Inner curvilinear low-speed large-torque water hydraulic motor with replaceable wearproof dish

A low-speed, high-torque, wear-resistant disc technology, applied in the hydraulic field, can solve problems such as poor lubrication performance, high vaporization pressure, and low water viscosity, and achieve the effects of low contact stress, high startup efficiency, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

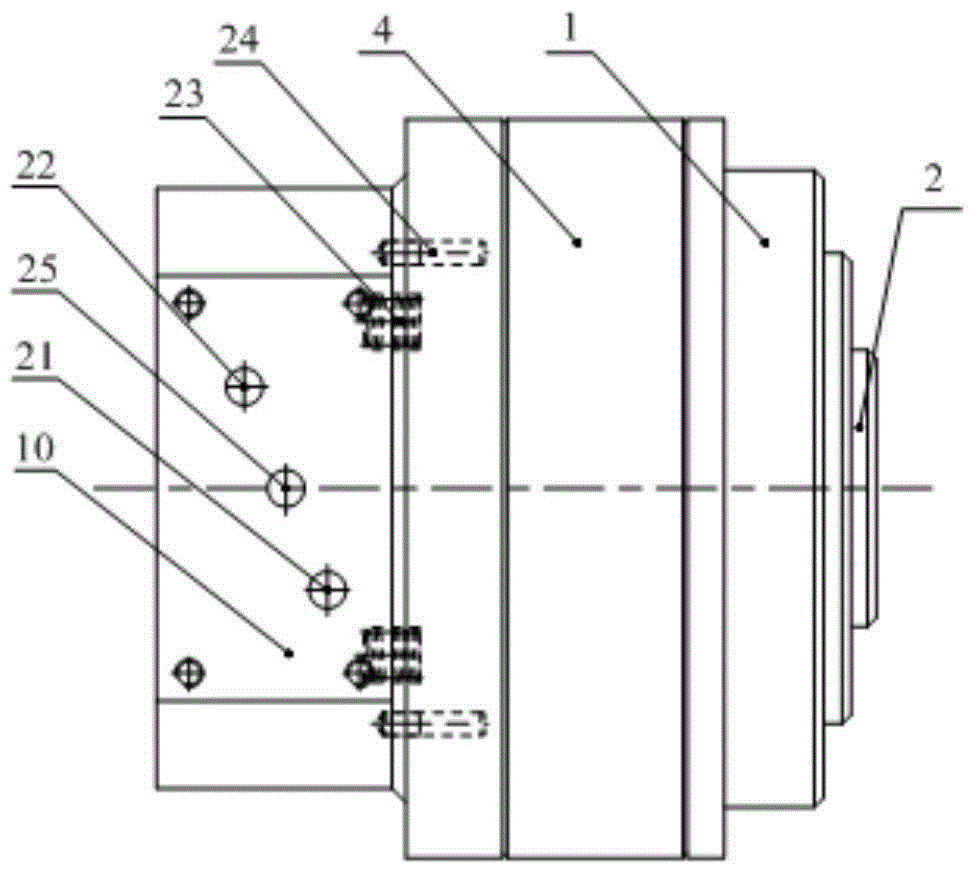

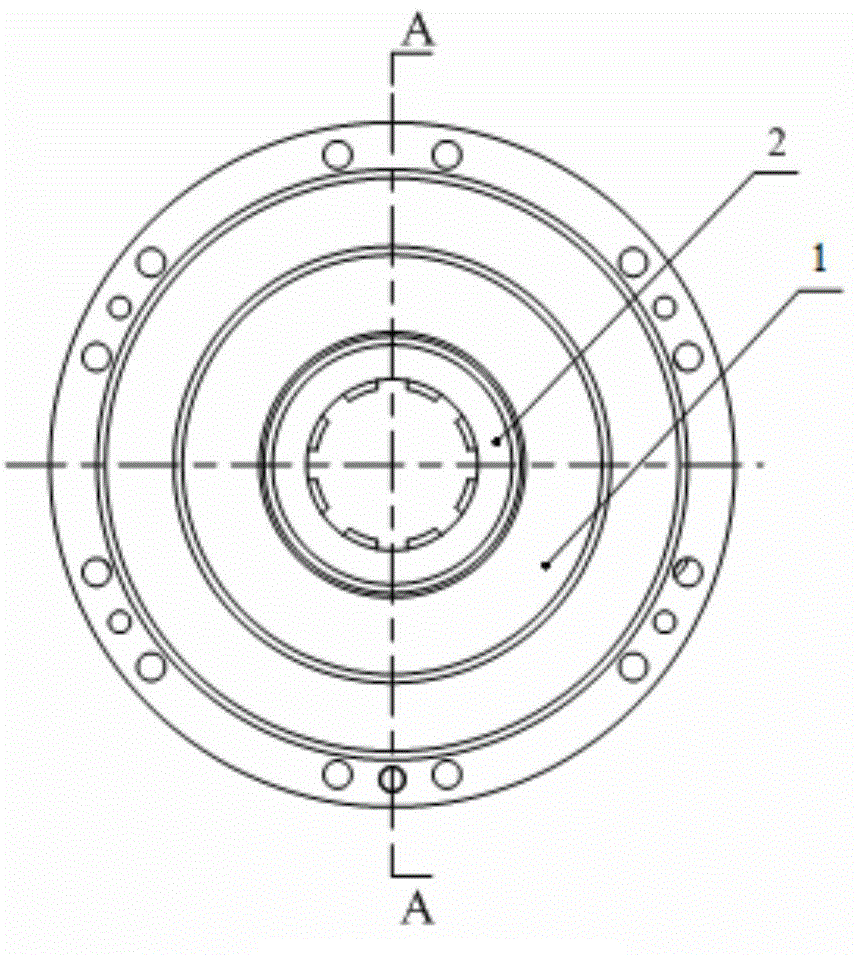

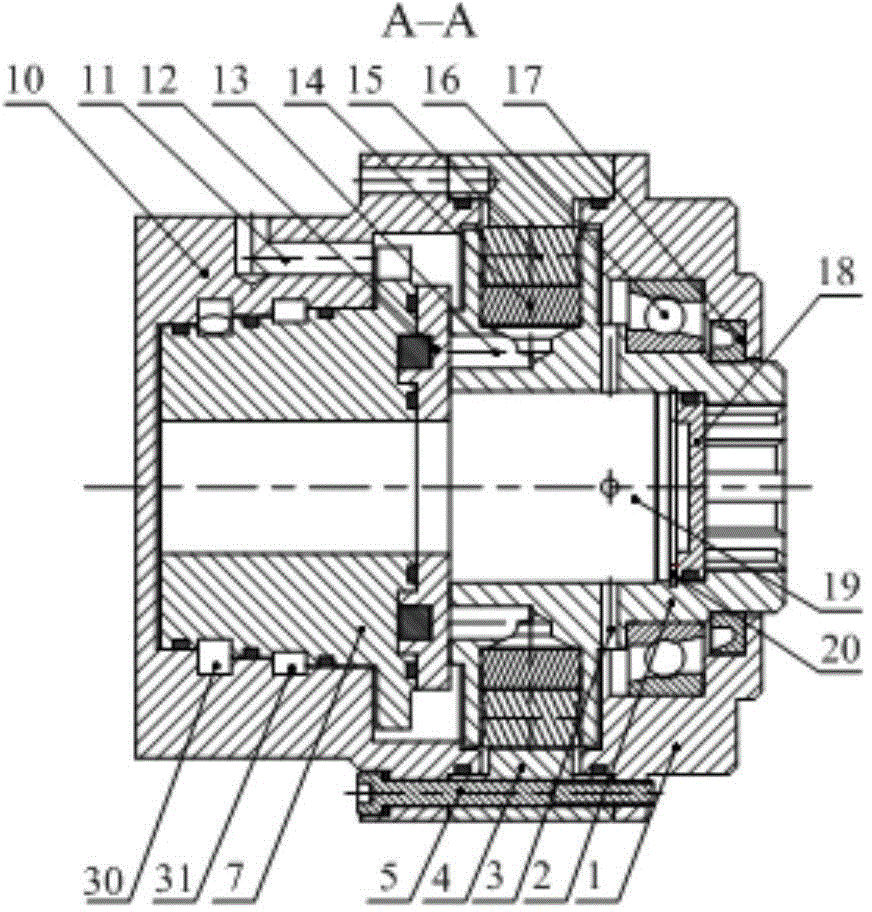

[0040] Such as figure 1 , 2 , 3, 4 and 14, the inner curve type low-speed high-torque water hydraulic motor with replaceable wear discs includes front cover 1, rotor 2, stator 4, replaceable wear discs 12, rear end cover 10, Distribution fluid 7, rolling element 15, plunger 14, bearing 16, lip seal 17 and combined spring 23; n combined springs 23 are evenly distributed in the spring blind hole 28 corresponding to the rear end cover 10; n≥4, And it is an even number; the distribution fluid 7 is installed in the center hole of the rear end cover 10, and pressed on the combined spring 23; the replaceable wear-resistant disc 12 is installed on the end face of the distribution fluid 7, and the rotor 2 is pressed on the replaceable wear-resistant disc The end face of 12; the replaceable wear-resistant disc 12 and the rotor 2 adopt end face matching, which s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com