Flocculation washing machine

A technology for flocculating washing machines and washing machines, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems of consuming a large amount of water resources, waste of water resources, etc., and achieve the effects of simple structure, sufficient contact, and improved washing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

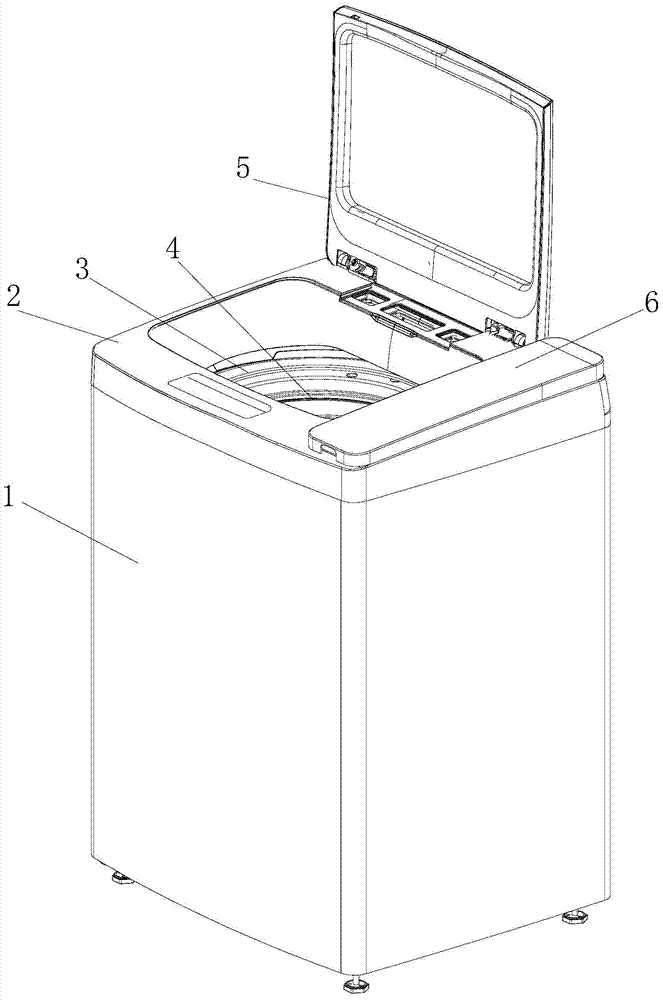

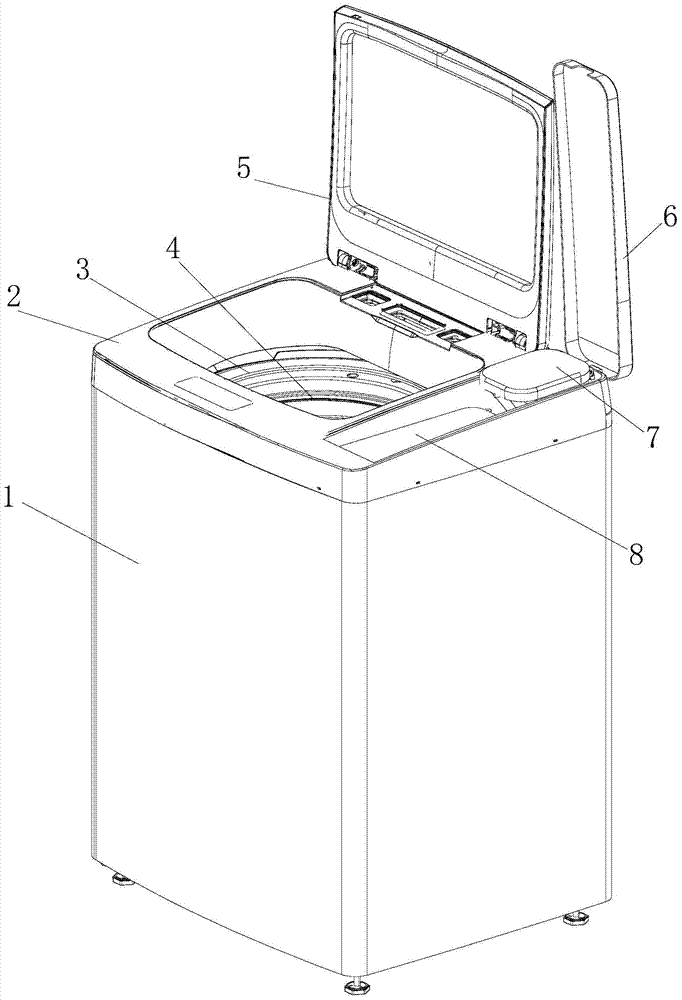

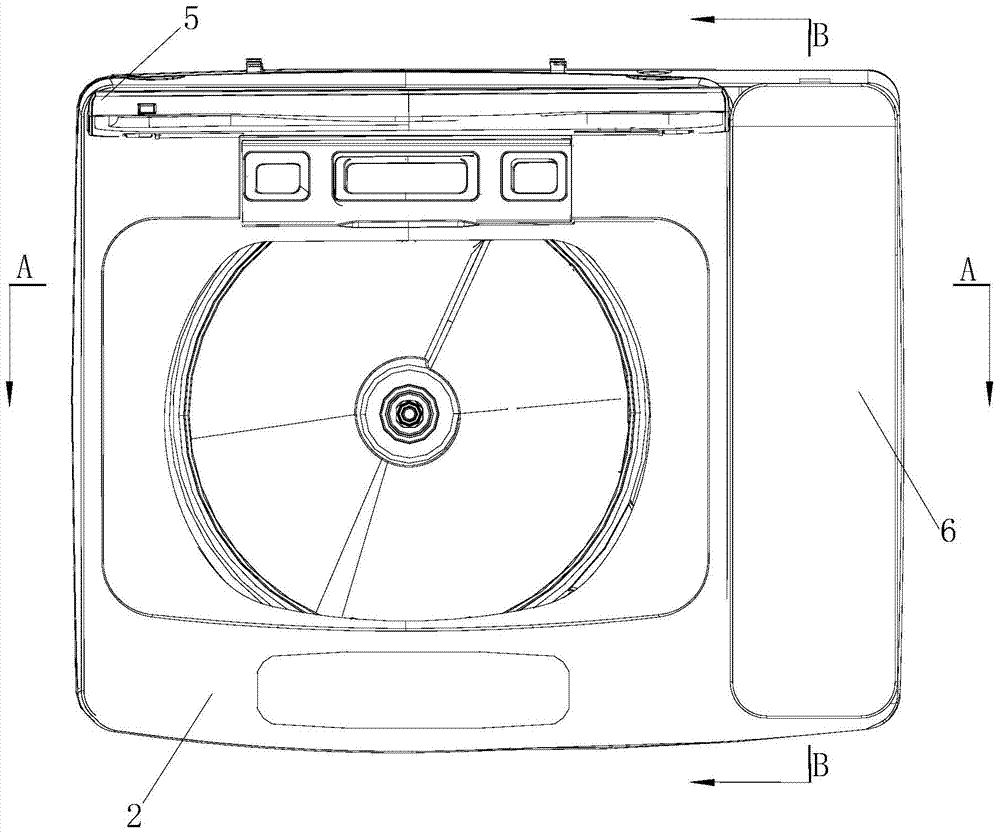

[0046] Such as Figure 1 to Figure 3 As shown, in this embodiment, the top of the shell 1 of the flocculation washing machine is provided with a control panel seat 2, and the control panel seat 2 is provided with a first opening corresponding to the top of the outer tub 3, and a second opening corresponding to the flocculation treatment device. Open your mouth. At the same time, a first upper cover 5 is installed on the control panel base 2 to control the opening and closing of the first opening to realize the picking and placing of clothes in the outer tub; a second upper cover 6 is also installed on the control panel base 2 to control the opening and closing of the first opening. The opening and closing of the two openings realize the addition of flocculant and the replacement of filter elements in the flocculation treatment device.

[0047] Preferably, in this embodiment, the first upper cover and the second upper cover are respectively installed on the top surface of the ...

Embodiment 2

[0055] In this embodiment, the water return port of the flocculation bucket 9 communicates with the spray structure 14 on the upper part of the outer bucket 3 through the water return pipe 17; or, as Figure 4 to Figure 8 As shown, the water return port of the flocculation