Pressurizing device and method of unpressurized oil cylinder

A booster device and booster oil cylinder technology, which is applied in fluid pressure actuators, accumulator devices, and fluid pressure actuation system tests, can solve the problem that the booster pressure build-up time is greatly affected and the pressure build-up time is insufficient To meet the problems of satisfaction and delayed pressure build-up time, etc., to achieve the effect of novel design, fast pressure build-up, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

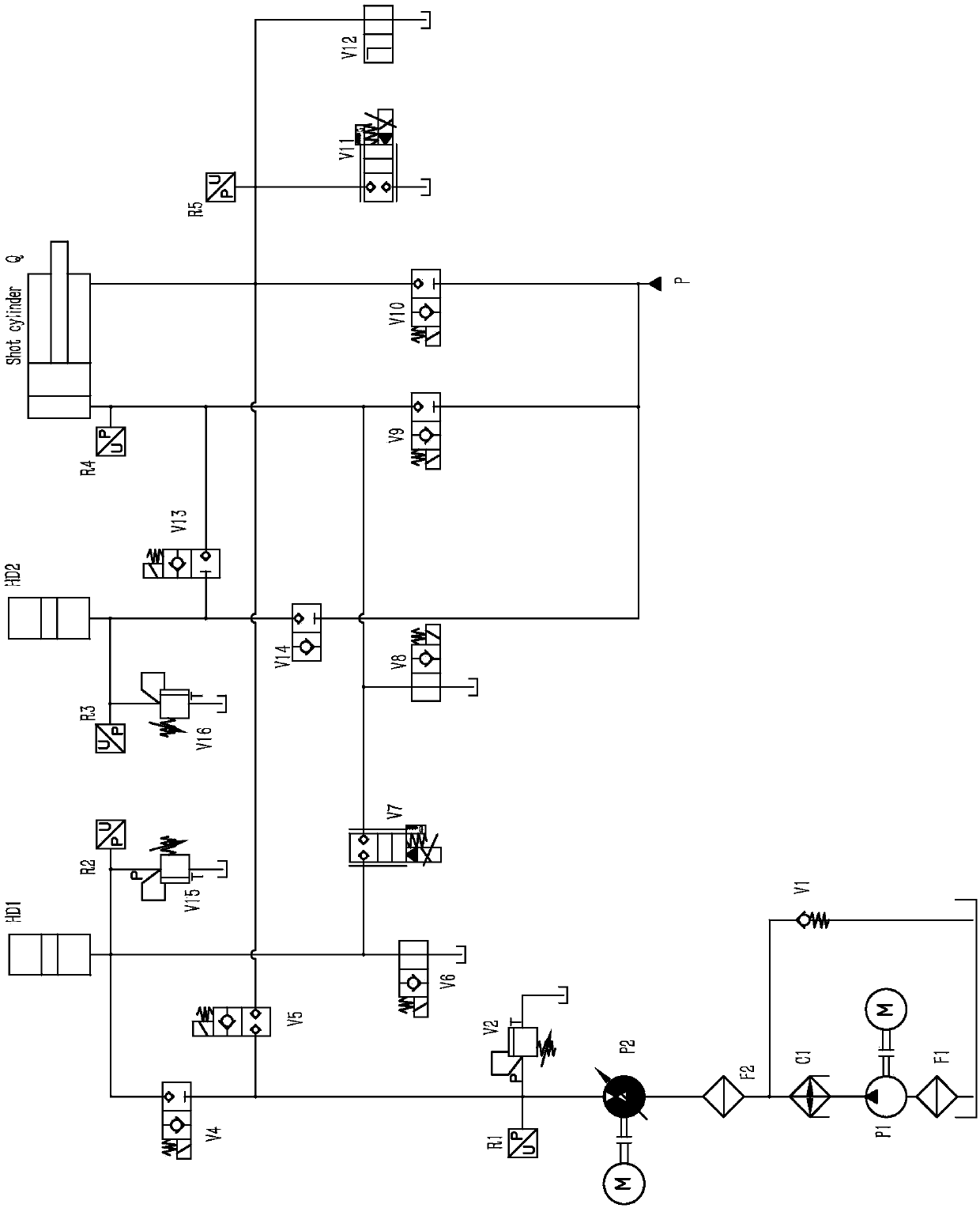

[0030] Such as figure 1 As shown, a booster device without a booster cylinder, including injection cylinder (Q), hammer front valve (V9), hammer rear valve (V10), low-pressure pump set (P1), high-pressure variable pump set (P2), HD1 energy storage valve (V4), high-pressure accumulator (HD1) and fast accumulator (HD2); the front end of the injection cylinder (Q) is provided with a hammer front valve (V9), and the hammer front valve (V9 ) is connected with a fast accumulator (HD2), the rear end of the injection cylinder (Q) is provided with a hammer rear valve (V10), and the hammer rear valve (V10) is connected with a P-end oil supply port, and the P The end oil supply port is connected to the fast accumulator (HD2); the low-pressure pump group (P1) is connected to the high-pressure variable pump group (P2), and the high-pressure variable pump group (P2) is connected to the HD1 energy storage valve (V4 ), the HD1 accumulator valve (V4) is connected with a high pressure accumula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com