A kind of hybrid fiber elastic fabric composite material bulletproof insert and preparation method thereof

A technology of mixed fibers and elastic fabrics, applied in protective equipment, chemical instruments and methods, offensive equipment, etc., can solve the problems of affecting the protection level of bulletproof plate products, large back bullet surface, poor mechanical properties in high temperature environment, etc., to achieve High-efficiency production, reduced delamination, and short molding process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

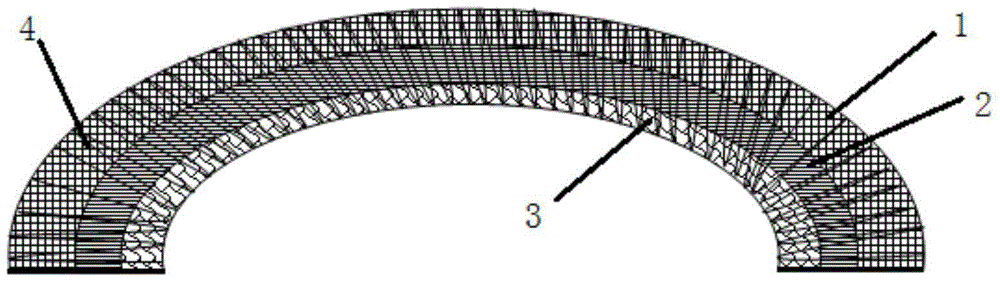

[0036] Preparation of the elastic fabric layer 1 of the hybrid fiber facing elastic fabric: UHMWPE fiber is used as the main fiber, and the ratio of UHMWPE fiber is 50%; aramid fiber is mixed with UHMWPE fiber, and the ratio of aramid fiber is 50%. The above-mentioned hybrid fibers are two-dimensionally woven with a plain weave structure, and the two-dimensional braids are arranged in a stacked manner, and the stacked thickness is 7 mm.

[0037] Preparation of mixed fiber intermediate elastic fabric layer 2: UHMWPE fiber is used as the basic material, and its ratio is 70%, mixed with aramid fiber, and the mixed ratio is 30%, and the middle elastic fabric layer is prepared by unidirectional fiber lamination. The fibers are multi-axially arranged at 0°, ±45° and 90°, and the laminate thickness is 6mm.

[0038] The preparation of the elastic fabric layer 3 of the hybrid fiber back elastic surface: UHMWPE fiber is used as the main fiber, and the carbon fiber is used as the hybrid ...

Embodiment 2

[0043] Preparation of the elastic fabric layer 1 of the hybrid fiber facing surface: UHMWPE fiber is used as the main fiber, and the proportion of UHMWPE fiber is 60%; basalt fiber is mixed with UHMWPE fiber, and the proportion of basalt fiber is 40%. The above-mentioned hybrid fibers are two-dimensionally woven with a twill structure, and the two-dimensional braids are arranged in a stacked manner, and the stacked thickness is 6 mm.

[0044] Preparation of hybrid fiber intermediate elastic fabric layer 2: UHMWPE fiber is used as the material, and the intermediate elastic fabric layer is prepared by stacking unidirectional fibers. The unidirectional fibers are arranged orthogonally at 0° and 90°, and the thickness of the stack is 8mm .

[0045] Preparation of hybrid fiber back elastic fabric layer 3: UHMWPE fiber is used as the main fiber and carbon fiber is used as hybrid fiber to prepare the three-dimensional elastic fabric layer on the back elastic surface, wherein the amou...

Embodiment 3

[0050] The preparation of the elastic fabric layer 1 of the mixed fiber facing surface: UHMWPE fiber is used as the main fiber, and the ratio of UHMWPE fiber is 55%; aramid fiber and basalt fiber are mixed with UHMWPE fiber, and the ratio between aramid fiber and basalt fiber is 1: 1. The total dosage of the two is 45%. The above-mentioned hybrid fibers are two-dimensionally woven with a plain weave structure and a twill weave structure. The ratio of the two fabric structures is 1:1. The two-dimensional braids are arranged in a laminated manner, and the laminated thickness is 4mm.

[0051] The preparation of the middle elastic fabric layer 2 of hybrid fiber: UHMWPE fiber is used as the basic material, and its ratio is 75%, mixed with aramid fiber and PBO fiber, the ratio of the two is 1:1, and the overall ratio of hybrid fiber is 25%. The middle elastic fabric layer is prepared by laminating the fibers. The unidirectional fibers are arranged in multiple directions at 0°, ±30°,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com