Looseness-proof fastening structure of counterweight bolts of large excavator and fastening method thereof

An excavator, anti-slack technology, applied in the direction of threaded fasteners, bolts, locking fasteners, etc., can solve problems affecting product reliability, difficult disassembly and maintenance, and easy loose connections, etc., to achieve easy implementation and assembly High efficiency and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

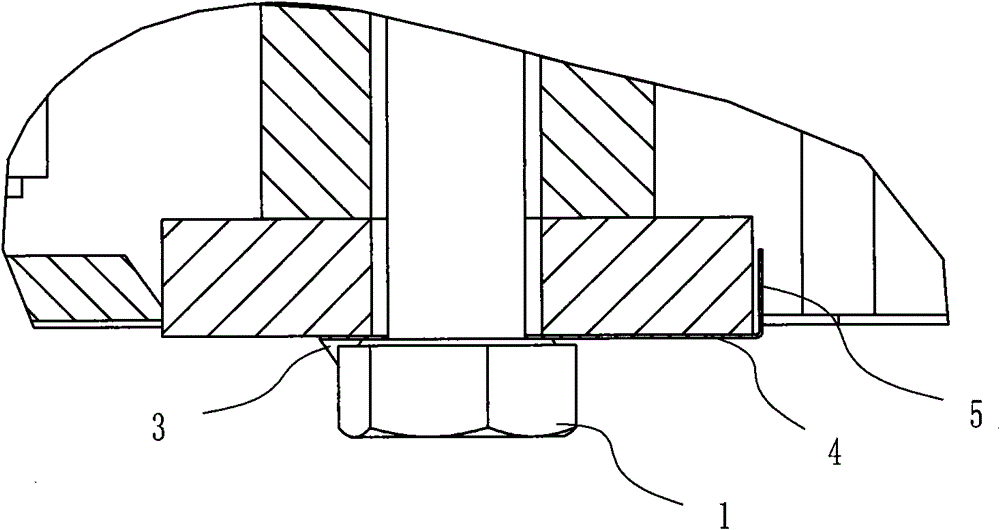

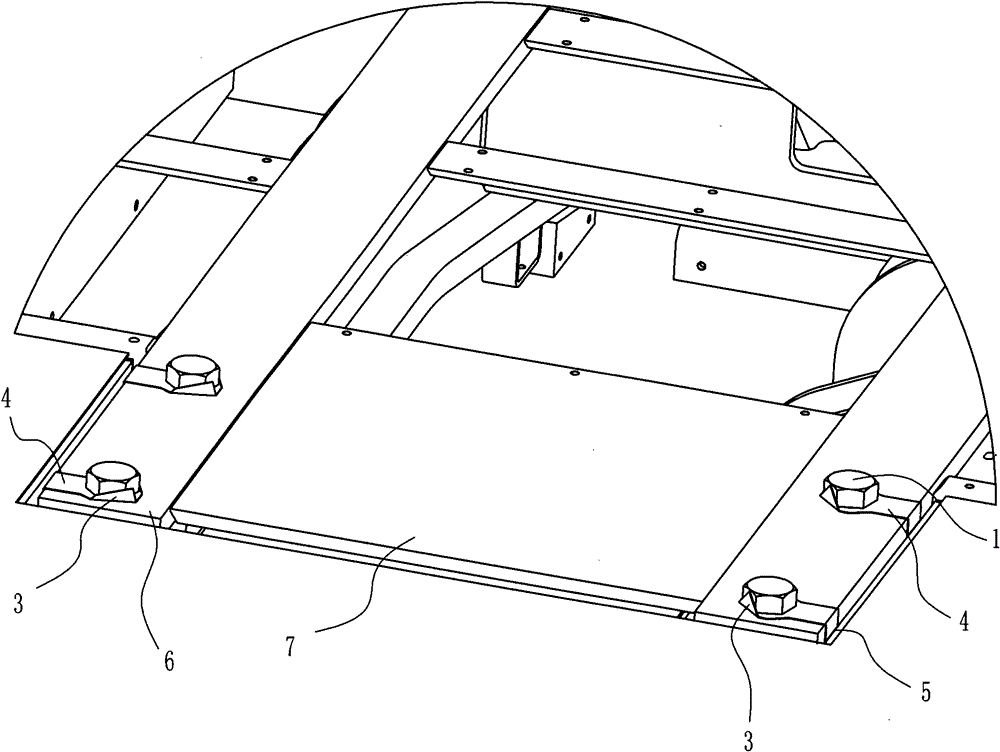

[0020] Embodiment one: see Figure 1~2 As shown, a large-scale excavator counterweight bolt anti-loosening fastening structure includes a counterweight bolt 1 and a gasket, and the gasket consists of an annular body and side wings 3 arranged on both sides of the annular body, and the 3 The extension piece 4 provided on the other side, the side wing 3 is wrapped on the hexagonal surface of the head of the weight bolt, the extension piece 4 is arranged parallel to the excavator platform assembly 6, and the end of the extension piece is provided with a flip The side 5 is wrapped on the outer edge of the excavator platform assembly 6, and the excavator platform assembly 6 and the counterweight assembly 7 are connected through the counterweight bolt 1;

[0021] Its fastening method steps include:

[0022] (1) The counterweight bolt passes through the ring body on the gasket, so that the extension piece 4 on one side of the ring body is parallel to the excavator platform assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com