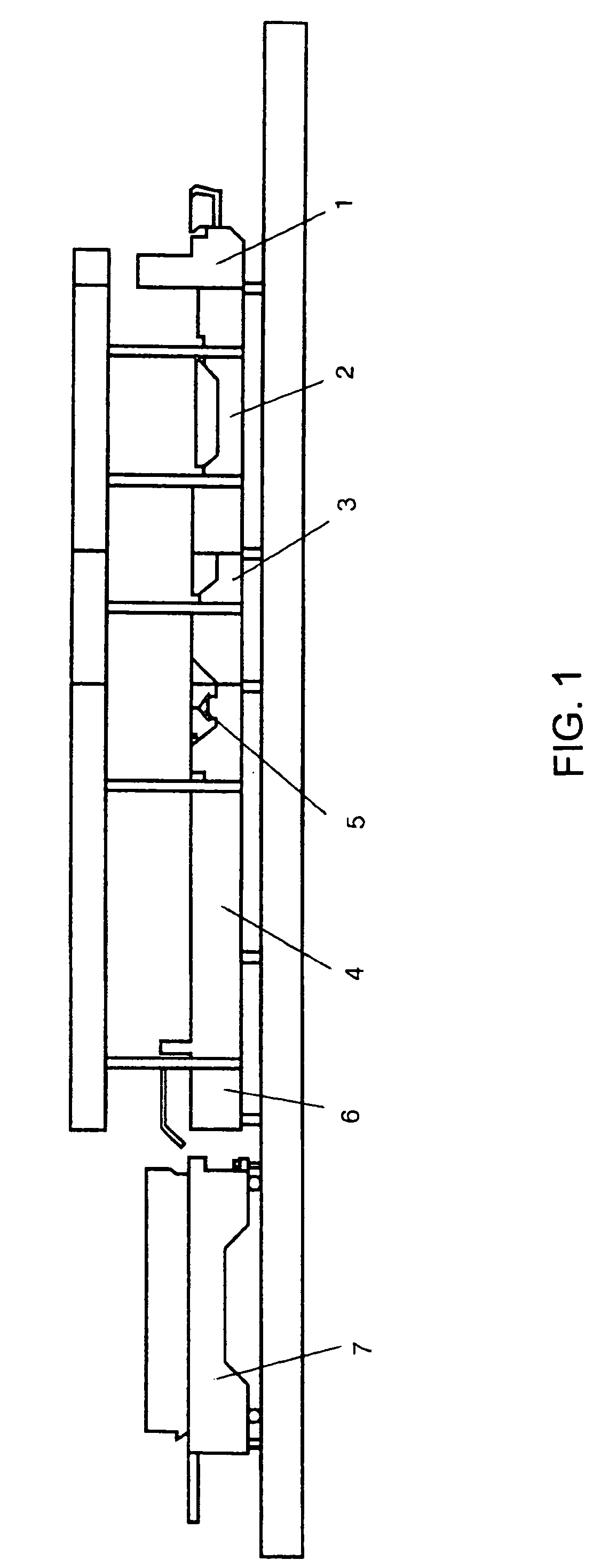

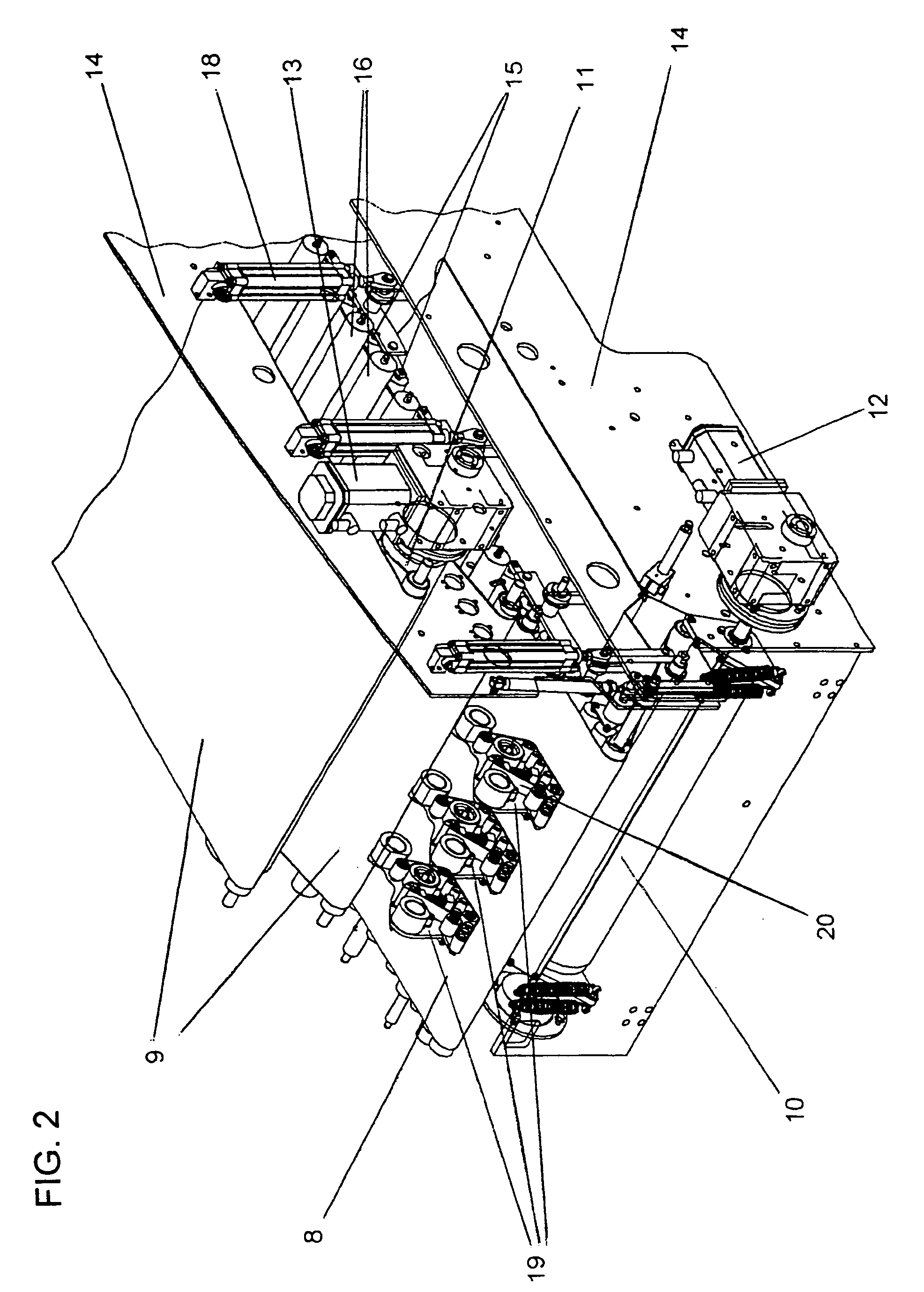

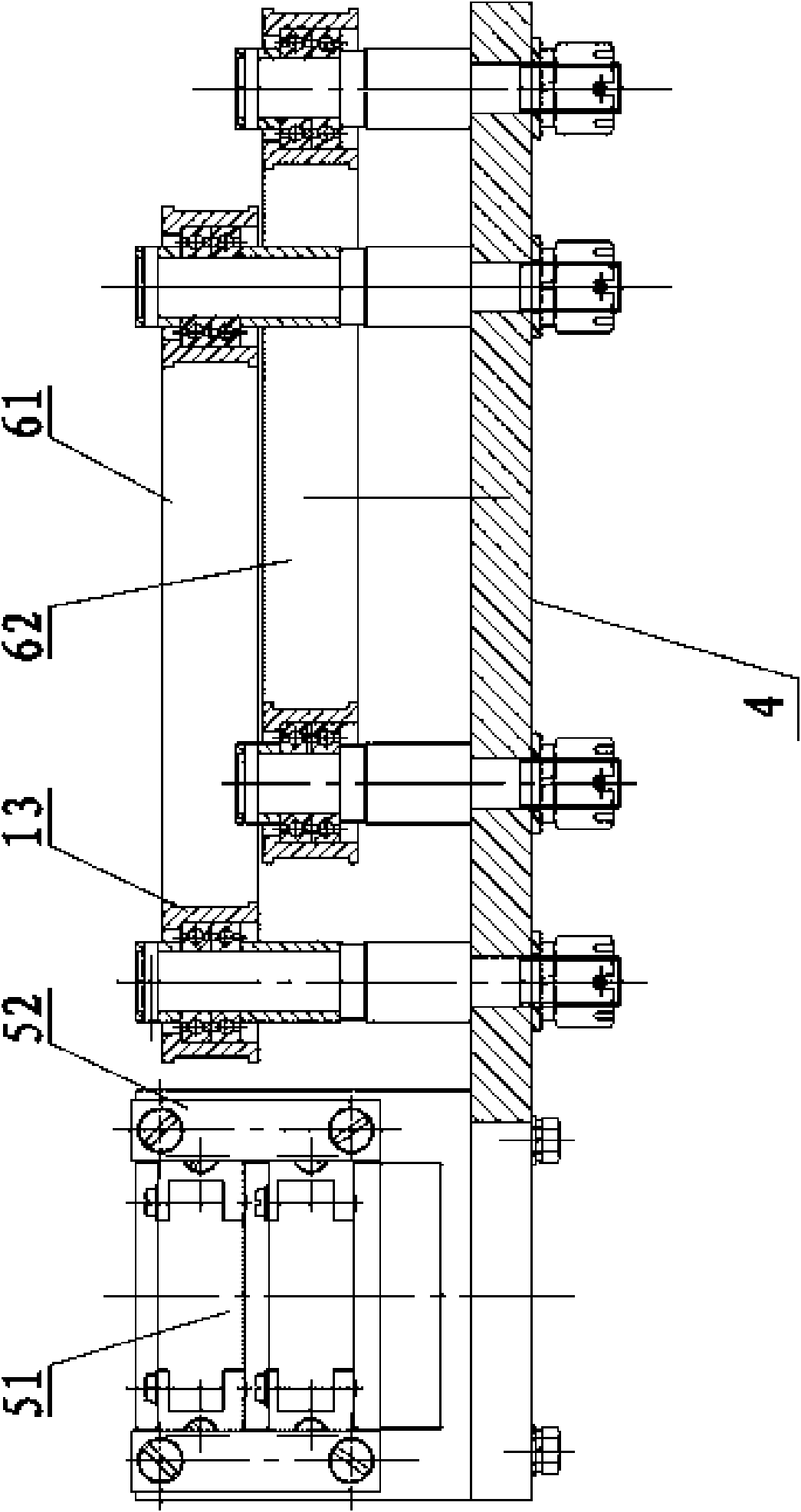

Gathering and pressing device for a folded box-gluing machine

ActiveUS7258655B2Increase production speedQuality improvementConveyorsBoxes/cartons making machineryEngineeringConveyor belt

Owner:MASTERWORK GROUP CO LTD

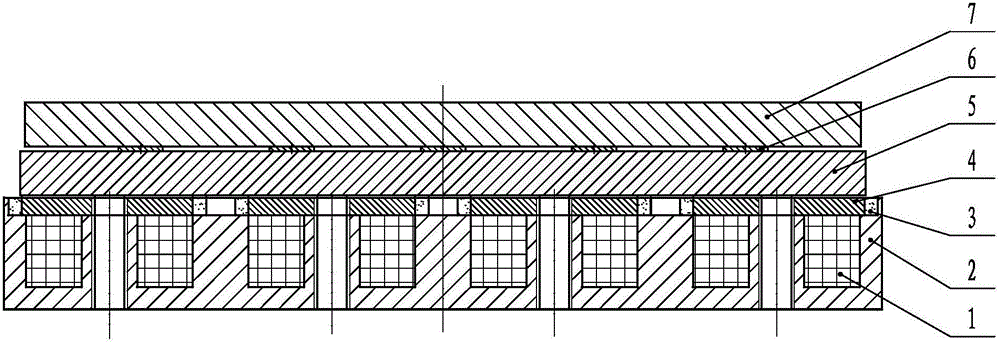

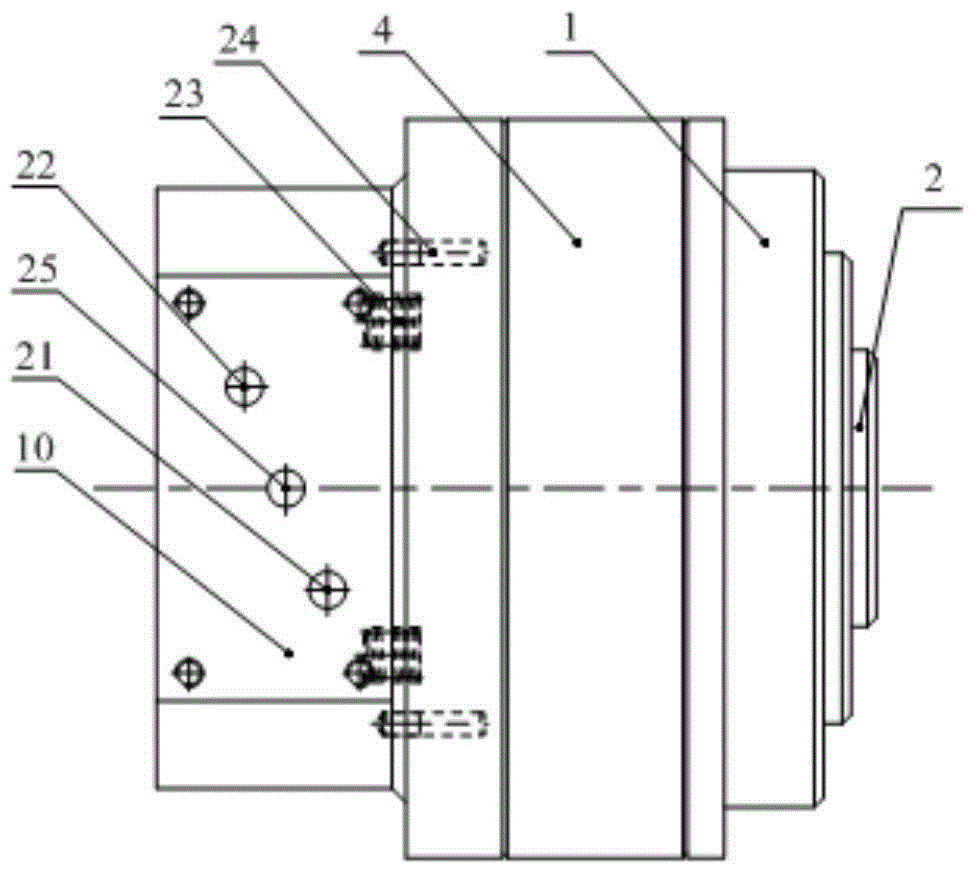

Linear motor permanent magnetic brake

ActiveCN105978291AReduce volumeReduce weightPermanent-magnet clutches/brakesMechanical energy handlingAutomatic controlLinear motor

The invention discloses a linear motor permanent magnetic brake. The linear motor permanent magnetic brake comprises a static iron core assembly and a moving plate assembly, wherein the static iron core assembly comprises multiple coils embedded in the static iron core; the upper portion of each coil is provided with a magnet yoke and magnet steel; the moving plate assembly comprises a fixed plate and a movable plate which are spaced by a spring sheet; and the fixed plate is placed above the magnet yokes and the magnetic steel. The linear motor permanent magnetic brake has the following advantages: 1, linear internal contracting brake is realized, the volume is small, and the weight is light; 2, the processing is simple, and the installation and maintenance are simple; 3, the connection is reliable, the brake is flexible, automatic control and long-distance operation of a work mechanism can be realized, and the brake time is extremely short; 4, the control power is small, and the service life is long; 5, the performance is stable, and the safety and reliability are high; 6, the structure is simple and compact, the operation is simple, and accurate combination can be guaranteed in quite short time; 7, diversified combination and application can be realized through adjusting features of the coils and the magnetic steel; and 8, the linear electromagnetic brake does not need motion at all, apart from an electromagnet, a brake using a permanent magnet does not need electric power, and thus the space and the efficiency can be reduced.

