Rapid press-shooting cut-off mechanism for magnesium alloy cold chamber die casting machine

A technology of cold chamber die-casting and magnesium alloy, applied in the field of fast injection cut-off mechanism, which can solve the problems of short pressure build-up time, enhanced stability, and extended pressure build-up time, and achieve short pressure build-up time, high stability, and adjustment response the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments and the accompanying drawings.

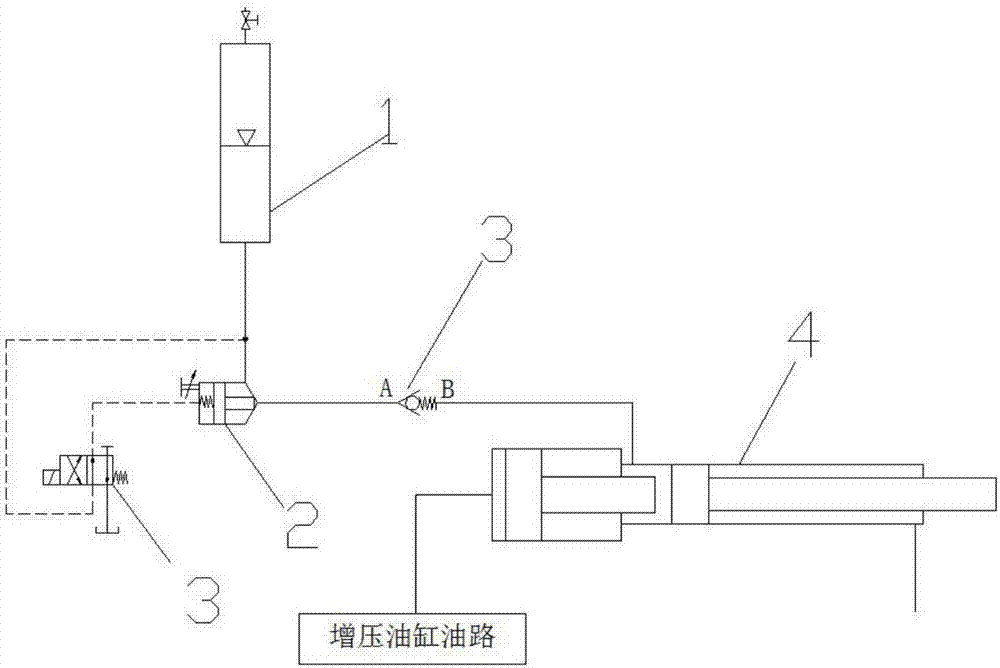

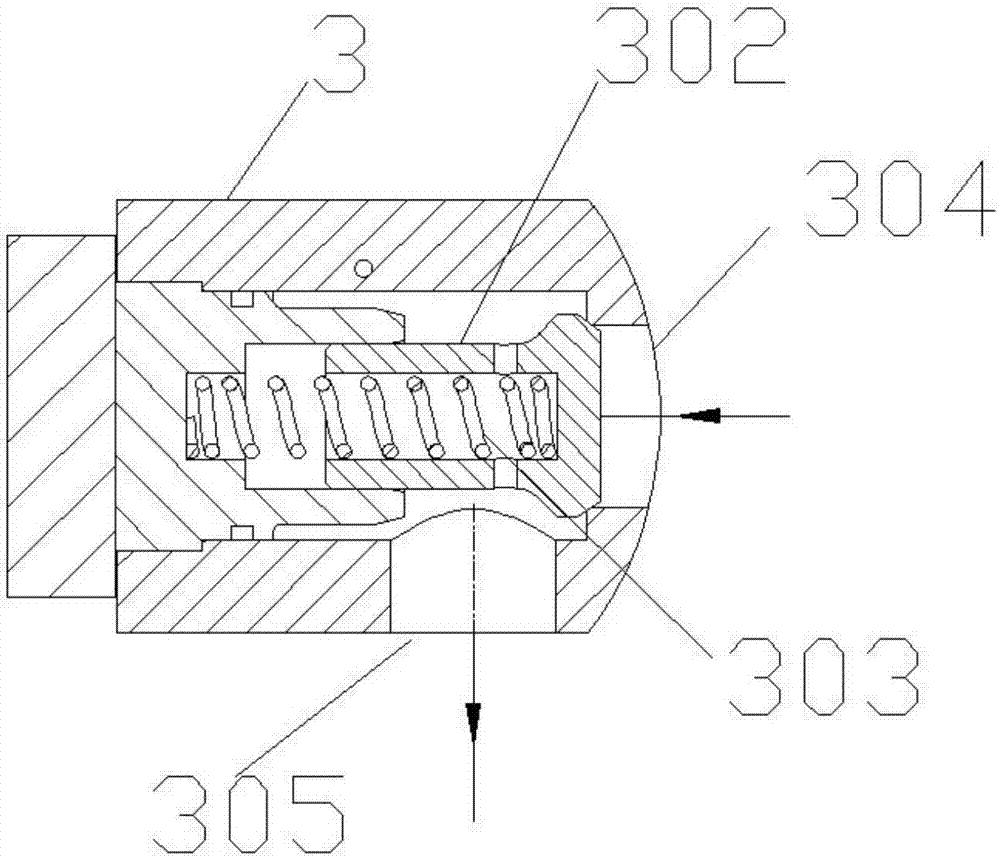

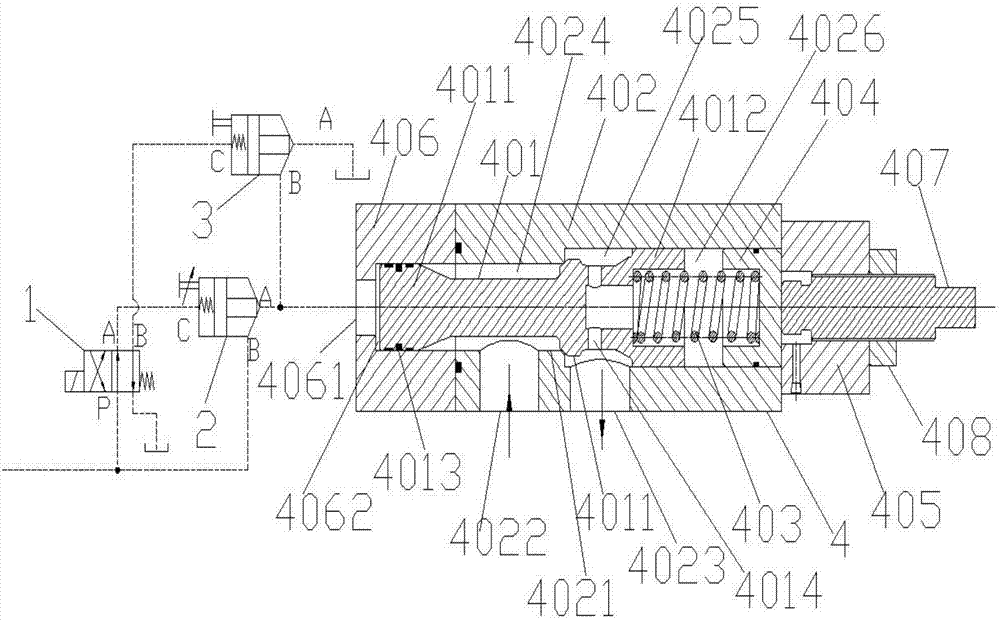

[0025] Such as image 3 The quick injection cut-off mechanism of a magnesium alloy cold chamber die-casting machine includes a first electromagnetic direction valve 1, a first cartridge valve 2, a second cartridge valve 3 and a stop valve 4. The first electromagnetic direction valve The P hole of the valve 1 is connected to the accumulator 5, and the A hole and the B hole of the first electromagnetic directional valve 1 correspond to the control hole C of the first cartridge valve 2 and the control hole C of the second cartridge valve 3 for controlling The on-off of the first cartridge valve 2 and the second cartridge valve 3 . The B hole of the first cartridge valve 2 communicates with the accumulator 5, the A hole of the second cartridge valve 3 communicates with the oil tank 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com