Vertical pressure charging press-shoot system

A technology of booster cylinder and booster oil cylinder, which is applied in the field of die casting machines, can solve the problems of short booster pressure build-up time, short booster stroke, breakage and shedding, etc. The effect of short injection and booster flow channels and short pressure build-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

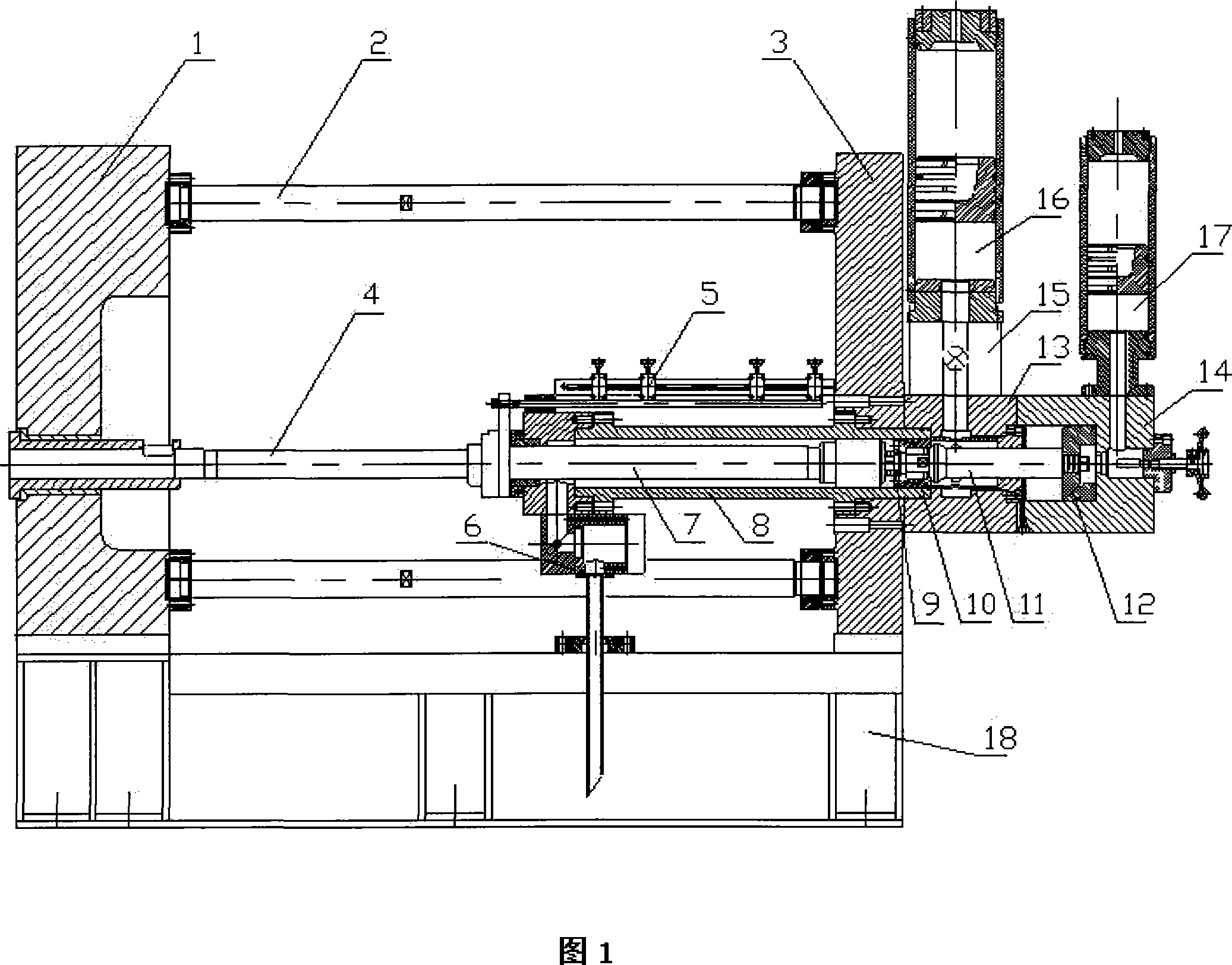

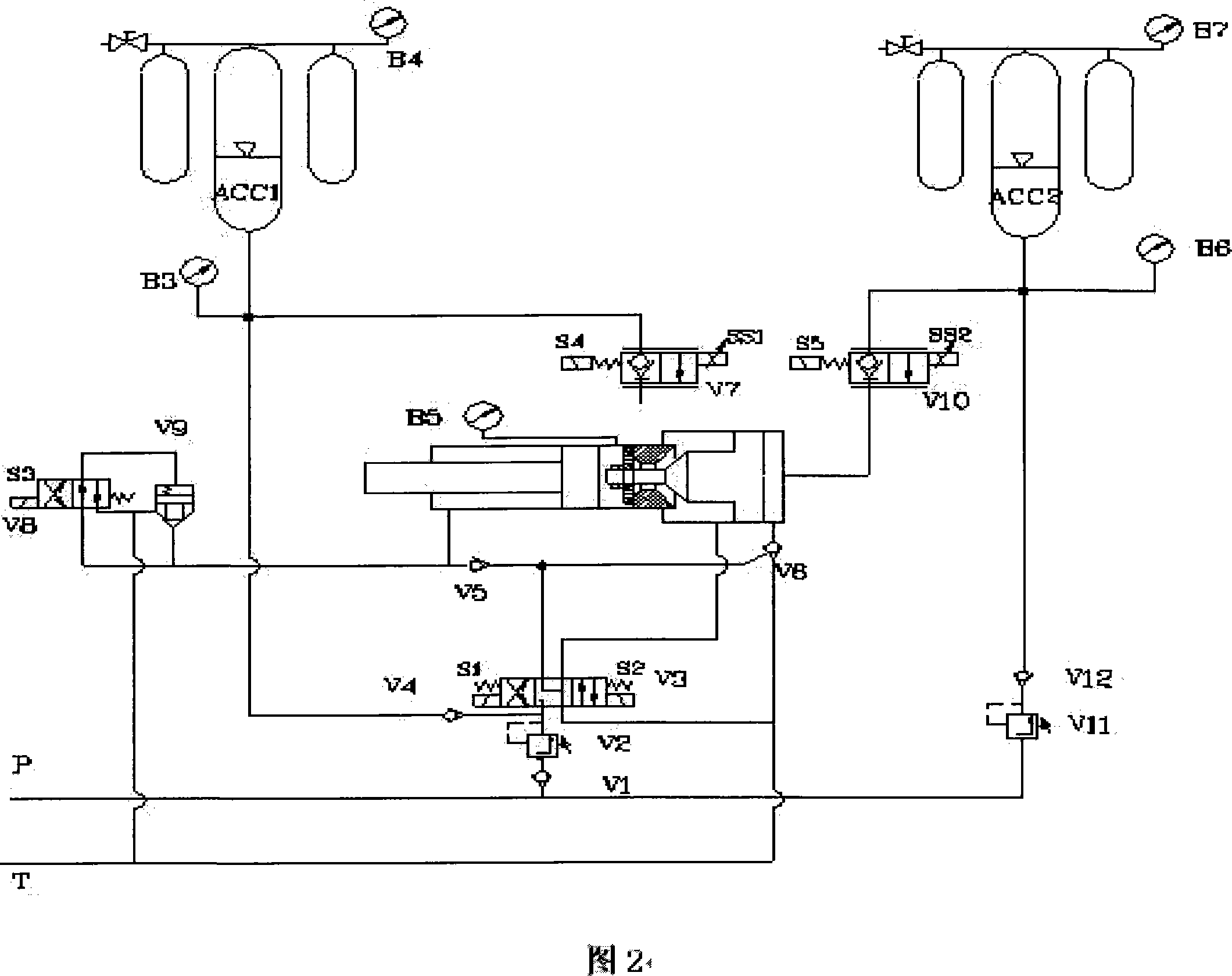

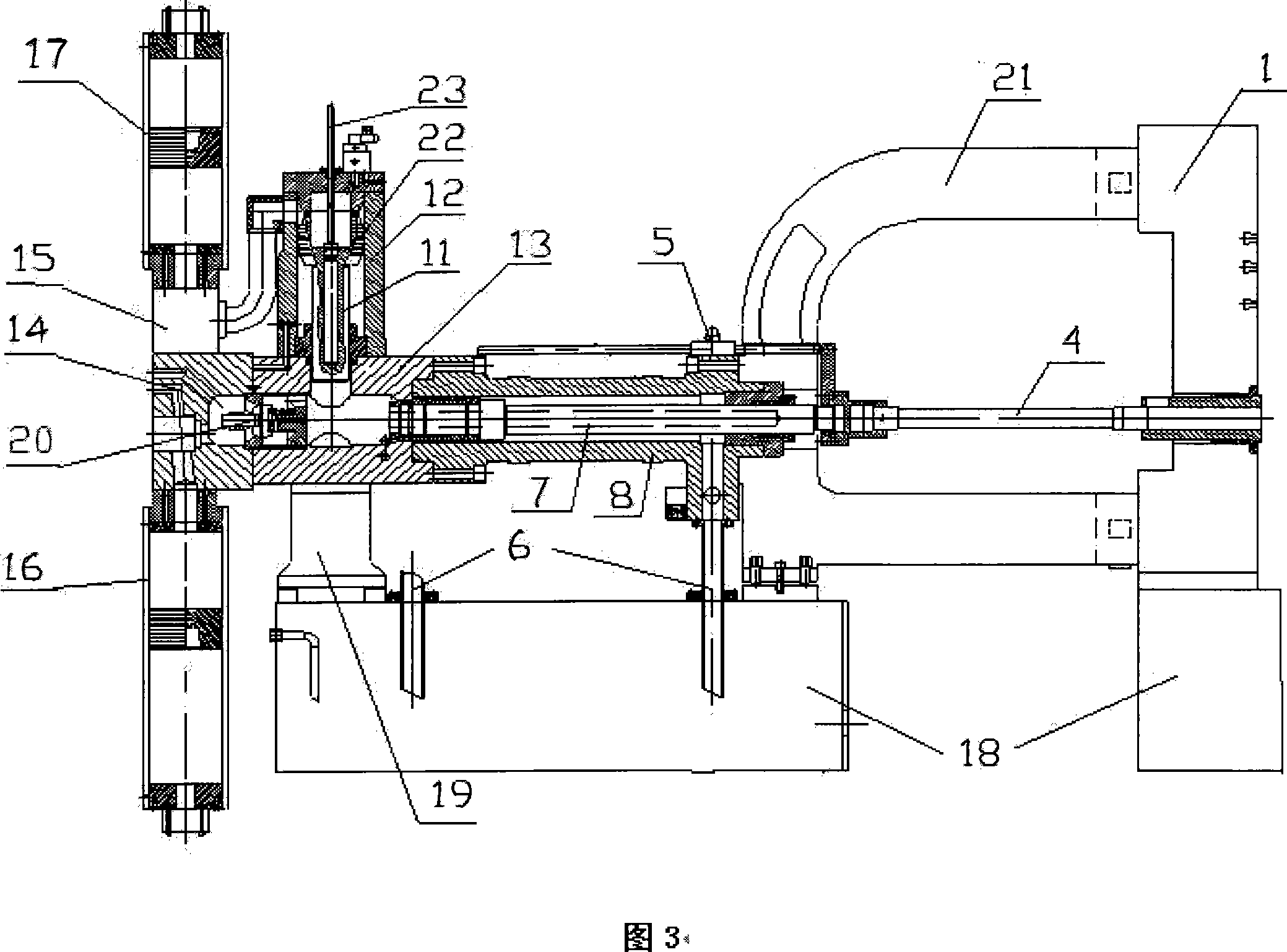

[0034]The present invention discloses a vertical pressurized injection system, which, like the prior art, includes a floor-standing machine base 18 and a fixed mold seat plate 1 fixed thereon as a mold clamping mechanism part of a die-casting machine. An injection cylinder is horizontally arranged on the machine base 18 opposite to the fixed mold seat plate 1 , and the injection cylinder includes an injection piston rod 7 and an injection cylinder barrel 8 . An injection punch assembly 4 is fitted between the injection piston rod 7 of the injection cylinder and the fixed mold seat plate 1 , and the injection cylinder and the fixed mold seat plate 1 are connected by a C-shaped frame 21 . A quick discharge assembly 6 , an oil passage middle plate 13 , and an oil passage tail plate 14 are matched with the injection cylinder. The injection oil circuit plate 19 is arranged on the oil circuit middle plate 13; the two-speed accumulator assembly 16 is arranged on the oil circuit tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com