Method for upwind starting of permanent magnet brushless direct-current motor

A technology of permanent magnet brushless DC and DC bus voltage, which is applied to the starter of a single DC motor, the deceleration device of an AC motor, the motor generator/starter, etc., and can solve the problems of reducing motor life, starting failure, motor wear, etc. problem, to achieve the effect of improving the success rate, good effect and fast braking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the present invention is described in further detail, and following example is only for illustrating the present invention, but is not used for limiting the scope of the present invention.

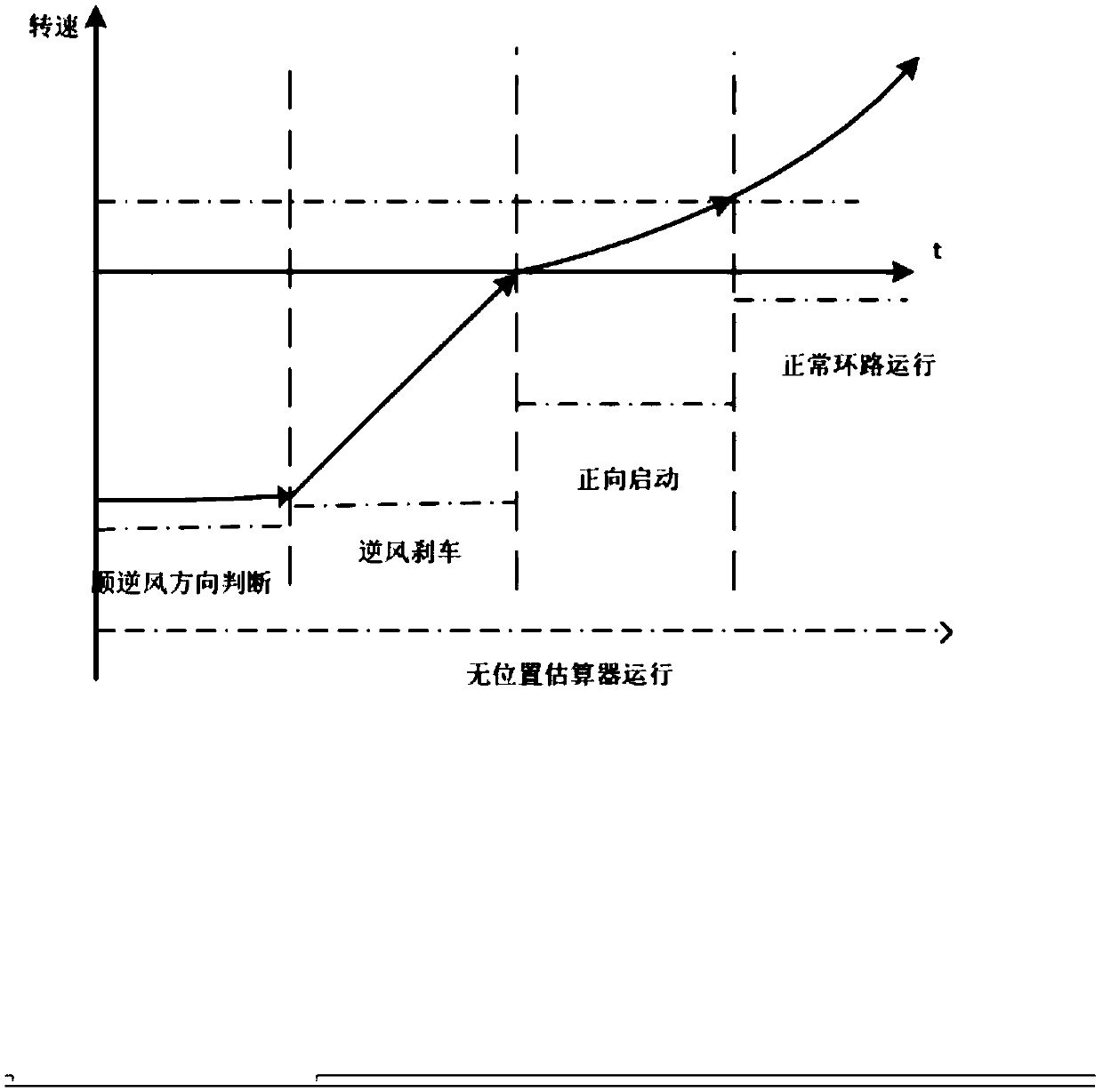

[0015] see figure 1 : Step 1: Using a phase-locked loop (PLL) estimation algorithm to quickly follow the state of the motor. Estimate the current motor speed by setting the current to 0, which will not bring braking effect to the motor. Because the PLL estimation and follow-up effect is good, if the motor is rotating, the speed and direction of the motor can be judged in one or two electrical cycles, which largely avoids the rise of the bus voltage. If the voltage rises significantly, the output can be properly turned off.

[0016] This method solves the problem that a hardware circuit is required to detect the back electromotive force of the motor, and the problem of judging the direction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com