Sleeve type fixed dust removal device

A kind of dust removal device and sleeve type technology, applied in separation device, cleaning method, use of liquid separation agent, etc., can solve the problem of not being able to temporarily stand by, achieve the effect of fast and stable connection, and avoid water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

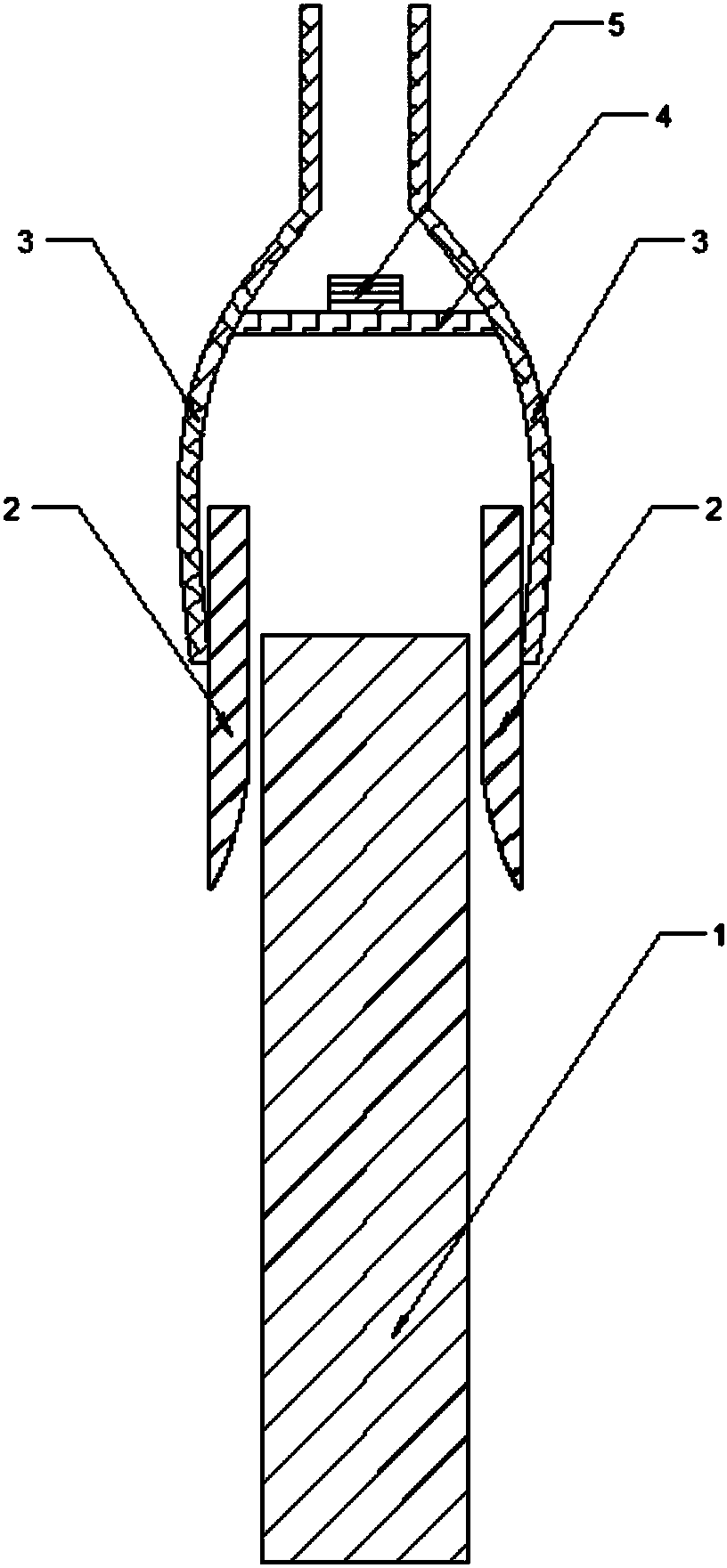

[0027] The technical solution of this embodiment is: a sleeve-type fixed dust removal device, including an elastic rubber plate 4 arranged between two brake pad driving parts 3, and the two ends of the elastic rubber plate 4 are respectively driven by the two brake pads. Part 3 is fixedly connected, and the upper end of the elastic rubber plate 4 is fixedly connected with a sprinkler mechanism 5;

