Fall prevention brake device of inclined shaft transportation car

A transport trolley and braking device technology, which is applied in the directions of transportation and packaging, railway braking systems, brakes where braking elements interact with rails, etc. Solve the problems of hoist risks, and achieve the effect of safety protection, timely braking, and prevention of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

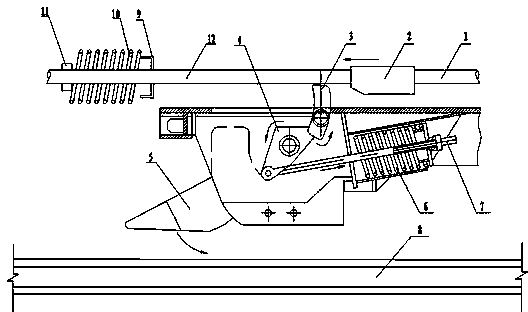

[0019] Such as figure 1 As shown, the anti-fall braking device for transport trolley of the present invention includes: main pull rod, iron striker 2, claw 3, support block 4, holding claw 5, brake spring 6, guide rod 7, baffle channel steel 9, actuating The spring 10; the striker 2 is installed on the main pull rod, and is connected by a pin shaft, which is divided into a front pull rod 1 and a rear pull rod 12, and one end of the rear pull rod passes through the baffle channel steel 9 and the actuating spring 11 to connect with the fastening nut, There is a fastening nut 11 at one end of the non-baffle channel steel of the actuating spring, and the fastening nut is fixed on the end of the rear pull rod. Adjusting the position of the fastening nut can control the elastic force of the actuating spring, thereby adjusting the reaction time of the braking device. The claw 3 is connected with the support block 4, the support block 4 is hinged with the guide rod 7, the brake spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com