Owner:KEDE NUMERICAL CONTROL CO LTD

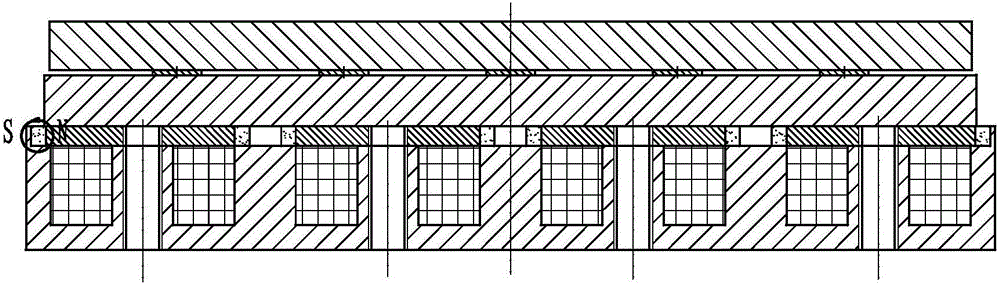

Method for upwind starting of permanent magnet brushless direct-current motor

ActiveCN110768585AShort braking timeGood effectAc motor stoppersDc motor startersMotor speedElectric machine

The invention discloses a method for upwind starting of a permanent magnet brushless direct-current motor. A phase-locked loop estimation algorithm is adopted, and the state of the motor is followed quickly; through the mode that a given current is zero, the current rotating speed of the motor is estimated; in the case of motionlessness or forward rotation of the motor, starting is easy to handle,and the method focuses on solving the situation of upwind operation; according to the rotating speed of reverse rotation, through formulas of Iq=k1*omega and Id=0, torque enabling the motor to stop quickly is generated; at the moment, the voltage of a direct-current bus is increased obviously, the voltage of the bus needs to be monitored in real time, when the voltage of the direct-current bus ishigher than a limit value, the current output is appropriately lowered, or the output is stopped, and the voltage of the bus is prohibited from continuing being increased; when reverse torque acts onthe motor, the motor is stopped quickly, when the reverse rotation speed of the motor is decreased to zero from a high speed, reverse rotation is switched into forward rotation; and when the forwardrotation speed of the motor reaches a certain value, the starting process is completed, the motor is switched into normal control loops such as control of the speed loop or the other loops.

