Patents

Literature

53results about How to "Short build-up time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

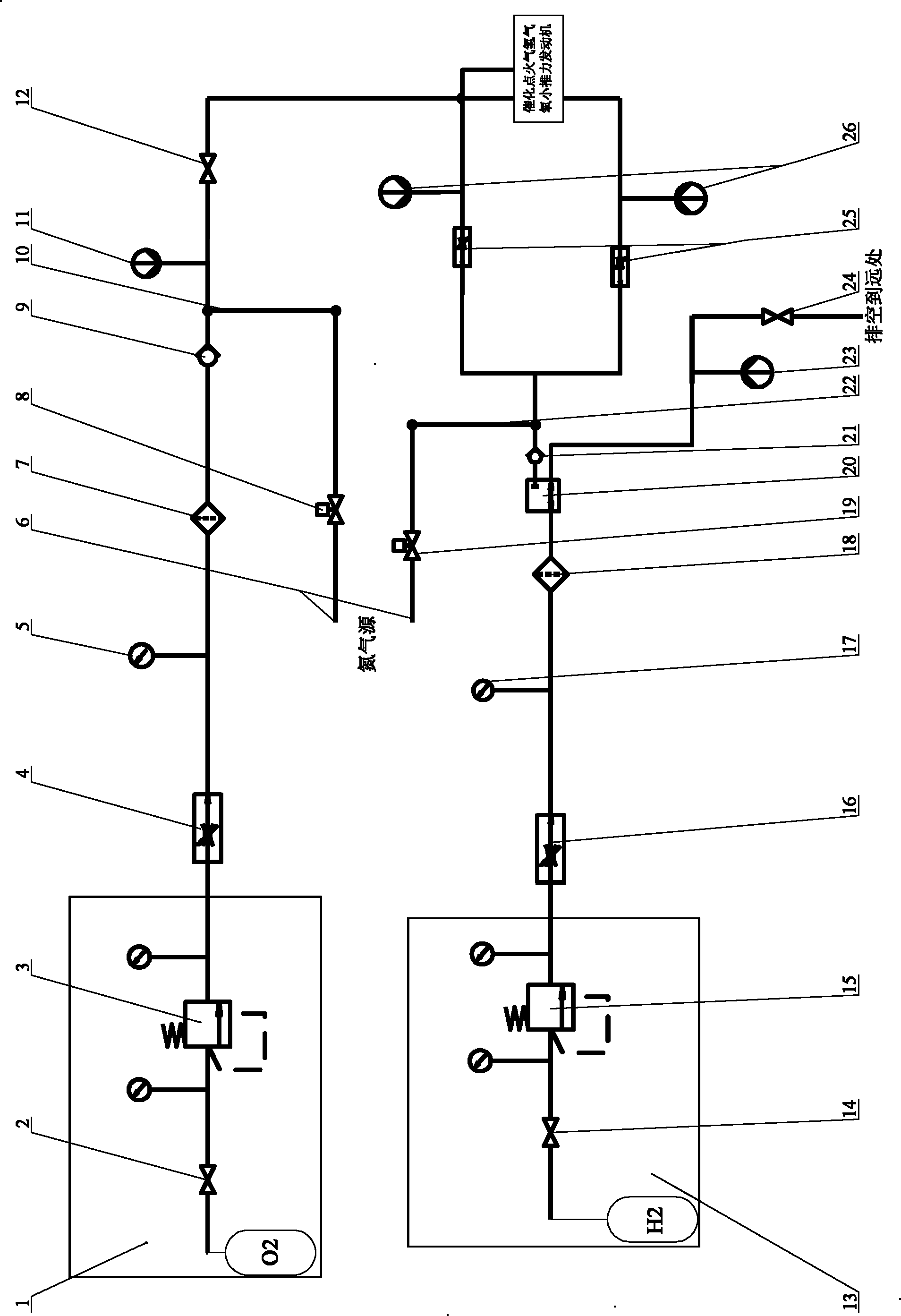

Propelling agent supply system for catalytic ignition hydrogen oxygen small-sized rocket thruster test

The invention discloses a propelling agent supply system for a catalytic ignition hydrogen oxygen small-sized rocket thruster test. The propelling agent supply system comprises an air bottle assembly, a flow controller, a solenoid valve, a check valve, a pressure gauge and a connecting device. A fuel hydrogen (H2) pipeline system consists of a test pipeline and an emptying pipeline, wherein the emptying pipeline is used for coarsely adjusting H2 flow and pressure required by the upstream of a catalytic ignition hydrogen oxygen small thrust engine before the test starts, so that the time of coarsely adjusting H2 flow and pressure intensity and the time of H2 passing through the pipeline in the test process can be shortened by the emptying pipeline to the maximum degree.

Owner:BEIHANG UNIV

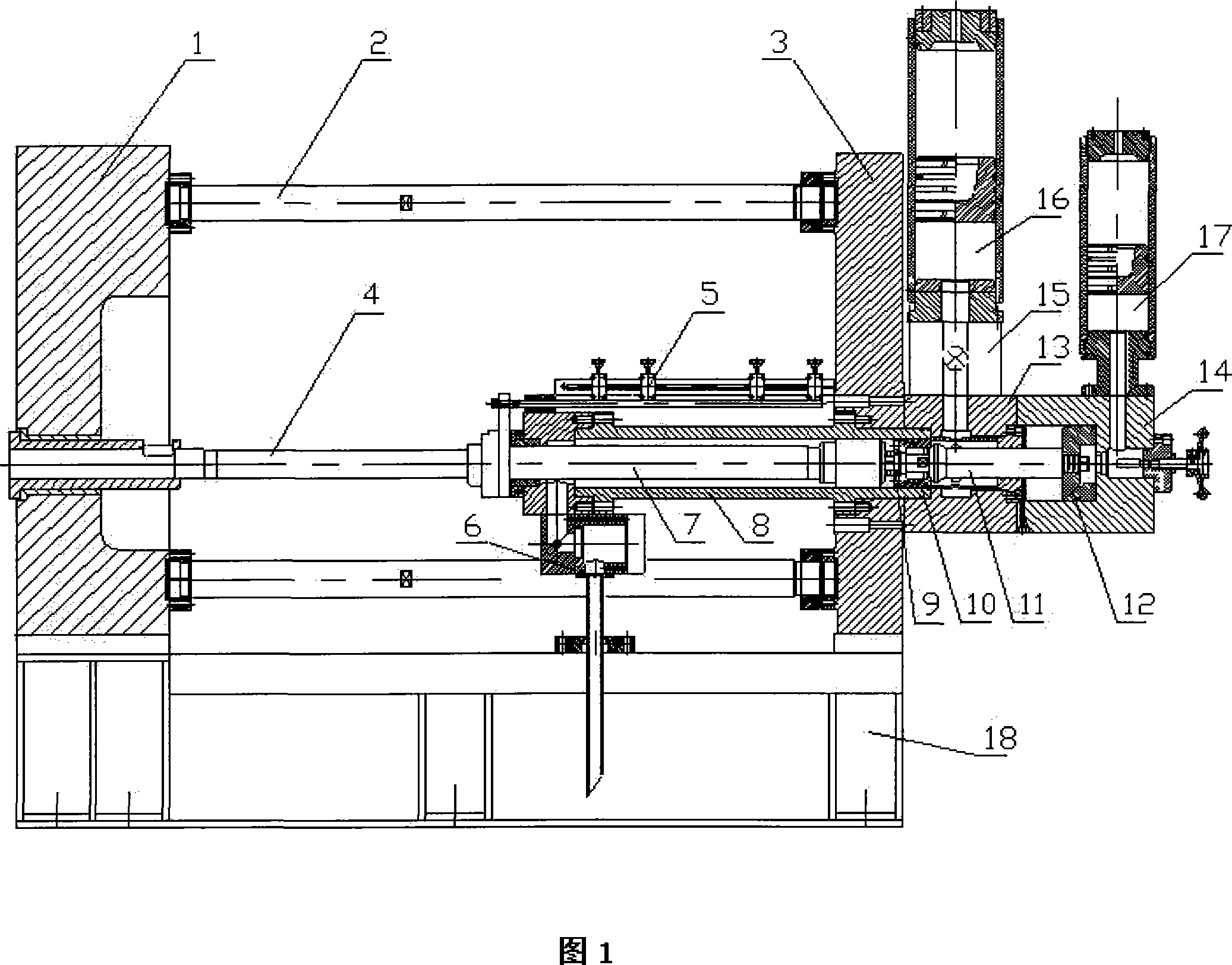

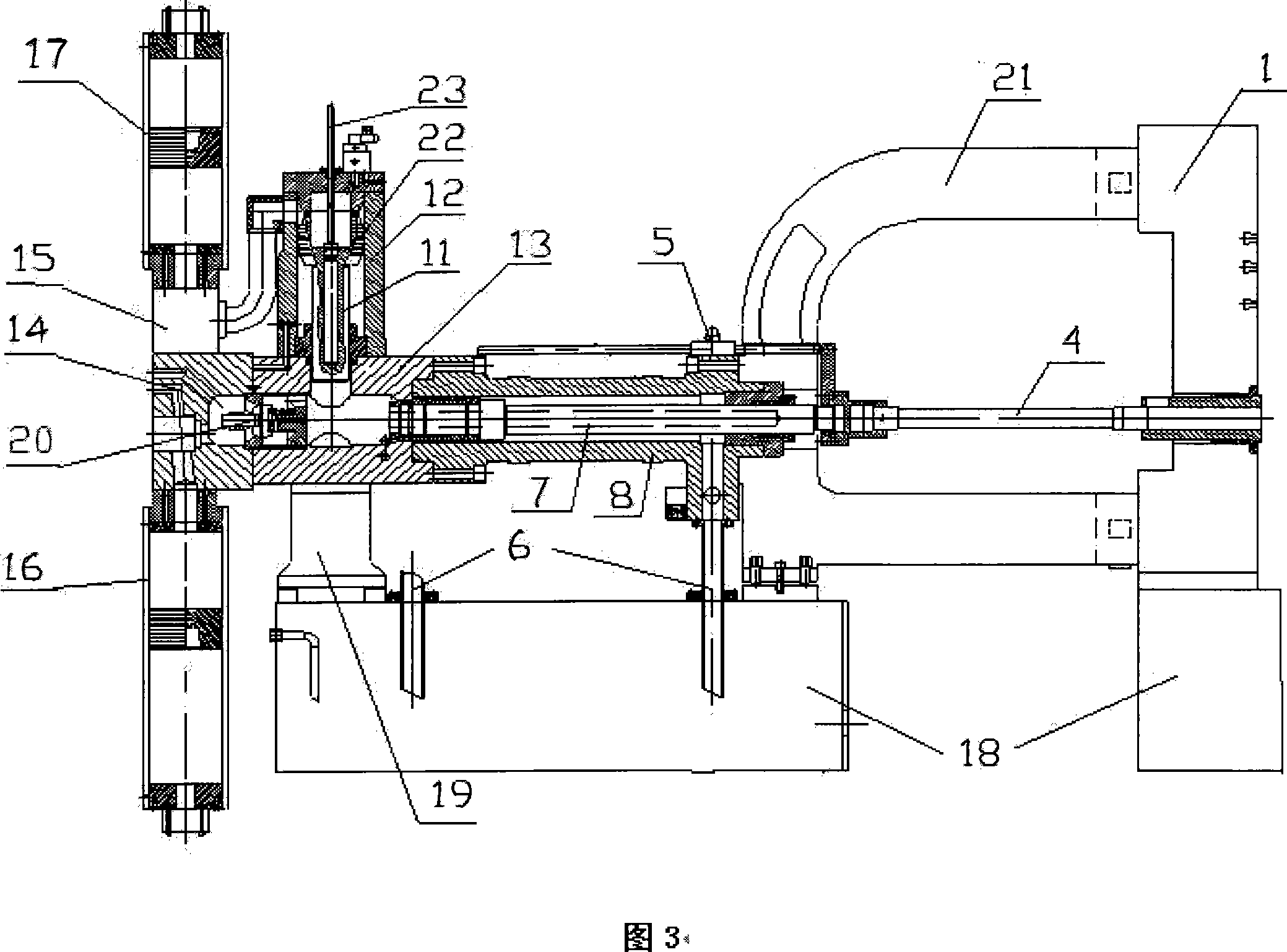

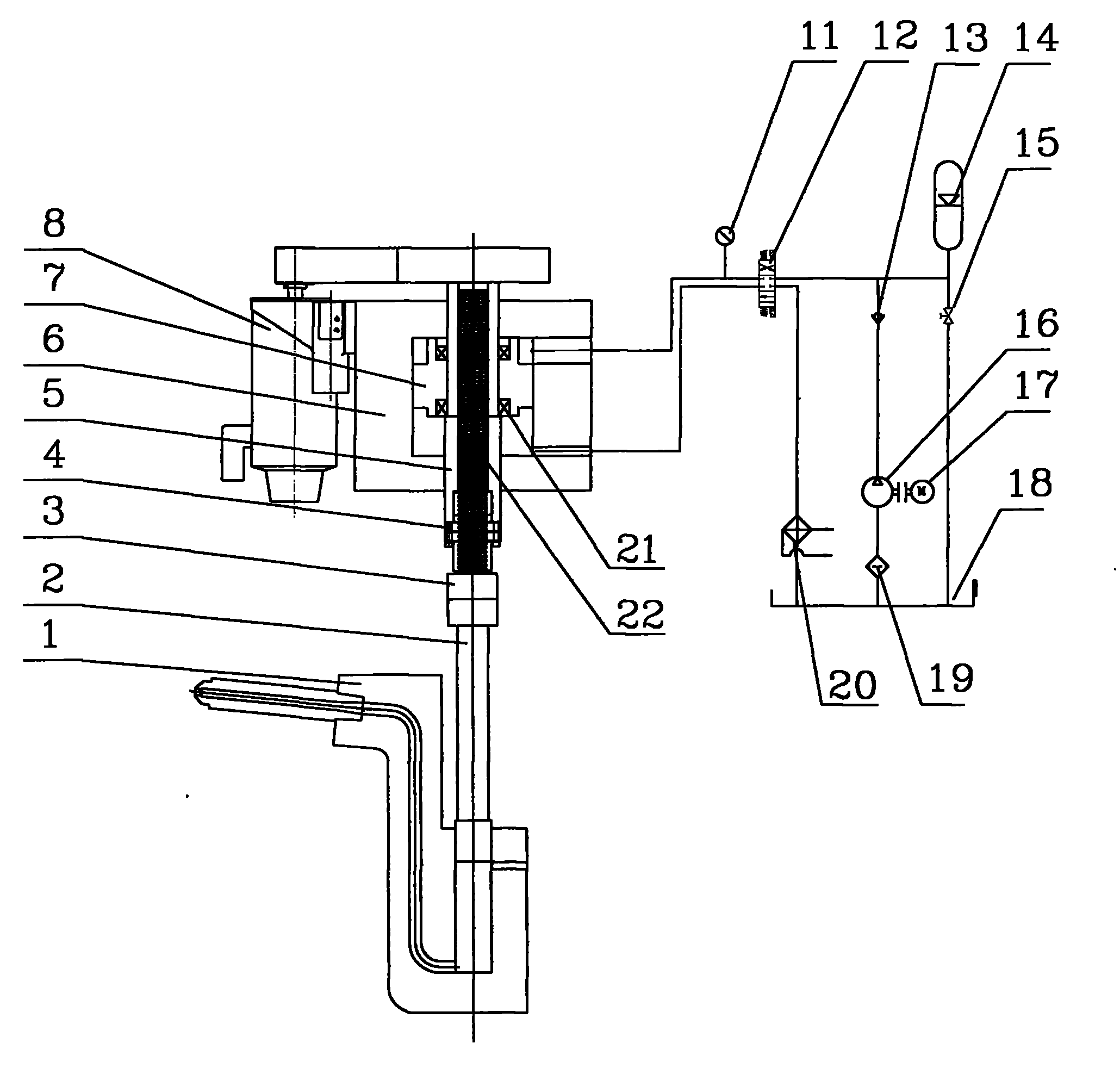

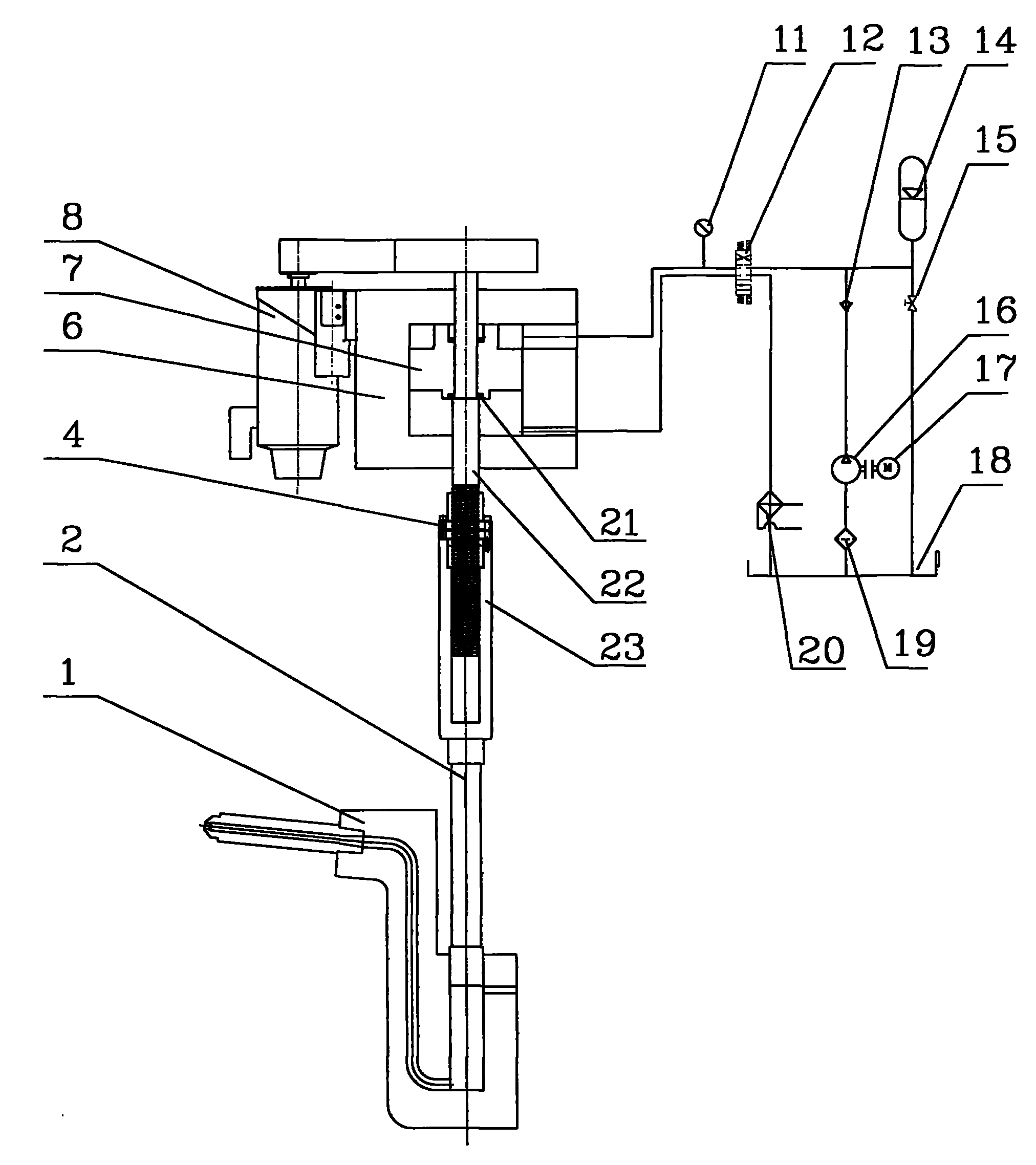

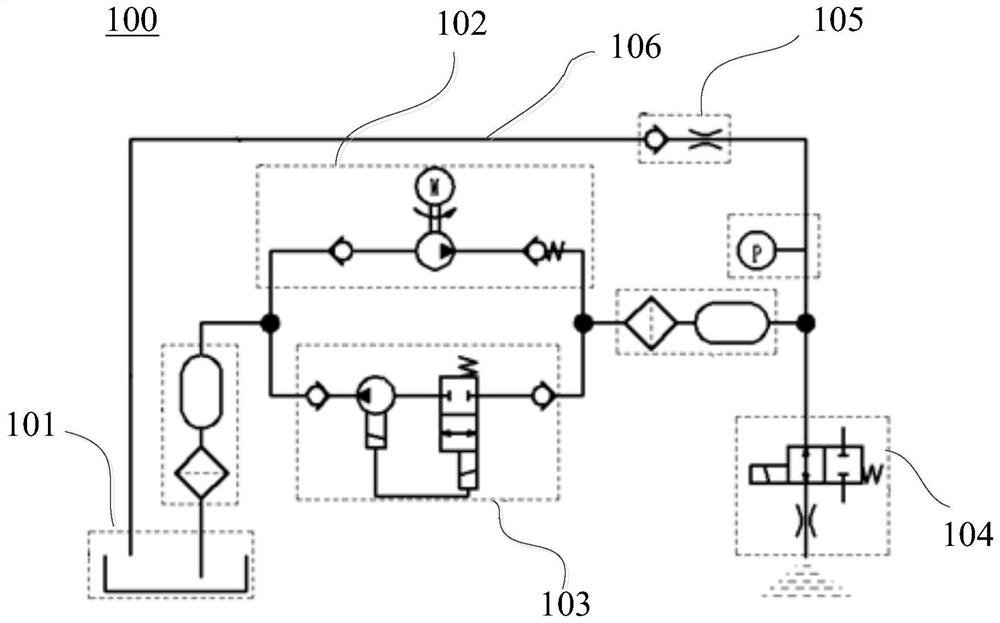

Vertical pressure charging press-shoot system

The invention provides a vertical pressure charging pressing system capable of enhancing pressing property, stability and safety of a die casting machine by using a structure with a pressure charging oil cylinder perpendicular to an injection oil cylinder. The slow-press hydraulic oil and the quick-press hydraulic oil enter the rear cavity of an injection oil cylinder through a large-through-diameter solo valve. The pressure charging oil cylinder is perpendicular to the injection oil cylinder, disposed at the upper or lower part and between the solo valve and the injection plug. Two pressure charting starting modes are provided, one depends on pressure feedback of the injection oil cylinder rear cavity, and the other depends on displacement feedback of the injection oil cylinder. When the PLC or the process control machine receives the feedback signal, the pressure charging valve opens, the pressure charging oil cylinder starts to work, the pressure in the rear cavity of the injection oil cylinder increases quickly, the solo valve closes at the same time, and the pressure charging function is completed. The invented system is provided with following advantages: quick injection, the pressure charging channel is large and shot, quick injection speed, short pressure build-up time, long pressure charging distance, and high energy charging type.

