Vehicle line control hydraulic brake system hardware-in-the-loop test bed

A technology of hydraulic braking and system hardware, which is used in vehicle testing, machine/structural component testing, measuring devices, etc., and can solve the problems of low rapid pressure build-up speed, insufficient test bench detection accuracy, and large steady-state error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

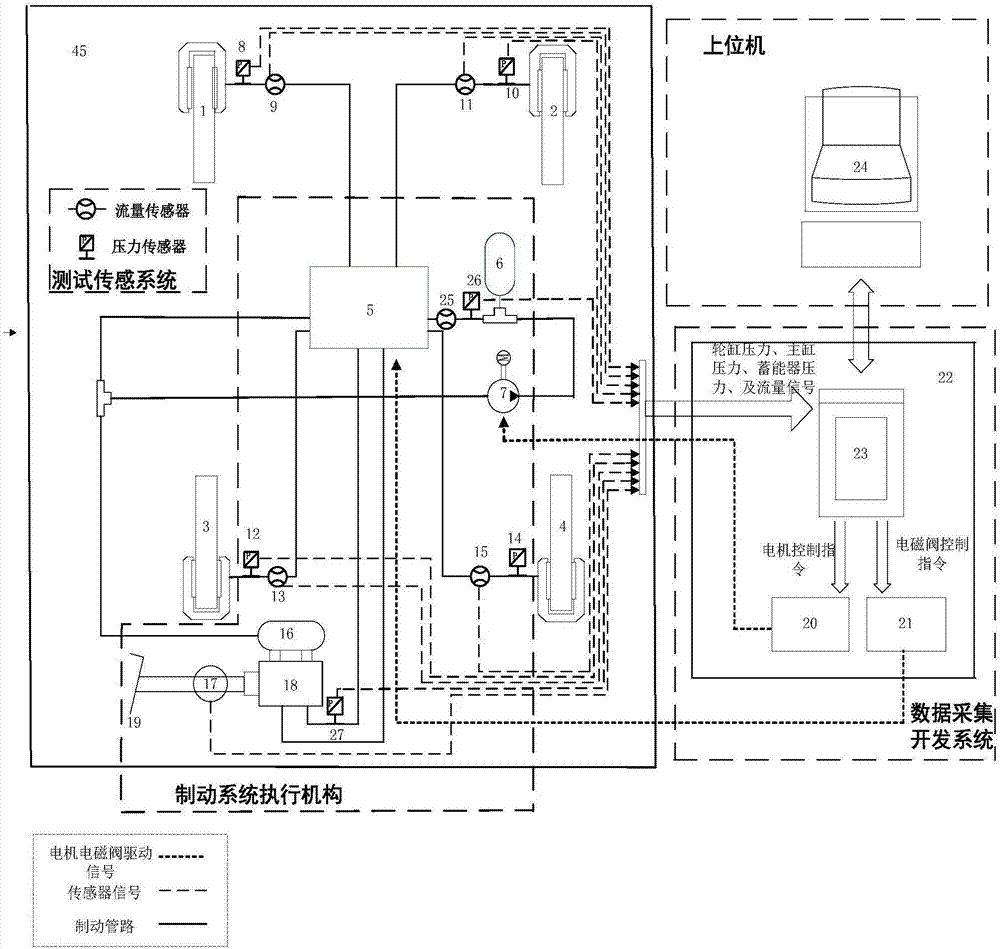

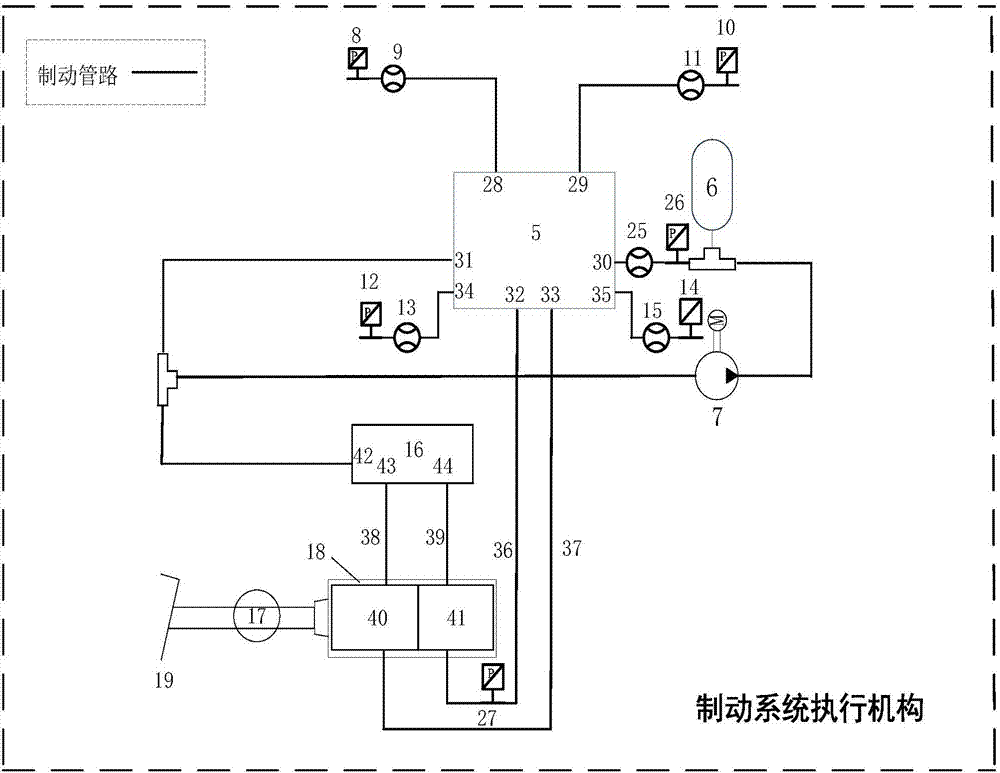

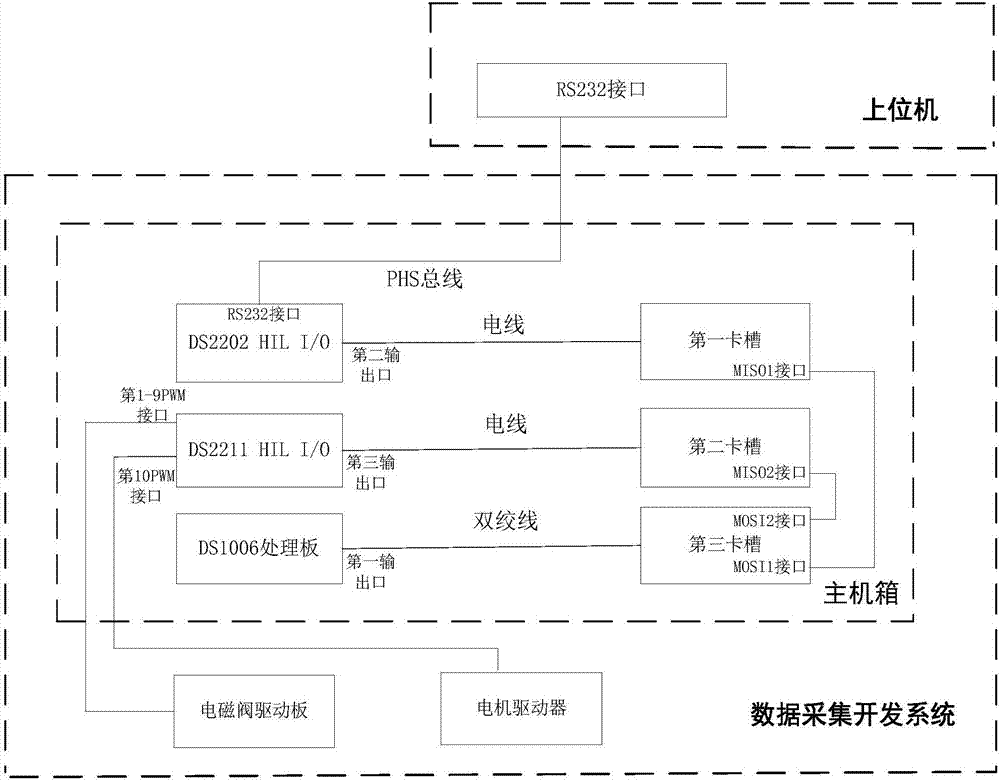

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

[0048] refer to figure 1 , the present invention provides a hardware-in-the-loop test bench for a vehicle-by-wire hydraulic braking system. The technical problem to be solved is to ensure that the test bench has good real-time performance, and can realize vehicle models and control algorithm models under different working conditions. , the data interaction between the wire-controlled hydraulic braking system and sensor signals, and analyze the response characteristics of the solenoid valve and the dynamic response characteristics of the wheel cylinder increase and decrease stages through simulation analysis and other means. It is also necessary to ensure that the test bench can quickly build pressure 10MPa , The pressure building time is less than 170ms, and the precise pressure control accuracy is less than 0.08MPa.

[0049] In order to solve the above technical problems, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com