Owner:深圳瑞德创新科技有限公司

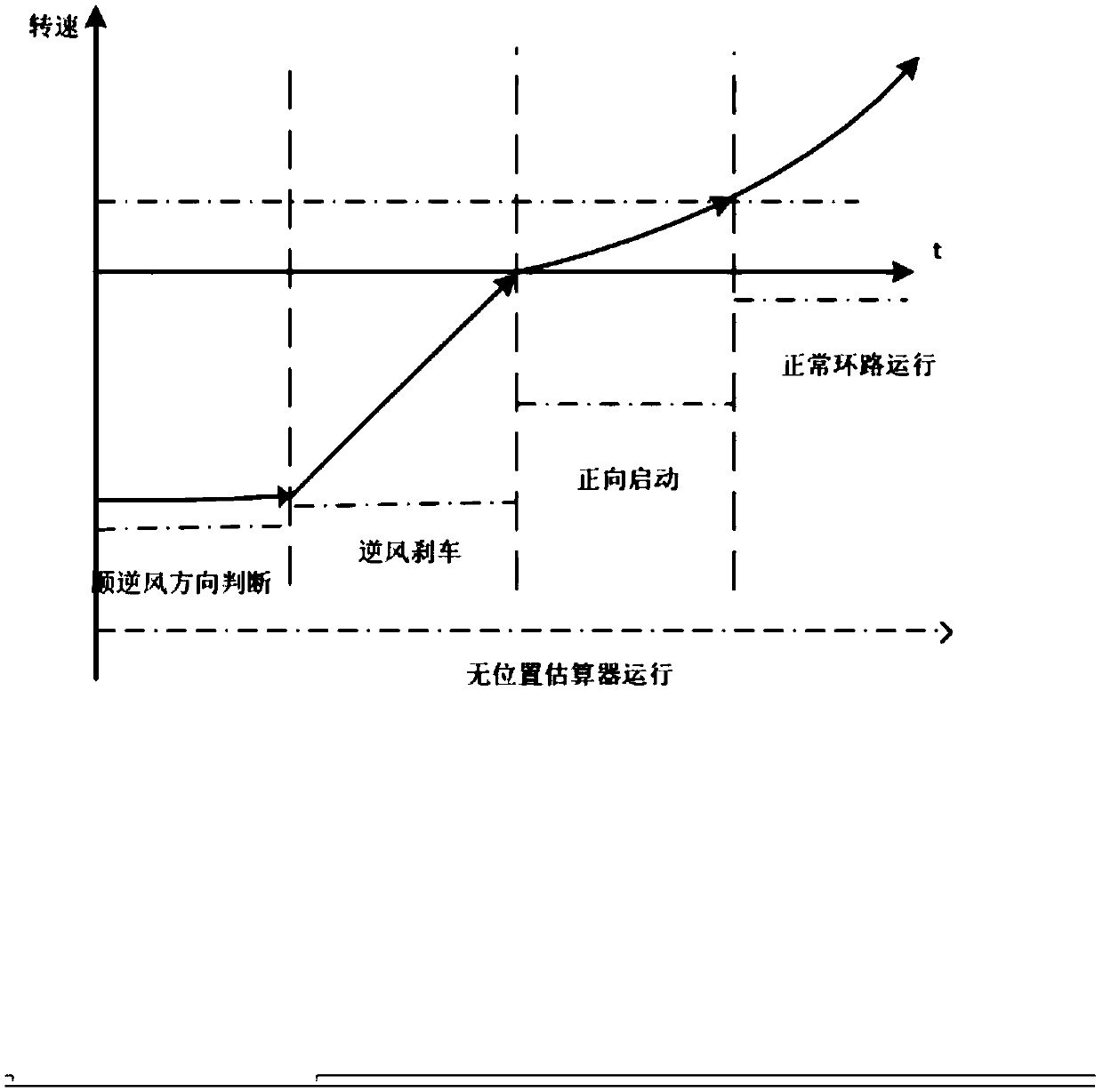

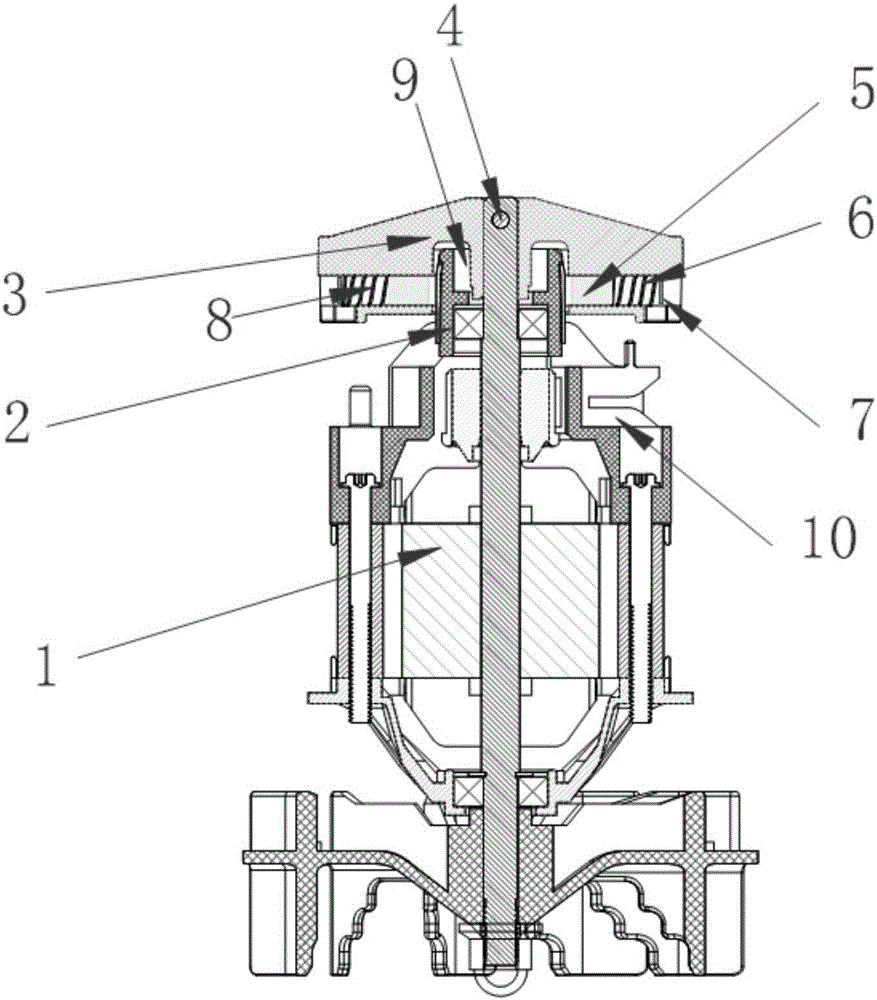

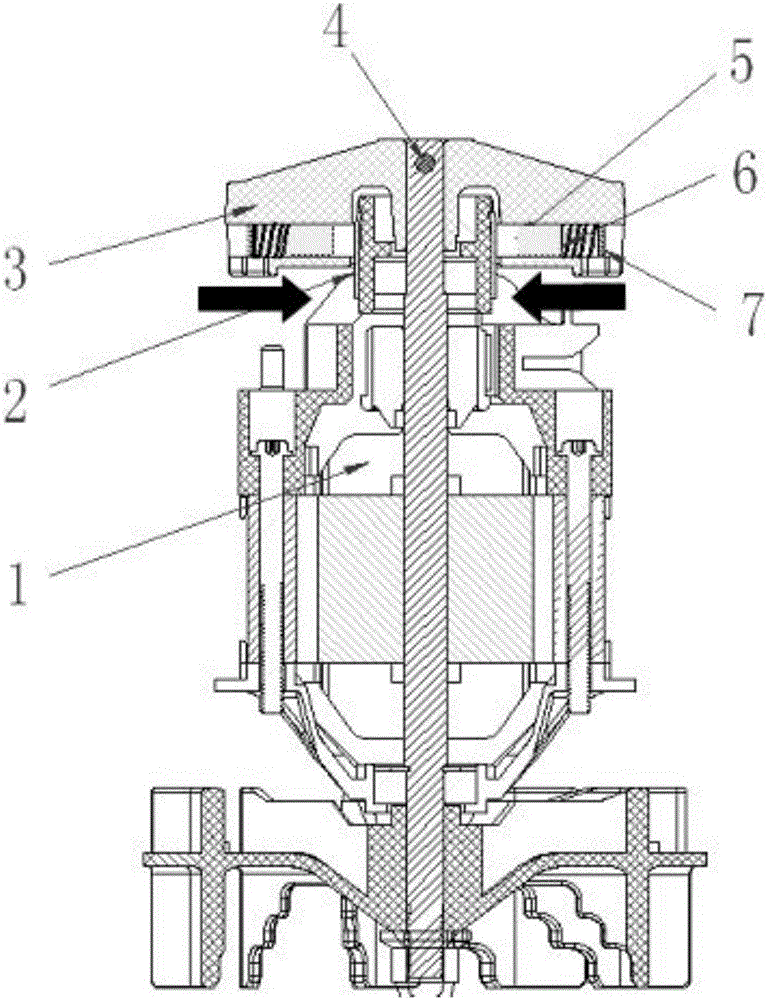

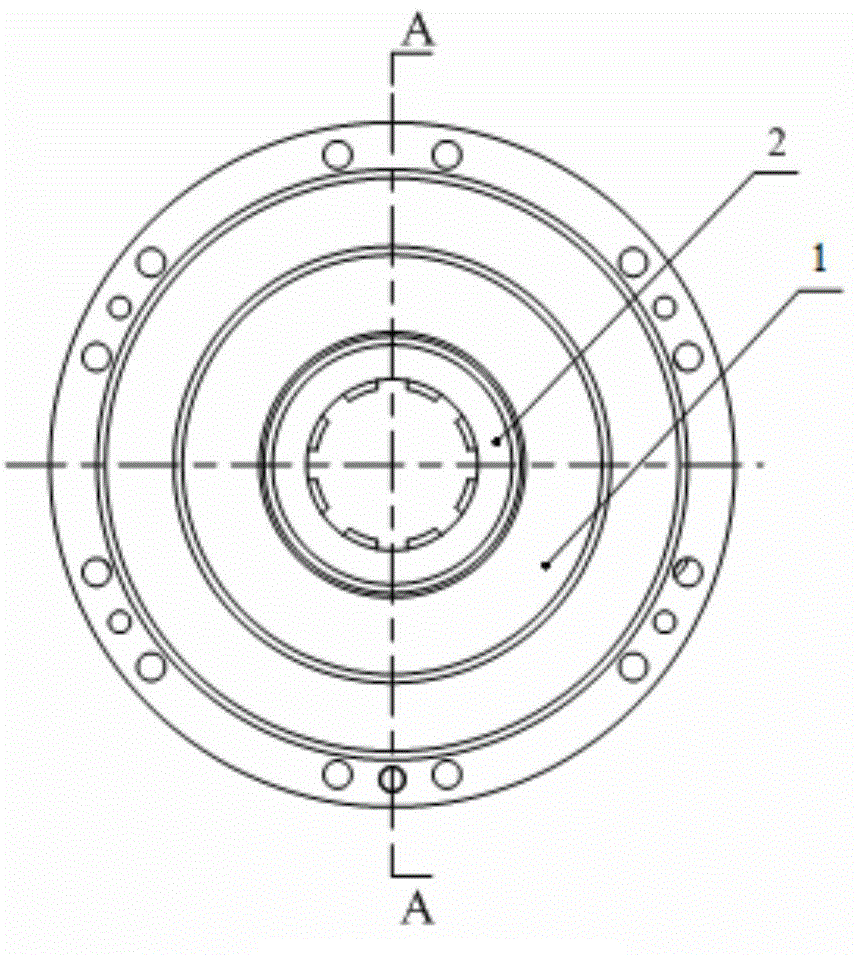

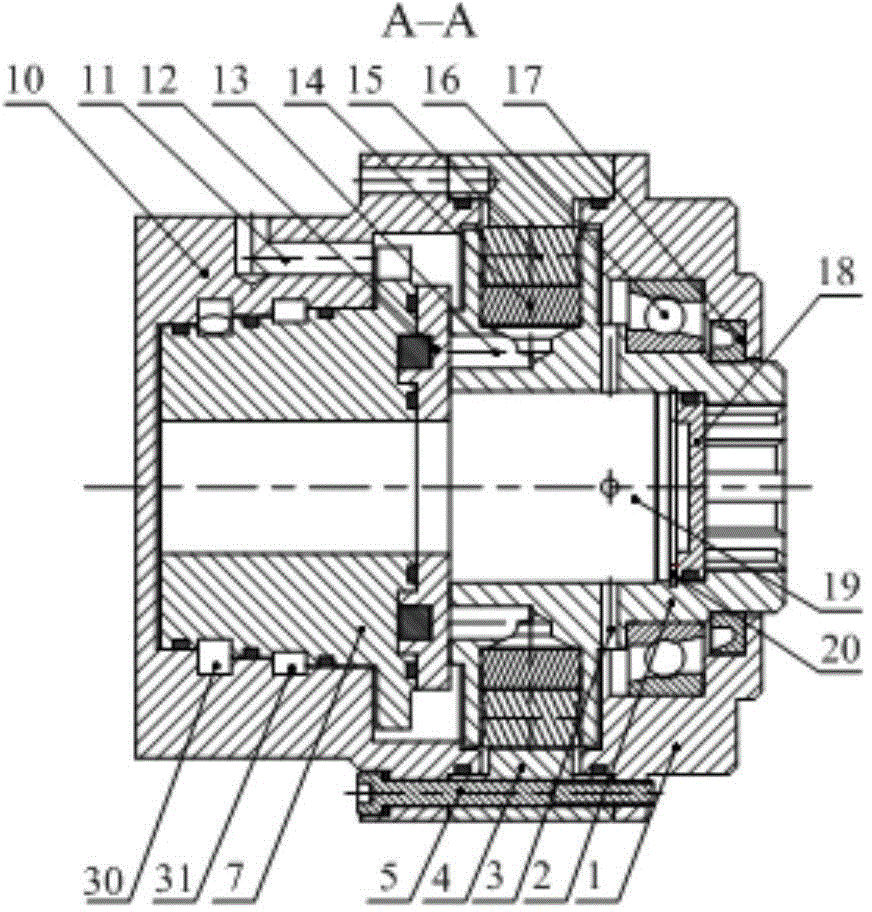

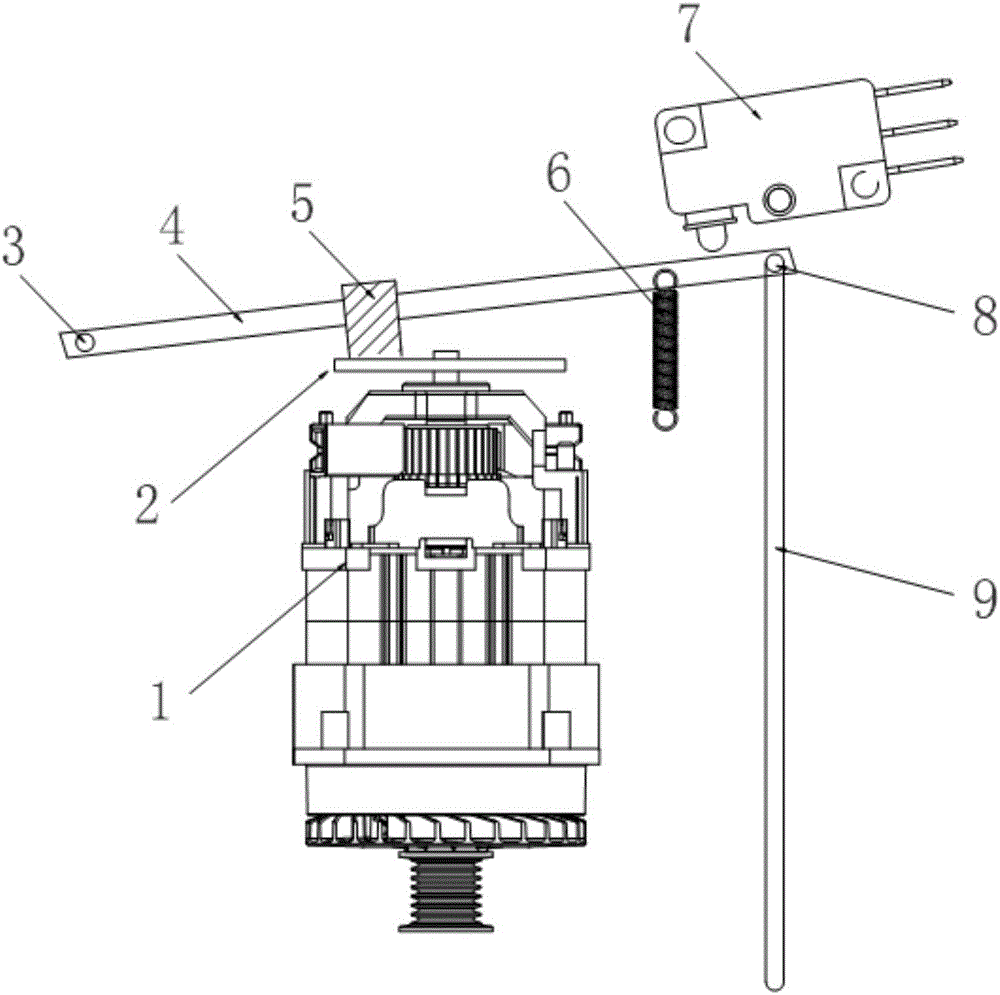

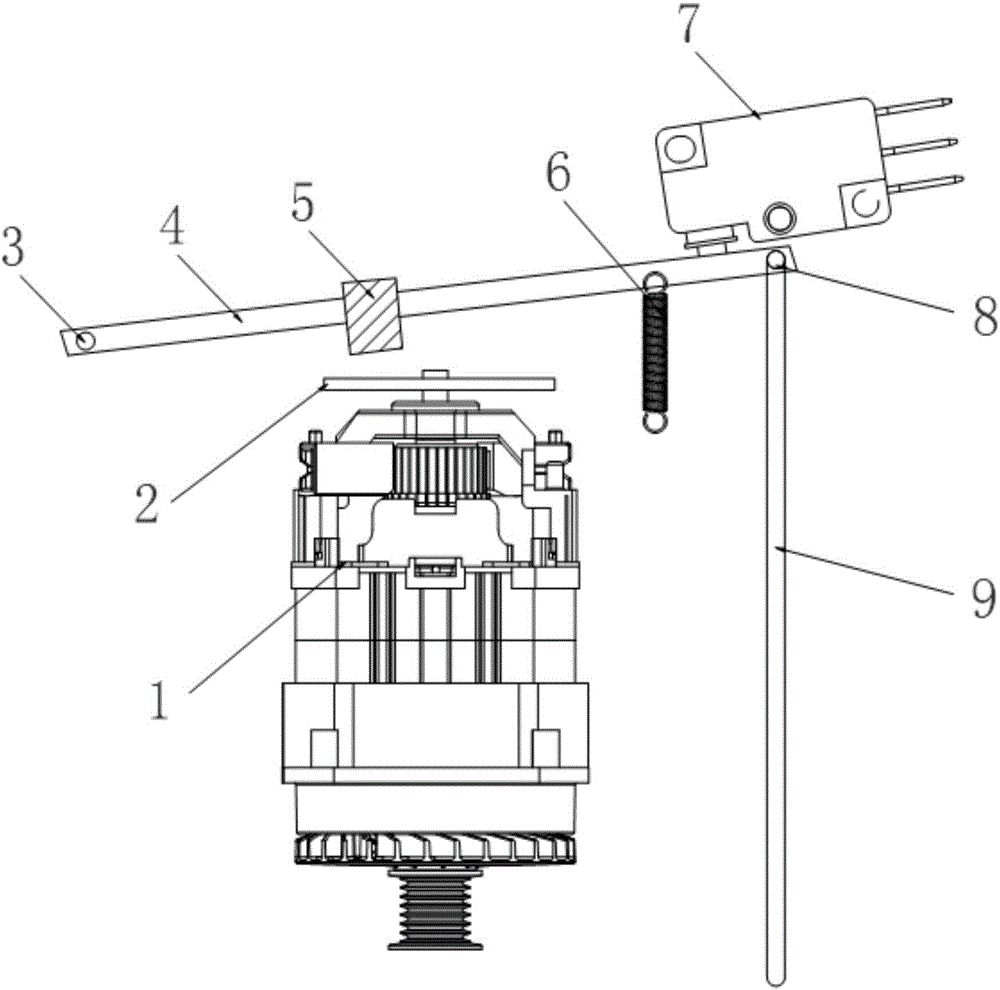

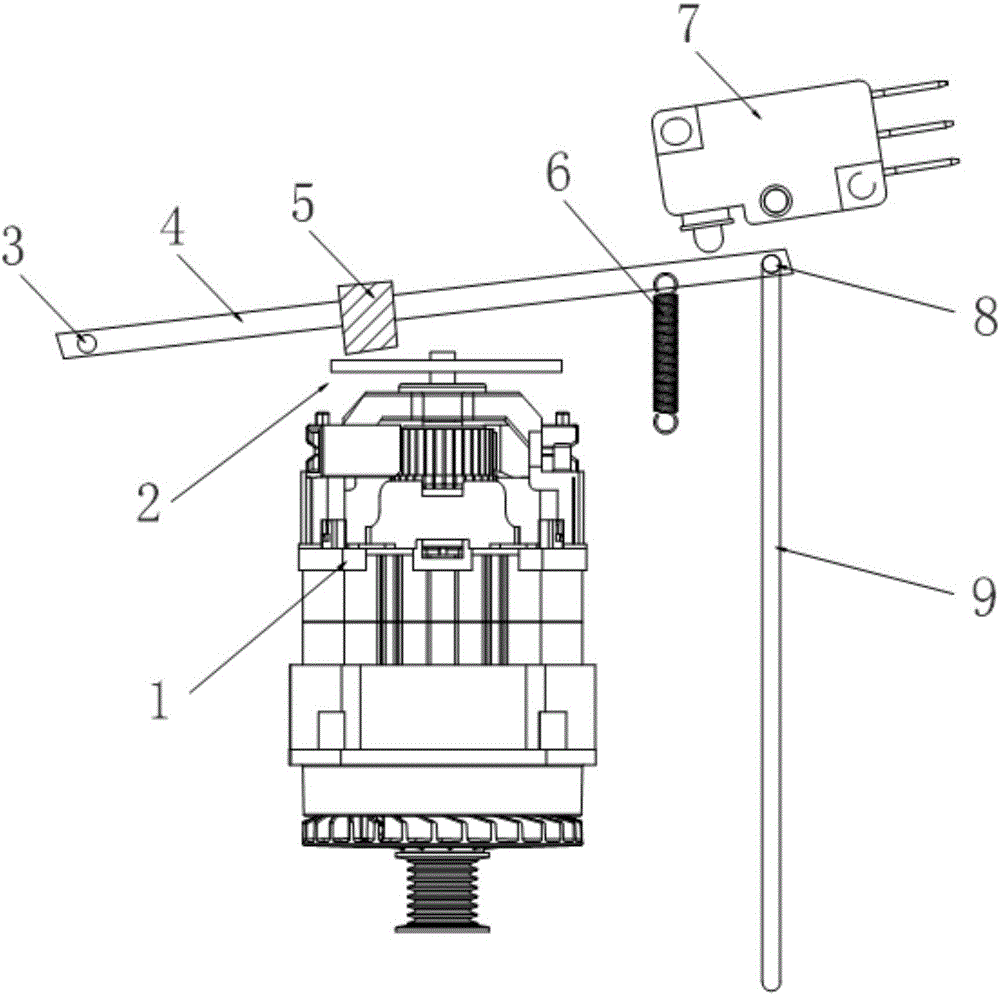

Centrifugal brake mechanism of motor

InactiveCN105864322AShort braking timeOperational securitySelf acting brakesMechanical energy handlingMotor driveCentrifugal force

The invention discloses a centrifugal brake mechanism of a motor. The centrifugal brake mechanism comprises the motor, a brake ring, a brake bracket, brake pads and elastic devices, and the brake bracket is fixed to a rotating shaft of the motor; the motor drives the brake bracket to rotate around the brake ring, when the centrifugal force applied to the brake pads is smaller than elasticity of the elastic devices, the brake pads are in contact friction with the brake ring to achieve brake, and when the centrifugal force of the brake force is larger than elasticity of the elastic device, the brake pads are separated from the brake ring. The centrifugal brake mechanism solves the technical problems that the brake mechanism of the motor is complex in structure and not high in reliability.