Owner:SUZHOU SANJI FOUNDRY EQUIP

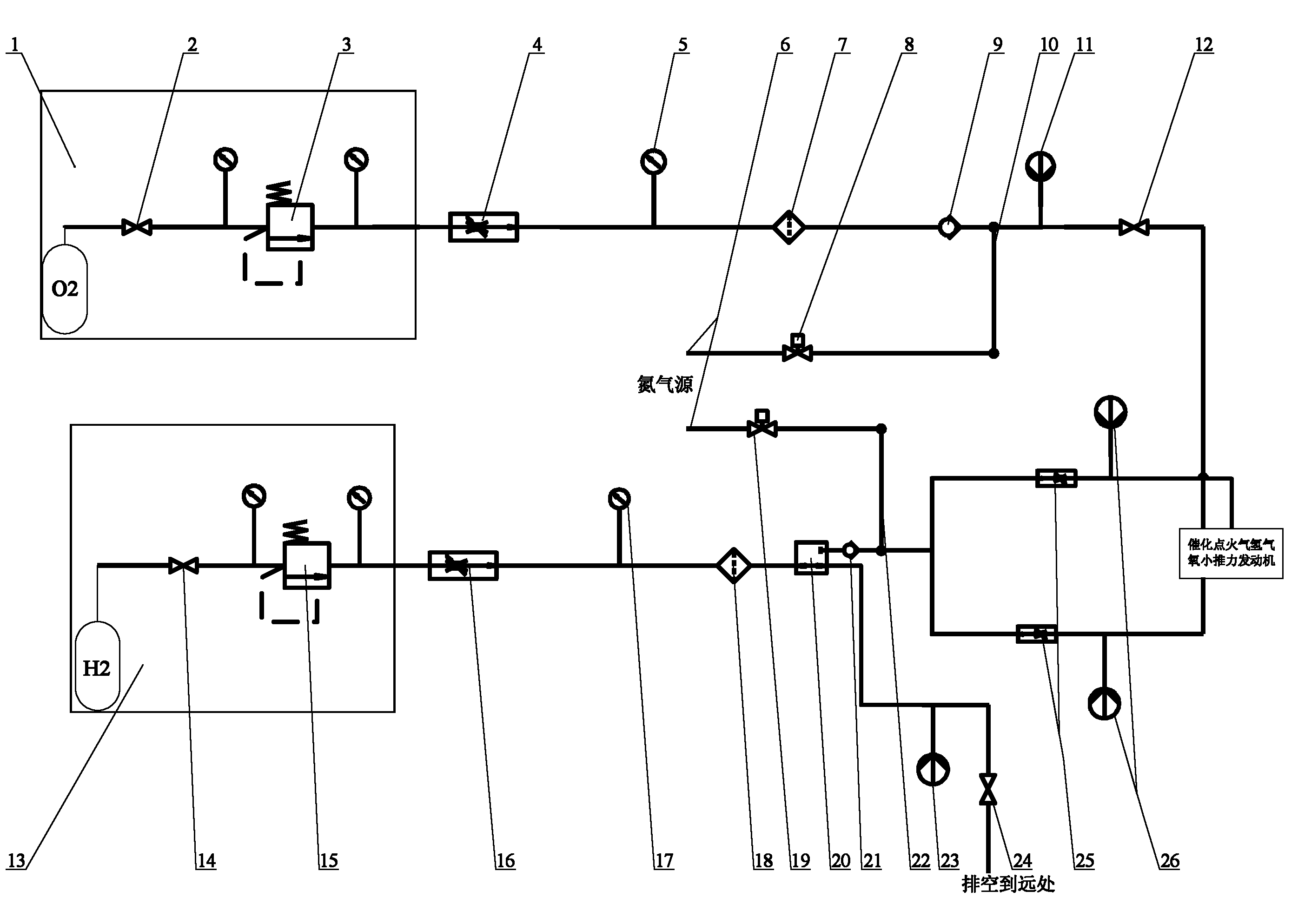

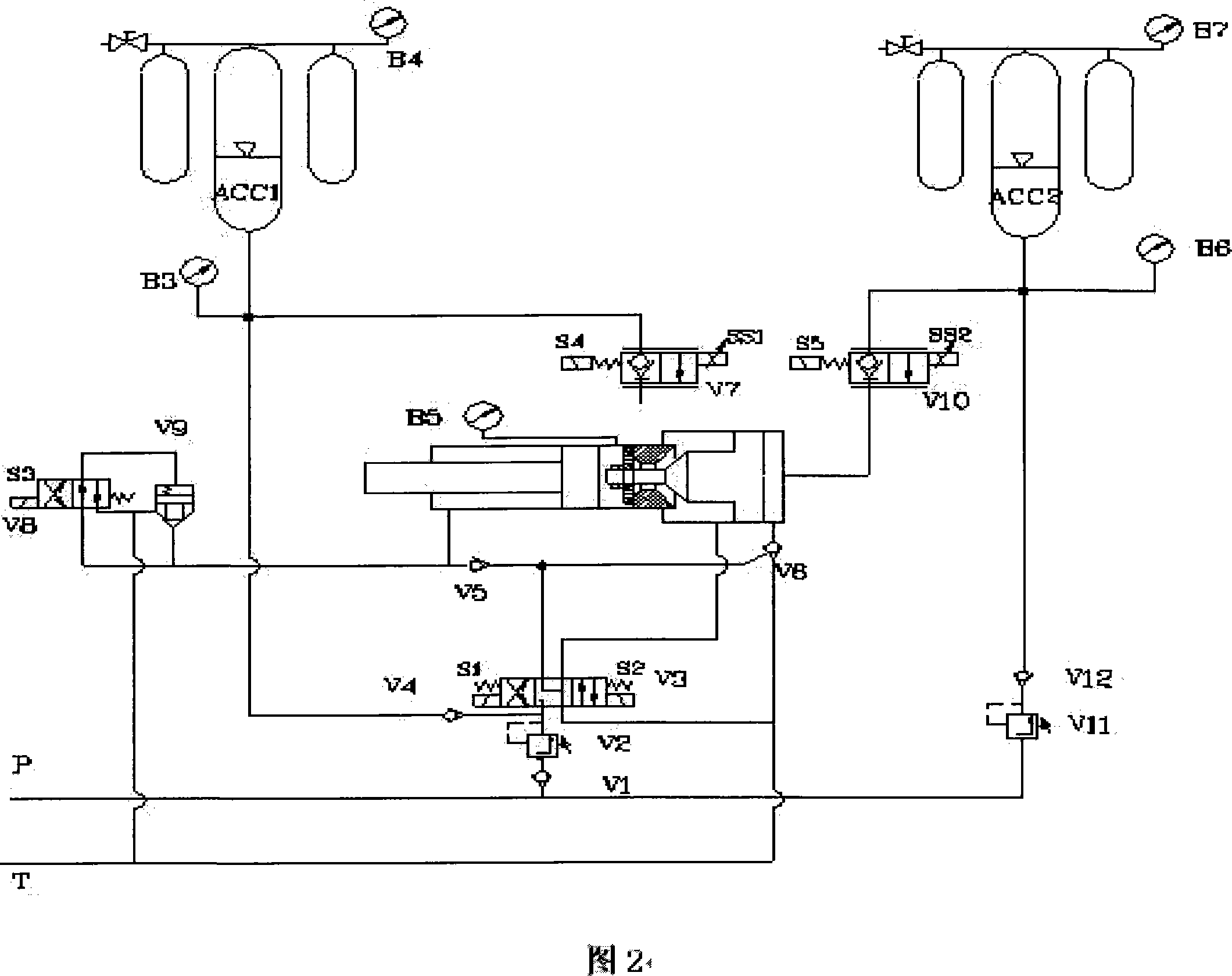

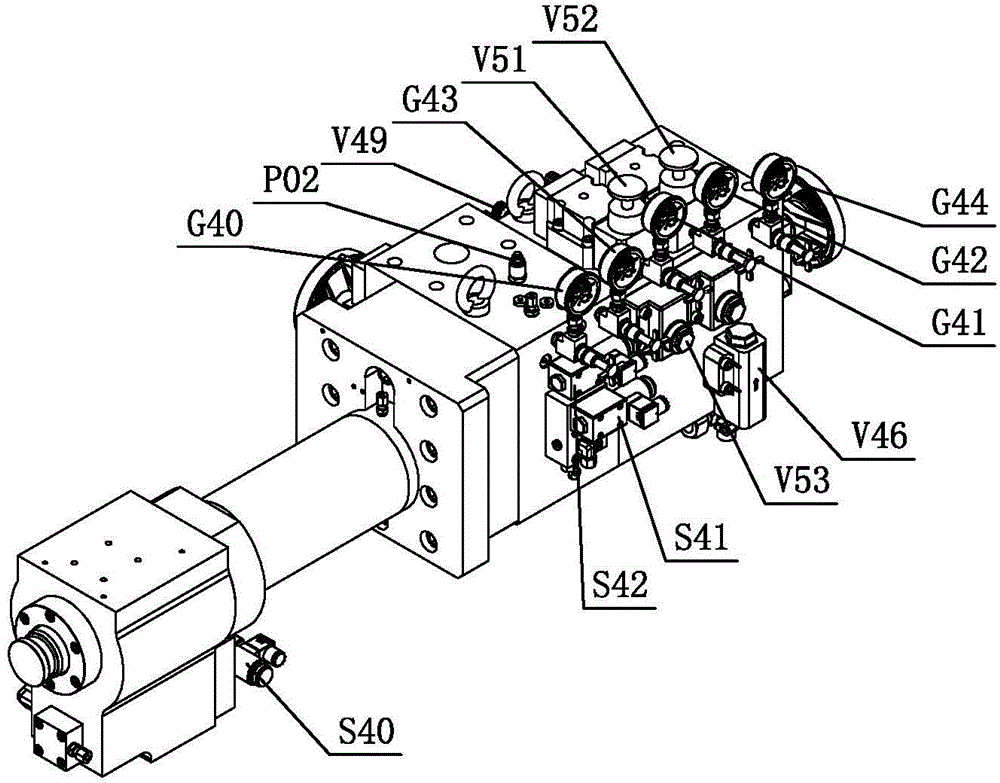

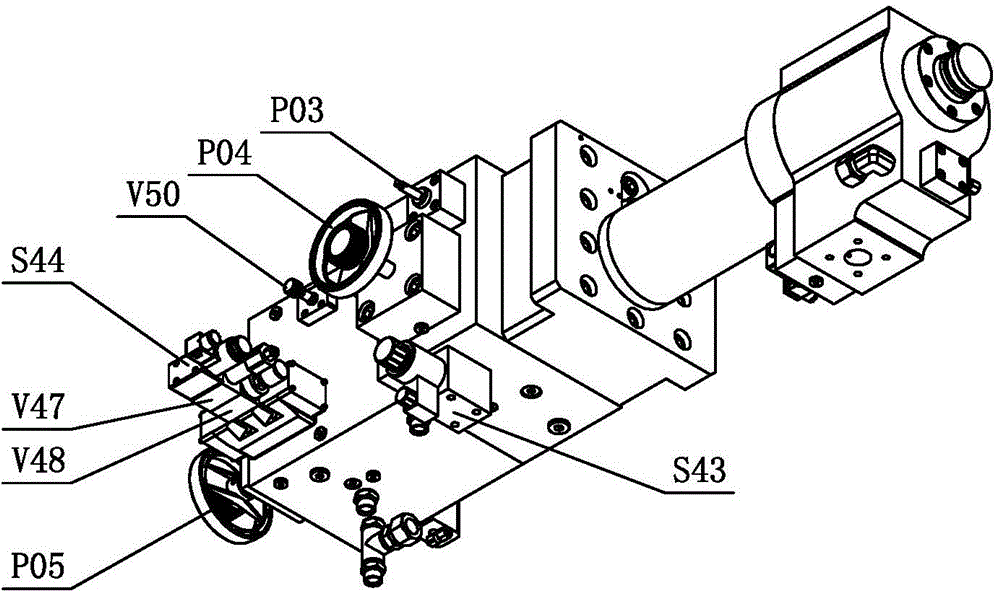

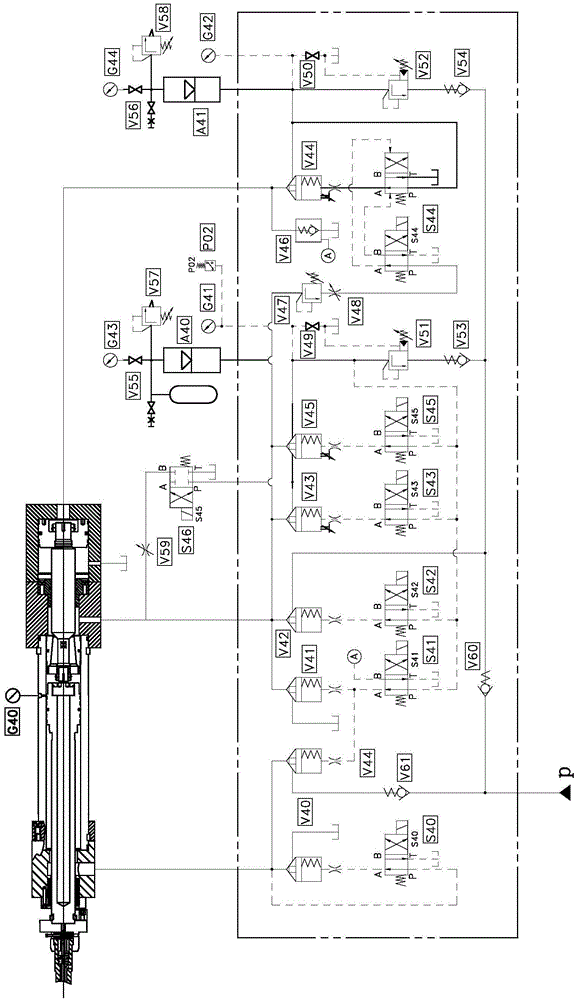

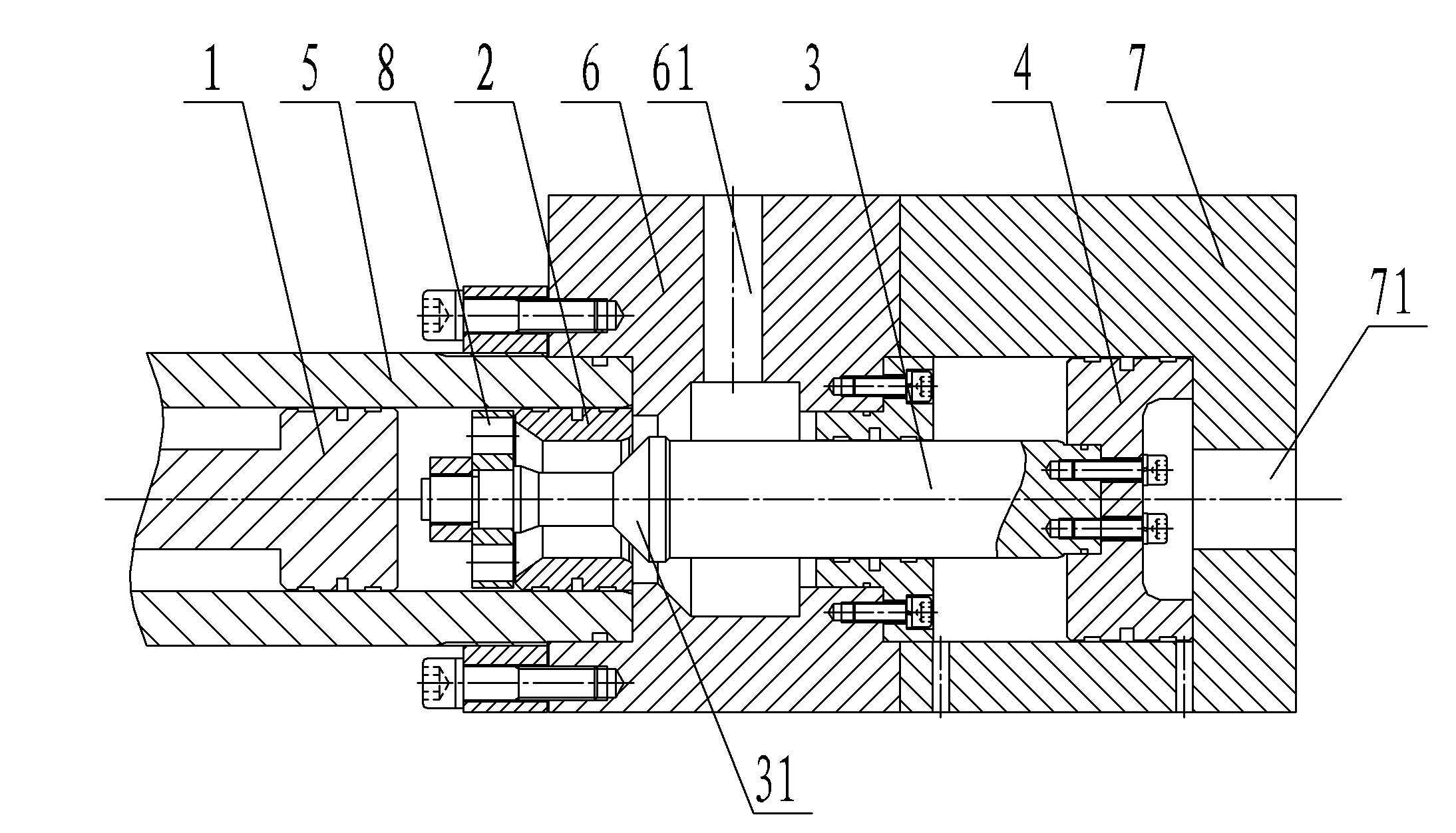

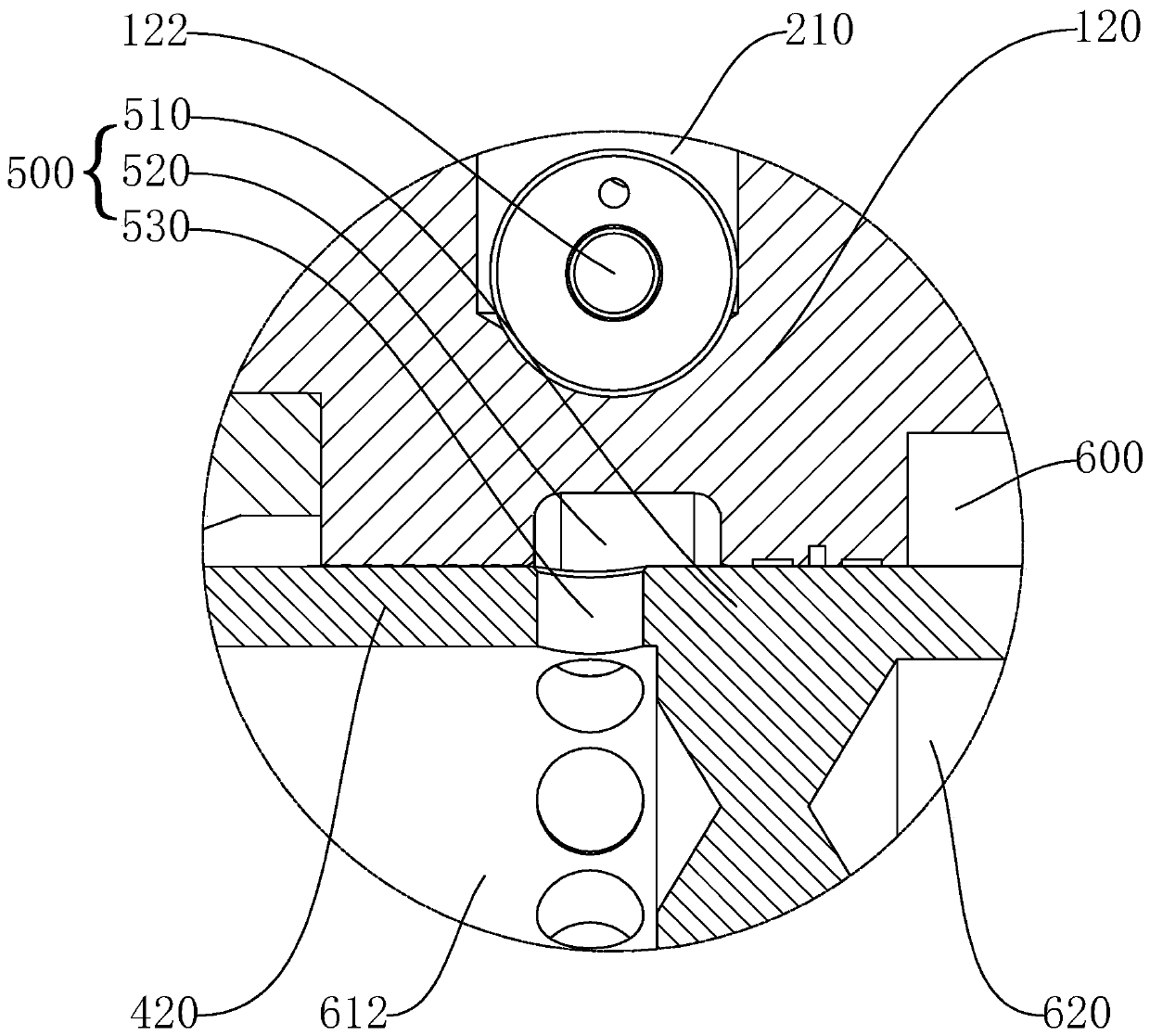

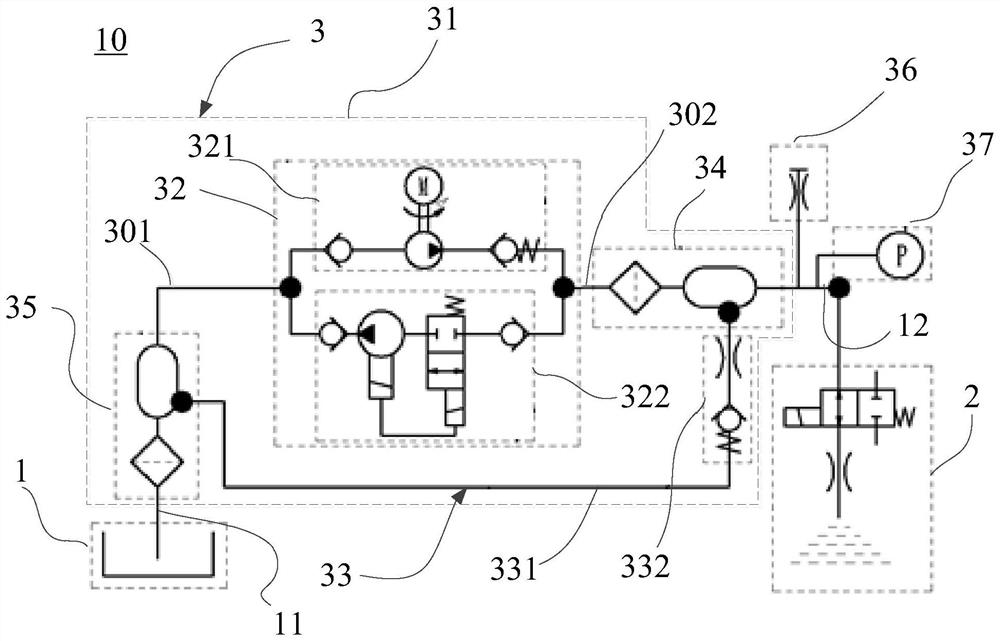

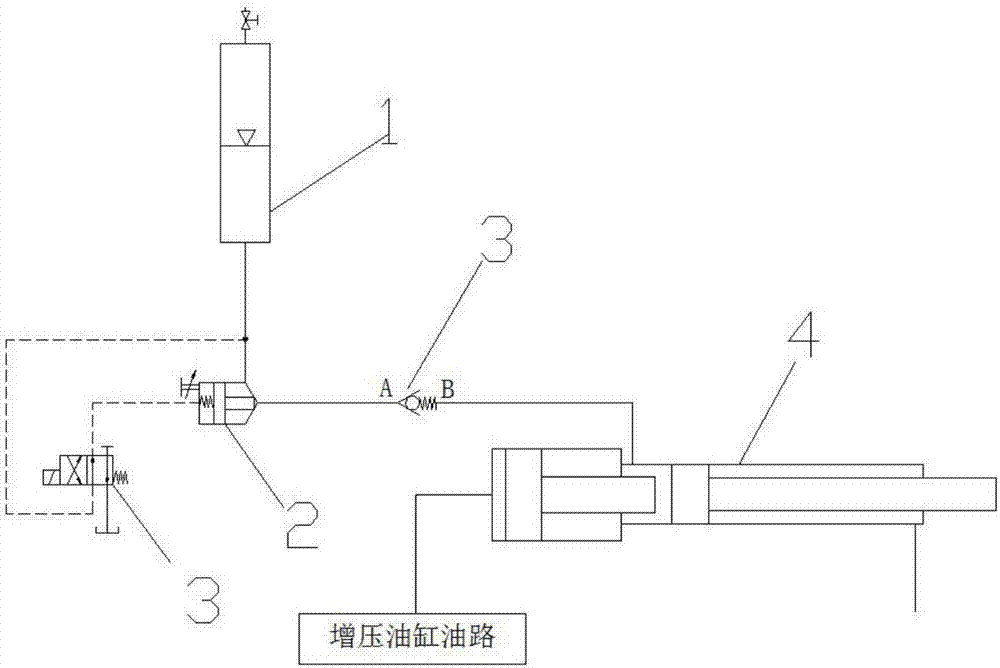

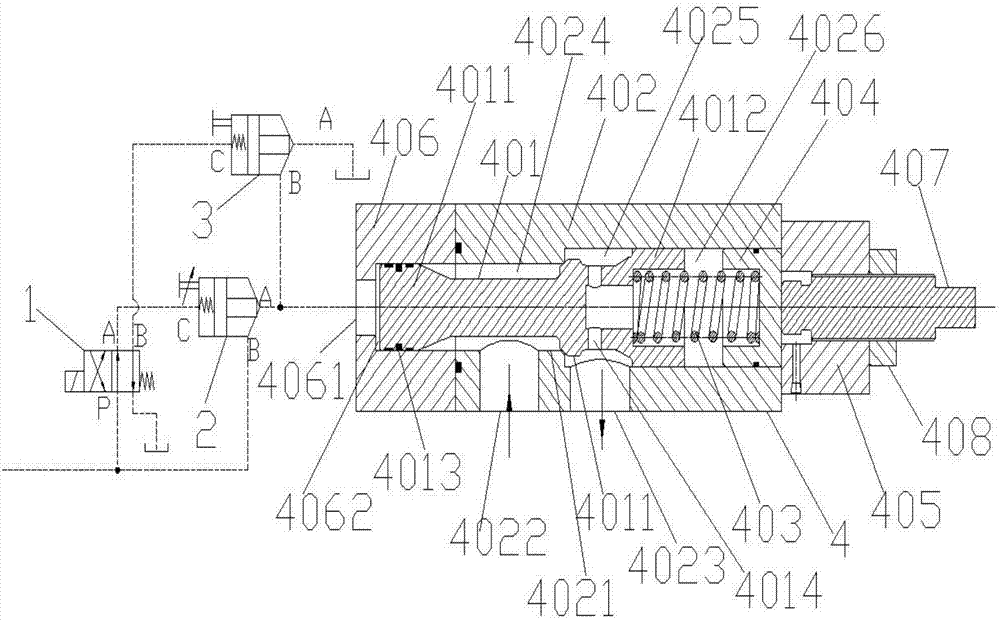

Efficient pressure buildup device for die casting machine

ActiveCN104948512AShorten the timeShort build-up timeServomotor componentsFluid-pressure convertersProgrammable logic controllerDie casting

An efficient pressure buildup device for a die casting machine comprises a boost oil cylinder and an injection oil cylinder, and is characterized in that an oil way comprises a fourth cartridge valve and a fourth electromagnetic directional valve which are mutually connected in series, a first cartridge valve and a first electromagnetic directional valve which are mutually connected in series, a third cartridge valve and a third electromagnetic directional valve which are mutually connected in series, a sixth cartridge valve and a sixth electromagnetic directional valve which are mutually connected in series, a fifth cartridge valve and a throttling screw which are mutually connected, a first energy accumulator, a first pressure reducing valve and a first one-way valve which are mutually connected in series, an overflow valve and a fifth electromagnetic directional valve which are mutually connected, as well as a second energy accumulator, a second pressure reducing valve and a second one-way valve which are mutually connected in series. According to the structure, power is gained while electromagnets are boosted during rapidly acting, signal receiving and action command transmitting time of a PLC (programmable logic controller) is saved, and only two processes including opening of cartridge valve cores and pushing-out of the boost oil cylinder are reserved, so that the pressure buildup time is shortened. The efficient pressure buildup device for the die casting machine has the characteristics of simple and reasonable structure, short pressure buildup time and low cost.