bucket 9 is connected to the water inlet of the filter unit 8 through the first circulation pipe 16, and the water outlet of the filter unit 8 is connected to the spray structure 14 through the return pipe 17, so that the clean water after the flocculation treatment The water is sprayed into the outer tub 3 of the washing machine in a divergent shape through the spray structure 14 .

[0056] Through the above settings, the backflow water flows into the outer tub in a divergent waterfall through the spray structure, so that the sprayed backflow water can effectively eliminate the foam generated by the detergent caused by the rotation of the inner tub during the washing process, so as to reduce the amount of wa...

Embodiment 3

[0061] Such as Figure 8 As shown, in this embodiment, the outer tub 3 of the washing machine is provided with an outer circulation pipe 20, one end of the outer circulation pipe 20 communicates with the bottom of the outer tub 3, and the other end communicates with the spray structure 14 on the upper part of the outer tub 3, The outer circulation pipe 20 is provided with a circulation pump, so that the water at the bottom of the outer tub 3 flows through the outer circulation pipe 20 to the upper part of the outer tub 3, so that the washing water in the outer tub realizes external circulation from bottom to top, so as to improve washing efficiency .

[0062] In this embodiment, the connection port 144 of the spray structure 14 is respectively connected to the outer circulation pipe 20 and the return pipe 17 through the tee 21, so that the return water after the flocculation treatment and the washing water at the bottom of the outer tub 3 can be sprayed. The shower structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com