Owner:SUZHOU KINGCLEAN PRECISION MACHINERY +1

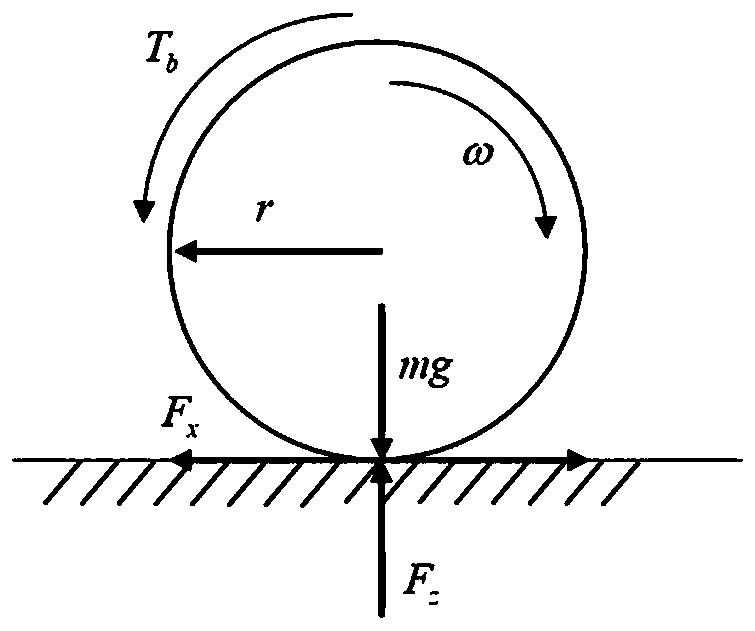

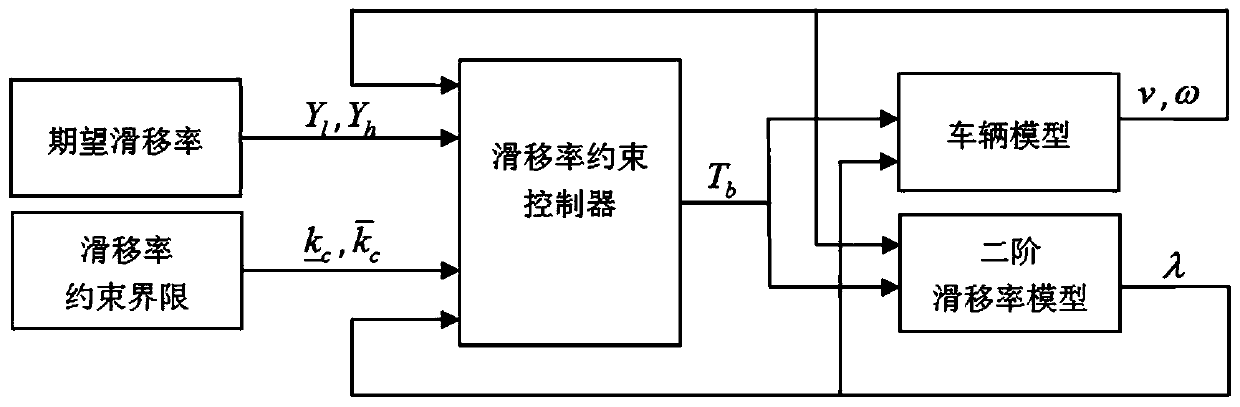

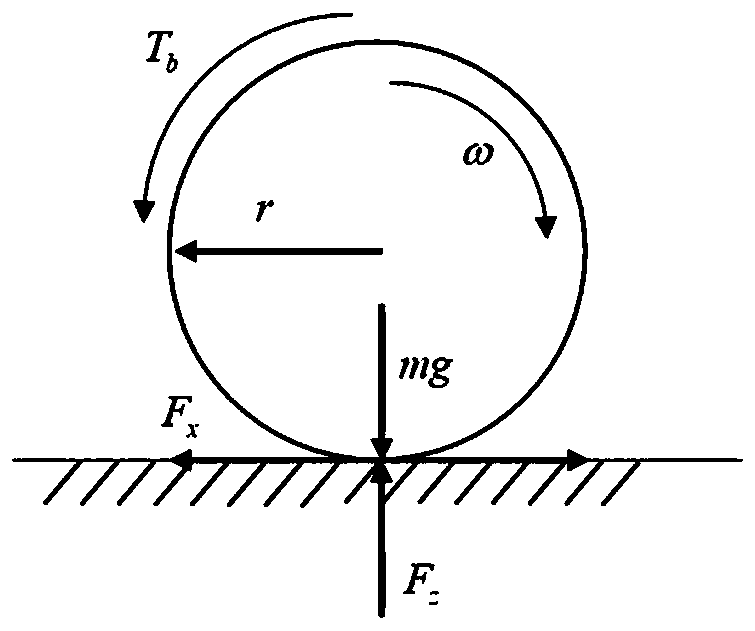

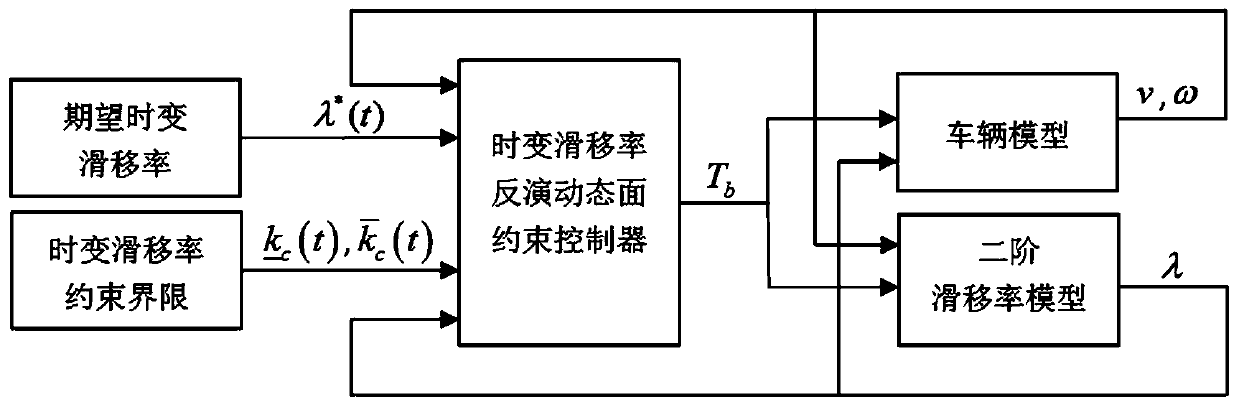

Vehicle anti-lock braking system slip rate constraint control algorithm based on second-order slip rate model

InactiveCN110254407AImprove comfortShort braking timeComplex mathematical operationsBraking systemsBrake torqueAutomotive engineering

The invention discloses a vehicle anti-lock braking system slip rate constraint control algorithm based on a second-order slip rate model. The vehicle anti-lock braking system slip rate constraint control algorithm comprises modeling of an anti-lock braking system and the design of the slip rate constraint control algorithm, in the case of modeling of the anti-lock braking system, the second-order slip rate model is built according to a quarter vehicle model and a Burckhardt tire model, and the change situation of the slip rate derivative is reflected, the slip rate constraint control algorithm is mainly responsible for designing an obstacle lyapunov function and a constraint controller, so that the slippage rate is ensured not to violate a constraint limit, and the slip rate is fundamentally prevented from operating in an unstable region. Meanwhile, the asymmetric barrier lyapunov function is adopted to solve the problem of non-symmetric slip rate constraint of the uneven road. According to the proposed algorithm, the slip rate can be ensured to work in a stable region all the time, and shorter braking time and shorter braking distance are achieved under the condition that the constraint condition is not violated. In the braking process, the wheel speed and the braking torque do not shake, so that the comfort of a vehicle is improved.

Owner:JIANGSU UNIV

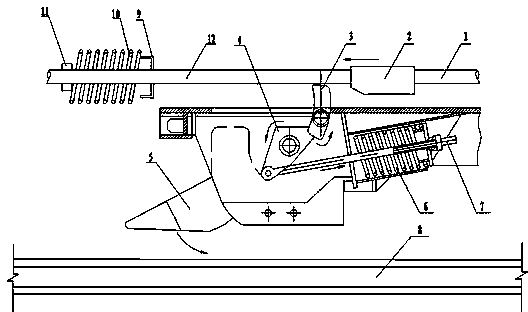

Brake mechanism

ActiveCN108725410APrevent affecting the braking effectSufficient amount of expansionFoot actuated initiationsFootplateAutomotive engineering

The invention belongs to the technical field of brake, and particularly relates to a brake mechanism which comprises a brake pedal, a second fixing plate, a first rack, a trapezoidal guide block spring, a trapezoidal guide block, a rotating shaft, a fourth rack, a small gear, a fan-shaped guide rail and the like. A loop moves towards a first telescopic sleeve, so that the downward movement amountof one end, positioned in the first telescopic sleeve, of a telescopic inner rod is larger than the upward movement amount of one end, positioned in a second telescopic sleeve, of the telescopic innerrod. Therefore, after a pedal connecting rod is rapidly pressed down, a brake connecting rod can be rapidly and greatly pressed down by rapid and low-amplitude downward pressing of the pedal connecting rod, the brake mechanism can more rapidly act within an extremely short time, the severe brake time of the rapid brake mechanism is shorter than that of a traditional automobile, the automobile canbe more rapidly stopped when in emergency, the possibility of touch accidents of the automobile is decreased after a driver rapidly brakes in emergency, and safety of the driver is more effectively protected.

Owner:山东森亚信息科技有限公司

Brake device

InactiveCN105253122AImprove stabilityImprove securityBraking element arrangementsAutomobile safetyBrake pad

The invention provides a brake device, belonging to the field of automobile safety protection devices. The brake device comprises a brake mechanism installed on an automobile body and a control mechanism for controlling the brake mechanism, wherein the brake mechanism comprises a junction plate and a brake pedal; one end of the junction plate is connected with the brake pedal; the other end of the junction plate is rotationally connected with the automobile body; one side, far away from the junction plate, of the brake pedal is provided with a friction plate; when the junction plate rotates, the brake mechanism can jack up the automobile body, and wheels are enabled to be off the ground. When an automobile is in a process of driving and encounters an emergency, the junction plate of the brake mechanism can jack up the automobile body by operating the control mechanism by a driver, the wheels are off the ground, and the automobile can timely stop by utilizing the friction force between the friction plate on a brake plate and the ground. The brake device provided by the invention is reasonable in design structure, ingenious, short in brake time, high in safety, and wide in application scope.

Owner:杨芝兵

Powerful brake device

The invention relates to a powerful brake device. The powerful brake device comprises a motor. The motor is provided with a speed reducer which is connected with a clutch. The output end of the clutch is connected with a drum through a spline. The drum is connected with a brake device. A hub of the brake device is fixed to the drum through bolts. The brake device is provided with a brake shoe and a wheel cylinder. The wheel cylinder is connected with a high-pressure oil inlet which is connected with a high-pressure oil outlet. The high-pressure oil outlet is connected with a gas-liquid pressurization device which is connected with low-pressure gas. According to the powerful brake device, the cutch and the high-power brake device are mainly added, the clutch is added to the drive end of a special electric winch, the brake device is arranged at the other end of the special electric winch, the rotation inertia is reduced, the power consumption is lowered in the braking process, large braking force is provided through drum type braking, the drum rotating at a high speed is rapidly braked, the gas-liquid pressurization device provides braking power, and the powerful brake device has the advantages of being high in running speed, short in braking time and large in braking torque.