Owner:广东联升精密机械制造有限公司

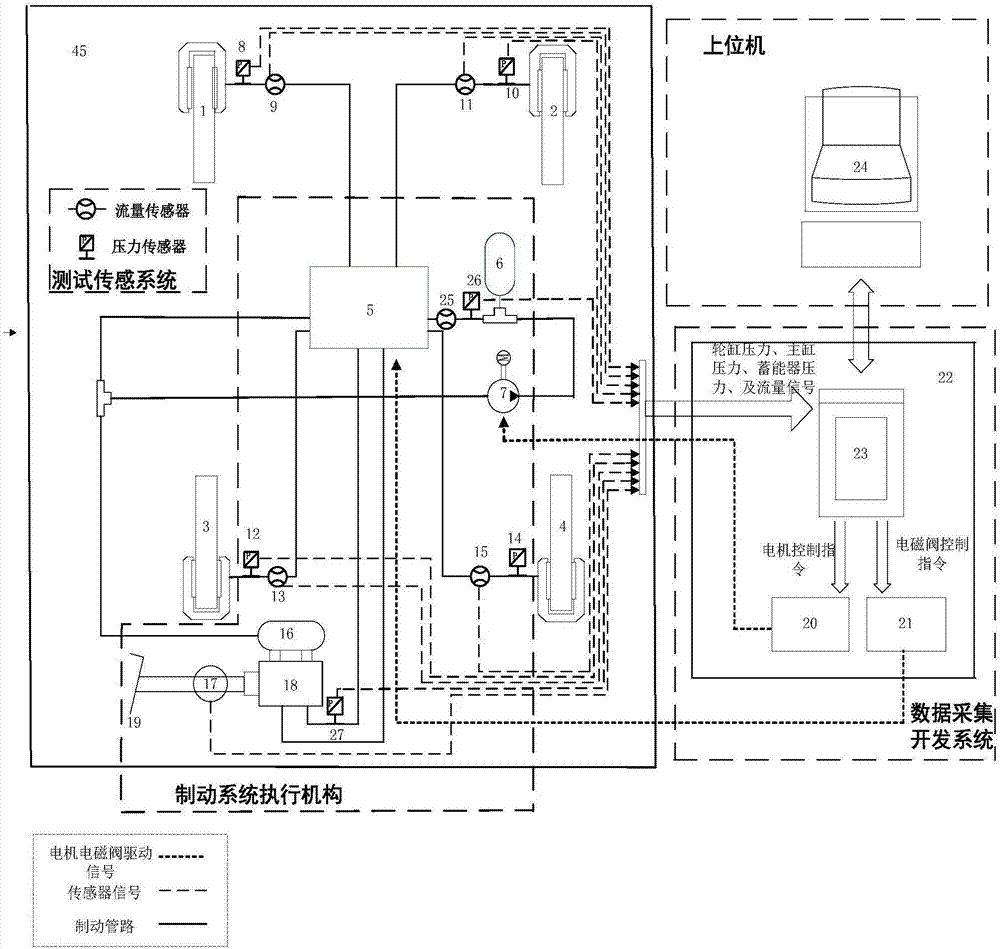

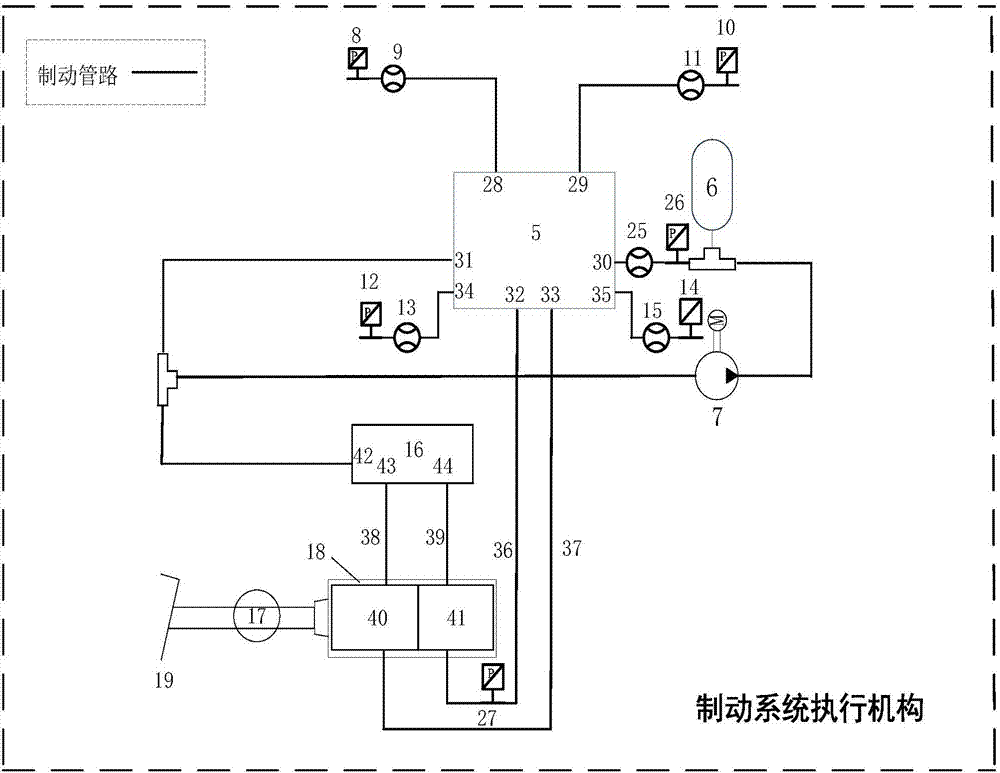

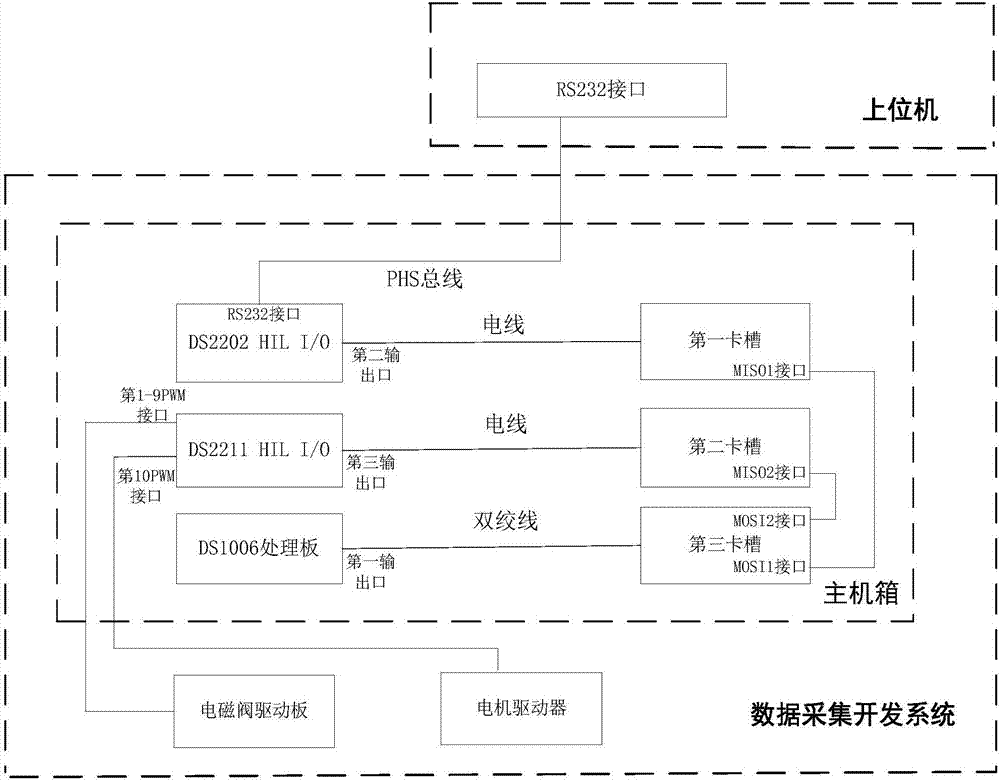

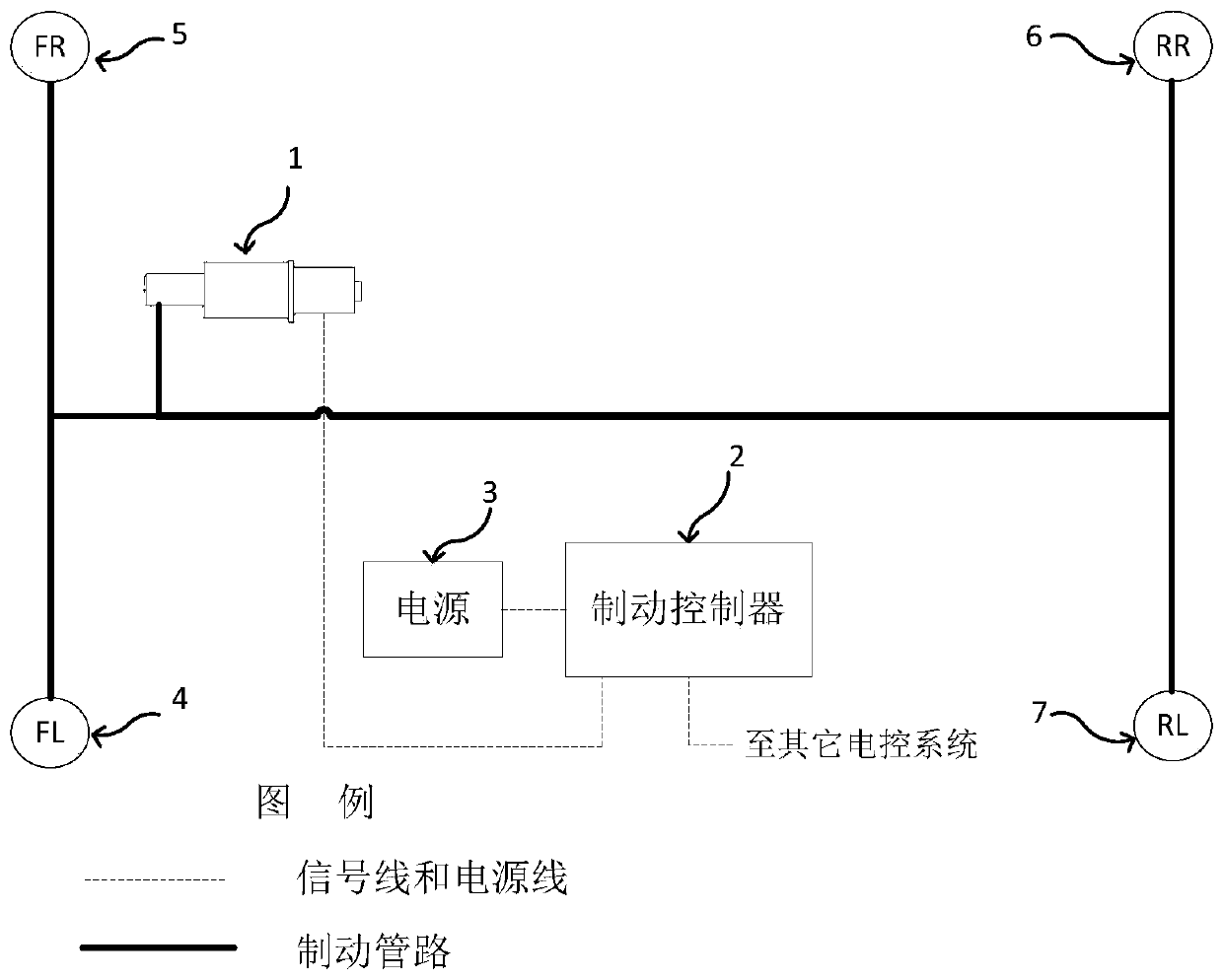

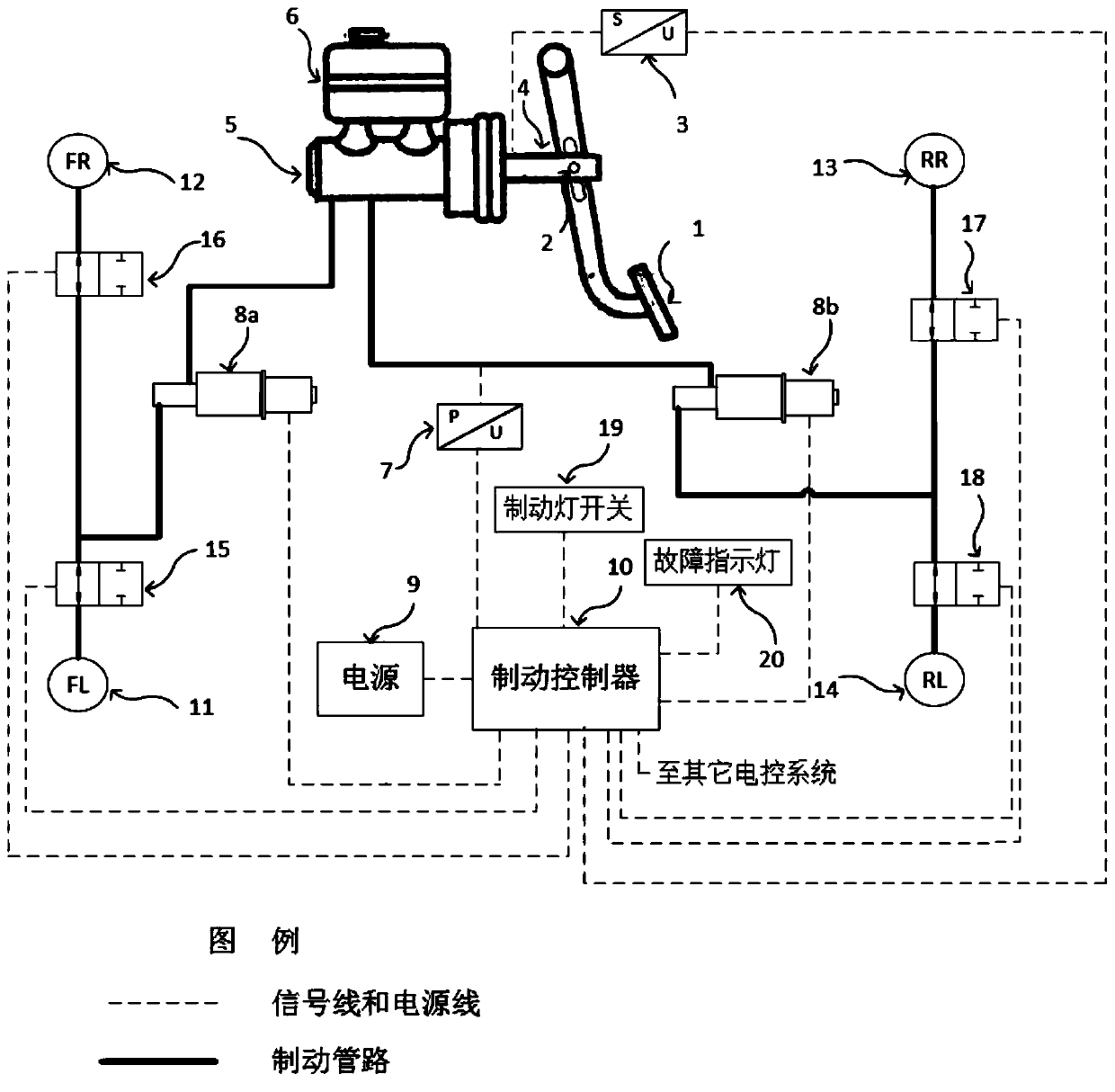

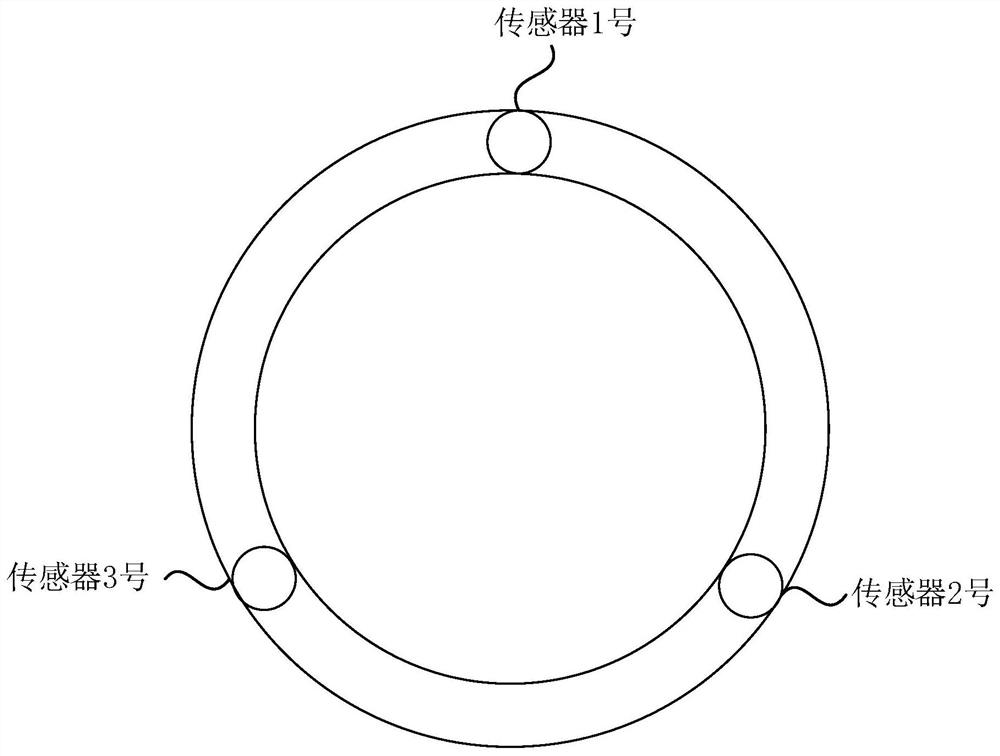

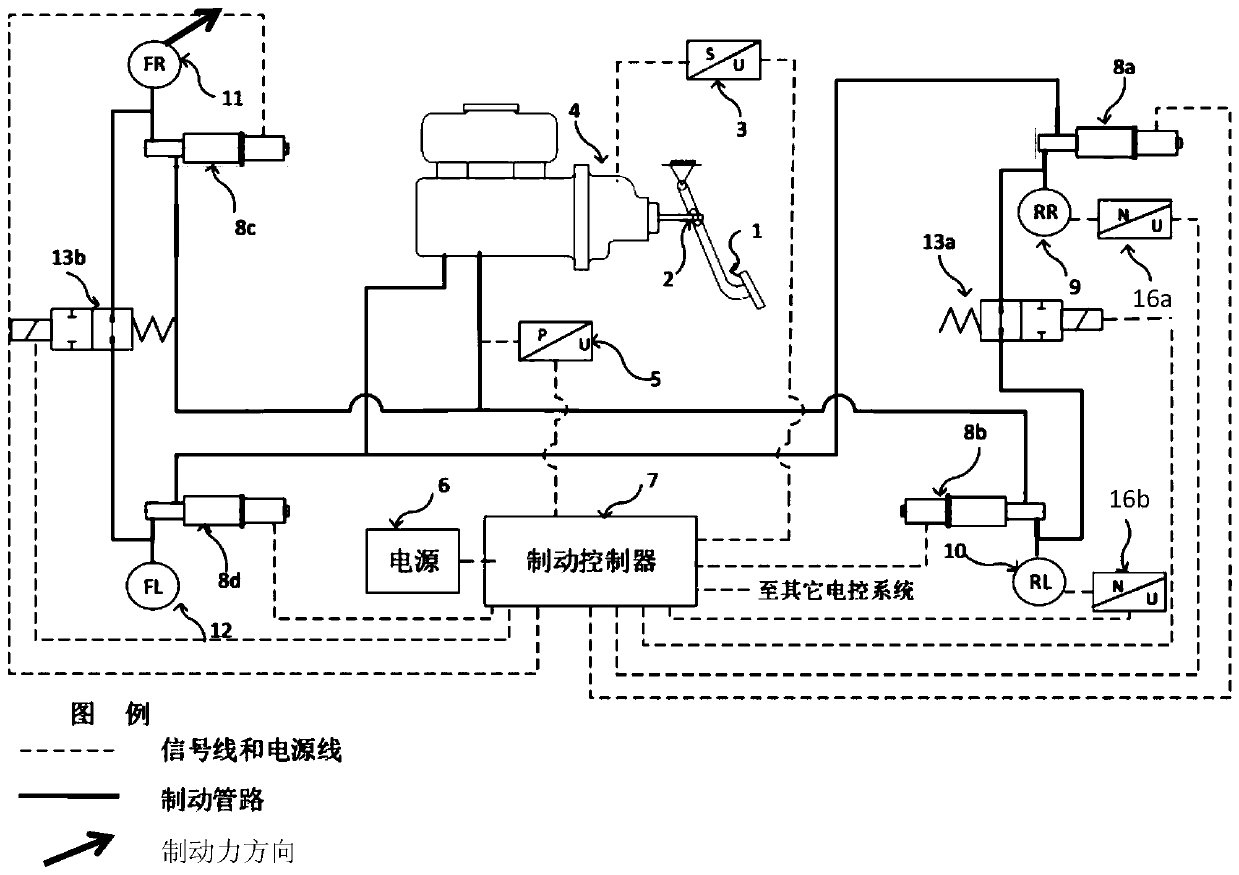

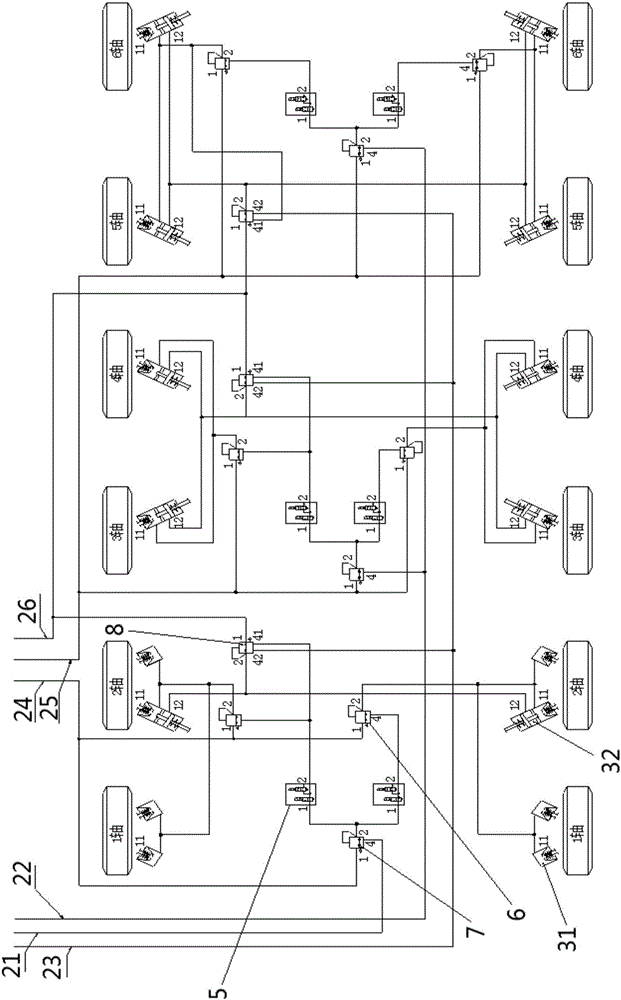

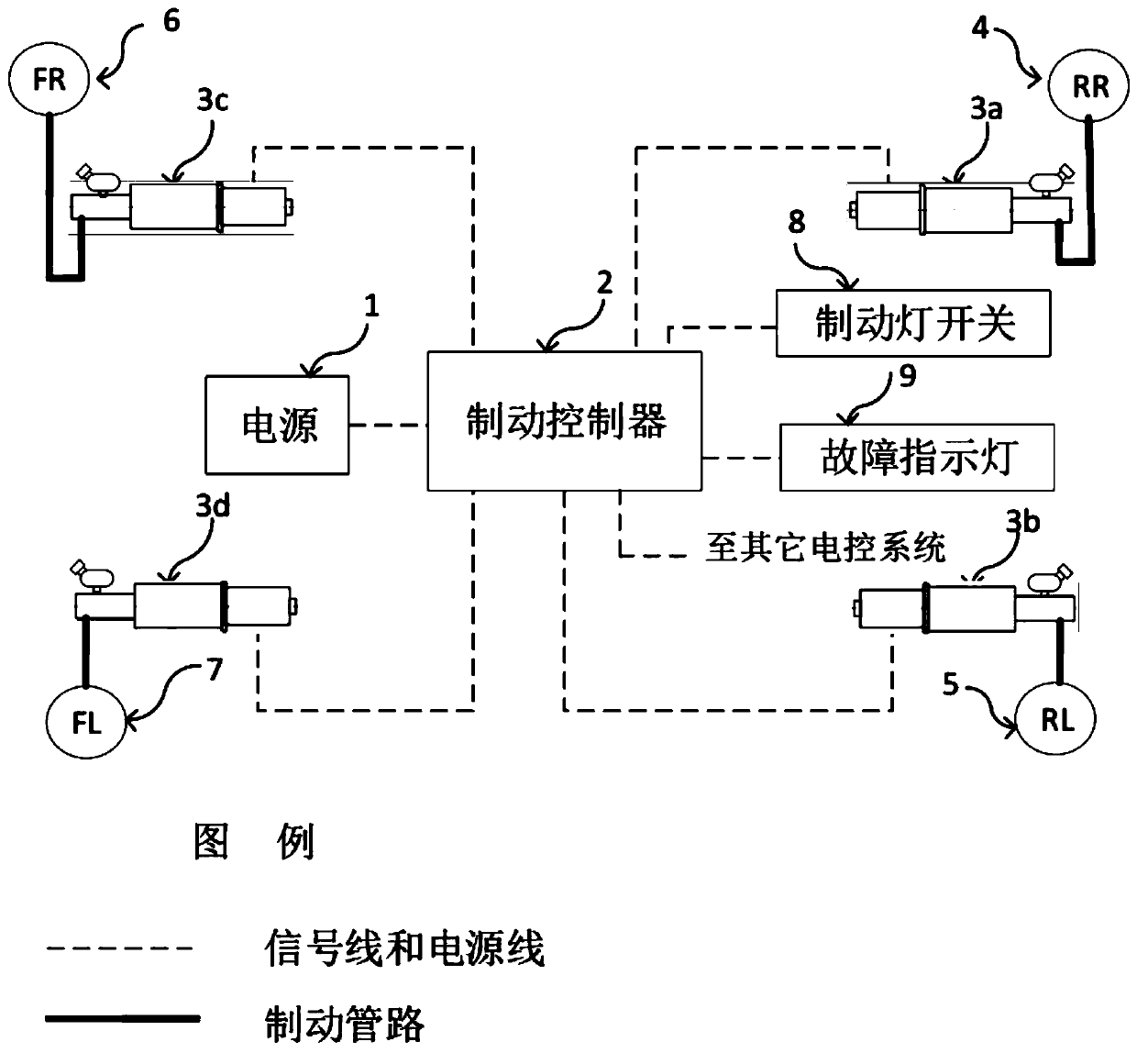

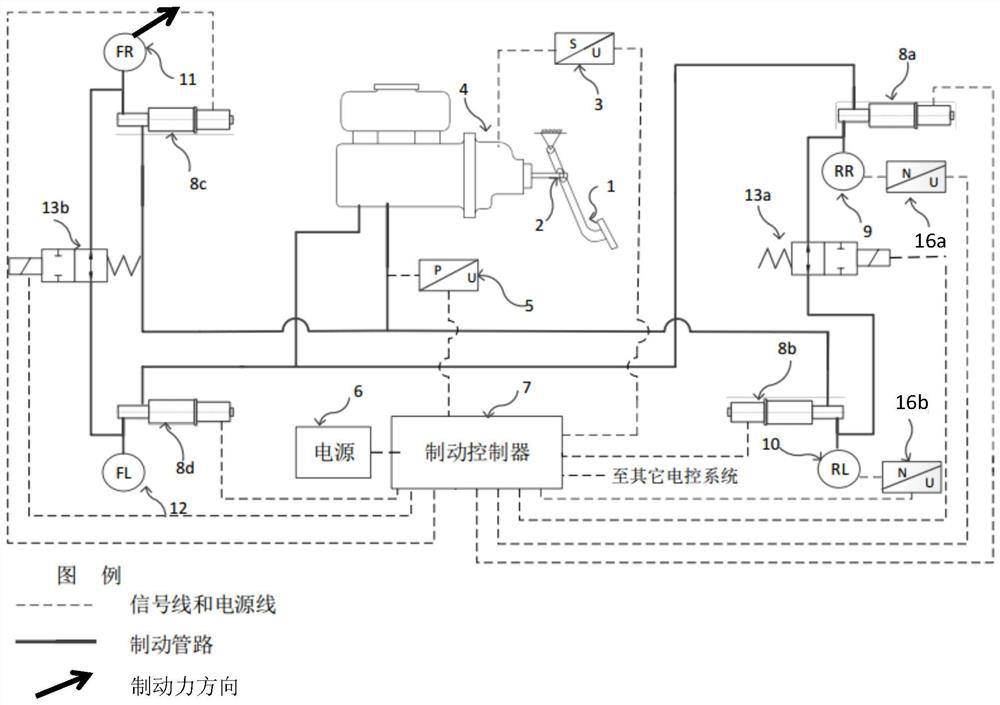

Vehicle line control hydraulic brake system hardware-in-the-loop test bed

ActiveCN106969920AReduce R&D costsReduce labor costsVehicle testingAutomotive engineeringPressure buildup

The invention discloses a vehicle line control hydraulic brake system hardware-in-the-loop test bed in order to solve the problem that with respect to an existing test bed, the detection precision is poor, the rapid pressure-buildup speed is too low and the steady-state error is too large. The vehicle line control hydraulic brake system hardware-in-the-loop test bed comprises a real-time platform and a line control hydraulic brake system, the real-time platform comprises a host computer and a data acquisition and exploitation system, and the host computer is in bus connection with the data acquisition and exploitation system; and the line control hydraulic brake system comprises a test sensing system, an experiment table basal body and a brake system execution mechanism. The experiment table basal body is installed on the foundation through a support platform, a left front-wheel brake, a right front-wheel brake, a left rear-wheel brake and a right rear-wheel brake of the experiment table basal body are installed on the support platform, and the test sensing system is connected with the four wheel brakes through brake hard tubes; the test sensing system is connected with the data acquisition and exploitation system through a wire; and the brake system execution mechanism is connected with the test sensing system through a brake hard tube, and the brake system execution mechanism is connected with the data acquisition and exploitation system through a wire.

