Linkage brake mechanism for motor

A technology of braking mechanism and motor starting, applied in the field of motor braking system, can solve the problems of reducing the stability and reliability of the braking mechanism, increasing the complexity and cost of the equipment, and the complex braking linkage mechanism, and achieving short braking time, less damage, and better overall performance. The effect of long machine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

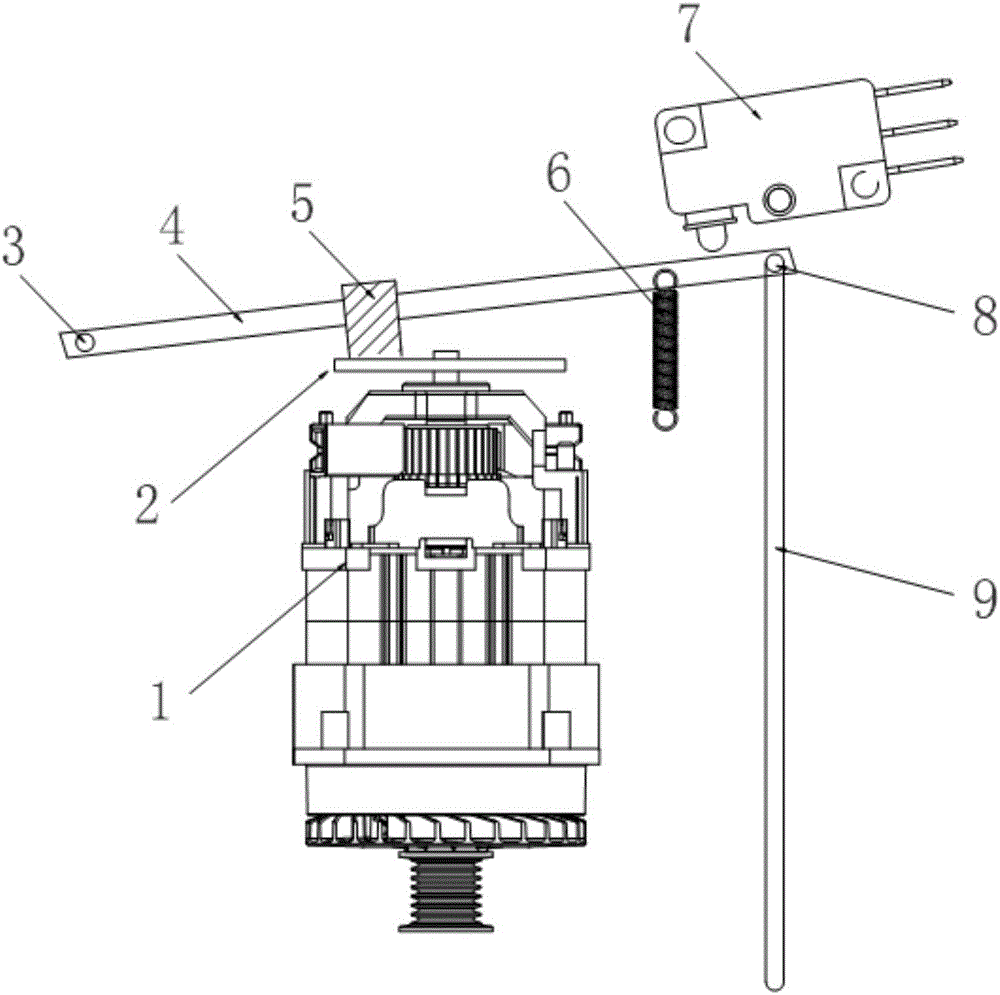

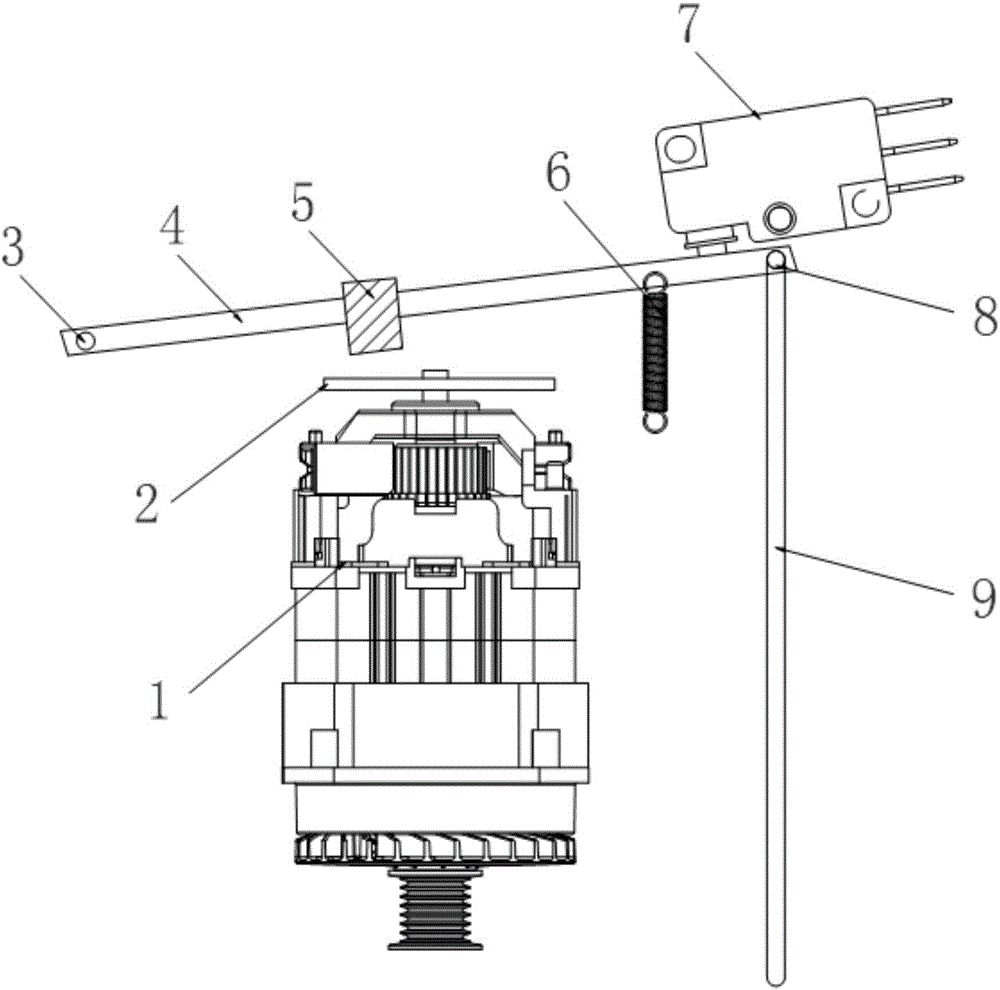

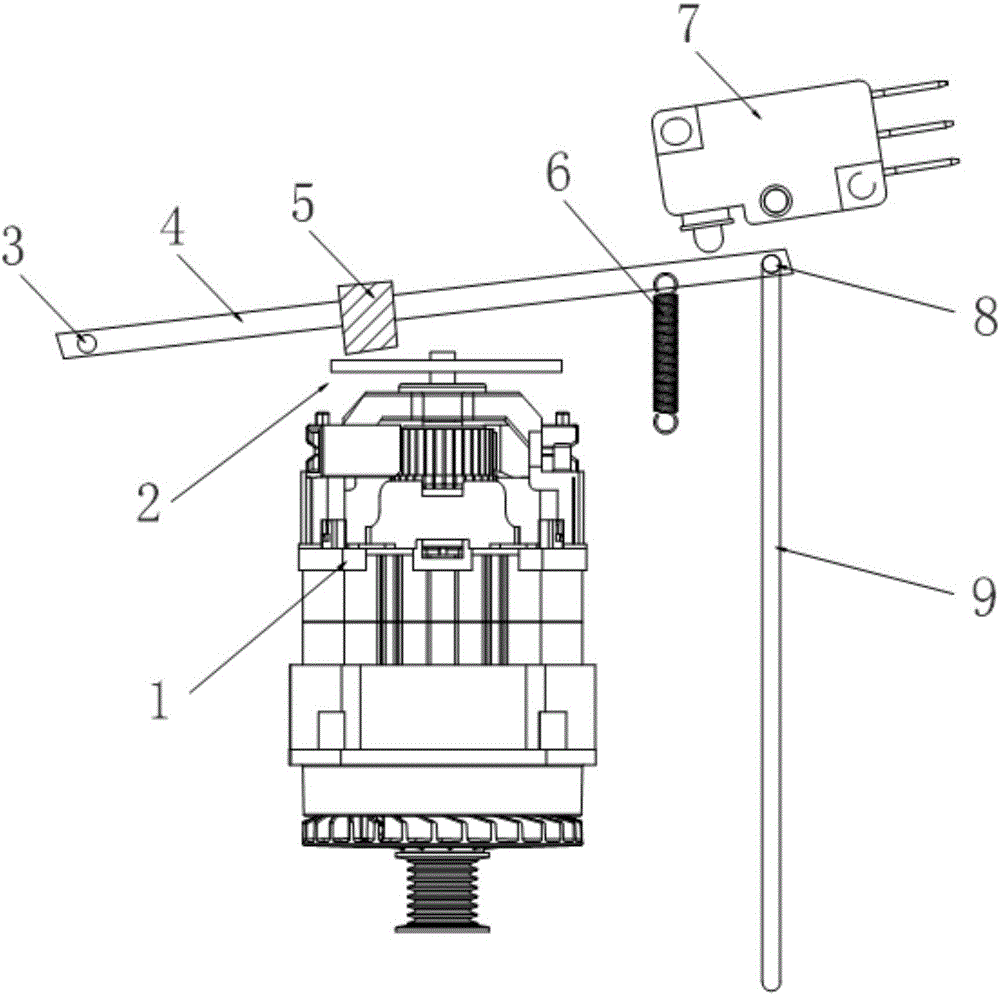

[0028] Such as Figure 1-4 As shown, the present invention provides a motor linkage braking mechanism, including: a motor 1, a brake disc 2, a first rotating shaft 3, a brake lever 4, a brake pad 5, a spring 6, a power switch 7, a second rotating shaft 8, and a trigger lever 9. The brake disc 2 is fixed on the motor 1 and rotates together with the motor 1; the brake pad 5 is fixed on the brake lever 4, and the brake lever 4 rotates around the rotating shaft 3, and when it rotates to a certain position, the brake pad 5 contacts the brake disc 2 to realize braking; the spring 6 It is fixed on the brake lever 4 to ensure that the brake lever 4 is subjected to a downward force; the trigger lever 9 is connected to the brake lever 4 through the rotating shaft 8, and the up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com