Owner:河南省汇隆精密设备制造股份有限公司

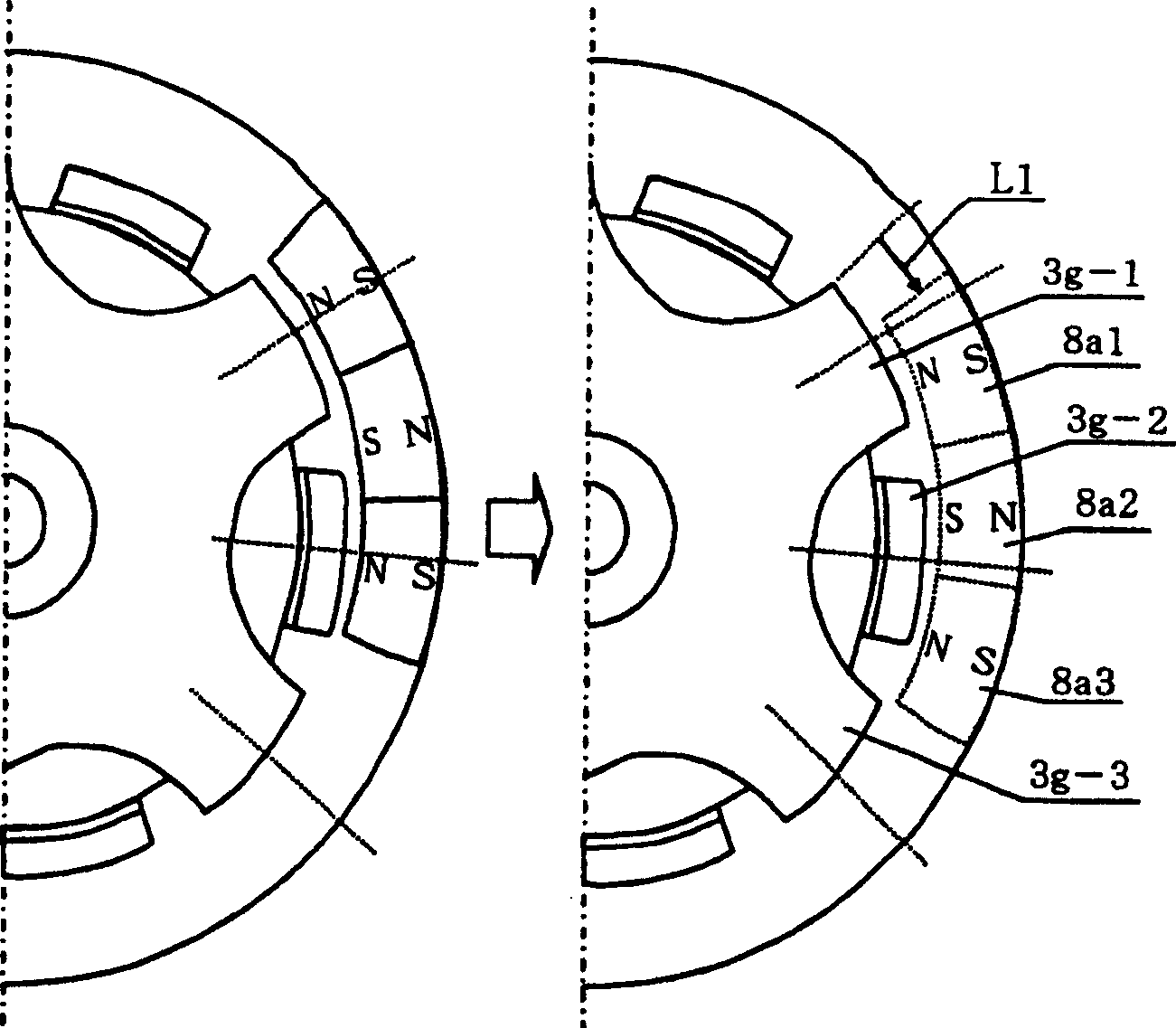

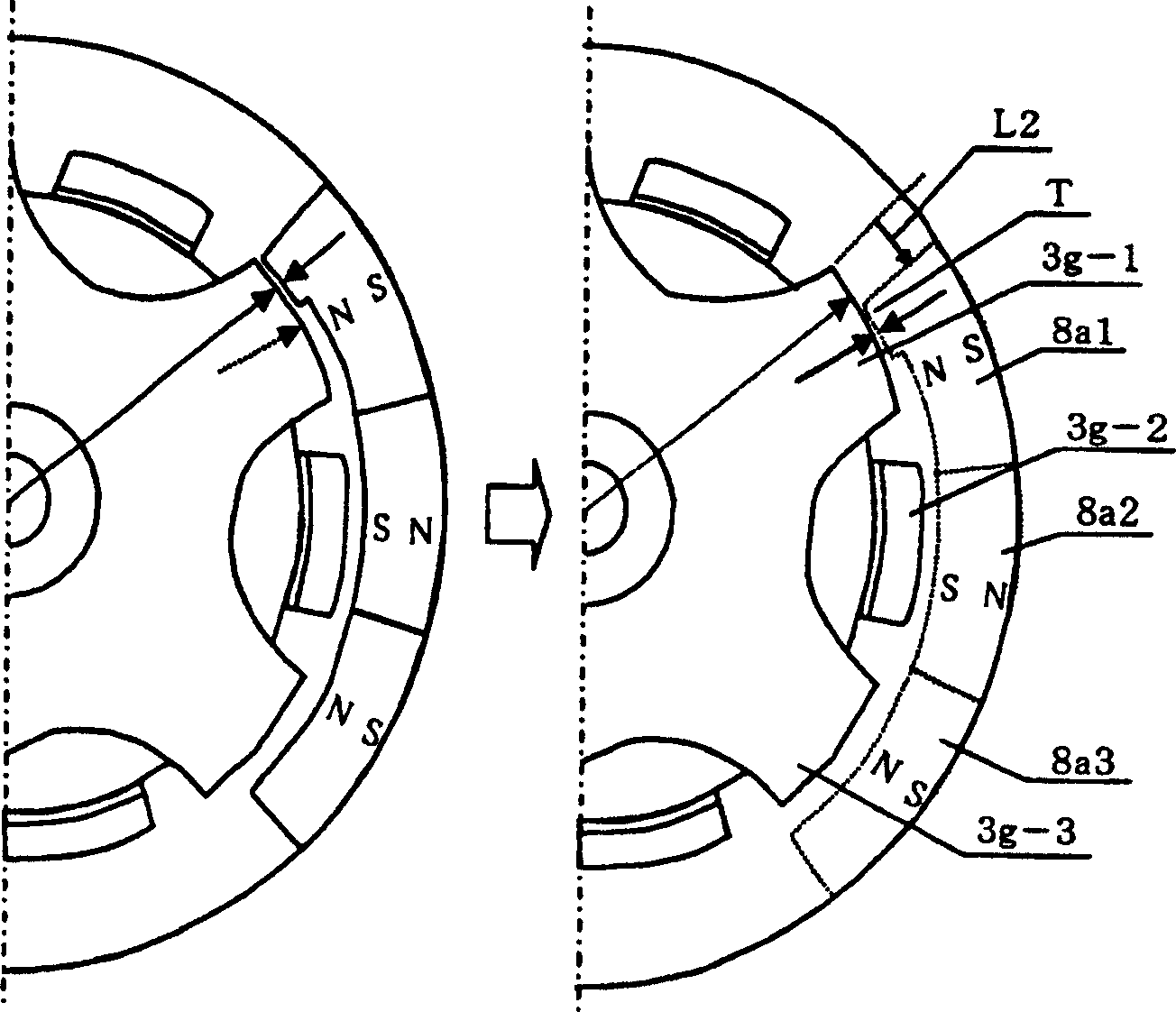

Method for braking an electric drive motor

ActiveUS9306478B2Short braking timeSimple processDynamo-electric converter controlAc motor stoppersElectricityField coil

The invention is directed to a method for braking an electric drive motor having a stator and a rotor. The stator has field coils which have electrical phase connections for three motor phases. To generate an electromagnetic rotating field driving the rotor, the phase connections are connected to a supply voltage via switches actuated by a control unit which closes the switches depending on the rotary position of the rotor. To brake a rotating rotor, a braking current is generated by short-circuiting the phase connections. A phase short circuit is switched in between each two phase connections of the field coils with a preset temporal sequence to brake the rotor. The phase connections short-circuited are each selected corresponding to the rotary position of the rotor so that that field coil is short circuited in which the voltage induced by the magnetic field of the rotating rotor passes through its maximum.