Owner:JILIN UNIV

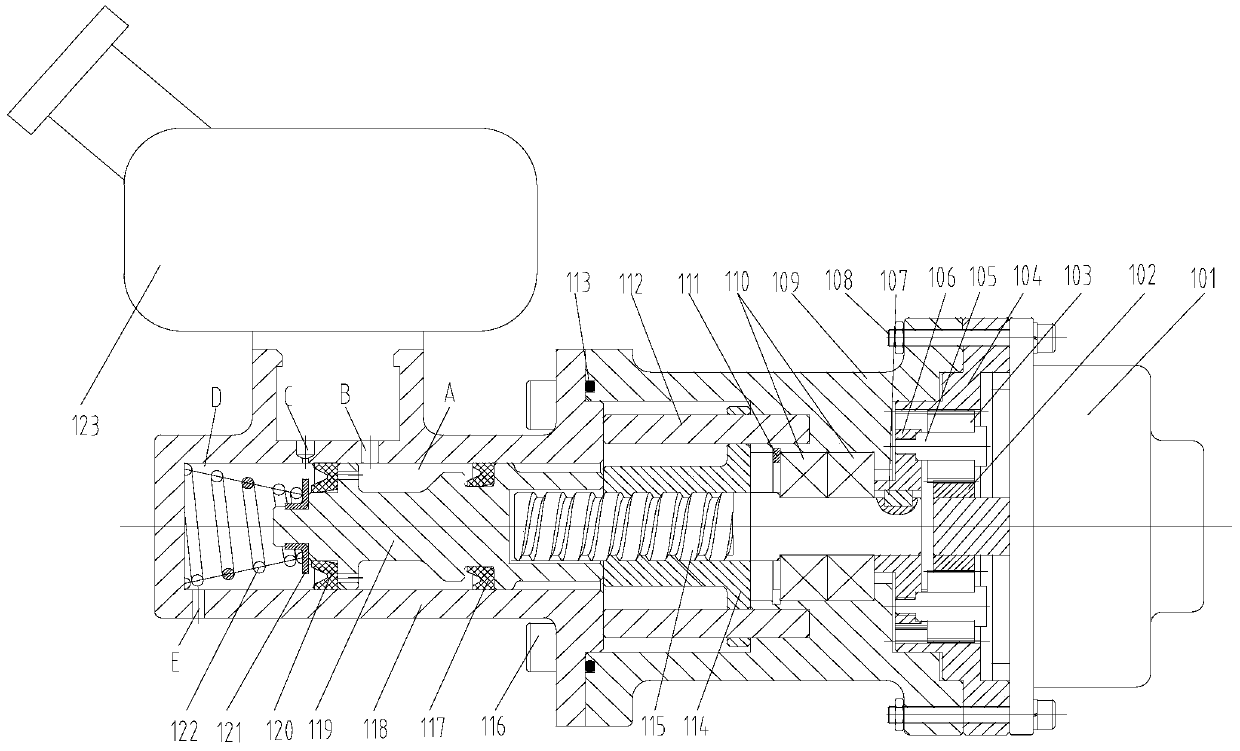

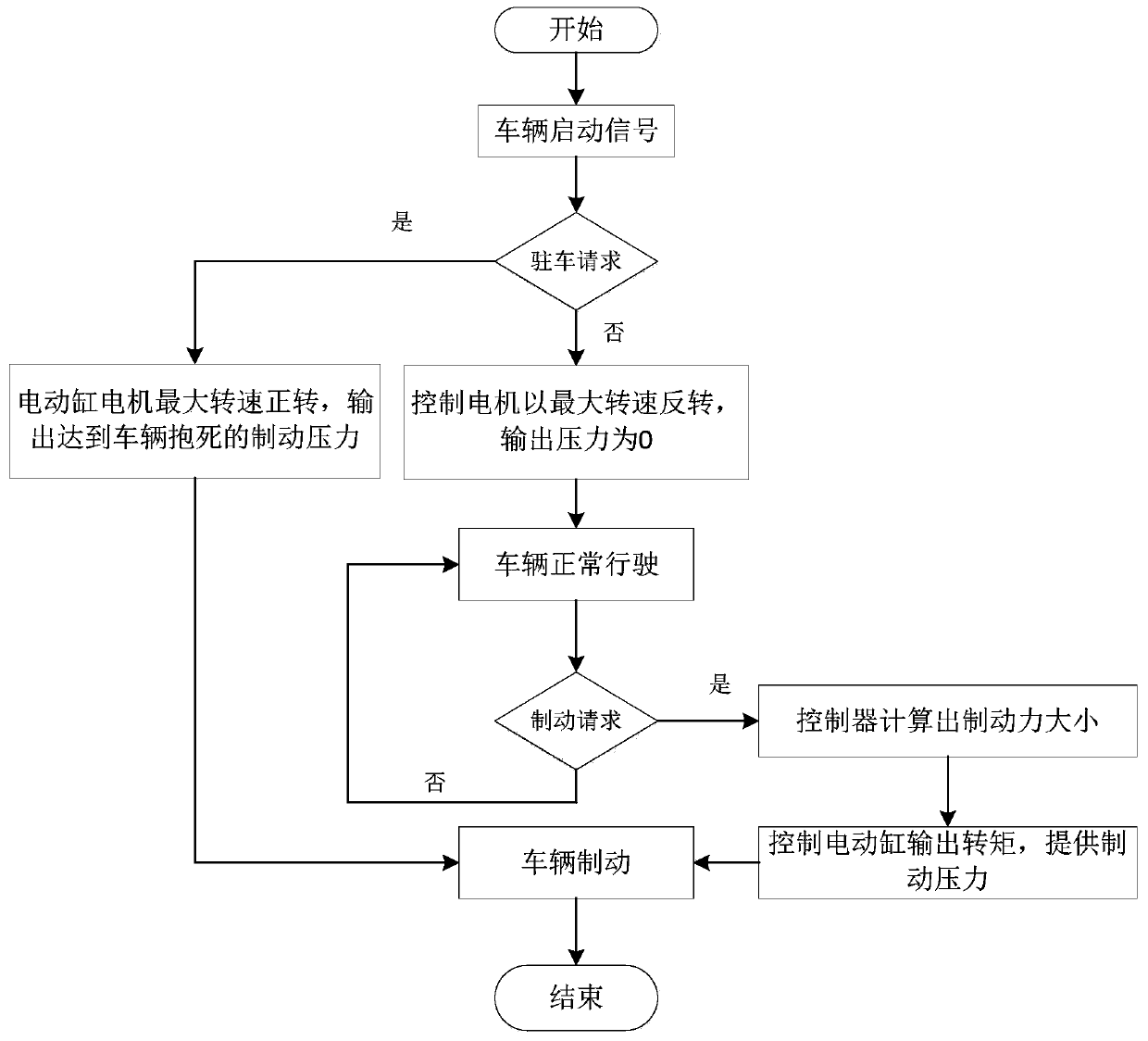

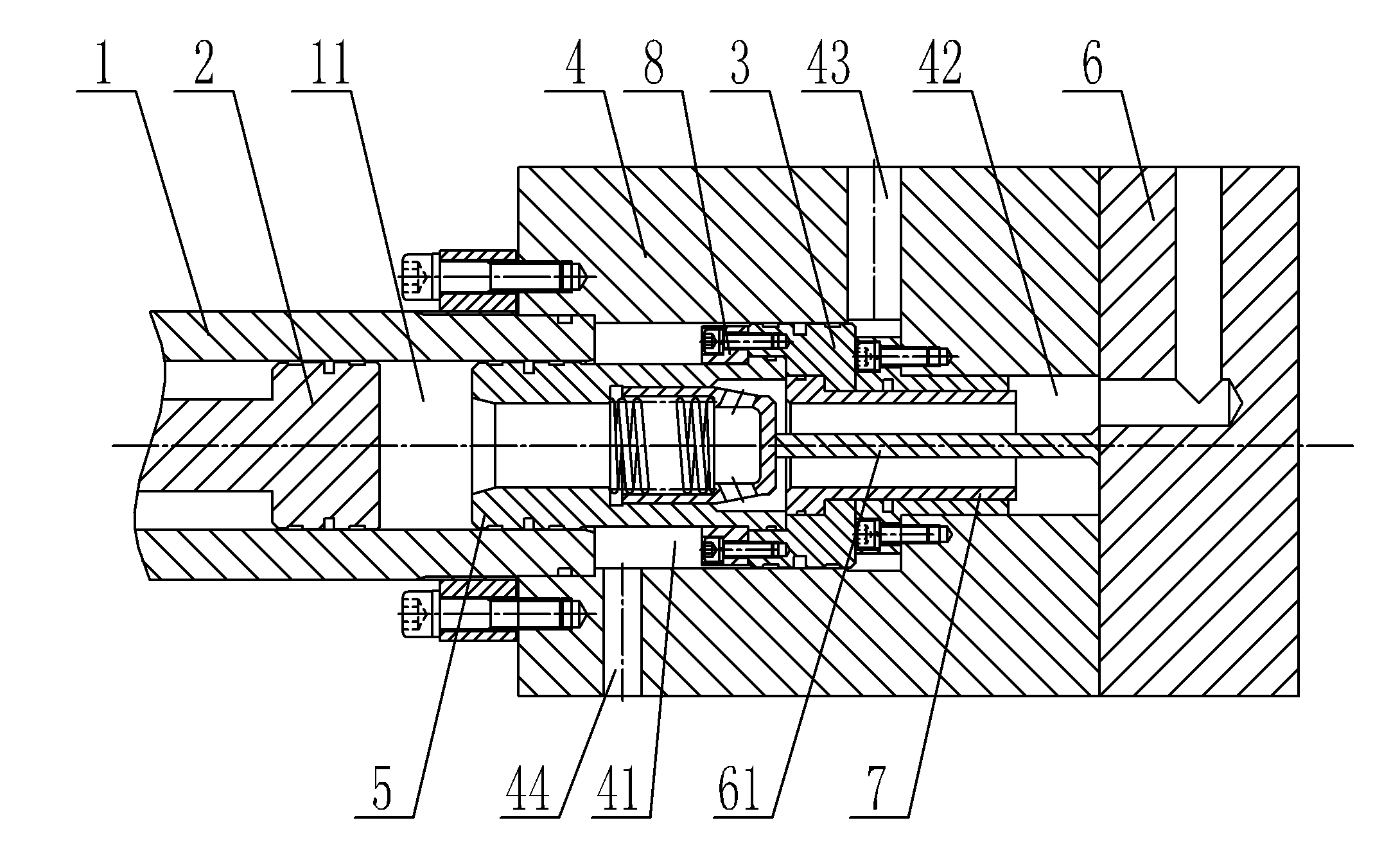

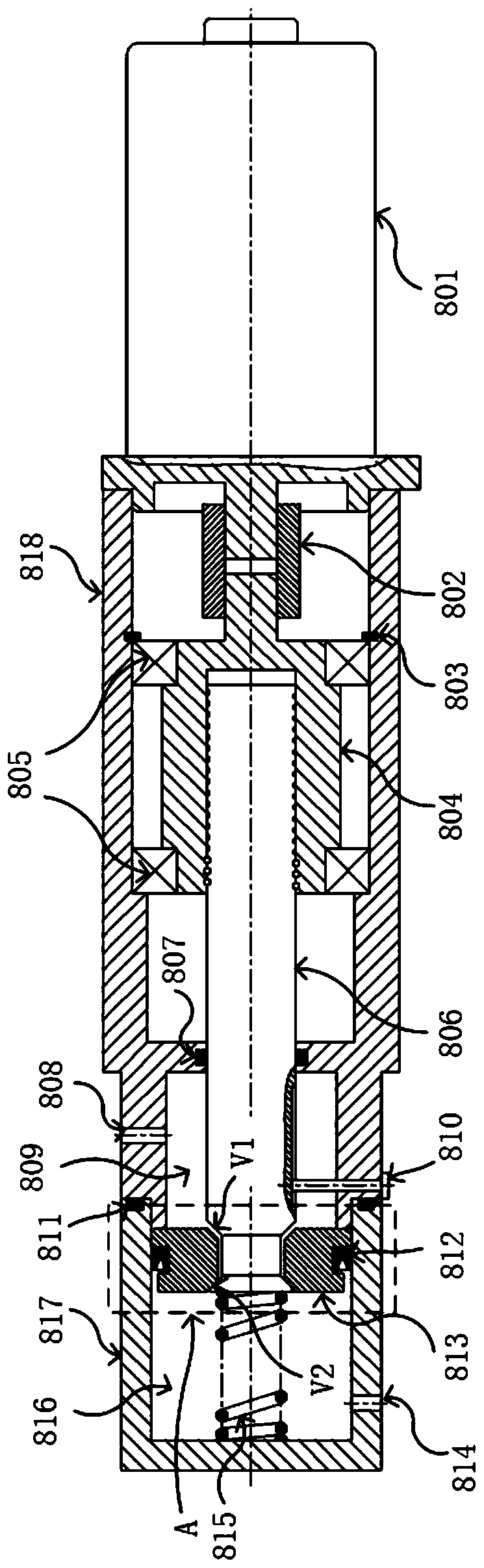

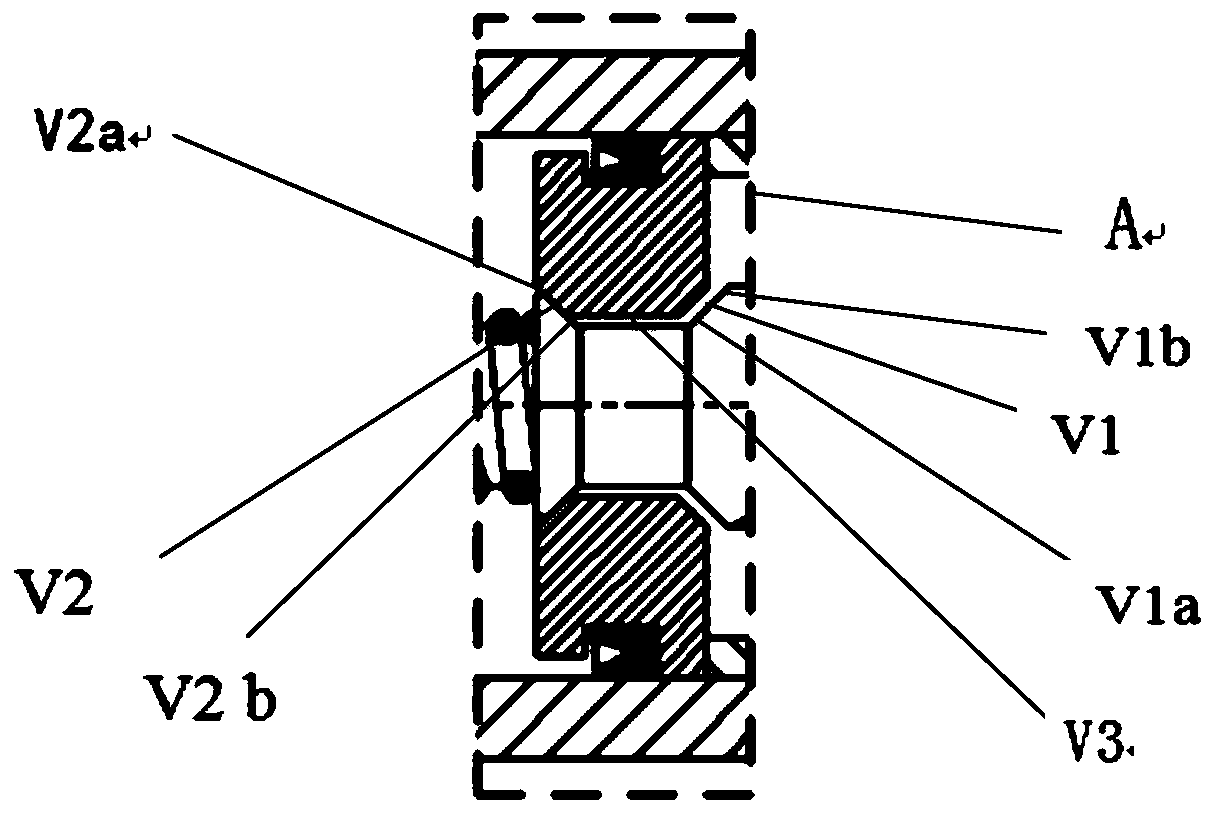

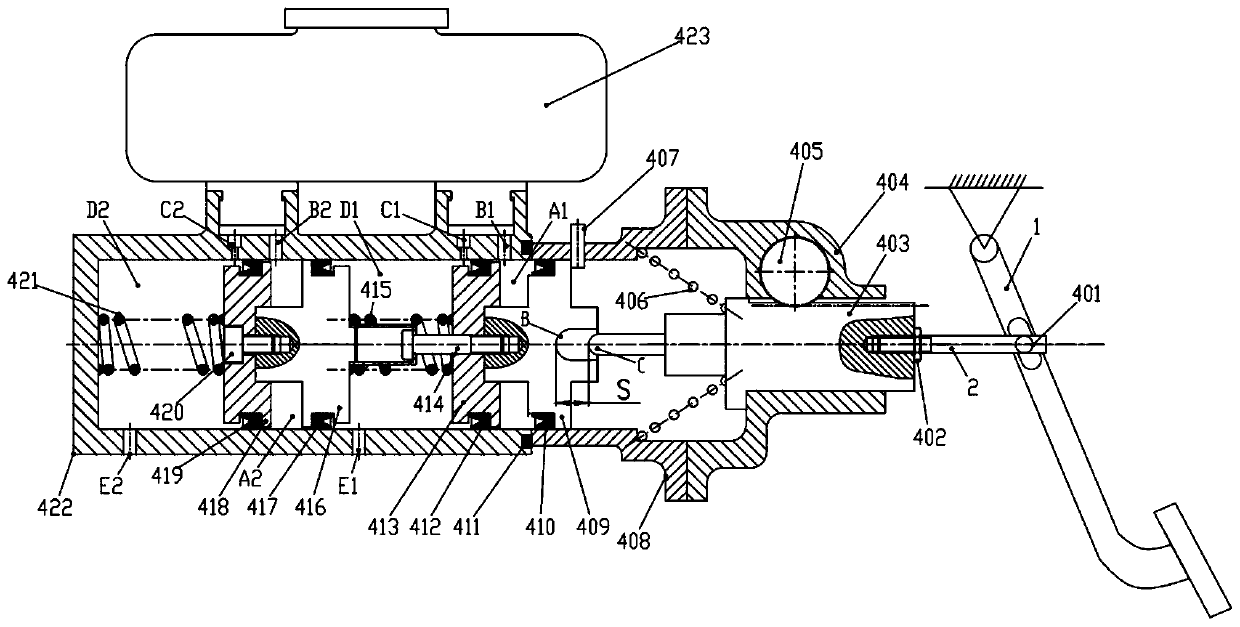

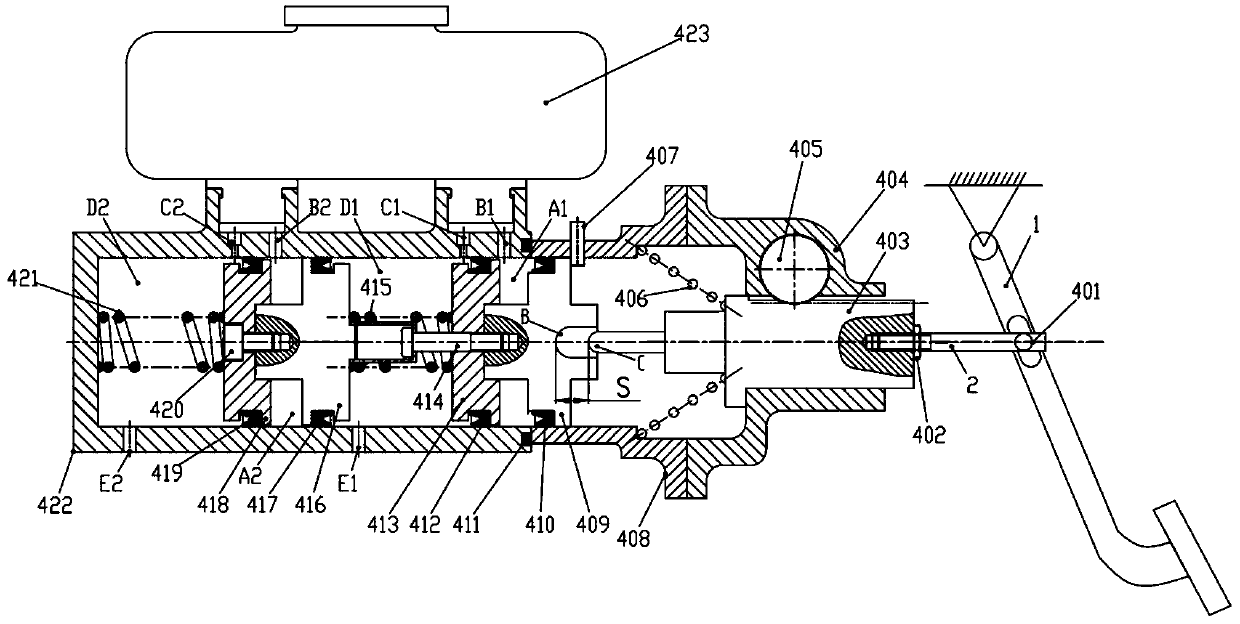

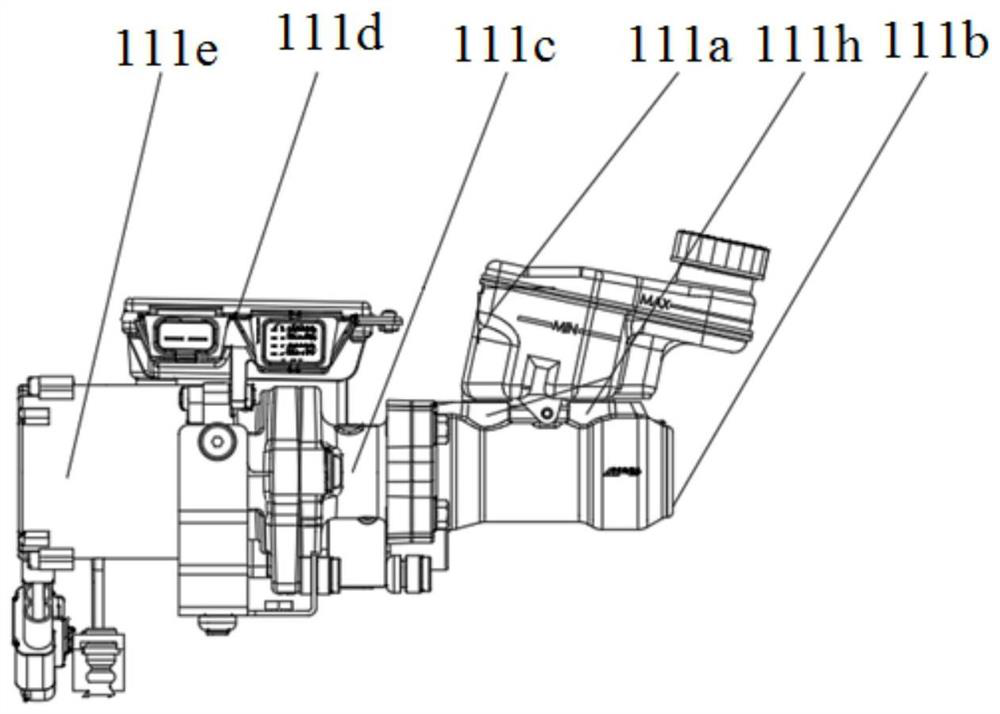

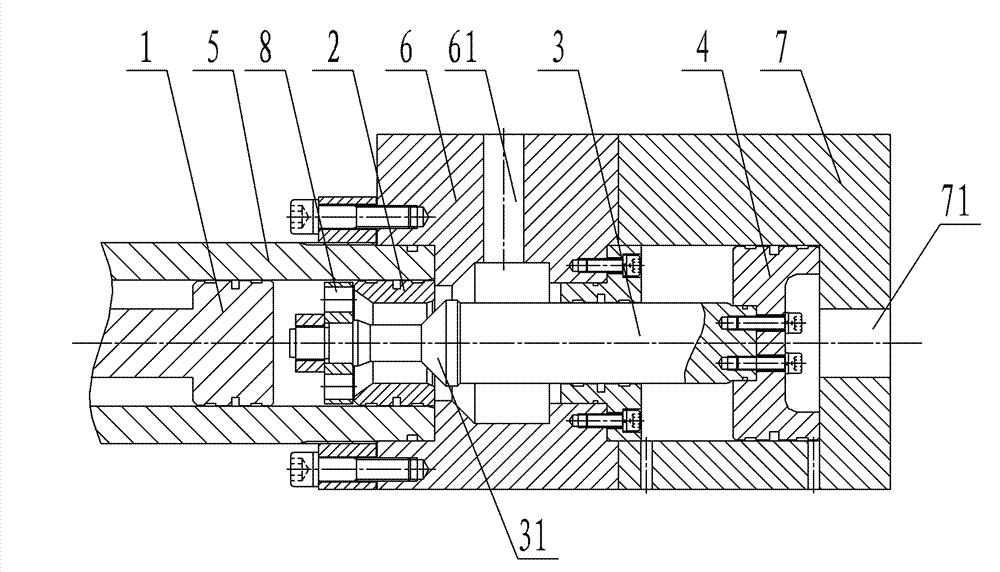

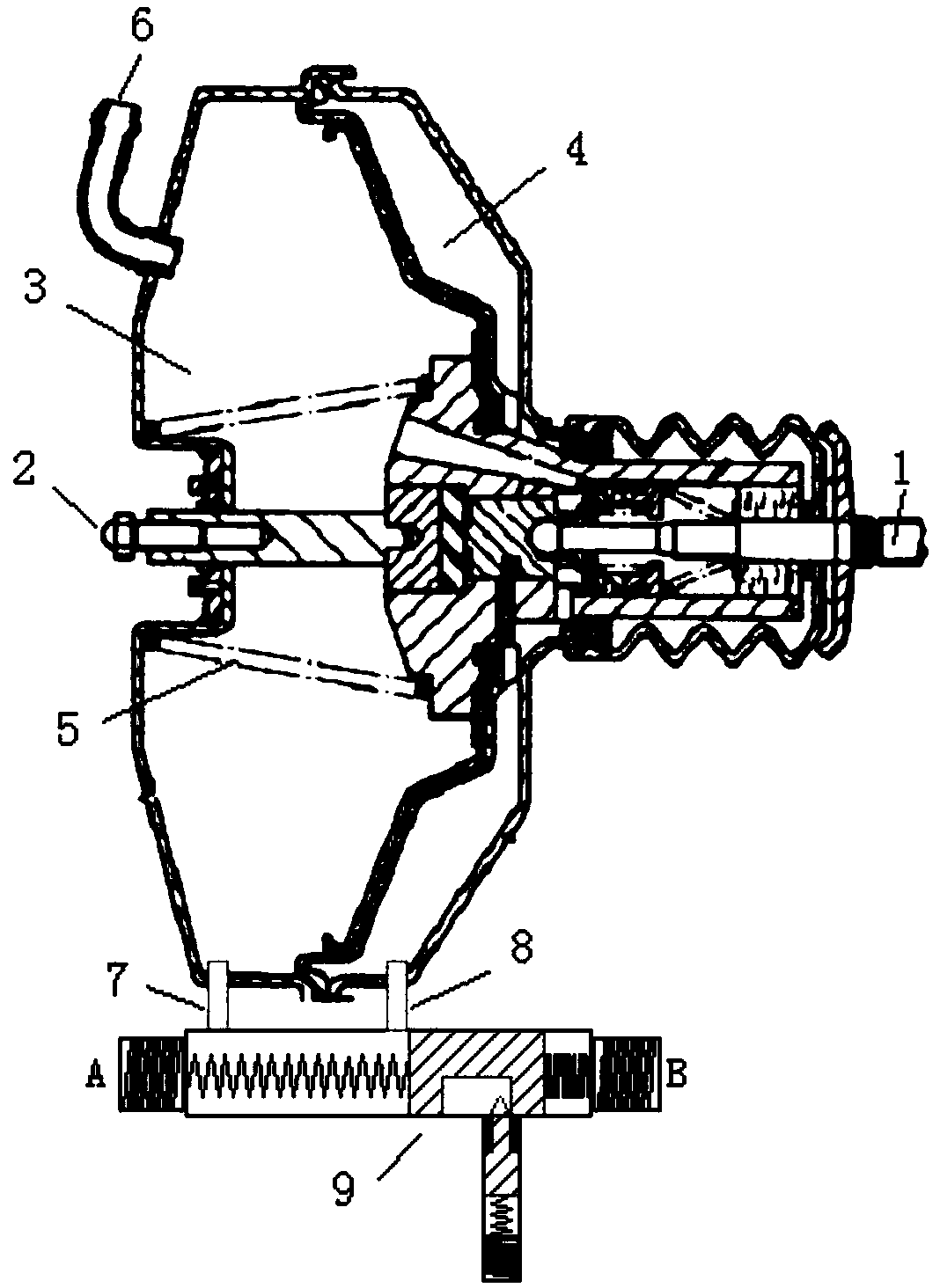

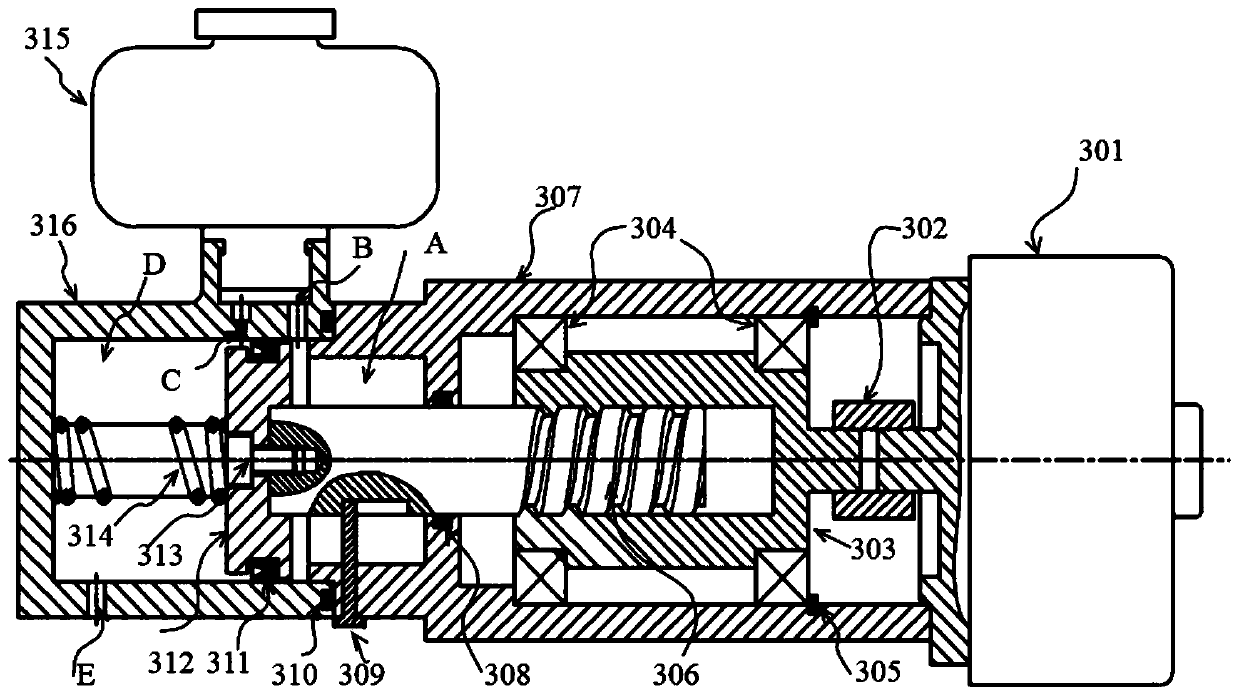

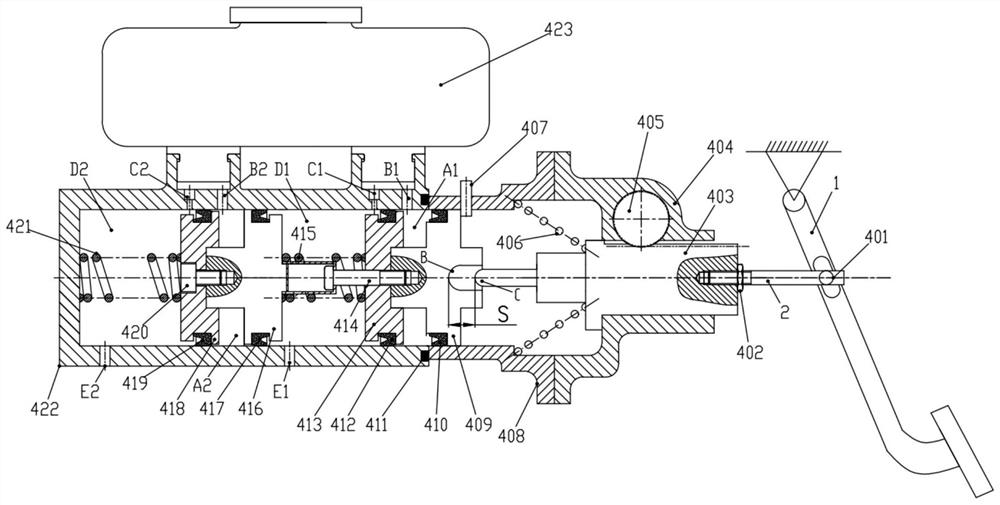

Electric cylinder device with autonomous braking and parking braking functions, braking system and braking control method

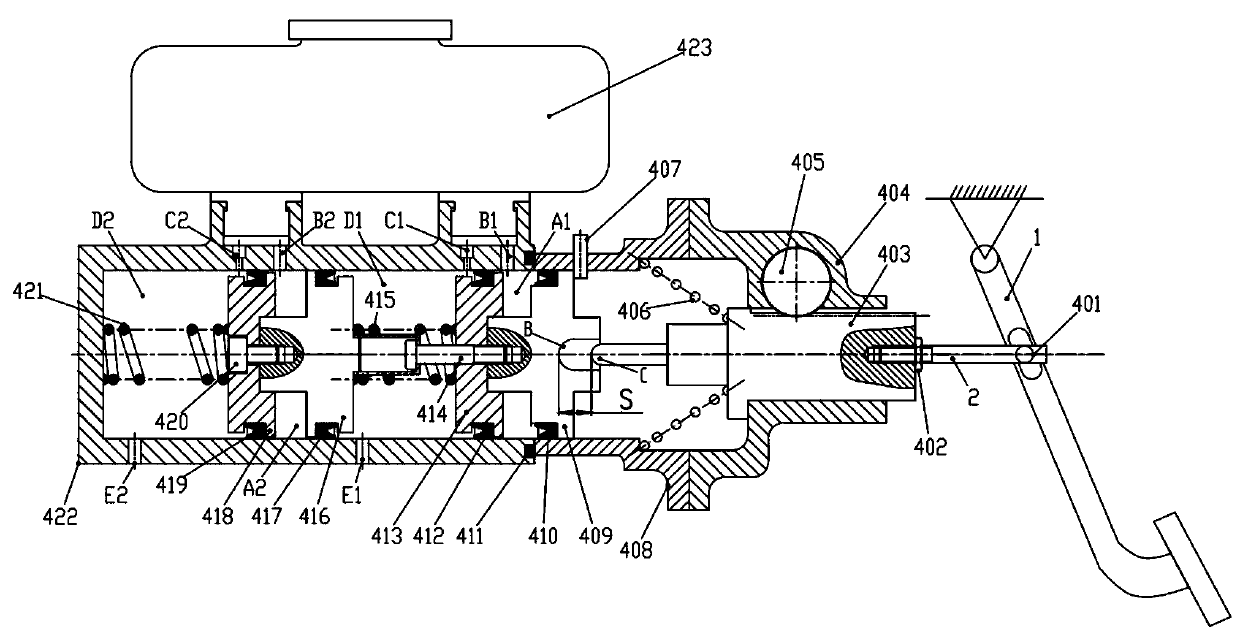

PendingCN110094444ASimple structureLow costBraking action transmissionGearing controlLiquid storage tankPiston

The invention discloses an electric cylinder device with autonomous braking and parking braking functions. The electric cylinder device with the autonomous braking and parking braking functions comprises a main cylinder shell, a screw rod shell and a motor, wherein a piston is slidably arranged in the main cylinder shell; a first cavity D and a second cavity A are formed between the front end of the piston and the main cylinder shell as well as between the middle part of the piston and the main cylinder shell; an inner hole is formed in the middle of the back end of the piston; a compensatinghole C for communicating a liquid storage tank and the first cavity D, a liquid supply hole B for communicating the liquid storage tank and the second cavity A, and a liquid drainage hole E for communicating the first cavity D and a wheel brake are formed in the main cylinder shell; a packing cup is arranged on the front end surface of the piston; a screw rod pair and a planetary gear reduction mechanism are arranged in the screw rod shell; the front end of a screw rod stretches into the inner hole; a gap is left between the front end surface of the screw rod and the inner hole; and the motorprovides rotation power for the screw rod through the planetary gear reduction mechanism. The invention further discloses a braking system and a braking control method thereof. The braking system hasthe autonomous braking and parking braking functions, and is simple in structure, low in cost and fast in braking response.