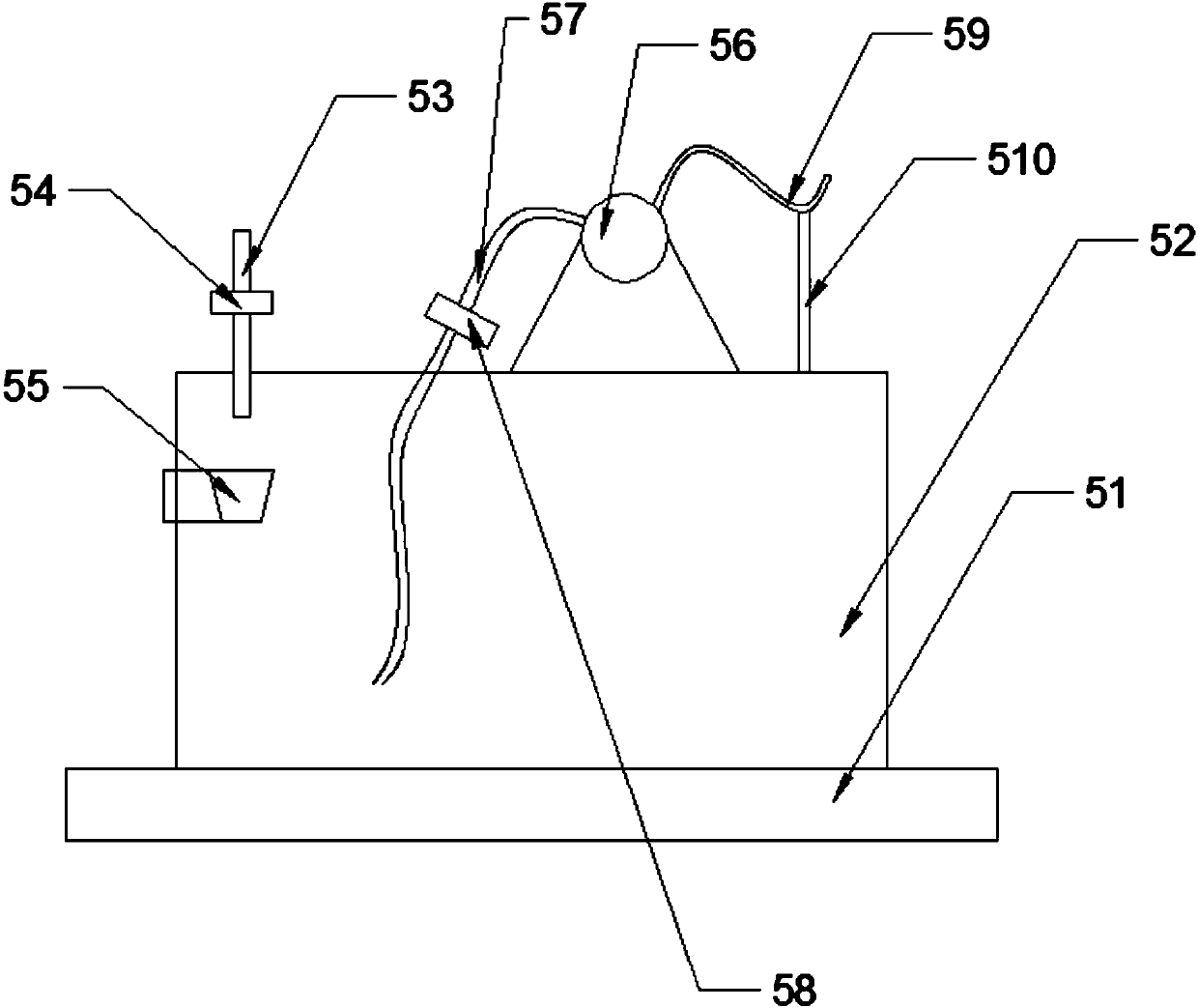

[0028] The sprinkling mechanism 5 includes a hard plate 51 fixedly connected with the elastic rubber plate 4, the upper end of the hard plate 51 is fixedly connected with a closed water tank 52, and the outer surface of the closed water tank 52 is provided with a water divider 56, and the water divider 56 The water inlet of the water inlet is connected with a water inlet pipe 57, and the water inlet pipe 57 stretches into the closed water tank 52, and the water outlet of the water separator 56 is connected with a nozzle 59, and the outer surface of the upper end of the closed water t...

Embodiment 2

[0036] On the basis of Embodiment 1, the technical solution of this embodiment is: a water inlet pipe 53 is arranged in the water inlet, a supercharger 54 is arranged on the water inlet pipe 53, a medicine feeding hole is opened on the closed water tank 52, and a water inlet pipe 53 is provided. A medicine feeding groove 55 is carded in the medicine hole, and one end of the medicine adding groove 55 stretches in the described closed water tank 52 , and the other end of the medicine added groove 55 stretches out of the described closed water tank 52 .

[0037] Such as figure 2 As shown, the dosing tank 55 is set to add an adsorbent with strong adsorption capacity to the water, and it will be sprayed out through the water separator to quickly combine with dust and incompletely burned particles, and the combined particles will combine with each other to form large particles and fall back to the ground. . A supercharger 54 is provided to enhance the pressure of the water enterin...

Embodiment 3

[0039] On the basis of the first embodiment, the technical solution of this embodiment is: an inlet filter 58 is arranged on the water inlet pipe 57 .

[0040] Such as figure 2 As shown, the inlet filter is used 58 to filter impurities such as sediment and rust in the closed water tank 52 to avoid blocking the water separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com