Owner:ANDREAS STIHL AG & CO KG

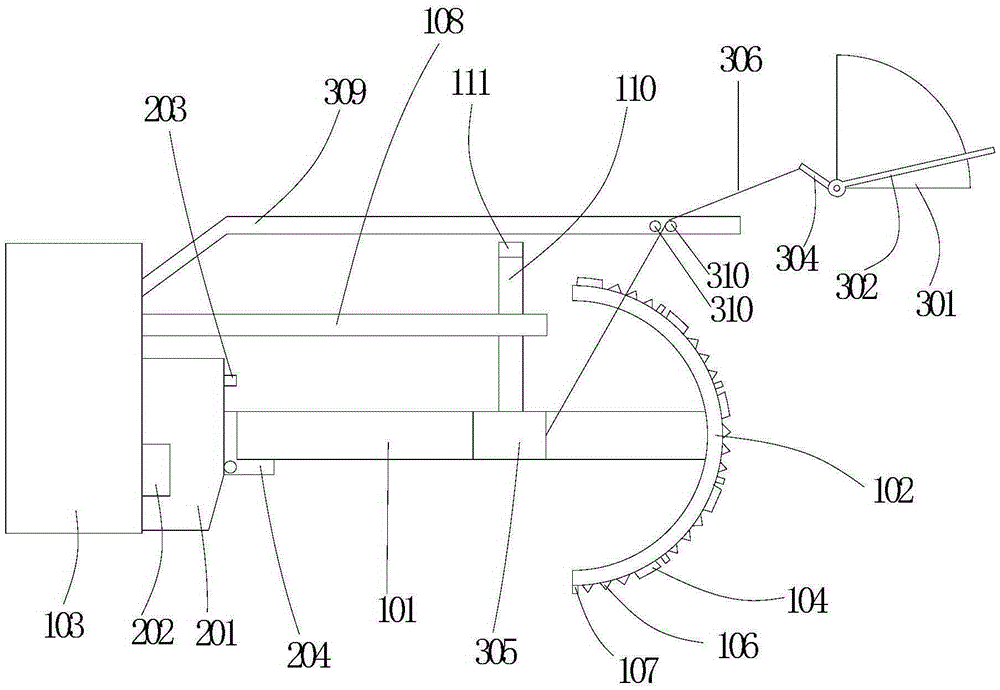

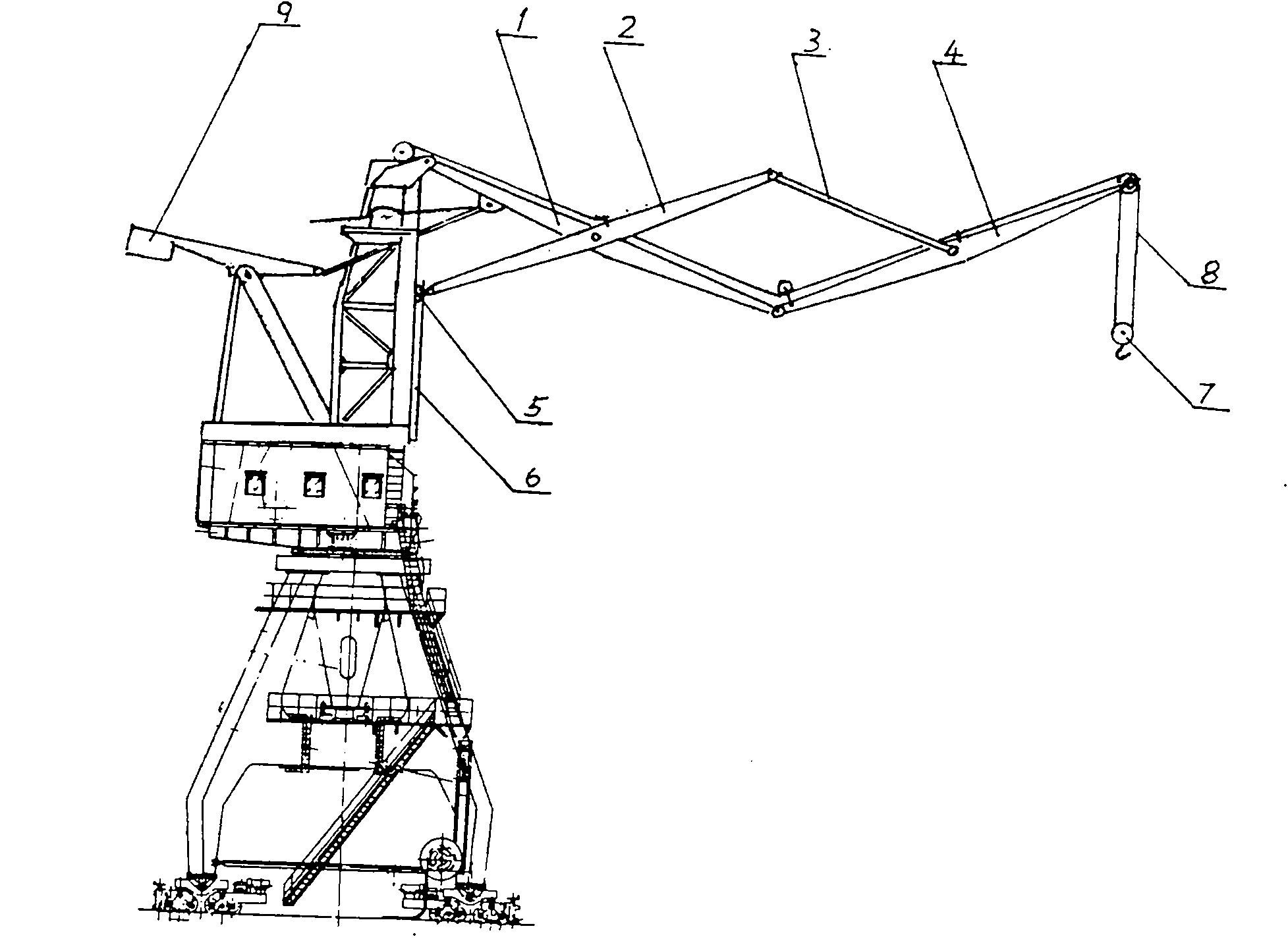

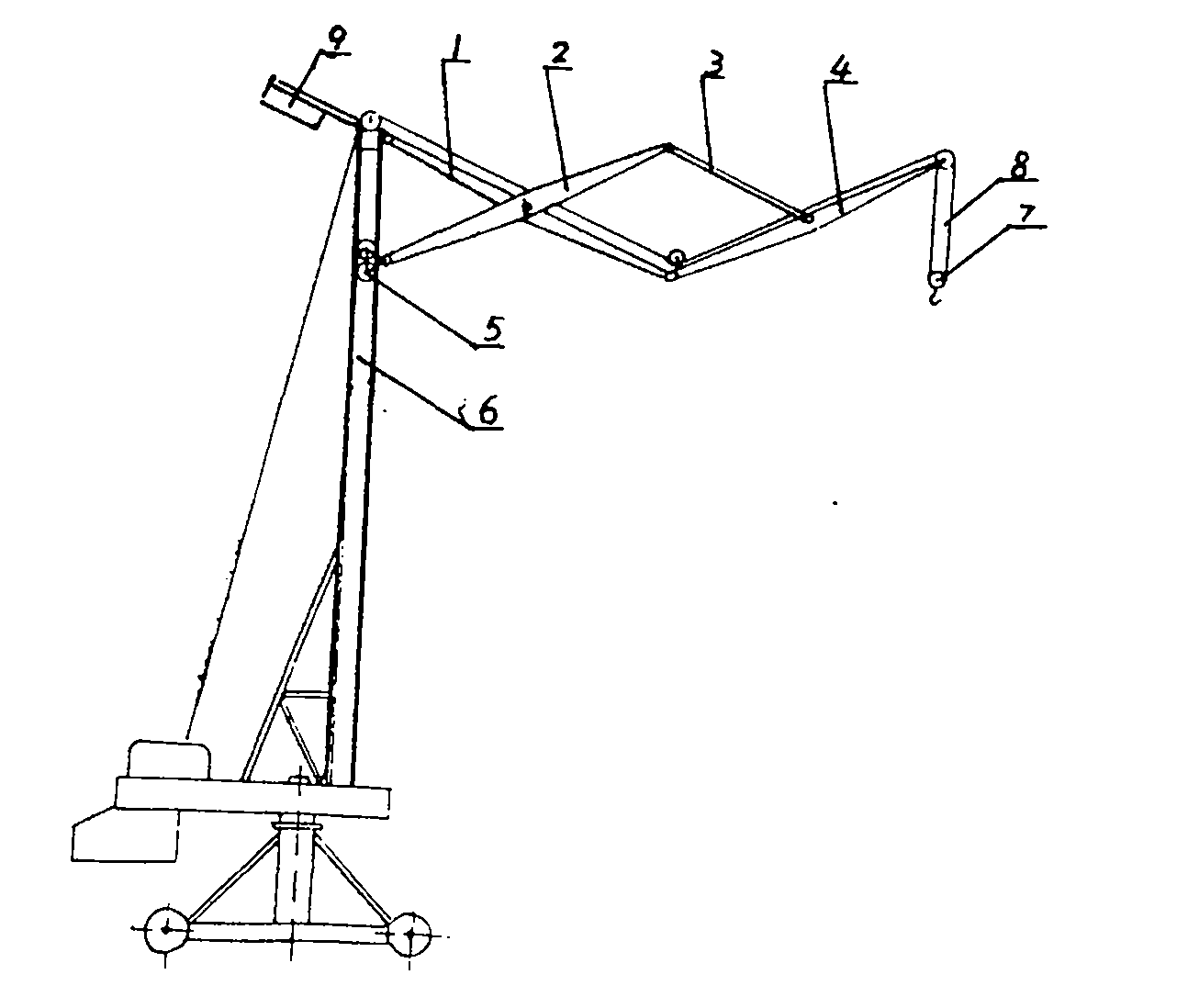

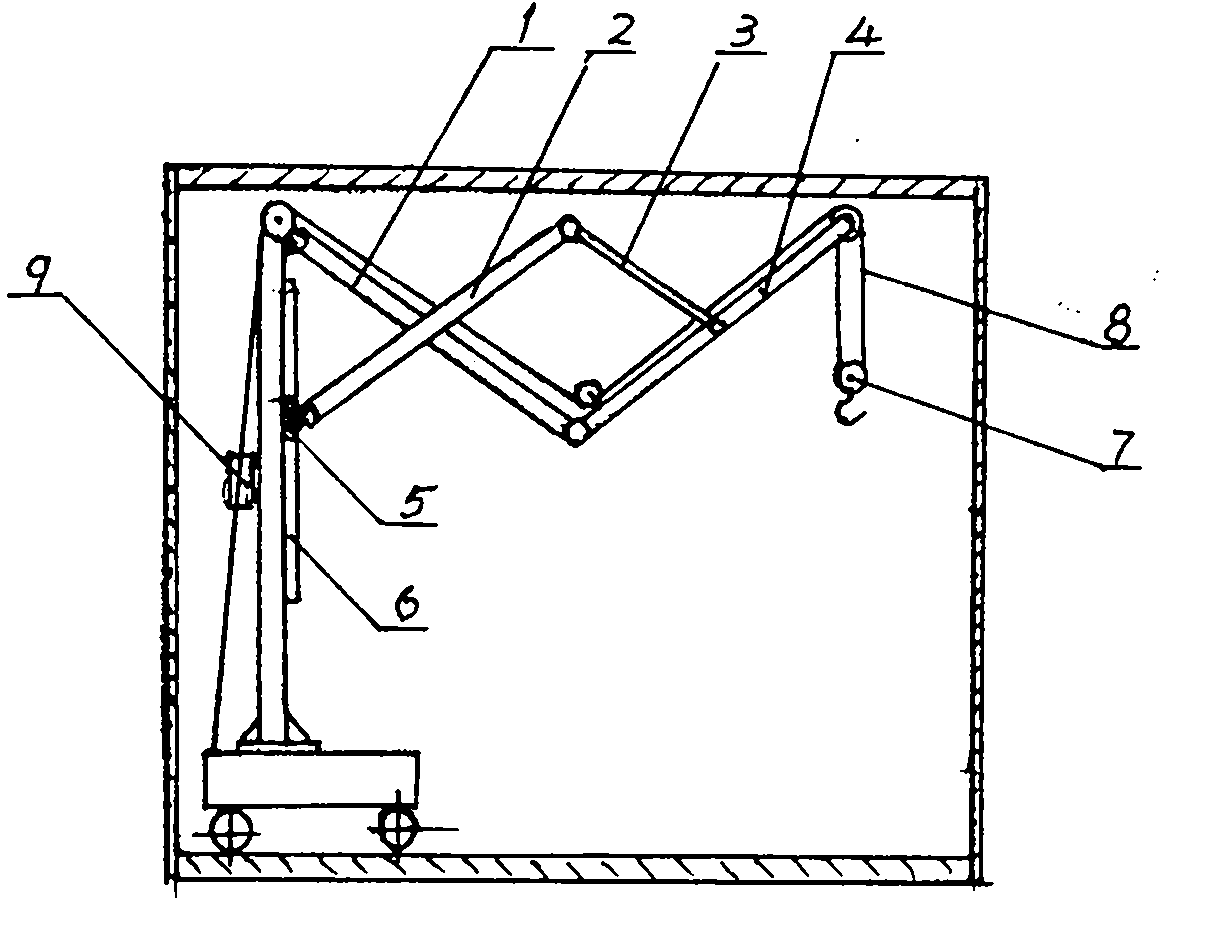

Four-rod-crossing amplitude compensation device

The invention discloses a four-rod-crossing amplitude compensation device, which can realize amplitude variation in horizontal direction, and is composed of a cross arm, a rear arm, a short arm, a front arm, a guide wheel, a vertical guide rail, a hanger steel wire rope winding system and a counter weight. The four-rod-crossing amplitude compensation device is characterized in that the upper end of the rear arm is hinged with an upper part of a crane, the middle point of the rear arm is hinged with the middle point of the cross arm, and the lower end of the rear arm is hinged with the lower end of the front arm; the lower end of the cross arm is provided with the guide wheel which can move up and down along the vertical guide rail, and the upper end of the cross arm is hinged with the upper end of the short arm; the lower end of the short arm is hinged with the middle point of the front arm; and the cross arm, the rear arm and the front arm are same in length, and the short arm is 1 / 2 of the front arm in length. The steel wire rope of the winding system extends along the rear arm to reach a pulley at the lower end of the rear arm after passing through a pulley at the top end of the rear arm, and then hangs downwards after reaching the pulley at the top end of the front arm by extending along the front arm. When the amplitude varies, the guide wheel at the lower end of the cross arm moves up and down along the vertical guide rail, the peal of the front arm moves horizontally, thus the amplitude variation in the horizontal direction of hangers is realized. The four-rod-crossing amplitude compensation device has the advantages of simple structure, low center of gravity, small appearance size, good stability, short guide rail length, easiness in overall arrangement, implementation of ideal horizontal amplitude variation, and saved energy consumption, and can be widely applied to various cantilever cranes.

Owner:吴文发

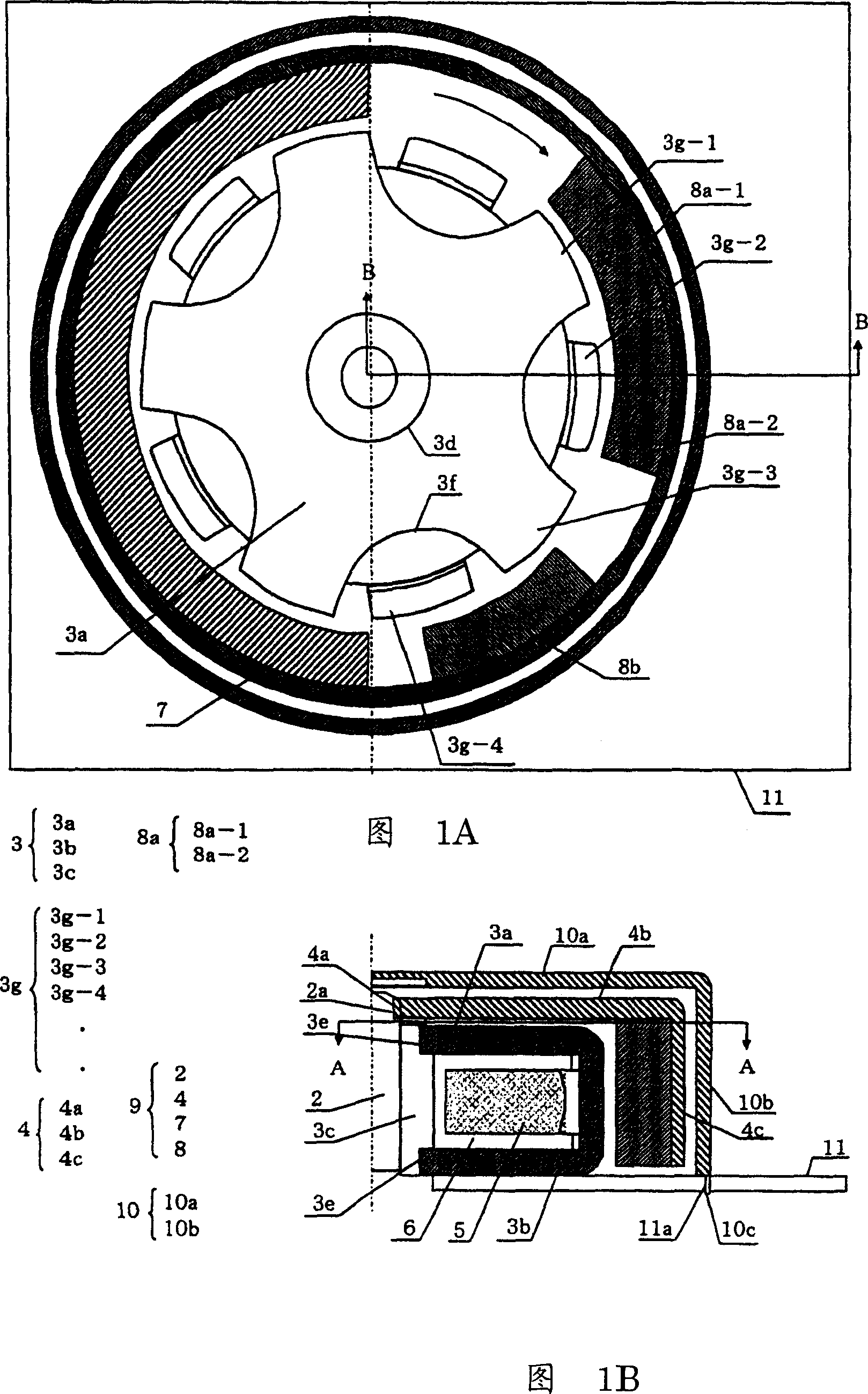

Vibrating motor and portable terminal apparatus using same

InactiveCN1747292ASimple structureChange vibrationMagnetic circuit rotating partsCurrent supply arrangementsStator coilTerminal equipment

A vibrating motor including a stepping motor in which control is simple, large vibration is generated, and drive torque can be efficiently generated, and a portable terminal apparatus using the same are provided. The vibrating motor includes a single-phase annular stator coil, a stator yoke disposed to surround the periphery of the single-phase annular stator coil and having pole teeth, an interface board fixing the stator yoke and having a wiring connected to the annular stator coil, plural arc-shaped magnets disposed to be opposite to the pole teeth and to be capable of rotating around a rotating shaft, and an eccentric weight capable of rotating around the rotating shaft.

Owner:MINEBEA MOTOR MFG

Time-varying slip rate inversion dynamic surface constraint control algorithm based on second-order slip rate model

InactiveCN110239500AShort braking timeAccurately describe the change law of slip rateABS control systemsBrake torqueProblem of time

The invention discloses a time-varying slip rate inversion dynamic surface constraint control algorithm based on a second-order slip rate model. Aiming at the situation that the slip rate is changed excessively quickly under the condition of the complex road surface, on the basis of a Burckhardt tire model, the second-order slip rate model is established, the slip rate change situation is reflected, the situation of derivative change of the slip rate can further be reflected, and the slip rate change rule of a vehicle antilock braking system (ABS) under the complex working condition can be described more. Meanwhile, a time-varying asymmetric obstacle Lyapunov function is introduced into the design of a slip rate controller, the problem of time-varying slip rate constraint control is solved, and the situation that the slip rate works in an unstable region is avoided fundamentally. The problem of differential explosion in an inversion control algorithm is solved by adopting a dynamic surface control algorithm. The designed slip rate constraint controller can have the shorter braking time and the shorter braking distance under the situation of not violating constraint conditions, the wheel speed and the braking torque do not jitter in the braking process, and the comfort of a vehicle is improved.

Owner:JIANGSU UNIV

Emergency braking system for machine tools

ActiveUS8689665B2Short braking timeShort timeYielding couplingSlip couplingRotational axisControl engineering

An emergency braking system for a machine tool for abruptly braking a revolving shaft includes at least one brake drum and at least one brake shoe which are engaged with one another in order to brake the shaft. The braking intervention between the brake drum and the brake shoe takes place under the influence of a centrifugal force resulting from the rotation of a shaft as soon as a locking device is released. Also provided in the braking system is a diagnostic system which allows the functionality of the locking device to be checked.

Owner:ROBERT BOSCH GMBH

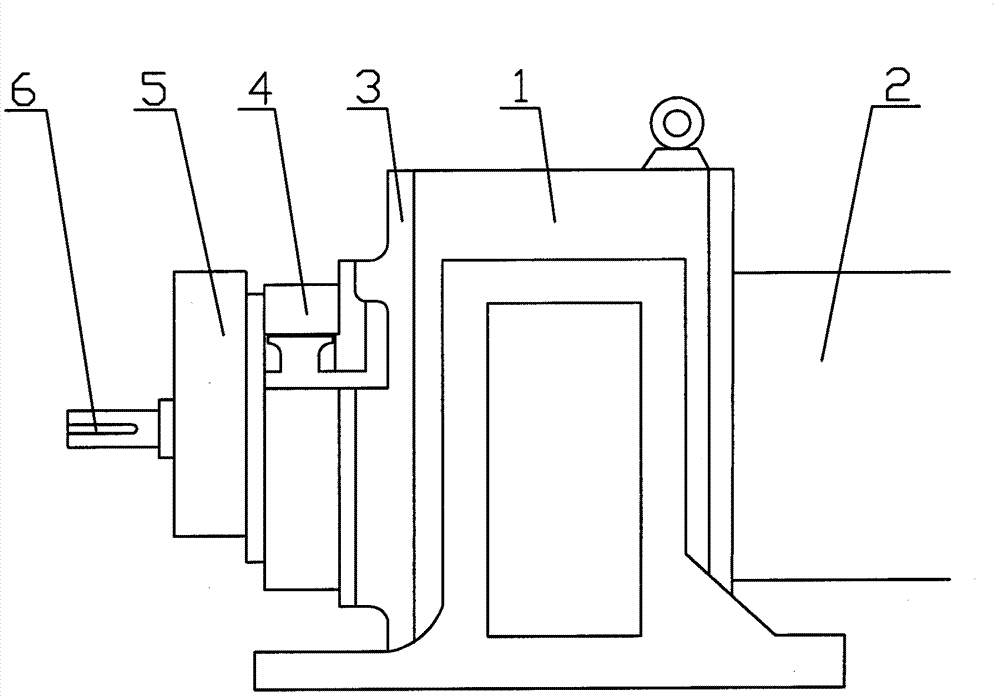

Gathering and pressing device for a folded box-gluing machine

ActiveUS20050250634A1Increase production speedQuality improvementConveyorsBoxes/cartons making machineryEngineeringConveyor belt

A gathering and pressing device for a folded box gluing machine has two machine-width, circulating conveyor belts which are connected to a drive and whose conveying runs are disposed horizontally, one above the other and running parallel to each another. An upper conveying run of the lower conveyor belt being mounted such it can be moved vertically with respect to the lower conveying run of the upper conveyor belt in order to press the folded blanks. Both the lower conveyor belt and the upper conveyor belt having their own drive which includes a servomotor with a resolver connected directly to the respective drive roll.