Owner:南京经纬达汽车科技有限公司

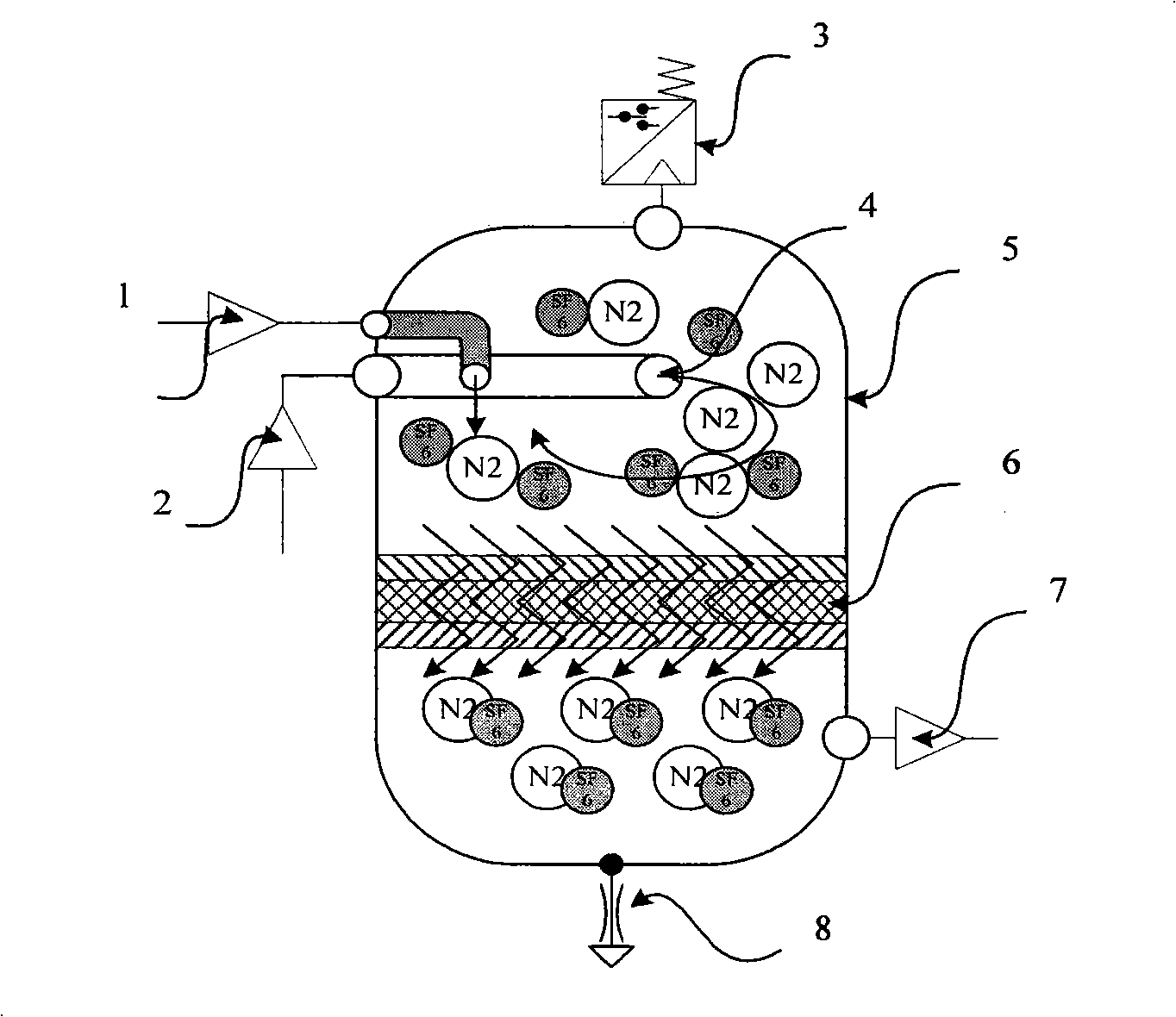

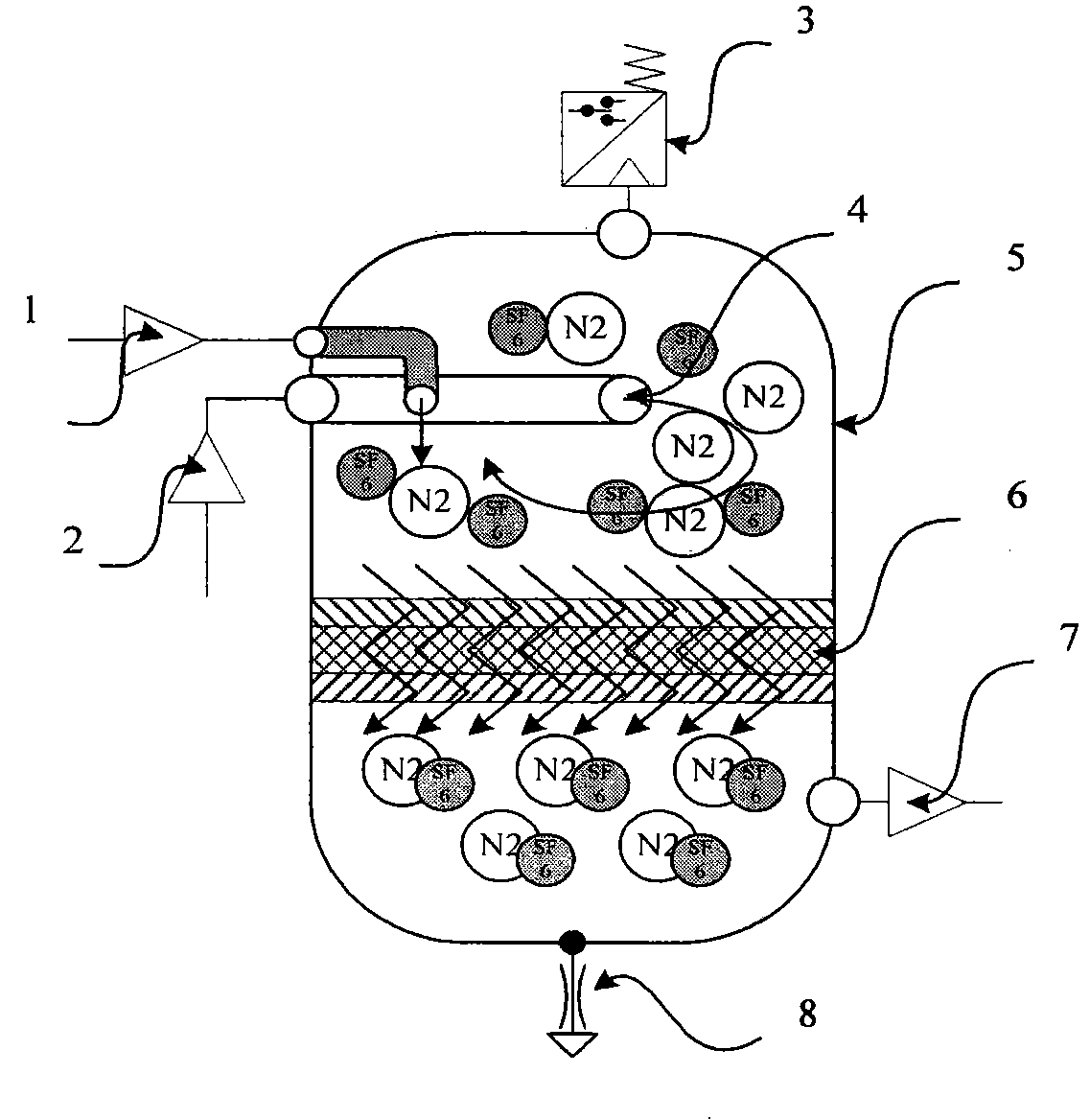

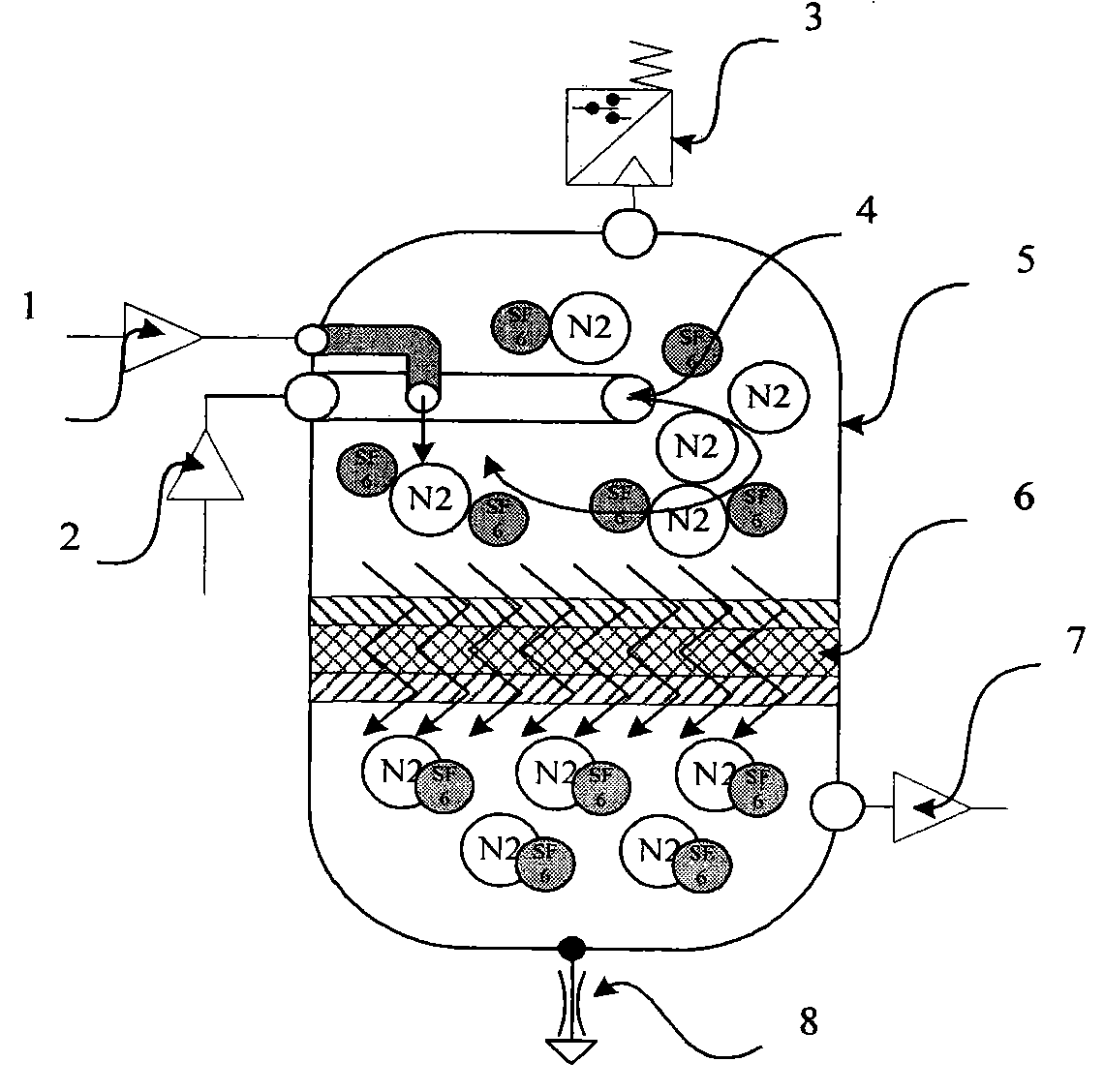

Efficient gas mixing device for magnesium alloys

ActiveCN101332416AImproved combustion safetyQuality improvementMaintainance of heating chambersMixer accessoriesCardingFiltration

The invention relates to a magnesium-alloy high-efficient gas mixing device which comprises a mixing pot, a first gas inlet joint, a second gas inlet joint and a pressure switch are arranged at the upper side end of the pot wall of the mixing pot in a seal and perforation way, a gas outlet joint is arranged at the lower side end of the pot wall of the mixing pot in a seal and perforation way and a discharging valve is arranged at the lower side end of the pot wall of the mixing pot; a ventilation pipe that is connected with the first gas inlet joint is of a right-angle bend pipe with a pipe mouth being arranged downwards; a ventilation pipe that is connected with the second gas inlet joint is of an arc bend pipe and a pipe mouth thereof is arranged horizontally and inwards to form a rotary spraying nozzle; a carding net which can carry out the second carding and filtration to the mixing gases is arranged at the middle-lower part of an inner cavity of the mixing pot. The invention uses two or more than two sorts of gases with different qualities for mixing, the gases are input from the gas inlet joint and injected into a mixing gas pot by the rotary spraying nozzle, so the high-pressure airflow and the fluid-state rotation movement can be formed, and two gases with different qualities are evenly and fully mixed together by the second carding and filtration by the stainless steel wire carding net. The device has the outstanding advantages of full and even mixing and stable output flux.

Owner:NINGBO XUNHUI ELECTRIC APPLIANCE

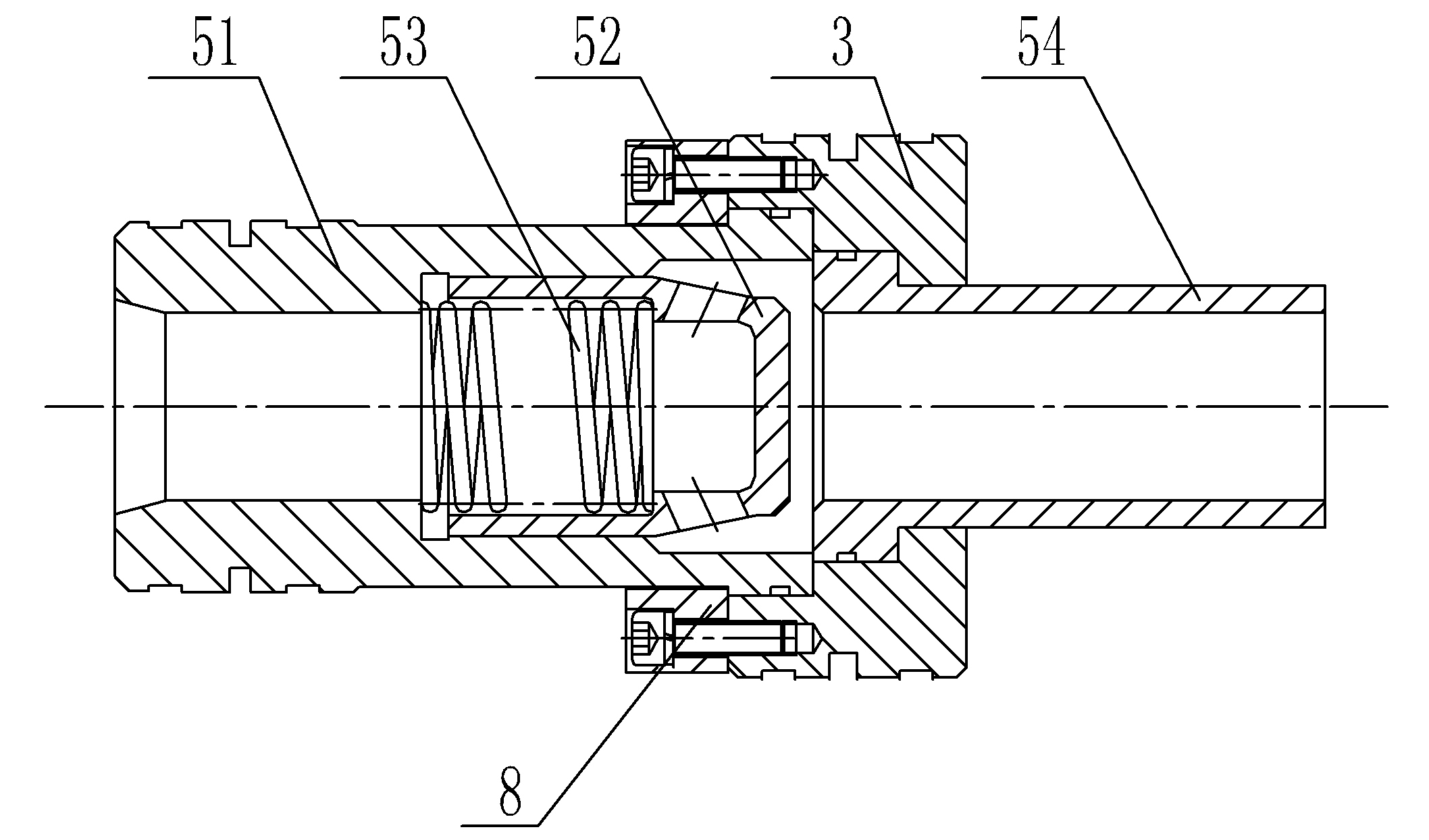

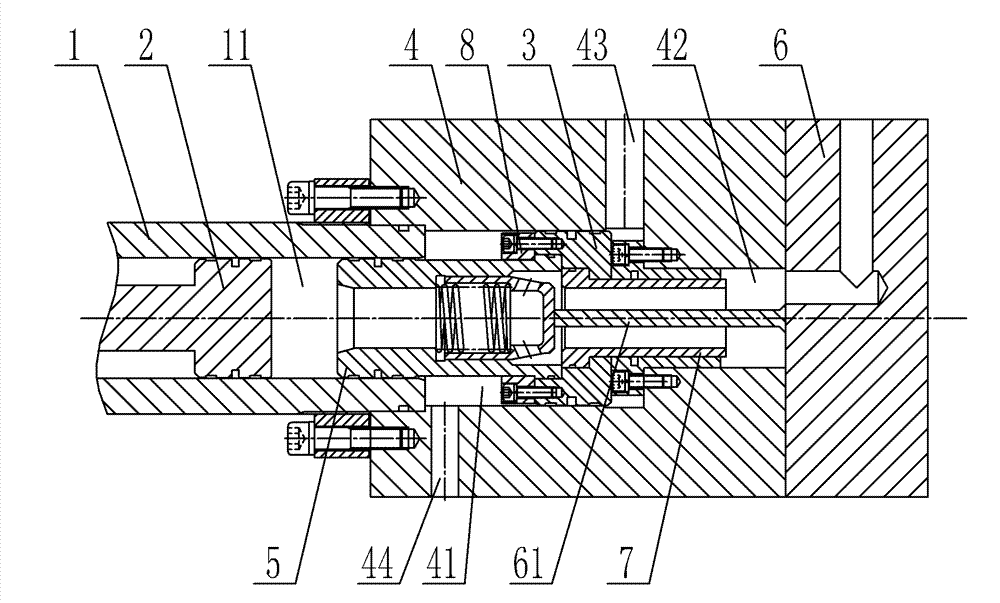

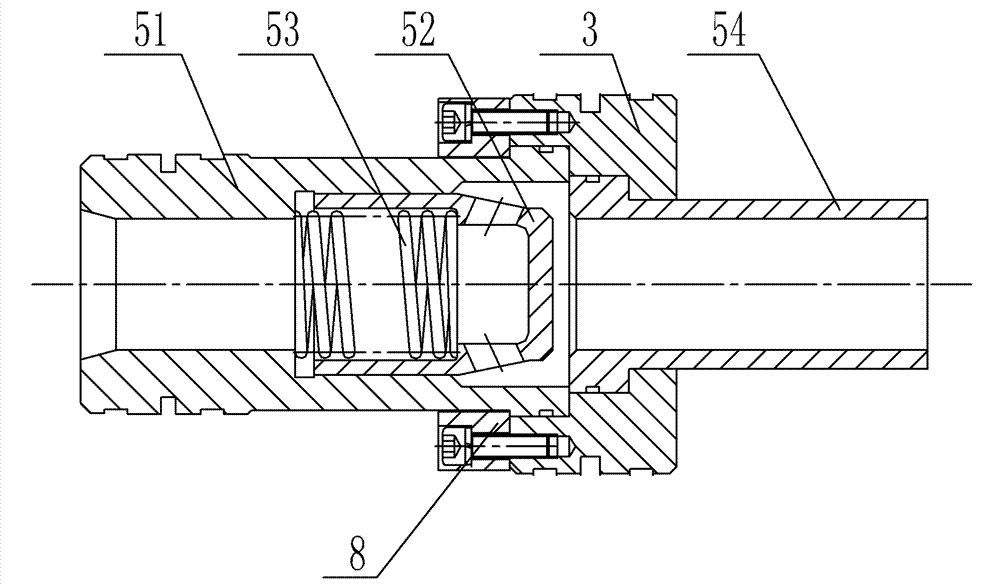

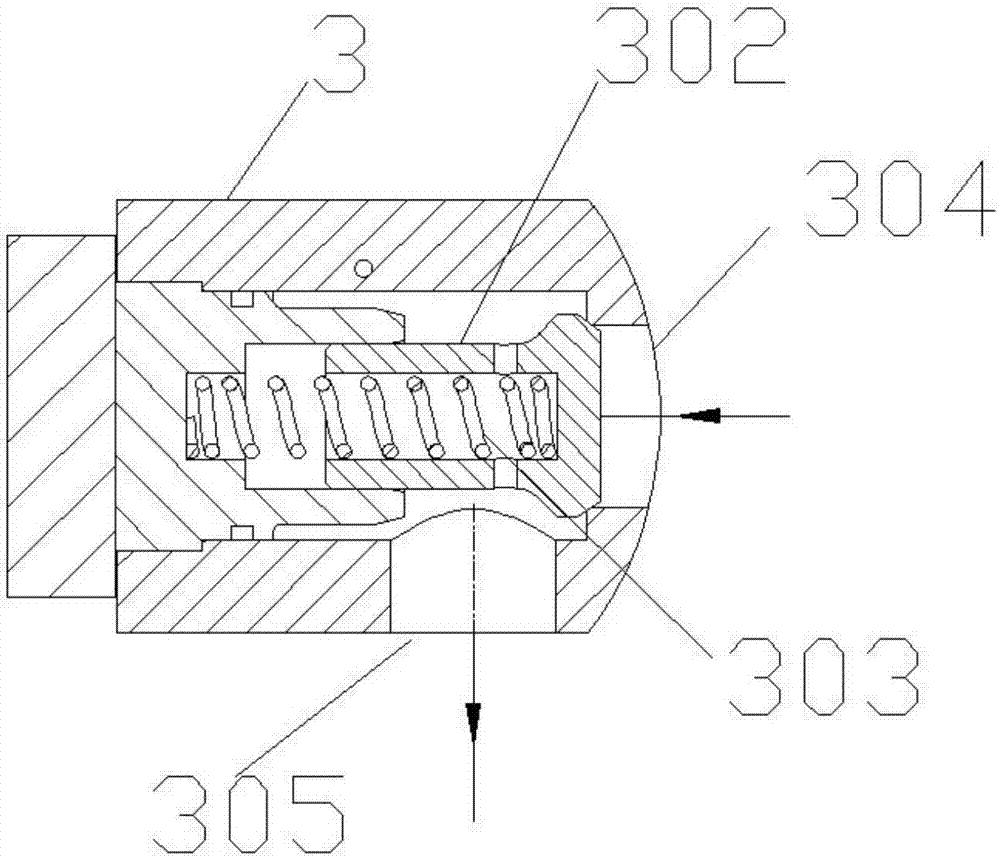

One-way valve injection device for die casting machine

The invention relates to a one-way valve injection device for a die casting machine, which comprises an injection cylinder, an injection piston, a pressurizing piston and a pressurizing valve plate, wherein the injection piston, the pressurizing piston and the pressurizing valve plate are arranged in the injection cylinder; the pressurizing valve plate is provided with a first valve hole and a second valve hole, the pressurizing piston is arranged in the first valve hole and is matched with the first valve hole in a dynamic sealing manner, the injection cylinder is connected with the first valve hole of the pressurizing valve plate in a sealing manner, a one-way valve is arranged between the injection piston and the pressurizing piston, one end of the one-way valve is arranged in the injection cylinder and is matched with the injection cylinder in a dynamic sealing manner, the other end of the one-way valve is fixedly connected with the pressurizing piston, and the second valve hole is communicated with an oil inlet of the one-way valve. Compared with a floating piston, the one-way valve injection device operates stably and reliably; the problem of instable speed when advanced pressurizing and stroke control pressurizing under a pressure control condition can be solved; and stroke or time control can be realized and pressing time is shortened through pressurization, thus the one-way valve injection device can adapt to the requirement for the traditional high-end die casting within larger range.

Owner:常州源通电子科技有限公司

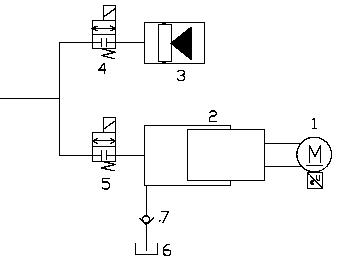

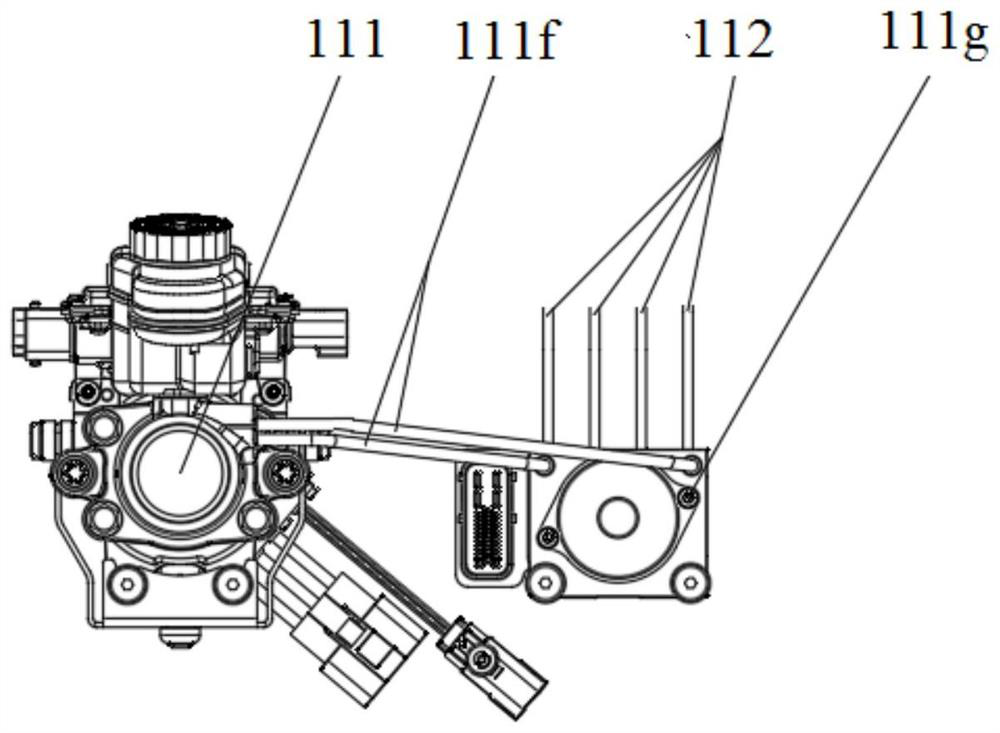

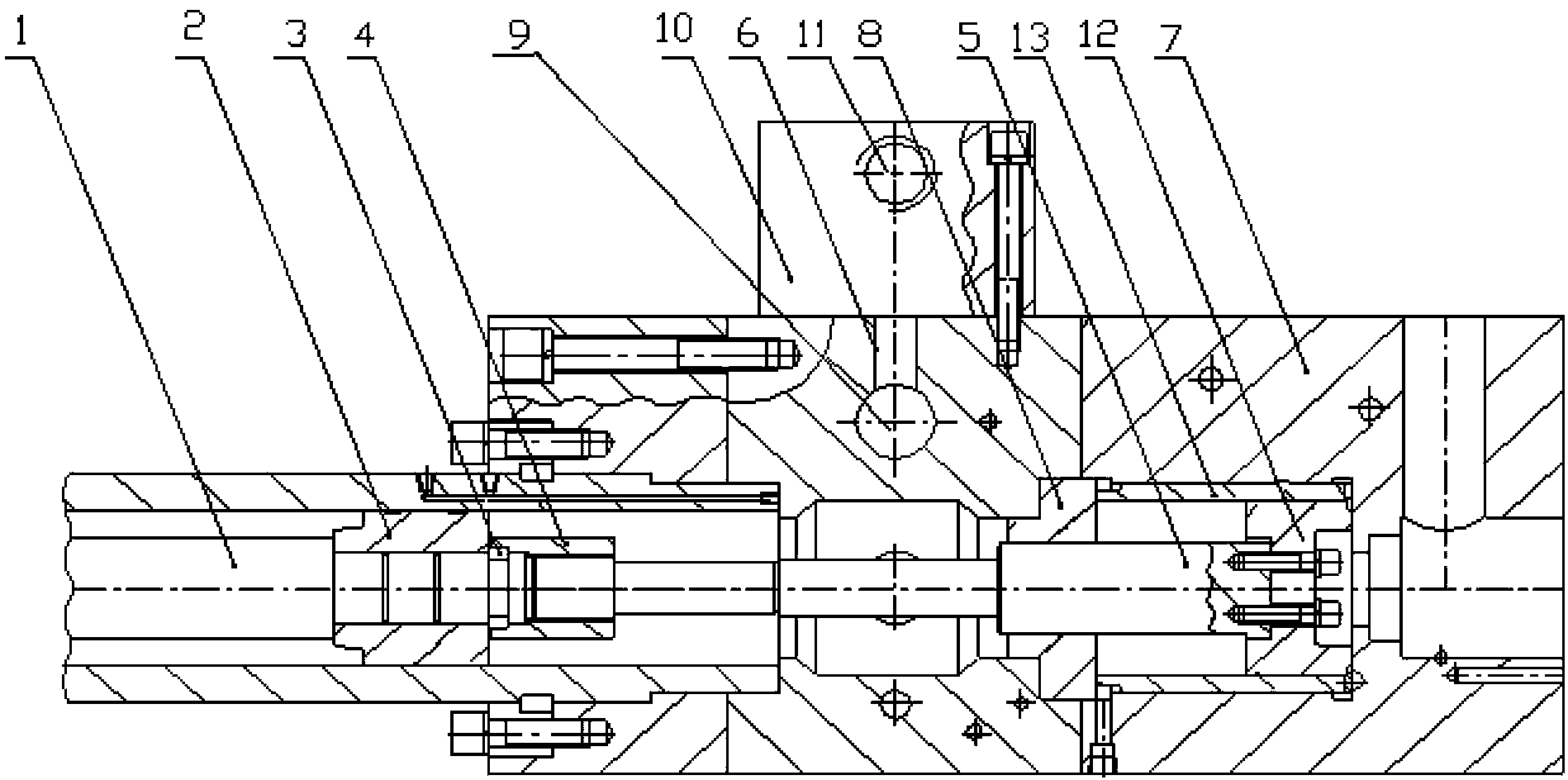

Electric drive hydraulic device for automobile braking system

PendingCN109305154AShort build-up timeReduce motor powerBraking action transmissionElectric machineryElectric drive

The invention provides an electric drive hydraulic device for an automobile braking system. The electric drive hydraulic device for the automobile braking system comprises a motor, a pressure cylinderand an oil pressure accumulator, wherein an accumulator electromagnetic valve is arranged at an outlet of the oil pressure accumulator; the oil pressure accumulator is controlled to supply oil to thebraking system through the accumulator electromagnetic valve; the motor is connected with the pressure cylinder through a transmission mechanism; an outlet of the pressure cylinder is connected witha pressure cylinder electromagnetic valve; the pressure cylinder is controlled to supply liquid by the pressure cylinder electromagnetic valve; and the motor drives the pressure cylinder to output hydraulic pressure to charge the accumulator. Through the control of two pressure output sources of the oil pressure accumulator and the motor-driven pressure cylinder, the voltage buildup time during emergency braking is shortened. The ABS action on the low-attachment road surface can consume the oil of the pressure cylinder, and the ABS function of the electric control braking system can be interrupted when the pressure cylinder is refilled. However, the intervention of the oil pressure accumulator can realize that the function can be interrupted during the ABS action on the low-attachment roadsurface, so that the safety during driving is ensured.