Owner:MASTERWORK GROUP CO LTD

Workstation of open ended rotor spinning machine and method for operating workstation

ActiveCN101956257ASimplify brakesExtended braking timeProgramme controlElectric motor controlElectric energyElectric generator

The invention relates to a workstation of an open ended rotor spinning machine having a rotor driver. The rotor driver is provided with a rotor motor and a control device, wherein the control device comprises a power supply circuit; the power supply circuit is provided with a voltage input, a voltage output and a power supply unit; the voltage input is at least connected to the power supply unit in the process of producing and operating the workstation; the rotor motor is connected to the voltage output; and the rotor motor can be operated as an electric generator in order to brake under the action of the control device. According to the invention, the workstation is provided with at least another electrical load required by producing and operating the workstation, the circuit is arranged for providing a braking electric energy output in the braking period of the rotor driver to at least another electrical load, and at least another electrical load is arranged for consuming the energy. The invention also relates to a method for operating the workstation.

Owner:SAURER GERMANY GMBH & CO KG

Electromagnetic speed-adjustable motor

InactiveCN102790465AEasy to controlReasonable structureMechanical energy handlingDynamo-electric brake controlVoltage generatorElectromagnetic shielding

The invention discloses an electromagnetic speed-adjustable motor, comprising a slip clutch. An electromagnetic speed-adjustable motor is disposed on an end of the slip clutch, and an end cover is disposed on the other end of the slip clutch. A magnetic powder controller is disposed on an end of the end cover. The other end of the magnetic powder controller is provided with a speed voltage generator. An output shaft disposed on an end of the electromagnetic speed-adjustable motor passes through the slip clutch, the electromagnetic speed-adjustable motor, the end cover, the magnetic powder controller, and the speed voltage generator, and the output shaft is disposed outside the speed voltage generator. The electromagnetic speed-adjustable motor is advantaged by reasonable structure, short braking time, and accurate positioning.

Owner:蔡国明

Quick brake mechanism

The invention belongs to the technical field of brakes, and particularly relates to a quick brake mechanism. The quick brake mechanism comprises a brake pedal, a pedal connecting rod, a telescopic rod, a first telescopic sleeve, a telescopic inner rod, a second telescopic sleeve, a ladder-shaped guiding block, a first hinging block and the like. A ring sleeve moves in the direction of the first telescopic sleeve, thus the downward moving amount of the end, in the first telescopic sleeve, of the telescopic inner rod is greater than the upward moving amount of the end, in the second telescopic sleeve, of the telescopic inner rod, in this way, after the pedal connecting rod is quickly pressed downwards, quick small-amplitude downward pressing of the pedal connecting rod can enable the brake connecting rod to generate quick large-amplitude downward pressing, and the brake mechanism can act more quickly in the very short time. The panic stop braking time of the quick brake mechanism is smaller than the panic stop braking time of a traditional automobile, the automobile can stop more quickly after encountering the emergency situation, the possibility that the automobile encounters the accidents after a driver suddenly step the brake during the emergency situation is decreased, and the safety of the driver is better protected.

Owner:齐河智谷产业发展有限公司

Inner curvilinear low-speed large-torque water hydraulic motor with replaceable wearproof dish

InactiveCN104912730AIncrease contactImprove impact performanceReciprocating piston enginesHydraulic motorLow speed

The invention discloses an inner curvilinear low-speed large-torque water hydraulic motor with a replaceable wearproof dish. The water hydraulic motor is applicable to a static pressure bearing interval and a structure based on water hydraulic transmission, so that the volume efficiency of the water hydraulic motor can be better met. N combined springs are arranged in a rear cover, a matched fluid is arranged on a center hole of the rear cover, and the matched fluid is pressed on the combined springs; the replaceable wearproof dish is arranged on the end surface of the matched fluid, the replaceable wearproof dish and the matched fluid are fixed, and a rotor is pressed on the end surface of the replaceable wearproof dish; k plungers are respectively arranged in corresponding radial plunger holes of the rotor, the plungers are internally filled with rolling bodies, and a stator sleeves the rotor; the inner walls of the plungers and the rolling bodies form friction pairs, the front end cover is supported on the rotor by virtue of a bearing, and the front end cover is fixed together with the stator and the rear end cover. Valve plate distribution is adopted by the inner curvilinear low-speed large-torque water hydraulic motor; the leakage of the matched fluid and the rotor is decreased by virtue of the combined springs, and the worn interval can be automatically compensated; an equal accelerated movement law curve is adopted by the inner curved surface of the stator, so that the low-speed stability under a multi-effect structure is ensured.

Owner:HANGZHOU DIANZI UNIV

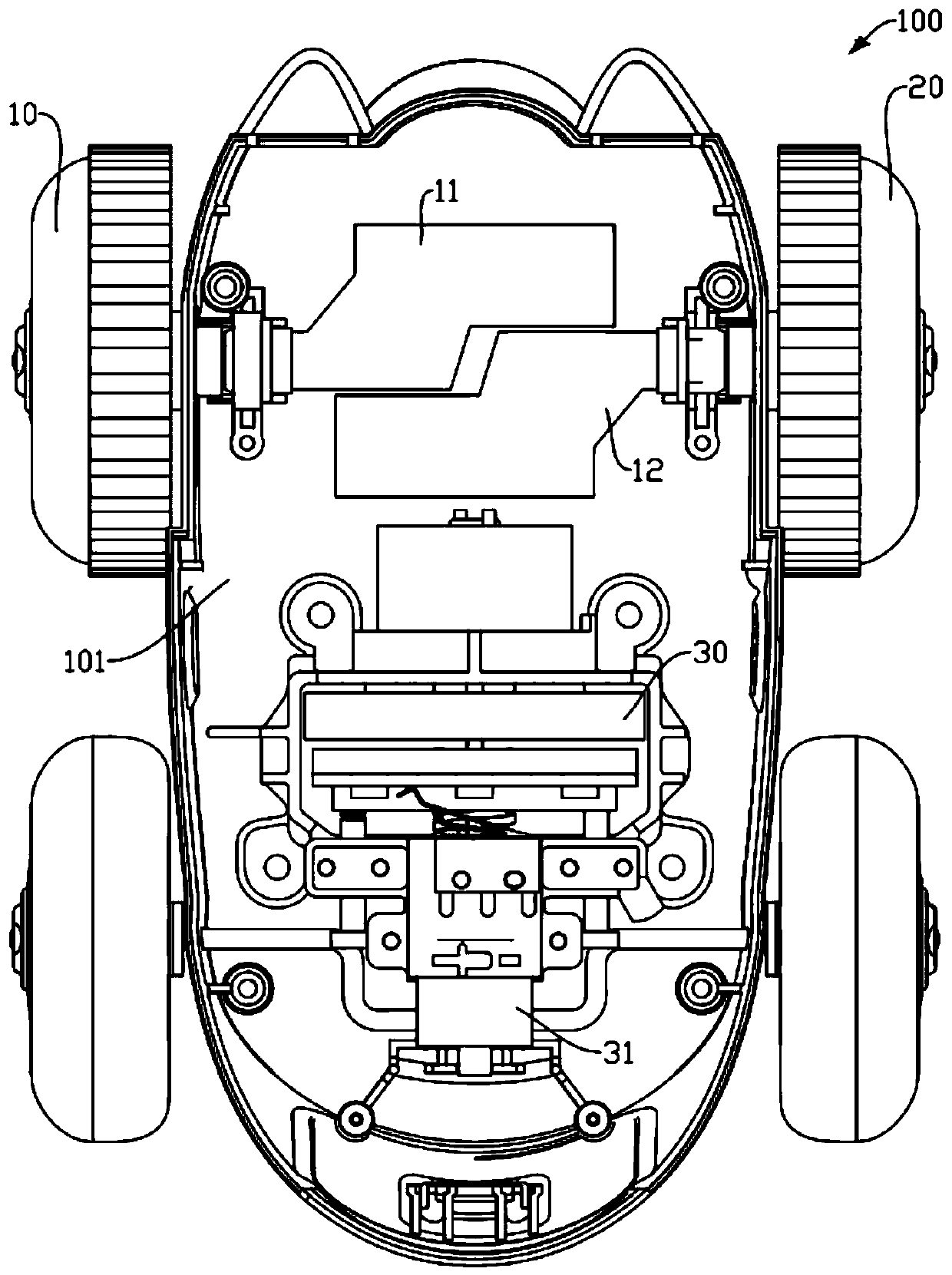

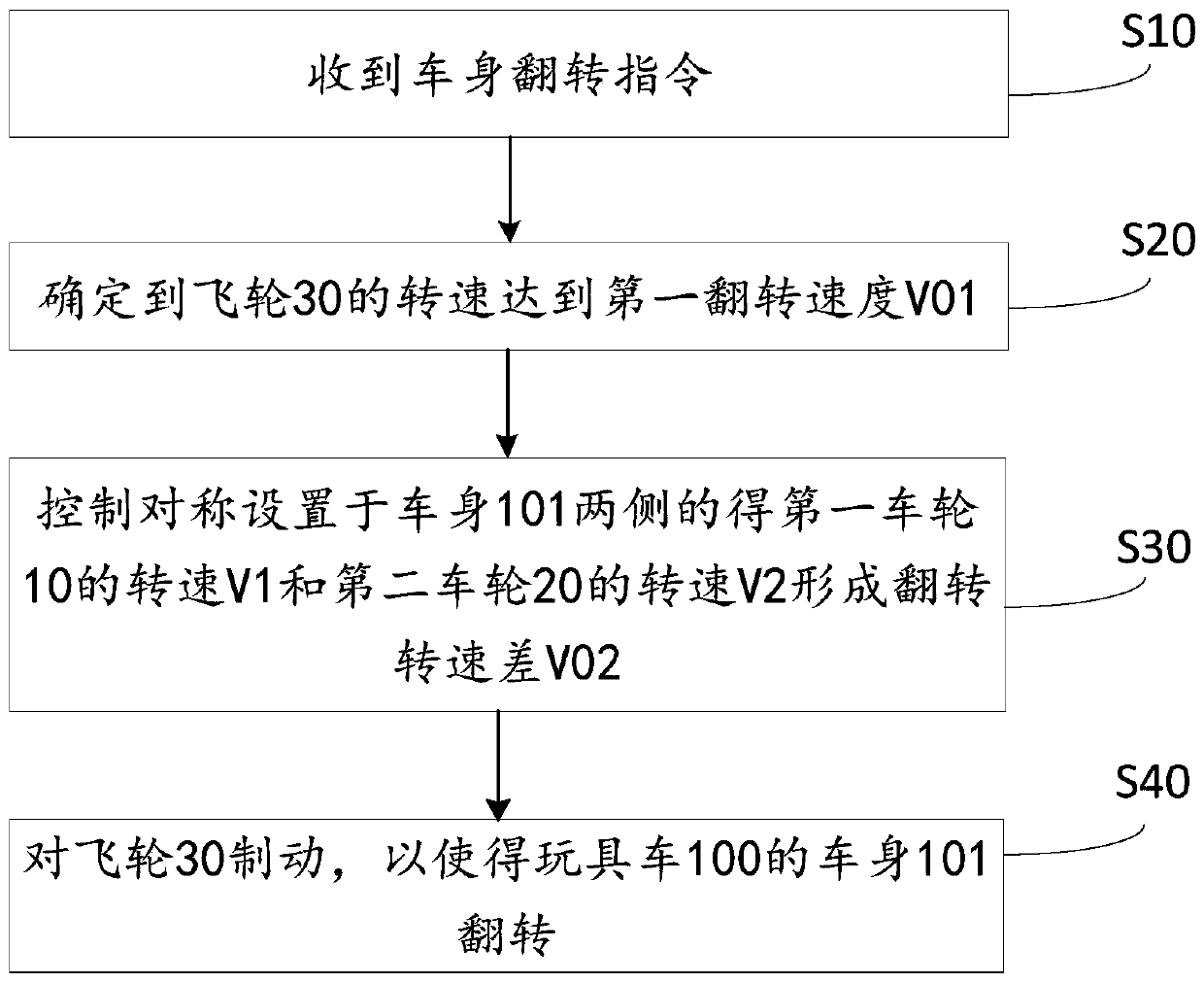

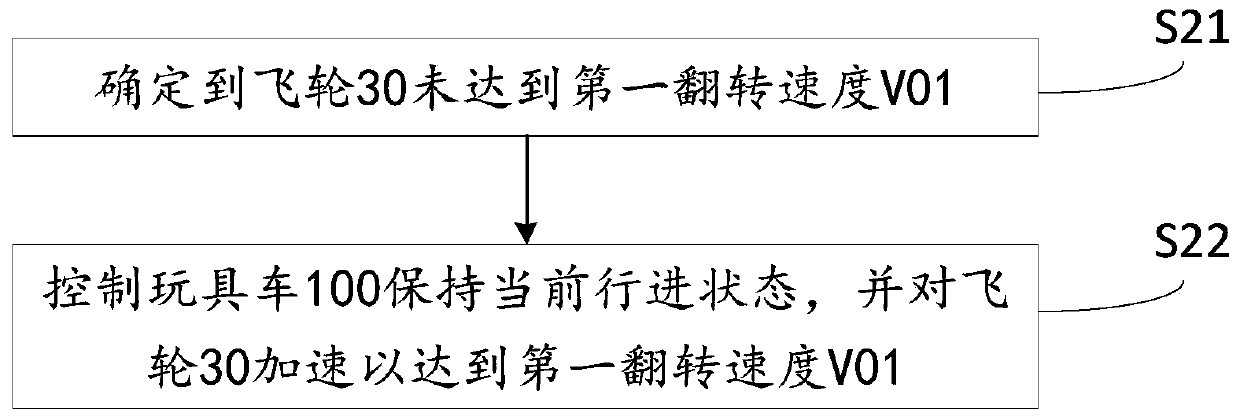

Toy car control method and toy car

A toy car (100) control method is disclosed. After the toy car (100) receives a car body overturning instruction, whether the rotating speed of a flywheel (30) reaches a first overturning speed or notis determined, and then an overturning rotating speed difference is formed between the rotating speeds of the first wheel (10) and the second wheel (20) by controlling the rotating speeds of a firstwheel (10) and a second wheel (20) which are symmetrically arranged on two sides of the car body. Finally, after the rotating speed of the flywheel (30) and the overturning rotating speed difference between the first wheel (10) and the second wheel (20) are formed, the flywheel (30) is braked so that the body (101) of the toy car (100) overturns. The toy car (100) control method can enable the body (101) of the toy car (100) to form an overturning trend under the action of inertia through the overturning speed difference between the first wheel (10) and the second wheel (20), and the overturning of the toy car (100) is formed by means of the overturning moment provided by the flywheel (30). The method can reduce the overturning moment of the flywheel (30) and reduce the power consumption and the cost of the toy car (100).