Owner:WUHU BETHEL ELECTRONICS CONTROL SYST

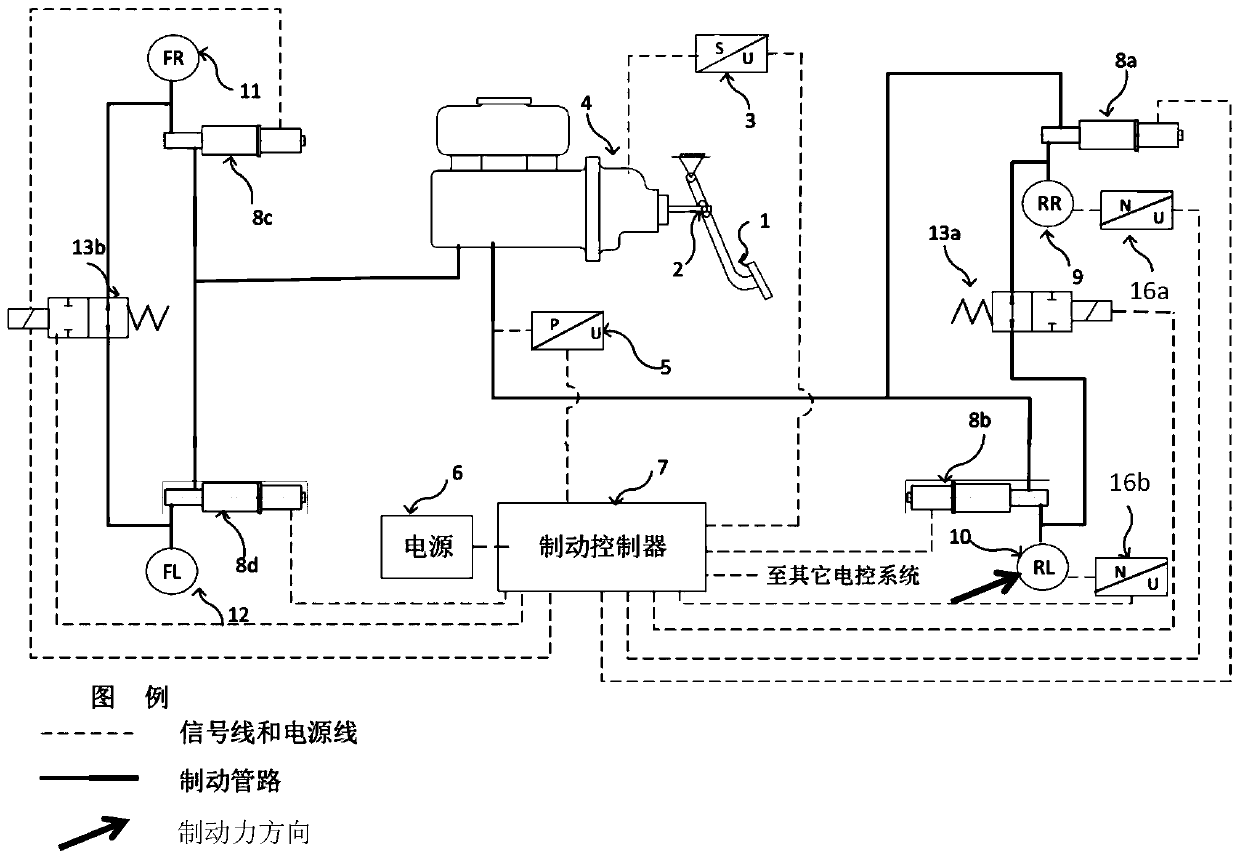

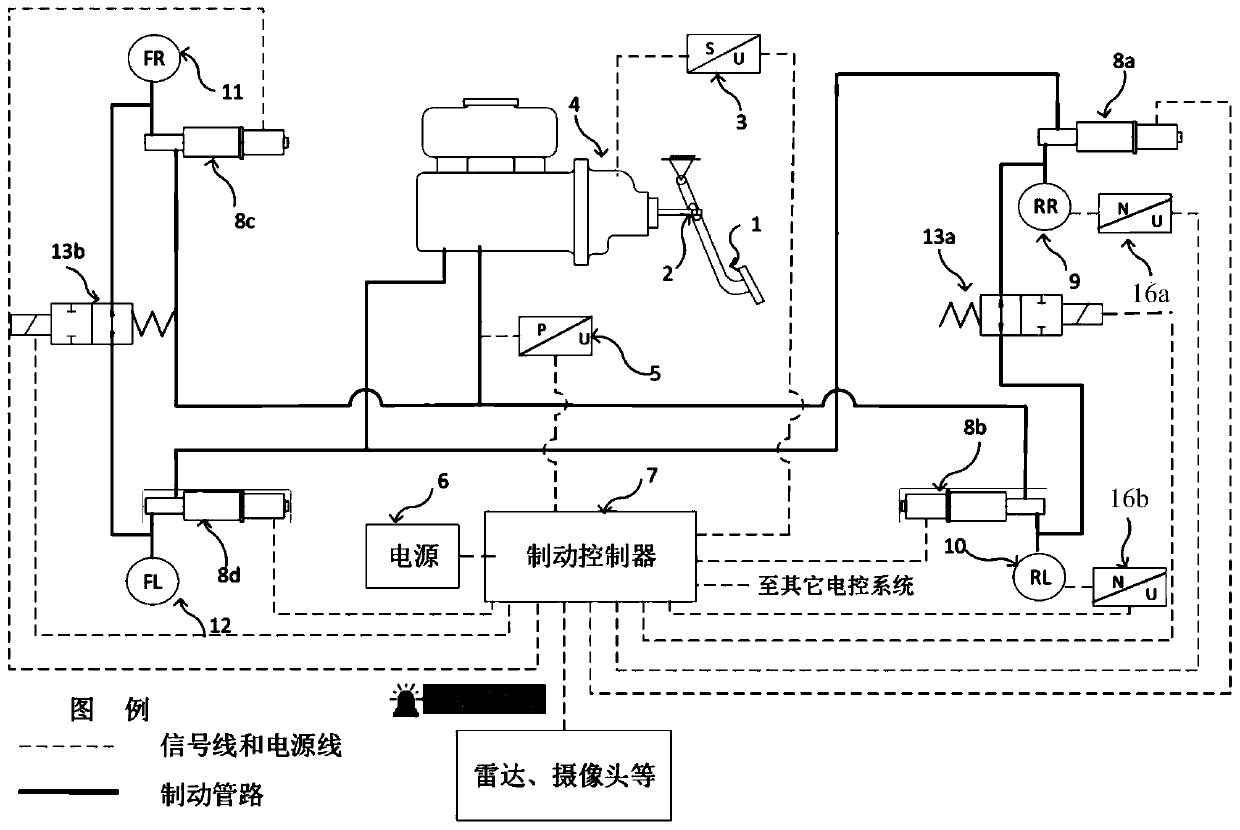

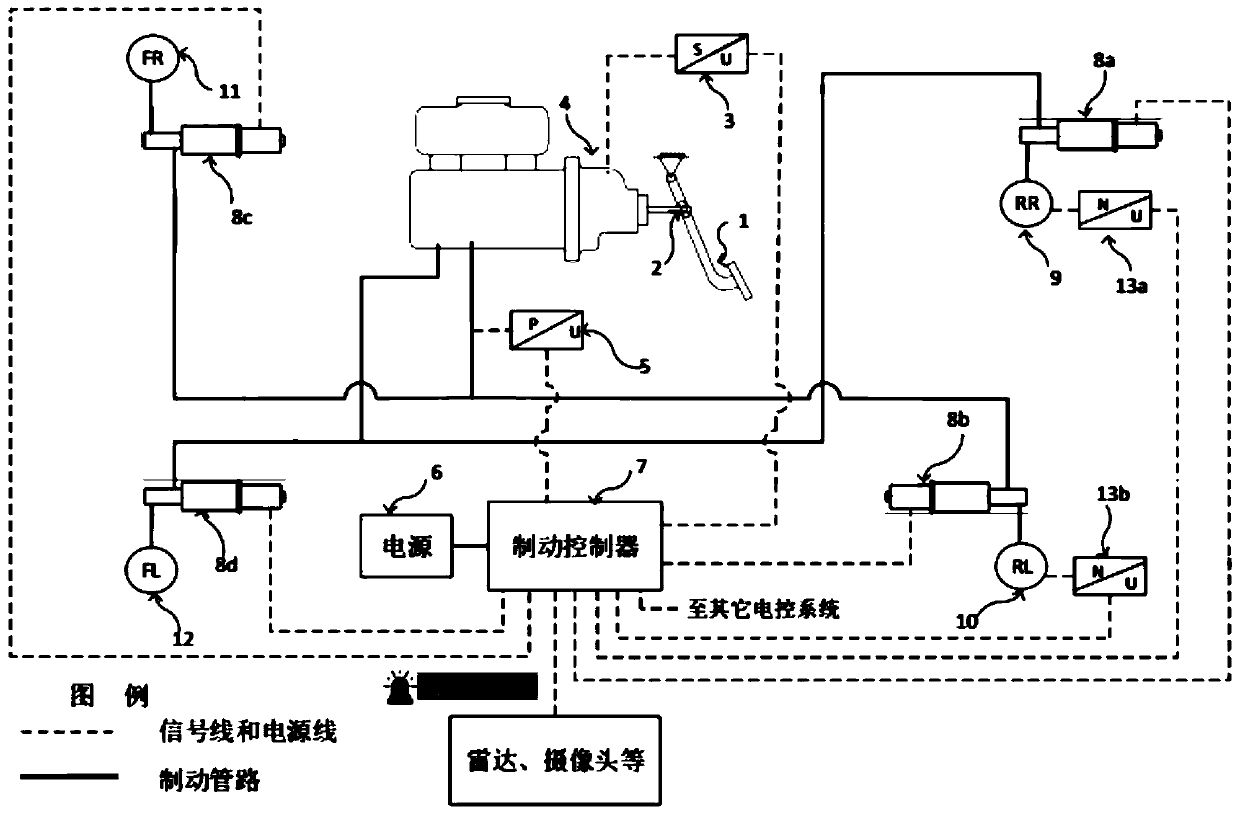

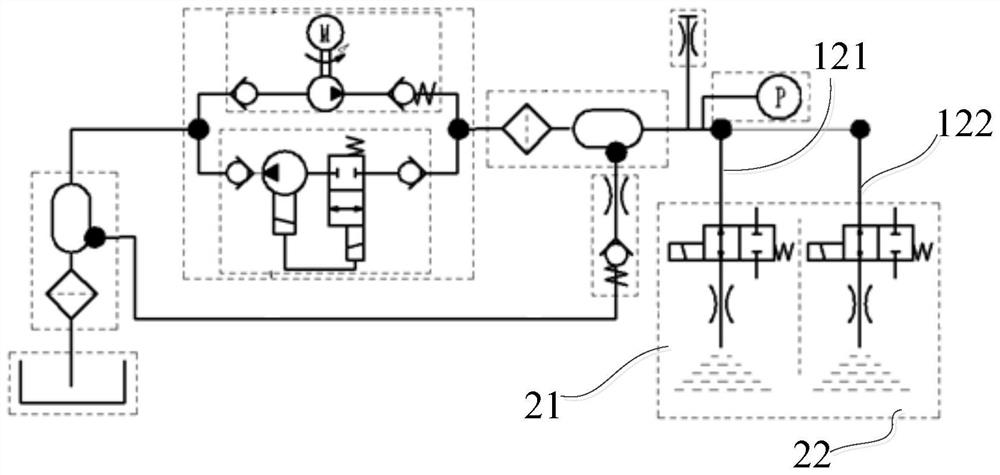

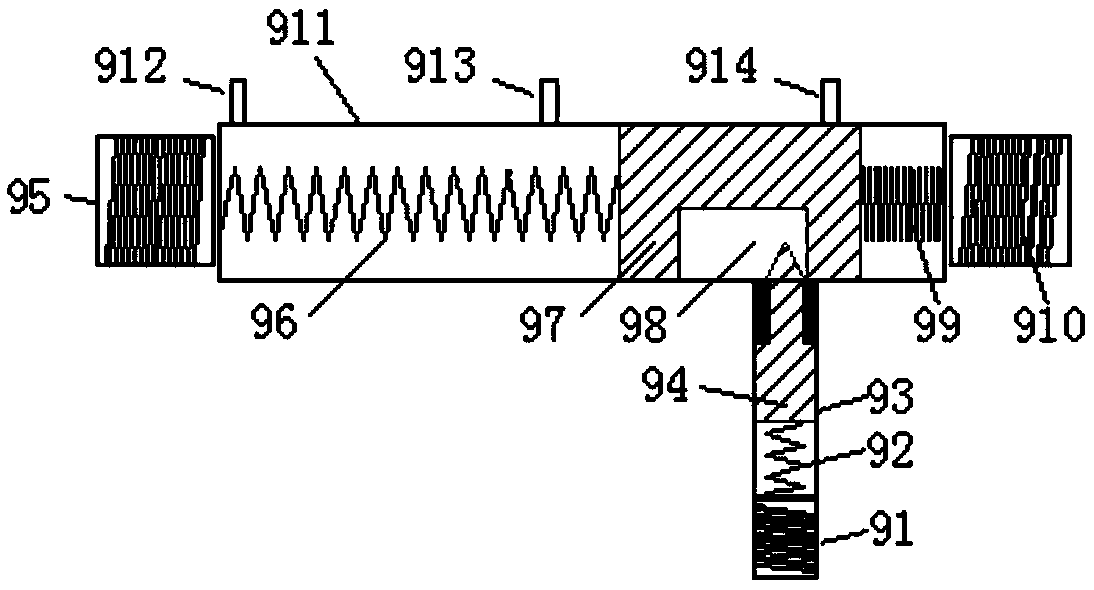

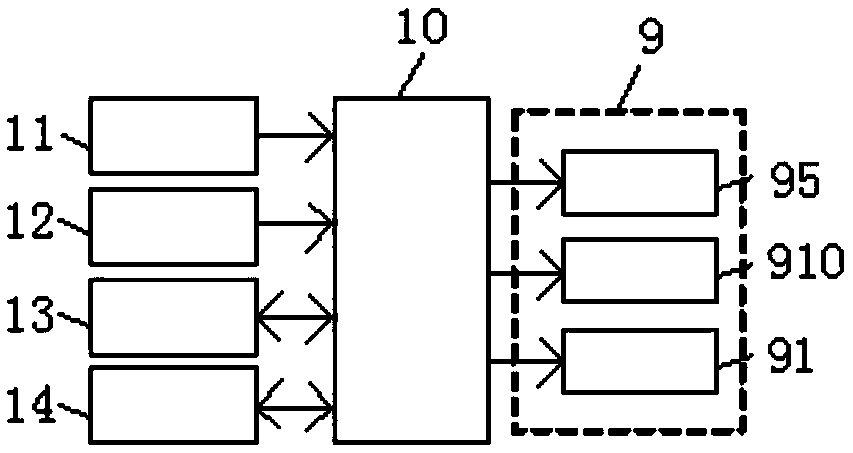

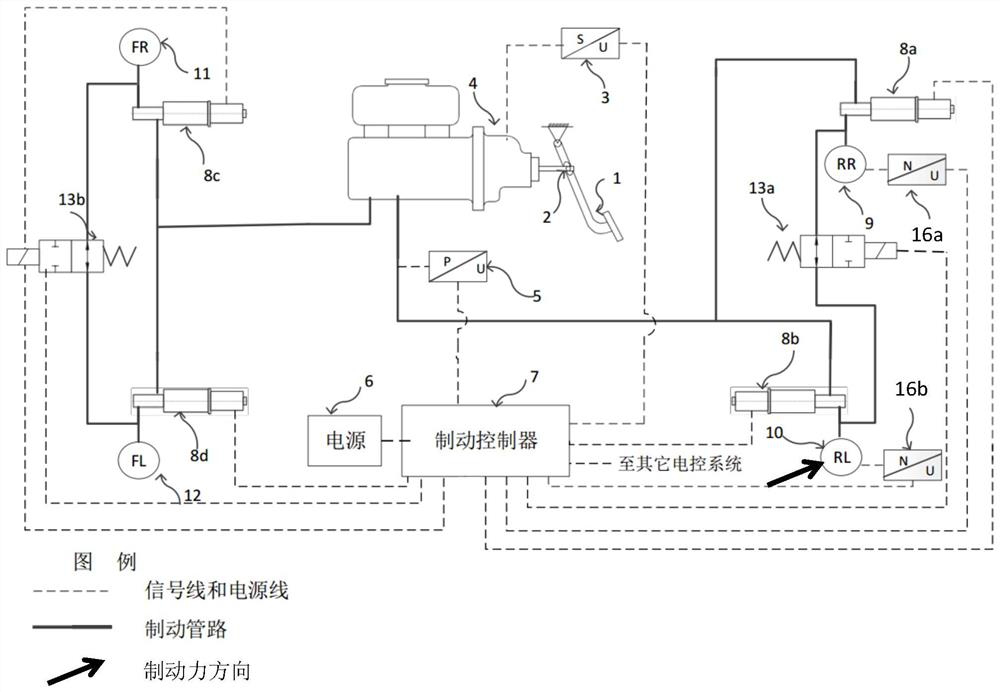

Time-sharing autonomous braking system with failure labor backup function and baking method

InactiveCN109955840AShort build-up timeFast brake responseBraking action transmissionBrake control systemsElectricityTime-sharing

The invention relates to the technical field of an autonomous braking system, and concretely provides a time-sharing autonomous braking system with a failure labor backup function and a baking method.The time-sharing autonomous braking system comprises a power supply (9) and a braking controller (10) and also comprises a first electric cylinder (8a), a second electric cylinder (8b) and a labor cylinder; the first electric cylinder (8a) and the second electric cylinder (8b) are electrically connected with the braking controller; the labor cylinder is electrically connected with the first electric cylinder (8a) and the second electric cylinder (8b); the first electric cylinder (8a) and the second electric cylinder (8b) are respectively connected to two wheel brakes arranged on an automobileto form two braking loops; an electromagnetic valve is arranged between each wheel brake and the corresponding electric cylinder. The braking method provided by the invention comprises an autonomousbraking mode, a failure labor backup braking mode and a failure protection braking mode. The time-sharing autonomous braking system has the advantages that the structure is simple; the cost is low; the braking response is fast; the reliability is high; the failure protection capability is high; the braking control and the ABS function of single wheels can be realized.

Owner:南京经纬达汽车科技有限公司

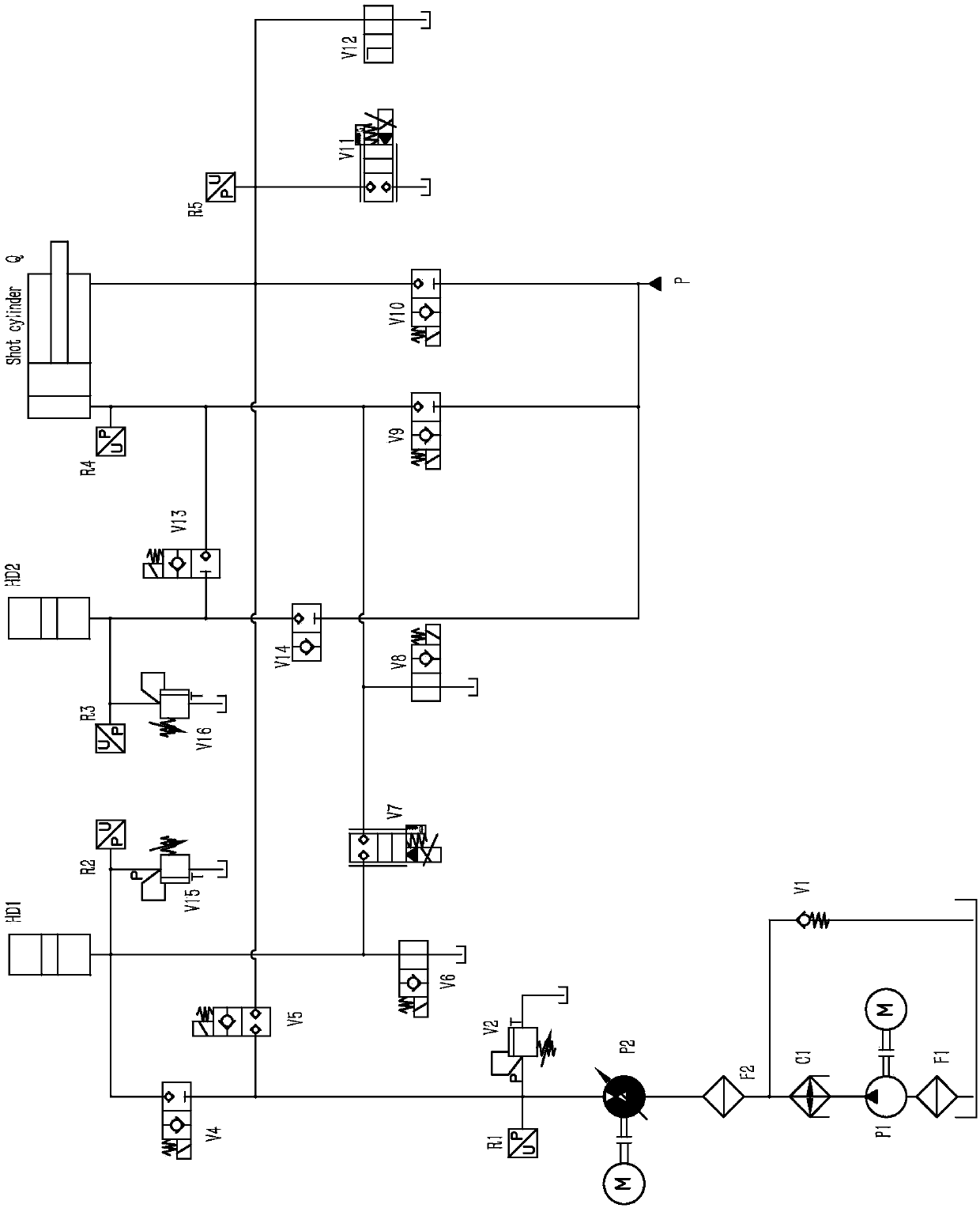

Pressurizing device and method of unpressurized oil cylinder

PendingCN108443240AIncrease boost effectSimple structureFluid-pressure actuator testingAccumulator installationsLow speedDie casting

The invention discloses a pressurizing device and method of an unpressurized oil cylinder. The device comprises an injection oil cylinder, a low-pressure pump set, a high-pressure variable pump set, ahigh-pressure energy storing device and a rapid energy storing device, wherein a hammer front valve is arranged at the front end of the injection oil cylinder and is connected to the rapid energy storing device; a hammer rear valve is arranged at the rear end of the injection oil cylinder and is connected to a P end oil supplying port; the P end oil supplying port is connected to the rapid energystoring device; the low-pressure pump set is connected to the high-pressure variable pump set which is connected to an HD1 energy storing valve; and the HD1 energy storing valve is connected to the high-pressure energy storing device. The method comprises the steps of early-stage preparation of action of an injection part, first-stage low-speed action, second-stage low-speed action, high-speed action, pressurizing, following and hammer returning. The device is simple in structure; the pressure buildup time can be increased to be 12ms, so that the pressurizing performance of the injection partof a large die-casting machine can be extremely improved; the difficulty that the parameters of a die casting machine in the prior art cannot meet the requirements of some precision products on casting technologies can be solved; and the yield of products can be effectively increased.

Owner:NINGBO HAITIAN METAL MOLDING EQUIP CO LTD

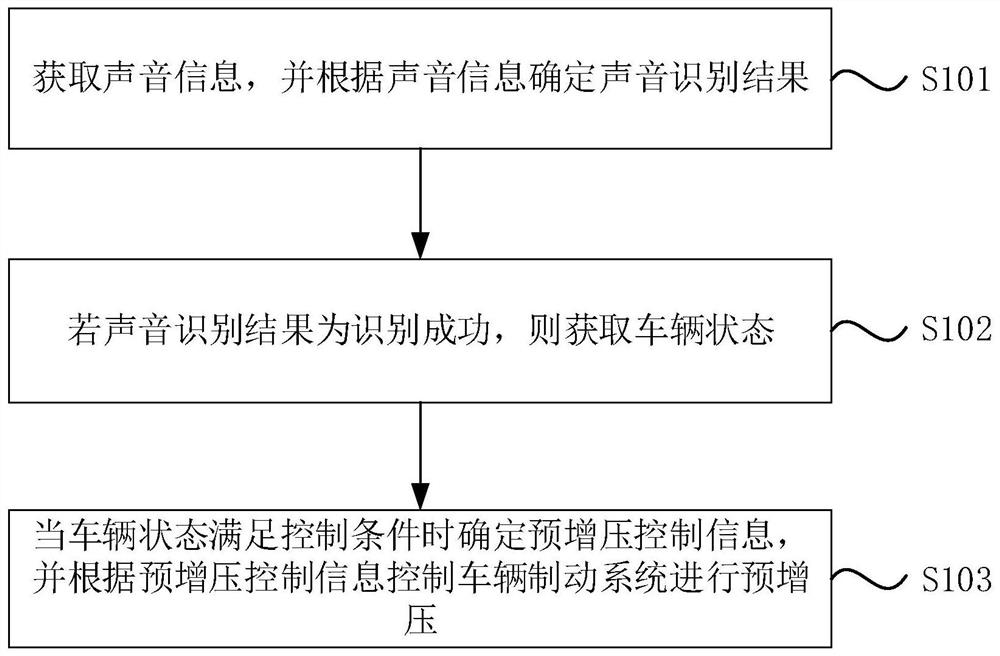

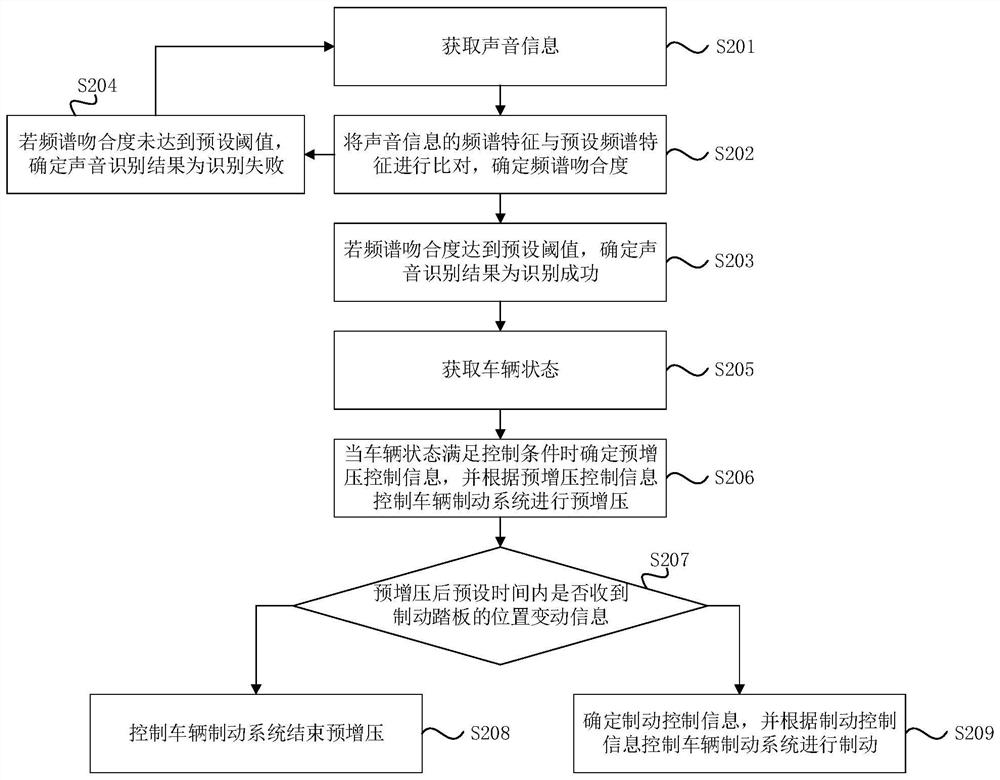

Pre-pressurization control method and device, vehicle and storage medium

ActiveCN112026732ASolve traffic accidentsImprove securityBraking action transmissionDriver/operatorTraffic crash

The embodiment of the invention discloses a pre-pressurization control method and device, a vehicle and a storage medium. The method comprises the following steps: acquiring sound information, and determining a sound recognition result according to the sound information; if the voice recognition result is that recognition succeeds, acquiring the vehicle state; and when the vehicle state meets a control condition, determining pre-pressurization control information, and controlling a vehicle braking system to conduct pre-pressurization according to the pre-pressurization control information. According to the technical scheme, the braking system can be pressurized in advance when a driver difficultly judges whether braking is needed or not, the vehicle braking system is controlled through sound to conduct pre-pressurization instead of directly controlling the braking system to conduct braking, and a problem that when a vehicle conducts braking judgment only through sound to generate misjudgment, traffic accidents are easily caused due to direct braking is solved, a revocation space is provided for an instruction generated due to misjudgment, the braking time and the braking distance are shortened, and the safety of vehicle driving is improved.

Owner:CHINA FIRST AUTOMOBILE

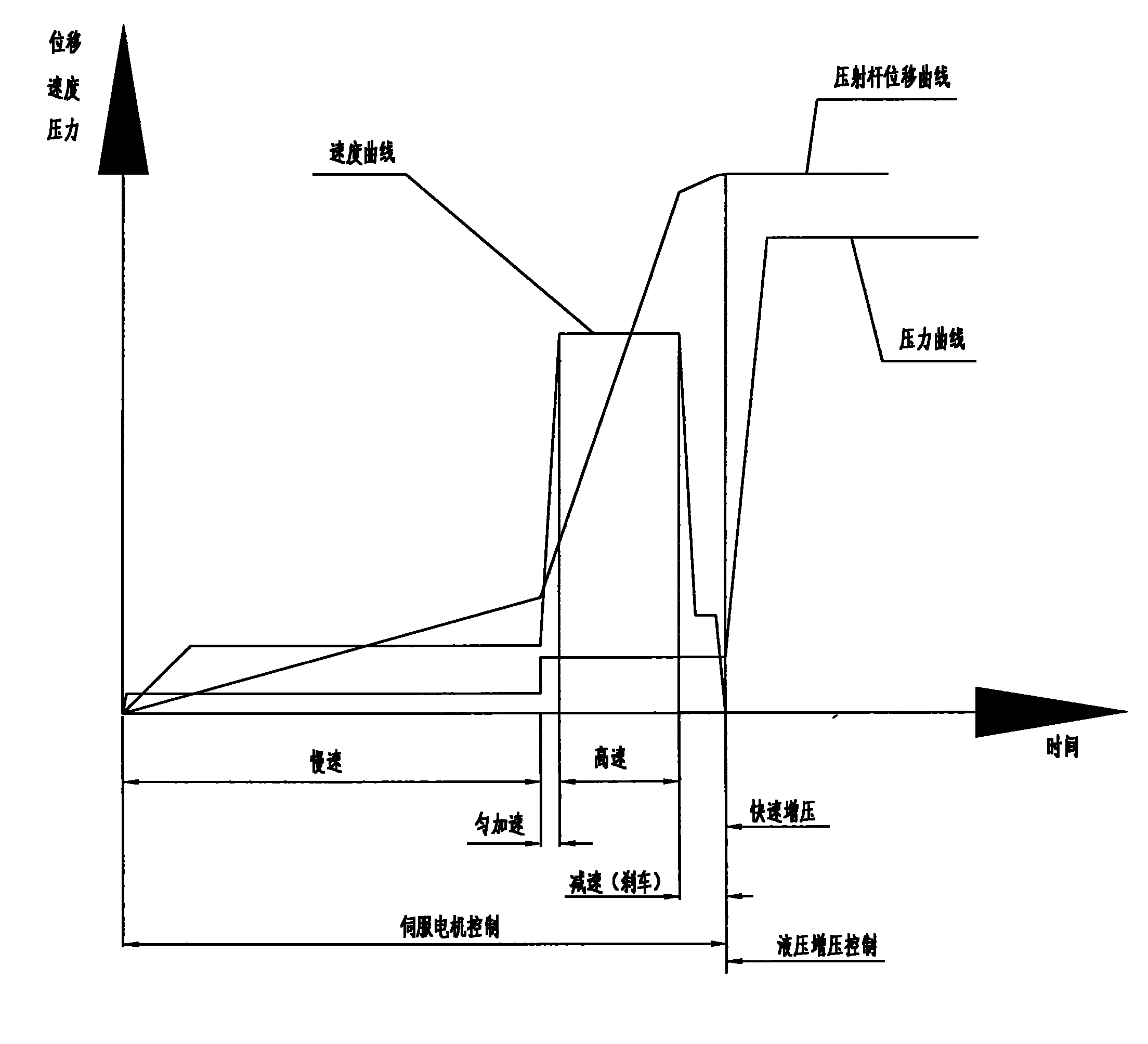

Oil-electric hybrid hot-chamber die casting machine injection system

The invention relates to an oil-electric hybrid hot-chamber die casting machine injection system, which comprises a melting pot sleeve, an injection rod, a servomotor controller and a hydraulic pressurizer, a servomotor drives the injection rod in order to control the injection speed in the process of injection, and the hydraulic pressurizer cooperates with the servomotor controller to drive the injection rod in order to control rapid pressurization in the process of injection. The injection speed is controlled by the servomotor, the servomotor controls multi-stage slow speed, uniform acceleration, multi-stage high speed, speed reduction and braking in the process of injection, and can realize the multi-stage stepless regulation of the injection speed, consequently, the flashless function of die casting is realized, and high-quality net-shaped products can be shaped. Meanwhile, a hydraulic system is utilized to carry out pressurization, pressurization is independently controlled, which can help to shorten the pressurization time, consequently, a large motor does not need to be adopted in order to achieve high increased pressure, and thereby the cost is reduced.

Owner:SHENZHEN LEADWELL TECH CO LTD

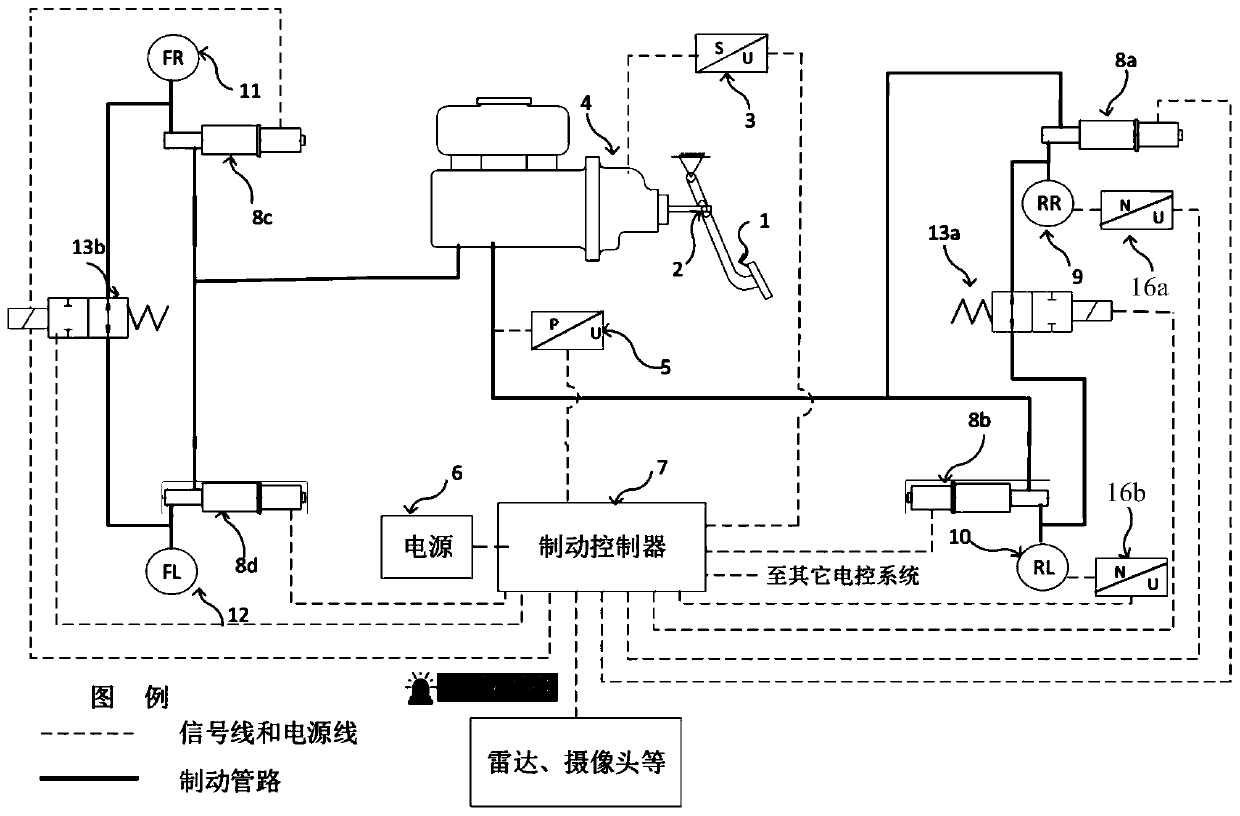

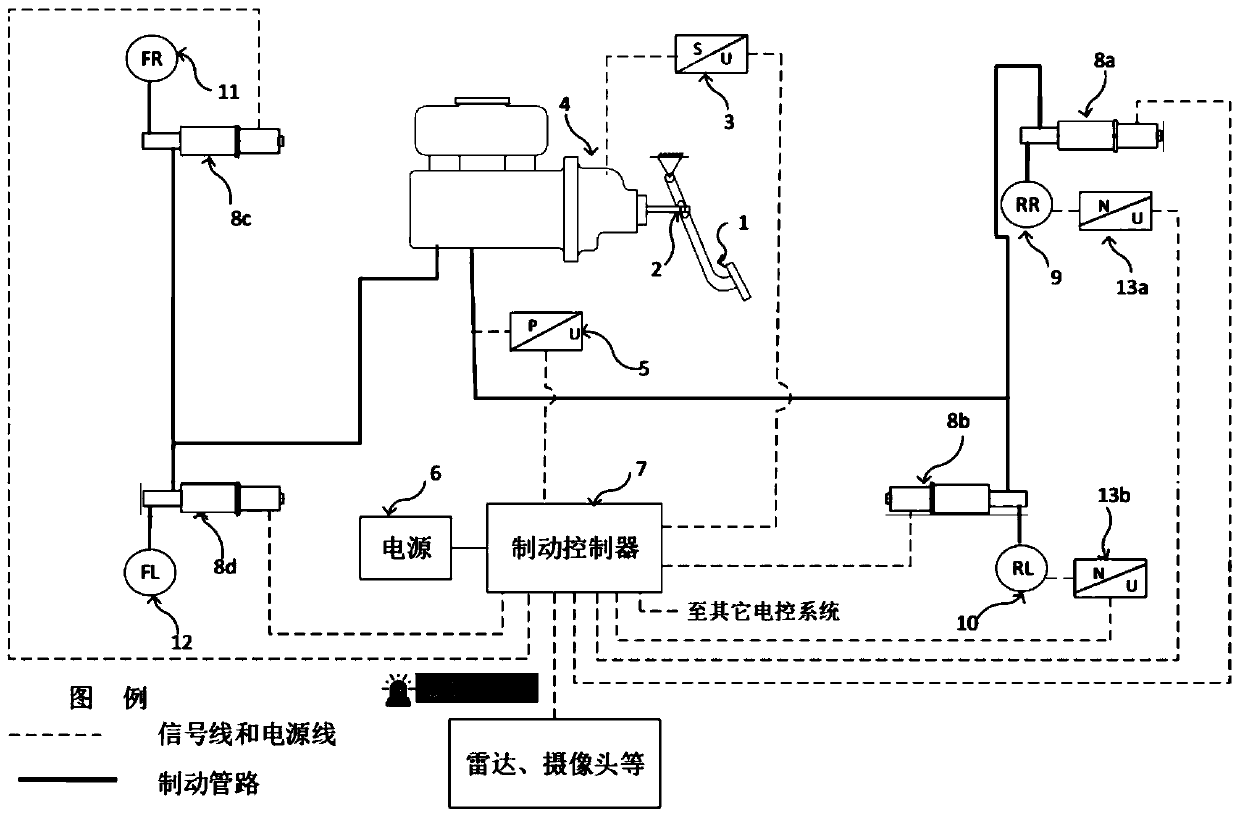

Distributed braking system with manpower failure backup and pressure adjusting control method therefore

ActiveCN110775033AShort build-up timeFast brake responseBraking action transmissionFoot actuated initiationsSolenoid valveControl theory

The invention provides a distributed braking system with manpower failure backup and a pressure adjusting control method therefore, and belongs to the technical field of automobile braking systems. The distributed braking system specifically comprises a brake pedal, a human cylinder, a brake controller and a power supply, and further comprises at least three electric cylinders and solenoid valveswhich are electrically connected with the brake controller, wherein the electric cylinders are connected with a liquid discharge hole of the human cylinder through a brake pipeline, the electric cylinders are connected to the same number of wheel brakes on an automobile in a one-to-one correspondence mode, and each electric cylinder and the corresponding one wheel brake form a braking circuit; thetwo wheel brakes at the two ends of the same shaft communicates through the brake pipeline, the brake pipeline is provided with the solenoid valves, and the solenoid valves are electrically connectedwith the brake controller. The distributed braking system has the dual functions of manpower failure backup and shaft pressure equalization function, so that the intelligent driving automobile is good in motion stability and high in reliability during braking.

Owner:南京经纬达汽车科技有限公司

Distributed braking system with failure backing-up and brake pressure vector control method for distributed braking system with failure backing-up

PendingCN110861625AShort build-up timeFast brake responseBraking action transmissionFoot actuated initiationsControl theoryVector control

The invention provides a distributed braking system with failure backing-up and a brake pressure vector control method for the distributed braking system with failure backing-up and belongs to the technical field of automobile braking systems. The distributed braking system comprises a braking pedal, a manpower cylinder, a braking controller and a power supply as well as at least three electric cylinders and at least three electromagnetic valves which are electrically connected to the braking controller, wherein each of the electric cylinders is connected to a liquid discharge hole of the manpower cylinder via a braking pipeline respectively; the electric cylinders are in one-to-one corresponding connection to wheel brakes, of the same quantity, on an automobile, and each of the electric cylinders forms a braking loop with the corresponding wheel brake; and the two wheel brakes on two ends of a same shaft communicate via a braking pipeline, one of the electronic valves is disposed on the braking pipeline, and the electromagnetic valve is electrically connected to the braking controller. The distributed braking system provided by the invention has double functions including manpowerfailure backing-up and shaft pressure balancing, so the automobile under intelligent driving can travel stably with high reliability during braking.

Owner:南京经纬达汽车科技有限公司

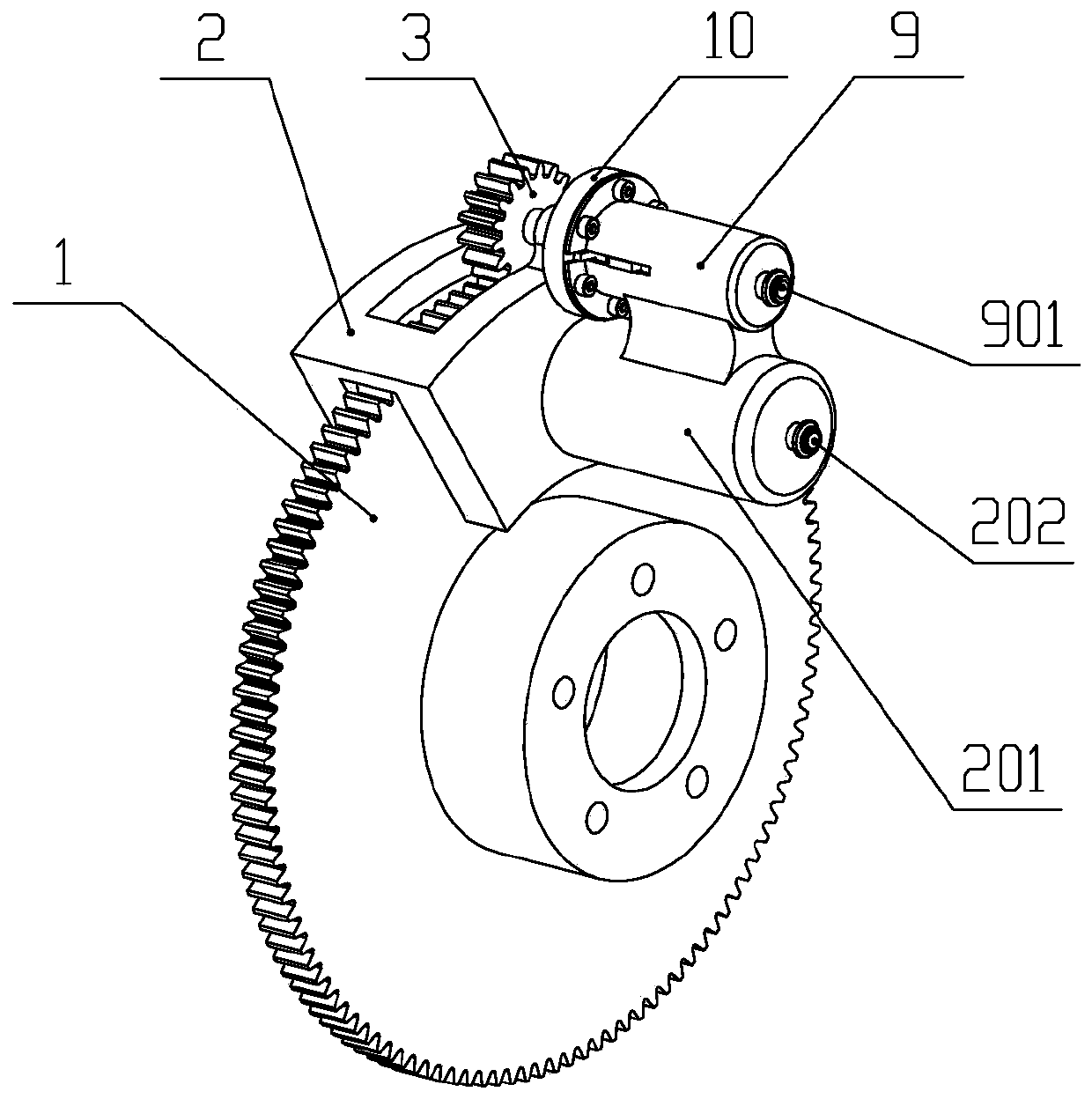

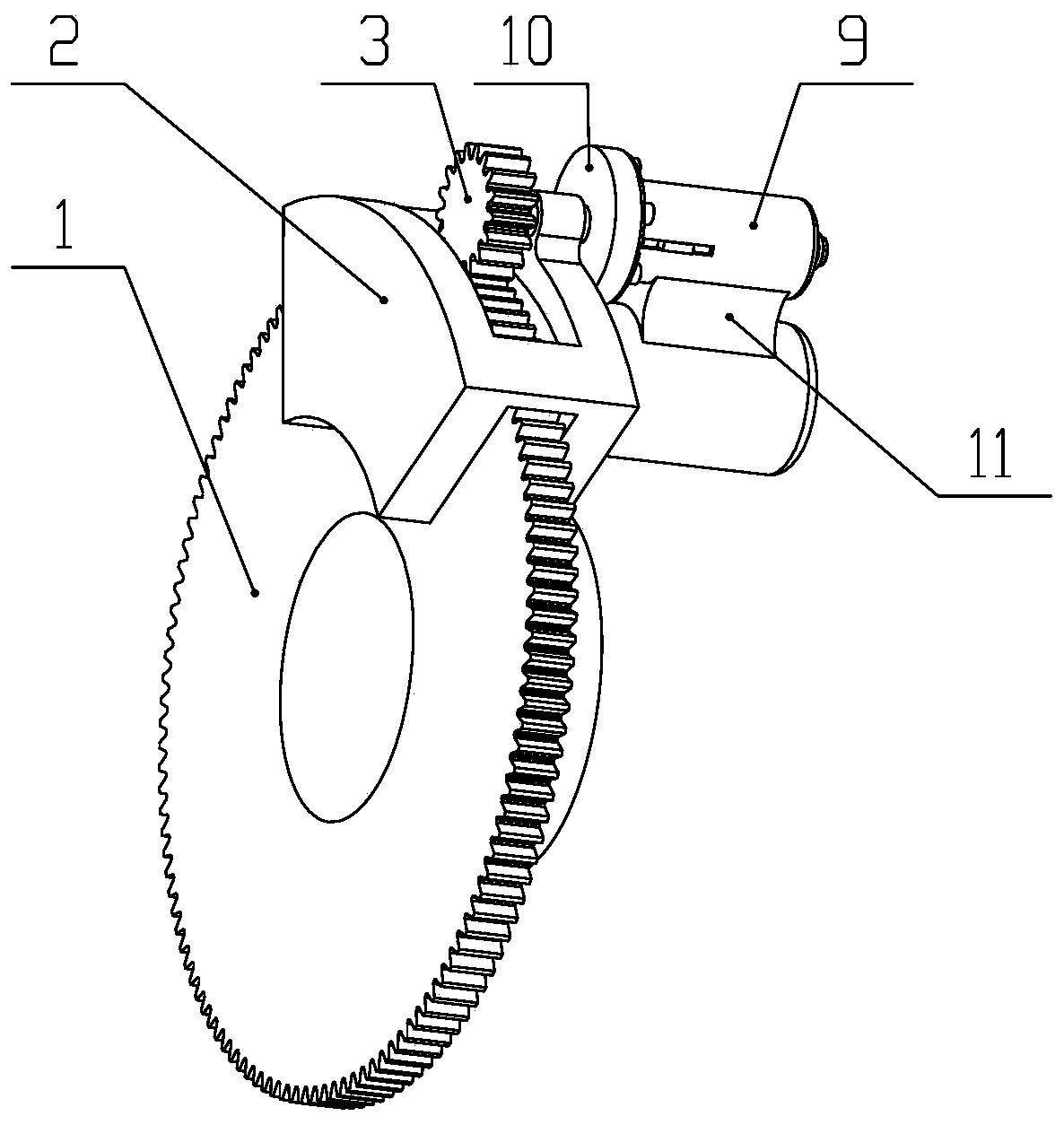

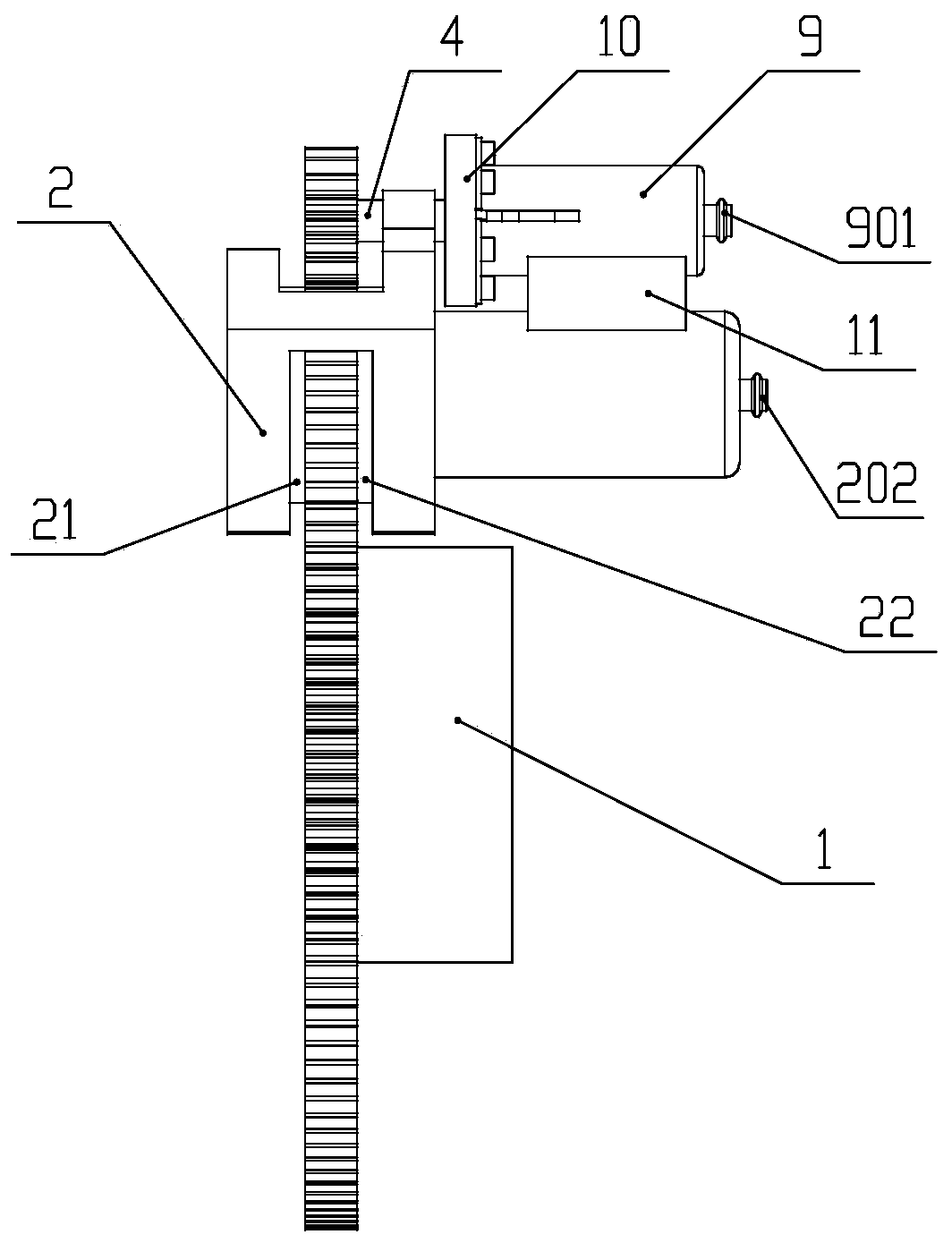

Electro-hydraulic brake-by-wire device with redundancy function and control method

ActiveCN110979282AShorten the lengthLow costBraking action transmissionGear wheelLiquid storage tank

The invention relates to an electro-hydraulic brake-by-wire device with a redundancy function and a control method. The device comprises a brake disc, calipers, a power take-off gear, a gear shaft, alead screw, a return spring, a piston nut, a sealing ring, a high-pressure oil cylinder shell, an electromagnetic clutch, a fixed seat, a hydraulic control unit, a split liquid storage tank, an energyaccumulator, a liquid storage tank, an angle sensor, a brake pedal, a brake push rod assembly, a brake master cylinder, a controller, a left friction plate and a right friction plate. Vehicle kineticenergy can be fully utilized as a power source, a driving motor is omitted, and the cost is effectively reduced. A gear power take-off mechanism is adopted to drive a high-pressure oil cylinder to generate high-pressure brake oil, and whether the high-pressure oil cylinder works or not is controlled through the electromagnetic clutch. The high-pressure oil cylinder is integrated on the brake oilcylinder, so that a brake pipeline is effectively shortened, brake pressure fluctuation caused by elastic deformation of the brake pipeline is reduced, and the brake response speed and the control precision are improved. The device has the advantages of high integration level, high response speed and low cost.

Owner:SHANDONG JIAOTONG UNIV

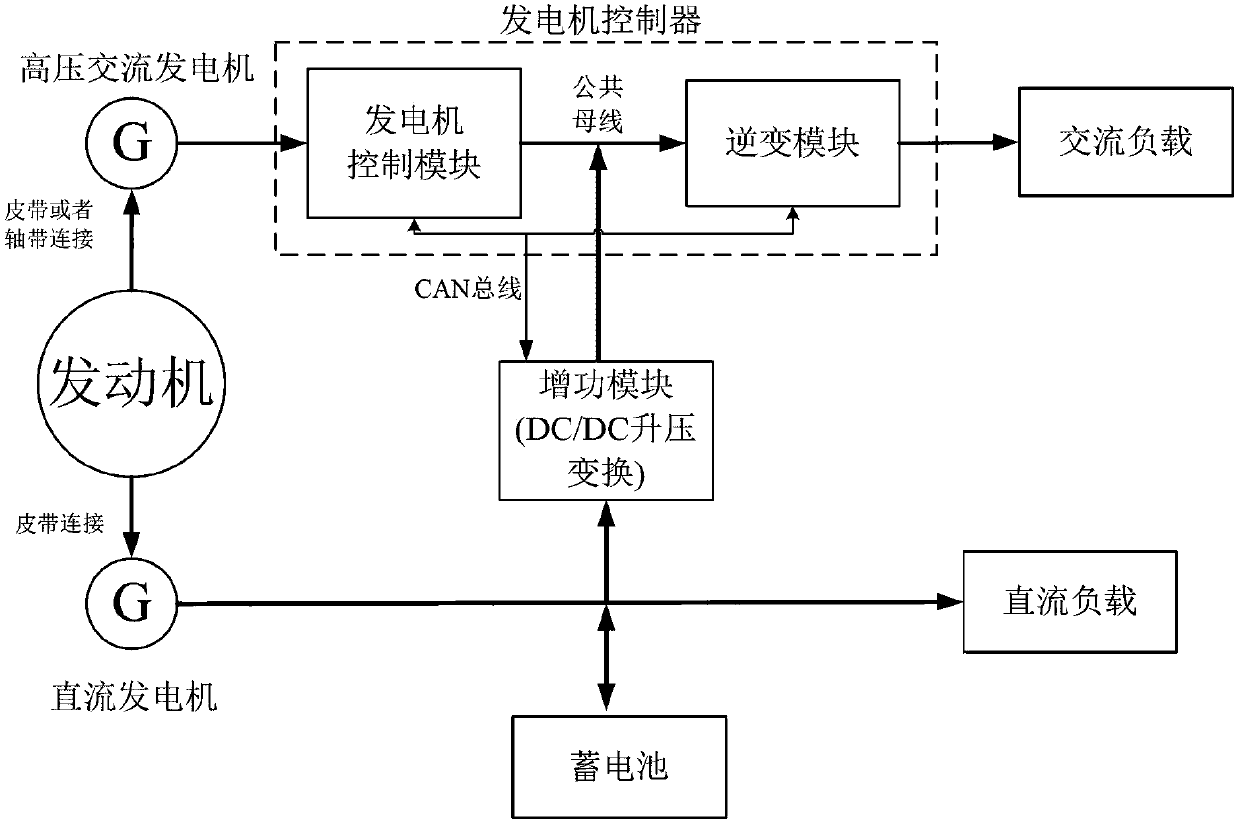

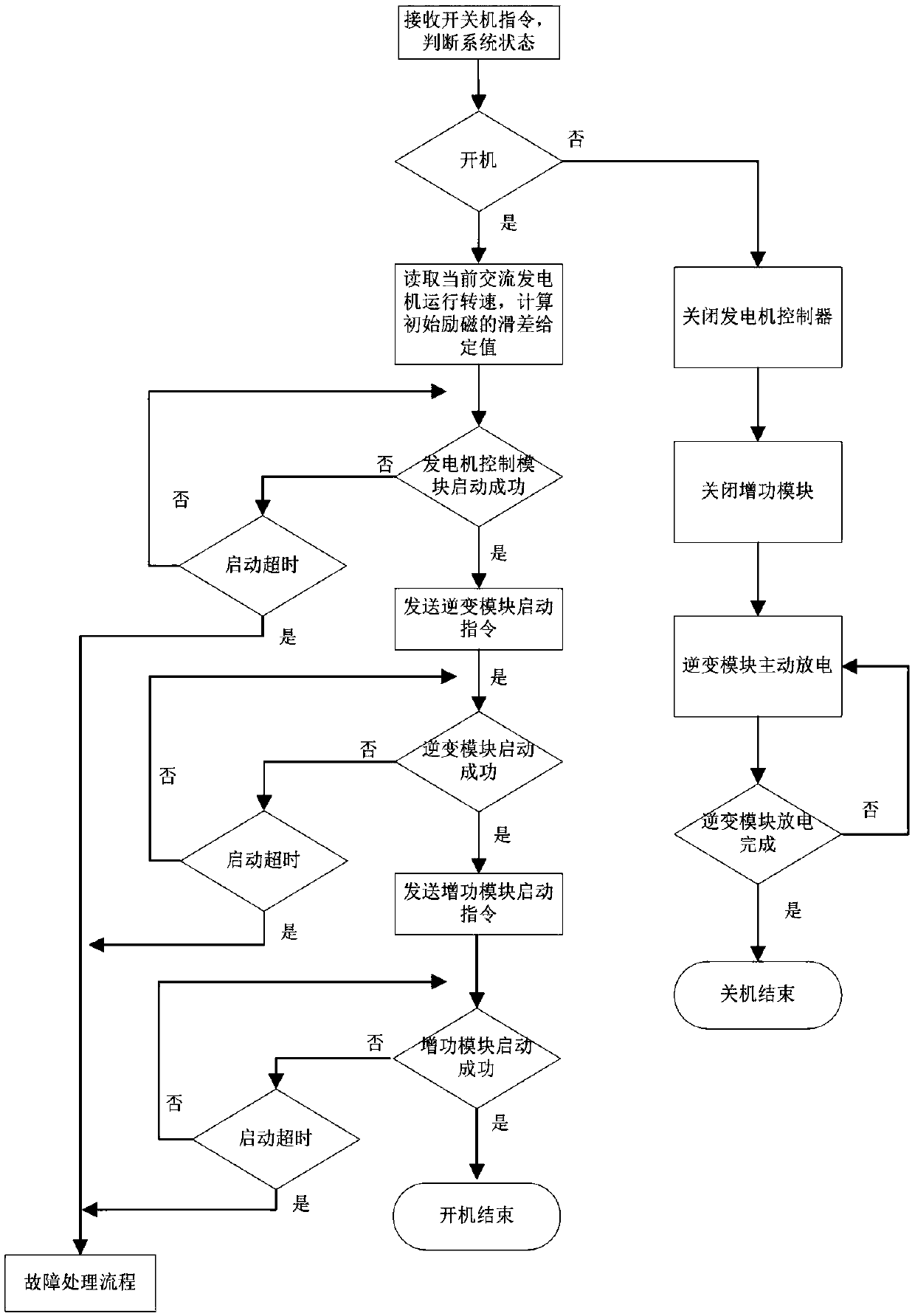

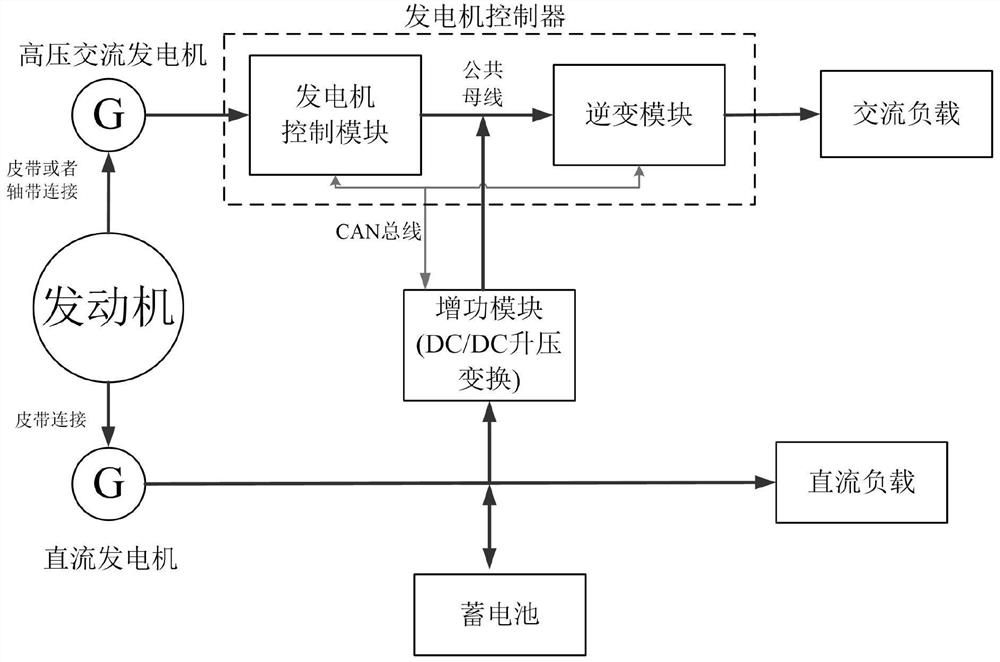

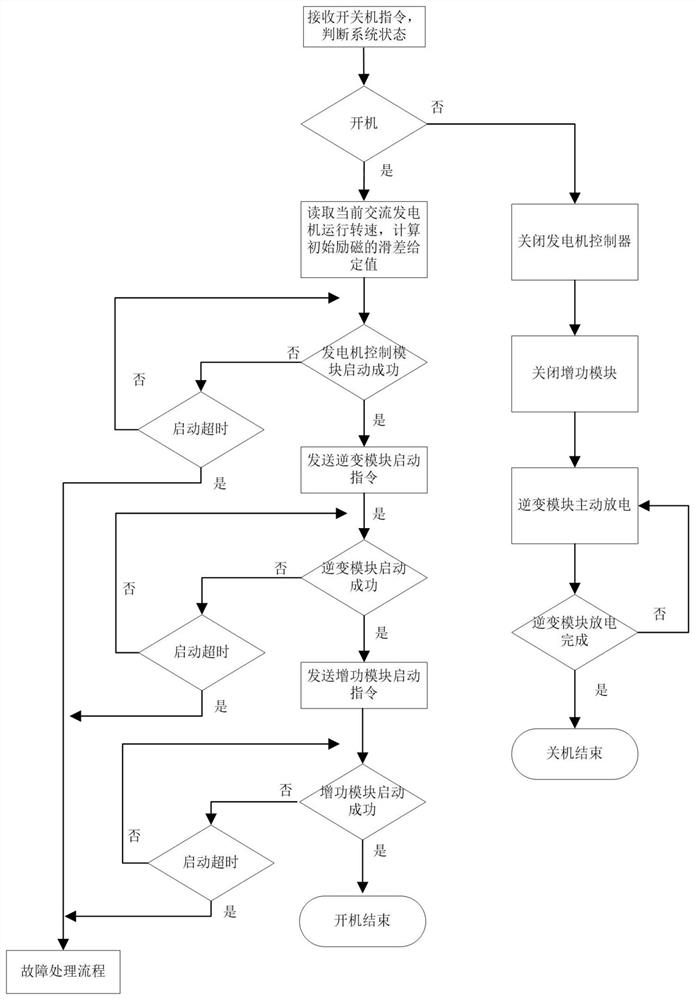

On and off control method of travelling power generation system

ActiveCN109617472AAdaptableShort build-up timeElectric generator controlEngineeringAlternating current

The invention discloses an on and off control method of a travelling power generation system. The travelling power generation system comprises an engine, an alternating current power generator, a direct current power generator, a power generation controller and a power increase module, wherein the power generation controller comprises a power generator control module and an inversion module; the engine is connected with the alternating current power generator and the direct current power generator respectively to drive the alternating current power generator and the direct current power generator to rotate; the power generator control module is connected with the alternating current power generator to control the alternating current power generator to operate and output electric energy; aninput end of the power increase module is connected with the direct current power generator and a storage battery respectively; an output end of the power increase module is connected in parallel with an output end of the power generator control module to form a common bus as an input of the inversion module; and the power generation controller is in communication connection with the power increase module by a CAN bus. A power takeoff generation system performs uniform control on the power generation controller and the power increase module; and the power generation controller and the power increase module are hot standby each other.