Owner:尤中乾

Quick brake equipment

ActiveCN111469819ANot easy to moveFast braking timeFoot actuated initiationsControl theoryMechanical engineering

The invention belongs to the technical field of braking, and especially relates to brake equipment. The equipment comprises a brake pedal, a pedal connecting rod, a telescopic rod, a first telescopicsleeve, a telescopic inner rod, a second telescopic sleeve, a trapezoidal guide block, a first hinge block and the like. A loop moves towards the direction of the first telescopic sleeve, and the downward movement amount of the end, located in the first telescopic sleeve, of the telescopic inner rod is larger than the upward movement amount of the end, located in the second telescopic sleeve, of the telescopic inner rod, so the following effects can be achieved: the pedal connecting rod is rapidly pressed down, the brake connecting rod can be rapidly and greatly pressed down through rapid andsmall-amplitude pressing of the pedal connecting rod, and a brake mechanism can act more quickly in an extremely short time. The emergency braking time of the quick brake mechanism is shorter than that of a traditional automobile, so the automobile can be stopped more quickly after meeting emergencies, the possibility that the automobile touches an accident after a driver suddenly steps on the brake in the emergencies is reduced, and the safety of the driver is better protected.

Owner:HANGZHOU ANNAT IND

Linkage brake mechanism for motor

ActiveCN105871116AShort braking timeOperational securityMechanical energy handlingBrake padAutomotive engineering

The invention discloses a linkage brake mechanism for a motor. The linkage brake mechanism comprises the motor, a brake disc, a first rotating shaft, a second rotating shaft, a brake rod, a brake pad, a spring, a power switch and a touch rod; the brake disc and the motor can rotate together, the brake pad is fixed to the brake rod, the brake rod can rotate around the first rotating shaft, and the brake pad touches the brake disc to brake when the brake rod rotates to a certain position; the spring is fixed to the brake rod and can guarantee that the brake rod is stressed by downward acting force; the touch rod is connected with the brake rod through the rotating shafts, and the touch rod can move up and down to drive the brake rod to rotate. In shutdown, the motor can quickly stop rotating through the brake pad. The linkage brake mechanism comprises the power switch, the brake mechanism does not work when the power switch is turned on, and the brake mechanism works when the brake mechanism is turned off, so that the motor can stop rotating in a short time. The linkage brake mechanism solves the technical problems that a motor brake mechanism is complex in structure and low in reliability.

Owner:SUZHOU KINGCLEAN PRECISION MACHINERY

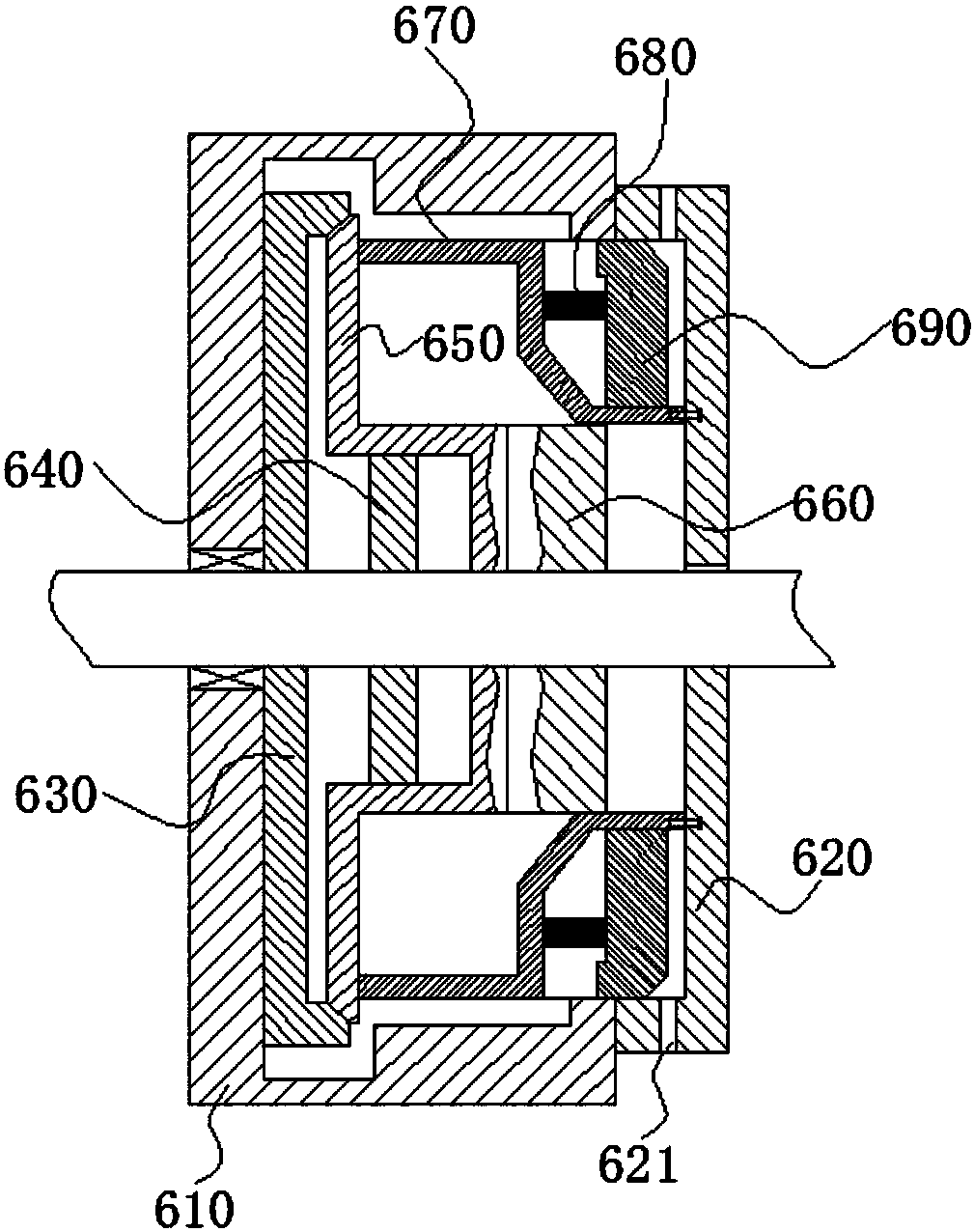

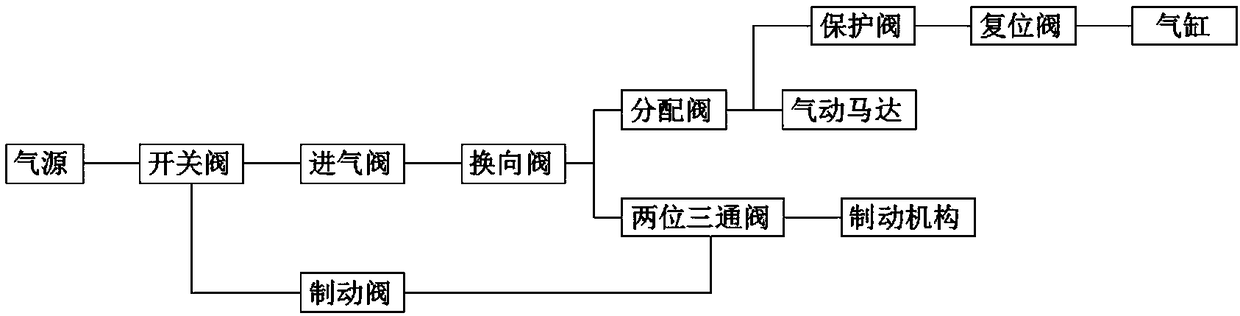

Pneumatic man-riding winch

ActiveCN108569632AReduce radial and axial dimensionsThe overall structure is compactWinding mechanismsClutchPneumatic motor

The invention provides a pneumatic man-riding winch, relates to the technical field of winch equipment and aims to solve the technical problem that a gearing-down mechanism of a pneumatic winch is notideal in design and slower in braking. The pneumatic man-riding winch comprises a pneumatic motor, a roller assembly, a gearing-down mechanism, a clutch assembly, a braking mechanism and an air distribution assembly, wherein the gearing-down mechanism is arranged in a roller and comprises a first-level planetary mechanism and a second-level planetary mechanism; the clutch assembly comprises a clutch disk connected with a second-level planetary carrier, and brakes are arranged at two ends of the clutch disk and used for braking the clutch disk and further braking the second-level planetary carrier; the brake mechanism comprises a first brake mechanism and a second brake mechanism, the first brake mechanism is arranged in the roller, and the second brake mechanism is arranged outside the roller. The pneumatic man-riding winch is reasonable in structural design and quicker in braking.

Owner:辽宁泰合实业股份有限公司

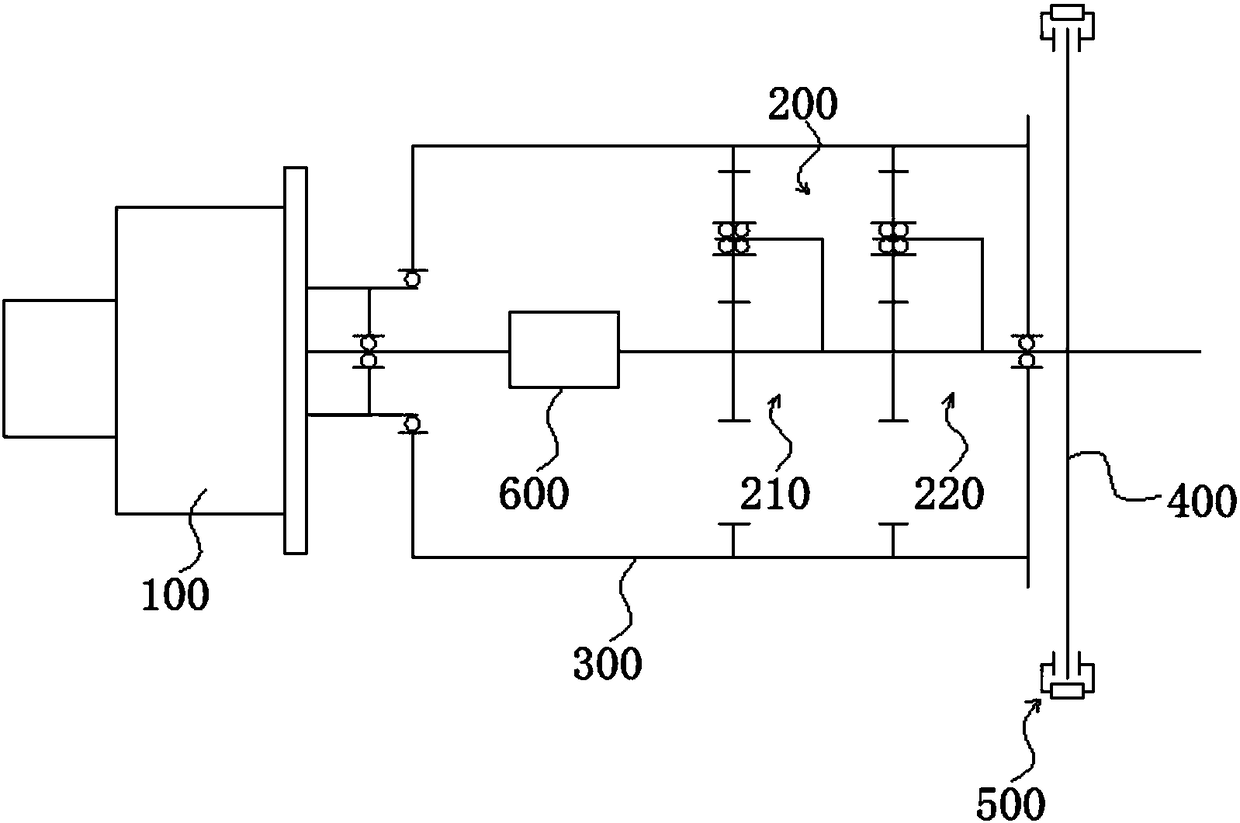

Autorotation driving device for automatic light inspection machine

InactiveCN101644662ACompact structureLow costOptically investigating flaws/contaminationTransmission beltEngineering

The invention relates to an autorotation driving device for an automatic light inspection machine. The autorotation driving device comprises a driving belt wheel, an autorotation driving mechanism, upper transmission belts, lower transmission belts and two transmission belt wheel groups with different heights, wherein the driving belt wheel is connected with the output end of the autorotation driving mechanism, each transmission belt wheel group comprises a pair of transmission belt wheels with equal height, the upper transmission belts are winded on the upper part of the driving belt wheel and on one transmission belt wheel group, and the lower transmission belts are winded on the lower part of the driving belt wheel and on the other transmission belt wheel group. The invention is the autorotation driving device for the automatic light inspection machine which has the advantages of simple and compact structure, low cost and high stability and can increase the inspection accuracy of animage acquisition device.

Owner:TRUKING TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com