Owner:HEFEI TONGZHI ELECTRICAL CONTROL TECH

Pneumatic braking system and working vehicle

ActiveCN106004847AReduce the burden onEasy dischargeApplication and release valvesPiping arrangementsRelay valveSolenoid valve

The invention relates to a pneumatic braking system and a working vehicle. The pneumatic braking system comprises an ABS (Anti-lock Braking System) solenoid valve (5), a first foot relay valve (6) and braking gas chambers which are arranged at the two ends of a vehicle axle of the working vehicle and are used for carrying out braking action on wheels, and is characterized in that the braking gas chambers are communicated with a system working gas path through the first foot relay valve (6); and an output port of the ABS solenoid valve (5) is communicated with a control chamber of the first foot relay valve (6). The braking gas chambers are communicated with the system working gas path through the first foot relay valve and the ABS solenoid valve is not used as a direct gas supply source of the braking gas chambers anymore, so that the amount of gas flow flowing through the ABS solenoid valve is greatly reduced when the ABS solenoid valve performs the actions, and furthermore, the burden of the ABS solenoid valve is alleviated and the system response frequency of the ABS solenoid valve is improved; and on the other hand, decompression time can be shortened when the braking gas chambers are used for braking and decompressing and high-pressure gas in the braking gas chambers can be rapidly discharged when the braking is relieved.

Owner:XUZHOU HEAVY MASCH CO LTD

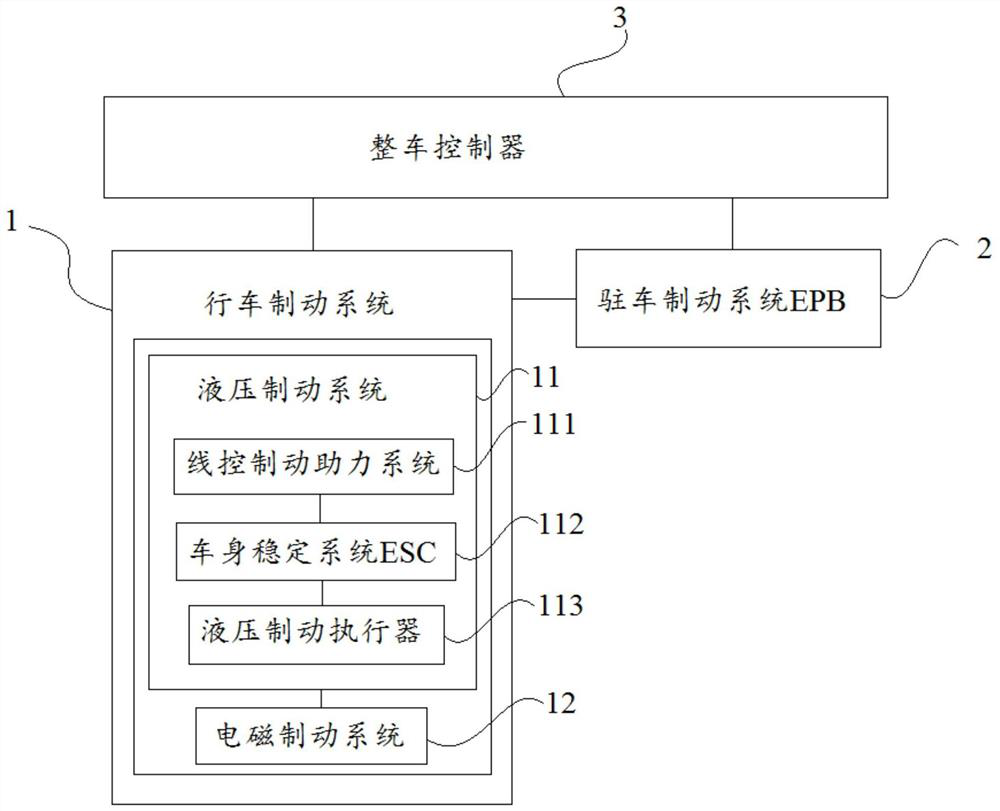

Unmanned vehicle braking system

InactiveCN113071463AReduce noiseAchieving braking needsBraking action transmissionBrushless motorsWheel cylinder

The invention belongs to the field of automobile unmanned driving, and particularly relates to an unmanned vehicle braking system which comprises a service braking system and a parking braking system EPB. The service braking system comprises a hydraulic braking system and an electromagnetic braking system. The hydraulic braking system comprises a brake-by-wire power assisting system, a vehicle body stabilizing system ESC and a hydraulic brake actuator integrated in a hub motor. The brake-by-wire power assisting system comprises a brake fluid storage pot, a main cylinder, a push rod, a brake control system ECU and a brushless motor. The brake control system ECU controls the brushless motor to work to drive the push rod to work, and the push rod pushes the main cylinder to form required oil pressure, so that the whole vehicle hydraulic brake system is pushed to work. Electro-hydraulic coupling braking is achieved, electromagnetic braking of the motor is utilized to the maximum degree to meet the whole vehicle braking requirement, the vehicle body posture and the wheel cylinder pressure can be adjusted through the vehicle body stabilizing system ESC, and the safety and stability of vehicle running are improved.

Owner:浙江亚太智能网联汽车创新中心有限公司

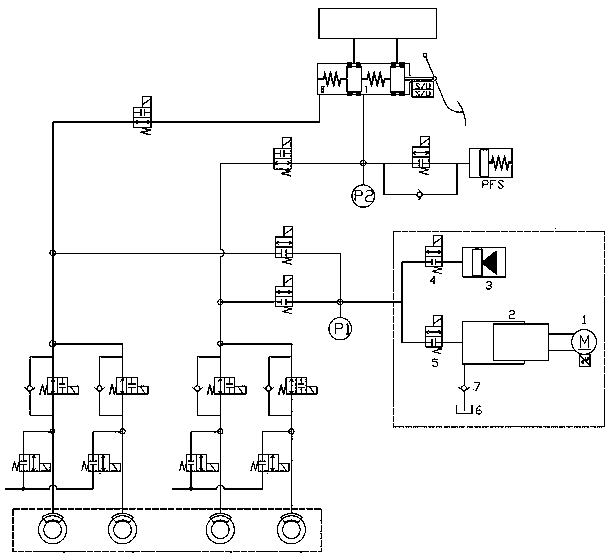

Press-shoot pressurization system and die-casting machine

The invention discloses a press-shoot pressurization system and also discloses a die-casting machine provided with the press-shoot pressurization system. The press-shoot pressurization system comprises a cylinder block, a press-shoot piston, a pressurization piston and a press-shoot switch, wherein a guiding hole is formed in the cylinder block; one end of the press-shoot piston is arranged in thecylinder block; a press-shoot cavity is formed between one end of the press-shoot piston and the pressurization piston in the cylinder block; a pressurization cavity is formed between the pressurization piston and the cylinder block; oil enters the press-shoot cavity and the pressurization cavity through a first oil inlet and a second oil inlet separately; the press-shoot switch is arranged on the inner side wall of the guiding hole and the pressurization piston, and the two ends of the press-shoot switch communicate with the press-shoot cavity and the first oil inlet separately; the pressurization piston slides in the guiding hole to turn off the press-shoot switch; and the press-shoot cavity forms a hermetic high-pressure resistant cavity to continuously push the pressurization piston,the press-shoot cavity raises to the set high pressure value immediately, and the process can shorten the pressure building time and improve the pressure building stability. The die-casting machine provided with the press-shoot pressurization system can improve the pressure casting effect and the product quality.

Owner:ZHONGSHAN DEGONG MACHINERY TECH CO LTD

Efficient gas mixing device for magnesium alloys

ActiveCN101332416BImproved combustion safetyQuality improvementMaintainance of heating chambersMixer accessoriesCardingFiltration

The invention relates to a magnesium-alloy high-efficient gas mixing device which comprises a mixing pot, a first gas inlet joint, a second gas inlet joint and a pressure switch are arranged at the upper side end of the pot wall of the mixing pot in a seal and perforation way, a gas outlet joint is arranged at the lower side end of the pot wall of the mixing pot in a seal and perforation way and a discharging valve is arranged at the lower side end of the pot wall of the mixing pot; a ventilation pipe that is connected with the first gas inlet joint is of a right-angle bend pipe with a pipe mouth being arranged downwards; a ventilation pipe that is connected with the second gas inlet joint is of an arc bend pipe and a pipe mouth thereof is arranged horizontally and inwards to form a rotary spraying nozzle; a carding net which can carry out the second carding and filtration to the mixing gases is arranged at the middle-lower part of an inner cavity of the mixing pot. The invention usestwo or more than two sorts of gases with different qualities for mixing, the gases are input from the gas inlet joint and injected into a mixing gas pot by the rotary spraying nozzle, so the high-pressure airflow and the fluid-state rotation movement can be formed, and two gases with different qualities are evenly and fully mixed together by the second carding and filtration by the stainless steel wire carding net. The device has the outstanding advantages of full and even mixing and stable output flux.

Owner:NINGBO XUNHUI ELECTRIC APPLIANCE

One-way valve injection device for die casting machine

The invention relates to a one-way valve injection device for a die casting machine, which comprises an injection cylinder, an injection piston, a pressurizing piston and a pressurizing valve plate, wherein the injection piston, the pressurizing piston and the pressurizing valve plate are arranged in the injection cylinder; the pressurizing valve plate is provided with a first valve hole and a second valve hole, the pressurizing piston is arranged in the first valve hole and is matched with the first valve hole in a dynamic sealing manner, the injection cylinder is connected with the first valve hole of the pressurizing valve plate in a sealing manner, a one-way valve is arranged between the injection piston and the pressurizing piston, one end of the one-way valve is arranged in the injection cylinder and is matched with the injection cylinder in a dynamic sealing manner, the other end of the one-way valve is fixedly connected with the pressurizing piston, and the second valve hole is communicated with an oil inlet of the one-way valve. Compared with a floating piston, the one-way valve injection device operates stably and reliably; the problem of instable speed when advanced pressurizing and stroke control pressurizing under a pressure control condition can be solved; and stroke or time control can be realized and pressing time is shortened through pressurization, thus the one-way valve injection device can adapt to the requirement for the traditional high-end die casting within larger range.

Owner:常州源通电子科技有限公司

Distributed braking system with parking function and braking pressure vector control method thereof

PendingCN110861624AFast dynamic responseShort build-up timeBraking action transmissionFoot actuated initiationsCircular discControl theory

The invention relates to the technical field of vehicle braking control systems or components thereof, in particular to a distributed braking system with multiple working modes and a parking function.The distributed braking system comprises a braking pedal, a manpower cylinder, a braking controller and a power supply, and further comprises at least three electric cylinders electrically connectedwith the braking controller; the electric cylinders are correspondingly connected to wheel brakes with the same number on a vehicle one to one; each electric cylinder and the corresponding wheel brakeform a braking loop; and each electric cylinder comprises a shell, a motor connected with the shell, a cylinder body, and a piston part slidingly arranged in the cylinder body. The distributed braking system is characterized by further comprising a disc part and a connecting rod; one end of the connecting rod is hinged with the piston part; and the other end of the connecting rod is eccentricallyand rotationally connected with the disc part. The distributed braking system has such advantages as compact structure, fast braking response, capability of realizing the parking function, reliable failure protection capacity and low manufacturing cost, and is high in vehicle braking reliability.

Owner:南京经纬达汽车科技有限公司

A switch control method of a driving power generation system

ActiveCN109617472BAdaptableShort build-up timeElectric generator controlAlternatorControl engineering

The invention discloses an on and off control method of a travelling power generation system. The travelling power generation system comprises an engine, an alternating current power generator, a direct current power generator, a power generation controller and a power increase module, wherein the power generation controller comprises a power generator control module and an inversion module; the engine is connected with the alternating current power generator and the direct current power generator respectively to drive the alternating current power generator and the direct current power generator to rotate; the power generator control module is connected with the alternating current power generator to control the alternating current power generator to operate and output electric energy; aninput end of the power increase module is connected with the direct current power generator and a storage battery respectively; an output end of the power increase module is connected in parallel with an output end of the power generator control module to form a common bus as an input of the inversion module; and the power generation controller is in communication connection with the power increase module by a CAN bus. A power takeoff generation system performs uniform control on the power generation controller and the power increase module; and the power generation controller and the power increase module are hot standby each other.

Owner:HEFEI TONGZHI ELECTRICAL CONTROL TECH

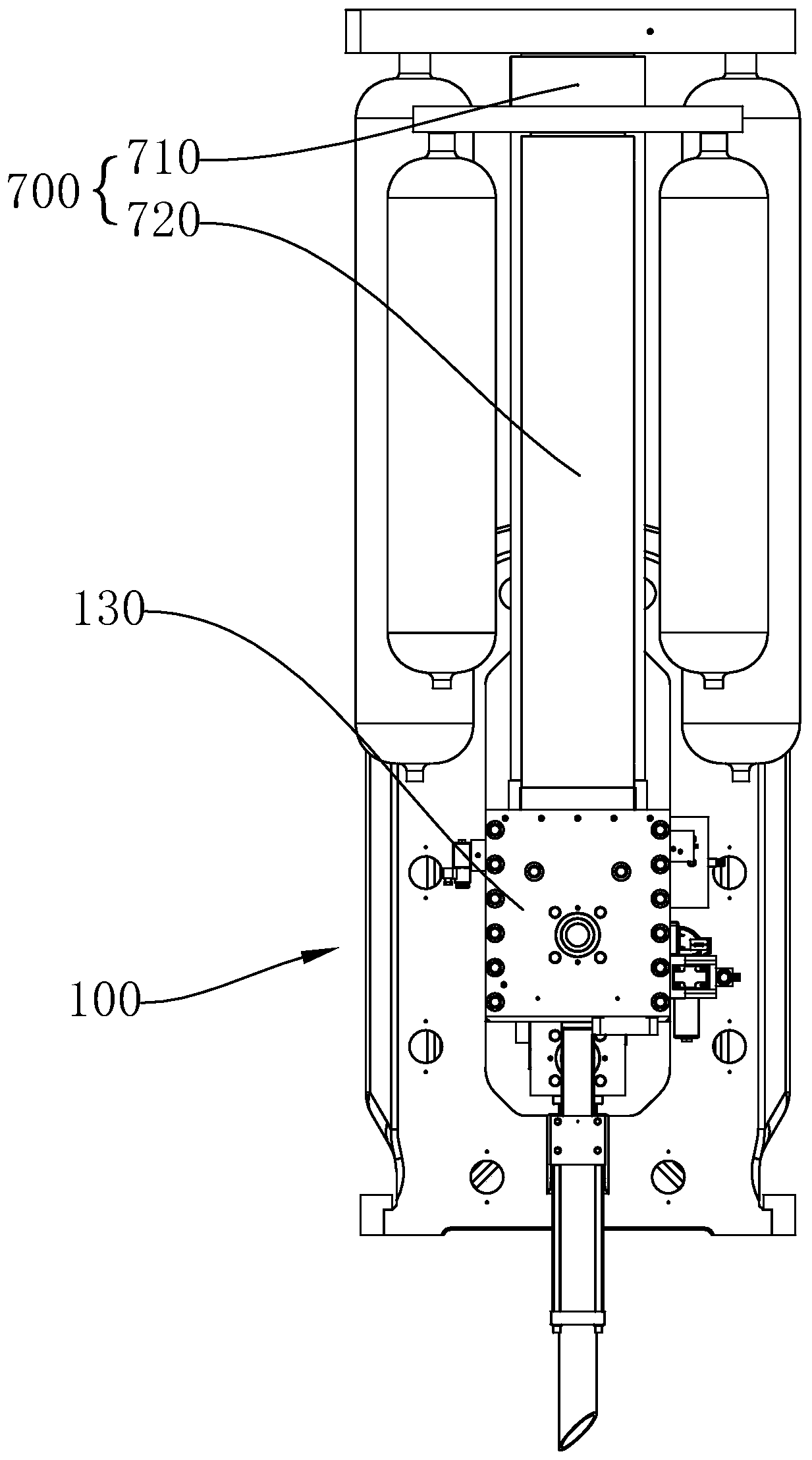

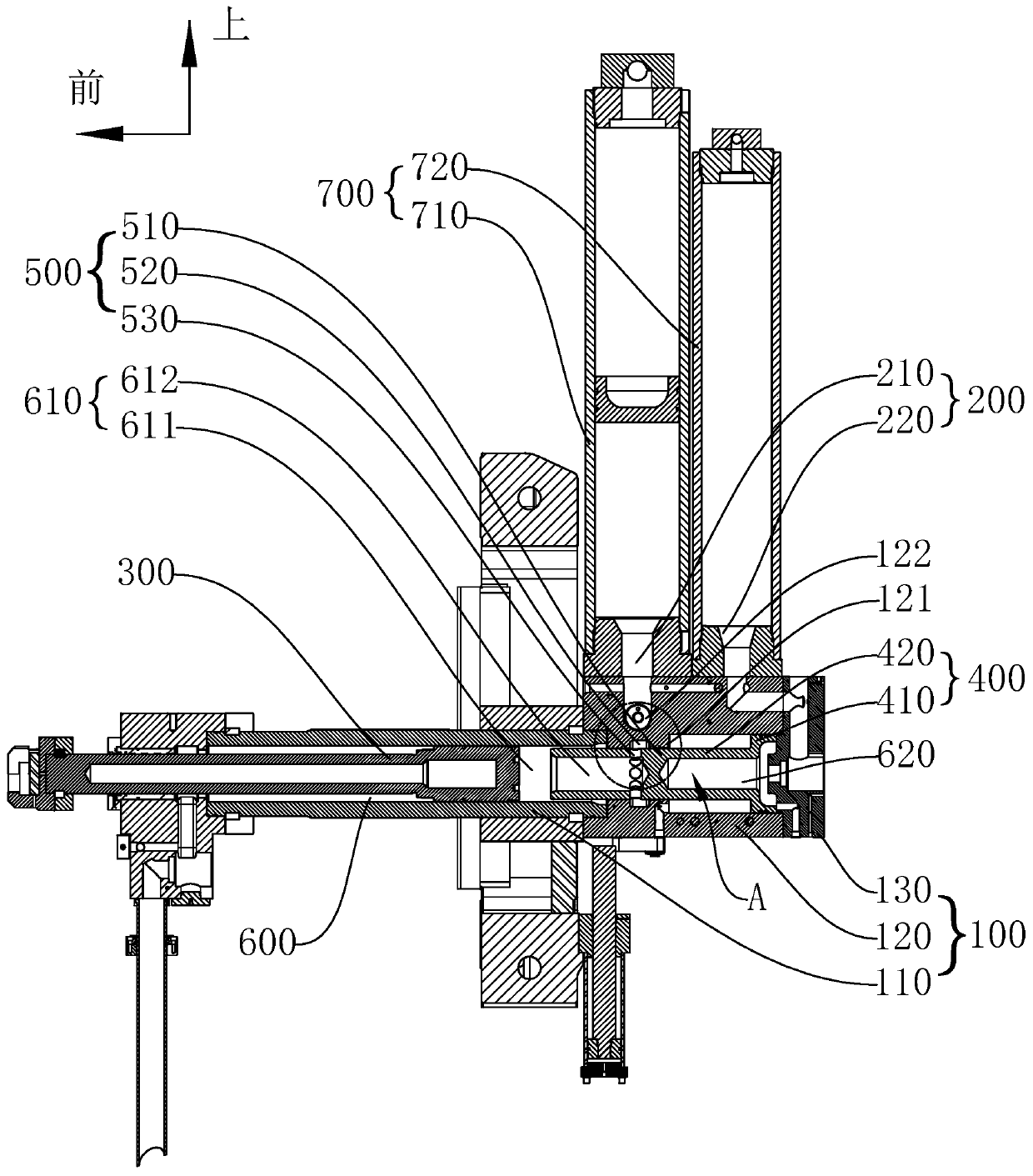

System for supplying urea solution

PendingCN114658518AShort build-up timeImproved pump pressure stabilityExhaust apparatusSilencing apparatusEnvironmental geologyMechanical engineering

The present disclosure provides a system for supplying a urea solution, comprising a storage tank, an injection module, and a urea pump, the urea pump comprising: a housing; the first liquid conveying pipeline and the second liquid conveying pipeline are arranged in the shell, the first liquid conveying pipeline is connected with the liquid inlet pipeline, and the second liquid conveying pipeline is connected with the liquid outlet pipeline; the pump core module is configured to be connected with the first liquid conveying pipeline and the second liquid conveying pipeline; the backflow structure is arranged in the shell and comprises a backflow pipeline and a one-way backflow valve arranged in the backflow pipeline, the inlet end of the backflow pipeline is connected to the second liquid conveying pipeline, and the outlet end of the backflow pipeline is connected to the first liquid conveying pipeline. Therefore, pipelines and pipeline heaters can be saved, and the liquid feeding efficiency of the urea pump can be improved.

Owner:西安秦泰汽车排放技术有限公司

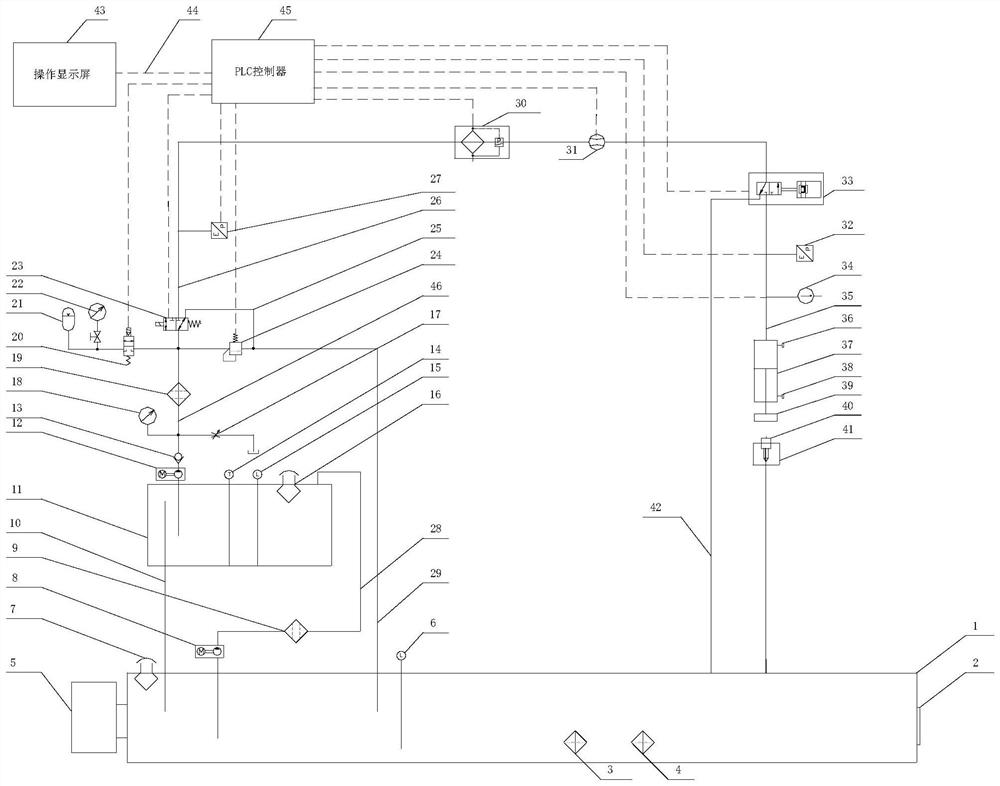

Fuel injector flow measurement system and measurement method

ActiveCN111551224BAvoid loss of accuracyHigh precisionTemperature measurement of flowing materialsVolume meteringTemperature controlInjector nozzle

The invention discloses a fuel injection nozzle flow measurement system and a measurement method. The measurement system adopts a double fuel tank mechanism to realize the circulating filtration rate of the measured oil. A throttle valve is arranged at the outlet end of the fuel tank to control the fuel injection nozzle flow, and through Setting the start-up pressure regulating valve realizes rapid adjustment of the measured oil pressure in the measuring circuit, and absorbs the pressure fluctuations in the measuring circuit by setting the pressure stabilizing component. In addition, the dual oil tank mechanism is provided with a constant temperature control component to adjust the temperature in the oil tank; the measurement method realizes the input of control parameters to the PLC controller by operating the display screen, and according to the actual measurement of the oil temperature at the measuring end. The flow value measured by the meter is compensated. After the measurement is completed, the corresponding measurement process parameters are formed into a formula, which is convenient to call, change, download or delete. The invention realizes accurate and rapid measurement of the flow rate of the online fuel injector.

Owner:FAW JIEFANG AUTOMOTIVE CO

A vehicle active power-assisted braking device and its control method

ActiveCN106218622BAvoid risk of leakageShort build-up timeBraking action transmissionBrake safety systemsElectricitySelf locking

The invention discloses an active assisting braking device of an automobile. The active assisting braking device comprises a brake pedal push rod, a braking main cylinder push rod, a vacuum cavity, a working cavity and a three-way electromagnetic valve. According to the active assisting braking device, a high-pressure accumulator is omitted, a two-position three-way electromagnetic valve is replaced with the three-position three-way electromagnetic valve with a self-locking function, the effect that pressure is maintained for a long time in the power-down state can be achieved, and meanwhile, the effectiveness and reliability of foot braking and failure mode braking can be guaranteed.

Owner:ANHUI POLYTECHNIC UNIV

Distributed type autonomous braking system with parking function and control method

PendingCN110803149ASimple structureLow costBraking action transmissionBrake actuating mechanismsElectric machineControl system

The invention relates to the technical field of vehicle brake control systems, and particularly provides a distributed type autonomous braking system with a parking function and a control method. Thesystem comprises a power supply, a brake controller and wheel brakes, and further comprises at least three electric cylinders which are connected with the wheel brakes and form brake loops; each electric cylinder comprises an electric cylinder body, a piston arranged in the electric cylinder body in a sliding manner, a motor for driving the piston to slide by a screw pair arranged in the electriccylinder body and a liquid storage pot connected with the electric cylinder body; the motors are electrically connected with the brake controller; each screw pair comprises a nut driven by the corresponding motor and a screw connected with the corresponding piston; and the electric cylinders are connected to the wheel brakes with the same number on an automobile in a one-to-one correspondence manner, and each electric cylinder and the corresponding wheel brake form one brake loop. Compared with the prior art, the system has a failure protection function, higher safety performance, the parkingfunction, simple structure and lower cost.

Owner:南京经纬达汽车科技有限公司

Rapid press-shooting cut-off mechanism for magnesium alloy cold chamber die casting machine

The invention discloses a rapid press-shooting cut-off mechanism for a magnesium alloy cold chamber die casting machine. The rapid press-shooting cut-off mechanism comprises a first solenoid directional valve, a first inserting valve, a second inserting valve and a stop valve, wherein a hole P, a hole A and a hole B of the first solenoid directional valve are respectively corresponding connected with an energy accumulator, a control hole C of the first inserting valve and the control hole C of the second inserting valve; a hole B of the first inserting valve is connected with the energy accumulator; the hole A of the second inserting valve is connected with an oil tank; the hole A of the first inserting valve is connected with the hole B of the second inserting valve and is connected with a port X of the stop valve; and the port X is used for controlling the stop valve to switch on and off. The rapid press-shooting cut-off mechanism is reasonably designed and is capable of realizing the functions of external controlled one-way flow and bidirectional cut-off, shortening the decompression time and promoting the stability of rapid press-shooting cut-off.

Owner:广东顺德固德威精密机械有限公司

Distributed braking system with human failure backup and pressure regulation control method

ActiveCN110775033BShort build-up timeFast brake responseBraking action transmissionFoot actuated initiationsSolenoid valveControl theory

The invention provides a distributed braking system with human failure backup and a pressure regulation control method, belonging to the technical field of automobile braking systems. It specifically includes a brake pedal, a manpower cylinder, a brake controller and a power supply, and also includes at least three electric cylinders and electromagnetic valves electrically connected to the brake controller, and the electric cylinders are respectively connected to the The drain holes of the manpower cylinders are connected, and the electric cylinders are connected to the same number of wheel brakes on the car one by one, and each of the electric cylinders forms a braking circuit with a corresponding wheel brake; the two ends of the same shaft The two wheel brakes are communicated through a brake pipeline, and a solenoid valve is arranged on the brake pipeline, and the solenoid valve is electrically connected with the brake controller. The invention has the dual functions of manpower failure backup and shaft pressure equalization function, so that the smart driving car has good motion stability and high reliability when braking.

Owner:南京经纬达汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com